#Global Digital Twin Market Industry

Explore tagged Tumblr posts

Text

The Global Digital Twin Market is projected to grow at a whopping 58% CAGR during the forecast period, i.e., 2023-28. The growth of the market expansion would be propelled mainly by the ever-increasing demand for asset monitoring, rising penetration of Industrial IoT (IIoT), and the growing number of smart building infrastructures to ensure optimum energy consumption. Digital twins help create predictive models to identify the possibility of success of physical prototypes before they are actually built. Hence, they allow for improved workflow across different stages of a product's lifecycle— design, engineering, maintenance, & sales.

#Global Digital Twin Market#Global Digital Twin Market Growth#Global Digital Twin Market Industry#Global Digital Twin Market size#Global Digital Twin Market share

0 notes

Text

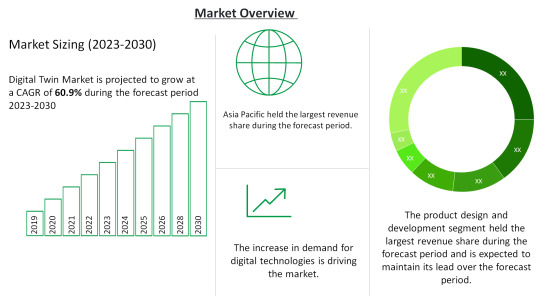

Digital Twin Market Size 2023-2030: ABB, AVEVA Group plc, Dassault Systemes

Digital Twin Market by Power Source (Battery-Powered, hardwired with battery backup, Hardwired without battery backup), Type (Photoelectric Smoke Detectors, Ionization Smoke Detectors), Service, Distribution Channel, and region (North America, Europe, Asia-Pacific, Middle East, and Africa and South America). The global Digital Twin Market size is 11.12 billion USD in 2022 and is projected to reach a CAGR of 60.9% from 2023-2030.

Click Here For a Free Sample + Related Graphs of the Report at: https://www.delvens.com/get-free-sample/digital-twin-market-trends-forecast-till-2030

Digital twin technology has allowed businesses in end-use industries to generate digital equivalents of objects and systems across the product lifecycle. The potential use cases of digital twin technology have expanded rapidly over the years, anchored in the increasing trend of integration with internet-of-things (IoT) sensors. Coupled with AI and analytics, the capabilities of digital twins are enabling engineers to carry out simulations before a physical product is developed. As a result, digital twins are being deployed by manufacturing companies to shorten time-to-market. Additionally, digital twin technology is also showing its potential in optimizing maintenance costs and timelines, thus has attracted colossal interest among manufacturing stalwarts, notably in discrete manufacturing.

The shift to interconnected environments across industries is driving the demand for digital twin solutions across the world. Massive adoption of IoT is being witnessed, with over 41 billion connected IoT devices expected to be in use by 2030. For the successful implementation and functioning of IoT, increasing the throughput for every part or “thing” is necessary, which is made possible by digital twin technology. Since the behavior and performance of a system over its lifetime depend on its components, the demand for digital twin technology is increasing across the world for system improvement. The emergence of digitalization in manufacturing is driving the global digital twin market. Manufacturing units across the globe are investing in digitalization strategies to increase their operational efficiency, productivity, and accuracy. These digitalization solutions including digital twin are contributing to an increase in manufacturer responsiveness and agility through changing customer demands and market conditions.

On the other hand, there has been a wide implementation of digital technologies like artificial intelligence, IoT, clog, and big data which is increasing across the business units. The market solutions help in the integration of IoT sensors and technologies that help in the virtualization of the physical twin. The connectivity is growing and so are the associated risks like security, data protection, and regulations, alongside compliance.

During the COVID-19 pandemic, the use of digital twin technologies to manage industrial and manufacturing assets increased significantly across production facilities to mitigate the risks associated with the outbreak. Amid the lockdown, the U.S. implemented a National Digital Twin Program, which was expected to leverage the digital twin blueprint of major cities of the U.S. to improve smart city infrastructure and service delivery. The COVID-19 pandemic positively impacted the digital twin market demand for twin technology.

Delvens Industry Expert’s Standpoint

The use of solutions like digital twins is predicted to be fueled by the rapid uptake of 3D printing technology, rising demand for digital twins in the healthcare and pharmaceutical sectors, and the growing tendency for IoT solution adoption across multiple industries. With pre-analysis of the actual product, while it is still in the creation stage, digital twins technology helps to improve physical product design across the full product lifetime. Technology like digital twins can be of huge help to doctors and surgeons in the near future and hence, the market is expected to grow.

Market Portfolio

Key Findings

The enterprise segment is further segmented into Large Enterprises and Small & Medium Enterprises. Small & Medium Enterprises are expected to dominate the market during the forecast period. It is further expected to grow at the highest CAGR from 2023 to 2030.

The industry segment is further segmented into Automotive & Transportation, Energy & Utilities, Infrastructure, Healthcare, Aerospace, Oil & Gas, Telecommunications, Agriculture, Retail, and Other Industries. The automotive & transportation industry is expected to account for the largest share of the digital twin market during the forecast period. The growth can be attributed to the increasing usage of digital twins for designing, simulation, MRO (maintenance, repair, and overhaul), production, and after-service.

The market is also divided into various regions such as North America, Europe, Asia-Pacific, South America, and Middle East and Africa. North America is expected to hold the largest share of the digital twin market throughout the forecast period. North America is a major hub for technological innovations and an early adopter of digital twins and related technologies.

During the COVID-19 pandemic, the use of digital twin technologies to manage industrial and manufacturing assets increased significantly across production facilities to mitigate the risks associated with the outbreak. Amid the lockdown, the U.S. implemented a National Digital Twin Program, which was expected to leverage the digital twin blueprint of major cities of the U.S. to improve smart city infrastructure and service delivery. The COVID-19 pandemic positively impacted the digital twin market demand for twin technology.

Regional Analysis

North America to Dominate the Market

North America is expected to hold the largest share of the digital twin market throughout the forecast period. North America is a major hub for technological innovations and an early adopter of digital twins and related technologies.

North America has an established ecosystem for digital twin practices and the presence of large automotive & transportation, aerospace, chemical, energy & utilities, and food & beverage companies in the US. These industries are replacing legacy systems with advanced solutions to improve performance efficiency and reduce overall operational costs, resulting in the growth of the digital twin technology market in this region.

Competitive Landscape

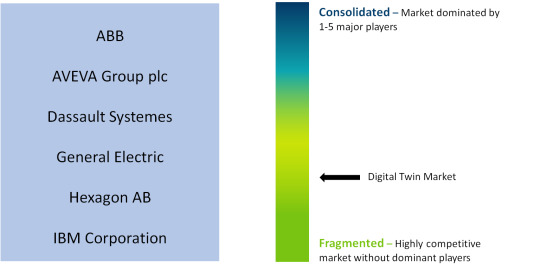

ABB

AVEVA Group plc

Dassault Systemes

General Electric

Hexagon AB

IBM Corporation

SAP

Microsoft

Siemens

ANSYS

PTC

IBM

Recent Developments

In April 2022, GE Research (US) and GE Renewable Energy (France), subsidiaries of GE, collaborated and developed a cutting-edge artificial intelligence (AI)/machine learning (ML) technology that has the potential to save the worldwide wind industry billions of dollars in logistical expenses over the next decade. GE’s AI/ML tool uses a digital twin of the wind turbine logistics process to accurately predict and streamline logistics costs. Based on the current industry growth forecasts, AI/ML might enable a 10% decrease in logistics costs, representing a global cost saving to the wind sector of up to USD 2.6 billion annually by 2030.

In March 2022, Microsoft announced a strategic partnership with Newcrest. The mining business of Newcrest would adopt Azure as its preferred cloud provider globally, as well as work on digital twins and a sustainability data model. Both organizations are working together on projects, including the use of digital twins to improve operational performance and developing a high-impact sustainability data model.

