#Foodandbeverageindustry

Explore tagged Tumblr posts

Text

7 Ways to Lower Down Food & Beverages Industry’s Operational Cost using CMMS software

Follow 7 effective ways to reduce operational costs in the Food & Beverages industry using CMMS software for improved efficiency and savings.

0 notes

Text

Future Outlook of the Canned Pineapple Market: Analyzing Size, Share, and Growth Patterns

The global canned pineapple market size is estimated to reach USD 2.68 billion in 2030 and is projected to grow at a CAGR of 4.7% from 2024 to 2030, according to a new report by Grand View Research, Inc. The convenience factor significantly contributes to market growth as canned pineapples provide consumers with an easy and quick way to enjoy this fruit without having to deal with peeling, coring, and cutting. This appeals particularly to the busy lifestyles of urban consumers who seek nutritious, ready-to-eat food options. Furthermore, canned pineapples offer a longer shelf life than fresh pineapples, making them a popular choice for consumers who wish to have tropical fruits available in their pantry all year round.

Furthermore, there is a burgeoning demand for healthy and natural food products. Pineapples contain bromelain, vitamin C, and other essential nutrients, which have been linked to various health benefits, including improved digestion and immunity. As awareness of these benefits increases, health-conscious consumers are more inclined to incorporate such nutrient-rich fruits into their diets. This health trend, coupled with the global reach of canned pineapples, which are accessible even in regions where fresh pineapples cannot be grown, further propels the market growth.

Canned Pineapple Market Report Highlights

North America is expected to grow with a CAGR of 5.4% over the forecast period from 2024 to 2030 due to increasing consumer preferences for convenient and healthy packaged foods.

Based on product type, canned pineapple chunks is expected to growth with a CAGR of 4.9% from 2024 to 2030. The market for canned pineapple chunks is growing due to their widespread use in food services and home cooking for their convenience and year-round availability.

Based on application, canned pineapple for bakery & snacks industry is expected to growth with a CAGR of 5.2% from 2024 to 2030. The demand for canned pineapple in bakery & snacks industry is increasing as it offers a consistent and ready-to-use ingredient for various recipes, enhancing flavor and texture.

Distribution of canned pineapple through B2B channel is expected to grow at a CAGR of 5.2% from 2024 to 2030, owing to the rising trend in online shopping, offering wider access and convenience to consumers.

For More Details or Sample Copy please visit link @: Canned Pineapple Market Report

Additionally, advancements in packaging and preservation technologies have significantly contributed to the growth of the canned pineapple market. Innovative packaging solutions not only extend the shelf life of the products but also improve their safety and quality by preventing contamination. Moreover, expanding distribution channels, including online retail, continues to drive consumer interest and market expansion for canned pineapples globally.

Major players in the canned pineapple market include Dole; Kraft Heinz; Pineapple India; V&K Pineapple Canning; Fresh Food Co., Ltd; Siam Pineapple; Jal Pan Foods; Winzintl; Annie’s Farm Company; and Sure Harvest Foodstuff. The players in the canned pineapple market employ various strategies to enhance their competitive edge and attract customers. These strategies include introducing new flavor varieties and leveraging social media platforms for targeted advertising, forming strategic partnerships with offline stores and expanding their product lines to cater to a broader audience.

List Of major companies In The Canned Pineapple Market

Dole

Kraft Heinz

Pineapple India

V&K Pineapple Canning

Fresh Food Co., Ltd

Siam Pineapple

Jal Pan Foods

Winzintl

Annie’s Farm Company

Sure Harvest Foodstuff

For Customized reports or Special Pricing please visit @: Canned Pineapple Market Analysis Report

We have segmented the canned pineapple market based on product, application, distribution channel, and region.

#CannedPineappleMarket#ProcessedFruitIndustry#PineappleProduction#CannedFruitMarket#FoodAndBeverageIndustry#FruitPreservation#FoodProcessing#PineappleImportExport#CannedFoods#ConvenienceFoods#PineappleSupplyChain#GlobalCannedPineapple#MarketTrends#ConsumerDemand#ReadyToEatFruit

0 notes

Text

#foodandbeverage#foodandbeverageindustry#spadesurvey#marketresearchservices#marketresearchbeverageindustry

0 notes

Text

Why Wastewater Treatment Plants are Essential for the Food and Beverage Segment

This blog highlights the vital role of wastewater treatment in the food and beverage industry, focusing on pollution prevention, water conservation, and sustainability. It addresses key challenges like high organic loads and nitrogen removal. Wipro Water provides innovative solutions that help companies meet regulatory standards, conserve resources, and ensure long-term sustainability.

