#Geotextile Material

Explore tagged Tumblr posts

Text

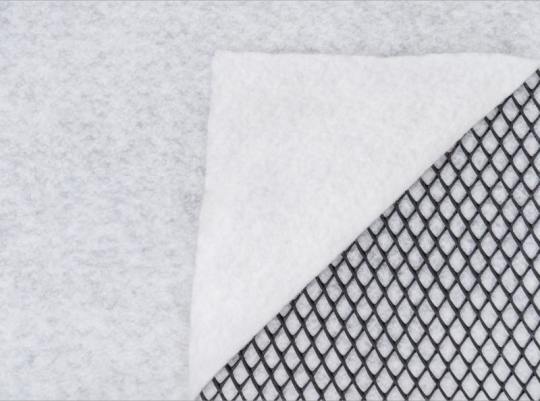

What is Geotextile & Why We Are the Top Geotextile Manufacturers?

Shankar Techx is a leading Geotextile manufacturer in India that provides versatile and durable Geotextile materials and is one of the leading geotextile fabric suppliers offering these technical fabrics with superior performances, exceptional uniformity, and strong durability to sustain damage in installation Contact us today for all your geotextile requirements.

#Different types of geotextiles#Agro tech products#Geotextiles use#geotextile material#Non-woven geotextiles#geotextile fabric suppliers#impression fabrics

0 notes

Text

0 notes

Text

What Are the Benefits of Using Non-woven Fabric?

You didn't know What Are the Benefits of Using Non-woven Fabric? Here, Shankar Packaging gave all info on Uses & Applications of Non Woven Fabric, and Benefits of Using Non Woven Fabrics, like Light Weight, Softness, Eco-friendly, etc. For more details on Non Woven Fabric Manufacturer in India, visit us!

#non woven fabric#non woven fabric bags#geotextile fabric manufacturers in Gujarat#non woven bags#non woven bag material#non woven fabric manufacturer in India#spunboud non woven material#PP cover manufacturers#filter material

0 notes

Text

What Are the Benefits of Using Non-Woven Fabric?

The non-woven fabrics are materials that are produced by thermal, mechanical and chemical processes. These are engineered fabrics that are used in various industrial and consumer products, by itself or with other materials. It is hygroscopic, UV resistant and flame retardant.

The non-woven fabrics have various benefits, including minimising solid wastes, and landfills and releasing no pollutants in the air and soil. In this blog, we will look into the various benefits of using non-woven fabrics that make them more practical and versatile than other traditional fabrics.

What is Non Woven Fabrics?

The non woven fabric is an engineered material manufactured from different fibers. These materials need not be converted to fibres into yarn, as the fibre yarns are bonded together due to inherent friction from one fibre to another.

Benefits of Using Non Woven Fabrics

Light Weight: The pp non-woven fabrics are the primary raw material for production. Its specific gravity is only 0.09, which is ⅗ of cotton. It is super-soft and pleasant to touch.

Softness: Its softness makes it ideal for non woven fabric bags. The bags are soft and comfy.

Eco-friendly: The reason why geotextile fabric manufacturers in Gujarat are in demand for its non-woven fabrics is its eco-friendly nature. This makes it applicable in different industries. With the rising concerns over environmental consciousness and sustainability, woven materials have gained immense popularity.

Air-Permeable: The non woven bags are made of fiber that exhibits excellent air permeability. This makes it easy to clean and maintain.

Non-Toxic and Non-irritant: The non woven bag material is non-toxic, non-irritant, odourless and stable. The manufacturers use food-grade materials, which makes it ideal for industries like pharmaceutical, personal care, cosmetics and other products.

Water Resistant: The non woven fabric manufacturer in India caters to different industries that need water-repellent materials. The non woven materials are made of polypropylene chips and are non-absorbent and water resistant properties. This makes the end-product exhibit excellent breathabilty and porous.

Excellent Physical Properties: As the material is made of PP spinning directly into the mesh and thermally bonded, it gives the products exceptional strength than other fibre materials.

Uses of Non Woven Fabric

The Non Woven Fabric is Used in a Variety of Applications, Such as:

Medical: The non-woven fabrics have gained a lot of popularity, especially during the pandemic. It is widely used in the manufacturing of various medical products like gloves, masks, surgical drapes, plastic, medical packaging, cleanroom wipes, disposal face masks and more.

Health & Hygiene: The spunboud non woven material has brought an evolution in the hygiene industry. It is used in producing various hygiene products like sanitary pads, diapers, make-up wipes, nail wipes, facial pads, and other products.

Geotextile and Construction: The PP cover manufacturers provide non-woven geotextiles that are used in various applications in the construction and engineering industry. It is primarily used for drainage systems, separation, canal construction, filtration, landfill lining and others.

Household: We are surrounded by non woven geotextiles. It is a part of everyday lives, ranging from water and air filters, household wipes, floor wipes, coffee filter material and much more. Shankar Packaging Ltd. is a prominent filtration fabric manufacturer. We offer a range of filtration materials in 100% multifilament, monofilament spun and other combinations.

Conclusion

Woven fabrics are used in different industrial sectors and play a pivotal role in the technical industry globally. Its soil stability, tear and puncture resistance, UV resistance, breathability, excellent weather ability and tensile strength make it a versatile material. Shankar Packaging Ltd. is a leading geotextile manufacturer and supplier in India.