Reasons to Acquire

Increase your understanding of the market for identifying the best and most suitable strategies and decisions on the basis of sales or revenue fluctuations in terms of volume and value, distribution chain analysis, market trends, and factors

Gain authentic and granular data access for Digital Twin Market so as to understand the trends and the factors involved in changing market situations

Qualitative and quantitative data utilization to discover arrays of future growth from the market trends of leaders to market visionaries and then recognize the significant areas to compete in the future

In-depth analysis of the changing trends of the market by visualizing the historic and forecast year growth patterns

Direct Purchase of Digital Twin Market Research Report at: https://www.delvens.com/checkout/digital-twin-market-trends-forecast-till-2030

Report Scope

Report FeatureDescriptionsGrowth RateCAGR of 60.9% during the forecasting period, 2023-2030Historical Data2019-2021Forecast Years2023-2030Base Year2022Units ConsideredRevenue in USD million and CAGR from 2023 to 2030Report Segmentationenterprise, platform, application, and region.Report AttributeMarket Revenue Sizing (Global, Regional and Country Level) Company Share Analysis, Market Dynamics, Company ProfilingRegional Level ScopeNorth America, Europe, Asia-Pacific, South America, and Middle East, and AfricaCountry Level ScopeU.S., Japan, Germany, U.K., China, India, Brazil, UAE, and South Africa (50+ Countries Across the Globe)Companies ProfiledABB; AVEVA Group plc; Dassault Systems; General Electric; Hexagon AB; IBM Corp.; SAP.Available CustomizationIn addition to the market data for Digital Twin Market, Delvens offers client-centric reports and customized according to the company’s specific demand and requirement.

TABLE OF CONTENTS

Large Enterprises

Small & Medium Enterprises

Product Design & Development

Predictive Maintenance

Business Optimization

Performance Monitoring

Inventory Management

Other Applications

Automotive & Transportation

Energy & Utilities

Infrastructure

Healthcare

Aerospace

Oil & Gas

Telecommunications

Agriculture

Retail

Other Industries.

Asia Pacific

North America

Europe

South America

Middle East & Africa

ABB

AVEVA Group plc

Dassault Systemes

General Electric

Hexagon AB

IBM Corporation

SAP

About Us:

Delvens is a strategic advisory and consulting company headquartered in New Delhi, India. The company holds expertise in providing syndicated research reports, customized research reports and consulting services. Delvens qualitative and quantitative data is highly utilized by each level from niche to major markets, serving more than 1K prominent companies by assuring to provide the information on country, regional and global business environment. We have a database for more than 45 industries in more than 115+ major countries globally.

Delvens database assists the clients by providing in-depth information in crucial business decisions. Delvens offers significant facts and figures across various industries namely Healthcare, IT & Telecom, Chemicals & Materials, Semiconductor & Electronics, Energy, Pharmaceutical, Consumer Goods & Services, Food & Beverages. Our company provides an exhaustive and comprehensive understanding of the business environment.

Contact Us:

UNIT NO. 2126, TOWER B, 21ST FLOOR ALPHATHUM SECTOR 90 NOIDA 201305, IN +44-20-8638-5055 [email protected] WEBSITE: https://delvens.com/

#Digital Twin Market#Digital Twin#Digital Twin Market Size#Digital Twin Market Share#Semiconductors & Electronics

2 notes

·

View notes

Text

The Role of Technology in Operational Excellence Consulting

In today’s fast-paced business environment, operational excellence is crucial for organizations striving for efficiency, productivity, and sustainable growth.

Consulting firms specializing in operational excellence help businesses streamline processes, reduce costs, and improve overall performance. However, with the advent of digital transformation, technology plays an increasingly significant role in operational excellence consulting. From data analytics and automation to artificial intelligence and cloud computing, technology enables consultants to offer more precise insights, implement faster solutions, and drive continuous improvements.

The Evolution of Operational Excellence Consulting

Traditionally, operational excellence consulting focused on Lean Six Sigma, process optimization, and change management methodologies. While these principles remain relevant, the digital era has introduced new tools and approaches that enhance their effectiveness. The shift towards Industry 4.0, which integrates smart technologies into operations, has redefined the way consultants approach process improvements.

Key Technologies Driving Operational Excellence Consulting

1. Data Analytics and Business Intelligence

Data analytics is a cornerstone of operational excellence consulting. By leveraging big data and business intelligence tools, consultants can:

Identify inefficiencies and bottlenecks within an organization.

Provide real-time performance metrics and predictive analytics.

Improve decision-making through actionable insights.

Advanced analytics platforms, such as Power BI, Tableau, and Google Analytics, allow consultants to visualize data effectively and drive data-driven strategies.

2. Automation and Robotic Process Automation (RPA)

Automation plays a vital role in reducing manual tasks and increasing efficiency. Robotic Process Automation (RPA) enables businesses to automate repetitive processes, such as data entry, report generation, and compliance tracking. Benefits of RPA include:

Enhanced accuracy and reduced human errors.

Faster processing times and increased productivity.

Cost savings through workforce optimization.

Operational excellence consultants integrate RPA solutions to help organizations optimize workflows and achieve higher efficiency levels.

3. Artificial Intelligence and Machine Learning

AI and machine learning are transforming how businesses approach problem-solving and decision-making. Consultants utilize AI-powered tools to:

Predict market trends and customer behaviors.

Optimize supply chain operations through demand forecasting.

Enhance customer experience with chatbots and AI-driven insights.

AI-driven technologies enable businesses to achieve operational excellence by improving efficiency, reducing waste, and personalizing customer interactions.

4. Cloud Computing and Digital Collaboration

The adoption of cloud computing has revolutionized operational excellence consulting by providing scalable, flexible, and cost-effective solutions. Cloud-based platforms offer:

Real-time data access and collaboration across global teams.

Secure and centralized storage for seamless information sharing.

Scalable infrastructure that supports business growth.

Tools like Microsoft Azure, Google Cloud, and AWS empower consultants to implement cloud-based solutions that enhance operational efficiency.

5. Internet of Things (IoT) and Smart Manufacturing

IoT technology enables businesses to collect and analyze data from connected devices, leading to smarter decision-making. In operational excellence consulting, IoT applications include:

Monitoring equipment performance and predictive maintenance.

Enhancing supply chain transparency through real-time tracking.

Improving workplace safety through sensor-based monitoring.

IoT-driven insights help businesses minimize downtime, reduce operational costs, and optimize resource allocation.

6. Process Mining and Digital Twins

Process mining tools analyze business processes in real time to identify inefficiencies and recommend optimizations. Digital twins, on the other hand, create virtual models of physical assets, allowing businesses to simulate and test improvements before implementation. These technologies:

Enhance process transparency and eliminate bottlenecks.

Reduce risks associated with process changes.

Enable continuous improvement through real-time insights.

Consultants use process mining and digital twins to enhance operational workflows and drive excellence across industries.

Benefits of Integrating Technology in Operational Excellence Consulting

Embracing technology in operational excellence consulting provides numerous benefits, including:

Increased Efficiency: Automation and AI-driven tools enhance productivity and reduce manual intervention.

Cost Reduction: Technology-driven process improvements lower operational costs and optimize resource utilization.

Enhanced Decision-Making: Data analytics and AI provide real-time insights for better strategic decisions.

Scalability and Flexibility: Cloud computing enables businesses to scale operations seamlessly.

Competitive Advantage: Companies leveraging technology gain a strategic edge in the market.

Challenges and Considerations

Despite its advantages, technology integration in operational excellence consulting comes with challenges such as:

Implementation Costs: Initial investments in technology can be high.

Change Resistance: Employees may resist digital transformation due to unfamiliarity.

Data Security Risks: Increased reliance on digital tools raises cybersecurity concerns.

