#Fraunhofer IWS

Explore tagged Tumblr posts

Link

0 notes

Text

Schwefel und Silizium als Bausteine für die Feststoffbatterie

Eine neue Generation von Lithium-Schwefel-Batterien steht im Fokus des Forschungsprojekts „MaSSiF – Materialinnovationen für Schwefel-Silizium-Festkörperbatterien“. Das Projektteam widmet sich dem Design, Aufbau und der Bewertung von leichten und kostengünstigen Prototypzellen auf Schwefelbasis mit hohen Speicherkapazitäten. Der Einsatz von Silizium als Anodenmaterial soll zudem die…

View On WordPress

0 notes

Photo

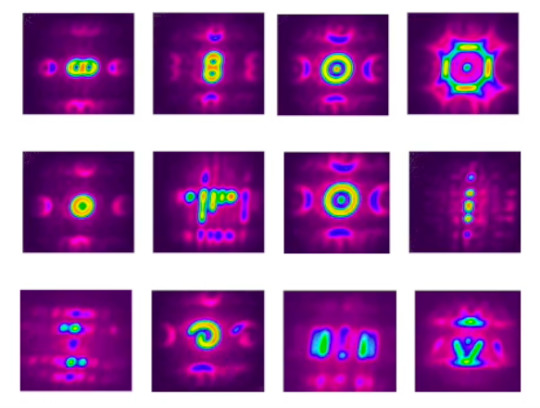

Nano- and microstructures incorporated into surfaces using lasers to create biomimetic effects

Nano- and microstructures can now be incorporated into surfaces in an instant using lasers. The technology is being developed and marketed by the Dresden-based start-up Fusion Bionic, a spin-off from the Fraunhofer Institute for Material and Beam Technology IWS. The possibilities are virtually endless when it comes to laser structuring. It has the advantage of being fast and much more versatile than coatings.

Product surfaces can be enhanced with all kinds of different effects. The lotus effect, for example, uses a microstructure to allow any dirt that might stick to the surface to simply wash away the next time it rains. The fine ripples of shark skin, meanwhile, improve the dynamics of air and water on the outside of airplanes and ships, thus saving fuel. With nature as their inspiration, many such effects have been developed by coating or applying a film to the surface into which the microstructures are incorporated. Coatings and films can wear away, however, causing the desired effect to diminish over time. In recent years, researchers at Fraunhofer IWS and Technische Universität Dresden have developed an alternative, market-ready method of permanently applying nano- and microstructures to surfaces: Direct Laser Interference Patterning (DLIP). This process incorporates the nano- or microstructure directly into the surface using a laser in order to create biomimetic effects. It is a remarkably quick process, and can currently handle up to one square meter of surface per minute. The new technology is so promising that it led to Fusion Bionic being founded this year as a spin-off from Fraunhofer IWS. Fusion Bionic develops and markets DLIP system solutions for biomimetic surface finishing, but also provides surface functionalization services to its customers.

Read more.

#Materials Science#Science#Surfaces#Lasers#Microstructures#Nanostructures#Optics#Biomimicry#Light#Structures

25 notes

·

View notes

Photo

New, Powerful Metal 3D Printing Tech Being Explored by Fraunhofer IWS The Fraunhofer Institute for Material and Beam Technology (Fraunhofer IWS) is experimenting with a new, high-powered metal 3D printing technology. Based on a technology called coherent beam combining... View the entire article via our website. https://buff.ly/3fd0MY5

1 note

·

View note

Photo

Doku Fraunhofer IWS - Dresden

#fraunhofer#fraunhoferiws#fraunhoferdresden#science#forschung#batterie#batterietechnologie#research#scientific research#battery#batteryresearch#batteryscience#siegfriedmichaelwagner#dresden#sachsen#germany#silliconsaxony#sogehtsaechsich#tech industry

0 notes

Text

Living labs create new products from residues

Laboratory experiments with 3D printing with renewable raw materials

The Bergakademie[1] Freiberg[2] in Saxony, Germany has started to set up a living lab in which new products made from waste or renewable raw materials will be tested in the future using 3D printing. The aim is to replace plastic and enable a circular economy, said the coordinator of the SAMSax[3] project, Henning Zeidler, on Thursday 1/9/2022.[4] A wide variety of powders made from straw, wood flour and paper fibres, for example, but also residues from industrial production could be used in the process.

