#Forklift Truck

Explore tagged Tumblr posts

Text

Revolutionize Logistics: Buy Autonomous Forklifts in United States NJ Atlanta CA

When searching to buy robotic pallet jack USA NJ Atlanta California, businesses can easily discover a vast array of choices customized to their requirements. These devices streamline procedures, decreasing effort costs while improving effectiveness. Also, those considering the most up to date technician might likewise desire to purchase robot pallet ports in USA NJ Atlanta CA or also purchase driverless vehicles in U.S.A. NJ Atlanta CA. With selections like purchase robot pallet unloaders in United States NJ Atlanta CA and buy driverless forklifts in USA NJ Atlanta California, providers may boost their strategies game substantially. To learn extra information on forklift, you must visit https://araplraas.com/ website.

ARAPL RaaS International LLC

1143-C Executive Circle, Suite 104, Cary NC 27511

+1 (919)–337–2473

0 notes

Text

Exploring Different Types of Material Handling Equipment and Their Uses

One thing that whether it is in a manufacturing plant, distribution center, or warehouse they all have material handling which becomes a necessity for everyone. Correct machinery is crucial for the efficiency and safety of material movement. Types of Material Handling Equipment include many helpful solutions ranging from lifting to transportation, all designed around specific requirements. This article is about material handling equipment with its uses and benefits.

1. High Lift Truck

High-Lift Truck — It is also called a scissor lift pallet truck. They have the functionality of possibly Pallet Pickup or perhaps Function Grip as well. It lifts pallets to an ergonomic work height, reducing the need for excessive bending or overstretching during manual handling.

Uses:

Perfect for lifting and unloading materials at a comfortable level.

Commonly used in assembly lines, workshops, and packaging areas.

perfect for tasks where you need to lift and lower pallets often.

Benefits:

Reduces worker’s overwork by minimizing the need for repetitive bending.

Enhances productivity by positioning loads at the correct working height.

2. Hydraulic Stacker

A Hydraulic Stacker is a manually operated designed to lift and stack heavy loads with ease. It features forks similar to those on a forklift but uses hydraulic power to effortlessly raise and lower the loads. This makes it an ideal choice for handling and organizing heavy items in a more controlled and efficient manner.

Uses:

It stacks pallets efficiently in warehouses with limited space.

It helps load and unload goods from delivery vehicles.

Useful in retail settings for stocking shelves.

Benefits:

provides a reasonably priced substitute for forklifts in smaller operations.

The compact design allows for easy handling in limited spaces.

3. Semi-Electric Stacker

A Semi-Electric Stacker combines manual and electric power. While the lifting is powered by an electric motor, the movement is typically manual. This design balances functionality and cost very well.

Uses:

Commonly utilized in manufacturing facilities, distribution hubs, and storage warehouses.

Perfect for arranging items at various heights up to several meters.

Ideal for stacking things at different heights of up to several meters.

Suitable for operations that require frequent lifting but not long-distance travel.

Benefits:

Easier to operate than fully manual stackers, reducing strain on operators.

Lower cost compared to fully electric stackers, making it accessible to smaller businesses.

4. Drum Lifter & Tilter

A Drum Lifter & Tilter is specialized equipment designed for handling cylindrical drums. It raises and tilts the container, making it easier to empty the contents or move the drum as needed.

Uses:

Most often employed in chemical, pharmaceutical, and food process industries. best for pouring from one container to another. Ideal for protection in the handling of hazardous materials.

Benefits:

Reduces the risk of spills and accidents by providing controlled tilting.

Ergonomically designed to minimize operator strain when handling heavy drums.

5. Hydraulic Floor Cranes

A hydraulic floor crane, or shop crane engine hoist, is a mobile lifter specifically designed for lifting and transporting heavy materials in a factory or warehouse. These devices use hydraulic power to lift loads vertically.

Uses:

Commonly used in automotive repair shops to lift engines and other heavy parts. Fits assembly lines where heavy components need to be carried and positioned. Used in low-volume fabrication for transporting components between work cells.

Benefits:

The portable design allows users to easily move and use it in various locations within a facility.

