#Gas Detection Equipment Market

Explore tagged Tumblr posts

Text

Trusted Portable Gas Detector Supplier in Luanda, Angola

Ensure safety in industrial environments with our reliable portable gas detectors. Based in Luanda, Angola, we provide high-quality, accurate gas detection solutions from leading manufacturers. Ideal for the oil, gas, mining, and construction industries, our detectors help monitor harmful gases to prevent accidents. Contact us for expert advice and competitive pricing on our top-tier products.

[email protected] +244 928 961 641 / +244 928 955 999

#gas detection equipment market#industrial equipment#safety#ecommerce#marketing#sales#commercial#business

0 notes

Text

0 notes

Text

The North America Gas Detection Equipment market is projected to grow at a CAGR of around 8.26% during the forecast period, i.e., 2022-27. The North America Gas Detection Equipment market has witnessed notable growth during the historical period. The factors that have driven the growth of the Gas Detection Equipment market are the rising concerns about the workforce & industrial plant safety as well as stricter government regulations regarding security standards & environmental safety. Notably, the rising gas leak incidents in the region have mandated the deployment of gas detection equipment to prevent any fatal accidents.

#North America Gas Detection Equipment market#North America Gas Detection Equipment market News#North America Gas Detection Equipment market Trends#North America Gas Detection Equipment market Growqth#North America Gas Detection Equipment market Report

0 notes

Text

Iraq Oil and Gas Construction Companies: Key Players in Energy Development

As one of the world’s largest oil-producing countries, Iraq relies heavily on its oil and gas industry to drive economic growth. Iraq oil and gas construction companies are essential in building the infrastructure needed for exploration, extraction, and distribution of oil and gas. These companies play a vital role in constructing pipelines, refineries, storage facilities, and processing plants, which are crucial for Iraq’s energy sector. The expertise and efficiency of Iraq oil and gas construction companies directly influence the country’s ability to maintain its role as a global energy provider.

The Importance of Iraq’s Oil and Gas Sector

The oil and gas sector contributes around 90% of Iraq’s national revenue, making it a cornerstone of the economy. With abundant reserves and a strategic location, Iraq has positioned itself as a major player in the global energy market. However, the sector faces challenges, including the need to update outdated infrastructure and improve efficiency in extraction and refining processes. This is where Iraq oil and gas construction companies step in, offering the expertise and technology to modernize and expand infrastructure. Through their work, these companies not only contribute to economic growth but also help secure Iraq’s future as a competitive energy producer.

Key Services Offered by Iraq Oil and Gas Construction Companies

Iraq’s oil and gas construction companies provide a variety of services to meet the complex demands of the industry. These services include:

Pipeline Construction and Maintenance One of the most critical components of the oil and gas infrastructure is pipelines. They enable the safe and efficient transport of crude oil and natural gas across long distances. Iraq oil and gas construction companies specialize in designing, building, and maintaining pipelines that meet both national and international safety standards. Regular maintenance of these pipelines is crucial for preventing leaks and ensuring smooth operation, making these companies indispensable to the sector.

Refinery Construction and Expansion Refineries are vital for processing crude oil into usable products, such as gasoline, diesel, and petrochemicals. Iraq oil and gas construction companies are skilled in constructing new refineries and expanding existing ones to meet the increasing demand. These projects require advanced engineering and the latest technology to maximize efficiency and reduce environmental impact.

Storage Facilities Efficient storage solutions are essential for managing the supply of oil and gas, especially as global demand fluctuates. Iraq’s construction companies build and maintain large-scale storage facilities, which help manage the country’s energy reserves and stabilize the supply chain. Properly constructed storage facilities also ensure the safe handling of hazardous materials, reducing the risk of accidents.

Processing Plants and Equipment Installation Processing plants convert raw oil and gas into products ready for distribution. Iraq oil and gas construction companies work on both the construction and maintenance of these plants, installing specialized equipment designed to maximize output and minimize waste. This involves incorporating technology that meets international standards for efficiency and environmental protection, supporting Iraq’s long-term goals for sustainable energy production.

