#Global Automotive Window Sealing Systems Market

Text

Specialty Chemicals Market is Estimated to Hit $364.8 billion by 2028

The report "Specialty Chemicals Market by Type (Plasticizers, Water-Based, Coagulants and Flocculants, Scale Inhibitors), Application (Paper and Packaging, Automotive, Consumer Goods, Construction), and Region– Global Forecast to 2028", size was USD 272.6 billion in 2022 and is projected to reach USD 364.8 billion by 2028, at a CAGR of 5.0%, between 2023 and 2028.

Specialty chemicals are used in various industries including construction, packaging, consumer goods, automotive, industrial, medical and others. One of the biggest consumers of specialty chemicals is the automotive sector. These chemicals are employed in the manufacture of a few automobile parts, including tires, coatings, and adhesives. New specialty chemicals that can enhance the performance of these components have been developed in response to the rising need for lightweight and fuel-efficient automobiles. To make automobiles lighter and more fuel-efficient, for instance, specialty chemicals like high-performance polymers and composites are used.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=165

Water-based adhesive technology accounted for the largest market share, in terms of volume, in 2022.

Water-based technology is expected to dominate the adhesives type of specialty chemicals, in terms of volume, during the forecast period. Factors such as environmental regulations, health and safety considerations, performance and versatility, and industrial requirements and preferences drive the demand for water-based adhesive technology across the globe. Stringent environmental regulations and increasing consumer awareness have prompted the industry to adopt more environmentally friendly adhesive technologies, such as water-based adhesives.

Medical is estimated to be the fastest-growing application of adhesives, in terms of value, during the forecast period.

With improvements in surgical methods, medical equipment, and wearable technologies, the medical sector is always developing. To ensure appropriate assembly, bonding, and performance, many of these advancements need trustworthy adhesives. For example, in minimally invasive surgeries, adhesives are used to secure medical devices and seal incisions. The development in medical sector is expected to drive the market for adhesives globally.

Asia Pacific is estimated to be the largest market for adhesives, in terms of value, during the forecast period.

Asia Pacific is the largest and fastest-growing adhesives market. Asia uses plastic packaging extensively, with nations like China and India making significant contributions through their food and beverage industries. The use of adhesives in green building initiatives is becoming more and more popular due to increasing focus on sustainability and energy efficiency. Insulation materials, building exterior systems, and energy-efficient windows are all installed using adhesives. The promotion of eco-friendly and energy-saving practices by governments and organizations in Asia Pacific drives the demand for such adhesive solutions.

Note: For illustration, fastest-growing application, largest type, region is provided for adhesives market similar information is provided for all the ten chemicals in the report.

Key Players:

The key players profiled in the report include BASF SE (Germany), DOW Inc. (US), Nouryon (The Netherlands), LANXESS AG (Germany), Evonik Industries AG (Germany), Huntsman Corporation (US), Covestro AG (Germany), Clariant AG (Switzerland), Solvay S.A. (Belgium), and Arkema (France).

Content Source: https://www.marketsandmarkets.com/PressReleases/specialty-chemicals-market.asp

#Specialty chemicals market#specialty chemicals industry#specialty chemicals market size#specialty chemicals#chemical industry#chemicals

1 note

·

View note

Text

India: A Frontrunner in the PTFE Fabric Market

India is poised to become a major consumer of polytetrafluoroethylene (PTFE) fabrics in the coming years, driven by factors such as rapid urbanization, infrastructure development, and a growing emphasis on sustainability. The country's expanding manufacturing base, coupled with rising disposable incomes, is further fuelling the demand for PTFE fabrics across various industries. Urbanization and Infrastructure Driving Growth India's rapid urbanization is creating a massive demand for new infrastructure, including roads, bridges, buildings, and transportation systems. PTFE fabrics are widely used in these construction projects due to their exceptional properties, such as high durability, chemical resistance, and weatherability. They are employed for roofing, waterproofing, expansion joints, and various other applications, ensuring long-lasting performance and reduced maintenance costs. India Infrastructure development Opens in a new window business.cornell.edu India Infrastructure development.

According to the Universal Data Solutions analysis and as per their “PTFE Fabrics Market” report, the global market was valued at USD 0.9 billion in 2022, growing at a CAGR of 5.15% during the forecast period from 2023 - 2030 to reach USD XX billion by 2030.

Manufacturing Boom and Disposable Income Rise

India's manufacturing sector is experiencing significant growth, contributing to the increasing demand for PTFE fabrics in industrial applications. These fabrics are utilized in filtration systems, electrical insulation, gaskets, seals, and other components, ensuring optimal performance and safety in various industries. Additionally, rising disposable incomes among Indian consumers are driving demand for PTFE fabrics in the automotive, healthcare, and consumer goods sectors.

Sustainability and Environmental Benefits

PTFE fabrics are gaining popularity due to their sustainability attributes. Their ability to withstand harsh conditions and extend the lifespan of products contributes to reducing waste and minimizing environmental impact. Moreover, PTFE fabrics are often used in energy-efficient applications, further promoting sustainability goals.

Government Initiatives and Industry Support

The Indian government is actively promoting the growth of the PTFE fabric industry through various initiatives, such as providing incentives for research and development, encouraging domestic manufacturing, and facilitating technology transfer. Additionally, industry associations and organizations are playing a crucial role in disseminating knowledge, enhancing manufacturing capabilities, and promoting the adoption of PTFE fabrics across various sectors.

Key End-Use Industries for PTFE Fabrics in India

PTFE fabrics are used in a wide variety of applications in India, with some of the key end-use industries including:

Construction: PTFE fabrics are used in a variety of construction applications, such as roofing, waterproofing, and expansion joints. India Construction applications

Automotive: PTFE fabrics are used in a variety of automotive applications, such as electrical insulation, gaskets, and seals. India Automotive applications

Filtration: PTFE fabrics are used in a variety of filtration applications, such as water and air filtration. Medical: PTFE fabrics are used in a variety of medical applications, such as surgical implants and prosthetics.

Protective clothing: PTFE fabrics are used in a variety of protective clothing applications, such as fire suits and chemical protective suits.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=51219

Factors Driving the Growth of PTFE Fabrics in India

The growth of the PTFE fabric market in India is being driven by several factors, including:

Increasing awareness of the benefits of PTFE fabrics: PTFE fabrics offer a number of benefits, such as high chemical resistance, heat resistance, and UV resistance. As awareness of these benefits increases, demand for PTFE fabrics is expected to grow. Expanding production capacity: Several PTFE fabric manufacturers are expanding their production capacity in India to meet the growing demand for their products. Government support for the development of the PTFE fabric industry: Several governments in India are providing support for the development of the PTFE fabric industry. This support is helping to attract new investment into the industry and is fostering innovation.

Conclusion

India is poised to become a major consumer of PTFE fabrics in the coming years, driven by a combination of favorable market conditions, government support, and industry-wide initiatives. The country's growing population, expanding economy, and increasing demand for sustainable solutions are creating a fertile ground for PTFE fabrics to flourish. As India continues to develop and modernize, PTFE fabrics are poised to play an increasingly significant role in various industries, contributing to infrastructure development, industrial growth, and environmental sustainability.