Capable of lifting extremely heavy loads, up to several tons, with precision.

6. Hydraulic Pallet Truck

The Hydraulic Pallet Truck also known as a pallet jack, is one of those tools that although simple. This lifter works manually and it uses hydraulic power only to get some lift to move the load.

Uses:

often used to move pallets in factories, warehouses, and stores.

Ideal for loading and unloading delivery trucks.

It can operate in tight spaces where forklifts cannot.

Benefits:

Simple to use and maintain, requiring minimal training.

A cost-effective way to transport large items with ease.

Conclusion

Maintaining productivity and safety at work requires a thoughtful selection of material-handling equipment. Understanding the different types of material handling equipment for each purpose helps determine the best fit for your business’s needs. Swift Technoplast offers all types of material handling equipment that are precisely engineered by maintaining the Highest Quality standards in the manufacturing process that are perfect to meet your requirements.

#Hand pallet truck#hand pallet trolley#hand pallet lifter#hand operated pallet truck#hydraulic pallet truck 2.5 ton#hydraulic hand trolley#hydraulic pallet truck#hydraulic hand pallet truck#fork lift#forklift machine#forklift truck#electric forklift

0 notes

Text

Forklift Truck Market: Top Technological Advancements

Materials handling operations face immense pressure from various fronts, including significant labor shortages, low-profit margins, and increasing productivity demands. While selecting an appropriate forklift may not completely solve these challenges, it undeniably has the potential to make a significant difference.

According to Triton Market Research, the global forklift truck market was valued at $68393.39 million in 2022 and is expected to reach $123258.01 million by 2030, at a CAGR of 8.08% in revenue and 6.09% in volume during the forecast period.

As the global market expands, manufacturers constantly strive to innovate and meet the growing demands of various industries, prompting them to develop new technologies and improve their production capabilities to remain competitive in a rapidly evolving landscape:

Rise of Electric Forklift Trucks: Manufacturers Embrace Sustainability

1. Battery Technology Advancements

Electric forklift trucks have gained significant traction due to their eco-friendly nature and operational efficiency. Cat Lift Trucks is a leading company that has invested in advanced battery technologies for electric forklift trucks. Their electric forklifts offer durability, operator comfort, and advanced features, providing a versatile and eco-friendly alternative to diesel or LPG models for indoor and outdoor applications. These innovations have reduced the environmental impact of forklift trucks and improved their performance & reliability.

The electric power segment is expected to achieve a revenue of $56,464.50 million by 2030, with an estimated CAGR of 8.51% during the forecast period.

2. Integration of Lithium-ion Batteries

One notable advancement is the integration of lithium-ion batteries into electric forklift trucks. These batteries offer higher energy density, longer lifespans, and reduced maintenance requirements compared to traditional lead-acid batteries. Hyster-Yale Group Inc stands out as a manufacturer that has effectively incorporated lithium-ion technology into their electric forklift trucks, pioneering the introduction of a commercially available, UL-recognized lithium-ion battery pack in the market. These lithium-ion-powered trucks offer consistent and reliable performance across multiple shifts, significantly reducing maintenance and charging time, making them ideal for efficient multi-shift operations.

Automation and Robotics: Enhancing Efficiency and Safety

Autonomous Forklifts

The emergence of autonomous forklifts has revolutionized material handling operations. With its innovative OTTO Lifter, OTTO Motors is at the forefront of self-driving forklift truck development. This autonomous forklift utilizes cutting-edge autonomy software to make intelligent, real-time decisions, efficiently delivering materials to their designated locations, thereby reducing costs associated with pallet transport workflows, all while maintaining the highest safety standards.

Collaborative Robots

Collaborative robots, or cobots, have also significantly contributed to the studied market. Companies such as Universal Robots have integrated cobots with forklifts, enabling them to work alongside human operators in a shared workspace. These cobots assist in palletizing, picking, and sorting tasks, improving operational efficiency and reducing the risk of injuries.