Technology and Innovation in Iraq’s Oil and Gas Construction Sector

To stay competitive and meet the demands of an evolving energy market, Iraq oil and gas construction companies are increasingly incorporating advanced technology into their projects. Key technologies used include:

Digital Monitoring and Automation: Digital sensors and automated systems help monitor pipeline pressure, detect leaks, and manage refinery operations more efficiently.

Drones and Robotics: Drones are now commonly used for aerial surveys and inspections, especially in challenging terrain. Robotics aid in tasks such as welding and equipment installation, enhancing precision and safety.

Environmental Technologies: New technologies designed to reduce emissions and manage waste are also being integrated. For instance, gas flaring reduction technology is becoming more common, helping to minimize environmental impact.

The Role of Local Expertise and International Partnerships

While Iraq oil and gas construction companies possess significant expertise, international partnerships are often crucial for large-scale projects. Collaborating with global firms allows Iraqi companies to leverage foreign technology, knowledge, and financing, enhancing their ability to complete complex projects successfully. These partnerships also facilitate knowledge transfer, training local engineers and workers in the latest techniques and technologies. This local expertise, combined with international standards, strengthens Iraq’s position in the global oil and gas market and builds a more sustainable workforce.

Challenges Faced by Iraq Oil and Gas Construction Companies

Despite their importance, Iraq oil and gas construction companies face several challenges. These include:

Security Concerns: Iraq has areas where security remains a concern, which can disrupt project timelines and create additional costs for safety measures.

Regulatory Hurdles: The regulatory environment can be complex, particularly for international partnerships. Compliance with both local and international regulations requires careful planning and adaptability.

Environmental Impact: With a growing emphasis on sustainability, Iraq oil and gas construction companies are increasingly pressured to reduce their environmental footprint, requiring additional investment in green technology and eco-friendly practices.

Conclusion

Iraq oil and gas construction companies are key drivers of the nation’s energy industry, enabling the development, maintenance, and expansion of crucial infrastructure. Their services in pipeline construction, refinery expansion, storage, and processing plants are foundational to Iraq’s energy production and economic stability. By embracing technological advancements and fostering international partnerships, these companies continue to support Iraq’s ambitions in the global energy sector. Despite challenges, the expertise and innovation of Iraq oil and gas construction companies remain essential for ensuring Iraq’s future as a competitive energy powerhouse.

2 notes

·

View notes

Text

Ad It Up

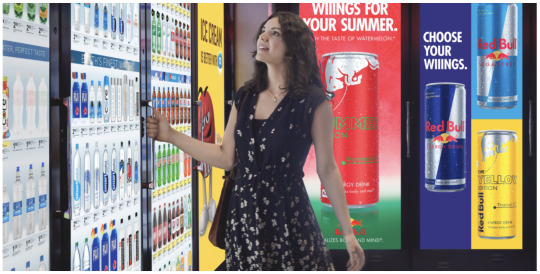

You only thought it was difficult to escape the marketer’s voice. From traditional media like outdoor, print, and broadcast, to a variety of ads littering our social media feeds, web pages, and search results, marketers have been seemingly everywhere trying to get our attention. And the more they tried, the louder they had to shout, because it’s crowded out there, and the decibel level—whether audible or visual—is increasing.

Except perhaps in stores and at the gas pump, where we felt like we at least had a few minutes of quiet. That, too, is changing rapidly, as in-store advertising has gone digital, to the point of it being called “broadcast-level scale.” Gas pumps too are now coming equipped with video screens to sell to us while we are filling our tank.

It’s all a mixed bag right now of ads, with gas stations able to deliver hyper-local advertising for third-party advertisers nearby. Inside the store, the campaigns are aimed at the masses instead of using an audience-of-one approach.