Additional Insights

This growth is being driven by several factors, including the increasing demand for PTFE fabrics in the construction and automotive industries, as well as the rising adoption of PTFE fabrics in other industries such as filtration, medical, and protective clothing. The demand for PTFE fabrics in India is also being driven by the country's growing emphasis on sustainability. PTFE fabrics are an environmentally friendly material due to their durability and long lifespan. Additionally, PTFE fabrics can be recycled, which further reduces their environmental impact.

For Sales related queries, please reach us at [email protected]

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

Global Top 15 Companies Accounted for 57% of total Automotive Body Sealing Systems market (QYResearch, 2021)

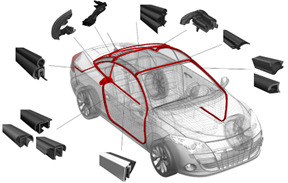

Body sealing system is commonly made of EPDM rubber and PVC, a thermoplastic elastomer (TPE) mix of plastic and rubber, and a thermoplastic olefin (TPO) polymer/filler blend. The goal of body sealing system is to prevent rain and water from entering entirely or partially and accomplishes this by either returning or rerouting water. A secondary goal of body sealing system is to keep interior air in, thus saving energy on heating and air conditioning.

The automotive body sealing system means the edges of a vehicle's windshield, windows, doors and trunk lid, etc. Automobile Sealing System strip is usually made into a hollow sponge foam tube.

According to the new market research report “Global Automotive Body Sealing Systems Market Report 2023-2029”, published by QYResearch, the global Automotive Body Sealing Systems market size is projected to reach USD 25.95 billion by 2029, at a CAGR of 13.3% during the forecast period.

Figure. Global Automotive Body Sealing Systems Market Size (US$ Million), 2018-2029

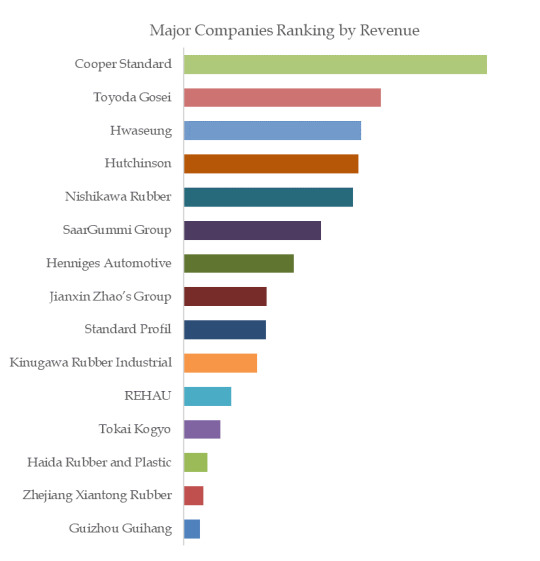

Figure. Global Automotive Body Sealing Systems Top 15 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Automotive Body Sealing Systems include Cooper Standard, Toyoda Gosei, Hwaseung, Hutchinson, Nishikawa Rubber, SaarGummi Group, Henniges Automotive, Jianxin Zhao’s Group, Standard Profil, Kinugawa Rubber Industrial, etc. In 2021, the global top five players had a share approximately 57.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Soundproof Sealing Strip Market will grow at highest pace owing to surging noise pollution concerns

Soundproof sealing strip is a thin rubber molding designed to fill gaps and block unwanted air, water, noise, dust and light infiltration. It improves the overall sound resistance of windows, doors, floors and walls by absorbing vibrations and blocking the transfer of sound energy. With rising noise pollution levels from traffic, construction and industrial activities, concern for noise reduction and soundproofing is increasing globally. This is fueling demand for soundproof sealing strips which help seal gaps and cracks to provide noise insulation.

The Global Soundproof Sealing Strip Market size was valued at US$ 1,007.4 million in 2023 and is expected to reach US$ 1,494.9 million by 2030, growing at a compound annual growth rate (CAGR) of 5.8 % from 2023 to 2030. 2024 to 2031.

Key Takeaways

Key players operating in the soundproof sealing strip market are PPG Industries, Inc., Axalta Coating Systems, LLC, BASF SE, Sherwin-Williams Company, Nippon Paint Holdings Co., Ltd., Kansai Paint Co., Ltd., Akzo Nobel N.V., 3M Company, KCC Corporation, Noroo Holdings Co., Ltd., Valspar Corporation, Jotun Group, Hempel A/S, Carpoly Chemical Group Co., Ltd., Guangdong Maydos Building Materials Limited Company. Growing application of Soundproof Sealing Strip Market Trends in construction, automotive and appliance sectors is fueling market growth. Technological advancements including development of more durable and efficient soundproof sealing strips through integration of advanced materials is further expanding market opportunities.

Market Trends

Increasing adoption of green building codes: Strict implementation of green building codes and standards requiring enhanced sound insulation is driving demand for sustainable soundproof sealing strips made from recycled materials.

Rising do-it-yourself (DIY) home improvement trend: Growing DIY home improvement trend worldwide has increased focus on soundproofing of floors, walls and ceilings, benefiting sales of cost-effective soundproof sealing strips suitable for amateur installation.

Market Opportunities

Development of multi-purpose soundproofing solutions: Market players can focus on developing innovative soundproof sealing strips with added functionalities like fire resistance and draught exclusion to meet multiple insulation needs.

Expansion in emerging nations: Emerging nations in Asia and Latin America witnessing rapid urbanization and infrastructure growth present lucrative expansion opportunities for soundproof sealing strip manufacturers.

Impact of COVID-19 on Soundproof Sealing Strip Market Growth

The COVID-19 pandemic has significantly impacted the growth of the soundproof sealing strip market. During the initial months of the pandemic, nationwide lockdowns severely disrupted construction activities and manufacturing processes. This led to a decline in demand for soundproof sealing strips from end-use industries such as automotive, building & construction, etc. However, with restricted lockdowns and gradual resumption of construction projects post pandemic, the demand is recovering steadily.

The pandemic has accelerated growth in the e-commerce and online retail sectors which is driving demand for warehouses and logistic infrastructure. Additionally, the focus on infrastructure development in developing nations is contributing to the market recovery. Various government stimulus packages aimed at reviving the construction industry are also fueling market growth. Manufacturers are focusing on developing acoustic and noise control solutions meeting stringent standards to tap opportunities in residential and commercial construction sectors. Advances in fabrication methods and materials are further expanding application areas of soundproof sealing strips in industrial and transportation sectors.

North America dominates Soundproof Sealing Strip Market in terms of value

North America currently dominates the global soundproof sealing strip market and holds the highest market share in terms of value. This is attributed to strong growth in construction activities across the US and Canada. Extensive R&D investments by key players and rapid adoption of innovative acoustic solutions are driving regional market growth. Growth in the automotive industry is supplementing demand for lightweight soundproof sealing strips. Stringent regulatory guidelines regarding noise pollution are encouraging use of acoustic insulation materials in industrial units and buildings.