Telematics and Connectivity: Data-Driven Decision Making

Real-Time Monitoring and Predictive Maintenance

Leading forklift truck manufacturers have integrated advanced telematics systems to gather data on vehicle performance, fuel consumption, and maintenance requirements. Businesses can optimize fleet management, proactively schedule maintenance, and minimize downtime by analyzing this data. Crown Equipment Corporation is one example of a company incorporating advanced telematics systems into its forklift trucks. With telematics solutions like Info Link, Crown Equipment Corporation collects, measures, benchmarks, analyzes, and acts on data from lift trucks, operators, services, applications, and fleets. This enables businesses to optimize fleet management, proactively schedule maintenance, and make data-driven decisions, improving operational efficiency and cost savings.

Fleet Management Optimization

Integrating connectivity technologies into fleet management has revolutionized how companies optimize resources and streamline operations. With improved visibility and control over the fleet, companies can monitor real-time data on vehicle performance, fuel consumption and maintenance requirements. This wealth of information enables informed decision-making that enables proactive maintenance planning and resource allocation and uncovers operational inefficiencies. Advanced tracking systems and route optimization software minimize delivery delays, reduce fuel consumption and improve overall productivity and cost savings. Using connectivity technologies in fleet management provides a competitive advantage by maximizing efficiency and delivering superior customer service.

Conclusion

As the forklift truck market continues to evolve, technological advancements are set to redefine its future, creating a more efficient and sustainable landscape for material handling operations worldwide. Also, rapid industrialization and economic development in India, Japan, and China have led to higher demand for efficient material-handling equipment, significantly boosting the Asia-Pacific forklift truck market to rise at a CAGR of 8.31% during the forecast period.

FAQs

Q1: What factors drive the forklift truck market?

Growing e-commerce demand and automation in manufacturing fuel market growth.

Q2: What segments are analyzed in the forklift truck market?

Segment by power source(IC engine power and electric power), type (class 1, class 2, class 3, and class 4 and 5), and by end-user (retail and e-commerce, construction, manufacturing, and other end-user).

Q3: What regions are studied in the market?

North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa.

#Forklift Truck Market#Forklift Truck#Building & Construction#Construction Materials#triton market research#market research reports

0 notes

Text

Buying a Forklift Truck: A Comprehensive Guide for First-Time Buyers

Investing in a forklift truck can significantly enhance your business's efficiency and productivity. However, purchasing the right forklift requires careful consideration and planning. This guide provides essential insights and tips for first-time buyers to make an informed decision.

Why Buy a Forklift Truck?

Long-Term Cost Savings Owning a forklift can be more economical in the long run, especially for businesses with consistent material handling needs.

Increased Productivity Having a dedicated forklift on-site ensures that your operations run smoothly without the delays associated with renting equipment.

Asset Ownership Purchasing a forklift adds a valuable asset to your company's balance sheet, which can be beneficial for financial planning and securing loans.

Key Considerations When Buying a Forklift

Assess Your Needs Identify the specific tasks the forklift will perform. Consider factors such as load capacity, lift height, and the type of terrain it will operate on.

Choose the Right Type Forklifts come in various types, including electric, diesel, and gas-powered models. Each type has its advantages and is suitable for different environments and uses.

New vs. Used Decide whether to buy a new or used forklift. New forklifts come with the latest technology and warranties but are more expensive. Used forklifts are more affordable but require careful inspection to ensure they are in good condition.

Budget Set a realistic budget that includes the purchase price, maintenance, and operational costs. Consider financing options if necessary.

Where to Buy a Forklift

Authorized Dealers Purchasing from authorized dealers ensures you get a genuine product with manufacturer support and warranties.

Online Marketplaces Online platforms offer a wide range of new and used forklifts. However, ensure the seller is reputable and provides detailed information about the equipment.

Auctions Industrial equipment auctions can be a good source of affordable forklifts. However, inspect the forklift thoroughly before bidding to avoid potential issues.

Inspection Checklist

Condition of Forks and Mast Check for any signs of damage or wear on the forks and mast. Ensure they operate smoothly and safely.

Engine and Transmission Inspect the engine and transmission for any leaks, unusual noises, or performance issues.

Hydraulics Test the hydraulic system for smooth operation and check for any leaks or malfunctions.

Safety Features Ensure all safety features, such as brakes, lights, and alarms, are functioning correctly.

