#Food and Beverage Position Sensors Market share

Explore tagged Tumblr posts

Text

Food & Beverage Position Sensors market is anticipated to reach $307 million by 2026 at a CAGR of 7.1% during the forecast period 2021-2026.

#Food & Beverage Position Sensors market#Food & Beverage Position Sensors market share#Food & Beverage Position Sensors market size

0 notes

Text

Global Industrial Vehicles Market Size, Share and Forecast 2032

Global Industrial Vehicles Market is projected to witness a CAGR of 6.08% during the forecast period 2025-2032, growing from USD 45.75 billion in 2024 to USD 73.36 billion in 2032. The industrial vehicles market on a global scale is showcasing significant growth due to several key factors. The growing acceptance of industrial vehicles in diverse industries, such as automotive, healthcare, chemicals, and food and beverages, where they assist during manufacturing, storage, and retrieval, is one of the paramount driving forces. Another developing parameter encouraging the market includes rapid improvements in vehicle technologies such as automation and telematics, which actively drive productive and operational efficiency. Manufacturers are investing in Internet of Things (IoT) solutions to enhance operational efficiency. Growth in e-commerce has further complicated the need for sophisticated warehousing and logistics arrangements, consequently increasing demand for industrial vehicles like forklifts and automated guided vehicles (AGVs).

In parallel with this, a considerable shift towards sustainability has been observed in electric and hybrid industrial vehicles, which are high up on the agendas formed by the stringent environmental regulations and consumer preferences towards emissions. Government investments in infrastructure development fuel demand for industrial vehicles, as modernizing transportation networks and constructing new warehouses necessitate a robust fleet for efficient material handling. Companies are increasingly seeking ways to reduce labor costs and enhance operational efficiency, such as battery-operated vehicles, which result in higher demand for automated industrial vehicles capable of performing tasks traditionally handled by human labor.

For instance, in October 2024, Konecranes Plc launched its new Konecranes E-ACE, the electric version of its trusted and reliable Konecranes Liftace range, marking a further step toward the total electrification of its product portfolio. The first Konecranes E-ACE lift trucks, which are empty container handlers for 9–10-ton loads, will start shipping in Asia and roll out in other markets starting in 2025.

Expansion in E-Commerce Drives the Global Market Growth

The rapidly expanding globalization of the industrial vehicle market results from rapid but correlated factors them. The increasing number of warehouses, which are established by e-commerce giants such as Amazon and eBay, primarily require moving goods from storage to consumers to be easily transported within industries. In addition to these similarities, the automation and digitalization of industrial operations also fuel the market. Through robotics and productivity improvements, companies are seeking efficient ways to manage material flows integrated into existing and future work processes. This, in turn, is propelling the requirement for automated guided vehicles and other advanced machinery. This trend also favors the logistics and warehousing sectors above others, as businesses like to adopt meager-steady operations in the e-commerce sector. The ongoing expansion of e-commerce and logistics operations further underscores this growth trajectory, positioning the market for continued development in the coming years.

For instance, in March 2024, Mitsubishi Logisnext Co., Ltd., a part of Mitsubishi Heavy Industries, Ltd., completed a demonstration of loading trucks utilizing automated guided forklifts (AGFs). The demonstration was conducted jointly with logistics services provider Konoike Transport Co., Ltd., which began utilizing the system for business operations in Japan.

Technological Advancements Propel the Global Industrial Vehicles Market Growth

Technological advancements have undoubtedly proved to be a booster for the global industrial vehicles market. Automation, artificial intelligence (AI), and new sensors are ushering in new operational efficiencies, allowing improvements in productivity in sectors as new technologies are integrated with other industrial operations processes. The demand for advanced industrial vehicles such as automated guided vehicles (AGVs) is on the rise due to the increasing trend toward process automation, enabling an improvement in health and safety standards coupled with reducing the amount of manual work done. Many manufacturers of such industrial vehicles are investing in IoT solutions for fast and easy connections between their vehicles and management systems. In this manner, the vehicles will be available for real-time monitoring and predictive maintenance. Such forward-thinking can minimize disruptions in operation, thus proving that there are tangible benefits from the integration of such technologies. Additionally, these technologies increase their applicability to the bar of materials handling, but they also go a long way in addressing the trends of automation and sustainability in the industrial world. In addition to the innovation of processes that businesses continuously seek to enhance productivity and lower costs, these technological advancements would provide good prospects for growth in industrial vehicles in the future.

For instance, in August 2023, Mitsubishi Logisnext Americas (Mitsubishi Logisnext Co., Ltd.), one of the world’s leading manufacturers and providers of material handling, automation, and fleet solutions, established its new production facility in Houston, Texas. The state-of-the-art facility will provide increased production capabilities to further support the growing demand for electric lift trucks and warehouse products.

Dominance of Forklifts in Global Industrial Vehicles Market

Forklifts are the critical machines that rule the global industrial vehicles market because they serve principally in almost all industries for material handling and logistics. There will be maximum sales of electric motor-powered forklifts in the coming time because companies are laying much emphasis on sustainable and cost-effective systems. Forklifts are the most flexible and offer a wide range of applications, including loading and unloading goods in warehouses and dockyards. They lift heavy loads and transport them over very short distances, making them the preference of many companies. The automated warehouses and an emerging sector of e-commerce are further stimulating the demand for forklifts, as businesses aspire to make greater use of supply chain operations when labor costs and shortage of skilled manpower are on the rise. Overall, forklifts are set to maintain their dominance in the global industrial vehicles market due to their essential role in material handling, which is supported by technological advancements and increasing demand from key industries.

For instance, in July 2024, Hyster-Yale, Inc. launched new integrated lithium-ion battery powered forklifts that deliver robust performance, comparable to an internal combustion engine (ICE) lift truck. The Hyster J2.0-3.5XTLG series, capable of lifting up to 3.5 tons, can be used in both indoor and outdoor operations, providing a durable, flexible option with zero exhaust emissions.

Asia-Pacific Dominates Global Industrial Vehicles Market Share

Asia-Pacific is the dominant region in the global industrial vehicles market. The major reason for this dominance can be attributed to the considerable growth of the automobile industry, which demands pragmatic transportation solutions and has strong manufacturing capabilities. Moreover, rapid urbanization and large investments in infrastructure development make the region more conducive to the use of industrial vehicles. additionally, the supply chain diversification across sectors such as electronic and consumer goods increases demand for industrial vehicles. Advances in manufacturing practices, such as electric vehicle productions and renewable energy components, are also expected to fortify industrial vehicles as a prospect for growth. However, Asia-Pacific’s combination of industrial activity, technological advancements, and infrastructure investment positions it as a global industrial vehicles market leader.

For instance, in October 2024, HELI, Anhui Forklift Group Corporation Ltd. participated in LogiMAT Southeast Asia 2024, held at the BITEC exhibition center in Bangkok, Thailand. The booth displayed a wide range of advanced material handling solutions. The highlight of HELI’s participation was the Thai debut of its AGV (Automated Guided Vehicle) products, marking a significant milestone in the company’s expansion of intelligent logistics solutions in the region.

Download Free Sample Report

Future Market Scenario (2025 – 2032F)

Rapid industrialization and a burgeoning e-commerce sector are expected to contribute to robust growth, fueled by rising manufacturing activities and a greater demand for efficient material handling solutions.

Adopting automation technologies e.g., AGVs, and smart warehousing powered by IoT and AI will improve operational efficiency.

Increased government funding for infrastructure development to modernize transportation networks and enhance logistics capabilities.