Asia Pacific is the fastest growing region for Soundproof Sealing Strip Market

Asia Pacific region is poised to be the fastest growing market for soundproof sealing strips during the forecast period. Burgeoning construction of commercial buildings and infrastructure projects in China, India, Indonesia, and other Southeast Asian countries is majorly fueling the regional market. Rising disposable income, changing lifestyles, and growing health awareness are propelling sales of soundproof strips in residential segment. Manufacturers are shifting their production bases to Asia owing to low labor costs and availability of raw materials. Government initiatives to develop smart cities and urban infrastructure will further augment the APAC soundproof sealing strip market in coming years.

Gets More Insights on, Soundproof Sealing Strip Market

About Author:

Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)

#Soundproof Sealing Strip Market Size#Soundproof Sealing Strip Market Share#Soundproof Sealing Strip Market Value#Soundproof Sealing Strip Market Forecast#Soundproof Sealing Strip#Coherent Market Insights#Soundproof Sealing Strip Market

0 notes

Text

Reed Switch vs. Hall Effect Sensors: Which is Better for Your Application?

When selecting sensors for your application, choosing between reed switches and Hall effect sensors can be challenging. Both technologies have unique characteristics and advantages, making them suitable for different scenarios. In this article, we’ll compare reed switches and Hall effect sensors to help you determine which is the best fit for your needs.

Understanding Reed Switches

What is a Reed Switch?

A reed switch is an electromechanical device that consists of two ferrous metal reeds sealed in a glass envelope. When exposed to a magnetic field, the reeds come together, closing the circuit and allowing current to flow. Reed switches are known for their simplicity, durability, and reliability.

Advantages of Reed Switches

Simplicity: Reed switches have a straightforward design with minimal components, making them easy to integrate and cost-effective.

Durability: These switches are resilient and can handle millions of actuations without degradation.

Low Power Consumption: Ideal for battery-operated devices due to their low power requirements.

Applications

Reed switches are commonly used in security systems (e.g., door/window sensors), automotive applications (e.g., seatbelt detection), and consumer electronics (e.g., laptop lid switches).

Stats and Facts

Longevity: Reed switches can last over 1 billion cycles in optimal conditions.

Market Growth: The global reed switch market was valued at $240 million in 2020 and is expected to grow to $450 million by 2027, with a CAGR of 8.5%.

Understanding Hall Effect Sensors

What is a Hall Effect Sensor?

A Hall effect sensor operates on the Hall effect principle, where a voltage is generated across a conductor when it is placed in a magnetic field. These sensors can detect the strength and direction of a magnetic field, providing a non-contact measurement.

Advantages of Hall Effect Sensors

Non-Contact Operation: Hall effect sensors provide measurements without physical contact, reducing wear and tear.

Versatility: They can measure magnetic fields, currents, and rotational speed, making them suitable for a wide range of applications.

Precision: Hall effect sensors offer high precision and can provide accurate measurements even in challenging environments.

Applications

Hall effect sensors are used in automotive systems (e.g., ABS and traction control), industrial automation (e.g., motor speed sensing), and consumer electronics (e.g., smartphone orientation).

Stats and Facts

Market Presence: The global Hall effect sensor market was valued at $2.5 billion in 2020 and is projected to reach $4.2 billion by 2027, growing at a CAGR of 8.5%.

Accuracy: Hall effect sensors can measure magnetic fields with precision as high as ±0.01% full scale.

Reed Switch vs. Hall Effect Sensors: Key Comparisons

1. Operating Principle

Reed Switch: Operates by mechanically closing or opening a circuit in response to a magnetic field.

Hall Effect Sensor: Operates by measuring the voltage generated across a conductor in a magnetic field, providing non-contact measurement.

2. Contact vs. Non-Contact

Reed Switch: Requires physical contact to operate, which can lead to mechanical wear over time.

Hall Effect Sensor: Provides non-contact operation, resulting in longer lifespan and less wear.

3. Power Consumption

Reed Switch: Generally low power, making it suitable for battery-operated devices.

Hall Effect Sensor: Can consume more power depending on the design and measurement requirements.

4. Accuracy and Precision

Reed Switch: Suitable for simple applications where accuracy is not critically dependent on fine measurements.

Hall Effect Sensor: Offers high precision and is ideal for applications requiring detailed magnetic field measurements.

5. Environmental Tolerance

Reed Switch: Can be affected by extreme temperatures and environmental conditions, though specialized versions are available.

Hall Effect Sensor: Generally more robust in challenging environments and can operate across a wider temperature range.

Conclusion

Choosing between reed switches and Hall effect sensors depends on your specific application requirements. Reed switches are a cost-effective, reliable solution for simple magnetic sensing tasks where contact operation is acceptable. On the other hand, Hall effect sensors offer precision, non-contact measurement, and versatility, making them suitable for more complex or demanding applications.

Additional Stats and Facts:

Technology Adoption: The adoption of Hall effect sensors is growing rapidly in automotive and industrial applications due to their versatility and precision.

Innovation: Advances in sensor technology are driving improvements in both reed switches and Hall effect sensors, leading to more reliable and efficient solutions.

By evaluating your application's needs and understanding the strengths of each sensor type, you can make an informed decision that ensures optimal performance and reliability for your project.

0 notes

Text

Sealing Coatings Market Industry Competition Analysis, Revenue and Forecast Till 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Sealing Coatings Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Sealing Coatings Market Trends share, size, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Sealing Coatings Market?

The sealing coatings market size reached US$ 14.9 Billion in 2023. Looking forward, Reports and Insights expects the market to reach US$ 21.4 Billion by 2032, exhibiting a growth rate (CAGR) of 4.1% during 2024-2032.

What are Sealing Coatings?

Sealing coatings are substances applied to surfaces to form a protective layer that guards against moisture, chemicals, corrosion, and other environmental factors. They are utilized on various surfaces like concrete, metal, and wood to prevent harm and prolong the lifespan of the substrate. Commonly used in construction, automotive, and industrial sectors, these coatings enhance durability and preserve the aesthetic appeal of surfaces.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1788

What are the growth prospects and trends in the Sealing Coatings industry?

The sealing coatings market growth is driven by various factors. The sealing coatings market is experiencing consistent growth due to rising demand for protective coatings across industries like construction, automotive, and manufacturing. These coatings safeguard surfaces against corrosion, moisture, and environmental damage, boosting the longevity of materials. As technology advances and sustainability gains importance, the sealing coatings market is poised for further expansion, offering a variety of solutions to meet the diverse needs of various industries. Hence, all these factors contribute to sealing coatings market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

Resin Type:

Acrylic

Silicone

Polyurethane

Epoxy

Others

Substrate:

Metal

Concrete & Masonry

Wood

Plastic

Others

End-Use Industry:

Building & Construction

Automotive

Industrial

Marine

Aerospace

Electrical & Electronics

Others

Application:

Roofing

Flooring

Walls & Ceilings

Windows & Doors

Tank Linings

Others

Technology:

Water-based

Solvent-based

Radiation-cured

Powder-based

Others

Sales Channel:

Direct Sales

Distributor Sales

Online Sales

Price Range:

Economy

Mid-Range

Premium

Functionality:

Waterproofing

Corrosion Resistance

Thermal Resistance

Chemical Resistance

Others

Curing Type:

Air Cure

Heat Cure

Moisture Cure

Others

Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

3M Company

Akzo Nobel N.V.

Axalta Coating Systems

BASF SE

Dow Inc.

