#Flexible Paper Packaging Demand

Explore tagged Tumblr posts

Text

More than US$ 79.1 billion in Revenues are Projected to be Accounted for by Flexible Paper Packaging Market by End of 2026

More than US$ 79.1 billion in Revenues are Projected to be Accounted for by Flexible Paper Packaging Market by End of 2026

The global flexible paper packaging market size is anticipated to increase from USD 64.4 billion in 2021 to USD 79.1 billion by 2026 at a CAGR of 4.2% from 2021 to 2026, according to the report “Flexible Paper Packaging Market by Packaging Type (Pouches, Roll Stock, Shrink Sleeves, Wraps), Printing Technology (Rotogravure, Flexography, Digital Printing), embellishing type (Hot Coil, Cold Coil),…

View On WordPress

#Asia Pacific Flexible Paper Packaging Market Share#bakery flexible packaging paper market Trends#china flexible packaging market#consumer goods packaging trends#COVID-19 Impact on Flexible Paper Packaging Market#flexible mailing envelopes#Flexible Packaging#Flexible Packaging Market#flexible packaging paper#Flexible Packaging Paper Market#flexible packaging pouches manufacturer#Flexible Paper Packaging#Flexible Paper Packaging Industry#Flexible Paper Packaging Market#Flexible Paper Packaging Demand#Flexible Paper Packaging Market Size#Glassine Paper Market Growth#Global Flexible Paper Packaging Market#Greaseproof Paper Companies#heat sealable flexible packaging paper#paper based flexible packaging#paper flexible packaging#Paper for Package of Medicine#Paper Packaging#Paper Packaging Market#Paper-Based packaging#Parchment Paper Manufacturers#Pharmaceutical Packaging Paper#Sulfite Paper Industry Insight#wrapping paper sheets

0 notes

Text

Role models: circular economy examples in manufacturing

Circular manufacturing or circular economy is a means of production, distribution, and consumption where producers bring materials from end-of-life goods back into the economy through reuse, recycling, and recovery instead of disposing of them as waste.

1. Stora Enso Sunila Mill: a pulp-based refinery plant

Stora Enso Sunila Mill in Finland was the first in the world to extract lignin in a pulp-based refinery plant. The pulp and paper industry is one of the largest manufacturing sectors in the world. It uses 12-15 percent of the wood from forests, which could double by 2050, according to the World Wildlife Fund (WWF).

To make the most of the wood they use, Stora Enso Sunila Mill, which owns one of the most extensive private forests in the world, has adopted the circular economy by reusing, recycling, and recovering materials at the mill.

The business sources pulp from their sustainably managed private forests to make paper and packaging to replace plastic. They also produce circular industrial products that are alternatives to fossil fuel-based non-renewable products

2. ReSolved Technologies: Closed-loop plastic recycling

A Dutch startup, ReSolved Technologies, has developed a closed-loop recycling solution for engineering plastics in electronic devices and automobiles.

Engineering plastics are complex and contain additives that make recycling difficult. 95 per cent of these plastics are downcycled, incinerated, or landfilled.

ReSolved Technologies’ solvent-based recycling technique removes additives like fillers, flame retardants, and colourants, and separates different types of plastics. The recycled plastics are good quality and they can be used to make engineering plastics again. This technology can be used to complement existing mechanical recycling facilities for plastics.

ReSolved Technologies closes the materials loop by turning electronic waste into new electronic devices. Their plastic recycling technology prevents the extraction of fossil fuels for new production and reduces plastic waste and pollution problems.

3. Batch.Works: Smart and circular manufacturing

Another Dutch startup, Batch.Works, offers 3D printing for “Circular Manufacturing as a Service (CmaaS)” using AI-driven factories.

The company uses circular materials like recycled plastics or agricultural waste from traceable sources to make new parts for the manufacturing industry. They offer smart 3D printing to meet on-demand digital production for just-in-time manufacturing, thus reducing overproduction and waste.

The company has a take-back policy for its products to recycle materials and leverages digital warehousing services from third parties for flexibility and scaling. Its novel manufacturing model creates short supply chains to reduce transportation costs and increase agility.