We offer a comprehensive range of technical textiles, indu-tech, geo-tech, agro-tech and pack-tech products to clients across the globe. Our geotextile is also ideal for geo tubes and geo bags. At SPL, we provide technical textiles in 3 different yarns viz PES multifilament, PP tape yarns and PPMF. To know more about geotextiles and other products, contact us.

#non woven fabric#non woven fabric bags#geotextile fabric manufacturers in Gujarat#non woven bags#non woven bag material#non woven fabric manufacturer in India#spunboud non woven material#PP cover manufacturers#filter material

0 notes

Text

Geosynthetic Materials in Modern Construction: Modern Uses & Benefits

In today's dynamic world of construction, geosynthetic materials have proven to be invaluable resources. Engineered to enhance the performance and longevity of various construction applications, these materials have brought about significant advancements in the industry. This article explores the multifaceted uses and advantages of geosynthetics, with a particular focus on their role in road construction and building projects.

Introduction to Geosynthetics

What are Geosynthetics?

Geosynthetics are synthetic materials specially manufactured for use in civil engineering, environmental, and construction projects. These engineered materials offer a wide range of properties and applications that contribute to the strength, stability, and sustainability of construction projects.

Geosynthetics in Road Construction

Overview and Applications

In road construction, geosynthetics have become indispensable for enhancing performance and durability. They are used for soil stabilization, base reinforcement, erosion control, and drainage, among other applications.

Geocells in Road Construction

Geocells are three-dimensional honeycomb-like structures that provide soil stabilization and load support. They are particularly effective in road construction over weak subgrades, reducing the risk of road deformation and failure.

Geogrid for Road Construction

Geogrids, with their grid-like structure, are used for soil reinforcement. They are essential in reinforcing the road base, improving load-carrying capacity, and extending the lifespan of roads.

Use of Geosynthetics in Road Construction

The use of geosynthetics in road construction enhances soil properties and aids in overcoming challenges like unstable soil, poor drainage, and high maintenance costs.

Benefits of Geosynthetic Materials in Construction

Enhanced Durability and Strength

Geosynthetic materials significantly increase the durability and load-bearing capacity of roads. This leads to a reduction in road damage and extends the overall lifespan of the construction.

Cost-Effectiveness

By improving soil stability and strength, geosynthetics reduce the need for traditional, more expensive construction materials like aggregates. This results in cost savings both in the short and long term.

Environmental Sustainability

Geosynthetics offer an environmentally friendly solution in construction. Their use minimizes the disturbance of natural soil layers and reduces the need for non-renewable resources.

Adaptability and Versatility

These materials are adaptable to a variety of soil types and construction conditions. Their versatility makes them suitable for a wide range of applications beyond road construction, including railways, landfills, and water containment systems.

Challenges and Considerations

Technical Expertise

The installation and utilization of geosynthetic materials require specialized knowledge and technical expertise. Proper installation is crucial for maximizing their effectiveness.

Quality and Standards

Maintaining high quality and adherence to standards is essential for the optimal performance of geosynthetic materials. This underscores the importance of choosing reliable and experienced manufacturers.

The Future of Geosynthetics in Construction

Innovations and Developments

The future of geosynthetics in construction is bright, with ongoing research and development. Innovations in material science and technology are continuously enhancing the capabilities and applications of geosynthetic materials.

In conclusion, geosynthetic materials have played a pivotal role in revolutionizing modern construction practices. As the industry continues to evolve, these engineered materials will remain at the forefront of innovation and sustainability.

Introducing Indonet Group

As a leading geosynthetics manufacturer based in Vadodara, India, Indonet Group offers a comprehensive product lineup that includes Indodrin geocomposites, Indian Geocell, Indo Drain geonets, and more. With a commitment to quality and innovation, Indonet Group continues to contribute to the advancement of the construction industry through the use of geosynthetic materials.

#Geotextiles#geosynthetic materials#indonetgroup#indonet#Geocell#geonets#Geocomposite#Salt Barriers#Dimple Boards

0 notes

Text

Geotextile Market Is Estimated To Witness High Growth Owing To Increasing Infrastructure Development and Growing Awareness of Environmental Protection

The global Geotextile Market is estimated to be valued at USD 7.10 billion in 2022 and is expected to exhibit a CAGR of 6.6% over the forecast period (2023-2030).

A) Market Overview:

Geotextiles are permeable fabrics that are used in various civil engineering applications, such as filtration, erosion control, reinforcement, and drainage. They are made from synthetic materials, including polyester, polypropylene, and polyethylene, and are widely used in infrastructure development projects, such as roads, railways, airports, and landfills. Geotextiles provide excellent strength, durability, and filtration properties, which make them suitable for various applications in the construction industry.

B) Market Dynamics:

The market is driven by two main factors:

1. Increasing Infrastructure Development: The rapid urbanization and industrialization worldwide have led to a surge in infrastructure development projects. Geotextiles play a crucial role in enhancing the stability and longevity of these infrastructures. They are used in road stabilization, ground improvement, soil erosion control, and environmental protection measures. The growing demand for geotextiles in infrastructure development projects is expected to drive market growth.