Report Scope

“Industrial Vehicles Market Assessment, Opportunities and Forecast, 2018-2032F”, is a comprehensive report by Markets and Data, providing in-depth analysis and qualitative and quantitative assessment of the current state of global industrial vehicles market, industry dynamics, and challenges. The report includes market size, segmental shares, growth trends, opportunities, and forecast between 2025 and 2032. Additionally, the report profiles the leading players in the industry, mentioning their respective market share, business models, competitive intelligence, etc.

Click here for full report- https://www.marketsandata.com/industry-reports/industrial-vehicles-market

Latest reports-

Contact

Mr. Vivek Gupta 5741 Cleveland street, Suite 120, VA beach, VA, USA 23462 Tel: +1 (757) 343–3258 Email: [email protected] Website: https://www.marketsandata.com

0 notes

Text

Machine Vision Market Size, Share & Trends Analysis Report By 2030

The global machine vision market size is expected to reach USD 41.60 billion by 2030, according to a new report by Grand View Research, Inc. The ability of machine vision systems to process a large amount of information in a fraction of seconds is a major factor driving the market. The quick processing ability of machine vision systems is paving the way for manufacturers to achieve new milestones in manufacturing products with negligible defects. Moreover, the increasing adoption of robots across the industrial sectors is leading to the application of vision-guided robotic systems. Industrial verticals such as automotive, pharmaceutical, packaging, and food and beverage are prominent sectors where robotic systems are used, eventually fueling the demand for machine vision systems.

The machine vision technology encompasses various components in order to capture images of products to analyze them depending on different parameters of quality and safety. The technology is a combination of software and hardware that provides operational control to devices to execute functions such as capturing and processing images and measuring various characteristics required for decision making. Major components of the system comprise lighting, lens, image sensors, vision processing, and communication devices. Machine vision systems assist in resolving complicated industrial tasks with reliability.

Gather more insights about the market drivers, restrains and growth of the Global Machine Vision Market

Industrial machine vision systems are usually more robust and demand high reliability, stability, and accuracy as compared to those used in institutional or educational applications. They cost lesser than systems used in military, aerospace, defense, and government applications. These factors are expected to lead to greater adaptability of the technology in the industrial sectors. In addition, the robotic vision systems used across the industries are also leading to the increasing adoption of the technology, thereby strengthening the overall market.

The technology has proven to be of key importance in the area of manufacturing and quality control owing to the increasing need for quality inspection and production. In addition, the growing automation in industrial segments is facilitating the growth of the market at a considerable rate. The technology has been witnessing extensive developments and innovative upgrades since its emergence. Several factors such as the growing inception of the technology and the increasing need for quality products are influencing the market growth. Furthermore, machine vision systems are gaining traction in medical and healthcare applications at a considerable pace. The analysis of medical images and robotic applications for carrying out various medical activities are the key roles of the technology in these sectors.

Machine Vision Market Report Highlights

The PC-based product segment accounted for the largest revenue share in 2022 and is estimated to dominate the market over the forecast period

The identification application segment is anticipated to exhibit the fastest growth rate over the forecast period followed by the positioning and guidance application segment

By end-use industry, the food and beverage industry is expected to register the highest CAGR over the forecast period

The industry is expected to witness substantial growth in the Asia Pacific region over the next decade. This growth is witnessed in the wake of ample opportunities offered due to the presence of large manufacturing hubs in prominent countries (across the food and packaging, automotive, pharmaceutical, industrial, and consumer electronic sectors) such as China and Japan

Browse through Grand View Research's Next Generation Technologies Industry Research Reports.

Next Generation Computing Market: The global next generation computing market size was valued at USD 152.13 billion in 2024 and is expected to grow at a CAGR of 16.6% from 2025 to 2030.

Artificial Intelligence In Marketing Market: The global artificial intelligence in marketing market size was estimated USD 20,447.1 million in 2024 and projected to grow at a CAGR of 25.0% from 2025 to 2030.

Machine Vision Market Segmentation

Grand View Research has segmented the global machine vision market based on offering, product, application, end-use industry, and region:

Machine Vision Offering Outlook (Revenue, USD Million, 2017 - 2030)

Hardware

Camera

Frame Grabber

Optics/Lenses

LED Lighting

Processor

Software

Barcode Reading

Standard Algorithm

Deep Learning Software

Services

Integration

Solution Management

Machine Vision Product Outlook (Revenue, USD Million, 2017 - 2030)

PC Based

Smart Camera Based

Machine Vision Application Outlook (Revenue, USD Million, 2017 - 2030)

Quality Assurance and Inspection

Positioning and Guidance

Measurement

Identification

Machine Vision End-use Industry Outlook (Revenue, USD Million, 2017 - 2030)

Automotive

Pharmaceuticals & Chemicals

Electronics & Semiconductor

Pulp & Paper

Printing & Labelling

Food & Beverage (Packaging and Bottling)

Glass & Metal

Postal & Logistics

Others (Agriculture, Security & Surveillance, Rubber, Plastics, Solar Paneling, Machinery, and Others)

Machine Vision Regional Outlook (Revenue, USD Million, 2017 - 2030)

North America

Europe

Asia Pacific

South America

Middle East & Africa

Order a free sample PDF of the Machine Vision Market Intelligence Study, published by Grand View Research.

0 notes

Text

Machine Vision Industry Size & Share | Statistics Report 2030

The global machine vision market size is expected to reach USD 41.60 billion by 2030, according to a new report by Grand View Research, Inc. The ability of machine vision systems to process a large amount of information in a fraction of seconds is a major factor driving the market. The quick processing ability of machine vision systems is paving the way for manufacturers to achieve new milestones in manufacturing products with negligible defects. Moreover, the increasing adoption of robots across the industrial sectors is leading to the application of vision-guided robotic systems. Industrial verticals such as automotive, pharmaceutical, packaging, and food and beverage are prominent sectors where robotic systems are used, eventually fueling the demand for machine vision systems.

The machine vision technology encompasses various components in order to capture images of products to analyze them depending on different parameters of quality and safety. The technology is a combination of software and hardware that provides operational control to devices to execute functions such as capturing and processing images and measuring various characteristics required for decision making. Major components of the system comprise lighting, lens, image sensors, vision processing, and communication devices. Machine vision systems assist in resolving complicated industrial tasks with reliability.

Gather more insights about the market drivers, restrains and growth of the Global Machine Vision Market

Industrial machine vision systems are usually more robust and demand high reliability, stability, and accuracy as compared to those used in institutional or educational applications. They cost lesser than systems used in military, aerospace, defense, and government applications. These factors are expected to lead to greater adaptability of the technology in the industrial sectors. In addition, the robotic vision systems used across the industries are also leading to the increasing adoption of the technology, thereby strengthening the overall market.

The technology has proven to be of key importance in the area of manufacturing and quality control owing to the increasing need for quality inspection and production. In addition, the growing automation in industrial segments is facilitating the growth of the market at a considerable rate. The technology has been witnessing extensive developments and innovative upgrades since its emergence. Several factors such as the growing inception of the technology and the increasing need for quality products are influencing the market growth. Furthermore, machine vision systems are gaining traction in medical and healthcare applications at a considerable pace. The analysis of medical images and robotic applications for carrying out various medical activities are the key roles of the technology in these sectors.