I see the day coming, though, in which advertising at the pump will be increasingly one-to-one (remember, you have to insert or tap your card first, which could then quickly allow them to access a profile of you).

And the same goes for inside the store, especially once retail formats like Amazon’s “Just Walk Out” technology are deployed widespread. Your presence and unique data would be detected wherever you go in the store as the system monitors your shopping basket, and messages could be directed straight to you when you ponder the pasta sauces or wherever you go.

We’ve come a long way when it comes to in-store advertising. The majority of what we have seen usually involves massive stacks of soft drinks, the red, white, and green packages from Coca-Cola cleverly arranged to spell words or form images. The same goes for snack foods and beer leading up to the Super Bowl. Otherwise, maybe some small shelf hangers might try to whisper a marketing message.

Now, though, there is the possibility of smart screens attached to the clear refrigerator doors, behind which beverages of all kinds reside. Stand-alone screens can also welcome customers as they walk in. The possibilities are limitless, because LCD screens are cheap, and can all be managed remotely.

All of which speaks to this emerging truth: the retail store and gas stations are now viable platforms for advertising, a rentable space little different from billboards, TV, and the internet. The battle for our attention just found a new place to stage that fight. It allows retailers to boost their revenues and bottom lines above and beyond just selling things.

It’s happening in the online arena as well. Have you noticed how many sponsored spots there are on any Amazon results page? Amazon scored $12 billion in ad revenues in Q3 2023 alone. That’s impressive, especially when you consider that Amazon’s total revenue that quarter was $143 billion. In other words, advertising made up one in every 12 dollars of its revenues.

I predict a similar such cascade of revenues for any retailer willing to parse out its interior—and exterior—space for advertising purposes. After all, why not? If you can hit people right when they are coming to spend money anyway, this is pretty simple.

Truthfully, I do not mind the ads, especially if they point me to things I might be interested in. Elevate it to audience-of-one capability, and it is even better. I know…some people will be creeped out by this, just like they have been with all the targeted advertising we see online. I would much rather hear and see ads for things I am likely to buy, as opposed to things I will never buy. Every time I hear that Tampax ad on one of my podcasts, I think about how they’re foolishly wasting half of their ad spend on men like me.

Others may see such ubiquitous advertising as further invasion of their private space, a harbinger of a dystopian society to come. Or maybe it has already arrived. To each their own, but there is no ad blocker yet for the brick and mortar world, and the best you can do is shut your eyes and ears, and walk on by.

Or out.

Dr “Talk To Me” Gerlich

Audio Blog

3 notes

·

View notes

Text

Reliable Backup Generators in San Antonio: Ensuring Uninterrupted Power

Power outages can be an inconvenience at best and a major disruption at worst. Whether due to severe weather, infrastructure issues, or unexpected grid failures, losing electricity can impact daily life, business operations, and safety. Synergystandby.com, the leading provider of backup generators in san antonio synergy standby, offers reliable solutions to ensure you never have to face the uncertainty of a power outage unprepared.

The Need for Backup Generators

San Antonio experiences a variety of weather conditions, including intense heat, thunderstorms, and occasional winter storms. These weather patterns can strain the electrical grid, leading to unexpected blackouts. Investing in a standby generator provides peace of mind by ensuring that essential appliances, heating and cooling systems, and security devices continue functioning even when the main power supply fails.

Benefits of a Standby Generator:

Uninterrupted Power Supply: Automatically restores electricity within seconds of an outage.

Protection for Home Appliances: Prevents damage from sudden power loss or voltage fluctuations.

Enhanced Security: Keeps security systems operational, reducing vulnerability to break-ins.

Comfort and Convenience: Ensures continued use of air conditioning, refrigeration, and internet connectivity.

Increased Property Value: A generator is a valuable asset that enhances a home’s marketability.

Why Choose Synergy Standby?

Synergy Standby is recognized as San Antonio’s premier backup generator provider, offering high-quality products and professional installation services. Here’s why we stand out:

Top-Quality Generators

We supply only the best standby generators from trusted brands, ensuring durability and efficiency. Our generators are designed to handle the power needs of both residential and commercial properties.