The short supply chain and digital warehousing cut transport pollution and emissions, and small-batch production makes manufacturing sustainable and cost-effective for client firms.

And many more examples in the link:

#solarpunk#solarpunk business#solarpunk business models#solar punk#startup#reculture#circular manufacturing#circular economy#industrial ecosystems

6 notes

·

View notes

Text

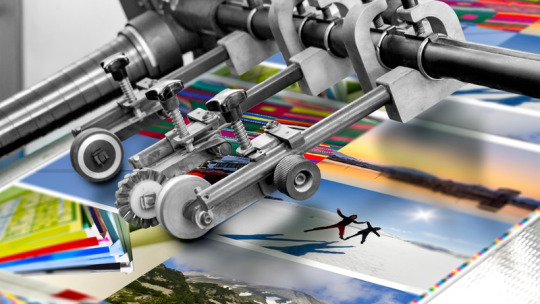

What is the Demand for the Printing Industry?

The printing industry has undergone a profound transformation in recent years, adapting to the challenges and opportunities presented by the digital age. Once considered a traditional and stable sector,

the printing industry is now a dynamic field shaped by technological advancements, changing consumer behaviors, and evolving market demands. This article explores the current state of the printing industry, delving into the demand factors that drive its growth and adaptation.

I. Historical Perspective:

To understand the current demand for the printing industry, it is essential to trace its historical evolution. Traditionally, printing was dominated by analog processes, including letterpress and offset printing. These methods were instrumental in disseminating information through newspapers, magazines, and books. However, the advent of digital technologies, particularly the internet, marked a paradigm shift in communication and information dissemination.

II. Technological Advancements:

a. Digital Printing: The rise of digital printing technologies has been a game-changer for the industry. Digital printing allows for shorter print runs, variable data printing, and quicker turnaround times. This flexibility has made it more cost-effective for businesses to produce personalized and on-demand print materials, catering to niche markets and individualized consumer preferences.

b. 3D Printing: In recent years, 3D printing has emerged as a revolutionary technology with implications across various industries. While not traditionally associated with the printing sector, 3D printing enables the production of three-dimensional objects layer by layer. This technology has found applications in prototyping, manufacturing, healthcare, and even construction, expanding the horizons of the printing industry.

III. Market Trends and Dynamics:

a. Packaging: The demand for printed packaging has witnessed substantial growth, driven by the e-commerce boom and the increasing need for visually appealing product packaging. Printers play a crucial role in creating eye-catching labels, boxes, and packaging materials that enhance brand visibility and influence consumer purchasing decisions.

b. Sustainable Printing: Environmental concerns have become a significant factor influencing consumer behavior and corporate practices. The printing industry has responded by embracing sustainable practices, including the use of eco-friendly inks, recycled paper, and energy-efficient printing processes. Sustainable printing has become a key selling point for businesses aiming to reduce their ecological footprint.

c. Personalization: Consumers today seek personalized experiences in all aspects of their lives, including print materials. The printing industry has capitalized on this trend by offering customized products, such as personalized books, calendars, and promotional materials. Variable data printing allows for the incorporation of individualized content, addressing the growing demand for unique and tailored printed items.

IV. Print vs. Digital: Finding the Balance

a. Coexistence of Print and Digital: While digital technologies have transformed communication, print media has not become obsolete. Instead, there is a growing recognition of the complementary roles played by print and digital formats. Print materials offer a tangible and tactile experience that digital content cannot replicate. Businesses and marketers are increasingly adopting integrated strategies that leverage both print and digital channels to reach a broader audience.

b. Print in the Digital Marketing Mix: Printed materials continue to hold a significant place in marketing strategies. Direct mail, brochures, and promotional materials remain effective in conveying a brand’s message and establishing a physical connection with consumers. The unique qualities of print, such as texture and color depth, contribute to creating memorable and impactful marketing collateral.