Machine Vision Market Report Highlights

The PC-based product segment accounted for the largest revenue share in 2022 and is estimated to dominate the market over the forecast period

The identification application segment is anticipated to exhibit the fastest growth rate over the forecast period followed by the positioning and guidance application segment

By end-use industry, the food and beverage industry is expected to register the highest CAGR over the forecast period

The industry is expected to witness substantial growth in the Asia Pacific region over the next decade. This growth is witnessed in the wake of ample opportunities offered due to the presence of large manufacturing hubs in prominent countries (across the food and packaging, automotive, pharmaceutical, industrial, and consumer electronic sectors) such as China and Japan

Browse through Grand View Research's Next Generation Technologies Industry Research Reports.

Next Generation Computing Market: The global next generation computing market size was valued at USD 152.13 billion in 2024 and is expected to grow at a CAGR of 16.6% from 2025 to 2030.

Artificial Intelligence In Marketing Market: The global artificial intelligence in marketing market size was estimated USD 20,447.1 million in 2024 and projected to grow at a CAGR of 25.0% from 2025 to 2030.

Machine Vision Market Segmentation

Grand View Research has segmented the global machine vision market based on offering, product, application, end-use industry, and region:

Machine Vision Offering Outlook (Revenue, USD Million, 2017 - 2030)

Hardware

Camera

Frame Grabber

Optics/Lenses

LED Lighting

Processor

Software

Barcode Reading

Standard Algorithm

Deep Learning Software

Services

Integration

Solution Management

Machine Vision Product Outlook (Revenue, USD Million, 2017 - 2030)

PC Based

Smart Camera Based

Machine Vision Application Outlook (Revenue, USD Million, 2017 - 2030)

Quality Assurance and Inspection

Positioning and Guidance

Measurement

Identification

Machine Vision End-use Industry Outlook (Revenue, USD Million, 2017 - 2030)

Automotive

Pharmaceuticals & Chemicals

Electronics & Semiconductor

Pulp & Paper

Printing & Labelling

Food & Beverage (Packaging and Bottling)

Glass & Metal

Postal & Logistics

Others (Agriculture, Security & Surveillance, Rubber, Plastics, Solar Paneling, Machinery, and Others)

Machine Vision Regional Outlook (Revenue, USD Million, 2017 - 2030)

North America

Europe

Asia Pacific

South America

Middle East & Africa

Order a free sample PDF of the Machine Vision Market Intelligence Study, published by Grand View Research.

0 notes

Text

Food & Beverage Position Sensors Market Industry Forecast, 2024–2030

Food & Beverage Position Sensors Market Overview

sample report:

Food & Beverage Position Sensors Market Report Coverage

The report: “Food & Beverage Position Sensors Market — Forecast (2024–2030)”, by IndustryARC covers an in-depth analysis of the following segments of the Food & Beverage Position Sensors market.

By Product Type: Contact and Contact-Less By Position Sensor Type: Ultrasonic, Radar Microwave, Tuning Fork, Electromagnetic, Capacitance, Others By Measuring Type: Point Level Measuring and Continuous Level Measuring By Geography: North America (U.S, Canada, Mexico), Europe(Germany, UK, France, Italy, Spain, Russia and Others), APAC(China, Japan India, SK, Aus and Others), South America(Brazil, Argentina and others) and RoW (Middle east and Africa)

Key Takeaways

Rising trends towards automation in food and beverage vertical is anticipated to propel the market growth.

The market expansion of the Food & Beverage Position Sensors Market is expected to be aided by technical improvements in position sensors as a result of the rising demand from the food and beverage sector.

APAC region is dominated the food and beverage position sensor market in 2020. The presence of major F&B manufacturing companies and large number of consumer is going to provide huge growth to F&B flow sensor market.

Food & Beverage Position Sensors Market share in %, by Geography, 2023

For More Details on This Report — Request for Sample

Inquiry Before Buying:

Food & Beverage Position Sensors Market Segment Analysis- By Product Type

This market is segmented into Contact and Contact-Less on the basis of product type. Contact less segment is anticipated to witness a significant amount of growth in the forecast period 2024–2030. The benefits of Contact-less position sensors, such as longer life, reduced wear and tear, unmatched precision, consistent outstanding performance, rapid reaction, and suitability for a variety of settings, are attributed for the market’s rise. Furthermore, non-contact position sensor applications in precise motion control, robotic movement, MEMS accelerometers, vibration monitoring, and other applications help to drive market expansion. The market for Contact-less position sensors is expected to expand due to reasons such as usability in precise measurement, contamination resistance, and high accuracy. Hence, such factors is analyzed to boost the market growth in 2024–2030.

Food & Beverage Position Sensors Market Segment Analysis- By Position Sensor Type

By Distribution channel, Food & Beverage Position Sensors market is segmented into Ultrasonic, Radar Microwave, Tuning Fork, Electromagnetic, Capacitance, Others. Ultrasonic position sensor held the highest market share in 2020. Higher working temperatures and pressures, as well as the presence of steam and potentially corrosive chemicals such as alcohol and solvents, need the use of strong measurement components that can perform reliably under extreme circumstances. Similarly, as machine footprints get smaller, there is a greater demand for sensors that take up less space. All of these aspects have driven the creation of a new line of ultrasonic sensors that will allow producers to achieve optimal performance in a number of food and beverage applications. Ultrasonic sensors have a stainless steel or alumina exterior construction that optimizes performance while adhering to strict food safety requirements. Accurate sensing is critical in applications such as milk metering and beverage distribution to guarantee proper container filling. Ultrasonic metering is a great way to improve accuracy while keeping a small footprint. Thus, above mentioned factors are analyzed to drive the market growth.

Schedule A Call :

Food & Beverage Position Sensors Market Segment Analysis- By Geography

APAC held the highest market share of 37% in 2020. The rising need for cost-effective and highly efficient position sensors from the food and beverage industries, as well as technical advancements in optical position sensors, are driving expansion in this area. North America region is anticipated to witness a significant amount of growth in the forecast period 2024–2030. Growing spending by key players in the development of position sensors, as well as an increase in the use of position sensors for level measurement in large alcohol tanks, are contributing factors to market growth in this area. Moreover, the growing number of restaurants, fast-food chains, and meal delivery apps such as grub hub, caviar, and others increase customer access, resulting in substantial development in the food and beverage business in this region. Furthermore, growing consumer desire for organic, natural, and fresh foods as a result of increased health consciousness is a significant driver predicted to boost demand for the food and beverage industry. Because of the shift in consumer food consumption trends and inclination toward a healthy lifestyle, the United States is witnessing a strong demand for gluten-free drinks, followed by Canada and Mexico. Consumers in the United States have good opinions of healthful food items, which may drive market expansion. The favorable regulatory environment, attempts by the Food and Drug Administration (FDA) to encourage gluten-free diets, and further subsidy allocations are expected to enhance the regional market throughout the projected period. The major element driving the strategy of Food and Beverage firms is the constantly altering customer trends. Consumers’ lifestyles are changing, and there is a greater demand for processed and ready-to-eat meals, which is fueling the expansion of the food and beverage industry in this area. Thus with the rise of market for food and beverages, the market for position sensors also develops.

Food & Beverage Position Sensors Market Drivers

Increasing focus of manufacturing industry on accurate measurements and detailed inspection are anticipated to drive the market growth

In order to meet industry requirements, the manufacturing business need a high level of precision. To develop high-quality products, manufacturers rely on two critical parameters: measurement precision and thorough inspection. A position sensor detects a number of important properties such as profiling, width, height, step, gap, V-gap, edge, angle, bend, groove, and surface. The profiles on various item surfaces are also detected, measured, and evaluated using these sensors. When the position sensor is linked to the analytics program, many measurement jobs become much easier. As a result, the position sensor is helpful for automating, testing, or monitoring operations where displacement, distance, length, or position characteristics need to be detected.