Expert Installation Services

Proper installation is crucial for a generator’s performance. Our team of certified professionals ensures seamless integration with your electrical system, guaranteeing optimal functionality when needed most.

Automatic Transfer Switch (ATS) Technology

Our generators come equipped with ATS technology, which detects power outages and switches to backup mode automatically. This means you don’t have to worry about manually starting the generator during an emergency.

Fuel Efficiency & Eco-Friendly Options

We offer generators powered by various fuel sources, including natural gas, propane, and diesel. Our eco-friendly models are designed to reduce emissions while maintaining exceptional performance.

24/7 Customer Support & Maintenance

A generator is only as good as its maintenance. Our comprehensive service plans ensure regular inspections, prompt repairs, and technical support whenever you need it.

Selecting the Right Generator for Your Needs

Choosing the right backup generator depends on several factors, including the size of your home or business, power consumption, and budget. Our team at Synergy Standby assists customers in determining the most suitable model by evaluating:

Power Requirements: Identifying essential appliances and systems that require backup power.

Fuel Type Preference: Offering guidance on the advantages of gas, propane, or diesel generators.

Installation Space: Assessing the available area for proper placement and ventilation.

With synergy standby llc, you can secure a dependable backup generator in San Antonio to keep your home or business running smoothly during unexpected outages. Our commitment to quality products, professional installation, and ongoing maintenance ensures long-term reliability and peace of mind. Don’t wait until the next blackout—contact Synergy Standby today and invest in uninterrupted power for your property!

1 note

·

View note

Text

Dissolved Gas Analyzer Market Analysis: Opportunities & Competitive Landscape

Introduction: The Dissolved Gas Analyzer (DGA) market is critical to industries such as power, oil, and gas, where equipment like transformers is continuously monitored for potential faults. The market for these analyzers has witnessed growth owing to the increasing demand for early detection of faults in electrical equipment. As energy demands rise, the need for effective diagnostic tools to monitor and maintain machinery health becomes more prominent.

The Dissolved Gas Analyzer Market Size was valued at USD 398.7 Million in 2023 and is expected to reach USD 492.2 Million by 2032, growing at a CAGR of 2.4% over the forecast period 2024-2032.

Market Trends:

Rising demand for automation: Automation and real-time monitoring are driving the adoption of DGAs, ensuring better predictive maintenance.

Technological advancements: There is continuous improvement in DGA technology, such as enhanced sensors and integration with advanced monitoring systems.

Growing adoption in power sector: The power and electrical distribution sector remains a significant driver due to the extensive use of transformers in power grids.

Growth:

Market Expansion: The market is expected to grow due to the increasing need for fault diagnosis in critical equipment, especially transformers, to avoid expensive downtime.

Regional Growth: Developing economies are expected to witness significant growth in demand due to rapid industrialization and urbanization.

Innovative Products: Technological advancements, such as wireless communication and IoT-based DGA systems, are creating new opportunities.

Challenges:

High Initial Cost: The installation cost of advanced DGA systems can be prohibitive for some smaller operations.

Complex Maintenance: The complexity of certain DGA systems requires highly skilled personnel for operation and maintenance, which could pose a challenge.

Market Penetration in Emerging Markets: Though there is potential for growth, the penetration of DGA systems in emerging markets remains slow due to cost concerns.

Future Outlook: The future of the Dissolved Gas Analyzer market looks promising with technological innovations like AI integration and enhanced data analytics. These advancements will further improve diagnostic accuracy and help industries manage their assets more effectively. The continued expansion of the energy sector, particularly in emerging markets, is expected to drive the demand for DGA systems. The market is likely to witness increased competition, leading to improved product quality, lower costs, and expanded applications in sectors beyond power generation.

