#Gear Shaft Manufacturer

Explore tagged Tumblr posts

Text

Environmentally Friendly Manufacturing

Our Gear Shaft is not only a product of superior engineering but also a testament to our commitment to environmental sustainability. We employ eco-friendly manufacturing processes that reduce waste and reduce our carbon footprint. The materials used in our gear shafts are selected for their recyclability and low environmental impact.

0 notes

Text

Leading SMSR Gear Box manufacturers in India - Shaft Mounted Speed Reducer Manufacturers In Ahmedabad - Nisuka Industries

Nisuka is a renowned name in the industry as one of the top SMSR gear box manufacturers in Ahmedabad, India and trusted Shaft Mounted Speed Reducer manufacturers. We specialize in providing high-quality, durable, and efficient gearboxes designed to meet the demands of various industrial applications. Our products are known for their superior performance, robust construction, and long service life, making them an ideal choice for industries like mining, quarrying, and material handling. At Nisuka, we are committed to delivering innovative solutions that enhance productivity while ensuring reliability and cost-effectiveness for our clients.

#SMSR Gear Box#Manufacturing#SMSR Gear Box manufacturer#Shaft Mounted Gearbox Manufacturer#Conveyor Gearbox Manufacturer

2 notes

·

View notes

Text

.

#every time a character does the whole “talk softly and reassure the dangerous person” thing while also walking ominously towards them ughh#it drives me absolutely nuts. like. you're trying to talk them down from paranoia while you're threateningly walking towards them?#someone does that to me and I'm shooting them at least in the leg or stabbing with whatever makeshift spear I've manufactured#anyway. criminal minds is getting real annoying with the whole pathologizing of people.#like. guy shows signs of being very good at torturing people and they go “ah yes.. a pure sadist” or whatever the fuck#I get that it's shitty crime drama stuff but still. ugh.#I just. I fucking hate when people take the obviously wrong route when talking to mentally destabilized people.#like. people are shit at talking to suicidal people. are shit at talking down irrational fears. people are shit at talking down paranoia.#I hate how people don't fucking know how to interact with freaks I hate how people don't know how to interact with me#everyone acts on their own level without understanding what it's like in any way#and so everyone just projects their own reality onto you without performing any sort of empathy or exercising any sort of understanding#and I want to scream so fucking loud#you're all living in a cotton candy world and your words disintegrate in my humidity#and it's so fucking lonely#and my mind has been clear this past week. the autistic need for pressure satisfied by this prescription pushing on my brain#and I can feel the cogs turning. the wheels and pins and linked gear trains and drive shafts and traction band motors.#all the parts of my brain churning around and I can't get close because the heat from my motor makes my hood hot to the touch.#I burn your hand as you try and press your palm against my flanks.#only think saddle and tack make contact. strict guidelines and harsh rules to govern me.#when I am free I buck and I shift gait and I drag you under too-low branches#also. compared to Hannibal I can basically listen to criminal minds as a podcast. none of the visuals really contribute anything to the show#like. feels very shallow

6 notes

·

View notes

Text

Invest in Quality and Precision with JS Gears' Range of Advanced Gear Solutions

At JS Gears, we pride ourselves on our commitment to excellence and innovation in the gearbox and motor manufacturing industry. As a leading gearbox manufacturer in India, we are dedicated to providing high-quality, reliable products that meet the diverse needs of our clients. Our extensive range of gear solutions ensures that businesses across various sectors can find the perfect fit for their mechanical requirements.

Our product lineup includes a variety of advanced options, such as parallel shaft geared motors, which are designed for high efficiency and performance in demanding applications. Our engineering team works tirelessly to develop these motors with precision and durability in mind, ensuring they withstand the rigors of industrial use. Alongside this, we also specialize as premium helical gearbox manufacturers, offering gearboxes that deliver smooth power transmission and robust functionality for a host of industrial applications.