2. Growing Awareness of Environmental Protection: Geotextiles offer eco-friendly solutions for various environmental protection measures. They help in preventing soil erosion, managing water drainage, and reducing the impact of pollutants on the environment. With increasing concerns about environmental degradation and regulations promoting sustainable practices, the demand for geotextiles is expected to rise.

C) Market Key Trends:

One key trend observed in the Geotextile Market is the increasing adoption of geosynthetic clay liners (GCLs). GCLs are composite materials that combine geotextiles and bentonite clay to enhance their barrier properties. They are widely used in landfill liners, mining containment, and environmental remediation applications. GCLs offer superior hydraulic performance, chemical resistance, and low permeability, making them an attractive alternative to traditional compacted clay liners.

D) SWOT Analysis:

- Strength: Strong demand for geotextiles in infrastructure development and environmental protection.

- Weakness: Lack of awareness and limited adoption in some regions.

- Opportunity: Growing research and development activities for innovative geotextile products.

- Threats: Intense competition from alternative materials and stringent government regulations.

E) Key Takeaways:

- The global geotextile for market is expected to witness high growth, exhibiting a CAGR of 6.6% over the forecast period, due to increasing infrastructure development and the growing awareness of environmental protection.

- Asia-Pacific is projected to be the fastest-growing and dominating region in the geotextile for market, driven by rapid urbanization and infrastructure investment in countries like China and India.

- Key players operating in the global geotextile for market include GSE Holdings Inc., The Dow Chemical Company, Royal Ten Cate Corporate EMEA, Fibertex Nonwovens A/S, Low & Bonar PLC., Huesker Synthetic GmbH, Tenax, CTM GEO Synthetics, Leggett & Platt Incorporated, and Kaytech Engineered Fabrics.

The geotextile for market is poised for significant growth due to the increasing demand for infrastructure development and the need to protect the environment. Geotextiles provide sustainable solutions for various civil engineering applications, making them a vital component of modern construction projects. The market is expected to witness substantial opportunities for innovation and expansion in the coming years.

0 notes

Text

Advanced Finite Element Simulation of Pullout Test on Asphalt-Geotextile/geogrid-Asphalt Layer using Abaqus

What is Pullout Test? The pullout test is a common test used in civil engineering to determine the bond strength between two materials, typically between a soil or concrete substrate and a reinforcement material such as a geotextile or a reinforcing bar. In this test, a specimen is inserted into a hole in the substrate and a pulling force is applied to the reinforcement material until it fails…

View On WordPress

#abaqus#asphalt#civil engineering#geogrid#geotextile#materials testing#pavement#pullout test#viscoelasticity

0 notes

Text

Manufacturer and Supplier of Geosynthetics

What is Manufacturer and Supplier of Geosynthetics

A manufacturer of geosynthetics is a company that produces various types of geosynthetic materials, such as geotextiles, geomembranes, geogrids, geocells, and geocomposites. These materials are typically used in civil engineering, environmental, and geotechnical applications, such as roads, landfills, retaining walls, drainage systems, and erosion control.

A supplier of geosynthetics, on the other hand, is a company that sources and distributes geosynthetic materials from various manufacturers to contractors, engineers, and other customers. Suppliers may also provide technical support and assistance with product selection and installation.

There are many companies that manufacture and supply geosynthetics, ranging from large multinational corporations to smaller regional and local firms. Some examples of prominent geosynthetic manufacturers and suppliers include TenCate Geosynthetics, GSE Environmental, Maccaferri, and Solmax.

Why We Use Manufacturer and Supplier of Geosynthetics

Quality assurance: Geosynthetics are critical components in many civil engineering and environmental projects, and their performance can have a significant impact on project success. Working with a reputable manufacturer and supplier can help ensure that the geosynthetics used in a project are of high quality and meet the required specifications.

Technical expertise: Manufacturers and suppliers of geosynthetics often have a deep understanding of the properties and applications of these materials. They can provide valuable technical support and advice to engineers, contractors, and other stakeholders on product selection, design, and installation.

Range of products: There are many different types of geosynthetics available, each with unique properties and applications. Working with a manufacturer or supplier that offers a wide range of products can help ensure that the most appropriate materials are selected for a given project.

Availability and logistics: Manufacturers and suppliers of geosynthetics typically have well-established supply chains and logistics networks, which can ensure timely delivery of materials to project sites. This can be particularly important for projects with tight deadlines or where materials need to be shipped internationally.

Overall, working with a manufacturer or supplier of geosynthetics can help ensure that the right materials are selected, delivered on time, and installed correctly, leading to successful project outcomes.

How It Work Manufacturer and Supplier of Geosynthetics

The process of working with a manufacturer and supplier of geosynthetics typically involves several steps:

Needs assessment: The manufacturer or supplier will work with the project owner, engineer, or contractor to assess the specific needs of the project. This may involve reviewing project plans and specifications, conducting site visits, and discussing project requirements and constraints.

Product selection: Based on the needs assessment, the manufacturer or supplier will recommend the most appropriate geosynthetic products for the project. This may involve selecting from a range of materials with different properties, such as strength, durability, and permeability.