Conclusion: The Dissolved Gas Analyzer market is poised for substantial growth driven by technological advancements, particularly in the power sector. While challenges such as high initial costs and complex maintenance procedures exist, the benefits of early fault detection and predictive maintenance outweigh these hurdles. As industrial demands for reliability and efficiency continue to grow, DGA systems will play a critical role in transforming maintenance practices across various sectors.

Read More Insights @ https://www.snsinsider.com/reports/dissolved-gas-analyzer-market-4820

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

0 notes

Text

Solid-State Hydrogen Sensors Market to Surpass $1.45B by 2034, Growing at 10.5% CAGR 🏭🔋

Solid State Hydrogen Sensors Market is set for significant expansion, reaching $1.45 billion by 2034, driven by the rising adoption of hydrogen energy and stringent safety regulations. These sensors ensure efficient and safe hydrogen usage across multiple industries, including automotive, aerospace, and energy, with advancements in sensor accuracy and reliability fueling market growth.

Key Growth Drivers:

🚗 Automotive Industry Leads (45% Market Share): The shift toward hydrogen-powered vehicles (FCEVs) and stringent emission regulations drive demand. 🏭 Industrial Safety Applications (30% Market Share): Increased adoption of hydrogen leak detection systems ensures workplace safety and regulatory compliance. 🏥 Healthcare & Environmental Monitoring (25% Market Share): Expanding usage in medical equipment and environmental tracking boosts growth.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS10765 &utm_source=SnehaPatil&utm_medium=Article

Regional Insights:

🌎 North America dominates, led by the U.S. hydrogen energy projects and strong R&D ecosystem. 🇪🇺 Europe follows closely, with Germany and the U.K. leading hydrogen initiatives for sustainability and clean energy. 🌏 Asia-Pacific emerging as a key market, driven by Japan and South Korea’s investments in hydrogen mobility and infrastructure.

Market Segmentation:

✔ Type: Electrochemical, Metal-Oxide, Optical, Palladium-based, Semiconductor ✔ Product: Portable, Fixed, Consumer Devices, Industrial Devices ✔ Technology: MEMS-based, Nanotechnology, Thin Film, Catalytic ✔ Application: Industrial Safety, Automotive, Oil & Gas, Power Generation, Healthcare ✔ End Users: Manufacturing, Aerospace, Energy & Utilities, Chemical Industry

Key Players:

🔹 Honeywell International 🔹 Figaro Engineering 🔹 Membrapor AG

#HydrogenSensors #CleanEnergy #HydrogenEconomy #FCEV #GreenHydrogen #HydrogenFuel #IndustrialSafety #GasDetection #SemiconductorSensors #AutomotiveTech #RenewableEnergy #FuelCellVehicles #HydrogenInfrastructure #SensorTechnology #SustainableFuture #HydrogenMonitoring #TechInnovation #SafetyFirst #EnergyTransition #SmartSensors #IndustrialInnovation #AerospaceTech #NextGenSensors #PowerGeneration #CarbonNeutral #HydrogenStorage

0 notes

Text

How Mining Insurance Shields Your Business From Disaster (And Why You Can’t Afford to Skip It)

Let’s face it: mining isn’t for the faint of heart. Between Mother Nature’s curveballs and the chaos of heavy machinery, disaster can strike when you least expect it. But here’s the good news—mining insurance isn’t just a safety net. It’s your financial lifeline when things go sideways. Think of it like a seatbelt for your balance sheet. In this guide, we’ll break down how the right insurance strategy can turn worst-case scenarios into manageable hiccups.

The Risks Lurking in Every Mine (Yes, Even Yours)

Mining’s a high-stakes game. One minute you’re on track for record output; the next, a landslide or equipment meltdown sends your plans up in smoke. And it’s not just natural disasters you’re up against. Ever had a rookie operator accidentally drill into a gas line? Or watched market prices nosedive overnight? These risks don’t just threaten safety—they can bankrupt unprepared operations.