Rising trends towards industrial automation tends to boost the market growth during the forecast period

Manufacturers in every industry are always under pressure to boost earnings while lowering expenses. Furthermore, the food and beverage sector is under pressure to adhere to FDA and other food safety and quality requirements. Automation is an obvious way to alleviate these constraints, since automated processes have been shown to boost efficiency, improve traceability, and preserve the brand’s reputation while adhering to the necessary laws. According to the World Health Organization, 600 million people worldwide become unwell after eating contaminated food each year, with 4,20,000 deaths, resulting in the loss of 33 million healthy years. As a result, rising concerns about food safety and cleanliness have driven the use of automation in the food and beverage sector to maintain sanitary standards. This in turn drives the market growth for position sensor market.

Buy Now :

Food & Beverage Position Sensors Market Challenges

High cost of ownership restrains the market growth

A position sensor is manufactured using numerous components, such as position magnets, sensing rods, diagnostic light-emitting diodes (LEDs), and connectors, which are supplied by multiple vendors. For instance, the average price of a crankshaft position sensor replacement cost is between $194 and $258, with the labor costs estimated between $104 and $133, while the cost of the parts is generally between $90 and $125. The major challenge for the companies is to increase these manufacturing capabilities, as well as reduce the overall cost of production.

Food & Beverage Position Sensors Market Landscape

Technology launches, acquisitions, Partnerships and R&D activities are key strategies adopted by players in the Food & Beverage Position Sensors market. In 2020, the market of Food & Beverage Position Sensors industry outlook has been fragmented by several companies. Food & Beverage Position Sensors top 10 companies include:

Hauser Management AG

GEMS Sensors Inc

First Sensor AG

ABB Ltd

Siemens AG

Endress

SICK

PCB Piezotronics

IFM

TR Electronics

Turck, among others.

Acquisitions/Technology Launches

In October 2020, sick launched new product for non-contact measurement of speed and length. With the SPEETEC®, SICK is expanding its product range for speed and length measurement of objects moving in a linear path to include technology that measures directly on the material surface. The non-contact sensor is able to measure a wide range of web and continuous materials, as well as blanks with an accuracy of just 4 μm.

Key Market Players:

The Top 5 companies in the Food & Beverage Position Sensors Market are:

GEMS Sensors Inc

ABB Ltd

Endress+Hauser

Baumer

SMD Fluid Controls

For more Automation and Instrumentation Market reports, please click here

0 notes

Text

Nanocellulose Industry Strategies With Forecast Till 2030

The global nanocellulose market was valued at USD 351.5 million in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 20.1% from 2023 to 2030. This growth is driven by increasing demand across diverse applications, along with a shift toward bio-based products. Nanocellulose, derived from plant cellulose, exhibits unique properties such as enhanced efficiency in paper manufacturing, higher filler content, lighter weight, and improved freeness (which improves paper-making flow). These characteristics make nanocellulose highly suitable for creating a variety of sustainable, high-performance products.

In the paper industry, nanocellulose is a key bio-based additive due to its high strength, low density, excellent oxygen barrier properties, and biocompatibility. These features make it a sustainable option for packaging and paper-based products. Additionally, nanocellulose composites find significant use in constructing materials, aqueous coatings, and other products, expanding its application scope.

Gather more insights about the market drivers, restrains and growth of the Nanocellulose Market

The United States represents the largest nanocellulose market in North America, contributing significantly to global revenue. A key driver is the country’s focus on health and sustainability, which has promoted the use of MFC (Microfibrillated Cellulose) and CNF (Cellulose Nanofibers) in functional foods, where nanocellulose enhances texture and stability. This trend boosts nanocellulose demand across food, beverage, and paper and pulp industries in the U.S., where consumers prioritize advanced sustainable products and eco-friendly, paper-based packaging solutions.

The pulp and paper industry uses nanocellulose to produce lighter, whiter paper with reduced environmental impact, thereby accelerating market growth. Nanocellulose’s biocompatible nature allows it to be used in healthcare for products such as biomedicines and personal hygiene items. Due to its high absorption properties, it is ideal for sanitary napkins and wound dressings, expanding its potential in healthcare. Ongoing research and development continue to stimulate market growth as well.

Application Segmentation Insights:

The pulp and paperboard sector led the nanocellulose market in 2022, holding over 25% of the revenue share. This dominance is driven by a shift in consumer preference toward packaging materials with minimal processing and no preservatives. Nanocellulose plays a vital role in the paper industry as a sustainable nanomaterial additive due to its strength, oxygen barrier performance, low density, mechanical stability, and compatibility with bio-based resources. These properties are valuable for creating eco-friendly and durable paper products.

Given the volume required in paper applications, the pulp and paperboard sector holds significant potential for nanocellulose usage. Nanocellulose enhances paper by improving coating quality, facilitating better absorption, and enabling the production of absorbent and hygienic products. It also produces smooth surfaces that enhance print quality, which is critical for industries needing high-quality prints.

Transparent nanocellulose paper is gaining attention in electronics. With qualities such as biodegradability, lightweight, affordability, and recyclability, it is being explored for applications in mobile devices, TVs, computers, solar cells, touch sensors, and even paper-based power generators. These unique qualities position nanocellulose as a potential alternative material in consumer electronics, offering a sustainable option in this field.

Data from the Confederation of European Paper Industries (Cepi) highlights that paper and board consumption rose by 5.8% between 2020 and 2021, while production increased by 6.1%, with paper mill operation rates jumping from 85.0% to 90.0%. Although the organization had anticipated reduced production and consumption levels during the pandemic, most mills continued to operate efficiently, with only minor reductions in output in low-demand phases. Given the rising demand for paperboard and packaging, nanocellulose consumption is anticipated to increase substantially during the forecast period, supporting sustainable development in the paper and packaging industries.

Order a free sample PDF of the Nanocellulose Market Intelligence Study, published by Grand View Research.

0 notes

Text

Nanocellulose Industry Dynamics, Growth Prospect and Consumption Analysis till 2030

The global nanocellulose market was valued at USD 351.5 million in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 20.1% from 2023 to 2030. This growth is driven by increasing demand across diverse applications, along with a shift toward bio-based products. Nanocellulose, derived from plant cellulose, exhibits unique properties such as enhanced efficiency in paper manufacturing, higher filler content, lighter weight, and improved freeness (which improves paper-making flow). These characteristics make nanocellulose highly suitable for creating a variety of sustainable, high-performance products.

In the paper industry, nanocellulose is a key bio-based additive due to its high strength, low density, excellent oxygen barrier properties, and biocompatibility. These features make it a sustainable option for packaging and paper-based products. Additionally, nanocellulose composites find significant use in constructing materials, aqueous coatings, and other products, expanding its application scope.

Gather more insights about the market drivers, restrains and growth of the Nanocellulose Market

The United States represents the largest nanocellulose market in North America, contributing significantly to global revenue. A key driver is the country’s focus on health and sustainability, which has promoted the use of MFC (Microfibrillated Cellulose) and CNF (Cellulose Nanofibers) in functional foods, where nanocellulose enhances texture and stability. This trend boosts nanocellulose demand across food, beverage, and paper and pulp industries in the U.S., where consumers prioritize advanced sustainable products and eco-friendly, paper-based packaging solutions.