Skill Gaps: Organizations may require upskilling programs to maximize technology benefits.

Consultants must develop tailored strategies to address these challenges and ensure smooth digital transformation.

Conclusion

Technology has become a game-changer in Operational Excellence Consulting Firms, enabling businesses to optimize processes, enhance efficiency, and drive innovation. By leveraging data analytics, automation, AI, IoT, and cloud computing, consultants can offer actionable insights and sustainable improvements. However, successful implementation requires careful planning, addressing challenges, and fostering a culture of continuous improvement. As technology continues to evolve, its role in operational excellence consulting will only grow, shaping the future of business optimization and performance excellence.

0 notes

Text

Rise of Digital Twins in Real Estate

Introduction

The real estate industry is rapidly evolving with the integration of advanced technologies, and one of the most groundbreaking innovations is the rise of digital twins—highly detailed virtual replicas of physical properties. These virtual models allow real estate professionals to showcase, analyze, and sell properties with unprecedented accuracy. By offering interactive, real-time simulations of properties, digital twins are enhancing marketing strategies, reducing sales cycles, and improving decision-making for both buyers and investors.

According to Omar Hussain, a real estate technology strategist, “Digital twins are not just 3D models; they are intelligent, data-driven assets that revolutionize how we understand and interact with real estate. They bridge the gap between the physical and virtual worlds, making property transactions more seamless than ever.”

What Are Digital Twins in Real Estate?

A digital twin is a highly detailed virtual replica of a property, created using data from 3D scans, IoT sensors, and AI-powered analytics. Unlike simple 3D models, digital twins integrate real-time data, such as environmental conditions, energy usage, and even occupancy trends. This technology allows potential buyers and investors to virtually explore properties from anywhere in the world, offering an immersive experience that traditional listings or static images cannot match.

“Digital twins have the power to transform real estate transactions by providing a dynamic, data-rich representation of properties," Omar Hussain explains. "Buyers can explore different design options, assess renovations, and even analyze a property's energy efficiency before making a decision.”

How Digital Twins Are Revolutionizing Real Estate Sales

1. Remote Property Showcasing

With digital twins, real estate agents can showcase properties to global buyers without requiring them to be physically present. This is especially beneficial for luxury real estate, commercial properties, and international investors who may not be able to visit properties in person. Virtual walkthroughs powered by digital twins provide an experience nearly identical to being there physically, making the sales process faster and more efficient.

"Virtual property replicas have removed geographical limitations from real estate sales,” says Omar Hussain. “With digital twins, potential buyers can experience a property in real time, as if they were walking through it, no matter where they are in the world.”

2. Enhancing Pre-Sales for Under-Construction Properties

Developers often struggle to market pre-construction properties, as buyers cannot physically visit or visualize them. Digital twins solve this problem by allowing developers to create virtual replicas of future buildings, complete with customizable layouts and design options. This enables buyers to experience the property before it’s built, boosting pre-sales and reducing uncertainty.

According to Omar Hussain, “Digital twins have become a game-changer for developers. By offering hyper-realistic previews of unbuilt properties, they instill confidence in buyers and investors, leading to faster pre-sales and stronger financial backing for projects.”

3. Data-Driven Decision Making for Buyers

Digital twins don’t just offer visuals—they provide real-time data on a property’s structural integrity, energy efficiency, and maintenance history. This enables buyers to make more informed decisions, reducing the risk of unexpected costs and improving overall transparency in transactions.

"With digital twins, buyers no longer have to rely solely on blueprints or outdated property records," says Omar Hussain. "They can access real-time data, from how a building's HVAC system performs to its sustainability metrics, ensuring a smarter investment decision.”

4. Streamlining Renovations and Customization

For buyers looking to renovate or customize a property, digital twins provide an accurate way to visualize modifications before they are made. By simulating different layouts, materials, and design choices, buyers can see the final outcome of their renovations virtually, eliminating guesswork and reducing costly mistakes.

“In the past, renovations often came with uncertainty and unforeseen challenges,” explains Omar Hussain. “With digital twins, homeowners and investors can preview changes before committing, making the entire process more predictable and cost-efficient.”

5. Reducing Environmental Impact and Costs

Digital twins also contribute to sustainability in real estate by optimizing energy consumption and reducing material waste. By simulating different scenarios, property owners can identify the most efficient energy solutions, reduce carbon footprints, and make their buildings more eco-friendly.

According to Omar Hussain, “Sustainability is a growing priority in real estate, and digital twins play a crucial role in making properties greener. By using digital replicas, we can analyze and optimize energy usage, improving both cost-efficiency and environmental impact.”

The Future of Digital Twins in Real Estate

The adoption of digital twins is set to expand rapidly, driven by advancements in AI, cloud computing, and IoT technology. As real estate firms increasingly recognize the financial and operational benefits of digital twins, we can expect to see:

• More widespread use of digital twins in residential real estate, allowing homeowners to interact with their properties like never before.

• Integration with smart cities, where digital twins of buildings connect with broader infrastructure for better urban planning and sustainability.

• Expansion in commercial real estate, where digital twins help optimize office space utilization, tenant experience, and predictive maintenance.

Conclusion

The rise of digital twins in real estate is revolutionizing how properties are marketed, sold, and managed. By offering hyper-realistic, data-rich representations of properties, digital twins enable remote property tours, improve buyer confidence, streamline renovations, and drive sustainability.

As Omar Hussain sums it up, “We are only scratching the surface of what digital twins can achieve in real estate. This technology is not just about visualization—it’s about making real estate smarter, more accessible, and more sustainable for future generations.”

With the ongoing evolution of digital twin technology, real estate professionals who embrace this innovation will gain a significant competitive edge, transforming the industry for years to come.

Originally Posted: https://vocal.media/journal/rise-of-digital-twins-in-real-estate-how-virtual-property-replicas-are-transforming-sales

0 notes

Text

Comprehensive Market Assessment: Data Center Support Infrastructure Trends & Innovations

The global data center support infrastructure market size was valued at USD 57.94 billion in 2024 and is anticipated to grow at a CAGR of 8.2% from 2025 to 2030. The industry encompasses critical components such as power systems (UPS, generators), cooling systems, racks, monitoring systems, and Racks and Enclosures solutions. These elements ensure the operational reliability, efficiency, and Racks and Enclosures of data centers.

The rapid adoption of cloud services, big data analytics, internet of things (IoT), and AI-driven Tier Levels is transforming the technology landscape. Organizations across industries are migrating their workloads to the cloud, leveraging its scalability, cost efficiency, and flexibility. This surge in demand for cloud computing fuels the need for robust data centers capable of handling massive volumes of data and ensuring uninterrupted services. To support these operations, data centers require advanced support infrastructure, including efficient cooling systems to manage heat from high-density servers, reliable power backup systems to prevent downtime, and intelligent management solutions for optimal performance and energy utilization. This trend drives continuous innovation and investment in Tier 3, enabling businesses to meet growing digital demands and ensure seamless operations in an increasingly data-driven world.

Hyperscale data centers cater to large-scale cloud operations, offering extensive Power Distribution Systems and computational capabilities, while edge data centers provide localized, low-latency services for real-time Tier Levels like IoT and 5G. The rise of these facilities has created a need for scalable and modular infrastructure to accommodate rapid growth and evolving technology demands. Hyperscale data centers require optimized cooling and power systems to manage high-density workloads, ensuring efficiency and reliability. Edge data centers, on the other hand, emphasize compact and flexible solutions to support deployment in remote or distributed locations. Together, these developments are transforming the data center landscape, driving innovation in infrastructure to meet the diverse and growing demands of modern digital ecosystems.