Henkel AG & Co. KGaA

Hempel A/S

Jotun Group

Nippon Paint Holdings Co., Ltd.

PPG Industries, Inc.

RPM International Inc.

Sherwin-Williams Company

Sika AG

Tikkurila Oyj

Wacker Chemie AG

View Full Report: https://www.reportsandinsights.com/report/Sealing Coatings-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

The Role of Rubber Seal Manufacturers in India: Driving Industrial Progress

Manufacturers of rubber seals in India, like GB Rubber Products, are essential for advancing industrial development both domestically and internationally. Innovators in the production of vital parts like rubber seals and molded rubber goods, these producers support a variety of industries' efficiency, safety, and dependability.

1. Diverse Applications:

Rubber seals are essential parts in many industries, including oil and gas, pharmaceuticals, aerospace, and the automobile and transportation industries. They protect systems and equipment's integrity by forming a barrier against pollutants.

2. Automotive Advancements:

Rubber seal manufacturers in India provide seals for doors, windows, transmissions, and engines in the automotive sector. These seals increase fuel efficiency, lower noise, and improve vehicle performance.

3. Aerospace Precision:

In aircraft applications, where accuracy and dependability are crucial, rubber seals are essential. Manufacturers like GB Rubber Products provide seals for hydraulic systems, cabin pressurization, and aviation engines.

4. Pharmaceutical Quality Assurance:

It's essential to keep a sterile atmosphere when producing pharmaceuticals. Rubber seals are important for preventing contamination, guaranteeing the safety of the product, and meeting regulatory requirements.

5. Energy Sector Support:

Rubber seals are subjected to abrasive conditions in the energy sector, which includes oil and gas. They offer wellhead, valve, and pipeline sealing systems, assisting in the safe and effective generation of energy.

6. Environmental Protection:

Water and wastewater treatment plants use rubber seals to stop leaks and safeguard the environment and general welfare.

7. Customization and Expertise:

Indian manufacturers of rubber seals are experts at customisation. They have the know-how to create seals that are suited to a given industry's requirements while taking into account variables like chemical resistance, pressure, and temperature.

8. Quality Assurance:

Indian makers of rubber seals follow strict quality control procedures in order to preserve their competitiveness on the worldwide market. They make investments in cutting-edge manufacturing techniques and components to provide seals of the highest caliber.

9. Sustainability Initiatives:

By utilizing environmentally friendly materials and energy-saving production techniques, several Indian rubber seal makers are embracing sustainable practices. This dedication to sustainability is consistent with environmental concerns around the world.

10. Global Presence:

Manufacturers of rubber seals in India, such as GB Rubber Products, have branched out internationally. They help India's industrial development by exporting high-quality sealing solutions to foreign markets.

Conclusion

The foundation of India's industrial development is provided by rubber seal makers, including GB Rubber Products. The smooth operation of crucial machinery and systems is guaranteed by their capacity to offer dependable, specialized, and high-quality sealing solutions across numerous industries. Indian rubber seal producers continue to play a crucial role in fostering innovation, sustainability, and global competitiveness as numerous industries continue to develop.

Coming to the molded rubber products manufacturers in India, they are experts at creating precise components for a variety of sectors. They play a crucial role in guaranteeing the effectiveness and safety of numerous applications thanks to their knowledge, quality, and customization abilities.

0 notes

Text

Polyurethane Sealants Market Size, Share, Growth, Major Players, Industry Analysis by Forecast

According to ChemAnalyst report, “Polyurethane Sealants Market Analysis: Plant Capacity, Production, Operating Efficiency, Demand & Supply, End Use, Distribution Channel, Region, Competition, Trade, Customer & Price Intelligence Market Analysis, 2015-2030”, Polyurethane Sealants market has witnessed significant growth as it reached 9.32 million tonnes in 2020 and is expected to achieve a healthy global CAGR of 4.75% in the forecast period until 2030. Rapidly increasing demand of Polyurethane Sealants from the flourishing building and construction industry is anticipated to boost the Polyurethane Sealants market across the globe in the span of the next ten years. Furthermore, Polyurethanes are sustainable, affordable, and doesn't contain any chemicals that can alter the endocrine and hormone systems, which can augment the demand of Polyurethane, further propelling the Polyurethane Sealants market in the future.

Polyurethane sealant is one of the most widely used technology for both new renovation and construction projects. Developments and advancements in Polyurethane Sealants have made it one of the most resilient and strongest adhesive and binding agents in the construction and building industry. Polyurethane Sealants are widely used in commercial, residential, and industrial applications including isolation joints, foundation, roofing, gutters, expansion and control joints, and others.

Polyurethane Sealants possesses dynamic properties such as excellent tear and abrasion resistance, good chemical and weather resistance, ability to be used in several joint sizes, adhesion compatibility with construction substrates like stone, metal and wood, and others. Several manufacturers are now mass-producing smart Polyurethane Sealants that offers tough and watertight seals, excellent joint movements, and aesthetic appeal characteristics, which is expected to drive the Polyurethane market in coming years. An exponential increase in the demand of Polyurethane Sealants by the major end-user industries including construction, automotive, and packaging is likely to boost the global Polyurethane Sealants market in the next few years. Surging demand for Polyurethane Sealants to insulate buildings and protect it from extreme weather conditions as PU-based Sealants prevent moisture and air penetration when used in building materials, is expected to fuel the global Polyurethane Sealants market in upcoming years.

Read Full Report Here: https://www.chemanalyst.com/industry-report/polyurethane-sealants-market-641

Global Polyurethane Sealants Market is segmented on the basis of type, application, end, sales channel and region. Based on the type, the global Polyurethane Sealants market is distributed into one component and two-component.

On the basis of end-use industries, the global Polyurethane Sealants market is segmented into building & construction, general industries, automotive, marine, and others. Building and Construction segment dominates the Polyurethane Sealants market across the globe followed by the automotive industry. Substantially increasing demand of Elastomeric Sealants by the construction industry due to the massive growth in the building and construction activities propelled by the rapid urbanization and rising per income in the Asia Pacific region is likely to boost the Polyurethane Sealants market over the next ten years.

Many leading players are merging with new companies in order to strengthen the R&D department and improve the market footprint. For example, Hodgson Sealants produced a new extremely elastic hybrid sealant in 2020 known as HY-SPEC® 25 for interior and exterior perimeter sealing of windows and doors applications.

On the start of COVID-19, in 2020, the global Polyurethane market was drastically affected. Leading authorities in emerging and industrialized economies caused countrywide lockdowns and strict social distancing norms, leading to the severe decline in the demand for Polyurethane Sealants in the first half of 2020. Major end-use industries including building & construction, marine, automotive and others halted their operations in order to curb the spread of deadly coronavirus. As the lockdown restrictions are gradually uplifting, operations may resume from early 2021, which will boost the demand of Polyurethane Sealants by the end of the year.