The pulp and paper industry uses nanocellulose to produce lighter, whiter paper with reduced environmental impact, thereby accelerating market growth. Nanocellulose’s biocompatible nature allows it to be used in healthcare for products such as biomedicines and personal hygiene items. Due to its high absorption properties, it is ideal for sanitary napkins and wound dressings, expanding its potential in healthcare. Ongoing research and development continue to stimulate market growth as well.

Application Segmentation Insights:

The pulp and paperboard sector led the nanocellulose market in 2022, holding over 25% of the revenue share. This dominance is driven by a shift in consumer preference toward packaging materials with minimal processing and no preservatives. Nanocellulose plays a vital role in the paper industry as a sustainable nanomaterial additive due to its strength, oxygen barrier performance, low density, mechanical stability, and compatibility with bio-based resources. These properties are valuable for creating eco-friendly and durable paper products.

Given the volume required in paper applications, the pulp and paperboard sector holds significant potential for nanocellulose usage. Nanocellulose enhances paper by improving coating quality, facilitating better absorption, and enabling the production of absorbent and hygienic products. It also produces smooth surfaces that enhance print quality, which is critical for industries needing high-quality prints.

Transparent nanocellulose paper is gaining attention in electronics. With qualities such as biodegradability, lightweight, affordability, and recyclability, it is being explored for applications in mobile devices, TVs, computers, solar cells, touch sensors, and even paper-based power generators. These unique qualities position nanocellulose as a potential alternative material in consumer electronics, offering a sustainable option in this field.

Data from the Confederation of European Paper Industries (Cepi) highlights that paper and board consumption rose by 5.8% between 2020 and 2021, while production increased by 6.1%, with paper mill operation rates jumping from 85.0% to 90.0%. Although the organization had anticipated reduced production and consumption levels during the pandemic, most mills continued to operate efficiently, with only minor reductions in output in low-demand phases. Given the rising demand for paperboard and packaging, nanocellulose consumption is anticipated to increase substantially during the forecast period, supporting sustainable development in the paper and packaging industries.

Order a free sample PDF of the Nanocellulose Market Intelligence Study, published by Grand View Research.

0 notes

Text

Global Top 15 Companies Accounted for 58% of total Boiler Feedwater Pump market (QYResearch, 2021)

A boiler feedwater pump is a specific type of pump used to pump feedwater into a steam boiler. The water may be freshly supplied or returning condensate produced as a result of the condensation of the steam produced by the boiler. These pumps are normally high pressure units that take suction from a condensate return system and can be of the centrifugal pump type or positive displacement type.

According to the new market research report “Global Boiler Feedwater Pump Market Report 2023-2029”, published by QYResearch, the global Boiler Feedwater Pump market size is projected to reach USD 0.88 billion by 2029, at a CAGR of 4.6% during the forecast period.

Figure. Global Boiler Feedwater Pump Market Size (US$ Million), 2018-2029

Figure. Global Boiler Feedwater Pump Top 15 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Boiler Feedwater Pump include KSB, Grundfos, Flowserve Corporation, Ebara Corporation, TORISHIMA, Sulzer, DESMI, MTH Pumps, SanChang Pump, Speck, etc. In 2021, the global top 10 players had a share approximately 58.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Industrial Robotics Market - Forecast(2024 - 2030)

Industrial Robotics Market Overview

Industrial Robotics Market size was valued at $49.25 Billion in 2030, and it is estimated to grow at a CAGR of 11.9% during 2024-2030. The advent of numerous sorts of techniques committed to production control and the introduction of automation solutions are the key components of present production improvement policies. In addition, the increasing awareness of industrial robots has resulted in their deployment ranging from manufacturing to the healthcare industry. Moreover, this market is majorly driven by a surge in labor charges worldwide, which in turn has forced manufacturers to replace human labor with machines. Asia and Europe are the key growth regions of the world, with leading players, namely ABB, Fanuc, KUKA, Kawasaki, and the Yaskawa Electric Corporation being based out in the region. Collaborative Robots (Cobots) are revolutionizing the industry by working alongside humans without the need for safety cages. This trend is gaining momentum due to the increasing demand for automation in smaller factories and their expanding role in diverse industries. Cobots enhance flexibility, efficiency, and safety in manufacturing processes. Simultaneously, advancements in AI and IoT are driving a paradigm shift in industrial robotics. AI empowers robots to learn and adapt, making them more intelligent and versatile. The integration of IoT enables robots to communicate with each other and other systems, fostering enhanced collaboration and efficiency. This synergy is propelling the industrial sector towards Industry 4.0, where smart manufacturing processes redefine automation standards. As a result, the industrial robotics market is evolving with the widespread adoption of Cobots and the integration of AI and IoT, ushering in a new era of intelligent and collaborative automation. Hence these benefits are analyzed to drive the market in the forecast period 2024-2030.

Report Coverage

The report: “Industrial Robotics Market Forecast (2024-2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the Industrial Robotics Market.

By Category: Articulated Robot, Cylindrical Robot, Linear Robots, Cartesian & Gantry, Parallel Robot, SCARA Robot, Spherical Robots, Dual arm, Others

By Configuration: Mounted, Cobots/ Collaborative Robots)

By Components: (Manipulator, Sensor Devices, Robot Tooling, RCU - Robot Controller Unit

By payload: Up to 5KG, 5.1 to 10 KG, 10.1 to 15 KG, and More than 15 Kg

By End User: Automotive and Autoparts, Electrical & Electronics, Food and Beverages, Metal Fabrication and Palletization, Medical, Chemical, and Life Sciences, Others

By Geography: North America, South America, Europe, APAC, RoW.

Request Sample

Key Takeaways

APAC dominated the Industrial Robotics Market in 2023 with a share of 58%. High and early adoption of advanced technologies is set to boost the market growth. The strong financial position allows it to invest heavily in the adoption of latest tools and technologies for ensuring effective business operations.

Parallel robots are estimated to grow at a CAGR of 11.8% market. These Robots will be formed by connecting parallelograms to a common base and are also referred to as spider-like robots.

Robotic automation enables to achieve innovation in a quick and impactful way which can drive quantifiable benefits to the industrial automation industry.

Category - Segment Analysis

Parallel robots are estimated to grow at a CAGR of 11.8% market. These Robots will be formed by connecting parallelograms to a common base and are also referred to as spider-like robots. These robots are mostly used in the food industry, pharmaceuticals, and electronic industries. As they can do delicate/precise movements. Similarly, these robots will use three servo motors and are very high in speed and perfectly suited for light-duty tasks within small working zones. These are the main reasons which tends to be used for high-speed sorting and packaging in the food, pharmaceutical, and electronic industries. In addition, the delta robot market is anticipated to be driven by the trend of miniaturization in the manufacturing industry, moreover, smaller sizes of objects lead to increased challenges of various micro-assembly tasks, expected to increase the demand for delta robots. Moreover, technologically advanced machine vision 3D cameras are being integrated with delta robots to enhance their efficiency and accuracy. In addition, Delta robots with vision systems can perform lethargic, dull, and monotonous tasks at high speed and accuracy with minimum imperfections and scrap. This will improve the performance of delta robots and increase their adoption in end-user industries. Additionally, several companies are investing heavily in research and development activities for these robots. In 2022, Omron expanded its i4H SCARA lineup with food-grade robots, catering to the food and beverage and packaging industry. These new additions prioritize safe handling, ensuring compliance with the industry's stringent hygiene standards. Similarly, companies such as ABB, KUKA AG, and so on are investing heavily in the development of advanced robots in the forecast period 2024-2030.