V. Challenges and Opportunities:

a. Economic Factors: The printing industry is not immune to economic fluctuations. Economic downturns can lead to reduced advertising budgets, impacting the demand for printed marketing materials. On the other hand, economic recovery and growth can stimulate business activities, prompting increased investment in print advertising and promotional campaigns.

b. Digital Competition: The rise of digital alternatives poses a challenge to the printing industry. Online platforms, social media, and digital advertising offer cost-effective and highly targeted ways to reach audiences. Printers must adapt by offering unique value propositions, such as high-quality printing, specialty finishes, and personalized services that differentiate them from digital alternatives.

c. Technological Disruption: While technological advancements present opportunities, they also pose challenges for traditional printing methods. As 3D printing and digital technologies continue to evolve, printers must invest in updating their equipment and skills to stay competitive. Embracing automation and artificial intelligence in print workflows can enhance efficiency and reduce costs.

VI. Future Outlook:

a. 3D Printing’s Role: The integration of 3D printing into mainstream manufacturing processes is expected to reshape the printing industry further. From producing prototypes to creating custom products on-demand, 3D printing holds the potential to revolutionize the way goods are designed and manufactured.

b. Augmented Reality (AR) and Print: Augmented Reality has the potential to merge the physical and digital worlds, offering interactive and immersive experiences. Print materials augmented with AR can provide additional layers of information, making them more engaging for consumers. This integration may open new avenues for creativity and innovation in the printing industry.

c. Continued Emphasis on Sustainability: As environmental concerns continue to gain prominence, the printing industry’s commitment to sustainability is likely to grow. Printers may increasingly adopt eco-friendly practices, and consumers may show a preference for products with environmentally conscious printing processes.

Conclusion:

The printing industry‘s demand is intricately tied to technological advancements, market trends, and evolving consumer preferences. While challenges persist, the industry has demonstrated resilience by embracing innovation and adapting to changing dynamics.

As we move forward, the coexistence of traditional and digital printing methods, coupled with a commitment to sustainability and personalized experiences, will shape the future of the printing industry. The key lies in finding the right balance between technological innovation and timeless print qualities to meet the diverse demands of a rapidly evolving landscape.

#3d printing#3d sign#3d signage#signage#branding#poster#printing company#print on demand services#print on demand#digital art#pod#print on demand company#print on demand in India

3 notes

·

View notes

Text

Investigating Auckland's High-Quality Printing Services

Businesses and people alike need dependable printing services in the dynamic city of Auckland, where creativity and innovation coexist. Auckland provides various printing choices to meet various demands, including digital and offset printing. The printing business in Auckland provides everything you could need, whether you are searching for environmentally friendly options or top-notch quality. In this blog article, explore Auckland printing services and illustrate the benefits of both digital and offset printing techniques.

Printing services in Auckland are well known for their outstanding quality and meticulousness. Some printing firms focus on providing your unique demands, whether you need large-scale banners, business cards, brochures, or promotional items. These services provide a wide variety of choices, enabling you to choose the best printing method for your project.

Due to its effectiveness, adaptability, and short turnaround times, Digital Printing Service Auckland have greatly increased in popularity in recent years. This technique applies the design to different printing mediums using digital data. Digital printing services in Auckland provide affordable options with brilliant colors and precise resolution, whether you need a short run of flyers or customized invites. It is the perfect option for firms needing shorter print runs or frequent design changes due to its ability to print on demand.

Offset printing services in Auckland are still dependable for jobs that call for exceptional quality and accuracy. You may obtain remarkable color accuracy, consistency, and sharpness using offset printing services in Auckland. This technique transfers ink from a printing plate to a rubber blanket and subsequently to the target surface. Large-scale projects like magazine publishing, business brochures, and packaging materials are perfect for offset printing. It is a popular option for many firms because of the precise attention to detail and the capacity to employ various printing materials.

Eco-friendly printing alternatives are now necessary when environmental sustainability is an increasing issue. Many printing companies in Auckland understand how crucial it is to reduce their environmental effect. These environmentally friendly printing services help create a cleaner future using recycled paper, soy-based inks, and energy-efficient printing techniques. Investigate Auckland's eco-friendly printing solutions if you value sustainability and wish to reduce carbon impact.

Digital and Offset Printing companies in Auckland give the best by combining the benefits of these printing. This hybrid method combines the remarkable quality and versatility of offset printing with the flexibility and speed of digital printing. These services handle various assignments, ensuring that each print work gets the consideration it requires.