Request Sample Report: Polyurethane Sealants Market Report

Among different regions, Asia Pacific region dominated the global Polyurethane Sealants market in 2020 and is expected to maintain its dominance until the next ten years. Rapid industrialization, increase in construction activities and significant economic growth led to the dominance of the Polyurethane sealants market in the Asia Pacific region. Continuously rising demand of Polyurethane Sealants for building and construction activities owing to increasing urbanization and rising per capita income in emerging countries like China, India, Singapore and others, is likely to accelerate the global Polyurethane Sealants market in the upcoming years. As China owns the world’s largest construction market, the initiatives for the construction and renovation of industrial, commercial, and residential buildings, is expected to influence the market growth of polyurethane sealants in the Asia Pacific region.

Major players for Polyurethane Sealants include BASF SE, The 3M Company, Arkema S.A., Sika AG, The DOW Chemical Company, H.B. Fuller, Henkel AG & Company, KGaA, Mapei S.P.A., Asian Paints limited, Itw Polymer Sealants North America Inc., Soudal N.V., Hodgson Sealants, Pidilite Industries Limited., and Others.

“Rapidly increasing demand of Polyurethane sealants from the blooming construction industry is expected to accelerate the global Polyurethane market in upcoming years. The number of initiatives for the construction and renovation of the commercial, industrial and residential buildings in the Asia Pacific region propelled by the increasing population and growing per capita income is likely to boost the overall demand of Polyurethane Sealants in the next few years. leading players are expanding their manufacturing units and merging with new companies in order to strengthen their R&D department and improve the market footprint. Increasing prices of raw materials for the manufacturing of polyurethane sealants can somehow hamper the market growth in the future.” said Mr. Karan Chechi, Research Director with TechSci Research, a research-based management consulting firm promoting ChemAnalyst worldwide.

About Us:

ChemAnalyst is a subsidiary of Techsci Research, which was established in 2008, and has been providing exceptional management consulting to its clients across the globe for over a decade now. For the past four years, ChemAnalyst has been a prominent provider of Chemical commodity prices in more than 15 countries. We are a team of more than 100 Chemical Analysts who are committed to provide in-depth market insights and real-time price movement for 300+ chemical and petrochemical products. ChemAnalyst has reverberated as a preferred pricing supplier among Procurement managers and Strategy professionals worldwide. On our platform, we provide an algorithm-based subscription where users can track and compare years of historical data and prices based on grades and incoterms (CIF, CFR, FOB, & EX-Works) in just one go.

The ChemAnalyst team also assists clients with Market Analysis for over 1200 chemicals including assessing demand & supply gaps, locating verified suppliers, choosing whether to trade or manufacture, developing Procurement Strategies, monitoring imports and exports of Chemicals, and much more. The users will not only be able to analyze historical data for past years but will also get to inspect detailed forecasts for the upcoming years. With access to local field teams, the company provides high-quality, reliable market analysis data for more than 40 countries.

ChemAnalyst is your one-stop solution for all data-related needs. We at ChemAnalyst are dedicated to accommodate all of our world-class clients with their data and insights needs via our comprehensive online platform.

Contact Us:

ChemAnalyst

B-44 Sector-57 Noida,

National Capital Region

Tel: 0120-4523990

Mob: +91-8882805349

Email: [email protected]

Website: https://www.chemanalyst.com/

0 notes

Text

Cellular Rubber Market Growth, Emerging Business Trends and Research Forecast From 2023-2030

Cellular rubber, also known as sponge rubber or foam rubber, is a type of elastomer material that is characterized by its cellular structure. It is produced by introducing gas bubbles into a liquid rubber compound and then solidifying it through vulcanization or chemical curing.

The cellular structure of rubber is created by incorporating a blowing agent into the rubber compound. When the compound is heated, the blowing agent releases gas, which forms bubbles throughout the material. These bubbles give cellular rubber its unique properties, such as low density, high flexibility, and excellent cushioning and insulation capabilities.

Cellular rubber is commonly used in various applications where its properties are advantageous. Some common uses include:

Sealing and gasketing: Cellular rubber is often used to create seals and gaskets in applications where airtight or watertight seals are required. The compressibility and resilience of the material make it ideal for filling gaps and preventing leakage.

Automotive industry: Cellular rubber is used in automotive applications for sealing doors, windows, and hoods. It helps to provide a tight seal, reducing noise, vibration, and harshness (NVH) levels inside the vehicle.

Cushioning and padding: The soft and flexible nature of cellular rubber makes it suitable for cushioning and padding purposes. It is used in products such as mattresses, pillows, seat cushions, and shock-absorbing materials.

Insulation: Cellular rubber's closed-cell structure provides excellent thermal and acoustic insulation properties. It is used in HVAC (heating, ventilation, and air conditioning) systems, pipes, and other applications where insulation is required.

Packaging and shipping: Cellular rubber is used for protective packaging to cushion delicate items during transportation. It helps to absorb shocks and vibrations, protecting the packaged goods from damage.

Sports and leisure: Cellular rubber is utilized in various sports and leisure applications, such as insoles, yoga mats, exercise mats, and flotation devices, due to its cushioning and shock-absorbing properties.

The cellular rubber market is a segment of the global rubber industry that focuses on the production, distribution, and consumption of cellular rubber materials. The market for cellular rubber has been witnessing steady growth in recent years due to the increasing demand from various end-use industries.

Here are some key factors driving the cellular rubber market:

Growing demand in automotive industry: The automotive sector is one of the major consumers of cellular rubber. The use of cellular rubber in automotive sealing systems, gaskets, and NVH applications has been increasing to enhance comfort, reduce noise, and improve fuel efficiency.

Expansion in construction and infrastructure: The construction industry utilizes cellular rubber for insulation, weatherstripping, and sealing applications. The rapid growth of the construction sector, particularly in developing regions, has contributed to the increased demand for cellular rubber.

Packaging and consumer goods: The use of cellular rubber in protective packaging materials, such as cushioning foams, has witnessed significant growth due to the expansion of the e-commerce industry and the need for safe transportation of goods.

Energy efficiency and insulation requirements: With a growing focus on energy efficiency and insulation in buildings and industrial applications, the demand for cellular rubber as a thermal and acoustic insulator has increased.

Technological advancements: Advancements in cellular rubber manufacturing techniques, such as improved blowing agents, advanced molding processes, and better material formulations, have expanded the range of applications and performance capabilities of cellular rubber.

Environmental regulations and sustainability: The shift towards eco-friendly and sustainable materials has driven the demand for cellular rubber, as it is often recyclable and offers potential energy-saving benefits.

The cellular rubber market is competitive, with several key players operating globally. These companies are involved in research and development activities to develop innovative products and expand their product portfolios. Additionally, strategic collaborations, mergers and acquisitions, and investments in emerging markets are common strategies employed by market players to gain a competitive edge.

Some of the major companies operating in the global cellular rubber market include PANA Foamtec GmbH, GCP, Monmouth Rubber & Plastic Corp, Monmouth Rubber & Plastics Corp, Stockwell Elastomerics, Rogers Foam Corp, American Foam Rubber, LP, Saint Gobain Performance Plastics, Foam Rubber LLC, Metro Industries, and Ace Hose & Rubber Co. McMaster-Carr.

The cellular rubber market has been experiencing steady growth over the past few years, and it is expected to continue growing at a healthy rate in the coming years. Several factors contribute to the growth of the cellular rubber market:

Increasing demand from end-use industries: The demand for cellular rubber is rising across various end-use industries such as automotive, construction, packaging, and consumer goods. The automotive industry, in particular, is a significant driver of growth due to the need for sealing systems, gaskets, and NVH solutions. The expanding construction sector and the growing e-commerce industry also contribute to the market's growth.