Ordering and logistics: Once the geosynthetic products have been selected, the manufacturer or supplier will process the order and coordinate logistics to ensure timely delivery of materials to the project site. This may involve working with freight forwarders, customs brokers, and other logistics providers to manage international shipments.

Installation support: In many cases, the manufacturer or supplier will provide technical support and guidance to the contractor or installer during the installation of the geosynthetic materials. This may include providing training on proper installation techniques, conducting site visits to monitor progress, and addressing any issues that arise during the installation process.

Quality control: Throughout the process, the manufacturer or supplier will conduct quality control checks to ensure that the geosynthetic products meet the required specifications and performance standards.

Overall, the manufacturer and supplier of geosynthetics will work closely with the project owner, engineer, or contractor to ensure that the right products are selected, delivered on time, and installed correctly, leading to a successful project outcome.

Conclusion

A&TEngineeringPrivateLimited.Construction and Technology providing company dedicated to infrastructure development, specialized in the manufacturing of geosynthetic products and design & execution of Civil/Structural works.

CALL US : 011-41720506

OFFICAL WEBSITE : https://www.antinfra.com/

2 notes

·

View notes

Text

What Exactly is Geotextile Fabric? Its Types and Uses

Shankar Techx is one of the leading geotextile manufacturing companies offering various geotextile materials in India and worldwide, we are FIBC bags exporters; the bulk bags are economical, dependable, and have high-endurance properties, for more information visit our blog.

#Geo textile materials#geo fabric manufacturers#geotextile fabric India#Woven geotextiles#geotextile fabric suppliers#FIBC bags exporters

0 notes

Text

Textile Coatings Market : Trends Shaping Global Markets

Straits Research has released its latest report on the Textile Coatings Market, offering a detailed analysis of the industry’s size, growth potential, key trends, and opportunities. The report provides valuable insights for stakeholders, industry leaders, and decision-makers to navigate the evolving market landscape.

Market Overview

The Textile Coatings Market was valued at USD 6.86 Billion in 2022 and is projected to grow at a robust pace, reaching an estimated value of USD 9.59 Billion by 2031. This growth is driven by increasing demand across diverse end-use industries such as automotive, construction, and healthcare, coupled with advancements in coating technologies. The market is poised for a compound annual growth rate (CAGR) that underscores its importance in the global industrial ecosystem.

Get Free Request Sample Report @ https://straitsresearch.com/report/textile-coatings-market/request-sample

Textile Coatings Market Definition

The Textile Coatings Market encompasses the application of specialized coatings to textile materials to enhance their functionality and performance. Coatings improve attributes such as durability, water resistance, UV protection, flame retardance, and aesthetics, making them indispensable in sectors like automotive interiors, protective clothing, medical textiles, and home furnishings.

Latest Trends:

Sustainability Focus: The rising demand for eco-friendly and sustainable coating solutions has led to the development of biodegradable and non-toxic coatings.

Smart Textiles Integration: Innovations in smart textiles are encouraging the use of advanced coatings that offer additional functionalities, such as temperature regulation and conductivity.

Advancements in Technology: The adoption of plasma coating and magnetron sputtering technologies is enabling precise application and enhanced performance of coated textiles.

Growth in Emerging Economies: Expanding manufacturing industries in countries like India and China are creating new opportunities for market growth.

Key Growth Factors

Rising Demand in Automotive and Transportation: Increasing use of coated textiles in vehicle interiors and components for durability and comfort.

Healthcare Sector Expansion: Demand for antimicrobial and water-resistant fabrics in medical applications is a significant driver.

Construction Industry Growth: Use of coated textiles in roofing, insulation, and other building applications is growing rapidly.

Technological Innovations: Advanced coating technologies like plasma and magnetron sputtering are creating higher-quality and more sustainable solutions.

Opportunities

Eco-Friendly Coatings: Development of green solutions to align with environmental regulations and consumer preferences.

Expanding Applications: Opportunities in emerging sectors such as sportswear, geotextiles, and smart textiles.

Regional Growth: High growth potential in Asia-Pacific due to increasing industrialization and investments in textile manufacturing.

Market Segmentation

The report segments the market into key categories:

1. By Type:

Thermosets Cellulosic

Natural Rubber

Polyvinyl Chloride

Thermoplastics

Acrylics

Polyurethane

2. By Technology:

Traditional

Advanced

Magnetron Sputtering

Plasma Coating

Dot Textile Coating Technology

Full Surface Textile Coating Technology

3. By Raw Material:

Thermoplastic Textile Coatings:

Polyvinyl Chloride (PVC)

Polyurethane (PU)

Acrylics

Others (Polyolefins, Nylon)

Thermoset Textile Coatings:

Styrene Butadiene Rubber (SBR)

Natural Rubber

Others (Nitrile Rubber, Butyl Rubber)

Other Textile Coatings:

Silicone

Fluoropolymers

4. By End-User:

Building & Construction Industry

Transportation

Agriculture

Automotive

Industrial

Fabric Filters

Key Players in the Textile Coatings Market

The report profiles major industry players, including:

Covestro AG (Germany)

Huntsman International LLC (U.S.)

Solvay S.A. (Belgium)

BASF SE (Germany)

Omnova Solutions Inc. (U.S.)

The Lubrizol Corporation (U.S.)

DSM (Netherlands)

Tanatex Chemicals (India)

National Coating Corporation (U.S.)