Key Data Center Support Infrastructure Company Insights

Key players operating in the industry include Corning, Schneider Electric, Leviton, Legrand, Eaton, ABB, Motivair, Panduit, Rittal, Chatsworth Products, APC by Schneider Electric, Raritan, Hubbell, Vertiv, and Emerson Network Power. The companies are focusing on various strategic initiatives, including new product development, partnerships & collaborations, and agreements to gain a competitive advantage over their rivals. The following are some instances of such initiatives.

In January 2025, Panduit partnered with Hyperview to offer modern Data Center Infrastructure Management (DCIM) software tools to enhance clients' capabilities in security, environment responsiveness, and operational efficiency. By integrating Hyperview’s cloud-based platform with Panduit's critical power solutions, the collaboration aims to provide comprehensive insights, optimize operations, and promote sustainability. This move ensures seamless service continuity for existing clients while leveraging the advanced capabilities of Azure-based infrastructure for scalability and privacy

In April 2024, Eaton partnered with Red Dot Analytics (RDA) to enhance data center operations with AI-focused solutions. This collaboration aims to improve predictive maintenance, anomaly detection, and energy optimization in data centers. By integrating RDA’s Cognitive Digital Twin technology with Eaton’s expertise in power management, the partnership seeks to boost sustainability, resilience, and efficiency in handling the growing demand for AI and high-density computing workloads.

Data Center Support Infrastructure Market Report Segmentation

Grand View Research has segmented the global data center support infrastructure market report based on Infrastructure, tier level, enterprise size, end use and region.

Infrastructure Outlook (Revenue, USD Million, 2018 - 2030)

Power Distribution Systems

Cooling Systems

Racks and Enclosures

Site and Facility Infrastructure

Security Systems

Tier Level Outlook (Revenue, USD Million, 2018 - 2030)

Tier 1

Tier 2

Tier 3

Tier 4

Enterprise Size Outlook (Revenue, USD Million, 2018 - 2030)

Large Enterprise

Small & Medium Sized Enterprises

End Use Outlook (Revenue, USD Million, 2018 - 2030)

Cloud Service Provider

Technology Provider

Telecom

Healthcare

BFSI

Retail & E-commerce

Entertainment & Media

Energy

Others

Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

UK

France

Asia Pacific

China

India

Japan

South Korea

Australia

Latin America

Brazil

Middle East & Africa

A.E

Saudi Arabia

South Africa

Order a free sample PDF of the Data Center Support Infrastructure Market Intelligence Study, published by Grand View Research.

0 notes

Text

0 notes

Text

Digital Twin Market,Size, Share, Key Players | BIS Research

A Digital Twin is a virtual representation or simulation of a physical object, system, or process, typically in real-time. It is created using data collected from sensors, devices, or other sources embedded in the physical counterpart. The digital twin mirrors the characteristics, behavior, and performance of the real-world entity, allowing for analysis, monitoring, and optimization.

The Global Digital Twin Market size was valued at $10.3 billion in 2023, and it is expected to grow with a CAGR of 58.52%

Digital Twin Overview

A digital twin is a virtual model designed to accurately reflect a physical object, process, system, or service. This innovative concept leverages the convergence of the Internet of Things (IoT), artificial intelligence (AI), machine learning (ML), and big data analytics to create a dynamic and real-time simulation of a physical entity or system. Digital twins are used across various industries, including manufacturing, healthcare, urban planning, and more, enabling professionals to simulate, predict, and optimize systems before they are built and throughout their lifecycle.

Request a free sample report of the Digital Twin Market Trends

Drivers and Trends

IoT Interrogation

Industry 4.0

Predictive Maintenance

Customization and Personalization

AI and Machine Learning Integration

5G Connectivity

Sustainability Focus

Increased Adoption and Emerging Markets

Applications of Digital Twin Market

Manufacturing

Healthcare

Automotive

Smart Cities

Market Segmentation

1 By Application

• Product Design Development

• Performance Monitoring

• Predictive Maintenance

• Inventory Management

• Others

2 By End Users

• Manufacturing

• Automotive

• Aviation

• Energy and Utilities

• Healthcare

• Logistics and Retail

• Others

3 By Type

• Asset Digital Twin

• Process Digital Twin

• System Digital Twin

• Digital Twin of an Organization (DTO)

4 By Product Offering

• Platforms

• Hardware

• Support Services

5 By Region

• North America — U.S. and Canada

• Europe — U.K., Germany, France, Russia, and Rest-of-the-Europe

• Asia-Pacific — China, India, Japan, and Rest-of-Asia-Pacific

• Rest-of-the-World — Latin America and Middle East and Africa

Key Components for Digital Twin Market

Allscripts Healthcare Solutions Inc.

AMD Global Telemedicine Inc.

Apple, Inc.

AT & T, Inc.

Biotricity

GE Healthcare

IBM

I Health Lab, Inc.

Download Complete TOC of the Digital Twin Market Trends

The global Digital Twin market, encompassing telemedicine, remote patient monitoring, mobile health applications, and electronic health records, is witnessing substantial growth due to increasing demand for accessible, cost-effective, and outcome-focused healthcare solutions. Digital Twin refers to the integration of digital technologies into healthcare systems to enhance the delivery of medical services, improve patient engagement, and promote proactive healthcare management.

Digital Twin Market Segmentation

1 By Application

2 By Offering

3 By Technology

4 By Region

Get more market insights on Advanced materials and chemicals

Key Market Players

Allscripts Healthcare Solutions Inc.

AMD Global Telemedicine Inc.

Apple, Inc.

AT & T, Inc.

Biotricity

GE Healthcare

Recent Developments

•In December 2023, Siemens signed a collaboration with Intel on advanced semiconductor manufacturing, which aimed to improve production efficiency and sustainability throughout the value chain. The collaboration explored initiatives such as optimizing energy management and mitigating carbon footprints throughout the value chain. A notable aspect involved investigating the use of digital twins for complex manufacturing facilities, aiming to standardize solutions and enhance efficiency in every aspect of the process.

• In September 2023, GE Vernova launched a new product, an AI-powered carbon emissions management software for the energy sector. Utilization of this new software would enable precise measurement, management, and operationalization of insights aimed at lowering carbon emissions. With the use of a reconciliation algorithm and digital twin technology driven by machine learning (ML) and data analytics, the software aimed to increase the accuracy of greenhouse gas (GHG) calculations on scope one gas turbines by as much as 33%.

• In April 2023, Siemens signed a partnership with IBM to create an integrated software solution for systems engineering, service lifecycle management, and asset management. The collaboration aimed to support traceability and sustainable product development across mechanical, electronics, electrical, and software engineering domains. The new suite, based on SysML v1 standards, would utilize a digital thread to link design, manufacturing, operations, maintenance, updates, and end-of-life management throughout the product lifecycle

Conclusion

The digital twin market represents a paradigm shift in how industries approach problem-solving and optimization. With its ability to simulate, predict, and enhance, digital twin technology is set to become an indispensable tool across various sectors.

0 notes

Text

Enterprise Asset Management Market Size And Share Report, 2030

Enterprise Asset Management Market Growth & Trends

The global enterprise asset management market size is estimated to reach a market size of USD 19.68 billion by 2030 and expand at a CAGR of 16.9% from 2023 to 2030, according to a new study by Grand View Research, Inc. The significant market growth can be attributed to the rising technical advancements, the growing acceptance of advanced technologies for developing asset lifecycles, and the advent of innovative digital technologies across industrial verticals, such as cloud-based EAM. For instance, in April 2023, Ernst & Young LLP, a consulting company, announced a partnership with Asset Lifecycle Intelligence, a division of Hexagon AB, to offer asset performance management and enterprise asset management (EAM) technologies. Through the partnership, EY would help its customers track, monitor, and extract value from assets while mitigating risks such as unplanned costs and operational downtime.

