#geosynthetic materials

Explore tagged Tumblr posts

Text

Geosynthetic Materials in Modern Construction: Modern Uses & Benefits

In today's dynamic world of construction, geosynthetic materials have proven to be invaluable resources. Engineered to enhance the performance and longevity of various construction applications, these materials have brought about significant advancements in the industry. This article explores the multifaceted uses and advantages of geosynthetics, with a particular focus on their role in road construction and building projects.

Introduction to Geosynthetics

What are Geosynthetics?

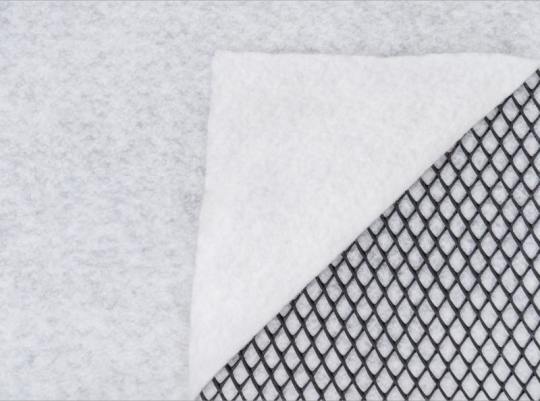

Geosynthetics are synthetic materials specially manufactured for use in civil engineering, environmental, and construction projects. These engineered materials offer a wide range of properties and applications that contribute to the strength, stability, and sustainability of construction projects.

Geosynthetics in Road Construction

Overview and Applications

In road construction, geosynthetics have become indispensable for enhancing performance and durability. They are used for soil stabilization, base reinforcement, erosion control, and drainage, among other applications.

Geocells in Road Construction

Geocells are three-dimensional honeycomb-like structures that provide soil stabilization and load support. They are particularly effective in road construction over weak subgrades, reducing the risk of road deformation and failure.

Geogrid for Road Construction

Geogrids, with their grid-like structure, are used for soil reinforcement. They are essential in reinforcing the road base, improving load-carrying capacity, and extending the lifespan of roads.

Use of Geosynthetics in Road Construction

The use of geosynthetics in road construction enhances soil properties and aids in overcoming challenges like unstable soil, poor drainage, and high maintenance costs.

Benefits of Geosynthetic Materials in Construction

Enhanced Durability and Strength

Geosynthetic materials significantly increase the durability and load-bearing capacity of roads. This leads to a reduction in road damage and extends the overall lifespan of the construction.

Cost-Effectiveness

By improving soil stability and strength, geosynthetics reduce the need for traditional, more expensive construction materials like aggregates. This results in cost savings both in the short and long term.

Environmental Sustainability

Geosynthetics offer an environmentally friendly solution in construction. Their use minimizes the disturbance of natural soil layers and reduces the need for non-renewable resources.

Adaptability and Versatility

These materials are adaptable to a variety of soil types and construction conditions. Their versatility makes them suitable for a wide range of applications beyond road construction, including railways, landfills, and water containment systems.

Challenges and Considerations

Technical Expertise

The installation and utilization of geosynthetic materials require specialized knowledge and technical expertise. Proper installation is crucial for maximizing their effectiveness.

Quality and Standards

Maintaining high quality and adherence to standards is essential for the optimal performance of geosynthetic materials. This underscores the importance of choosing reliable and experienced manufacturers.

The Future of Geosynthetics in Construction

Innovations and Developments

The future of geosynthetics in construction is bright, with ongoing research and development. Innovations in material science and technology are continuously enhancing the capabilities and applications of geosynthetic materials.

In conclusion, geosynthetic materials have played a pivotal role in revolutionizing modern construction practices. As the industry continues to evolve, these engineered materials will remain at the forefront of innovation and sustainability.

Introducing Indonet Group

As a leading geosynthetics manufacturer based in Vadodara, India, Indonet Group offers a comprehensive product lineup that includes Indodrin geocomposites, Indian Geocell, Indo Drain geonets, and more. With a commitment to quality and innovation, Indonet Group continues to contribute to the advancement of the construction industry through the use of geosynthetic materials.

#Geotextiles#geosynthetic materials#indonetgroup#indonet#Geocell#geonets#Geocomposite#Salt Barriers#Dimple Boards

0 notes

Text

Protecting the Environment with Innovative Geomembrane Liners

What are Geomembranes? They are synthetic membrane liners made from plastic polymers such as HDPE (high-density polyethylene), LLDPE (linear low-density polyethylene), PVC (polyvinyl chloride), or EPDM (ethylene propylene diene monomer rubber). These liners are used in environmental engineering applications to contain liquid pollutants and prevent their migration into soil or groundwater. They provide an effective hydraulic barrier with very low permeability. Uses in Construction They have various uses in construction where liquid containment or barriers are needed: - Landfill Liners: Geomembrane are widely used as the bottom liner in municipal solid waste and hazardous waste landfills. They prevent leachate from liquid waste from seeping into the soil and groundwater below the landfill. - Lagoons and Ponds: Liners made of them form the impermeable bottom of containment ponds and lagoons used to hold wastewater, sewage, or other liquid wastes from industrial and mining sites. - Mining Applications: They are employed to line tailings ponds, heap leach pads, and other containment areas at mining operations. This protects surrounding environments from contaminants in process wastewater. - Tunnel and Canal Liners: Long sections are installed to line transportation tunnels and canals to prevent water ingress or seepage through walls made of soil or rock. - Reservoir and Canal Covers: They covers are placed over reservoirs and canals to reduce evaporation of stored water. Some are made of lighter materials for easy handling. - Drainage and Irrigation Systems: Drainage ditches and channels built using liners aid in collecting, transporting, and discharging excess water from agricultural fields. Manufacturing Processes The material and manufacturing process used depend on the specific application requirements for a project: - Extrusion is most common for HDPE and LLDPE membranes. Plastic resin pellets are heated and squeezed through a die to form a thin, wide sheet. - Calendering produces PVC by passing PVC resin between heated rollers to form sheets. - Thermally bonding small pellets produces seams for field-welding membrane sections together. - Coextrusion layers two plastics to combine properties like adding polypropylene for strength to HDPE’s flexibility. - Blown film extrusion forms thin tubular geomembranes, cooled and sliced open, useful for irregular landfill shapes. Quality Standards Manufacturers adhere to ASTM international standards for geomembranes to ensure consistency and performance reliability. Key tests include: - Thickness measurement ensures uniformity. - Low-temperature bend tests determine flexibility at cool temperatures during installation. - Tensile strength tests evaluate membrane durability under stresses like overlying materials. - Tear resistance testing mimics punctures from construction or wind-blown debris. - Hydrostatic pressure analysis simulates ability to withstand hydraulic head from liquids. - Chemical resistance ensures stability when in contact with landfill leachate or industrial wastes. On-Site Installation of Geomembranes Proper installation methods avoid performance issues from handling, seaming, or surrounding site conditions: - Membranes are seamed in the field by thermal or extrusion welding machines moving along seams to fuse edges together under controlled temperature and pressure conditions. - Seams are non-destructively tested by air lance method locating holes from defective welds to be repaired before use. - Geomembranes are anchored at edges with soil, sand bags, or engineered anchor trenches to prevent movement from wind or water pressures. - Subgrade surfaces must be smooth with no sharp objects, changes, or desiccation cracks where membrane could be damaged during unfurling and laying processes. - Manufacturers provide installation guidelines like heat-welding temperatures, weather limitations, personnel training certification, and quality assurance inspection programs. Benefits for Environmental Protection