Premium Helical Gearboxes Designed for Smooth Power Transmission

In addition to our standard offerings, JS Gears also excels as a custom gear manufacturer. We understand that unique projects require tailored solutions, and our skilled engineers are adept at crafting custom gear designs that meet the specific needs of our clients. This personalized service, combined with state-of-the-art manufacturing techniques, ensures that every custom gear is crafted to perfection, enhancing the performance and efficiency of your machinery.

As a company that values customer satisfaction above all, JS Gears is committed to providing innovative designs, precision engineering, and exceptional service. Whether you require a standard gearbox or a custom solution, our expertise and dedication make us the ideal parallel shaft geared motor manufacturers for your mechanical needs. Trust JS Gears to deliver unparalleled quality and innovation, ensuring your operations run smoothly and efficiently. Partner with us and experience the difference that precision and dedication can make in your industrial applications.

#parallel shaft geared motor manufacturers#custom gear manufacturer#premium helical gearbox manufacturers#gearbox manufacturer in India

0 notes

Text

Structural and Functional Aspects of Selecting Power Shift Transmissions

If you are using modern time vehicles, then you are already aware of the Power-Shift Transmission. These are very much similar to the manual type of transmission, but with a minor shift. One major benefit is that they offer safe powershift.

This ensures that it gets better power from the engine drive. During a power shift, the driver have to use the accelerator pedal for generating more power.

When using Powershift and automatic transmission the driver will also have to engage the clutch pedal so more power can be generated for the vehicle

It eliminates the chance of damaging the engine and the vehicle.

This type of power shift is more reliable, especially when driving on uneven terrains.

Distinct gear ratio

One major advantage of using Powershift and automatic transmission is that a very distinct gear ratio can be expected. The transmission is used for directly connecting the drive shaft with the vehicle engine. This simple task will offer the driver to make use of the gear ratio factor when powering.

Consistent power

The moment you are making use of power shifts, it is certain that your vehicle gets a consistent supply of power. This ensures that you can expect high power output even at varying driving speeds. This, in turn, allows the wheels to relax, even on uneven terrains

The benefit of twin camshafts

The traditional type of transmissions made use of a single camshaft. But the moment you are using Powershift and automatic transmission you can ensure that the vehicle is provided with twin camshafts. This is one of the features that prove beneficial for offering the vehicle with much better control.

Offers better uplift

As the vehicles are provided with twin camshafts, so it means that while driving, the vehicles are offered with a high uplift factor. So the moment you are driving on uneven terrains, it is certain that you may not have to worry about shifting gears very often.

In modern time vehicles, powershift type of transmission is always considered as more beneficial.

#auto components manufacturers in india#automatic transmissions#transmission components#transmission parts manufacturer#powershift transmissions#transmission gears and shafts#powertrain manufacturer in india#powertrain components

0 notes

Text

Driving Efficiency: A Closer Look at Spline Shaft Manufacturers in India

In the world of machinery and automotive engineering, the role of spline shafts cannot be overstated. Spline shafts play a crucial part in transmitting torque between two rotating objects, ensuring smooth and efficient power transfer. In this blog post, we delve into the realm of spline shafts and shine a spotlight on the leading spline shaft manufacturers in India.

Before we delve into the specifics of spline shaft manufacturers, it's essential to understand the pivotal role these components play in power transmission. Spline shafts are cylindrical rods with a series of ridges or teeth, known as splines, machined onto their surface. These splines enable a secure and precise connection between the shaft and the mating component, allowing for the efficient transfer of torque.

Sourcing Excellence: Why India?

India has emerged as a hub for manufacturing precision engineering components, and spline shafts are no exception. The country boasts a robust manufacturing sector, characterized by a blend of skilled labor, cutting-edge technology, and cost-effectiveness. Indian spline shaft manufacturers are known for their adherence to international quality standards, making them reliable partners for industries worldwide.