To provide EAM and Asset Performance Management (APM) technologies as part of digital transformation and cloud migration initiatives through innovation and solution expertise. For clients aiming to address business challenges and issues regarding assets, this alliance employs EAM and APM service offerings. To promote the sustainability of digital realities and promote autonomous futures, this partnership draws together technological expertise in sustainability, digital twin, cyber, supply chain, and manufacturing execution systems, along with installation and upgrade assistance.

Cloud EAM deployment eliminates the need for extensive on-premises hardware and reduces IT infrastructure costs, allowing organizations to allocate resources more efficiently. Furthermore, cloud deployment offloads maintenance tasks, such as software updates and security patches, to the service provider, allowing the organization's IT team to focus on core business activities. For instance, in November 2022, as global's an IT services provider, announced a partnership with Dynaway, a provider of Microsoft Dynamics platform-based enterprise asset management. Through the partnership, the former company will add Dynaway’s EAM solution to its offering portfolio. The new solution would help sa.global’s clients to improve asset performance with predictive maintenance and create connected ecosystems that boost productivity, efficiency, and quality.

Several enterprises worldwide were impacted by the pandemic's breakout and the following lockdowns, travel bans, limits on people's liberty of movement, and company closures. Numerous businesses worldwide have adopted enterprise asset management solutions to manage assets, equipment, IT systems, and other resources efficiently and effectively, avoid potential hardware or machine failures, cut downtime, and maintain continuous operations. Several companies allowed remote working as part of their efforts to preserve and defend their employees' well-being following the pandemic outbreak, which resulted in a persistent demand for EAM solutions. Due to this factor, demand for enterprise asset management solutions is expected to increase notably in the forecast period.

Organizations across the world are increasingly concerned about data security at the time of implementation of an advanced IT or cloud-based EAM solution. Several manufacturing organizations wanting to improve business efficiency, asset management, and industrial operations believe security and compliance as the main barriers restricting the deployment of EAM solutions. For instance, in October 2022, Oracle launched an asset-based customer service for Oracle Fusion Cloud Applications Package to assist organizations in improving service effectiveness and customer experience.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/enterprise-asset-management-market-report

Enterprise Asset Management Market Report Highlights

The cloud service segment is anticipated to emerge as the fastest-growing solution segment over the forecast period. Organizations that want to control customer and company information security tend to prefer the on-premises version of EAM. A company's internal IT team is responsible for setting up, hosting, and managing this deployment

The small & medium enterprise segment is anticipated to emerge as the fastest-growing solution segment from 2023-2030. SMEs are starting to invest in cloud-based EAM software and transition to upgraded solutions. It has a low initial investment requirement, enables users to manage assets remotely, and allows for mobile usage, giving workers more freedom in their jobs

The government segment is anticipated to emerge as the fastest-growing solution segment over the forecast period. Government organizations can boost accountability and transparency throughout the entire organization and extend the life of their most valuable assets by implementing EAM software

The APAC market is estimated to be the fastest-growing segment, offering lucrative growth opportunities for the industry players. Businesses in APAC countries such as India still in the development stage are focusing on globalization to build a regional economic outlook and get traction in the local EAM market

Enterprise Asset Management Market Segmentation

Grand View Research has segmented the global enterprise asset management market based on deployment, enterprise size, end use, and region.

Enterprise Asset Management (EAM) Deployment Outlook (Revenue, USD Million; 2018 - 2030)

Cloud

On-premise

Enterprise Asset Management (EAM) Enterprise Size Outlook (Revenue, USD Million; 2018 - 2030)

Large Enterprise

Small & Medium Enterprise

Enterprise Asset Management (EAM) End Use Outlook (Revenue, USD Million; 2018 - 2030)

Manufacturing

Facility Management

Healthcare

Education

Government

Others

Enterprise Asset Management (EAM) Regional Outlook (Revenue, USD Billion; 2018 - 2030)

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

List of The Key Player in the Enterprise Asset Management Market

Aptean

AssetWorks, LLC

CGI, Inc.

IFS AB

Infor

International Business Machines (IBM) Corporation

Oracle Corporation

PcsInfinity (Asset Infinity)

Sage Group PLC

SAP SE

Browse Full Report: https://www.grandviewresearch.com/industry-analysis/enterprise-asset-management-market-report

#Enterprise Asset Management Market Size#Enterprise Asset Management Market Share#Enterprise Asset Management Market Trends

0 notes

Text

The Future of Wire Machinery: Cutting-Edge Innovations You Need to Know

The wire machinery industry is undergoing a remarkable transformation, driven by technological advancements that enhance efficiency, precision, and sustainability. As industries demand higher-quality wire products and faster production cycles, manufacturers are embracing cutting-edge innovations to stay ahead of the curve. In this blog, we explore the latest breakthroughs shaping the future of wire machinery.

Wire Machine Manufacturers

1. Automation and Smart Manufacturing

Automation is revolutionizing wire machinery, reducing manual intervention, and increasing production speed. Advanced robotics and AI-powered systems are streamlining processes such as wire drawing, stranding, and coating. Smart sensors and IoT-enabled devices provide real-time monitoring, ensuring precise control over quality and minimizing downtime.

2. Artificial Intelligence and Predictive Maintenance

AI and machine learning are playing a crucial role in predictive maintenance. By analyzing machine performance data, AI can detect potential failures before they occur, reducing costly breakdowns and unplanned stoppages. This not only enhances efficiency but also extends the lifespan of machinery, optimizing overall operational costs.

3. 3D Printing in Wire Manufacturing

Additive manufacturing, or 3D printing, is emerging as a game-changer in the wire industry. From designing customized wire components to producing intricate dies and tools, 3D printing enables rapid prototyping and reduces material waste. This innovation enhances flexibility in production and accelerates product development cycles.

Cable Machinery Manufacturers

4. Energy-Efficient and Eco-Friendly Solutions

Sustainability is a growing focus in wire manufacturing. Companies are adopting energy-efficient machines that consume less power while maintaining high output. Innovations in eco-friendly coatings, recyclable materials, and low-emission production processes are helping reduce the industry's carbon footprint. These advancements align with global sustainability goals and regulatory requirements.

5. High-Speed and Precision Engineering

Modern wire machinery is designed for ultra-fast operations without compromising accuracy. Innovations such as laser-guided cutting, precision wire straightening, and automated tension control ensure flawless output. These technologies enable manufacturers to meet the increasing demand for high-quality wire products across various industries, from automotive to telecommunications.

6. Advanced Materials and Coating Technologies

The development of new wire materials, including superalloys and composites, is expanding the possibilities in various applications. Enhanced coating techniques, such as nano-coatings and corrosion-resistant treatments, are improving wire durability and performance in harsh environments. These innovations are particularly beneficial in aerospace, medical, and energy sectors.

7. Digital Twins and Virtual Prototyping

The concept of digital twins—virtual models of wire machinery—allows manufacturers to simulate production processes before implementing changes in real-time. This reduces trial-and-error costs, optimizes machine settings, and ensures smoother transitions when upgrading machinery or introducing new products.

Wire Machine Manufacturers

Final Thoughts

The future of wire machinery is being shaped by automation, AI, sustainability, and precision engineering. As these innovations continue to evolve, manufacturers must embrace digital transformation to remain competitive in a fast-changing landscape. Investing in cutting-edge technology will not only enhance efficiency and product quality but also open new opportunities for growth in the global market.

Are you ready to embrace the future of wire machinery? Stay ahead by integrating these innovations into your manufacturing process today!

#Wire Machine Manufacturers#Wire Machinery Manufacturers#Cable Machinery Manufacturers#Cable Making Machine Manufacturers#Wire Making Machine Manufacturers

0 notes

Text

Exploring the Future of Industry: Industrial Metaverse and Its Applications

The industrial metaverse is revolutionizing how industries operate by seamlessly merging the physical and digital worlds. It enables businesses to optimize processes, enhance collaboration, and drive efficiency across sectors such as manufacturing, healthcare, logistics, and more. With an estimated compound annual growth rate (CAGR) of 17.5% from 2023 to 2031, the industrial metaverse market is projected to grow from US$ 22.1 billion in 2022 to US$ 93.5 billion by 2031, signaling a paradigm shift in industrial operations.