Final Steps

Test Drive Always test drive the forklift to evaluate its performance and handling. Pay attention to any unusual sounds or vibrations.

Negotiate Don’t hesitate to negotiate the price and terms with the seller. You might be able to secure a better deal or additional services.

Finalize the Purchase Once you’re satisfied with the forklift and the terms, complete the purchase and arrange for transportation to your site.

Conclusion

Buying a forklift truck hire is a significant investment that requires careful consideration and planning. By assessing your needs, choosing the right type, and following the inspection checklist, you can ensure a smart and informed purchase that will benefit your business for years to come.

0 notes

Text

Driving Growth: Exploring Opportunities and Challenges in the Forklift Truck Market

The forklift truck market, a vital component of the global logistics and industrial landscape, is currently witnessing a dynamic phase of growth, accompanied by a set of intriguing opportunities and formidable challenges. This sector's expansion is primarily driven by the escalating demand for efficient material handling and warehousing solutions across diverse industries such as manufacturing, e-commerce, and construction. As businesses strive to optimize their supply chains and enhance operational efficiency, the need for reliable and versatile forklift trucks becomes paramount.

One of the prominent opportunities in this market lies in the integration of advanced technologies. Automation, artificial intelligence, and IoT are gradually transforming traditional forklifts into intelligent, data-driven machines. Automated guided vehicles (AGVs) and autonomous forklifts are gaining traction, promising enhanced precision, reduced human intervention, and heightened safety. This technological leap not only elevates operational speed and accuracy but also contributes to cost savings and increased productivity.

However, this pursuit of growth is not without its challenges. Sustainability and environmental concerns are casting a critical spotlight on the forklift industry. Despite the challenges of higher upfront costs and concerns about range, the Electric Truck Market is witnessing increased consumer interest as businesses prioritize environmental responsibility and seek long-term cost savings through lower operational expenses. As governments and industries embrace greener practices, the pressure to reduce emissions and minimize the carbon footprint of forklifts is intensifying.

Manufacturers and stakeholders are thus tasked with developing electric and alternative fuel-powered forklifts that strike a balance between performance and ecological impact. Furthermore, the evolving labor landscape poses another set of challenges. The forklift industry relies heavily on skilled operators, whose shortage is becoming increasingly apparent. Addressing this issue requires investments in training and upskilling programs, as well as the development of user-friendly interfaces for next-gen forklifts to make operation more intuitive for a broader workforce.

The forklift truck market is undergoing a period of robust expansion fueled by the imperative for streamlined logistics and material handling. The global Forklift Truck Market size was valued at US$ 40.24 billion in 2022 and is anticipated to witness a compound annual growth rate (CAGR) of 11.1% from 2023 to 2030. The infusion of advanced technologies is opening doors to heightened efficiency and innovation, while sustainability concerns and labor dynamics present complex hurdles. Navigating this landscape requires a strategic blend of technological innovation, environmental consciousness, and workforce development.

#Forklift Truck Market#Forklift Truck Market Opportunities#Forklift Truck Market Challenges#Forklift Truck#Automotive and Transportarion#Coherent Market

0 notes

Text

0 days since the last shoplifter

this will be a series, so 1/10 of giving my “parasites” target uniforms

#the owl house#titan’s council#target au#oc#the owl house oc#the owl house fanart#my art#darian vernworth#he went an extra mile in regards to the dress code: this universe’s target accepted it#i forgot to include where darian works in this au: he’s part of the morning shift with eirwen and chemist#darian is in charge of unloading incoming merch from trucks and storing them on the shelves by driving forklifts and lifting stuff by tail#he nearly got injured by boxes falling on him one day but as a master illusionist he escaped from the impending catastrophe#darian sometimes goes out to stock items on shelves for customers to get with a big cart for his tail to pull by the handles

9 notes

·

View notes

Text

Heavy Equipment for Sale

We sell a variety of excavators, not limited but including:

Crawling Excavators,

Wheeled Excavators,

Skid Steer Excavators,

Backhoe Excavators,

Long-Reach Excavators,

Dragline Excavators, and

Suction Excavators.