Using 3D printing, new parts and products could be made from it, such as elements for stage sets, architectural models or packaging that could replace styrofoam, for example, explained the professor of additive manufacturing. “The technology is there.” The goal is close cooperation with companies in the region, who can test the implementation of their ideas here. There are already 50 permanent partners and other contacts via various networks.

The Geomin Erzgebirge lime works[5], that quarries white marble in Hammerunterwiesenthal,[6] for example, is interested in the possibilities of this process. In the production of building materials, secondary components such as rocks and dust accumulated that had to be disposed of, explained Richard Kühnel from Geomin. The idea is to use such rock powder for new products instead. The 3D printing process offers promising possibilities for this.

The construction of the living laboratory is funded by the state Saxony with one million euros. According to Zeidler, the devices should be operational by the beginning of next year. Any complex shapes up to a volume of one cubic meter could be created with the process. It applies also to larger quantities of several hundred or thousands of copies. In addition to the Bergakademie Freiberg, the Technical Universities of Dresden[7] and Chemnitz[8] are also involved in the project.

Environmental technology know-how meets additive expertise

The Institute for Natural Materials Technology at the TU Dresden wants for example to feed injection moulding machines with a mass of processed wood fibres in order to give discarded plywood tables and similar furniture a second life as wooden spoons, book covers, mugs or flower tubs.

There are also several institutes in Saxony that specialise in various additive manufacturing technologies. These include the Fraunhofer Institutes IWS[9], IKTS[10] and IWU[11], that deal with laser deposition welding, fused filament fabrication (FFF), lithography-based ceramic 3D printing and other technologies.

Sources

Dpa, Reallabor lässt neue Produkte aus Reststoffen entstehen, In: Süddeutsche Zeitung ,1/9/2022, https://www.sueddeutsche.de/wissen/forschung-reallabor-laesst-neue-produkte-aus-reststoffen-entstehen-urn:newsml:dpa.com:20090101:220901-99-596908

Heiko Weckbrodt, Sachsen wollen 3D-Drucker mit Abfall füttern, in: Oiger, 30-04-2022, https://oiger.de/2022/04/30/sachsen-wollen-3d-drucker-mit-abfall-fuettern/182983

[1] The six faculties of the Technical University Bergakademie Freiberg develop efficient and alternative technologies for a sustainable economy and industry. The focus is on exploring and processing a wide variety of raw materials; the production, storage and conversion of energy; the development of materials and substances as well as recycling processes. With the engineering, natural, geo, materials and economic sciences, the university combines the necessary subjects and disciplines and covers all areas from basic research to application-oriented research. to the university profile

[2] Freiberg is a university and former mining town in the Free State of Saxony, Germany. It is a so-called Große Kreisstadt (large county town) and the administrative centre of Mittelsachsen district.

[3] „Sustainable Additive Manufacturing in Saxony“ (Samsax – in German: Nachhaltige additive Fertigung in Sachsen)

[4] In a new real-world laboratory called “Samsax” in Freiberg, researchers in Saxony are testing how industrial 3D printers can be used, for example, to produce stage sets or other components from organic agricultural waste. Regional Minister Thomas Schmidt (CDU) has now promised one million euros in funding for this. https://oiger.de/2022/04/30/sachsen-wollen-3d-drucker-mit-abfall-fuettern/182983

[5] As a merger of ard Baustoffwerke, SH Natursteine and GEOMIN, GEOMIN Erzgebirgische Kalkwerke GmbH is one of the largest raw material companies in the Saxony and Saxony-Anhalt area with a total of seven locations. https://geomin.de/

[6] Hammerunterwiesenthal is a district of the town of Oberwiesenthal in the Saxon Erzgebirge district, which developed around the Schlössel hammer mill founded in the 16th century. The place was incorporated on January 1, 1997 after Oberwiesenthal. His district precipitation was reclassified to Bärenstein.