They provide many economic and environmental advantages over traditional earthen liners and surface coatings: - Higher impermeability rating of 10-11 m/sec versus 10-9 m/sec for clay reduces leakages minimizes environmental liabilities from spills or releases. - Thinner membrane footprints require less excavation and materials handling compared to compacted clay liners, reducing project costs and schedules. - seam ability to flex and move with subsidence prevents damage versus rigid asphalt or concrete coatings prone to cracking from soil movement. - Resistance to punctures, root penetration and desiccation cracking maintain full containment integrity for the 40-60 year design life of modern hazardous waste landfills and surface impoundments. - Higher durability and chemical stability withstand corrosive wastes and harsh conditions better than other barrier methods. As environmental regulations evolve, innovative geomembrane technology will continue modernizing the design of containment structures to ensure sustainable waste management practices that always place protection of human health and the natural environment as top priorities.

Get more insights on Geomembrane

Vaagisha brings over three years of expertise as a content editor in the market research domain. Originally a creative writer, she discovered her passion for editing, combining her flair for writing with a meticulous eye for detail. Her ability to craft and refine compelling content makes her an invaluable asset in delivering polished and engaging write-ups.

(LinkedIn: https://www.linkedin.com/in/vaagisha-singh-8080b91)

#Geomembrane#Geosynthetics#Waterproofing#Containment#Liner#Landfill#Environmental Protection#Civil Engineering#Construction Materials

0 notes

Text

Global Geosynthetics Market Assessment, Opportunities, and Forecast, 2030

Global Geosynthetics Market size was valued at USD 12.36 billion in 2022, which is expected to grow to USD 20.3 billion in 2030 with a CAGR of 6.4% during the forecast period between 2023 and 2030. Geosynthetics offer a cost-effective alternative to traditional construction materials, driving their widespread use. By minimizing resource usage and reducing labour costs, they contribute to substantial long-term savings, making them an attractive choice for various construction projects. Infrastructure development projects necessitate the use of geosynthetics for applications like roads, railways, airports, and more. These materials provide essential reinforcement, erosion control, and drainage solutions, making them indispensable in the construction industry. In regards with water management and environmental protection, geosynthetics play a crucial role as they find extensive application in reservoirs, dams, coastal protection, and landfill liners, effectively preventing soil erosion and managing water resources efficiently.

In addition to civil engineering functions, geosynthetics serve the mining and agriculture sectors, enhancing operational efficiency and sustainability. Applications such as mine tailings management, soil stabilization, water retention, and erosion control showcase their versatility and significance in these industries. Finally, stringent environmental regulations and a heightened focus on sustainability are propelling the use of geosynthetics. They help in reducing environmental impact, managing waste, and promoting eco-friendly construction practices.

Sample report- https://www.marketsandata.com/industry-reports/geosynthetics-market/sample-request

Rising Investments in Water Management to Drive the Demand for Geosynthetics

Geosynthetics plays an important role in several water management solutions. Firstly, in reservoirs and dams, geosynthetics are employed to enhance structural integrity and stability. Moreover, geosynthetic liners act as impermeable barriers, preventing water leakage and ensuring optimal water storage, therefore utilized in Coastal protection, given the increasing vulnerability of coastlines to erosion and rising sea levels. Furthermore, geosynthetics aid in controlling sedimentation, a major concern in water management.

For instance, in March 2023, India committed over USD 240 billion in investments towards improving its water sector. Concurrently, it is executing the most extensive dam rehabilitation initiative globally, complemented by endeavours to revitalize groundwater levels. Similarly, the rising investments towards water management by other developing countries drives the demand for geosynthetics globally.

Strong Developments of Railways and Roadways to Heighten the Demand for Geosynthetics

In road construction, geosynthetics are employed for various applications, such as reinforcing weak soils, improving load-bearing capacity, controlling ground movement and enhances the lifespan of the road but also reduces maintenance costs over time. Similarly, in the railway sector, geosynthetics play a crucial role in track stabilization, embankment reinforcement, and slope protection.

For instance, over the upcoming decade to fifteen years, an investment of USD 324 billion will be dedicated to enhancing roads, railways, and waterways in Germany. The “Digital Rail Germany” initiative, introduced in January 2020, aims to elevate the efficiency of the German rail network by a significant margin, potentially reaching a performance increase of up to 35%. Huge Projects of improving roads and railways across several countries to improve the requirement of geosynthetics globally.

Strong Demand from Agriculture Sector to Increase the Requirement for Geosynthetics

Geosynthetics are indispensable in modern agriculture, profoundly influencing efficiency and sustainability. These engineered materials offer diverse applications crucial for managing soil, optimizing water usage, and enhancing agricultural productivity. Geosynthetics like geotextiles and geogrids provide essential soil stabilization, preventing erosion and enabling a stable base for crops. They effectively address erosion challenges, preserving topsoil and its fertility. Furthermore, these materials aid in water retention and drainage systems, ensuring optimal moisture levels for crops while preventing waterlogging.

As per the United States Department of Agriculture (USDA), an anticipated 1.3 billion individuals might face food insecurity in 2022, reflecting a 10% rise from 2021. Enhancing crop productivity is imperative to mitigate this critical circumstance. The global demand for geosynthetics is increasing as it elevates crop productivity and sustainability.

Increasing Offshore Projects to Improve Geosynthetics Demand

Geosynthetics are widely employed in marine structures to enhance soil stability, drainage, and erosion control in quay walls, jetties, and port expansion projects. They contribute to the longevity and safety of these critical components. Additionally, geosynthetics find application in underwater revetments and submerged structures, providing protection against scour and erosion, reinforcing the seabed, and maintaining the stability of underwater installations.

For instance, China’s inaugural offshore carbon storage endeavour, led by the China National Offshore Oil Corporation (CNOOC), has embarked on operations in June 2023. This pioneering project aims to store over 1.5 million tonnes of carbon dioxide (CO2), equivalent to planting approximately 14 million trees. Simultaneously, China has initiated the construction of its foremost large-scale offshore wind turbine initiative, boasting a capacity of 16 megawatts, during February 2023. These ambitious offshore ventures in several countries are raising geosynthetics usage globally.