SRS Gears: Pioneering Excellence in Spline Shaft Manufacturing

One name that stands out in the Indian spline shaft manufacturing landscape is SRS Gears. With a legacy of craftsmanship and a commitment to innovation, SRS Gears has positioned itself as a frontrunner in the industry. Let's explore what sets SRS Gears apart:

Precision Engineering

SRS Gears places a premium on precision engineering. The spline shafts produced by SRS Gears undergo meticulous machining processes to ensure dimensional accuracy and optimal performance. This commitment to precision is instrumental in enhancing the efficiency of the overall machinery.

Advanced Technology Integration

Staying at the forefront of technological advancements is a hallmark of SRS Gears. The company invests in state-of-the-art machinery and technologies, empowering its manufacturing processes with the latest innovations. This not only ensures superior product quality but also enables SRS Gears to adapt to the evolving needs of the industry.

Customization Capabilities

Recognizing the diverse requirements of its clientele, SRS Gears excels in providing customized solutions. Whether it's a unique spline profile or specific material specifications, the company collaborates closely with clients to deliver tailor-made solutions that align with their exacting standards.

Material Innovation

Spline shafts are exposed to varying levels of stress and environmental conditions. To address this, SRS Gears and other manufacturers in India have embraced material innovation. High-quality alloys and heat-treated steels are now commonplace, ensuring enhanced durability and longevity of spline shafts in demanding applications.

Sustainability Practices

As the global focus on sustainability intensifies, manufacturers like SRS Gears are integrating eco-friendly practices into their operations. From using recyclable materials to optimizing energy consumption during manufacturing, these efforts contribute to reducing the environmental footprint of spline shaft production.

Looking Ahead: The Future of Spline Shaft Technology

The future of spline shafts holds exciting possibilities. Advancements in materials, manufacturing processes, and digital technologies are poised to further enhance the performance and reliability of these critical components. Indian manufacturers like SRS Gears are actively engaged in research and development, staying ahead of the curve to meet the evolving needs of industries around the world.

Conclusion: Empowering Industries through Precision

As industries continue to demand higher efficiency and reliability, the role of spline shafts becomes increasingly vital. In India, SRS Gears stands as a beacon of excellence, driving efficiency through precision engineering and technological prowess. The synergy of traditional craftsmanship and modern innovation positions SRS Gears as a trusted partner for industries seeking reliable and high-performance spline shafts.

In the grand tapestry of manufacturing, the spline shaft may be a small component, but its impact is monumental. As we celebrate the prowess of Indian manufacturers like SRS Gears, we acknowledge the integral role they play in propelling industries forward, one precisely crafted spline at a time.

0 notes

Text

Shaft Mounted Speed Reducer Gear Box - Manufacturer

Makoda Gears have extensive experience in engineering, manufacturing, designing and supplying shaft mounted speed reducer gearboxes. We have some of the most advanced shaft mounted speed reducers that have been designed, tested and approved as per the Indian and international standards. Our shaft mounted speed reducers are available to manufacturers, wholesalers, dealers and end users. Our gear boxes are extremely well-built to withstand extreme pressure and torque while providing the maximum efficiency. We emphasize quality in our products and all products are tested and inspected in our own laboratory to ensure they meet the highest of expectancies. We also offer custom gears and gearing solutions for any requirement. Our customer service team is available round the clock to attend to all your queries. We pride ourselves on providing the best quality gear boxes with competitive price points.

https://makodagears.com/shaft-mounted-speed-reducer-gear-box-manufacturer/

1 note

·

View note

Text

Electric Motor Long Rotor Stainless Steel Gear Shaft

The gear shaft, often an unsung hero in the world of mechanical engineering, is a crucial component that provides support to rotating parts while efficiently transmitting movement, torque, and bending forces. In essence, it serves as the backbone of many machines and devices, facilitating the conversion of electrical energy into mechanical work.