Auckland offers various printing solutions that may be adjusted to fit various needs. Auckland's printing sector has the know-how to make your ideas come to life, whether you pick digital printing for its quickness and flexibility or offset printing for its unsurpassed quality. In addition, many printing businesses in Auckland use sustainable techniques to reduce their environmental effect in response to the growing demand for eco-friendly operations. As you peruse Auckland's printing options, consider your project's particular requirements, and choose a printing company that shares your vision and produces top-notch outcomes.

2 notes

·

View notes

Text

Why Is Thermal Transfer Ribbon a Must-Have for High-Quality Label Printing?

In today’s fast-paced business environment, high-quality and durable labels are essential for product identification, branding, and inventory management. Whether you’re in retail, manufacturing, healthcare, or logistics, the need for professional-grade labels has never been greater. One of the key components that ensure the quality and longevity of your labels is the thermal transfer ribbon. But what exactly is this product, and why should your business consider using it for your label printing needs? Let’s explore the importance of thermal transfer ribbons in the world of label printing.

What Is a Thermal Transfer Ribbon?

A thermal transfer ribbon is an essential part of the thermal transfer printing process, which uses heat to transfer ink from the ribbon onto the label material. Unlike direct thermal printing, which requires heat-sensitive paper, thermal transfer ribbons feature an ink-coated layer that melts under the heat of the printer's printhead and bonds with the label surface.

These ribbons are typically made from different materials—wax, resin, or a blend of both—which determine the quality and durability of the print. Depending on your needs, choosing the right type of ribbon can greatly affect the performance and longevity of your labels.

Why Should You Use Thermal Transfer Ribbon for Your Labeling?

Durable and Long-Lasting Prints Labels printed with thermal transfer ribbons are highly durable. The ink is resistant to fading, scratching, smudging, and even exposure to chemicals, heat, or moisture. This makes thermal transfer ribbons ideal for products and labels that will be subjected to harsh conditions. Industries like manufacturing, logistics, and healthcare rely on these ribbons to create labels that withstand time and wear, ensuring the labels remain intact throughout the product’s lifecycle.

Superior Print Quality One of the key advantages of thermal transfer ribbons is their ability to produce high-resolution, sharp prints. Whether you’re printing small barcodes, fine text, or complex graphics, the clarity and detail are unmatched. The precision of the print ensures that every label looks professional, making it easier to maintain brand consistency and readability, even at smaller sizes.

Cost-Effective Solution for High-Volume Printing While thermal transfer ribbons may have a slightly higher upfront cost than direct thermal printing, they are a cost-effective solution for high-volume or long-term label printing. Once the printer is set up, you only need to replace the ribbon as needed, unlike pre-printed labels, which require storage, handling, and inventory. The flexibility to print labels on demand also helps reduce waste and unnecessary costs associated with excess label inventory.

Wide Compatibility Thermal transfer ribbons are compatible with a wide variety of label materials. Whether you're working with paper, synthetic labels, or even polyester films, thermal transfer ribbons can adapt to the surface and deliver a high-quality print. This versatility ensures that businesses can print a range of labels—product packaging, shipping labels, and barcodes—on different materials, all using the same printer.

Types of Thermal Transfer Ribbons and Their Applications

Not all thermal transfer ribbons are the same. Choosing the right ribbon for your label material and environmental conditions is crucial for getting the best print quality and durability. Here are the most common types of thermal transfer ribbons:

Wax Ribbons: Wax ribbons are the most economical choice and are designed for printing on paper labels. While they offer good print quality, wax ribbons are more susceptible to fading and wear in harsh environments. These ribbons are perfect for basic labeling applications like retail price tags and inventory labels.

Resin Ribbons: Resin ribbons provide the highest level of durability and print quality. These ribbons are perfect for synthetic labels, as they can withstand exposure to chemicals, abrasions, and extreme temperatures. Industries such as automotive, electronics, and healthcare often rely on resin ribbons for their rugged and long-lasting labels.