[7] T U Dresden (for German: Technische Universität Dresden, abbreviated as TUD and often translated as "Dresden University of Technology") is a public research university, the largest institute of higher education in the city of Dresden, the largest university in Saxony and one of the 10 largest universities in Germany with 32,389 students as of 2018.

[8] Chemnitz University of Technology (German: Technische Universität Chemnitz) is a public university in Chemnitz, Germany. With over 9,000 students, it is the third largest university in Saxony. It was founded in 1836 as Königliche Gewerbschule (Royal Mercantile College) and was elevated to a Technische Hochschule, a university of technology, in 1963. With approximately 1,500 employees in science, engineering and management, Chemnitz University of Technology is among the most important employers in the region.

[9] Fraunhofer Institute for Material and Beam Technology IWS. Fraunhofer IWS develops complex system solutions in materials and laser technology. We define ourselves as idea drivers developing customized solutions based on laser applications, functionalized surfaces and material and process innovations – from easy-to-integrate custom solutions to cost-efficient solutions for small and medium-sized enterprises to industry-ready one-stop solutions. Our sector research focuses on aerospace, energy and environmental technology, automotive, medical and mechanical engineering, toolmaking, electrical engineering and microelectronics, and photonics and optics. In our five future and innovation fields of battery technology, hydrogen technology, surface functionalization, photonic production systems and additive manufacturing, we are already creating the basis today for the technological answers of tomorrow. https://www.iws.fraunhofer.de/en/profile.html

[10] Fraunhofer Institute for Ceramic Technologies and Systems IKTS. The Fraunhofer Institute for Ceramic Technologies and Systems IKTS conducts applied research on high-performance ceramics. The institute‘s three sites in Dresden and Hermsdorf (Thuringia), Germany, collectively represent Europe‘s largest R&D institute dedicated to the study of ceramics. As a research and technology service provider, the Fraunhofer IKTS develops advanced high-performance ceramic materials, industrial manufacturing processes as well as prototype components and systems in complete production lines up to the pilot-plant scale. In addition, the research portfolio also includes materials diagnostics and testing. The test procedures in the fields of acoustics, electromagnetics, optics and microscopy contribute substantially to the quality assurance of products and plants. https://www.ikts.fraunhofer.de/en.html

[11] Fraunhofer Institute for Machine Tools and Forming Technology IWU. Fraunhofer Institute for Machine Tools and Forming Technology IWU is a driver for innovations in the research and development of production engineering. Around 670 highly qualified employees at our locations in Chemnitz, Dresden, Leipzig, Wolfsburg, and Zittau tap the new potential for competitive manufacturing in automotive and mechanical engineering, aerospace technology, medical engineering, electrical engineering, and precision and micro engineering. We focus on scientific developments and contract research concerning components, processes, methods, and the associated complex machine systems – the entire factory. https://www.iwu.fraunhofer.de/en.html

0 notes

Text

Lithium-Schwefel-Batterien in die industrielle Anwendung überführen

Lithium-Schwefel-Batterien in die industrielle Anwendung überführen

Seit Juli 2021 läuft das Forschungsprojekt SoLiS unter Leitung des Fraunhofer IWS. Verschiedene Partner arbeiten gemeinsam daran, Lithium-Schwefel-Feststoffbatterien in die Praxis zu überführen. Schwefel als Batteriematerial ist günstig und besitzt eine hohe Speicherkapazität, entsprechende Feststoffbatterien sind jedoch noch wenig erforscht. (more…)

View On WordPress

0 notes

Text

How Can Aircraft Engines Increase Their Efficiency?