Impact of COVID-19

The COVID-19 pandemic significantly disrupted global supply chains related to the production and distribution of geosynthetics and its raw materials. These disruptions resulted from factory closures and transportation restrictions, causing delays and shortages in the supply chain for upstream polymers. The lockdowns and economic slowdowns further amplified the problem by causing a notable reduction in demand across various industries such as construction, marine structures, and mining. Furthermore, the geosynthetics market also faced price fluctuations during the pandemic due to the disruptions in both supply and demand dynamics.

Key Outlook

The improvements in the advanced extraction process and an increase in mining activities in South America provide an opportunity for growth for geosynthetics.

The versatile application of geosynthetics in waste management, as they are used in landfills and wastewater mitigation, strengthens the global demand for engineered material.

Global Geosynthetics Market: Report Scope

“Geosynthetics Market Assessment, Opportunities and Forecast, 2016-2030F”, is a comprehensive report by Markets and Data, providing in-depth analysis and qualitative and quantitative assessment of the current state of geosynthetics market globally, industry dynamics and challenges. The report includes market size, segmental shares, growth trends, COVID-19 and Russia-Ukraine war impact, opportunities and forecast between 2023 and 2030. Additionally, the report profiles the leading players in the industry mentioning their respective market share, business model, competitive intelligence, etc.

Click here for full report- https://www.marketsandata.com/industry-reports/geosynthetics-market

Contact

Mr. Vivek Gupta 5741 Cleveland street, Suite 120, VA beach, VA, USA 23462 Tel: +1 (757) 343–3258 Email: [email protected] Website: https://www.marketsandata.com

#Chemicals and Materials#Real Estate#Technology#Geosynthetics Market#Geosynthetics Market Assessment

0 notes

Text

Role of geosynthetics in road construction

Geosynthetics can be described as key components of structures and systems that are deployed to facilitate various engineering purposes and aspects. Usually, they are made from polymeric materials. In this case, the word geo signifies Earth or the soil and the word synthetics represents the synthetic or polymeric materials. They are capable of serving a wide range of purposes starting from erosion control to improvements in subsurface drainage and embankment reinforcement. One of the commonest reasons why they are used is for road construction. This is especially true for temporary roads such as construction roads, forest routes, and access roads. Following are the main advantages of using them for road construction.

1. Bearing capacity

It is crucial for architecting roads as well as parking lots to create a subgrade that is stable enough with the necessary bearing capacity. When you use geogrids between the base course and the subsoil you increase the bearing capacity. Geosynthetics interlock with the cover soil and this offers a horizontal force transfer that serves to improve the bearing capacity. In a lot of situations this also allows for the lessening of the thickness of the base course.

2. Rutting

One of the biggest concerns while building unpaved roads on soft subsoil is rutting. Yet another major issue in this context is when the cover material blends into the subsoil. Geosynthetics improve the load distribution and make sure that both soil inter-blending and rutting are prevented. The specifications of the geogrid that you need for a particular project would depend requirements of the same.

3. Force extension

Geosynthetics have low extension features and these are necessary for a reinforcement application to be successful. In a lot of undertakings, the force absorption at elongation needs a product whose quantity is between 2% and 5%. If the project is more demanding you may need products with a maximum of 8% extension at break.

4. Installation robustness

Finally, it is important that you consider the geosynthetic products’ resistance to installation loads. If the stresses are highly dynamic it could take a toll on reinforcement when you condense and install base course elements and cover soils. The right way to deal with the stress would be to use geosynthetics that have thick and monolithic reinforcement bars.

5 notes

·

View notes

Text

Manufacturer and Supplier of Geosynthetics

What is Manufacturer and Supplier of Geosynthetics

A manufacturer of geosynthetics is a company that produces various types of geosynthetic materials, such as geotextiles, geomembranes, geogrids, geocells, and geocomposites. These materials are typically used in civil engineering, environmental, and geotechnical applications, such as roads, landfills, retaining walls, drainage systems, and erosion control.

A supplier of geosynthetics, on the other hand, is a company that sources and distributes geosynthetic materials from various manufacturers to contractors, engineers, and other customers. Suppliers may also provide technical support and assistance with product selection and installation.

There are many companies that manufacture and supply geosynthetics, ranging from large multinational corporations to smaller regional and local firms. Some examples of prominent geosynthetic manufacturers and suppliers include TenCate Geosynthetics, GSE Environmental, Maccaferri, and Solmax.

Why We Use Manufacturer and Supplier of Geosynthetics

Quality assurance: Geosynthetics are critical components in many civil engineering and environmental projects, and their performance can have a significant impact on project success. Working with a reputable manufacturer and supplier can help ensure that the geosynthetics used in a project are of high quality and meet the required specifications.

Technical expertise: Manufacturers and suppliers of geosynthetics often have a deep understanding of the properties and applications of these materials. They can provide valuable technical support and advice to engineers, contractors, and other stakeholders on product selection, design, and installation.

Range of products: There are many different types of geosynthetics available, each with unique properties and applications. Working with a manufacturer or supplier that offers a wide range of products can help ensure that the most appropriate materials are selected for a given project.

Availability and logistics: Manufacturers and suppliers of geosynthetics typically have well-established supply chains and logistics networks, which can ensure timely delivery of materials to project sites. This can be particularly important for projects with tight deadlines or where materials need to be shipped internationally.

Overall, working with a manufacturer or supplier of geosynthetics can help ensure that the right materials are selected, delivered on time, and installed correctly, leading to successful project outcomes.

How It Work Manufacturer and Supplier of Geosynthetics

The process of working with a manufacturer and supplier of geosynthetics typically involves several steps:

Needs assessment: The manufacturer or supplier will work with the project owner, engineer, or contractor to assess the specific needs of the project. This may involve reviewing project plans and specifications, conducting site visits, and discussing project requirements and constraints.

Product selection: Based on the needs assessment, the manufacturer or supplier will recommend the most appropriate geosynthetic products for the project. This may involve selecting from a range of materials with different properties, such as strength, durability, and permeability.

Ordering and logistics: Once the geosynthetic products have been selected, the manufacturer or supplier will process the order and coordinate logistics to ensure timely delivery of materials to the project site. This may involve working with freight forwarders, customs brokers, and other logistics providers to manage international shipments.

Installation support: In many cases, the manufacturer or supplier will provide technical support and guidance to the contractor or installer during the installation of the geosynthetic materials. This may include providing training on proper installation techniques, conducting site visits to monitor progress, and addressing any issues that arise during the installation process.

Quality control: Throughout the process, the manufacturer or supplier will conduct quality control checks to ensure that the geosynthetic products meet the required specifications and performance standards.

Overall, the manufacturer and supplier of geosynthetics will work closely with the project owner, engineer, or contractor to ensure that the right products are selected, delivered on time, and installed correctly, leading to a successful project outcome.

Conclusion

A&TEngineeringPrivateLimited.Construction and Technology providing company dedicated to infrastructure development, specialized in the manufacturing of geosynthetic products and design & execution of Civil/Structural works.