Materials and Manufacturing Excellence:

One of the key highlights of JULI's Electric Motor Long Rotor Stainless Steel Gear Shaft is the choice of material. It is meticulously crafted from stainless steel, a material known for its exceptional properties, including corrosion resistance, high tensile strength, and excellent durability. The use of stainless steel ensures that the gear shaft can withstand the test of time, even in challenging environmental conditions.

0 notes

Text

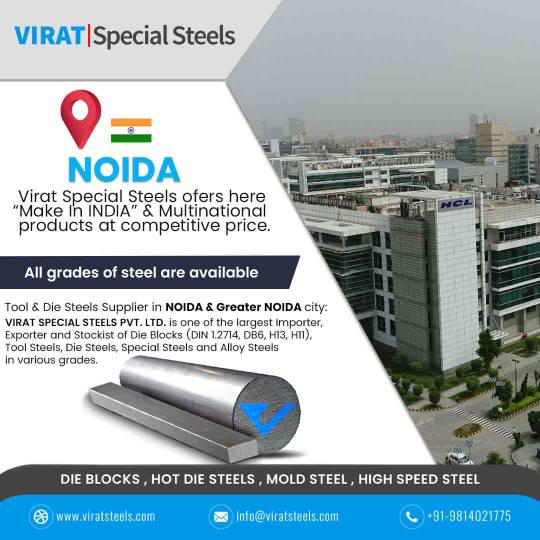

Exciting News for Noida & Greater Noida Industries! 🔥 VIRAT SPECIAL STEELS PVT. LIMITED , INDIA is thrilled to announce that we are now supplying SPECIAL STEELS directly to Noida and Greater Noida! 🌟

🏭 Whether you're a large car manufacturer, an engineering unit, or even a micro-industry, our high-quality special steels are crucial for your production needs. From heavy vehicle components to precision engineering, our steels are designed to meet your toughest requirements.

🔧As one of India's top suppliers of Tool Steel, Die Steel, and Mould Steel, we also offer a comprehensive range of special steel grades to cater to your specific needs.

Product List:

DIE STEEL ( HH 370 - 410 BHN ) (DIN-1.2714 / AISI L6 )

HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

ALLOY STEELS, EN-SERIES ETC.

🚗🔩 Our product range is perfect for:

Heavy vehicle, tractors, and automobile transmission parts

General engineering applications

Ball and roller bearings, gears of all types

Camshafts, universal joints, driving pinions

Link components, axles, arbours

Gear shafts and spinning tools

📍 Located near Noida in Gurgaon, our headquarters are at the heart of India's industrial hub, ensuring quick and reliable service.

🤝 Let Virat Special Steels be your trusted partner in driving industrial growth in the Noida and Greater Noida region.

For more information visit: https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-noida/

Contact us today to discuss your special steel needs and how we can help propel your projects forward!

📞+91-98140 21775 🌐www.viratsteels.com 📩 [email protected]

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#noida#GreaterNoida#SpecialSteels#ColdWorkSteels#HighSpeedSteels#SteelTrades

2 notes

·

View notes

Text

JS Gears - Pioneering High-Quality Gearboxes and Geared Motors in India

JS Gears stands at the forefront of the transmission industry as a leading gearbox manufacturer in India of high-quality gearboxes and geared motors. With a commitment to precision engineering, innovation, and reliability, we take pride in delivering custom solutions that power industries and businesses across the country with efficiency and performance.

As one of the premier parallel shaft geared motor manufacturers, JS Gears excels in producing robust and efficient motors that are tailored to meet the diverse needs of industrial applications. Our parallel shaft geared motors are designed to deliver smooth operation, high torque, and durability, making them an ideal choice for a wide range of machinery and equipment.

Driving Industrial Efficiency with Advanced Gearbox Technology

Experience the superior craftsmanship and precision engineering of our helical gearbox solutions proudly manufactured in India. At JS Gears, we are renowned for our expertise as helical gearbox manufacturers in India, offering a comprehensive range of helical gearboxes that ensure smooth power transmission, minimal noise, and maximum efficiency in various industrial settings.