Wax/Resin Blend Ribbons: A combination of both wax and resin, these ribbons offer a balance between cost-effectiveness and durability. Wax/resin blend ribbons are perfect for businesses that require labels that resist fading and scratching but don’t necessarily need the extreme durability of resin ribbons. These ribbons are commonly used in logistics, warehousing, and product packaging.

Industries That Benefit from Thermal Transfer Ribbons

Retail: Retailers can rely on thermal transfer ribbons to print price tags, product labels, and barcodes that are clear, durable, and easy to scan. The ability to print on-demand also helps eliminate the need for pre-printed labels, reducing waste and cost.

Logistics and Shipping: For businesses that need accurate and readable shipping labels and barcodes, thermal transfer ribbons are a must. The durability of the prints ensures that they remain legible throughout the shipping process, no matter the conditions.

Healthcare: In healthcare, accurate and durable labeling is crucial for compliance and patient safety. Thermal transfer ribbons provide clear, legible prints that withstand exposure to chemicals, UV light, and wear, making them perfect for pharmaceutical packaging and medical device labels.

Manufacturing: For manufacturers, thermal transfer ribbons are used to print product identification labels, barcodes, and regulatory labels. The ability to print durable, long-lasting labels helps ensure products are clearly marked throughout the production process and beyond.

How to Choose the Right Thermal Transfer Ribbon for Your Needs

When selecting a thermal transfer ribbon for your business, consider the following factors:

Label Material: Make sure the ribbon type is compatible with the material of the labels you’re using. Wax ribbons are perfect for paper-based labels, while resin ribbons are best for synthetic or durable labels.

Environmental Conditions: If your labels need to endure exposure to chemicals, moisture, or high temperatures, resin ribbons are your best option. If durability is not as critical, a wax or wax/resin blend ribbon may be a more cost-effective choice.

Print Volume: High-volume printing may benefit from using wax/resin blend ribbons, which offer a balance of quality and cost efficiency.

Conclusion: Why Invest in Thermal Transfer Ribbon?

If your business requires durable, high-quality labels that stand the test of time, investing in thermal transfer ribbons is essential. These ribbons ensure crisp, professional prints that resist fading and wear, making them ideal for a variety of industries. Whether you're printing labels for retail, logistics, healthcare, or manufacturing, thermal transfer ribbons provide the reliability and longevity your business needs.

By choosing the right thermal transfer ribbon, you can improve label quality, reduce operational costs, and ensure your labels remain clear and effective throughout their use. Make the switch to thermal transfer printing today, and experience the difference it can make in the efficiency and durability of your labeling process.

0 notes

Text

Corrugated Fanfold Market Insights: Opportunities, Challenges, and Winning Strategies

Corrugated fanfold market dynamics are evolving rapidly, driven by the growing demand for efficient packaging solutions across a variety of industries. This versatile product, primarily used in the packaging and printing sectors, offers businesses a cost-effective and environmentally friendly alternative to traditional packaging materials. As companies seek to reduce waste and enhance operational efficiency, the corrugated fanfold market has seen significant growth, particularly in the logistics, automotive, and retail industries. This article explores the current trends, opportunities, challenges, and winning strategies within this expanding market.

Market Overview

Corrugated fanfold is a packaging material that combines the durability and flexibility of corrugated cardboard with the convenience of a foldable design. It is widely used for packaging, shipping, and storage purposes, offering both strength and protection for a variety of products. The material’s folding design makes it easier to store, handle, and transport, which has been a key factor in its rising popularity.

The corrugated fanfold market is benefitting from increased e-commerce activities, which demand robust packaging solutions that can withstand shipping and handling stresses. The market is also expanding as industries push for more sustainable packaging options, as corrugated fanfold is biodegradable, recyclable, and can be produced using sustainable practices.

Opportunities

E-commerce Boom: With the surge in online shopping, there has been a significant uptick in demand for packaging materials that can protect products during delivery while minimizing costs. Corrugated fanfold offers a lightweight yet durable solution, which is ideal for this growing sector.

Sustainability Trends: Consumer and regulatory pressure on reducing plastic waste is prompting industries to turn to eco-friendly alternatives. Corrugated fanfold’s recyclability and renewable nature make it an attractive option for businesses looking to enhance their environmental sustainability credentials.