Technological advancements and product innovations: Ongoing advancements in cellular rubber manufacturing techniques, including improved blowing agents and enhanced material formulations, have resulted in the development of high-performance products. Manufacturers are focusing on developing cellular rubber with improved properties such as higher durability, better insulation, and increased resistance to chemicals and temperature variations. These innovations are driving market growth by expanding the range of applications and increasing customer adoption.

Energy efficiency and sustainability initiatives: Increasing awareness of energy efficiency and sustainability has led to the adoption of cellular rubber as an insulation material in buildings, HVAC systems, and industrial applications. Cellular rubber offers excellent thermal and acoustic insulation properties, which can help reduce energy consumption and improve overall energy efficiency. Additionally, cellular rubber is often recyclable and contributes to sustainability efforts, further driving its demand.

Growing construction and infrastructure activities: The construction industry is a significant consumer of cellular rubber products for applications such as weatherstripping, gaskets, and sealing materials. The rapid growth of the construction sector, particularly in emerging economies, is fueling the demand for cellular rubber. Infrastructure development projects, including transportation and utilities, also contribute to market growth.

Increasing urbanization and lifestyle changes: Urbanization and changing lifestyles have led to a rise in consumer demand for comfort, convenience, and improved living standards. Cellular rubber products, such as cushioning foams for mattresses, pillows, and seating applications, cater to these demands, driving market growth.

Regional market expansion: The cellular rubber market is expanding globally, with emerging economies witnessing significant growth due to industrialization, urbanization, and infrastructure development. Asia-Pacific, in particular, is a key region for market growth, driven by countries like China, India, and Southeast Asian nations.

The demand for cellular rubber in the market is influenced by various factors and driven by the needs of different industries. Here are some key factors impacting the demand for cellular rubber:

Automotive industry: The automotive sector is a major consumer of cellular rubber products. The demand for cellular rubber in this industry is driven by the need for sealing systems, gaskets, vibration dampening, and noise reduction. As the automotive industry continues to grow, particularly in emerging economies, the demand for cellular rubber is expected to increase.

Construction and infrastructure: The construction industry is a significant consumer of cellular rubber for applications such as weatherstripping, sealing, and insulation. The demand for cellular rubber in construction is driven by factors such as energy efficiency requirements, infrastructure development projects, and the need for sound and thermal insulation in buildings.

Packaging and consumer goods: Cellular rubber is used in packaging materials to provide cushioning and protection during transportation. With the rise of e-commerce and the need for safe packaging, the demand for cellular rubber as a protective packaging material has increased. Additionally, cellular rubber is used in consumer goods such as mattresses, pillows, and seating cushions, driving demand from the consumer goods industry.

Industrial applications: Cellular rubber finds applications in various industrial sectors for insulation, sealing, and gasketing purposes. Industries such as HVAC (heating, ventilation, and air conditioning), appliances, electronics, and machinery utilize cellular rubber for its thermal and acoustic insulation properties, as well as its ability to provide sealing solutions.

Energy efficiency and sustainability: Increasing emphasis on energy efficiency and sustainability in various industries has driven the demand for cellular rubber. Cellular rubber's thermal insulation properties contribute to energy conservation in buildings, HVAC systems, and industrial applications. Moreover, cellular rubber is often recyclable, aligning with sustainability initiatives.

Emerging markets: The demand for cellular rubber is growing significantly in emerging markets, particularly in Asia-Pacific and Latin America. Rapid industrialization, urbanization, and infrastructure development in these regions are driving the demand for cellular rubber in various applications.

Cellular rubber finds a wide range of applications across various industries due to its unique properties. Some of the key applications of cellular rubber include:

Sealing and gasketing: Cellular rubber is commonly used for sealing and gasketing applications due to its excellent compressibility and resilience. It is used in industries such as automotive, aerospace, appliances, and machinery to create airtight and watertight seals.

Automotive industry: Cellular rubber is widely used in the automotive sector for applications such as weatherstripping, door and window seals, gaskets, and NVH (noise, vibration, and harshness) solutions. It helps to provide a tight seal, reduce noise transmission, and improve comfort in vehicles.

Insulation: Cellular rubber's closed-cell structure makes it an excellent thermal and acoustic insulator. It is used in HVAC systems, pipes, appliances, and construction applications to provide insulation and energy efficiency.

Cushioning and shock absorption: Cellular rubber's flexible and resilient nature makes it suitable for cushioning and shock-absorbing applications. It is used in products such as mattresses, pillows, seat cushions, shoe insoles, sports equipment, and packaging materials to provide comfort and protect against impacts and vibrations.

Packaging and shipping: Cellular rubber is used as a protective packaging material to cushion fragile items during transportation. It absorbs shocks and vibrations, reducing the risk of damage to the packaged goods.

Construction and building industry: Cellular rubber is used in the construction industry for applications such as weatherstripping, expansion joints, sealing profiles, and insulation. It helps to seal gaps, prevent air and water leakage, and provide thermal and acoustic insulation in buildings.

Electrical and electronics: Cellular rubber is utilized in electrical and electronics applications for gasketing, sealing, and vibration isolation. It helps to protect sensitive electronic components from environmental factors and reduce vibrations that can impact performance.

Marine and offshore applications: Cellular rubber is resistant to water, chemicals, and UV radiation, making it suitable for marine and offshore applications. It is used for sealing, gasketing, insulation, and vibration isolation in marine equipment, offshore structures, and shipbuilding.

Aerospace industry: Cellular rubber is employed in the aerospace industry for sealing, gasketing, vibration damping, and insulation applications. It helps to meet stringent requirements for safety, performance, and weight reduction in aerospace components and systems.

Medical and healthcare: Cellular rubber is used in medical and healthcare applications such as prosthetics, orthopedic devices, medical equipment, and protective padding. It provides comfort, cushioning, and protection in these applications.

The cellular rubber market offers several advantages, making it a preferred choice in various industries. Here are some key advantages of cellular rubber:

Lightweight: Cellular rubber has a low density due to its cellular structure, making it lightweight. This property is beneficial in applications where weight reduction is desired, such as automotive and aerospace industries, as it helps improve fuel efficiency and reduce overall weight without compromising on performance.

Excellent cushioning and shock absorption: Cellular rubber exhibits excellent cushioning and shock-absorbing properties, making it suitable for applications where impact protection is required. It helps absorb and dissipate energy from impacts, reducing the risk of damage to products, machinery, or structures. This advantage is valuable in applications like packaging, automotive components, sports equipment, and protective padding.

Flexibility and resilience: Cellular rubber is highly flexible and resilient, allowing it to adapt to various shapes and recover its original form after compression. This property enables it to provide effective sealing and gasketing solutions, filling gaps and irregularities to create a tight and reliable seal. It also contributes to the comfort and durability of products like mattresses, seat cushions, and footwear.