Enhance your machinery's performance with JS Gears' inline helical geared motors, designed to deliver exceptional power transmission and reliability. Our inline helical geared motor combine the efficiency of helical gears with the compactness of inline design, providing a space-saving solution without compromising on performance.

At JS Gears, customer satisfaction is at the core of everything we do. Our team of skilled engineers and technicians is dedicated to providing personalized service, expert advice, and innovative solutions to address your specific gearbox and geared motor requirements.

#gearbox manufacturer in India#parallel shaft geared motor manufacturers#helical gearbox manufacturers in India#inline helical geared motor

0 notes

Text

Pioneering Sustainable Mobility with EV Transmissions for Passenger Cars

In the era of sustainable transportation, AVTEC takes the driver's seat in revolutionizing the automotive industry with its cutting-edge EV transmissions for passenger cars. As the world shifts towards electric mobility, AVTEC's commitment to innovation and sustainability is steering the course. Let's explore why AVTEC's EV transmissions are capturing the attention of a diverse audience and reshaping the future of passenger car mobility.

AVTEC's EV transmissions for passenger cars are at the forefront of the electric vehicle revolution. These transmissions are the vital components that enable electric cars to efficiently harness and distribute power, ensuring optimal performance and range. AVTEC's commitment to precision engineering and sustainable solutions shines through in every aspect of its EV transmissions, contributing to cleaner, greener, and more energy-efficient transportation.

AVTEC's EV transmissions are designed not only to provide exceptional performance but also to maximize energy efficiency. With seamless gear shifting and intelligent power management, these transmissions optimize the driving experience while extending the range of electric cars. AVTEC's dedication to enhancing the efficiency of EVs ensures that passengers enjoy a smooth and powerful ride while reducing their carbon footprint.

AVTEC recognizes that the world of passenger cars is diverse, with different manufacturers and models catering to unique customer needs. Therefore, AVTEC's EV transmissions are highly customizable, tailored to meet the specific requirements of various electric car models. Whether it's a compact urban EV or a high-performance electric sports car, AVTEC's transmissions are designed to seamlessly integrate and enhance the driving experience.

As a leader in EV transmissions for passenger cars, AVTEC is driving the transformation towards sustainable mobility. Its commitment to innovation, performance, and efficiency is not only reshaping the passenger car industry but also attracting a diverse audience keen on experiencing the future of eco-friendly transportation. AVTEC's EV transmissions are paving the way for cleaner, greener, and more exhilarating journeys on the road ahead.

#auto components manufacturers in india#automatic transmissions#powertrain components#transmission components#powershift transmissions#transmission parts manufacturer#transmission gears and shafts#precision auto components#engine parts manufacturers in india

0 notes

Text

Building the Backbone of Machinery: Spline Shaft Manufacturers in India

Spline shafts are mechanical components that generate anti-rotation if used as a linear guide. Additionally, along the shaft length, you would find grooves, splines, and tongues. So, when it comes to Spline Shaft, it is recommended that you purchase it from the best Spline Shaft manufacturers in India.

Thus, in this article, we will cover everything about Spline shafts. Let us have a look: -

Splined Shaft – What is the functionality?

One of the most important functionalities of a splined shaft is to work as an anti-rotatory device. This typically happens in positions of the linear guide. On the other hand, if it doesn't work as a linear guard, then torque is transmitted to another device. So, Splined Post functionality changes based on several aspects.

Also, spline is available in different shapes and designs and tends to have different functionality and roles when working alongside the shaft.

Splined Shaft – What are the applications?

Splined Shafts tend to have a wide range of applications which include locomotives, manufacturing, automobiles, and industrial facilities to name a few.

Thus, splined shafts are used in several places but the most common applications include aviation, automobile, and earth-moving machinery.

The good thing is that splined shafts are capable of offering great torque and rotation speed that is very high. The reason a lot of torque is offered is due to its structure.