CALL US : 011-41720506

OFFICAL WEBSITE : https://www.antinfra.com/

2 notes

·

View notes

Text

Why Ground Improvement is Essential for Sustainable Construction

Sustainable construction is gaining momentum as the world moves towards eco-friendly and long-lasting infrastructure solutions. A crucial aspect of sustainable construction is Ground Improvement, a technique used to enhance soil properties for better stability, strength, and load-bearing capacity. Without proper ground enhancement, structures can suffer from settlement issues, foundation failures, and environmental damage. This article explores why Ground Improvement is essential for sustainable construction and how it contributes to building resilient infrastructure.

1. Understanding Ground Improvement

Ground Improvement refers to the modification of soil properties to make them more suitable for construction. This is done through various mechanical, chemical, and biological methods. These techniques improve soil strength, reduce compressibility, and increase durability, ensuring that structures built on them remain stable over time.

2. The Need for Ground Improvement in Construction

Many construction projects are built on weak or problematic soils that cannot support heavy structures. If left unaddressed, poor soil conditions can lead to:

Uneven settlement of buildings

Cracks in walls and foundations

Structural instability and potential failure

Increased maintenance costs and environmental hazards

By implementing Ground Improvement techniques, engineers can create a stronger foundation, reducing the risk of these issues.

3. Contribution to Sustainable Construction

a) Reducing Material Wastage

Traditional construction methods often involve removing poor-quality soil and replacing it with better material, which is both expensive and environmentally damaging. Ground Improvement techniques allow the in-situ soil to be enhanced, reducing the need for excavation and landfill disposal.

b) Lowering Carbon Footprint

By stabilizing soil on-site instead of transporting new materials, Ground Improvement reduces the carbon emissions associated with transportation and heavy machinery usage. Sustainable construction depends on reducing environmental impact, and soil enhancement plays a crucial role in achieving this.

c) Enhancing Structural Longevity

Buildings constructed on well-improved ground experience fewer foundation issues, reducing the need for repairs and maintenance. This extends the lifespan of structures, minimizing material consumption over time and contributing to sustainability.

d) Preventing Soil Erosion and Land Degradation

Unstable ground can lead to soil erosion, which not only affects the structure but also harms the surrounding environment. Ground Improvement stabilizes the soil, preventing erosion and reducing negative ecological effects.

4. Common Ground Improvement Techniques

Various Ground Improvement methods are used in sustainable construction, including:

a) Soil Stabilization

Uses lime, cement, or fly ash to enhance soil strength

Reduces permeability and increases durability

b) Vibro Compaction and Vibro Replacement

Improves loose granular soils using vibration

Strengthens the soil by introducing stone columns

c) Deep Soil Mixing

Involves mixing soil with a binder (cement or lime)

Enhances soil strength and stiffness

d) Grouting

Injecting cement or chemical solutions to fill voids in soil

Improves load-bearing capacity

e) Geosynthetics

Use of geotextiles, geogrids, and geomembranes

Enhances soil stability and drainage

Each of these methods contributes to making construction projects more sustainable by reinforcing the ground and reducing environmental impact.

5. Applications of Ground Improvement in Sustainable Construction

a) Infrastructure Development

Roads, bridges, and railway projects require Ground Improvement to ensure long-term stability. Weak soil conditions can lead to structural failures, making soil enhancement crucial for infrastructure longevity.

b) Residential and Commercial Buildings

Skyscrapers and heavy structures require a strong foundation. Ground Improvement techniques prevent uneven settlements and foundation cracks, ensuring long-lasting stability.

c) Renewable Energy Projects

Wind farms and solar power plants are often constructed on vast, uneven terrain. Ground Improvement helps stabilize these areas, allowing for the secure installation of turbines and panels.

d) Coastal and Flood-Prone Areas

In regions vulnerable to flooding, Ground Improvement methods like soil stabilization and deep mixing help prevent water ingress and soil erosion, making structures more resilient.

6. Cost-Effectiveness and Economic Benefits

While Ground Improvement may seem like an additional expense, it ultimately leads to cost savings in the long run. By preventing structural failures, reducing maintenance costs, and minimizing environmental damage, these techniques make construction more economically viable. Governments and developers are increasingly recognizing the importance of soil enhancement in sustainable infrastructure planning.

Conclusion

Ground Improvement is a fundamental element of sustainable construction. It strengthens soil, enhances structural stability, minimizes environmental impact, and promotes long-term resilience. With advancements in soil enhancement technologies, construction can become more eco-friendly, cost-effective, and durable. As sustainable development becomes a global priority, Ground Improvement will continue to play a crucial role in shaping the future of construction.

0 notes

Text

Uniaxial Geogrid: A Comprehensive Overview

Uniaxial geogrids are specialized geosynthetic materials widely utilized in civil engineering and construction projects. They are designed to provide reinforcement in a single direction, making them particularly effective for various applications such as retaining walls, embankments, and slope stabilization. This article delves into the properties, applications, benefits, and the market landscape of uniaxial geogrids, specifically focusing on the role of uniaxial geogrid exporters and manufacturers in Ahmedabad and India.

0 notes

Text

How Basal Reinforcement Enhances Soil Stability

In geotechnical engineering, soil stability is a critical factor that determines the success of infrastructure projects. Whether it's constructing embankments, retaining walls, or foundations on soft soil, challenges such as uneven settlement, slope failure, and poor load-bearing capacity often arise. A highly effective solution to these challenges is Basal Reinforcement, a method that significantly improves soil stability by providing additional support at the base of soil structures.

What is Basal Reinforcement?

Basal Reinforcement refers to the installation of geosynthetic materials, such as geogrids or geotextiles, at the base of an embankment or soil structure. These materials act as a stabilizing layer, distributing loads more evenly and enhancing the overall strength of the soil. The reinforcement prevents excessive deformation and failure, making it particularly beneficial for projects involving soft or weak soils.

The Mechanism of Basal Reinforcement

The primary function of Basal Reinforcement is to provide tensile strength to the soil. When applied, geosynthetics interact with the soil particles, creating a composite system that resists shear forces and distributes loads uniformly.

Load Distribution: Basal reinforcement spreads the applied loads from structures like embankments over a wider area. This reduces stress on the underlying weak soil layers and prevents localized failures.

Prevention of Lateral Spreading: In soft soils, lateral spreading is a common issue. The reinforcement layer acts as a barrier, minimizing lateral movement and maintaining the integrity of the soil structure.

Enhanced Bearing Capacity: By reducing the stress concentration on the foundation soil, basal reinforcement increases its load-bearing capacity. This is especially important in areas with low-strength soils, such as clay or peat.

Reduction of Settlement: Uneven settlement can lead to structural instability. Basal reinforcement minimizes differential settlement by distributing loads more uniformly across the foundation.

Applications of Basal Reinforcement

Basal Reinforcement has widespread applications in construction and infrastructure development, including:

Embankment Construction: When building embankments over soft soil, basal reinforcement ensures stability and prevents excessive settlement. It is particularly useful for highway and railway embankments.

Retaining Walls: Reinforcement is often used at the base of retaining walls to prevent failure due to lateral soil pressure and to enhance overall stability.