Thermal and acoustic insulation: The closed-cell structure of cellular rubber provides excellent thermal and acoustic insulation properties. It helps to minimize heat transfer and sound transmission, making it suitable for insulation applications in buildings, HVAC systems, pipes, and industrial equipment. Cellular rubber can contribute to energy efficiency and noise reduction.

Chemical and weather resistance: Cellular rubber exhibits resistance to various chemicals, oils, weathering, and UV radiation. This property makes it suitable for use in demanding environments, such as marine, offshore, automotive, and industrial applications, where exposure to harsh conditions is common. Cellular rubber can maintain its performance and integrity over extended periods.

Versatility in material formulation: Cellular rubber can be formulated with different materials and additives to achieve specific properties and meet diverse application requirements. This versatility allows for customization of cellular rubber products in terms of density, hardness, flame retardancy, electrical conductivity, and other performance characteristics.

Easy fabrication: Cellular rubber is easy to fabricate into desired shapes and sizes. It can be cut, molded, extruded, or die-cut, making it adaptable to various manufacturing processes and enabling the production of complex shapes and intricate designs. This ease of fabrication contributes to cost-effectiveness and efficient manufacturing processes.

Environmental sustainability: Cellular rubber is often recyclable, contributing to environmental sustainability. It can be reused or recycled into new products, reducing waste and promoting a circular economy.

These advantages make cellular rubber a versatile and desirable material in several industries, providing benefits such as weight reduction, impact protection, sealing efficiency, insulation, and resistance to harsh conditions.

0 notes

Text

Automotive Window and Exterior Sealing Systems Market Strategies and Insight Driven Transformation 2022-2028

The research reports provide deep insights into the global market revenue, market trends, macro-economic indicators, and governing factors, along with market attractiveness per market segment. The report provides an overview of the growth rate of Automotive Window and Exterior Sealing Systems market during the forecast period, i.e., 2022–2030. The report, most importantly, identifies the qualitative impact of various market factors on market segments and geographies. The research segments the market on the basis of product type, application type, technology type, and region. To offer more clarity regarding the industry, the report takes a closer look at the current status of various factors, including but not limited to supply chain management, distribution Trade, channels, supply and demand, and production capability differ across countries.

Get Exclusive Sample Pages of this Report @ https://iconmarketresearch.com/inquiry/sample/IMR0460

Automotive Window and Exterior Sealing Systems Market Company Profiles Analysis:

Toyoda Gosei Co Ltd. (Japan)

Copper- Standard Holdings Inc. (U.S.)

Magna Magna International Inc. (Canada)

Note – The Covid-19 (coronavirus) pandemic is impacting society and the overall economy across the world. The impact of this pandemic is growing day by day as well as affecting the supply chain. The COVID-19 crisis is creating uncertainty in the stock market, massive slowing of supply chain, falling business confidence, and increasing panic among the customer segments. The overall effect of the pandemic is impacting the production process of several industries. This report on ‘Automotive Window and Exterior Sealing Systems Market’ provides the analysis on impact on Covid-19 on various business segments and country markets. The reports also showcase market trends and forecast to 2030, factoring the impact of Covid -19 Situation.

Market Segmentation:

Automotive Window and Exterior Sealing Systems Market Size, Share & Trends Analysis Report By Component Type (Glass Run Channels, Roof Ditch Molding, Exterior Seals (Front Windshield, Hood Seals, Trunk Seals)), Vehicle (PC, LCV, HCV and EV) Global Industry Insights, Trends, and Forecast, 2021-2028.

For More Discount Details @ https://iconmarketresearch.com/inquiry/discount/IMR0460

Regional Framework

The report provides a detailed overview of the industry including both qualitative and quantitative information. It provides an overview and forecast of the global Automotive Window and Exterior Sealing Systems Market based on various segments. It also provides market size and forecast estimates from the year 2022 to 2028 with respect to five major regions. The Automotive Window and Exterior Sealing Systems Market by each region is later sub-segmented by respective countries and segments. The report covers the analysis and forecast of 18 countries globally along with the current trend and opportunities prevailing in the region.

Promising Regions & Countries Mentioned in The Automotive Window and Exterior Sealing Systems Market Report:

North America

Europe

Asia-Pacific

Latin America

The Middle East & Africa

Major Features of Automotive Window and Exterior Sealing Systems Market Report:

Save and reduce time carrying out entry-level research by identifying the growth, size, leading players and segments in the global Automotive Window and Exterior Sealing Systems market.

Highlights key business priorities in order to assist companies to realign their business strategies.

The key findings and recommendations highlight crucial progressive industry trends in the global Automotive Window and Exterior Sealing Systems market, thereby allowing players across the value chain to develop effective long-term strategies.

Develop/modify business expansion plans by using substantial growth offering developed and emerging markets.

Scrutinize in-depth global market trends and outlook coupled with the factors driving the market, as well as those hindering it.

Enhance the decision-making process by understanding the strategies that underpin commercial interest with respect to client products, segmentation, pricing and distribution.

Purchase a Copy of this Study @ https://iconmarketresearch.com/inquiry/buying/IMR0460

Note: If you have any special requirements, please let us know and we will offer you the report as you want.

About Us:

Icon Market Research is a one-stop industry research provider of actionable intelligence. Through our syndicated and consulting research services, we help our clients get solutions to their research requirements. We specialise in industries such as Semiconductor and Electronics, Aerospace and Défense, Energy, Automotive and Transportation, Healthcare, Manufacturing and Construction, Media and Technology, Chemicals, and Materials.

Contact Us:

If you have any queries about this report or if you would like further information, please contact us:

Contact Person: Gaurav B

E-mail: [email protected]

Phone: (+1) 812 506 4440.

0 notes

Photo

Global Automotive Window Sealing Systems Market 2019 | In-depth, Detailed Survey and Outlook Report 2019-2025 Global Automotive Window Sealing Systems Market Analysis : Marketdesk.us published new study/research report titled “Global Automotive Window Sealing Systems Market 2019 Research Report Analysis and Forecast: 2019 - 2025…

0 notes

Text

Global Automotive Window and Exterior Sealing Systems Market Size Trends Companies Driver Segmentation Forecast to 2027

0 notes

Text

Customised Reed Switch Sensor Solutions for Automotive Industry

Have you wondered how a same type of component can be modified into different types of sensors, then without further delay read this article explores how customised reed switch sensor solutions are driving innovations in the automotive industry, providing tailored solutions to meet the unique demands of this sector.

Understanding Reed Switch Sensors

Reed switch sensors consist of two ferromagnetic blades enclosed in a hermetically sealed glass tube. When exposed to a magnetic field, these blades either come together or separate, closing or opening an electrical circuit. This fundamental mechanism offers numerous benefits, including high durability, low power consumption, and the ability to operate in harsh environments.

Why Customise Reed Switch Sensors for Automotive Applications?

Customization allows reed switch sensors to be tailored to specific automotive applications, ensuring optimal performance and integration. Here are some key reasons why customization is essential:

Precision Fit: Customise sensors can be designed to fit specific spaces within vehicle systems, ensuring seamless integration.

Enhanced Performance: Tailoring sensor specifications, such as sensitivity and activation points, improves overall performance and reliability.

Environmental Adaptability: Custom sensors can be designed to withstand extreme temperatures, vibrations, and other harsh conditions typical in automotive environments.