Another important aspect of Spline shafts is that it is used in the production of several items that are used in a wide range of industries. Likewise, it is used in giving controlled and uniform torque. Hence, the changes of misalignment are also greatly reduced to a very large extent.

What are the materials used for Spline Shaft manufacturing?

Splined Shafts are manufactured using metallic elements due to the stress that occurs in the tongues or teeth of the shaft. Some of the materials which are used for the manufacturing are as follows: -

Alloy Steels

Alloy Steels are ferrous alloys made using carbon, iron, and alloying elements such as molybdenum, chromium, nickel, and vanadium. Some of the things that are included in Alloy Steels are high-strength low-alloy steels, hardened high-alloy steels as well and other kinds of high-speciality steel alloys.

Aluminium alloys

Aluminum alloys are another material that is used in Spline Shaft manufacturing. They provide great toughness at various strength levels alongside great corrosion resistance and perhaps at half the steel density.

Carbon steel

Spline Shaft is also manufactured using carbon steel which contains about 1.7 percent carbon as an alloy constituent. In suitable conditions, it can be malleable and it can be differentiated from cast iron through low carbon content and malleability.

Stainless Steel

The good thing about stainless steel is that they are corrosion resistant. They are also known to be ferrous alloys as it has nickel and chromium present in it.

Final Verdict

The best thing about splined shafts is that they can be used in a wide range of industries. They are quite sophisticated machines that make everyday tasks easy.

The best part is that splined shaft manufacturing doesn't need any kind of fancy materials. Further, shafts & their designs can be customized easily as per the taste and need. So, it is recommended that you purchase it from the best Spline shaft manufacturers in India.

0 notes

Text

Nickel 200 Wires Exporters in UAE

Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is a Wires provider and exporter of Nickel 200 wires. We Manufacture them open in custom nuances, plans, lengths, thickness, widths, and that is only a brief gander at something more prominent. We are known Exporters in the general market of ferrous and nonferrous things. Our clients can intercessors for nickel wires as shown by their application necessities.

Nickel 200 Wires are made with the assistance of the different Amalgam affiliations like carbon, manganese, silicon, copper, sulfur, chromium, iron, nickel, nitrogen, etc. too. These nickel wires ought to have physical and mechanical properties like thickness, loosening up point, flexibility, yield strength, astonishing rigid nature, broadening, warm conductivity, electrical conductivity, and modulus of extension. These wires are made with different decisions like broadness, shape, size, length, width, thickness, types, structures, condition, surface, application, standard, finish, obstacles, etc. as well. These wires are accessible in many sorts, for example, reshape wire, made never-ending wire.

Nickel 200 Wires are material in various organizations, for instance, offshore oil entering undertakings, petrochemicals industry, power age plant, drug industry, substance gear, seawater equipment, drug equipment, special engineered industry, paper industry, pound industry, heat exchanger, and condenser. These wires are also significant in many general purposes like valves, shaft, shipbuilding, structure advancement, transportation equipment, range improvement, radiator parts, and various temperature-safe things.

Nickel 200 Wires are made with the best material and incredible mechanical and real properties. These wires are a good blend of formability, usefulness, welding, and resistance from the high temperatures. These wires are outrageous, hard, and made with the protected material to work at high temperatures. These wires are furthermore protected against the entire expansive disintegration like gap utilization, stress breaking, pitting block, and impact disintegration. These wires are protected in the oxidizing, decreasing and unprejudiced circumstances. These wires have the low electrical and warm conductivity that helps the wires with contradicting the electric.

Nickel 200 Wires need to go through many tests after the creation from the business, for example, erupting test, straightening test, large scale test, miniature test, hydrostatic test, ultrasonic test, pitting test, radiography test, hardness test, synthetic test, mechanical test, PMI test, etc too.