Inquiry Before Buying

End User - Segment Analysis

Electrical & Electronics is the fastest-growing segment in the Industrial Robotics Market and is estimated to grow at a CAGR of 9.4%. The Electronics sector has also been slowly emerging as a major end-user for the Industrial Robotics Market with its higher adaptability due to growing digitalization. Since accuracy and precision are of important factors in an electronic production plant, thus due to ease of use, the electronics sector has been proactively adopting industrial robots, boosting its market growth. With the growing shift towards automation of manufacturing processes, industries like electrical and electronics have been widely deploying industrial robots to perform high-precision tasks, thus improving productivity standards. The usage of industrial robots helps electrical and electronics companies to automate almost every manual task while adding value to their business growth. Thus, growing adoption has been causing a positive impact on the market growth of industrial robots. With growing development of the electronics sector due to rising demands for electronic devices by consumers has been also acting as a major driver toward higher requirements for industrial robots. As industries are shifting towards smart technologies, industrial robots are gaining much popularity in the electronics sector due to their capabilities of performing tasks like integration and assembling of various small-sized components within electronic devices such as mobile phones, computers, and many others more efficiently within less time intervals. Since electronics manufacturers have to work under tight profit margins, industrial robots act as a cost-effective solution for improving the automation standards in their industry. Industrial Robots are used in applications ranging from cutting metal housings to assembling miniature components on boards, to applying adhesives and polishing surfaces, thus performing quality inspections and packing of finished products, at lower costs. Moreover, in the electrical and electronics sector, industrial robots are utilized mainly in assembly, screw tightening, electronic parts insertion as well as inspection processes as the robots are highly capable of sustaining harsh working environments. Such growing deployments help the industry to continue with their production process with quality preservation even at times of lack of skilled labor. Additionally, with innovations in the field of industrial robotics, lightweight and smaller robots are facing high demands in this sector.

Geography- Segment Analysis

APAC dominated the Industrial Robotics Market in 2023 with a share of 58%, followed by Europe and North America. High and early adoption of advanced technologies in countries such as India, and China is set to boost the market growth. The strong financial position allows it to invest heavily in the adoption of latest tools and technologies for ensuring effective business operations. The Chinese government’s ‘Made in China 2025’ policy aims at improving the competitiveness of Chinese companies through automation. According to the Ministry of Industry and Information Technology, in 2022, China's industrial robot output grew by 5.4% to 222,000 units in the first half of the year. Service robot production surged by 9.62% to 3.53 million units. China maintained its global lead in industrial robot installations in 2022, capturing over 50% of the market share. Moreover, the automotive industry is the major adopter of industrial robotics with a wide variety of applications and thus the growing automotive industry in this region will propel the market. Companies such as BAIC Motors, and Changan Automobile Group, have been investing heavily in the adoption of robotics in the forecast period 2024-2030. In addition, the launch of ‘Make in India’ has increased the focus on the Indian manufacturing sector, which is set to be among the fastest-growing markets in the APAC region as well as globally. The manufacturing sector’s growth output has increased and is projected to exhibit high growth. For instance, the government of India has committed to investing more than $13 billion in industrial robotic R&D. The government estimates the manufacturing sector value could reach $1 trillion by 2025. Major companies such as GE, Bosch, and Panasonic are planning to invest in the country which would boost India’s economic growth.

Schedule a Call

Drivers – Industrial Robotics Market Robotic Process Automation and Artificial Intelligence Automation Spending Driving the Growth of Industrial Robots

The Robotics process automation landscape has changed in the past couple of years and has evolved from an emerging factor for the industrial robotics industry. Robotic automation enables to achieve innovation in a quick and impactful way which can drive quantifiable benefits to the industrial automation industry. Across the globe, automation companies are investing lots of capital to develop and innovate new technology in research and development. In 2023, ABB committedto investing $280 million in Sweden's Västerås to boost its European Robotics hub, catering to rising demand for AI-driven collaborative and industrial robots. The expanded campus, aligned with ABB's local production strategy, aims to enhance capacity by 50%, meeting evolving market needs amid supply chain challenges. Similarly, companies such as Mitsubishi Electric Corp, Ellison, and so on are investing heavily for the development of industrial robots in the forecast period. Some of the key factor affecting robotic process automation includes process with higher automation potential, with higher headcount reduction that offer a great cost saving to the manufacturers. Robotic Process Automation (RPA) recurring costs including licensing, hosting, and monitoring vary significantly by vendor and type of solution, the lower the recurring cost for RPA, the higher the cost saving. Various service providers are implementing RPA tools in various areas of end-user processes focusing on achieving consistency, risk reduction, and cost reduction factors.

Rising Labor Costs Amidst the Aging Workforce to Boost the Industrial Robots Demand

The labor cost is highly significant in the total industrial operating cost, making generally 62%-65% of the total cost. In majority of the cases, manual jobs typically consist of two categories of staff: direct and indirect where industries cover an area of more than 2, 00,000 square feet. Direct staff is responsible for executing the process while indirect staff is for the back-end support for direct staff. The presence of both direct and indirect staff coupled with department managers presents a crucial cost in operating a warehouse. For instance, according to the U.S. Bureau of Labor Statistics' Employment Cost Index, wages and salaries rose by 4.3% in the 12 months ending December 2023, while benefit costs increased by 3.8% over the same period. Moreover, according to the U.S. Bureau of Labor Statistics,total nonfarm payroll employment increased by 353,000 in January, maintaining the momentum from December's gain of 333,000. Throughout 2023, employment rose by an average of 255,000 jobs per month. As average hourly earnings will rise further amidst the rising global inflation with weekly hours to remain constant or decline in the coming years, the operating costs are bound to advance. Apart from this, the developing nations have seen constant growth in the aging workforce resulting in issues related to safety, quality control, and productivity. Thus, the automation of industries has become a notable means to tackle the rising wages and workforce age. This has resulted in industrial operators relying upon robotics to provide a convenient and efficient way of reducing operational costs while simultaneously maintaining productivity at optimum levels.

Challenges – Industrial Robotics Market Limited Flexibility of Robots for Handling Skus Posing Challenge for Industrial Robotics

The dawn of electronic commerce enabled by the increasing accessibility to mobile devices has resulted in consumers shopping online from a multitude of merchandisers. As the delivery to the consumer in working time of 3-5 days is crucial for retailers, it has resulted in multi-varied stock-keeping units (SKUs) and caseloads. This scenario often becomes challenging in the Food & Beverage sector where companies need to address the consumer demand at a much faster pace. The robots utilized in the process industries are simply robots used in manufacturing operations that only require limited flexibility in handling pallets. Although over time, robots have developed to handle the SKUs with greater precision and accuracy but still require a great deal of evolution in handling mixed SKUs with consistent speed and accuracy without damaging the product. Hence these kinds of challenges hamper the market growth in the forecast period 2024-2030.

Buy Now

Industrial Robotics Market Landscape

Product launches, acquisitions, Partnerships, and R&D activities are key strategies adopted by players in the industrial robotics market. Industrial Robotics' top 10 companies include Fanuc, KUKA AG, ABB Group, Yaskawa Electric Corporation, EPSON, Kawasaki Heavy Industries, Ltd, Mitsubishi Electric Corporation, Omron Adept Technology, Staubli, Denso Corporation, and Automation among others.