Landfills: In landfill projects, basal reinforcement prevents foundation instability caused by uneven waste settlement or weak soil conditions.

Slope Stabilization: Basal reinforcement helps stabilize slopes, reducing the risk of landslides and erosion in hilly or coastal areas.

Foundations on Soft Soil: It is commonly used for constructing buildings or infrastructure on marshy, clayey, or loose sandy soils.

Advantages of Basal Reinforcement

Improved Safety and Durability: By enhancing soil stability, basal reinforcement ensures the longevity and safety of structures built on weak foundations.

Cost-Effective Solution: While it involves an initial investment, the use of basal reinforcement reduces maintenance costs and prevents expensive repairs caused by structural failures.

Faster Construction: With reinforcement in place, projects can proceed more quickly, as it minimizes delays caused by soil-related issues.

Sustainability: Basal reinforcement can reduce the need for soil excavation and replacement, making it an environmentally friendly solution.

Versatility: The method can be adapted to a variety of soil conditions and construction requirements, making it a reliable option for diverse projects.

Case Studies Demonstrating the Effectiveness of Basal Reinforcement

Highway Embankments: In areas with soft clay soil, highway embankments reinforced with geogrids have shown significantly reduced settlement and increased load-bearing capacity.

Flood Protection Levees: Basal reinforcement has been effectively used in constructing levees to prevent failures during floods, ensuring safety and durability.

Railway Tracks: The use of basal reinforcement under railway embankments has improved track stability, reducing maintenance needs and enhancing operational safety.

Challenges and Considerations

Despite its numerous advantages, the success of Basal Reinforcement depends on proper design, material selection, and installation. Engineers must assess factors such as soil type, load requirements, and environmental conditions to ensure optimal performance. Improper installation or the use of substandard materials can compromise the effectiveness of the reinforcement.

Conclusion

Basal Reinforcement is a transformative approach in geotechnical engineering that addresses the challenges of building on weak or soft soils. By enhancing load distribution, preventing lateral spreading, and minimizing settlement, it provides a robust foundation for infrastructure projects. Its versatility, cost-effectiveness, and sustainability make it an indispensable technique in modern construction. As infrastructure demands continue to rise, the role of Basal Reinforcement in improving soil stability will remain crucial, paving the way for safer and more durable structures.

0 notes

Text

Albatec: Pioneering Geotechnical Engineering Excellence

youtube

In the ever-evolving field of civil engineering, geotechnical engineering emerges as a cornerstone discipline, ensuring the success and stability of construction projects. Albatec, a leader in this specialized area, is dedicated to providing innovative solutions for complex subsurface challenges. From designing resilient foundations to assessing soil behavior and mitigating risks, Albatec’s expertise empowers projects across diverse sectors to thrive.

Understanding Geotechnical Engineering Geotechnical engineering focuses on the analysis of earth materials like soil, rock, and groundwater to determine their suitability for construction. This discipline underpins the stability of critical infrastructure such as skyscrapers, bridges, dams, and tunnels. By evaluating subsurface conditions, geotechnical engineers address risks like landslides, soil erosion, earthquakes, and groundwater flow, ensuring structures are safe, stable, and efficient.

Albatec: Your Trusted Geotechnical Partner Albatec stands out as a trusted name in geotechnical engineering, blending technical expertise with cutting-edge technology to tackle even the most demanding projects. Let’s explore the services that position Albatec as a leader in the field:

Comprehensive Site Investigations Before construction begins, Albatec’s team conducts detailed site investigations to assess geological conditions. Using advanced techniques like cone penetration testing (CPT), borehole drilling, and soil sampling, they gather critical data to guide design decisions and ensure project viability.

Precision Foundation Design Foundations are the bedrock of any structure. Albatec excels in crafting custom foundation solutions, whether for low-rise residential buildings or towering skyscrapers. Their designs ensure stability by aligning with site-specific conditions and project demands.

Slope Stability Solutions In hilly or mountainous regions, slope stability is paramount. Albatec employs advanced modeling tools to analyze potential risks and recommend reinforcement measures such as retaining walls, ground anchors, or soil nailing, safeguarding both the structure and the surrounding environment.

Earthquake-Resilient Engineering Seismic activity poses unique challenges to construction. Albatec’s expertise in earthquake engineering ensures structures can endure ground motion. Their dynamic analysis integrates seismic considerations into every design, prioritizing resilience and safety.

Ground Improvement Techniques Weak or unstable soil? No problem. Albatec offers advanced ground improvement methods, including soil compaction, grouting, and the use of geosynthetics. These techniques enhance soil properties, paving the way for secure construction.

Geotechnical Risk Assessments Construction projects carry inherent subsurface risks. Albatec’s thorough geotechnical risk assessments identify potential hazards and develop mitigation strategies, ensuring projects progress smoothly and safely.

What Sets Albatec Apart?

Innovative Technology Leveraging tools like ground-penetrating radar, geotechnical software, and 3D modeling, Albatec ensures precise and reliable results. These technologies enable real-time visualization of subsurface conditions, enhancing decision-making and project outcomes.

Customized Solutions Every project is unique, and Albatec tailors its services to meet specific needs. From small-scale residential developments to major infrastructure projects, their client-focused approach guarantees optimal results.

Experienced Professionals Albatec’s team brings unparalleled expertise to the table. With extensive knowledge of soil mechanics, geology, and structural engineering, their engineers deliver world-class solutions for projects of all scales.

Commitment to Sustainability Recognizing the importance of eco-friendly practices, Albatec prioritizes sustainability by minimizing soil disruption and reducing carbon footprints. Their designs align with environmental standards, supporting a greener future.

Real-World Impact of Albatec’s Expertise Albatec’s geotechnical solutions play a critical role in diverse projects:

Infrastructure Development: Stabilizing highways, railways, and bridges to handle heavy loads and environmental pressures.

Commercial Construction: Securing foundations for skyscrapers and industrial facilities in challenging terrains.

Renewable Energy: Supporting wind turbines and solar farms with optimized foundations for varying soil conditions.

Disaster Mitigation: Preventing landslides, floods, and earthquake damage with proactive engineering strategies.

The Future of Geotechnical Engineering As urbanization and climate change redefine construction challenges, the demand for innovative geotechnical solutions continues to rise. Albatec is at the forefront of this evolution, embracing technologies like AI-driven predictive models and smart sensors that monitor ground movement in real time. These advancements position Albatec as a pioneer, ready to tackle emerging challenges with confidence.

Conclusion Geotechnical engineering forms the backbone of safe and sustainable construction. Albatec’s expertise, bolstered by innovation and a commitment to excellence, ensures every project is built on a solid foundation. Whether you’re embarking on a residential development, infrastructure initiative, or renewable energy project, Albatec’s tailored geotechnical solutions are the key to success. Partner with Albatec and lay the groundwork for a future of stability and resilience.