To name a few examples. Contact us to discuss your excavator needs.

#Equipment Dealer in Dallas#Equipment for sale in Dallas#Forklifts for sale#Used forklifts for sale#Used Forklifts Trucks for sale#Equipment dealer#Equipment for sale#Selling Equipment#Selling Used Equipment#Used Equipment for sale#Heavy Equipment#Construction Equipment Dealer#Sell Construction Equipment#Tractors for sale#Sell Used Equipment#Sell Equipment Near Me#Sell Used Equipment Near Me

2 notes

·

View notes

Text

Okay, I was an anxious mess over this new job for nothing lol

#🎃 Cryptid sighting#I’m sure there will be tasks that will be challenging but most of it is very familiar#And tbh- I was most nervous over the driving component of the job because they made a big deal of verifying my driving record#Which is spotless … because I haven’t driven a car on a road in almost a decade lol#I’ve driven a lot of other vehicles but not something with a stick shift or general street legal vehicle complexities#Like- forklifts & pullers & ride-on utility vacuums/scrubbers are super basic control wise#But I was terrified that I’d be driving a regular truck right away#And instead once I do drive anything here it’ll be a glorified golf cart with a little pick-up back & simpler controls than a puller#And besides having to learn my way around a hecking labyrinth- it sounds like it’ll be a manageable job#Also like 90% of my department is lgbtqia+ dgfdgfdgd

5 notes

·

View notes

Text

sometimes i think abt how i've technically been in college since 2018 and i wont be done until 2028, and that makes me cry a little.

#granted we went from trucking and forklifts to nursing and then microbiology and stuff#progress isn't always linear or whatever#i wear many a hat and haves many a debt

4 notes

·

View notes

Text

Coming from the rough parts of Florida and moving to a VERY small town in Massachusetts with a population so low we don't legally qualify to be on a mail route has been a jarring experience. I'm still in all my town facebook groups from Florida so I see 5+ posts a day about armed robbery, house raids and other nefarious things. Meanwhile, my towns facebook pages' biggest drama is someones' rv parked next to the post office looking "unsightly". It was a huge deal for like a month. The cops were even called.

That was the talk of the town for a while BUT TODAY THAT CHANGED.

Today's exciting news? An 18 wheeler stuck on a hill. Truly riveting.

#he bottomed out right next to my house lmao#spent 20 minutes trying to shimmy out#eventually highway patrol and some officers showed up#they used a forklift to lift the bed of the truck so it could drive down the hill#they had to take all the cars he was towing off and put one of them in my lawn lmao#personal

6 notes

·

View notes

Text

New guy got a haircut that makes him look like a very butch lesbian and I am the one who is training the new guy and tbh the Desperately Confused Looks we have gotten from customers and vendors today are the only good thing about this fucking job.

#chit chat#work stuff#my third coworker: yes that's [gender neutral name on the masc side] and [gender neutral name on the fem side]#customer looking at us while neither are wearing our nametag: *sweats*#mr 'pardon me but are you a homosexual' this one's for you#truck drivers will nervously look between us to decide who looks more capable of driving a forklift#i am having the time of my life in this area only

5 notes

·

View notes

Text

Forklift Truck Market: Top Technological Advancements

Materials handling operations face immense pressure from various fronts, including significant labor shortages, low-profit margins, and increasing productivity demands. While selecting an appropriate forklift may not completely solve these challenges, it undeniably has the potential to make a significant difference.

According to Triton Market Research, the global forklift truck market was valued at $68393.39 million in 2022 and is expected to reach $123258.01 million by 2030, at a CAGR of 8.08% in revenue and 6.09% in volume during the forecast period.

As the global market expands, manufacturers constantly strive to innovate and meet the growing demands of various industries, prompting them to develop new technologies and improve their production capabilities to remain competitive in a rapidly evolving landscape:

Rise of Electric Forklift Trucks: Manufacturers Embrace Sustainability

1. Battery Technology Advancements

Electric forklift trucks have gained significant traction due to their eco-friendly nature and operational efficiency. Cat Lift Trucks is a leading company that has invested in advanced battery technologies for electric forklift trucks. Their electric forklifts offer durability, operator comfort, and advanced features, providing a versatile and eco-friendly alternative to diesel or LPG models for indoor and outdoor applications. These innovations have reduced the environmental impact of forklift trucks and improved their performance & reliability.