As the aviation industry continues to seek out advanced technologies for the means of reducing emissions and the amount of fuel needed for flight, aircraft engines parts are constantly being improved. Beyond initiatives centered around the efficiency of fuel combustion, manufacturers also seek ways to achieve more efficient cooling and heat management to reduce the strain and wear placed on engine components as fuel is continuously burned at intense temperatures. In recent years, several technologies have been researched and developed for the means of creating more efficient aircraft, one of which is capable of increasing combustion efficiency, reducing heat strain, and achieving greener operations.

From the Fraunhofer Institute for Material and Beam Technology IWS, professors Frank Brückner and Mirko Riede developed laser-fabricated microstructures which are capable of maintaining the service lives of thermal barrier coatings. While this assists in heat reduction, such advancements also pose to mitigate the number of pollutant emissions expelled from an aircraft engine. The project was achieved due to close collaboration with Rolls-Royce, whom of which is a world-renowned engine manufacturer.

The technology developed by the partnership is based on additively manufactured microstructures which are relied on for the construction of Thermal Barrier Coatings (TBCs). These TBCs are then implemented on turbine components and aircraft engine parts to affix a ceramic insulating layer to an oxidation-resistant adhesion promoter layer. As many aircraft engine parts and aircraft turbine tools are damaged from expansion as a direct result of heat, the technologies designed by IWS initiate vertical segmentation cracks of the ceramic material layer so that tensile stresses are mitigated for avoiding high amounts of damage. To produce the microstructures that are paramount for such engine advancement, single-mode fiber lasers touting high precision are used to create microstructures as small as 30 microns.

While the insulation and microstructure technologies are capable of increasing the efficiency of an aircraft engine, they also serve to increase combustion temperature. While increasing temperatures can be thought of as detrimental, such heat will create more efficiency as fuel is more optimally burned. As such, fuel consumption rates can be decreased by up to ten percent, and greenhouse gas emissions will be cut down as well. With the reduction of fuel consumption, aircraft operators can save upwards of $2.9 million every year with the implementation of such microstructures.

As of the present, the technology developed by Fraunhofer researchers and Rolls-Royce has had successful test flights in 2015, also being approved by the European Aviation Safety Agency (EASA). With the completion of production-ready manufacturing, such technology has already seen implementation in long-haul aircraft such as the Airbus A350-1000. In the coming years, the partnered entities hope to see further implementation of their microstructure technology on other aircraft for the benefit and efficiency of engines.

Beyond specific changes to the engine itself, aircraft may also increase their fuel efficiency through improving aerodynamics and navigation. With the addition of winglets, flexible navigation systems, continuous climb, and descent operations, lighter construction, and more, drag can be reduced while also ensuring optimal operations that expend less fuel. If you require various aircraft engine parts, airframe structural materials, and other various aircraft components for increasing efficiency, look no further than Dynaron Enterprises.