1 note

·

View note

Text

Innovations in Geosynthetics: What Manufacturers Are Bringing to the Market

Geosynthetics have transformed modern engineering and construction practices, offering solutions for challenges such as soil stabilization, erosion control, and environmental sustainability. As the demand for advanced materials grows, geosynthetic manufacturers are continuously innovating to develop products that meet the evolving needs of infrastructure, environmental, and geotechnical projects. This article explores the latest innovations in geosynthetics and how manufacturers are driving advancements in this dynamic field.

Understanding Geosynthetics

Geosynthetics are synthetic materials used in geotechnical applications. These include geotextiles, geogrids, geomembranes, geocells, geonets, and geo-composites. Their primary functions include reinforcement, separation, filtration, drainage, and containment, making them indispensable for projects ranging from roads and railways to landfills and coastal protection.

As industries demand more efficient, sustainable, and durable solutions, geosynthetic manufacturers are rising to the challenge by introducing cutting-edge materials and technologies.

Innovations in Geosynthetics

Here are some of the most significant innovations brought to the market by geosynthetic manufacturers:

1. Advanced Polymer Technologies

Modern geosynthetics leverage advanced polymers that enhance strength, durability, and flexibility. Innovations in polymer science have led to geosynthetics that are resistant to chemical exposure, UV radiation, and extreme temperatures, making them ideal for diverse environments.

Impact: Longer lifespans and reduced maintenance costs.

2. Biodegradable Geosynthetics

Sustainability is a top priority for industries worldwide. Manufacturers are now producing biodegradable geosynthetics, which decompose naturally after fulfilling their purpose, such as temporary erosion control.

Impact: Reduced environmental footprint, aligning with green construction practices.

3. Multi-Functional Geocomposites

Geocomposites combine two or more geosynthetic materials to perform multiple functions simultaneously, such as drainage and reinforcement. These products offer enhanced efficiency and reduce the need for additional materials.

Impact: Cost savings and simplified installation processes.

4. Smart Geosynthetics

The integration of sensors and smart technology into geosynthetics is a game-changer. Smart geosynthetics can monitor stress, strain, moisture levels, and temperature in real-time, providing critical data for infrastructure health monitoring.

Impact: Improved maintenance strategies and early detection of potential failures.

5. Recycled Geosynthetics

In response to environmental concerns, manufacturers are creating geosynthetics from recycled materials without compromising performance. These products support sustainable construction practices and contribute to circular economies.

Impact: Lower carbon footprint and reduced waste in production.

6. High-Strength Geogrids

Recent advancements in geogrid technology have resulted in products with exceptional tensile strength and load-bearing capacity. These high-strength geogrids are particularly useful for large-scale infrastructure projects such as highways and railways.

Impact: Enhanced structural stability and extended project lifespans.

7. Innovative Installation Techniques

Manufacturers are designing geosynthetics that are easier and faster to install. Pre-cut panels, adhesive-backed membranes, and modular systems reduce labor time and costs while improving project efficiency.

Impact: Faster project completion and reduced installation errors.

8. Hydraulic Geosynthetics

Hydraulic geosynthetics, such as improved geomembranes and geonets, are designed to manage water flow more effectively. These products are particularly valuable in water reservoirs, canals, and landfill applications.

Impact: Enhanced water management and reduced leakage risks.

9. Anti-Microbial Geotextiles

In applications where contamination is a concern, such as landfill covers or wastewater treatment, manufacturers are introducing anti-microbial geotextiles to inhibit the growth of harmful microorganisms.

Impact: Improved safety and longevity in critical projects.

10. Carbon Footprint Analysis in Manufacturing

Leading geosynthetic manufacturers are integrating carbon footprint analysis into their production processes. By optimizing material use and energy consumption, they aim to create eco-friendly products with a reduced environmental impact.

Impact: Support for sustainable development goals and green certifications.

Benefits of Innovations in Geosynthetics

The advancements in geosynthetics are providing numerous benefits to construction and engineering projects:

Cost Efficiency: Multi-functional and durable products reduce material and maintenance costs.

Sustainability: Eco-friendly solutions align with global environmental standards.

Enhanced Performance: Smart and high-strength geosynthetics offer superior functionality.

Project Flexibility: Innovative designs cater to a wide range of geotechnical challenges.

The Future of Geosynthetics

As the construction and engineering industries face increasing challenges such as urbanization, climate change, and resource scarcity, geosynthetic manufacturers will continue to innovate. Future developments may include:

Wider adoption of AI-driven smart geosynthetics.

Enhanced recycling and reuse of geosynthetic materials.

New composites tailored for specific environments and industries.

These advancements will further cement geosynthetics as an essential component of modern infrastructure development.

Conclusion

The relentless innovation by geosynthetic manufacturers is reshaping the way construction and engineering projects address challenges like soil stability, erosion control, and environmental protection. With advancements ranging from biodegradable materials to smart geosynthetics, these products are not only improving project efficiency but also contributing to sustainability goals. As industries demand smarter, greener, and more cost-effective solutions, geosynthetics are poised to remain at the forefront of modern engineering innovation. By adopting these advanced materials, businesses can ensure durable and environmentally responsible infrastructure for the future.

0 notes

Text

Future of U.S. Geosynthetics Market: Insights from Industry Experts

The U.S. geosynthetics market size was estimated at USD 3.08 billion in 2023 and is expected to grow at a CAGR of 5.8% from 2024 to 2030. The U.S. is expected to account for a significant market share of the total shale gas consumption in the future on account of increasing drilling activities for shale gas and tight oil supply conditions. This is projected to positively drive the geosynthetics market in the country over the forecast period.

Geosynthetics are used for base reinforcement, separation, and stabilization of roads and pavements. Furthermore, these products also find their application in subsurface drainage systems for dewatering, road base, and structure drainage. Geotextiles are used in the strengthening of industrial units, car parks, and new roadways. The incorporation of geosynthetics entails sustainable development, a small volume of earthwork, low carbon footprint, and an increased rate of construction. The growth of the construction industry around the world, including the U.S., is expected to remain one of the key market drivers for the global geosynthetics market, further boosting the market in the U.S.

Gather more insights about the market drivers, restrains and growth of the U.S. Geosynthetics Market

Key U.S. Geosynthetics Company Insights

The market is majorly run by petrochemical manufacturers across the U.S. The competition in the market is also high due to the presence of a large number of manufacturers. Market players have established strategic partnerships with the distributors to supply their product offerings. Stringent government regulations and depleting petroleum feedstock have contributed to shifting the focus of manufacturers on renewable energy sources and prompted extensive research and development of bio-based raw materials.

Some of the prominent players in the U.S. geosynthetics market are TenCate Geosynthetics Americas; Maccaferri; Concrete Canvas Ltd.; NAUE GmbH & Co. KG; and Propex Operating Company, LLC

• NAUE GmbH & Co. KG, formerly known as Naue Fasertechnik GmbH & Co. KG, was established in 1967. It changed its name to NAUE GmbH & Co. KG in 2005. The company has its headquarters in Germany, with a global presence across North America, Asia, Europe, Australia, South America, and the Middle East & Africa.