Textiles Coated International (Australia)

The Dow Chemical Company (U.S.)

Sumitomo Chemical Company (Japan)

Clariant AG (Switzerland)

These players are at the forefront of innovation, sustainability, and product development, driving the industry forward.

Buy Now @ https://straitsresearch.com/buy-now/textile-coatings-market

Contact Us

For more information and detailed insights, contact Straits Research:

Email: [email protected]

Website: https://straitsresearch.com

#Textile Coatings Market#Textile Coatings Market Share#Textile Coatings Market Size#Textile Coatings Market Research#Textile Coatings Market Industry#What is Textile Coatings Market?

1 note

·

View note

Text

All You Must Know About PP Woven Fabric

The pp cover manufacturers constitute a key centre of production. Shankar Packaging Ltd is a prominent manufacturer of PP woven textiles and Our geotextile is widely used to filter, stabilize, drain, reinforce, and isolate soils in many construction processes. For more information visit our blog.

#PP woven geotextiles#woven polypropylene material#polypropylene ground cover#woven polypropylene bags#pp cover manufacturers#laminated woven bags#manufacturer of PP woven textiles#fibc bags manufacturers in ahmedabad

0 notes

Text

Keystone Retaining Wall Ideas to Elevate Your Landscape with Citi Landscape Supplies

A well-designed landscape can transform a mundane outdoor space into a stunning retreat. One of the most effective ways to achieve this transformation is by incorporating a keystone retaining wall into your design. These walls not only offer structural benefits but also add aesthetic appeal to your property. With the right materials and guidance from Citi Landscape Supplies, you can create a landscape that is both functional and visually captivating.

The Versatility of Keystone Retaining Walls

Keystone retaining walls are known for their versatility. They can be used to manage slopes, create terraced gardens, or provide a decorative boundary for flower beds and patios. The interlocking design of keystone blocks ensures durability while allowing for flexibility in design. Whether you are looking to build a small garden border or a large retaining wall to manage a significant elevation change, keystone retaining walls offer a solution that is both practical and stylish.

Choosing the Right Materials

Selecting the right materials is crucial for the success of your retaining wall project. At Citi Landscape Supplies, you’ll find an extensive range of products to suit any landscape design. From the robust Firth Retaining Wall blocks to the elegant Bowers Retaining Wall systems, there are options to match any aesthetic and structural requirement. These materials not only provide strength and stability but also enhance the overall appearance of your outdoor space.

Incorporating Decorative Elements

To elevate the visual appeal of your keystone retaining wall, consider integrating decorative elements like River Stones or white stones for garden NZ or River Stones Auckland. These stones can be used to create striking contrasts or subtle enhancements that draw attention to your landscape’s features. The natural beauty of Gunsmoke river stones adds a rustic charm, while the smooth finish of white stones offers a modern and clean look.

Functional Enhancements with Geotextile Fabric

A key aspect of building a durable retaining wall is proper drainage and soil stabilization. Geotextile Fabric plays an essential role in this process. It prevents soil erosion and ensures water flows away from the wall, reducing the risk of structural damage. This fabric, available at Citi Landscape Supplies, is easy to install and provides long-term benefits by maintaining the integrity of your retaining wall.

Sustainable Landscaping with Retaining Walls

Sustainability is a growing concern in landscape design, and keystone retaining walls offer an eco-friendly solution. By utilizing local materials and incorporating Weed Care practices, you can create a landscape that thrives with minimal environmental impact. A well-maintained wall not only supports plant growth but also minimizes the need for chemical treatments and excessive watering.

Innovative Design Ideas

There are countless ways to integrate keystone retaining walls into your landscape. Here are a few innovative ideas to inspire your next project:

Terraced Gardens: Create multi-level garden beds with retaining walls, allowing you to grow a variety of plants in a compact space. This design not only maximizes your garden area but also adds depth and dimension to your landscape.

Outdoor Living Spaces: Use keystone retaining walls to define outdoor living areas such as patios or seating areas. Incorporate cinder blocks to build benches or tables that blend seamlessly with your wall design.

Water Features: Enhance your retaining wall with a water feature such as a cascading fountain or a small pond. The sound of flowing water adds a tranquil ambiance to your outdoor space.

Accent Lighting: Integrate lighting into your retaining wall to highlight its structure and surrounding landscape. This not only improves visibility at night but also creates a dramatic effect that enhances the overall atmosphere.

Maintaining Your Retaining Wall

Regular maintenance is essential to ensure the longevity of your keystone retaining wall. This includes inspecting the wall for any signs of wear or damage, cleaning the surface to prevent moss and algae buildup, and ensuring proper drainage. Citi Landscape Supplies offers a range of products to help you maintain your wall, from cleaning solutions to replacement blocks.

Conclusion

Keystone retaining walls or Garden Stones are a valuable addition to any landscape, providing both functional and aesthetic benefits. With the right materials and guidance from Citi Landscape Supplies, you can create a retaining wall that not only supports your landscape but also elevates its overall appeal. Whether you’re managing a sloped garden, creating an outdoor living space, or simply looking to add a decorative touch, keystone retaining walls offer endless possibilities to enhance your outdoor environment.