0 notes

Text

Efficient boilers for food and beverages industry is reliable processing. Optimize production with high-quality, dependable steam solutions tailored to your needs.

#Boilers#FoodAndBeverageIndustry#RossThermal#SteamGeneration#FoodProcessing#BeverageProduction#IndustrialBoilers#ProcessHeating#EnergyEfficiency

0 notes

Text

Concerns about #ERP can be daunting, but let's set the record straight-

• Worried about ERP costs?

Investing in a versatile tool to manage your daily operations is well worth it, saving you time and effort in the long run.

• Nervous about staff handling it?

With Eazy ERP, our implementation and support teams are here to handhold you every step of the way.

• Doubting double entries?

Eazy ERP integrates with Tally and Busy, eliminating the hassle of manual entries. Plus, our in-house accounting system means no additional purchases necessary.

• Wondering if it fits your industry?

Eazy ERP caters to a wide range of sectors including Food & Spices, Electric & Electrical, Auto Components, Paints & Chemicals, Plastic & Packaging, Apparels, and Footwears.

With customizable solutions, intuitive interfaces, and industry-specific modules, EazyERP makes ERP implementation a breeze.

Learn more at eazyerp.com

#foodandbeverageindustry#electricindustry#autocomponents#paintindustry#apparelindustry#erpsoftware#enterpriseresourceplanning#eazyerp

1 note

·

View note

Text

Advancing Transparency in the Food and Beverage Supply Chain

Originally Published on: SpendEdge |Making of a Transparent Supply Chain for Food and Beverage Industry

The Imperative of Transparency for Food & Beverage Enterprises

The food and beverage sector consistently faces scrutiny, demanding increased transparency and accountability. The growing preference for organic food and heightened focus on hygiene keep businesses in this industry on high alert. Transparency in the supply chain process is a crucial objective for companies in the food service, aiming to achieve openness and clarity in information, actions, and processes. This ensures honesty, accountability, and the ability to make well-informed judgments.

Transparency in the food and beverage industry fosters trust, informs consumer choices, and enhances food safety. Providing open ingredient information empowers consumers to make healthier selections, fostering loyalty and preventing allergen risks through clear communication.

Supply Chains in the Food & Beverage Industry

Typically, a food and beverage supply chain begins at the farm where the raw product is produced and concludes with the final consumers. Freight carriers, forward warehouses, distribution centers, and 3PLs constitute other components in this extensive and interconnected chain of events. Ensuring that all stakeholders involved meet regulatory demands and make their work processes open to the public is challenging due to the inherent complexity and fragmented nature of supply chains.

Achieving alignment among all stakeholders is a goal that many players in the food service industry actively pursue.

The Need to Innovate Beyond Traditional Frameworks

For a transparent and seamless supply chain mechanism, it is essential to collect the right data and utilize it intelligently. The traditional framework of data analysis is rather restricted, often limited to the peripheral analysis of operational data. The lack of alignment with technology makes it challenging for traditional frameworks to swiftly decipher large volumes of information, creating difficulties in bringing transparency to the entire supply chain process and leaving minimal room for innovation.

As industry experts, we assert that technology should play a pivotal role in ensuring any supply chain stays up-to-date and transparent. In this context, data analytics, spend analysis, and benchmarking need to work hand in hand. This approach makes it much easier to process vast amounts of data, identify, and predict potential problems that might arise over time.

A transparent supply chain is the outcome of the optimal use of technology, converting generated data into actionable strategies.

Strategies for Implementing a Transparent Supply Chain

Detailed Labeling: Provide comprehensive ingredient lists, nutritional information, and sourcing details on packaging to give consumers clear insights into the product’s origin and components.

Supplier Collaboration: Establish partnerships with suppliers committed to ethical practices. Share information about sourcing, production processes, and quality standards to maintain transparency throughout the supply chain.