• Maccaferri provides advanced solutions for problems related to erosion control, soil reinforcement, stabilization of the soil, and infrastructure development in application areas such as roads, railways, canals, rivers, coastal defenses, and landfills. It owns over 70 subsidiaries in over 100 countries. As of 2018, the company employed over 3,000 individuals globally.

• TENAX Group was established in 1960 and headquartered in Viganò, Italy. The company majorly specializes in extruding thermoplastic polymers. Its product range includes fences, screens, plastic nets, geogrids, and geosynthetics, which find applications in areas such as pipeline, packaging, industrial, geotechnical, gardening, fencing, construction, and agriculture.

U.S. Geosynthetics Market Report Segmentation

This report forecasts market share and revenue growth at country levels and provides an analysis of industry trends in each of the sub-segments from 2018 to 2030. For the purpose of this study, Grand View Research has segmented the U.S. geosynthetics market report based on product:

Product Outlook (Volume, Million Square Meters; Revenue, USD Billion, 2018 - 2030)

• Geotextiles

o By Raw Material

o By Product

o By Application

• Geomembranes

o By Raw Material

o By Application

o By Technology

• Geogrids

o By Raw Material

o By Application

o By Product

• Geonets

o By Raw Material

o By Application

• Geocells

o By Raw Material

o By Application

Order a free sample PDF of the U.S. Geosynthetics Market Intelligence Study, published by Grand View Research.

#U.S. Geosynthetics Market#U.S. Geosynthetics Market Size#U.S. Geosynthetics Market Share#U.S. Geosynthetics Market Analysis#U.S. Geosynthetics Market Growth

0 notes

Text

Steel plastic geogrid

Steel-plastic geogrid is a key geosynthetic material. It consists of high-strength steel wire (or other fibres) after special treatment, mixed with polyethylene (PE) or polypropylene (PP) and other additives, and then through the extrusion process to make composite high-strength tensile strips, and the surface of the rough embossed, it is a high-strength reinforced geotechnical tape.

0 notes

Text

India Geosynthetics Market Size, Share, Demand, Report, Forecast 2024-2032

Geosynthetics Market- India

Base Year: 2023

Historical Years: 2018-2023

Forecast Years: 2024-2032

Market Growth Rate: 8.80% (2024-2032)

The India geosynthetics market is expanding rapidly, fueled by increasing infrastructure projects, stricter environmental regulations, and the growing demand for durable, long-lasting materials. According to the latest report by IMARC Group, the market is projected to grow at a CAGR of 8.80% from 2024 to 2032.

Download sample copy of the Report: https://www.imarcgroup.com/india-geosynthetics-market/requestsample

India Geosynthetics Market Trends and Drivers:

Infrastructure Boom: With more roads, railways, and waterways being built, geosynthetics are in high demand to improve durability and stability.

Focus on Sustainability: Geosynthetics are helping reduce environmental impact, which is becoming a priority for projects across India.

Government Investment: Big government projects like highways, dams, and waste management systems are using more geosynthetics, driving market growth.

Support from Construction and Agriculture: Both sectors use geosynthetics for erosion control, water management, and improving soil quality.

Better Materials: Advanced products like geotextiles, geomembranes, and geogrids offer better performance and are becoming more popular.

Eco-Friendly Innovations: New, greener geosynthetic solutions are entering the market, meeting the demand for sustainable building materials.

Smart Cities and Green Building: The focus on smart cities and eco-friendly construction is boosting the use of geosynthetics for long-lasting, efficient infrastructure.

Increased R&D: Companies are investing in research to develop stronger, more efficient geosynthetics, keeping the market on a strong growth path.

India Geosynthetics Market Industry Segmentation:

The market report offers a comprehensive analysis of the segments, highlighting those with the largest India Geosynthetics Market size It includes forecasts for the period 2024-2032 and historical data from 2018-2023 for the following segments.

Beakup by Product:

· Geotextiles

· Geomembranes

· Geogrids

· Geonets

· Geosynthetic Clay Liner (GCL)

· Pre-Fabricated Vertical Drains (PVD)

· Others

Beakup by Type:

· Woven

· Non-Woven

· Knitted

· Others

Beakup by Material:

· Polypropylene

· Polyester

· Polyethylene

· Polyvinyl Chloride

· Synthetic Rubber

· Others

Beakup by Application:

· Road Construction and Pavement Repair

· Railroads

· Drainage Systems

· Soil Reinforcement and Erosion

· Water and Waste Management

· Others

Beakup by Region:

· North India

· West and Central India

· South India

· East and Northeast India

Competitive Landscape:

The report offers an in-depth examination of the competitive landscape. It includes a thorough competitive analysis encompassing market structure, key player positioning, leading strategies for success, a competitive dashboard, and a company evaluation quadrant.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=21612&flag=C

Key highlights of the Report:

Market Performance (2018-2023)

Market Outlook (2024-2032)

COVID-19 Impact on the Market

Porter’s Five Forces Analysis

Strategic Recommendations

Historical, Current and Future Market Trends

Market Drivers and Success Factors

SWOT Analysis

Structure of the Market

Value Chain Analysis

Comprehensive Mapping of the Competitive Landscape

Note: If you need specific information that is not currently within the scope of the report, we can provide it to you as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services.

IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

#India Geosynthetics Market#India Geosynthetics Market Size#India Geosynthetics Market Share#India Geosynthetics Market Demand#India Geosynthetics Market Report#India Geosynthetics Market Trends#India Geosynthetics Market Growth

0 notes

Text

Composites Market Dynamics: Opportunities, Challenges, and Growth Forecast

The global composites market was valued at USD 93.69 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.2% from 2023 to 2030. This growth is primarily driven by the increasing demand for lightweight components, particularly in the automotive and transportation sectors. Additionally, the growing adoption of advanced lightweight components across various manufacturing industries is expected to further boost market growth during the forecast period.

Composites are widely used in the aerospace and defense sectors due to their ability to significantly reduce the weight of military aircraft and helicopters. The reduction in weight is critical for enhancing fuel efficiency and improving overall performance, making it a key driver of growth in these industries.

Regional Insights

Asia Pacific:

The Asia Pacific region dominated the global composites market, accounting for 45.4% of the global demand in 2022. The region is expected to continue its strong growth trajectory during the forecast period, largely driven by the presence of key manufacturers in major economies such as China, India, and Japan. These countries serve as key hubs for industries like automotive, construction, aerospace, and electronics, which are major consumers of composite materials.

US:

In the United States, the demand for composites is primarily fueled by the growing need for lightweight materials in the automotive industry. The increasing capacity of the electrical and electronics sectors, along with steady growth in the automotive and aerospace industries, are expected to contribute significantly to the market expansion in the U.S. over the forecast period.