0 notes

Text

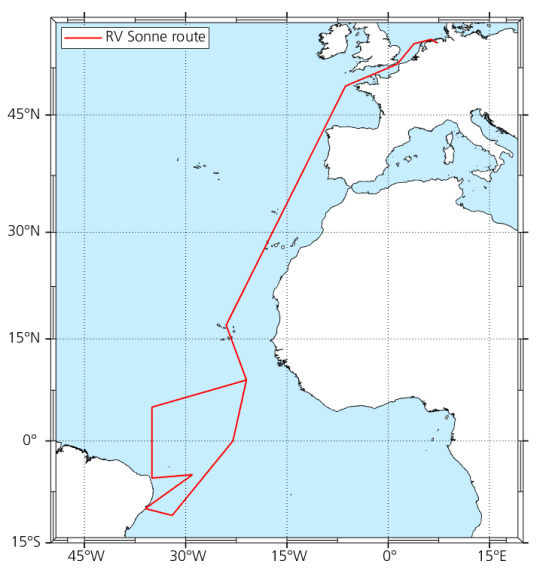

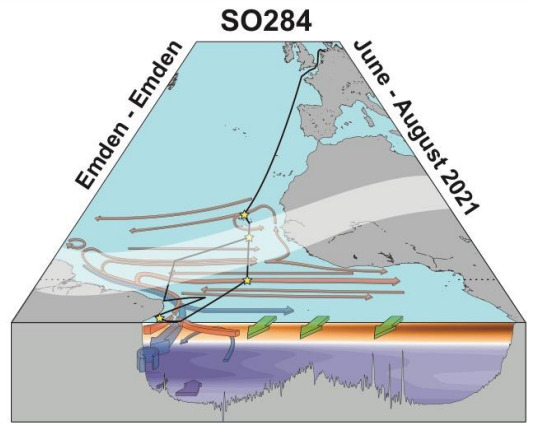

14 Days offshore, 10th of July

Today everything is working without issues, so I think it is the right moment to talk to you about the measurement campaign onboard the RV Sonne.

The name of the campaign, led by Prof. Dr. Peter Brandt (GEOMAR) and co-lead by Dr. Julia Windmiller (Max Plank Institute for Meteorology), is “Mooring rescue”. This name refers to the main goal of the campaign, which is to service and collect scientific data from several moorings located in the central and tropical region of the Atlantic Ocean. The scientific crew is composed of 15 ocean researchers from GEOMAR (Helmholtz Centre for Ocean Research Kiel), as well as 9 researchers focused on atmospheric measurements from the Max Plank Institute for Meteorology, the Leibniz Institute for Tropospheric Research (TROPOS), the FU Berlin and the Fraunhofer Institute for Wind Energy Systems (IWES). During the execution of the campaign, measurements are taken both in the atmosphere and the ocean, providing meaningful information to investigate the coupling and interaction between these two systems. Parameters like the wind profiles and velocities, wind direction, or precipitation are measured, as well as ocean variables like salinity, temperature, or current speed and direction. All these observations will contribute to a better understanding of the circulation and climate in the tropical Atlantic.

If you are interested, you can read more information about the cruise and the weekly reports on the following site: https://www.ldf.uni-hamburg.de/en/sonne/wochenberichte.html

Figure: planned ship rout of RV Sonne during the campaign

Figure: logo of the campaign

0 notes

Text

Feststoffbatterie soll Sprung in die industrielle Anwendung gelingen

Feststoffbatterie soll Sprung in die industrielle Anwendung gelingen: Projekt SoLiS von @FraunhoferIWS und Partnern

Das im Juli 2021 gestartete Forschungsprojekt „SoLiS – Entwicklung von Lithium-Schwefel Feststoffbatterien in mehrlagigen Pouchzellen“ zielt darauf ab, ein vielversprechendes Batteriekonzept aus der Grundlagenforschung in die industrielle Anwendung zu überführen. Dank hoher Speicherkapazitäten und geringer Materialkosten des Schwefels ermöglicht diese Zelltechnologie potenziell den Aufbau sehr…

View On WordPress

0 notes

Photo

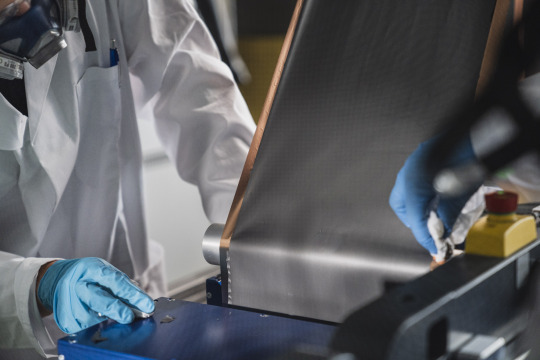

Device bonds metal and plastic within seconds

Scientists at the Fraunhofer Institute for Material and Beam Technology IWS in Dresden have developed a joining gun that creates a connection between metal and thermoplastic materials within seconds. This gun is of a modular design and can easily be integrated into the production process, for example by mounting on a robot arm in place of a spot welding gun. At the preview leading up to the Hanover Trade Fair on January 24, 2019 on the trade fair grounds in Hall 19, scientist Annett Klotzbach will be demonstrating the advantages of the joining gun.