Traceability Technology: Implement digital solutions like blockchain to track and share real-time data about product movements, origins, and handling conditions, enabling consumers to verify the journey of their food and beverages.

Third-Party Verification: Engage independent organizations to audit and verify your supply chain practices. Certification and auditing provide external validation of your transparency efforts, enhancing credibility with consumers.

Contact us.

0 notes

Text

How IoT-Based Energy Monitoring Systems Are Transforming the Food & Beverages Business?

See how IoT-based energy systems are changing the game in the food and beverage industry, making operations smarter and more cost-effective.

0 notes

Text

Deploying COBOT's is an innovative new way by which restaurants today handle the growing demand from more customers. Made for food-grade materials and handling both hot oils and wet surfaces, the Doosan E-Series COBOT's help restaurants and other businesses in the Food & Beverage (F&B) industry to meet the increasing volumes of business. Doosan Robotics E Series COBOT's help improve safety through vision systems and sensors by detecting defects, contaminants and foreign objects in food. Easy programmability makes signature dishes easy to create, and ensures uniform taste of dishes over time. Not to mention repetitive tasks such as packaging, sorting and assembly, and time-consuming jobs like cutting vegetables, are all easily performed - resulting in increased productivity and efficiency. For more info: https://zurl.co/CmBr

0 notes

Text

#foodandbeverage#foodandbeverageindustry#spadesurvey#marketresearchservices#marketresearchbeverageindustry

0 notes

Text

Sustainable Solutions: MBBRs in Food & Beverage Wastewater Treatment

Discover how Moving Bed Bio-Reactors (MBBRs) are transforming wastewater management in the food and beverage industry. This blog highlights the benefits of MBBR technology, from efficient treatment to space and energy savings, and outlines the steps for successful implementation. Learn how Wipro Water’s expertise in MBBR systems helps industries meet regulations and drive sustainable growth.

0 notes

Text

Join us from 23 - 26 October 2023 at Riyadh International Convention and Exhibition Centre for the 40th edition of the Saudi agriculture international trade exhibition. Hall No: 5, Stand No: 321. Meet Our Experts: Engage with our team members, who will be available to provide in-depth insights, answer your questions, and discuss about your packaging requirements:

To know more about, please visit www.trivenipackaging.com

#saudiagriculture#foodandbeverage#absolutepackaging#foodandbeverageindustry#fooddelivery#packagingsolutions#packagingmachinery#packaginginnovation#packagingequipment#packagingline

0 notes

Link

do you know #FoodPremises Design & Maintenance #AwarenessTraining is necessary to ensure the health and safety of consumers, comply with regulations, reduce costs, and maintain a positive reputation.

1 note

·

View note

Photo

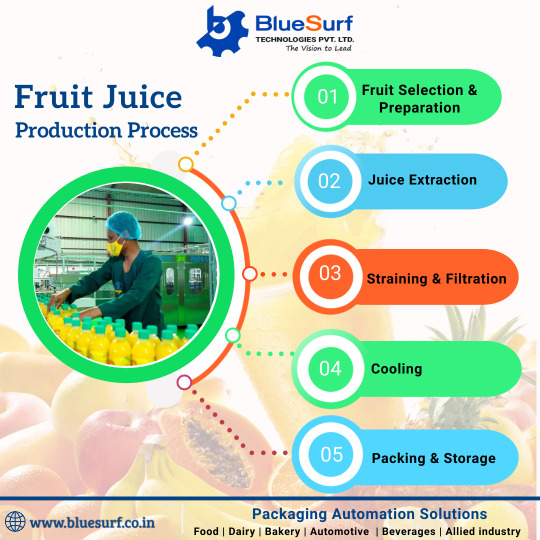

Increase Profit & Reduce Food Waste Today! The production process for fruit juices is fairly standard, regardless of the type of juice you are making. The process starts with the pretreatment of raw fruit material and then moves to extraction, clarification, and filtration. From there, the production process continues with homogenization, deoxidation, concentration, and ingredient adjustments. Collaborate with Blusurf Technologies for food process optimization solution. Request For A Quote Now [email protected] More Info Visit Us:https://bit.ly/3PwoGye

#bluesurf#bluesurftechnologies#EnergyEfficientSolutions#foodprocessing#foodandbeverageindustry#dairyprocessing

0 notes