The electric power segment is expected to achieve a revenue of $56,464.50 million by 2030, with an estimated CAGR of 8.51% during the forecast period.

2. Integration of Lithium-ion Batteries

One notable advancement is the integration of lithium-ion batteries into electric forklift trucks. These batteries offer higher energy density, longer lifespans, and reduced maintenance requirements compared to traditional lead-acid batteries. Hyster-Yale Group Inc stands out as a manufacturer that has effectively incorporated lithium-ion technology into their electric forklift trucks, pioneering the introduction of a commercially available, UL-recognized lithium-ion battery pack in the market. These lithium-ion-powered trucks offer consistent and reliable performance across multiple shifts, significantly reducing maintenance and charging time, making them ideal for efficient multi-shift operations.

Automation and Robotics: Enhancing Efficiency and Safety

Autonomous Forklifts

The emergence of autonomous forklifts has revolutionized material handling operations. With its innovative OTTO Lifter, OTTO Motors is at the forefront of self-driving forklift truck development. This autonomous forklift utilizes cutting-edge autonomy software to make intelligent, real-time decisions, efficiently delivering materials to their designated locations, thereby reducing costs associated with pallet transport workflows, all while maintaining the highest safety standards.

Collaborative Robots

Collaborative robots, or cobots, have also significantly contributed to the studied market. Companies such as Universal Robots have integrated cobots with forklifts, enabling them to work alongside human operators in a shared workspace. These cobots assist in palletizing, picking, and sorting tasks, improving operational efficiency and reducing the risk of injuries.

Telematics and Connectivity: Data-Driven Decision Making

Real-Time Monitoring and Predictive Maintenance

Leading forklift truck manufacturers have integrated advanced telematics systems to gather data on vehicle performance, fuel consumption, and maintenance requirements. Businesses can optimize fleet management, proactively schedule maintenance, and minimize downtime by analyzing this data. Crown Equipment Corporation is one example of a company incorporating advanced telematics systems into its forklift trucks. With telematics solutions like Info Link, Crown Equipment Corporation collects, measures, benchmarks, analyzes, and acts on data from lift trucks, operators, services, applications, and fleets. This enables businesses to optimize fleet management, proactively schedule maintenance, and make data-driven decisions, improving operational efficiency and cost savings.

Fleet Management Optimization

Integrating connectivity technologies into fleet management has revolutionized how companies optimize resources and streamline operations. With improved visibility and control over the fleet, companies can monitor real-time data on vehicle performance, fuel consumption and maintenance requirements. This wealth of information enables informed decision-making that enables proactive maintenance planning and resource allocation and uncovers operational inefficiencies. Advanced tracking systems and route optimization software minimize delivery delays, reduce fuel consumption and improve overall productivity and cost savings. Using connectivity technologies in fleet management provides a competitive advantage by maximizing efficiency and delivering superior customer service.

Conclusion

As the forklift truck market continues to evolve, technological advancements are set to redefine its future, creating a more efficient and sustainable landscape for material handling operations worldwide. Also, rapid industrialization and economic development in India, Japan, and China have led to higher demand for efficient material-handling equipment, significantly boosting the Asia-Pacific forklift truck market to rise at a CAGR of 8.31% during the forecast period.

FAQs

Q1: What factors drive the forklift truck market?

Growing e-commerce demand and automation in manufacturing fuel market growth.

Q2: What segments are analyzed in the forklift truck market?

Segment by power source(IC engine power and electric power), type (class 1, class 2, class 3, and class 4 and 5), and by end-user (retail and e-commerce, construction, manufacturing, and other end-user).

Q3: What regions are studied in the market?

North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa.