0 notes

Text

B2B Genie is proud to be at the forefront of driving innovation in modern construction materials. With the increasing demand for advanced and efficient construction practices, geotextiles are emerging as a vital component for enhancing the performance and longevity of infrastructure.

We collaborate with highly rated, industry-leading suppliers recognized for their stringent quality standards, ensuring that you receive premium geotextile materials directly at your doorstep.

By choosing geotextiles, you’re not just investing in quality and durability but also optimizing your projects with materials that provide superior functionality and reduced maintenance.

Unlock the magic with B2B Genie and take your construction projects to the next level. For more details, please reach us at [email protected] or 977-331-8772

0 notes

Text

Agricultural Textiles Market Analysis of Key Dynamics Emerging Trends and Strategic Developments for Future Growth

The agricultural textiles market is experiencing significant growth due to the increasing demand for sustainable farming solutions, technological innovations, and the need to address global challenges like climate change and food security. Agricultural textiles, which include products such as crop covers, nets, geotextiles, and mulch films, are designed to improve agricultural productivity, enhance resource efficiency, and protect crops from environmental stress. As the market evolves, several key dynamics, emerging trends, and strategic developments are shaping the future of agricultural textiles. This article examines these factors in detail.

Key Dynamics of the Agricultural Textiles Market

1. Climate Change and Growing Environmental Challenges

One of the primary drivers of the agricultural textiles market is the need to adapt to climate change and mitigate its impacts on farming. Increasingly erratic weather patterns, including droughts, floods, and extreme temperatures, pose significant threats to crop yields and food security. Agricultural textiles, such as shade nets, anti-hail covers, and soil erosion prevention fabrics, are essential in protecting crops from these adverse conditions. They help maintain stable growing conditions, conserve water, and reduce the need for chemical pesticides, making them a critical solution for climate-resilient agriculture.

2. Rising Demand for Sustainable Farming Practices

As the global population continues to grow, there is a pressing need to increase agricultural productivity while minimizing environmental impact. Sustainable farming practices are becoming central to meeting this demand, and agricultural textiles play a crucial role. These products are designed to optimize resource use, reduce water consumption, and minimize the environmental footprint of farming. The growing focus on sustainability and the adoption of organic and eco-friendly farming practices are driving the increased demand for agricultural textiles.

3. Technological Innovation and Smart Agrotextiles

Technological advancements in agriculture are transforming the agrotextile market. The integration of sensors and smart technologies into agricultural textiles is a key trend driving the market forward. Smart agrotextiles, which include textiles embedded with sensors that monitor soil moisture, temperature, and crop health, provide farmers with real-time data to optimize resource management. These innovations are closely aligned with the rise of precision farming, where data-driven decisions help farmers reduce waste, increase yields, and improve overall efficiency. The adoption of smart agrotextiles is expected to accelerate as the demand for precision agriculture grows.

4. Government Support and Policy Initiatives

Governments around the world are increasingly recognizing the importance of sustainable agriculture and providing financial incentives, subsidies, and policies that support the use of agricultural textiles. These initiatives are designed to encourage the adoption of eco-friendly farming practices, improve resource efficiency, and enhance food security. Such support is crucial for the widespread adoption of agrotextiles, particularly in developing countries where small-scale farmers may face financial constraints.

Emerging Trends Shaping the Agricultural Textiles Market

1. Biodegradable and Eco-Friendly Materials

As sustainability becomes a central focus of the agricultural sector, the demand for biodegradable and eco-friendly agricultural textiles is increasing. Traditional agrotextiles made from synthetic, non-biodegradable materials can contribute to environmental pollution if not disposed of properly. In response, there has been a surge in the development of biodegradable agrotextiles made from renewable resources such as plant-based fibers and biopolymers. These materials decompose naturally, reducing environmental impact and aligning with the growing trend of circular economies. The shift toward biodegradable products is expected to continue, driven by consumer demand for more sustainable solutions.

2. Increased Adoption of Smart Agrotextiles

Smart agrotextiles are one of the most exciting developments in the agricultural textiles market. These textiles are integrated with sensors and wireless technologies that provide farmers with real-time data on soil moisture, weather conditions, and crop health. By enabling precision farming practices, smart agrotextiles help farmers optimize irrigation, reduce water waste, and enhance crop protection. As the adoption of digital technologies in agriculture increases, the demand for smart agrotextiles is expected to grow rapidly. This trend is supported by the growing popularity of IoT-based solutions in farming and the need for more data-driven decision-making.

3. Focus on Controlled-Environment Agriculture (CEA)

Controlled-environment agriculture (CEA), which includes practices such as greenhouse farming and vertical farming, is gaining traction as a solution to the challenges posed by traditional farming. CEA systems require agricultural textiles such as shade nets, insect nets, and ground covers to regulate temperature, humidity, and light. These textiles create optimal growing conditions for crops, improving yields and extending the growing season. The increasing adoption of CEA, particularly in urban areas, is expected to drive demand for agricultural textiles in the coming years.

4. Growth in Emerging Markets

The agricultural textiles market is experiencing significant growth in emerging economies, particularly in Asia-Pacific, Africa, and Latin America. These regions face numerous challenges, including water scarcity, climate change, and the need to improve food security. Agricultural textiles offer solutions that address these challenges by conserving water, reducing the risk of crop damage, and improving overall productivity. As these regions continue to modernize their agricultural practices, the demand for agrotextiles is expected to rise, creating new opportunities for market expansion.