For more information : Visit our website : https://www.merakimetals.ae/ Contact us : +971-523973687, +971-48801107, +971-48240333 Email : [email protected]

#Nickel 200 Wires Manufacturers in UAE#Nickel 200 Wires Suppliers in UAE#Nickel 200 Wires Stcokists in UAE#Nickel 200 Wires Exporters in UAE

3 notes

·

View notes

Text

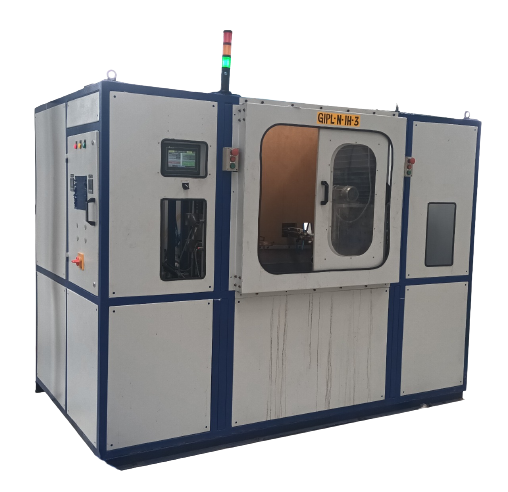

Abinduction’s Induction Hardening Solutions for Aerospace and Defense Applications

In aerospace and defense industries, precision, reliability, and durability are critical. Components must withstand extreme conditions, such as high stresses, temperature variations, and prolonged use. Abinduction provides state-of-the-art induction hardening solutions tailored to meet the rigorous demands of these industries, ensuring superior performance and extended lifespan of critical parts.

Why Choose Abinduction for Aerospace and Defense Applications?

Precision Engineering:

Abinduction’s machines deliver precise and localized hardening, ensuring that components meet exact specifications with minimal distortion. This is vital for parts like turbine blades, landing gear, and fasteners used in aerospace applications.

Custom Solutions for Complex Components:

With the ability to design machines and processes specific to intricate geometries and high-performance materials, Abinduction ensures efficient and effective hardening for even the most challenging aerospace and defense parts.

Enhanced Durability:

Induction hardening from Abinduction improves wear resistance and fatigue strength, essential for components subjected to high stress, such as engine parts and structural components.

Energy Efficiency:

Utilizing advanced induction technology, Abinduction’s systems minimize energy consumption while maximizing output, making them an eco-friendly and cost-effective choice.

Automation and Connectivity:

Abinduction integrates smart automation and Industry 4.0 capabilities, enabling real-time monitoring, process optimization, and seamless integration into advanced manufacturing environments.

Key Applications in Aerospace and Defense:

Landing Gear Components:

Strengthening parts like axles and shafts to ensure they can withstand extreme loads during takeoff and landing.

Turbine Blades:

Hardening blades to improve resistance to wear and thermal stresses in high-temperature environments.

Fasteners and Bolts:

Enhancing surface hardness for improved durability in critical joints.

Armor Components:

Hardening defense equipment and vehicle armor for enhanced protection and performance.

Engine Parts:

Treating crankshafts, camshafts, and other high-stress components to ensure long-term reliability.

Abinduction’s Advantages

Global Expertise: Decades of experience in providing induction solutions for high-stakes industries.

Cutting-Edge Technology: Incorporates the latest advancements in induction heating and hardening.

Comprehensive Support: From design to maintenance, Abinduction offers end-to-end solutions for its clients.

Compliance with Industry Standards: Machines and processes are designed to meet or exceed aerospace and defense regulations and quality benchmarks.

Conclusion

Abinduction’s induction hardening solutions empower aerospace and defense manufacturers to produce parts that meet the highest standards of quality and reliability. By combining advanced technology, precision engineering, and customizable solutions, Abinduction ensures its clients achieve optimal performance and efficiency.

Would you like additional details about specific products or case studies from Abinduction?

For more information, visit abinduction.in.

Address : 96PX+RR7, Nawada Village, Sector 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for : https://abinduction.in/vertical-induction-hardening-machine-manufacturer/

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

0 notes