The HeatPressCool-Integrative process HPCI

The connection of plastics and metals poses a challenge, due to the different physical properties of the two materials. All conventional joining options, such as bonds using adhesives or rivets have their disadvantages: adhesives need time to harden, which delays further processing. Plastics can be easily damaged during riveting. Furthermore, both adhesive bonding and riveting require additional materials which increases production costs.

The HeatPressCool-Integrative process, developed at the Fraunhofer IWS Dresden, is integrated into the joining gun enabling the direct and precise bonding between metal and plastic components in a matter of seconds. During this process, the two materials are pressed together and the metal at the bonding point is subjected to targeted inductive heat. This causes the thermoplastic material to partially melt, which in turn directly forms a firm bond with the metal as the plastic solidifies.

Read more.

27 notes

·

View notes

Photo

Fraunhofer and RMIT Form Cross-Continental 3D Printing Partnership While RMIT University is known for specializing in technology and design, Fraunhofer Institute for Material and Beam Technology IWS is a force to contend with, known as a leading applied... The post... View the entire article via our website. https://buff.ly/308S7Pf

1 note

·

View note

Text

Kekuatan Baling-Baling Berputar di Pegunungan Rocky

Kekuatan Baling-Baling Berputar di Pegunungan Rocky

Kekuatan baling-baling berputar di pegunungan Rocky merupakan hasil karya para ahli. Sukses menciptakan teknologi pengolah kekuatan angin menjadi tenaga kelistrikan, bisnis pun menjanjinkan prospek yang cerah, dan tidak bergantung pada fosil atau minyak bumi. Dengan menggunakan kamera siistem pemantul dapat dideteksi deformasi (perubahan) pada tiga sumbu utama pisau atau bilah Kekuatan…

View On WordPress

0 notes

Text

New "smart blade" technology will make wind turbines even more efficient

(Natural News) The Fraunhofer Institute for Wind Energy Systems (Fraunhofer IWES) is testing a new rotor blade that incorporates bend-twist coupling (BTC) technology. Wind turbines equipped with the new blade can get the most out of fluctuating winds, reported an AlphaGalileo article. The German wind energy sector leads its European peers by a good margin. Germany operates more than 28,000 wind...

from NaturalNews.com https://ift.tt/2DRhCpy via IFTTT

0 notes

Text

BSH awards geophysical survey contract for German offshore wind zone-Offshore-Renewables.com

Germany’s Federal Maritime and Hydrographic Agency (BSH) has awarded Fraunhofer IWES with a contract to carry out geophysical site investigation in the N-6 offshore wind area.

The geophysical survey is set to be conducted this summer as part of the geological preliminary investigation at the N-6.6 and N-6.7 areas in the North Sea.

The work includes the measurement of approximately 1,100km using…

View On WordPress

0 notes

Text

Lotus-Effekt macht Flugzeuge eisfrei: Winzige Hügel auf der Außenhaut senken den Treibstoffbedarf

Flugzeuge werden vor dem Start bei Bedarf enteist. Während des Fluges kann sich jedoch neues Eis bilden. Es erhöht das Gewicht und reduziert den Auftrieb. Gefährdete Regionen werden deshalb beheizt. Das führt zu erhöhtem Kerosinverbrauch. Forscher am Fraunhofer-Institut Werkstoff- und Strahltechnik (IWS) in Dresden haben gemeinsam mit dem Flugzeugbauer Airbus und der Technischen Universität Dresden … http://bit.ly/2wr54aA

0 notes