Nature’s Fury: More Than Just Bad Weather Even if your site’s not in earthquake alley, don’t get too comfortable. Flash floods can drown machinery in hours. A freak heatwave might warp rails. Heck, I’ve seen a “minor” landslide in Western Australia delay a project for six months. The fix? Know your terrain like the back of your hand and prep like a doomsday prepper.

Human Error: The Silent Budget-Killer Here’s an open secret: most mining disasters start with a simple mistake. A skipped maintenance check. A misread safety protocol. One client learned this the hard way when a rusty conveyor belt snapped, costing them $2M in downtime. Rigorous training isn’t optional—it’s what keeps your crew alive and your profit margins intact.

How Insurance Turns Disasters Into Speed Bumps

Picture this: A flash flood wrecks your drill site. Without coverage, you’re staring at months of lost income and repair bills that’d make Scrooge McDuck sweat. But with smart insurance? You’re back on your feet before the mud dries. Here’s the breakdown:

Your Insurance Toolkit

Coverage Type

Why It Matters

Property Insurance

Covers everything from flooded excavators to lightning-fried control panels

Business Interruption

Pays the bills when operations grind to a halt (yes, even worker salaries)

Liability Shield

When a third party sues over damages, this keeps you out of court

Worker Safety Net

Covers medical costs if someone gets hurt—because OSHA fines are no joke

Environmental Backup

Spills happen. This cleans up messes before regulators come knocking

Pro tip: Mix and match these like a insurance bartender. A Queensland coal operation we worked with dodged $5M in losses by bundling equipment coverage with a business interruption rider.

Picking Your Policy: 5 Make-or-Break Factors

Location, Location, Location Mining in flood-prone Indonesia? Skip earthquake coverage. Digging in Chile’s copper belt? Seismic insurance isn’t optional—it’s survival.

Size Matters A family-run opal mine needs different coverage than a multinational lithium giant. Don’t pay for coverage you’ll never use.

Reputation Roulette Always vet insurers like you’re hiring a CFO. One client learned this the hard way when their “cheap” provider took 18 months to pay a claim.

Fine Print Frenzy That “all-risk” policy? It probably excludes cyberattacks. Get every exclusion in writing.

Stay Nimble Found a new mineral deposit? Expanded to a riskier region? Update your policy faster than a TikTok trend.

Disaster-Proofing 101: Beyond the Policy

Risk Audits: Your Crystal Ball Before buying coverage, play detective. Map every possible threat—yes, even that “1-in-100-year” flood. A gold mine in South Africa avoided total collapse by spotting unstable bedrock during their audit.

Emergency Drills That Don’t Suck Forget boring fire drills. Run realistic scenarios:

“Chemical spill at 3 AM during monsoon season”

“Cave-in with 50 workers underground” Debrief over beers. It works.

Community Hacks Local tribes blocked your access road last quarter? Maybe because you didn’t include them in safety planning. One Papua New Guinea mine now shares real-time hazard alerts with villages. Result? Zero protests this year.

When Your Policy Needs a Checkup

Insurance isn’t “set and forget.” That policy from 2019? It’s probably missing:

Cyber Extortion Coverage (ransomware loves industrial controls)

Climate Change Riders (hello, unprecedented storms)

Supply Chain Meltdowns (COVID taught us all that lesson)

Do this every 6 months:

Compare claims against coverage

Grill your broker about new risks

Adjust deductibles like you’re tuning a rig

The Bottom Line

Here’s the truth miners won’t tell you: Insurance isn’t a cost—it’s profit protection. That $50K annual premium? It’s cheap compared to a single uninsured disaster. The smartest operations treat coverage like their best drill bit: always sharp, regularly upgraded, and ready to punch through chaos.

#MiningInsuranceDisasterMitigation#MiningRiskManagementInsurance#NaturalDisasterInsuranceForMines#MiningOperationalRiskCoverage#MiningInsurancePolicySelection

0 notes

Text

Indian Safety Equipment Manufacturers Revolutionizing Workplace Protection

In today's workplace safety has emerged as a for all businesses across industries. With increasing awareness of the demand for quality safety equipment is at an all-time high. Among the global players contributing to this essential industry, Indian safety equipment manufacturers are making a difference by revolutionizing workplace protection standards.