What Is the Industrial Metaverse?

The industrial metaverse is a dynamic ecosystem combining digital twins, IoT, AI, augmented reality (AR), and virtual reality (VR) to replicate and optimize physical industrial environments. It offers virtual representations of systems, assets, and spaces, allowing businesses to simulate, monitor, and control operations in real-time. This transformative technology is redefining traditional industrial processes by fostering automation, remote collaboration, and data-driven decision-making.

Market Dynamics and Key Drivers

1. Increasing Adoption of Digital Twin Technology

Digital twins are at the core of the industrial metaverse, enabling businesses to create virtual counterparts of physical systems. This technology facilitates real-time monitoring, predictive maintenance, and performance optimization, driving operational excellence across industries.

For instance, BMW AG is leveraging NVIDIA’s Omniverse platform to build a virtual version of its Debrecen, Hungary manufacturing plant. This digital twin enables BMW to test factory layouts, logistics, and robotics before the facility becomes operational in 2025, showcasing the power of digital twins in industrial planning.

2. Emergence of 5G Technology

5G connectivity plays a pivotal role in advancing the industrial metaverse by enabling real-time data transmission, ultra-low latency, and massive device connectivity. This robust network infrastructure supports applications like remote robotics, AR maintenance, and virtual collaboration, making industrial processes more responsive and efficient.

With 5G, industries can create immersive AR/VR experiences, enhancing employee training, design simulations, and operational oversight, all while reducing downtime and improving productivity.

3. Growing Demand for Industry 4.0 Solutions

The integration of smart technologies and automation through the industrial metaverse aligns with the goals of Industry 4.0. It empowers organizations to:

Optimize supply chains

Enhance production workflows

Minimize operational costs

Achieve sustainable practices

These capabilities make the industrial metaverse a critical tool for businesses looking to stay competitive in a rapidly evolving global economy.

Industry Vertical Applications

The industrial metaverse spans several industry verticals, each benefiting from its transformative potential:

Manufacturing: Streamlined production processes, real-time monitoring, and predictive maintenance.

Healthcare: Enhanced training simulations, telemedicine, and operational efficiency in hospitals.

Energy & Utilities: Monitoring and optimizing power grids, renewable energy operations, and infrastructure management.

Logistics & Transportation: Improved fleet management, supply chain visibility, and warehouse automation.

Retail & E-commerce: AR-powered virtual shopping experiences and efficient inventory management.

Regional Market Insights

North America leads the global industrial metaverse market due to the presence of tech giants like Microsoft, NVIDIA, and Unity Technologies. These companies drive innovation with advanced metaverse platforms and solutions.

Asia Pacific is expected to witness the fastest growth, fueled by rapid digital transformation in major economies such as China, India, Japan, and South Korea. A strong manufacturing base and increasing adoption of smart technologies further accelerate market expansion in the region.

Competitive Landscape

Key players in the industrial metaverse market are focused on R&D and innovation to stay ahead. Major companies include:

Microsoft Corporation

Siemens AG

PTC Inc.

NVIDIA Corporation

Unity Technologies

Dassault Systèmes

These leaders are investing in new technologies to meet the growing demand for industrial metaverse solutions, creating a highly competitive market landscape.

Conclusion: Unlocking the Future of Industry

The industrial metaverse represents a transformative leap for industries worldwide. By integrating advanced digital technologies with physical operations, businesses can achieve unparalleled efficiency, innovation, and sustainability.

As the market continues to expand, companies embracing the industrial metaverse will be better positioned to capitalize on its potential, driving progress in sectors ranging from manufacturing to healthcare.

The journey toward a fully realized industrial metaverse is just beginning, and its impact will undoubtedly shape the future of global industries.

0 notes

Text

Digital Twin Market Size, Share & Industry Trends Growth Analysis Report by Application (Predictive Maintenance, Business Optimization, Performance Monitoring, Inventory Management), Industry (Automotive & Transportation, Healthcare, Energy & Utilities), Enterprise and Geography - Global Growth Driver and Industry Forecast to 2028

0 notes

Text

Why NX CAM Dealers in India Are Transforming Smart Manufacturing

NX CAM

In the evolving world of manufacturing, adopting advanced technologies has become essential. NX CAM, a leading Computer-Aided Manufacturing (CAM) software, is paving the way for smarter and more efficient production. This blog explores why NX CAM is the future of smart manufacturing and how authorized NX CAM dealers in India play a crucial role in driving this transformation.

Understanding NX CAM

NX CAM, developed by Siemens, is a powerful tool for automating and optimizing machining processes. It enables manufacturers to create precise and efficient toolpaths for CNC (Computer Numerical Control) machines. This software integrates seamlessly with the broader Siemens Digital Industries Software ecosystem, making it a preferred choice for manufacturers across industries.

The Importance of Smart Manufacturing

Smart manufacturing focuses on using data, automation, and advanced technologies to improve production efficiency, quality, and flexibility. NX CAM supports this approach by offering tools to:

Automate repetitive tasks.

Reduce production errors.

Optimize machining time and material use.

Connect seamlessly with other systems, enhancing collaboration.

These features make NX CAM a vital component for manufacturers seeking to stay competitive in the global market.

Why NX CAM Is the Future of Smart Manufacturing

1. Advanced Automation Features

NX CAM eliminates manual programming by automating toolpath creation. Its advanced algorithms generate optimized machining strategies for complex parts. This saves time and reduces errors.

2. Integration with Digital Twins

NX CAM allows users to create and simulate digital twins of machining processes. These virtual models ensure that machining strategies are tested and optimized before production begins. This reduces downtime and material waste.

3. High Precision and Accuracy

Modern industries demand precision. NX CAM delivers this by enabling manufacturers to create detailed and accurate machining plans. This is especially valuable in industries such as aerospace, automotive, and medical devices.

4. Customizable and Scalable Solutions

NX CAM can adapt to the needs of small workshops and large factories alike. Its modular design allows manufacturers to start with basic features and expand as their requirements grow.

5. Seamless Integration with NX Software

As part of the broader Siemens NX software suite, NX CAM integrates with design and simulation tools. This ensures a smooth flow of data from design to production, enabling manufacturers to innovate faster.

Originally Published Corengg Technologies on December 9, 2024

0 notes

Text

Latest Trends in QA Technology for Manufacturers: Embracing Innovation

Embracing Innovation: Latest Trends in QA Technology for Manufacturers

In the ever-evolving manufacturing landscape, staying competitive means continually improving processes and products. One area undergoing significant transformation is quality assurance (QA). With advancements in technology, manufacturers now have access to innovative tools and methodologies that revolutionize QA practices, ensuring higher efficiency, precision, and customer satisfaction. For QA Managers, QA Leads, and Project Managers, understanding and adopting these trends is crucial to maintaining a competitive edge.

In this article, we explore the latest trends in QA technology that are shaping the manufacturing sector, focusing on how software quality assurance companies are driving innovation to meet the demands of Industry 4.0.

The Driving Forces Behind QA Innovation

The surge in QA innovation can be attributed to several factors, including:

Increasing Customer Expectations: Modern consumers demand flawless products, leaving no room for quality compromises.

Global Competition: As global markets expand, manufacturers must meet international quality standards to remain competitive.

Technological Advancements: Breakthroughs in AI, IoT, and data analytics are enabling smarter and faster QA processes.

Regulatory Requirements: Stricter compliance mandates require more rigorous quality checks and documentation.