Regulatory Compliance: Ensuring sensors meet industry standards and regulations is critical for automotive applications.

Key Applications of Customized Reed Switch Sensors in Automotive Industry

1. Anti-Lock Braking Systems (ABS)

Reed switch sensors play a crucial role in ABS, providing real-time feedback on wheel speed to prevent skidding and maintain control during sudden braking. According to Grand View Research, the global ABS market is expected to reach $37.2 billion by 2027, highlighting the importance of reliable sensors in these systems.

2. Gear Position Sensing

Customized reed switch sensors are used to detect the position of gears, ensuring accurate transmission control. This precision is vital for both manual and automatic transmission systems, enhancing driving performance and safety.

3. Fluid Level Monitoring

In applications such as fuel tanks, brake fluid reservoirs, and coolant systems, reed switch sensors monitor fluid levels, providing alerts for low levels to prevent potential damage. The automotive fluid market, as reported by MarketsandMarkets, is projected to reach $43.5 billion by 2025.

4. Door and Window Positioning

Reed switch sensors are used to detect the open or closed position of doors and windows, contributing to vehicle security and safety. These sensors ensure that doors are properly latched and windows are closed, providing peace of mind to drivers and passengers.

5. Seat Belt Detection

Customised reed switch sensors are employed in seat belt detection systems to ensure passengers are securely fastened. This is a critical safety feature, as seat belts significantly reduce the risk of injury during accidents.

Benefits of Customised Reed Switch Sensor Solutions

Enhanced Reliability

Customized reed switch sensors are designed to meet the specific demands of automotive applications, ensuring high reliability and long operational life. This reliability is essential for maintaining the safety and performance of vehicles.

Cost-Effectiveness

By tailoring sensors to specific applications, manufacturers can optimise production processes and reduce costs. Custom sensors eliminate the need for additional modifications or adjustments, streamlining the manufacturing process.

Improved Safety

Safety is a top priority in the automotive industry. Customized reed switch sensors enhance vehicle safety systems, such as ABS and seat belt detection, providing drivers and passengers with greater protection on the road.

Environmental Resistance

Automotive environments can be harsh, with exposure to extreme temperatures, moisture, and vibrations. Custom reed switch sensors are designed to withstand these conditions, ensuring consistent performance and durability.

Real-World Examples of Custom Reed Switch Sensor Solutions

Tesla Model S

The Tesla Model S utilises customised reed switch sensors in its advanced driver-assistance systems (ADAS). These sensors provide precise feedback for various functions, including gear position sensing and fluid level monitoring, contributing to the vehicle's high performance and safety standards.

Ford F-150

The Ford F-150, one of the best-selling trucks in the world, incorporates custom reed switch sensors in its door and window positioning systems. These sensors ensure that all doors and windows are properly closed, enhancing vehicle security and passenger safety.

Future Trends in Customised Reed Switch Sensors

The future of reed switch sensors in the automotive industry is bright, with ongoing advancements driving innovation and expanding their applications. Here are some key trends to watch:

Integration with IoT

The integration of reed switch sensors with Internet of Things (IoT) platforms is set to revolutionize automotive applications. This integration allows for real-time data collection and analysis, enabling predictive maintenance and enhanced vehicle performance. A McKinsey report estimates that IoT applications could have an economic impact of $3.9 trillion to $11.1 trillion per year by 2025.

Miniaturisation

As automotive technology evolves, the demand for smaller, more compact sensors continues to grow. Miniaturisation efforts are leading to the development of even smaller reed switch sensors, expanding their application range and improving vehicle design flexibility.

Wireless Connectivity

Advancements in wireless technology are paving the way for reed switch sensors with built-in wireless connectivity. These sensors can communicate with other vehicle systems and external devices, providing seamless integration and enhanced functionality.

Conclusion

Customized reed switch sensor solutions are transforming the automotive industry, offering tailored solutions that enhance performance, reliability, and safety. By understanding the unique needs of automotive applications and leveraging the benefits of customization, manufacturers can stay ahead of the curve and drive innovation in this dynamic sector.

Investing in customised reed switch sensors is not just about improving existing systems; it's about shaping the future of automotive technology. As the industry continues to evolve, these sensors will play an increasingly important role in ensuring vehicles are safer, more efficient, and more reliable.

0 notes

Text

Sealing Coatings Market Industry Competition Analysis, Revenue and Forecast Till 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Sealing Coatings Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Sealing Coatings Market Forecast share, size, trends, and growth. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Sealing Coatings Market?

The sealing coatings market size reached US$ 14.9 Billion in 2023. Looking forward, Reports and Insights expects the market to reach US$ 21.4 Billion by 2032, exhibiting a growth rate (CAGR) of 4.1% during 2024-2032.

What are Sealing Coatings?

Sealing coatings are substances applied to surfaces to form a protective layer that guards against moisture, chemicals, corrosion, and other environmental factors. They are utilized on various surfaces like concrete, metal, and wood to prevent harm and prolong the lifespan of the substrate. Commonly used in construction, automotive, and industrial sectors, these coatings enhance durability and preserve the aesthetic appeal of surfaces.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1788

What are the growth prospects and trends in the Sealing Coatings industry?

The sealing coatings market growth is driven by various factors. The sealing coatings market is experiencing consistent growth due to rising demand for protective coatings across industries like construction, automotive, and manufacturing. These coatings safeguard surfaces against corrosion, moisture, and environmental damage, boosting the longevity of materials. As technology advances and sustainability gains importance, the sealing coatings market is poised for further expansion, offering a variety of solutions to meet the diverse needs of various industries. Hence, all these factors contribute to sealing coatings market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

Resin Type:

Acrylic

Silicone

Polyurethane

Epoxy

Others

Substrate:

Metal

Concrete & Masonry

Wood

Plastic

Others

End-Use Industry:

Building & Construction

Automotive

Industrial

Marine

Aerospace

Electrical & Electronics

Others

Application:

Roofing

Flooring

Walls & Ceilings

Windows & Doors

Tank Linings

Others

Technology:

Water-based

Solvent-based

Radiation-cured

Powder-based

Others

Sales Channel:

Direct Sales

Distributor Sales

Online Sales

Price Range:

Economy

Mid-Range

Premium

Functionality:

Waterproofing

Corrosion Resistance

Thermal Resistance

Chemical Resistance

Others

Curing Type:

Air Cure

Heat Cure

Moisture Cure

Others

Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

3M Company

Akzo Nobel N.V.

Axalta Coating Systems

BASF SE

Dow Inc.

Henkel AG & Co. KGaA

Hempel A/S

Jotun Group

Nippon Paint Holdings Co., Ltd.

PPG Industries, Inc.

RPM International Inc.

Sherwin-Williams Company

Sika AG

Tikkurila Oyj

Wacker Chemie AG

View Full Report: https://www.reportsandinsights.com/report/Sealing Coatings-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Link

Automotive Window and Exterior Sealing System Market

0 notes

Photo

Global Automotive Window and Exterior Sealing Systems Market 2019 | In-depth, Detailed Survey and Outlook Report 2019-2025 Global Automotive Window and Exterior Sealing Systems Market Analysis : Marketdesk.us published new study/research report titled “

0 notes