Ø In November 2023, ABB Robotics introduced the IRB 930 SCARA robot, enhancing pick-and-place and assembly tasks in electronics, automotive, and renewable energy sectors. With a 10% increase in throughput and 200% stronger push-down capability, it optimizes productivity and quality, addressing evolving industry needs for heavier workpieces and force-intensive operations.

Ø In November 2023, Yaskawa Electric Corporation has unveiled the MOTOMAN NEXT series, pioneering adaptive robotics in the industrial sector. With five models boasting payloads ranging from 4kg to 35kg, these robots possess autonomous adaptivity, a groundbreaking feature for making environment-based judgments, driving innovation in industrial automation

Ø In April 2023, Doosan Robotics introduced the NSF-certified E-SERIES, a line of collaborative robots tailored for the food and beverage sector. This launch expands their product range with 13 new offerings, marking a significant milestone in the cobot market.

#Industrial Robotics Market#Industrial Robotics Market Share#Industrial Robotics Market Size#Industrial Robotics Market Forecast#Industrial Robotics Market Report#Industrial Robotics Market Growth

0 notes

Text

Capacitive Sensors Market Analysis 2023 Dynamics, Players, Type, Applications, Trends, Regional Segmented, Outlook & Forecast till 2032

The global Capacitive Sensors market size was valued from at USD 29,056.76 million in 2023 to USD 60,615.07 million in 2033, and is expected to expand at a CAGR of 7.63% during the 2024-2033.

The competitive analysis of the Capacitive Sensors Market include a comprehensive analysis of market trends, competitor landscape, consumer behavior, and potential opportunities. It should cover key demographics, market size, growth projections, and risk factors. The report should also highlight the methodology used for data collection and analysis, presenting findings with visual aids such as charts and graphs. Additionally, recommendations and strategic insights for stakeholders to make informed decisions are crucial. The report should be concise, well-organized, and provide actionable information for businesses aiming to navigate the market effectively.

Key Function:

A Capacitive Sensors market research report serves to assess market dynamics, identify opportunities, and mitigate risks for businesses. It analyzes consumer preferences, competitor strategies, and economic trends. The report facilitates informed decision-making by presenting data on market size, growth potential, and emerging patterns. It aids in product development, pricing strategies, and market positioning. Additionally, market research reports help businesses understand their target audience, enhance marketing efforts, and optimize resource allocation. By offering actionable insights, these reports empower organizations to stay competitive, adapt to changing market conditions, and foster sustainable growth in a dynamic business environment.

Key Dynamics:

Market research reports capture vital dynamics, including market trends, competitive analysis, and consumer behavior. They reveal market size, growth projections, and regional nuances. SWOT analysis examines internal strengths and weaknesses, along with external opportunities and threats. Consumer insights delve into preferences, impacting product development and marketing strategies. The competitive landscape unveils key players, strategies, and market shares. Regulatory factors and industry challenges are explored, aiding risk assessment. Timely and accurate information empowers businesses to adapt strategies, capitalize on opportunities, and navigate challenges, ensuring informed decision-making and sustained competitiveness in dynamic markets.

Receive the FREE Sample Report of Capacitive Sensors Market Research Insights @ https://stringentdatalytics.com/sample-request/capacitive-sensors-market/12363/

Market Segmentations:

Global Capacitive Sensors Market: By Company • Synaptics • Microchip Technology • Cypress Semiconductor • STMicroelectronics • NXP Semiconductors • Texas Instruments • Renesas Electronics • Infineon Technologies • Analog Devices • Cirque Global Capacitive Sensors Market: By Type • Touch Sensors • Motion Sensors • Position Sensors • Others Global Capacitive Sensors Market: By Application • Consumer Electronics • Food & Beverages • Oil & Gas • Healthcare • Automotive • Defense • Industrial Manufacturing • Others

Regional Analysis of Global Capacitive Sensors Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Capacitive Sensors market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Capacitive Sensors Market Research Report @ https://stringentdatalytics.com/purchase/capacitive-sensors-market/12363/

Reseason To Purchase:

Purchasing a market research report is essential for businesses seeking a competitive edge. It provides in-depth insights into market trends, consumer behavior, and competitor strategies. This knowledge empowers informed decision-making, mitigates risks, and identifies growth opportunities. Market reports streamline strategic planning, enhance product development, and optimize resource allocation. For businesses entering new markets, these reports offer critical data for successful market entry. Additionally, the comprehensive analysis instills investor confidence, ensures regulatory compliance, and saves time compared to independent research efforts. Ultimately, investing in market research reports is a strategic move that enhances efficiency, minimizes uncertainties, and fosters sustainable business growth.

Our More Reports:

1. Emission Monitoring System Market

2. Synchronous Condenser Market

3. Nano GPS Chip Market

About Stringent Datalytics

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Reach US

Stringent Datalytics

+1 346 666 6655

Social Channels:

Linkedin | Facebook | Twitter | YouTube

0 notes

Text

Palletizer - SWOT analysis, Growth, Share, Size and Demand outlook by 2033

A palletizer is a machine that helps in the packaging of products on a pallet. It is mainly used in the food and beverage industry, where it helps in the packing of products like fruits, vegetables, and meat. The machine is also used in the pharmaceutical and cosmetics industry. It helps in the packing of products like drugs and cosmetics. The machine is also used in the packaging of electronic products.

Unlock Growth Potential in Your Industry – Get Your Sample Report Now@https://www.globalinsightservices.com/reports/palletizer-market/?utm_source=PranaliP-organic

Key Trends

There are three key trends in palletizer technology:

1. The first is the trend towards higher throughputs. This is driven by the need to increase efficiency and productivity in manufacturing and distribution operations.

2. The second trend is towards more flexible palletizing systems. This is driven by the need to accommodate a wider range of product sizes and shapes, as well as the need to change palletizing configurations quickly and easily to adapt to changing production requirements.

3. The third trend is towards more intelligent palletizing systems. This is driven by the need to improve safety and reduce operator error. Intelligent palletizing systems use sensors and other forms of feedback to ensure that products are correctly positioned on the pallet and that the palletizing process is proceeding smoothly.

0 notes

Text

Title: "Maximizing Success: Unleashing the Potential of Supply Chain Data"

Originally Published on: SpendEdge |Optimising Supply Chain Data: Mastering the Flow for Success

Navigating Towards Success: Optimising Supply Chain Data

In today's ever-changing business landscape, optimizing supply chain data stands as a cornerstone for maintaining competitiveness. This essay explores the pivotal role of supply chain data optimization and reveals strategies to steer towards sustainable success.

The Significance of Supply Chain Data Optimization

Enhanced Visibility Through the utilization of RFID tracking and real-time inventory management systems, a multinational electronics manufacturer gains comprehensive visibility across its global operations. This proactive approach empowers the company to anticipate disruptions, fine-tune inventory levels, and ensure timely deliveries to customers.

Improved Efficiency Implementing advanced data analytics and automation technologies, an e-commerce retailer streamlines supply chain processes, resulting in reduced order processing times, minimized shipping costs, and heightened customer satisfaction.

Demand Forecasting Accuracy Leveraging machine learning algorithms, a global food and beverage company enhances its demand forecasting models, achieving greater precision in predicting consumer demand and optimizing inventory levels.

Enhanced Collaboration Close collaboration with suppliers and logistics partners allows a large car manufacturer to streamline production workflows and reduce lead times, fostering operational excellence across the supply chain network.

Strategies for Optimizing Supply Chain Data

Data Standardization Adopting industry-standard data exchange protocols ensures seamless integration and interoperability across the supply chain ecosystem.