Key Trends in QA Technology

The integration of cutting-edge technologies into QA processes is reshaping the way manufacturers ensure quality. Below are some of the most impactful trends:

1. AI-Powered Quality Assurance

Artificial Intelligence (AI) has become a game-changer in QA. By leveraging machine learning algorithms, AI tools can analyze vast amounts of data to identify patterns, detect anomalies, and predict potential issues. Key benefits include:

Predictive Analytics: AI anticipates defects before they occur, enabling proactive interventions.

Automated Decision-Making: Smart algorithms can make real-time quality decisions, reducing human error.

Improved Efficiency: Faster analysis and defect detection speed up the QA process, ensuring timely production schedules.

2. IoT-Enabled Quality Monitoring

The Internet of Things (IoT) is revolutionizing real-time quality monitoring. IoT sensors embedded in production equipment collect data on variables like temperature, pressure, and humidity, which can impact product quality. This data helps:

Monitor Production Conditions: Ensure consistent quality by maintaining optimal production parameters.

Trigger Alerts: Detect deviations and notify teams immediately to prevent defects.

Enable Traceability: Track each product’s journey through the production line for enhanced accountability.

3. Automation in QA Testing

Automation has streamlined QA processes by reducing manual intervention. Automated testing tools perform repetitive tasks such as inspections, measurements, and reporting, offering benefits like:

Scalability: Handle large volumes of testing without compromising quality.

Consistency: Eliminate variability associated with manual testing.

Time Savings: Accelerate testing cycles, enabling faster product launches.

4. Digital Twins

Digital twins—virtual replicas of physical systems—enable manufacturers to simulate production processes and test quality in a virtual environment. This technology offers:

Proactive Problem Solving: Identify potential issues before they occur in real-world production.

Cost Reduction: Minimize waste and downtime by optimizing processes in the digital model.

Enhanced R&D: Accelerate product development by testing prototypes virtually.

5. Cloud-Based QA Solutions

Cloud technology is making QA more accessible and flexible. Cloud-based platforms allow manufacturers to perform testing and quality monitoring from anywhere. Key advantages include:

Centralized Data Storage: Easy access to QA data for analysis and decision-making.

Collaboration: Teams across locations can work together seamlessly.

Cost-Effectiveness: Reduce the need for on-premise infrastructure.

Benefits of Partnering with Software Quality Assurance Companies

Software quality assurance companies are at the forefront of these innovations, providing manufacturers with the tools and expertise needed to implement modern QA technologies. Collaborating with these companies offers:

Expertise in Emerging Trends: Access to the latest technologies and methodologies.

Customized Solutions: Tailored QA processes to meet specific manufacturing needs.

Scalability: Adapt to changing production demands with flexible solutions.

Compliance Support: Ensure adherence to industry standards and regulatory requirements.

The Role of QA in Industry 4.0

The fourth industrial revolution, or Industry 4.0, is characterized by smart factories, connected systems, and data-driven decision-making. QA practices are evolving to align with this transformation. Some key aspects include:

Integration with Smart Systems: Seamless connectivity between QA tools and production systems for real-time monitoring.

Data-Driven Insights: Advanced analytics to drive continuous improvement in quality.

Collaborative Robots (Cobots): Cobots assist in QA tasks, enhancing precision and efficiency.

Practical Steps for Adopting QA Innovations

To stay competitive, manufacturers must embrace these QA trends. Here are actionable steps:

Invest in Training: Equip teams with the skills needed to operate advanced QA tools.

Adopt Scalable Solutions: Choose technologies that can grow with your business.

Collaborate with Experts: Partner with software quality assurance companies for guidance and support.

Leverage Data Analytics: Use insights from QA data to drive continuous improvement.

Stay Updated: Keep up with industry trends and emerging technologies to remain competitive.

Conclusion: Innovation as the Backbone of Modern QA

The manufacturing sector is entering an exciting era of transformation, driven by technological advancements in quality assurance. By adopting trends like AI, IoT, and automation, manufacturers can achieve higher efficiency, reduce defects, and meet the ever-growing expectations of customers.

For QA Managers, QA Leads, Marketing Managers, and Project Managers, staying ahead means embracing these innovations and collaborating with software quality assurance companies to implement cutting-edge solutions. By doing so, manufacturers can ensure consistent quality, enhance customer trust, and secure long-term success in an increasingly competitive market.

#qualityassuranceservices#qualityassurancetesting#quality assurance services#qualityassurancecompany

0 notes

Text

Digital Twin Market,Size, Share, Key Players | BIS Research

A Digital Twin is a virtual representation or simulation of a physical object, system, or process, typically in real-time. It is created using data collected from sensors, devices, or other sources embedded in the physical counterpart. The digital twin mirrors the characteristics, behavior, and performance of the real-world entity, allowing for analysis, monitoring, and optimization.

The Global Digital Twin Market size was valued at $10.3 billion in 2023, and it is expected to grow with a CAGR of 58.52%

Digital Twin Overview

A digital twin is a virtual model designed to accurately reflect a physical object, process, system, or service. This innovative concept leverages the convergence of the Internet of Things (IoT), artificial intelligence (AI), machine learning (ML), and big data analytics to create a dynamic and real-time simulation of a physical entity or system. Digital twins are used across various industries, including manufacturing, healthcare, urban planning, and more, enabling professionals to simulate, predict, and optimize systems before they are built and throughout their lifecycle.

Request a free sample report of the Digital Twin Market Trends

Drivers and Trends

IoT Interrogation

Industry 4.0

Predictive Maintenance

Customization and Personalization

AI and Machine Learning Integration

5G Connectivity

Sustainability Focus

Increased Adoption and Emerging Markets

Applications of Digital Twin Market

Manufacturing

Healthcare

Automotive

Smart Cities

Market Segmentation

1 By Application

• Product Design Development

• Performance Monitoring

• Predictive Maintenance

• Inventory Management

• Others

2 By End Users

• Manufacturing

• Automotive

• Aviation

• Energy and Utilities

• Healthcare

• Logistics and Retail

• Others

3 By Type

• Asset Digital Twin

• Process Digital Twin

• System Digital Twin

• Digital Twin of an Organization (DTO)

4 By Product Offering

• Platforms

• Hardware

• Support Services

5 By Region

• North America — U.S. and Canada

• Europe — U.K., Germany, France, Russia, and Rest-of-the-Europe

• Asia-Pacific — China, India, Japan, and Rest-of-Asia-Pacific

• Rest-of-the-World — Latin America and Middle East and Africa

Key Components for Digital Twin Market

Allscripts Healthcare Solutions Inc.

AMD Global Telemedicine Inc.

Apple, Inc.

AT & T, Inc.

Biotricity

GE Healthcare

IBM

I Health Lab, Inc.

Download Complete TOC of the Digital Twin Market Trends

The global Digital Twin market, encompassing telemedicine, remote patient monitoring, mobile health applications, and electronic health records, is witnessing substantial growth due to increasing demand for accessible, cost-effective, and outcome-focused healthcare solutions. Digital Twin refers to the integration of digital technologies into healthcare systems to enhance the delivery of medical services, improve patient engagement, and promote proactive healthcare management.

Digital Twin Market Segmentation

1 By Application

2 By Offering

3 By Technology

4 By Region

Get more market insights on Advanced materials and chemicals

Key Market Players

Allscripts Healthcare Solutions Inc.

AMD Global Telemedicine Inc.

Apple, Inc.

AT & T, Inc.

Biotricity

GE Healthcare

Recent Developments

•In December 2023, Siemens signed a collaboration with Intel on advanced semiconductor manufacturing, which aimed to improve production efficiency and sustainability throughout the value chain. The collaboration explored initiatives such as optimizing energy management and mitigating carbon footprints throughout the value chain. A notable aspect involved investigating the use of digital twins for complex manufacturing facilities, aiming to standardize solutions and enhance efficiency in every aspect of the process.