Innovation, quality, and reliability have been embraced by Safety equipment manufacturers in India to meet the growing demands of industries such as manufacturing, construction, oil and gas, and healthcare. Manufacturers are not only catering to domestic needs but are also emerging as strengthening India's position in the global market.

Safety Equipment Manufacturers in India: Innovation, Quality, and Reliability to Meet Growing Demands

One of the most notable contributions by Safety equipment manufacturers in India is to safeguard workers in hazardous environments. Companies have taken the lead by offering premium safety products industrial requirements. Their commitment to quality and reliability is evident in their products, the AHA Gas Safety Device and the Horizontal Safety System.

AHA Gas Safety Device

The AHA Gas Safety Device is one of the most excellent innovations in enhancing safety in areas where gas leakage can be a threat. It is designed to detect and prevent accidents that might occur due to gas leakage, thereby protecting the workers and minimizing property damage. This AHA Gas Safety Device uses cutting-edge technology, providing a proactive approach to workplace safety, making it the most preferred among industrial and residential users.

Horizontal Safety System

The Horizontal Safety System is another remarkable offering from Akshay Enterprises. It is designed to provide. This system ensures stability and security, reducing the and boosting confidence among workers. The Horizontal Safety System reflects the company's dedication to prioritizing safety while maintaining user convenience and adaptability to diverse working conditions.

Indian Manufacturers in Workplace Safety

The growth of Safety equipment manufacturers in India is not only a reflection of also an indication of how the country's industrial landscape is evolving. Indian manufacturers such as between global safety standards and local industry needs, bringing safety solutions within easy reach and affordable to people without losing out on quality.

Driving Innovation

Indian manufacturers use research and development for innovative safety products that help them overcome various industry-specific issues from heavy machinery to very small operations. The AHA Gas Safety Device is an example of Indian Safety equipment manufacturers in India providing new answers to the unique risks from gas usage.

Cost-Effective Solutions

Indian manufacturers, including cost-effectiveness. These organizations are offering businesses the chance to invest in worker safety without putting a company. This makes both worker safety better, as well as higher productivity and morale.

Although Safety equipment manufacturers in India are making growth in India, the industry comes with its issues. The understanding of workplace safety in some localities and which create constraints to it at the same time, this presents scope for manufacturers to help spread awareness regarding that investment into safety equipment presents to businesses.

The role is also very important in this industry. Ensuring Safety equipment manufacturers in India, especially at workplaces where the risk of danger is higher, have resulted in an increased demand and the development of more products from manufacturers. In that case, stands to benefit on grounds of innovation and outstanding solutions to its customers, for example, the AHA Gas Safety Device and the Horizontal Safety System.

Future of Workplace Safety in India

The future of workplace safety in India is promising due to the continuous efforts of safety equipment manufacturers. As industries grow and evolve, the demand for advanced safety solutions will increase. Indian manufacturers are well-equipped to meet this demand by combining technological expertise with a deep understanding of industry requirements.

With AHA Gas Safety Device and the Horizontal Safety System, Akshay Enterprises epitomize the ability of Indian safety equipment manufacturers protection.

Their commitment to quality, innovation, and affordability sets new standards for millions of workers in India.

Conclusion

Safety equipment manufacturers in India are changing the workplace safety landscape by providing innovative, reliable solutions. By offering the required safety products for critical industries, companies such as Akshay Enterprises safety needs in every industry. Its product that includes AHA Gas Safety Device and Horizontal Safety System has set an example for the growth of the sector in India.

As the importance of workplace safety is the role of Indian manufacturers will only grow. Through innovation, and a commitment to affordability, Indian safety equipment manufacturers are but are also the more secure industrial future.