Leveraging Advanced Analytics Embracing predictive modeling and artificial intelligence empowers organizations to extract actionable insights and adjust inventory levels in response to changing market dynamics.

Real-time Monitoring and Tracking Deployment of IoT-enabled sensors and GPS tracking systems enables real-time monitoring of goods movement, facilitating proactive issue detection and intervention.

Collaboration and Data Sharing Establishing collaborative partnerships and leveraging cloud-based platforms facilitate secure data sharing and information exchange throughout the supply chain network.

Continuous Improvement Fostering a culture of continuous improvement and data-driven decision-making enables organizations to drive ongoing enhancements in supply chain processes, maintaining a competitive edge in the market.

Conclusion

Optimizing supply chain data is essential for organizations to thrive in today's dynamic business environment. By harnessing the power of supply chain data and implementing strategic initiatives, businesses can pave the way for sustainable success and maintain a leading position in the global marketplace.

Contact us.

0 notes

Text

New Research Report On Industrial Robotics Market is Going to Boom by Size, Share, Scope and Forecast-2030

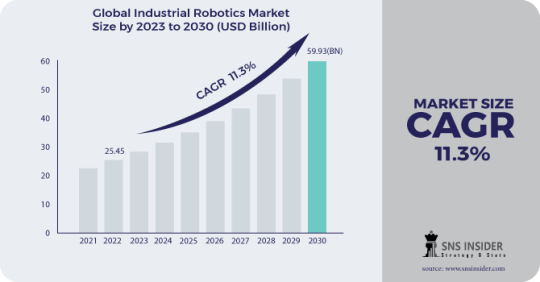

Industrial Robotics Market is going to reach USD 59.93 billion by 2030 and grow at a CAGR of 11.3% over the forecast period 2023-2030.

The most recent Industrial Robotics study evaluates global and regional market estimates and forecasts for all research segments. This study examines market trends, leading companies, supply chain trends, technological advances, key breakthroughs, and future strategies. Market figures were compiled using a combination of primary and secondary sources. Sales revenue from all of the study's specified segments and sub-segments are used to calculate market size. The market sizing analysis employs both top-down and bottom-up approaches for data validation and accuracy checks.

The study uses historical market data to estimate revenue. Other aspects of the industry, such as the supply chain, downstream buyers, and sourcing strategy, have been investigated in order to provide a complete and in-depth picture of the market. Customers who purchase the Industrial Roboticsmarket report will also be subjected to a market positioning analysis, which will take into account factors like target consumer, brand strategy, and pricing strategy. In addition, the study report computes current and prior market values in order to forecast possible market management over the forecast period.

Download Sample Copy of Report: https://www.snsinsider.com/sample-request/1058

Market Segmentation

The Industrial Robotics market segment analysis will assist in determining how each segment will affect market growth in the coming years. In order to determine the market's true potential, the research report also examines all market classifications and sub-segments. In today's global economy, the dynamic nature of the corporate environment is increasing demand for business experts who can keep up with current market conditions.

By Application

Palletizing

Assembling

Welding

Material Handling

Painting

By Types

6-Axis Robots

SCARA

Cartesian

Articulated

Redundant

Delta

Dual-Arm and Parallel

By End-user

Entertainment

Electronics

Automotive

Rubber & Plastic

Food & Beverage

Pharmaceuticals

By Component

Robotic Arms

End Effectors

Drive Units

Robot Accessories

Controllers

Vision Systems

Sensors

Get Exclusive Discout on this Report: https://www.snsinsider.com/discount/1058

Major Questions Answered in the Report

What are the key trends influencing the Industrial Robotics market's growth?

What are the primary strategies used by leading organizations to control a sizable portion of the global market?

How has the rapidly changing business environment of the market influenced growth?

What are the primary macroeconomic factors driving market growth?

Competitive Outlook

For each of the market's top competitors, the research includes current business profiles, gross margins, selling price, sales income, sales volume, product specs with images, and contact information. In the report's conclusion, a descriptive section highlights the feasibility of new projects that may succeed in the global market in the near future, as well as the overall scope of the global market in terms of investment feasibility in various segments of the Industrial Robotics market.

Top Keyplayers:

ABB, DÜrr, FANUC, YASKAWA, KUKA, Denso Corporation, Mitsubishi Electric, Kawasaki Heavy Industries, Universal Robots A/S, NACHI-FUJIKOSHI, Panasonic Corporation, Rockwell Automation, Inc., Bosch GmbH, Yaskawa Electric Corporation, Toshiba Corporation, Seiko Epson

About US:

SNS Insider is a frontrunner in global market research and consulting. We empower clients with the insights they need to navigate evolving landscapes.

Our team leverages a global network to deliver cutting-edge market data, consumer trends, and actionable insights. Through surveys, focus groups, and video discussions, we provide the information you need to make confident decisions.

We are committed to delivering reliable data across a wide range of industries. Recognized as a global leader, we have the expertise to design and implement tailored research programs, from surveys to focus groups, catering to virtually any sector.

Key improvements:

Stronger verbs and adjectives: uses words like "frontrunner," "empower," "navigate," "cutting-edge," to create a more dynamic and confident tone.

Focus on benefits: emphasizes how SNS Insider helps clients make confident decisions and navigate change.

Conciseness: streamlines the text while maintaining key information.

Actionable language: highlights the "tailored" research programs offered by SNS Insider.

Contact Us: Akash Anand – Head of Business Development & Strategy [email protected] Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

0 notes

Text

Vision Sensor Market Analysis, Size, Share, Trends, Growth and Forecast 2030

The Insight Partners is excited to announce the release of groundbreaking findings in its latest market research report, "Overview of Vision Sensor Market Share, Size, and Forecast | 2030". The panoramic research, conducted by our team of seasoned experts, provides valuable insights on the Vision Sensor market forecast, key trends, drivers, challenges, and opportunities within the Vision Sensor market.

The report unveils a detailed Vision Sensor market analysis of the current Vision Sensor market size and projects future growth trends based on historical data and market dynamics. At our research firm, we aim to help investors by providing both qualitative and quantitative data through this study. This global Vision Sensor market report, competitive landscape, risks and barriers to entry for market players, sales channels, distributors, and Porter's Five Forces Analysis.

Businesses must have a firm understanding of the market, before making significant investments. It makes financial sense to allocate a modest portion of your company's expenditure to reliable market research. With a team of well-versed experts, we deliver actionable insights and strategic intelligence to help businesses navigate the complexities of the market landscape. Our commitment to excellence and innovation sets us apart as a trusted partner for organizations seeking a competitive edge.

Why Opt for Our Vision Sensor Market Research Report?

Our researchers employ a multi-faceted approach to data collection, utilizing primary and secondary sources to ensure the breadth and depth of information.

Our researchers analyze consumer behavior, market trends, and brand positioning methods. Every piece of data undergoes a rigorous validation process to ensure accuracy and reliability.

We prioritize clarity and conciseness in our reporting, presenting findings in a format that is easily digestible for our clients.

We develop customized analytical models tailored to the specific nuances of the Vision Sensor market, allowing us to uncover hidden patterns and trends.

The report answers the following questions:

What are the primary factors driving the Vision Sensor market growth during the projected period?

What region is likely to witness the most substantial growth?

Which Vision Sensor market trend will take center stage in the coming years?

What are the key challenges hindering the Vision Sensor market expansion?

Emerging Trends: Our report uncovers emerging trends that are poised to reshape the Vision Sensor market equipping businesses with the foresight to stay ahead of the competition.