• In September 2023, GE Vernova launched a new product, an AI-powered carbon emissions management software for the energy sector. Utilization of this new software would enable precise measurement, management, and operationalization of insights aimed at lowering carbon emissions. With the use of a reconciliation algorithm and digital twin technology driven by machine learning (ML) and data analytics, the software aimed to increase the accuracy of greenhouse gas (GHG) calculations on scope one gas turbines by as much as 33%.

• In April 2023, Siemens signed a partnership with IBM to create an integrated software solution for systems engineering, service lifecycle management, and asset management. The collaboration aimed to support traceability and sustainable product development across mechanical, electronics, electrical, and software engineering domains. The new suite, based on SysML v1 standards, would utilize a digital thread to link design, manufacturing, operations, maintenance, updates, and end-of-life management throughout the product lifecycle

Conclusion

The digital twin market represents a paradigm shift in how industries approach problem-solving and optimization. With its ability to simulate, predict, and enhance, digital twin technology is set to become an indispensable tool across various sectors.

0 notes

Text

Jeff Elton, CEO at ConcertAI – Interview Series

New Post has been published on https://thedigitalinsider.com/jeff-elton-ceo-at-concertai-interview-series/

Jeff Elton, CEO at ConcertAI – Interview Series

Jeff Elton, Ph.D., is CEO of ConcertAI, an AI SaaS solutions company providing research solutions and patient-centric solutions for life sciences innovators and the world’s leading providers. ConcertAI is focused on accelerating and improving the precision of retrospective and prospective clinical studies using provider EMRs, LISs, and PACSs systems as the source for all study data. It is a long-term partner partner with the American Society of Clinical Oncology and its CancerLinQ program, US FDA, NCI Health Equity initiatives, and almost 100 healthcare providers across the US.

Prior to ConcertAI, Jeff was Managing Director, Accenture Strategy/Patient Health; Global Chief Operating Officer and SVP Strategy at Novartis Institutes of BioMedical Research, Inc.; and partner at McKinsey & Company. He is also a founding board member and senior advisor to several early-stage companies. Jeff is currently a board member of the Massachusetts Biotechnology Council. He is the co-author of the widely cited book, Healthcare Disrupted (Wiley, 2016). Jeff has a Ph.D. and M.B.A. from The University of Chicago.

As the founding CEO of ConcertAI, can you share your vision for the company at its inception? How has that vision evolved since 2018?

We started with the idea that improved patient outcomes come from deep and actionable insights. Gaining those insights requires data completeness, data scale, data representativeness and advanced AI intelligence. So, we created a Data-as-a-Service and AI Software-as-a-Service company. We targeted AI that allows inferencing and prediction. This included predicting events to avoid, such as patients’ non-adherence to their therapy or discontinuation of care because of a lack of positive response, which informed when clinical trials might be the next option.

Our vision has remained steadfast, and we continue to expect more out of our solutions. With the latest generation of LLMs, agentic AI and other generative AI solutions, we can operate at scale (and almost in real-time—something we did not expect or anticipate in 2018). With partners like NVIDIA, we can advance our solutions to perform better than expected, recognize limitations and unique characteristics, and move at the pace of the entire market’s innovations—the journey so far has been extraordinarily productive and exhilarating.

We have opened up previously unimaginable performance in clinical trial automation solutions, automating the placement of patients on evidence-based clinical pathways, advanced workflows in radiological interpretation, and the use of digital twins as a decision-enhancing tool for care and research.

Today, we serve almost 50 biopharma innovators and 2,000 healthcare providers—so while not at quite the scale of the entire market, we are the broadest-reaching AI solutions for oncology in the industry.

What inspired you to focus on oncology and hematology datasets specifically, and how did you see ConcertAI making a difference in these fields?

The United States started the “War on Cancer” in 1971 with the National Cancer Act. This catalyzed large-scale government funding, which generated insights into the mutations that drive cancers, new modalities for therapies, expanded National Cancer Institute-designated treatment centers, and more. Under the Obama administration, funding increased again by $10 billion in electronic stimulus going to the NIH and, in turn, to the NCI. Under Biden, the Cancer Moonshot 2.0 program was launched in 2022, again catalyzing an entirely new generation of research and seed funding investment for academic, community, and private-public partnerships.

I give this history because few diseases or areas of healthcare have the level of data: genomic, transcriptomic, digital pathology, digital radiology, detailed electronic medical records, etc., and the level of research that contextualizes these data with validated insights through rigorous, multi-center, peer-review studies. As further evidence, the American Society of Clinical Oncology annual meeting is the largest medical meeting in the world, with the greatest number of new publications, posters and abstracts of any scientific forum on any topic.

So, if you are going to be data and AI-centric, there are few better areas to advance solutions with confidence and at scale than oncology. ConcertAI has the largest collection of research-grade data of anyone in the world. It includes hundreds of peer-reviewed publications enabled by that data, significant evidence resulting from those publications changing how patients are treated and assuring the most positive possible outcomes, and now AI SaaS technologies that are integral to the processes of care and research that bring the power of that data and evidence to bear at all points and for all decisions along a patient’s care journey. What is really important here is that we don’t do this unilaterally. It is done transparently with our healthcare provider and biopharma innovator partners to engender the greatest confidence and use. So, we are evolving toward real-time, advanced, AI intelligence-enabled decision augmentation.

ConcertAI has become a leading player in real-world evidence (RWE) and AI technology for healthcare. What were some of the early challenges you faced in positioning the company as a leader in this space?

You have to be trusted and evolve towards being the reference source. That is earned. The trust comes from your provider partners, believing that the data you are accessing is in the best interests of their patients. Trust comes from your academic and industry partners, who see the evidence of and believe that your data is derived as a perfect reflection of the original patient records and that the concepts you advance are ‘true’ and reflective of current clinical and scientific practice. You also have to achieve a scale that your data solutions represent not only the entire population but also produce conclusions that are confidently generalizable back to the full population being treated with a particular medicine. Technology is similar. Scientists and clinicians are inherently skeptical—as they should be—and don’t trust black boxes or algorithms they don’t understand. So we needed to establish trust there, too, through publications and being open about how our solutions work.

ConcertAI holds the world’s largest oncology and hematology dataset. What unique opportunities does this data create for transforming cancer research and treatment?

I love that question. We are working on this every day! The opportunities to provide value to providers, patients and innovators are almost limitless. In early-phase trials, we are evolving study simulation approaches with digital twins that will change the programs we take into clinical trials. Our data and AI optimizations will lower the time required to go from finalized protocol to finalized submission to regulators by 30 to 40%—meaning new medicines get to patients faster. Our decision augmentation AI solutions will recommend pathways for treatment that are evidence-based and specifically tailored to those pathways, monitor responses in line with the predicted response, and look for potentially beneficial clinical trials when response or benefit is below expectations. Our imaging clinical interpretation solutions operate at the level of operational processes, clinical interpretation, and longer-term view of new interpretations or new interventions that should be considered based on insights and evidence in the future. No longer is an action “once and done�� but rather it becomes “once, and then again and again” such that beneficial reassessments and future decisions are an ongoing process! What’s different here is that the view is the entire patient journey—this is a horizontal view versus a series of narrow, deep, vertical views that have to be stitched together. This is an innovation enabled by AI and a profound process change that provides new ways of working to the expert humans involved.

Can you explain how ConcertAI’s Digital Trial Solution works to match cancer patients with life-saving clinical trials? What impact have you seen so far in terms of patient outcomes?

Clinical trials are very complex and require hours of effort by a wide range of highly expert individuals. For most organizations, clinical trials are offered as a responsibility and commitment to patients where the current standard of care may not represent a viable alternative. Trials have not really been very available to patients in community treatment centers, where 80% of patients receive their care. Yet, these are the patients who will ultimately be receiving newly approved medicines. This creates a double dilemma: the majority of patients who need access to trials are limited, and those who are reflective of the ultimate standard of care population are not in the trial dataset. We set a path to resolve these problems.