0 notes

Text

The North America Gas Detection Equipment market is projected to grow at a CAGR of around 8.26% during the forecast period, i.e., 2022-27. The North America Gas Detection Equipment market has witnessed notable growth during the historical period. The factors that have driven the growth of the Gas Detection Equipment market are the rising concerns about the workforce & industrial plant safety as well as stricter government regulations regarding security standards & environmental safety. Notably, the rising gas leak incidents in the region have mandated the deployment of gas detection equipment to prevent any fatal accidents.

#North America Gas Detection Equipment market#North America Gas Detection Equipment market Newws#North America Gas Detection Equipment market Report

0 notes

Link

Searching for ワイヤレス検知器の需要で著しい成長を遂げるガス検知器市場? We got you covered here at iCrowdNewswire Japanese

0 notes

Text

Sensor Mart: Your Trusted Provider of SMKB-SUVY UV Sensors

In the modern world, where technology is the backbone of innovation, sensors play a critical role in ensuring accuracy, efficiency, and safety across various industries. Among these, UV sensors have become indispensable for applications ranging from environmental monitoring to industrial processes. Sensor Mart, a leading provider of SMKB-SUVY UV sensors, offers cutting-edge solutions designed to meet the needs of a rapidly evolving market.

What Are UV Sensors and Why Are They Important?

UV sensors are devices designed to detect and measure ultraviolet (UV) radiation. This type of radiation, invisible to the naked eye, has significant applications in both scientific and industrial domains. UV sensors are essential in monitoring solar radiation, detecting ozone levels, sterilization processes, and even in flame detection systems. Their ability to provide precise and reliable data makes them a valuable tool for industries striving for efficiency and compliance with safety standards.

Introducing the SMKB-SUVY UV Sensor

The SMKB-SUVY UV sensor series from Sensor Mart is a game-changer in UV detection technology. Engineered for high performance and reliability, these sensors are ideal for a broad spectrum of applications. With advanced features and robust design, they deliver exceptional accuracy, even in challenging conditions.

Key features of the SMKB-SUVY UV sensors include:

High Sensitivity: Capable of detecting a wide range of UV wavelengths with unmatched precision.

Durability: Built to withstand harsh environments, ensuring consistent performance over time.

Compact Design: Easy to integrate into various systems without compromising functionality.

Low Power Consumption: Energy-efficient operation makes them suitable for long-term use.

Applications of SMKB-SUVY UV Sensors

Environmental Monitoring: Accurate measurement of UV radiation levels for weather stations, climate studies, and agricultural applications.

Industrial Processes: Used in UV curing systems, photolithography, and sterilization equipment to ensure optimal performance.

Health and Safety: Monitoring UV exposure in workplaces and public spaces to safeguard human health.

Flame Detection: Detecting UV emissions from flames, crucial for fire safety systems in industries like oil and gas.

Why Choose Sensor Mart?

Sensor Mart is committed to delivering top-notch sensor solutions that cater to the diverse needs of its clients. Here’s why Sensor Mart stands out in the market:

Quality Assurance: All products undergo rigorous testing to ensure they meet the highest standards of quality and performance.

Expertise: With years of experience in sensor technology, Sensor Mart provides reliable solutions backed by technical expertise.

Customer Support: From selection to installation, Sensor Mart offers comprehensive support to ensure customer satisfaction.

Competitive Pricing: Premium products at competitive rates, providing excellent value for your investment.

The Future of UV Sensing with Sensor Mart

As industries continue to adopt smarter technologies, the demand for high-quality UV sensors will only grow. Sensor Mart is at the forefront of this revolution, offering innovative SMKB-SUVY UV sensors that empower businesses to achieve greater efficiency and accuracy.

With Sensor Mart’s SMKB-SUVY UV sensors, you gain not just a product but a reliable partner in your journey toward technological excellence. Explore the future of UV sensing with Sensor Mart—because precision matters.

0 notes

Text

0 notes