Europe:

In Europe, the demand for composites is predominantly driven by Western European countries, where large-scale manufacturing industries are well-established. The automotive, aerospace and defense, construction, and electrical and electronics sectors play a key role in driving the demand for composites. The emergence of new aircraft manufacturers, such as Commercial Aircraft Corporation of China, Ltd., is expected to further boost aircraft production and intensify competition among manufacturers, stimulating growth in the composite materials market.

Central & South America:

The composites market in Central and South America is showing solid growth, particularly in Brazil, where the construction sector has seen robust expansion in recent years. This growth, along with the increasing demand for composites in other end-use industries, makes the region an attractive market for both regional and local players, further strengthening the demand for composite materials.

Browse through Grand View Research's Category Advanced Interior Materials Industry Research Reports.

The New England air compressor market size was estimated at USD 225.0 million in 2024 and is projected to grow at a CAGR of 3.5% from 2025 to 2030.

The Central and South America geosynthetics market size was estimated at USD 1.16 billion in 2024 and is projected to grow at a CAGR of 6.4% from 2025 to 2030.

Key Composites Companies

The competitive rivalry among manufacturers in the composites market is intense, driven by the presence of both global and regional players competing for market share. As the demand for composite materials increases across various industries, such as automotive, aerospace, construction, and electronics, manufacturers are vying to offer innovative and cost-effective solutions.

Some prominent players in the composites market include:

Teijin Ltd.

Toray Industries, Inc.

Owens Corning

PPG Industries, Inc.

Huntsman Corporation LLC

SGL Group

Hexcel Corporation

DuPont

Compagnie de Saint-Gobain S.A.

Weyerhaeuser Company

Momentive Performance Materials, Inc.

Cytec Industries (Solvay, S.A.)

China Jushi Co., Ltd.

Kineco Limited

Veplas Group

Order a free sample PDF of the Market Intelligence Study, published by Grand View Research.

0 notes

Text

Future Trends in Basal Reinforcement: What to Expect in Geotechnical Engineering

Basal reinforcement has become a cornerstone of modern geotechnical engineering, playing a crucial role in ensuring stability and efficiency in construction projects involving soft soils and challenging terrains. From embankments to retaining walls, the application of basal reinforcement has grown significantly due to advancements in materials and techniques. As the construction industry evolves, so does the need for innovative solutions in basal reinforcement. This article explores the future trends that are shaping the use of basal reinforcement in geotechnical engineering.

The Growing Importance of Basal Reinforcement

Before delving into future trends, it’s essential to understand why basal reinforcement is indispensable. This technique involves the use of geosynthetic materials, such as geogrids or geotextiles, to strengthen the foundation of structures like embankments, roads, and bridges. By distributing loads evenly and enhancing soil stability, basal reinforcement addresses issues like settlement, slope failures, and bearing capacity inadequacies.

As infrastructure projects expand into areas with poor soil conditions, the demand for more efficient and sustainable basal reinforcement solutions will continue to rise.

Future Trends in Basal Reinforcement

1. Advanced Geosynthetic Materials

The development of geosynthetic materials is at the forefront of basal reinforcement advancements. Future materials will focus on improved durability, higher tensile strength, and enhanced resistance to environmental factors such as UV radiation and chemical exposure. Innovations like nanomaterials and smart polymers will make geosynthetics more adaptable to varying project requirements.

For example, self-healing geosynthetics, which can repair minor damage autonomously, are being researched to improve the longevity of basal reinforcement systems.

2. Integration of Smart Monitoring Systems

As construction projects become more data-driven, the integration of smart monitoring systems into basal reinforcement is gaining momentum. These systems use embedded sensors in geosynthetics to monitor parameters such as strain, temperature, and moisture in real-time. The data collected enables engineers to assess the performance of the reinforcement and identify potential issues before they escalate.

This trend aligns with the broader adoption of the Internet of Things (IoT) in construction, allowing for proactive maintenance and reducing the likelihood of structural failures.

3. Focus on Sustainability

Sustainability is a key driver in the evolution of basal reinforcement. Future solutions will prioritize environmentally friendly materials and processes. Biodegradable geosynthetics and recycled materials are emerging as viable alternatives to conventional products. These innovations aim to reduce the carbon footprint of geotechnical projects without compromising performance.

Moreover, the use of renewable energy sources during the manufacturing of geosynthetics will contribute to a greener construction industry.

4. Enhanced Computational Tools for Design Optimization

The design of basal reinforcement systems is becoming more precise with the advent of advanced computational tools. Finite Element Analysis (FEA) and machine learning algorithms are being employed to simulate and optimize reinforcement designs. These tools allow engineers to predict the behavior of reinforced systems under various conditions, minimizing risks and material wastage.

Future software developments will integrate artificial intelligence (AI) to provide automated recommendations for optimal reinforcement designs based on site-specific data.

5. Modular and Prefabricated Solutions

To reduce construction time and costs, modular and prefabricated basal reinforcement systems are gaining popularity. These systems involve pre-assembled geosynthetic units that can be easily installed on-site. This trend is especially beneficial for large-scale infrastructure projects where efficiency is critical.

In the future, prefabricated solutions will become more sophisticated, with customizable options to meet unique project requirements.

6. Expansion of Applications

As the capabilities of basal reinforcement improve, its applications will expand beyond traditional uses. Future trends indicate a growing role in offshore construction, seismic retrofitting, and urban development projects. For instance, basal reinforcement could play a pivotal role in stabilizing foundations for offshore wind farms or earthquake-resistant infrastructure.

7. Collaboration with Emerging Technologies

Basal reinforcement will increasingly collaborate with other emerging technologies such as 3D printing and robotics. 3D-printed geosynthetics offer the potential for highly customized reinforcement designs, while robotic installation techniques can enhance precision and safety on-site.

Challenges Ahead

While the future of basal reinforcement is promising, challenges remain. High initial costs of advanced materials and technologies may limit widespread adoption. Additionally, the lack of standardized guidelines for newer innovations could slow down their implementation. Addressing these challenges will require collaboration among researchers, engineers, and policymakers.

Conclusion

The future of basal reinforcement in geotechnical engineering is bright, driven by advancements in materials, sustainability, and technology. From smart monitoring systems to modular solutions, these trends promise to revolutionize the way engineers approach soil stabilization and load distribution. As the construction industry embraces innovation, basal reinforcement will continue to play a pivotal role in shaping resilient and sustainable infrastructure.

Whether you’re a geotechnical engineer, contractor, or stakeholder, staying updated on these trends is essential to leverage the full potential of basal reinforcement in your projects.

0 notes

Text

Understanding Uniaxial Geogrids: A Comprehensive Overview

Uniaxial geogrids are a specialized type of geosynthetic material predominantly used in civil engineering for soil reinforcement and stabilization. Their unique structure and properties make them particularly effective for applications requiring strength in one primary direction. Uniaxial geogrid exporters in Ahmedabad This article explores the characteristics, applications, and benefits of uniaxial geogrids, while also highlighting key manufacturers and exporters in Ahmedabad and India.

0 notes