Strategic Developments for Future Growth

1. Research and Development for Advanced Materials

To stay competitive in the market, manufacturers of agricultural textiles must invest in research and development to create innovative products that meet the evolving needs of farmers. This includes the development of advanced materials that offer improved durability, performance, and sustainability. For example, agrotextiles that combine multiple functions, such as pest control, UV protection, and water conservation, will appeal to farmers seeking more versatile solutions. Additionally, the development of more affordable and scalable biodegradable materials will be crucial for driving the widespread adoption of sustainable agrotextiles.

2. Strategic Partnerships and Collaborations

Strategic partnerships between agricultural textile manufacturers, technology companies, and research institutions are expected to play a key role in driving future growth. Collaborations with technology companies can help integrate smart features into agrotextiles, while partnerships with research institutions can accelerate the development of new materials and solutions. Such collaborations will be essential for advancing innovation and ensuring that agricultural textiles meet the changing needs of the global agricultural sector.

3. Expansion into Emerging Markets

To tap into the growing demand in emerging markets, agricultural textile manufacturers should focus on expanding their presence in regions like Asia-Pacific, Africa, and Latin America. This can be achieved through local manufacturing, partnerships with regional distributors, and tailored product offerings that address the specific challenges faced by farmers in these areas. By focusing on emerging markets, manufacturers can capture a larger share of the global market and contribute to the modernization of agriculture in these regions.

4. Integration with Precision Agriculture

As precision agriculture continues to grow, there will be increasing opportunities for agricultural textiles that are integrated with digital tools and data analytics. Agrotextiles that work in conjunction with sensors, drones, and satellite technologies to provide real-time data on crop conditions will be in high demand. Manufacturers that focus on creating textiles compatible with precision farming systems will be well-positioned to capitalize on this trend and contribute to the ongoing evolution of agriculture.

Conclusion

The agricultural textiles market is poised for significant growth, driven by factors such as climate change, the rising demand for sustainable farming practices, and technological advancements. Emerging trends, including the adoption of biodegradable materials, smart agrotextiles, and the expansion of controlled-environment agriculture, are shaping the market’s future. Strategic developments such as investment in research and development, partnerships, and market expansion will be crucial for capturing new opportunities and ensuring long-term growth. As the agricultural sector continues to evolve, agricultural textiles will play a vital role in meeting the challenges of modern farming and promoting sustainable practices globally.

Request Sample PDF Report : https://www.pristinemarketinsights.com/get-free-sample-and-toc?rprtdtid=NDMy&RD=Agricultural-Textiles-Market-Report

#AgriculturalTextilesMarket#AgriculturalTextilesMarketTrends#AgriculturalTextilesMarketInsights#AgriculturalTextilesMarketGrowth#AgriculturalTextilesMarketForecast#AgriculturalTextilesMarketOpportunities

0 notes

Text

Geotextile Fabric: Engineering Solutions for a Stronger Tomorrow

Introduction

Geotextile fabric, a versatile synthetic material, plays a crucial role in modern civil engineering projects. These permeable fabrics, typically made from polymers like polypropylene or polyester, are designed to improve soil properties and enhance the performance of various structures. This comprehensive guide explores the key features, applications, and significance of geotextile fabric in the construction industry.

Key Features of Geotextile Fabric

High Tensile Strength: Geotextiles possess excellent tensile strength, enabling them to withstand significant stresses and strains.

Permeability: These fabrics allow for the passage of fluids while retaining soil particles, ensuring proper drainage and filtration.

Chemical Resistance: Geotextiles are resistant to a wide range of chemicals, ensuring long-term durability and performance in various environments.

UV Resistance: Many geotextiles are treated with UV stabilizers to resist degradation from sunlight exposure.

Flexibility: Geotextiles are flexible and easy to install, making them adaptable to various project requirements.

Applications of Geotextile Fabric

Geotextiles find diverse applications in civil engineering, including:

Road Construction: Used to reinforce roadbeds, stabilize subgrades, and improve drainage, enhancing road longevity and reducing maintenance costs.

Railway Construction: Employed to stabilize Geo fabric sheet in India railway tracks, prevent soil erosion, and improve drainage in railway embankments.

Retaining Walls: Used to reinforce retaining walls, preventing soil movement and enhancing their stability.

Landfill Construction: Employed to control leachate seepage, prevent erosion, and stabilize landfill slopes.

Erosion Control: Used to prevent soil erosion in slopes, embankments, and riverbanks.

Drainage Systems: Used to enhance drainage in various applications, such as underground parking lots, tunnels, and sports fields.

Geo Fabric Manufacturers in India

The Geo sheet manufacturers india boasts a thriving construction industry, and consequently, a robust market for geotextile fabrics. Several leading manufacturers in India produce high-quality geotextiles, catering to diverse project needs. Some prominent players in the Indian market include:

These manufacturers offer a wide range of geotextile products, including woven, non-woven, and composite fabrics, to meet specific project requirements.

Geo Fabric Sheet in India

The Geo fabric manufacturers in India is available in various forms, including sheets. These sheets are widely used in various applications, such as road construction, drainage systems, and erosion control.