#Forklift Truck Market#Forklift Truck#Building & Construction#Construction Materials#triton market research#market research reports

0 notes

Text

These are the little guys I found outside next to the forklift at my job. It’s been a week since I took them home and they’re doing very well! They are now double the size of what they are in this picture. These kittens had been literally born the day we found them with the mother no where in sight, there was a thunder storm right before we found them so the mother might’ve gotten spooked. I’ve had people keeping an eye out for the mother but so far we haven’t seen her sadly. As someone who’s done foster care for kittens before I’ll be taking care of them til they hit 8 weeks and get new homes. Might update periodically on my main blog about them from time to time!

#pirate speaks#honestly they are so strong and thriving for being found abandoned in a puddle under a pallet of lumber.#I would’ve loved to rescue the mom too of course be we couldn’t find her at all#and I had people watching behind the building all week#I’m glad we found these kittens when we did because we have a lot of forklifts and trucks driving around that spot so it was dangerous

3 notes

·

View notes

Text

Seismic Pallet Rack, Racking, new and used, shelving, cantilever rack (concord / pleasant hill / martinez)

#d uprights#8' long x 4#d#GREEN SEISMIC TEARDROP UPRIGHTS. Ask for the innovative uprights that are knocked down for ease of shipping; and are easily set up with nut#Then we have ORANGE BEAMS that are 6'#8'#9'#10'#12' long with capacities from 2200 lbs./pair to 8204 lbs./pair.#Don't forget about the wire decks made necessary by the fire dept. They want you to have “flow through” decks that allow the sprinklers to#the heat to rise#set off the alarm and activate the vents. Call for prices.#We also sell USED PALLET RACK if it is AMERICAN SEISMIC DESIGN. Chinese made and most of the used pallet rack are not seismic design. Chine#increasing the number of connector rivets on the ends of the beams from 2 to 3#and sometimes requiring backers (double columns) on the upright channels to at least the first beam level.#How do you get your forklift from the ground to your dock or the bed of a truck? Use a MOBILE YARD RAMP. They roll around to various locati#Ground-to-trailer application best served with 36' ramp including a 6' level off. Note the lip on the top end that is welded onto a frame f#000 lbs. capacity as opposed to a flimsy hinged steel plate that doesn't have 20#000 lbs. capacity. Other sizes and capacities available.#All steel welded construction. MADE IN AMERICA. Ramps made in China do not have quality control of their steel. Therefore#the capacities cannot be guaranteed.#Add the full undercarriage with solid 18#or 48“ length of forks. We used to sell used pallet jacks but within a few weeks the customer would come back and want to get a refund beca#WHERE-IS#CASH AND CARRY#NO REFUNDS#CREDITS#WARRANTY#EXCHANGES OR RETURNS#Cash and carry

2 notes

·

View notes

Text

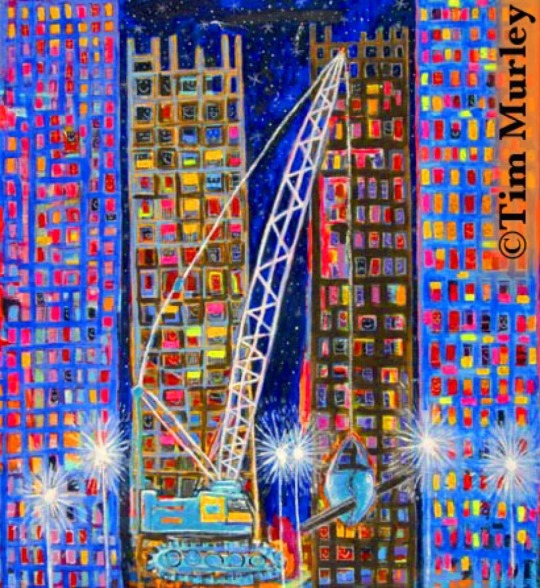

The night construction crew. 🏗🦺🚧🔨⚙️⛓🌃🚚🌗(mixed media collage on paper)💥🚛

#cityscape#cityscape painting#cityscape art#urban sketch#real estate#art for sale#basquiat#jean michel basquiat#pop art#contemporary art#folk art#construction#construction site#construction company#construction workers#construction safety#construction crew#bulldozer#dump truck#crane operator#heavy equipment#scaffolding#flares#night world#fine art#forklift#modern art#andy warhol#street art#keith haring

4 notes

·

View notes