Conclusion

Geotextile fabrics have emerged as indispensable tools in modern civil engineering. Their versatility, durability, and environmental benefits make them essential components in various construction projects. By understanding their key features and applications, engineers can effectively utilize geotextiles to enhance project performance, improve sustainability, and contribute to a more resilient infrastructure.

Frequently Asked Questions (FAQs)

1. How is Geotextile Fabric Installed?

Geotextile fabric installation varies depending on the specific application. Common methods include:

Layering: Placing the fabric in layers within the soil mass.

Anchoring: Securing the fabric to the ground or other structures using stakes or other methods.

Overlapping: Overlapping the fabric sheets to ensure proper coverage and prevent gaps.

2. What are the Factors to Consider When Selecting Geotextile Fabric?

Selecting the appropriate geotextile fabric requires careful consideration of several factors, including:

Soil Properties: Soil type, strength, and drainage characteristics.

Project Requirements: Specific project needs, such as load-bearing capacity, drainage requirements, and environmental conditions.

Project Budget: Cost considerations are crucial in selecting the most suitable and cost-effective geotextile option.

3. What are the Environmental Benefits of Geotextiles?

Geotextiles offer several environmental benefits:

Reduced Soil Erosion: They help prevent soil erosion and sedimentation, protecting water bodies.

Improved Drainage: They enhance drainage, reducing the risk of flooding and waterlogging.

Reduced Construction Waste: They can reduce the amount of soil excavation and fill material required.

Increased Project Lifespan: By improving soil stability and drainage, geotextiles contribute to longer-lasting infrastructure projects.

0 notes

Text

Future of U.S. Geosynthetics Market: Insights from Industry Experts

The U.S. geosynthetics market size was estimated at USD 3.08 billion in 2023 and is expected to grow at a CAGR of 5.8% from 2024 to 2030. The U.S. is expected to account for a significant market share of the total shale gas consumption in the future on account of increasing drilling activities for shale gas and tight oil supply conditions. This is projected to positively drive the geosynthetics market in the country over the forecast period.

Geosynthetics are used for base reinforcement, separation, and stabilization of roads and pavements. Furthermore, these products also find their application in subsurface drainage systems for dewatering, road base, and structure drainage. Geotextiles are used in the strengthening of industrial units, car parks, and new roadways. The incorporation of geosynthetics entails sustainable development, a small volume of earthwork, low carbon footprint, and an increased rate of construction. The growth of the construction industry around the world, including the U.S., is expected to remain one of the key market drivers for the global geosynthetics market, further boosting the market in the U.S.

Gather more insights about the market drivers, restrains and growth of the U.S. Geosynthetics Market

Key U.S. Geosynthetics Company Insights

The market is majorly run by petrochemical manufacturers across the U.S. The competition in the market is also high due to the presence of a large number of manufacturers. Market players have established strategic partnerships with the distributors to supply their product offerings. Stringent government regulations and depleting petroleum feedstock have contributed to shifting the focus of manufacturers on renewable energy sources and prompted extensive research and development of bio-based raw materials.

Some of the prominent players in the U.S. geosynthetics market are TenCate Geosynthetics Americas; Maccaferri; Concrete Canvas Ltd.; NAUE GmbH & Co. KG; and Propex Operating Company, LLC

• NAUE GmbH & Co. KG, formerly known as Naue Fasertechnik GmbH & Co. KG, was established in 1967. It changed its name to NAUE GmbH & Co. KG in 2005. The company has its headquarters in Germany, with a global presence across North America, Asia, Europe, Australia, South America, and the Middle East & Africa.

• Maccaferri provides advanced solutions for problems related to erosion control, soil reinforcement, stabilization of the soil, and infrastructure development in application areas such as roads, railways, canals, rivers, coastal defenses, and landfills. It owns over 70 subsidiaries in over 100 countries. As of 2018, the company employed over 3,000 individuals globally.

• TENAX Group was established in 1960 and headquartered in Viganò, Italy. The company majorly specializes in extruding thermoplastic polymers. Its product range includes fences, screens, plastic nets, geogrids, and geosynthetics, which find applications in areas such as pipeline, packaging, industrial, geotechnical, gardening, fencing, construction, and agriculture.

U.S. Geosynthetics Market Report Segmentation

This report forecasts market share and revenue growth at country levels and provides an analysis of industry trends in each of the sub-segments from 2018 to 2030. For the purpose of this study, Grand View Research has segmented the U.S. geosynthetics market report based on product:

Product Outlook (Volume, Million Square Meters; Revenue, USD Billion, 2018 - 2030)

• Geotextiles

o By Raw Material

o By Product

o By Application

• Geomembranes

o By Raw Material

o By Application

o By Technology

• Geogrids

o By Raw Material

o By Application

o By Product

• Geonets

o By Raw Material

o By Application

• Geocells

o By Raw Material

o By Application

Order a free sample PDF of the U.S. Geosynthetics Market Intelligence Study, published by Grand View Research.

#U.S. Geosynthetics Market#U.S. Geosynthetics Market Size#U.S. Geosynthetics Market Share#U.S. Geosynthetics Market Analysis#U.S. Geosynthetics Market Growth

0 notes