Customization and Versatility: The ability to customize corrugated fanfold for various shapes and sizes makes it an attractive option for companies in diverse industries. From electronics to automotive components, businesses are seeking packaging that can be tailored to the specific needs of their products. This customization offers a distinct competitive advantage.

Cost-Efficiency: Corrugated fanfold provides significant cost savings compared to other packaging materials, particularly in large-volume operations. It reduces the need for pre-formed boxes and cuts down on inventory space, which can contribute to lower overall operating costs.

Challenges

Competition from Alternative Materials: Despite its many advantages, corrugated fanfold faces competition from other sustainable materials like biodegradable plastics and molded pulp. These alternatives often offer similar performance characteristics, which could limit the growth potential of corrugated fanfold in certain markets.

Raw Material Price Volatility: The cost of corrugated materials is influenced by fluctuations in the prices of raw materials, such as wood pulp and recycled paper. This volatility can make it difficult for manufacturers to stabilize production costs, which in turn impacts pricing strategies.

Supply Chain Disruptions: The global supply chain has faced several disruptions due to factors like geopolitical tensions and pandemics, which have affected the availability and cost of raw materials. Companies involved in the production of corrugated fanfold may experience delays and higher costs due to these disruptions.

Consumer Perception: While corrugated fanfold is an environmentally friendly option, some consumers still perceive it as a less durable or less premium packaging solution. Overcoming this perception will require clear communication about the product's strength, efficiency, and eco-friendliness.

Winning Strategies

To capitalize on the opportunities in the corrugated fanfold market, businesses should consider the following strategies:

Invest in Technology and Automation: Embracing advanced production techniques and automation can improve efficiency, reduce costs, and increase the scalability of corrugated fanfold production. This could provide businesses with a competitive edge by allowing them to meet the rising demand for cost-effective packaging.

Focus on Sustainability: Given the growing importance of sustainable packaging, companies should focus on marketing the environmental benefits of corrugated fanfold, including its recyclability and use of renewable resources. This can enhance brand image and appeal to environmentally conscious consumers.

Strengthen Supply Chain Resilience: To mitigate the impact of supply chain disruptions, manufacturers should diversify their supplier base and invest in more resilient logistics networks. This can help ensure a steady supply of raw materials at competitive prices.

Diversify Applications: Companies should explore new and innovative applications for corrugated fanfold in emerging industries, such as pharmaceuticals and food delivery services, where specialized packaging needs are growing.

Conclusion

The corrugated fanfold market is poised for continued growth, driven by evolving consumer demands, sustainability trends, and technological advancements. However, companies operating in this space must navigate challenges such as material cost fluctuations and competition from alternative packaging solutions. By focusing on innovation, cost-efficiency, and sustainability, businesses can leverage the many opportunities presented by this versatile material to stay ahead in a competitive market.

Get Free Sample and ToC : https://www.pristinemarketinsights.com/get-free-sample-and-toc?rprtdtid=NTE5&RD=Corrugated-Fanfold-Market-Report

#CorrugatedFanfoldMarketInsights#CorrugatedFanfoldMarketTrends#CorrugatedFanfoldMarketGrowth#CorrugatedFanfoldMarketOutlook#CorrugatedFanfoldMarketAnalysis

0 notes

Text

Guide to Food Packaging Materials in India

In recent years, the food industry in India has seen notable growth. With this rise, the demand for safe food packaging has become more important. Food packaging is about ensuring safe transport, appealing design, and environmental responsibility. Read this blog until the end to learn about some of the primary food packaging materials and provide helpful insights for selecting the right food packaging design for your products.

Why is Food Packaging Important?

Packaging is fundamental in delivering fresh, safe, and visually appealing products to customers. Good packaging keeps food protected from contamination and extends its shelf life. It also helps with the branding and marketing of a product, as packaging design often draws the customer’s eye. In India, where the climate varies across regions, food packaging materials must be durable, moisture-resistant, and budget-friendly.

5 Common Food Packaging Materials

Different types of materials are used to package food in India. Each type of packaging material offers distinct benefits, and understanding these will help you make better choices for your packaging needs.

Plastic is one of India’s most widely used materials for food packaging. It is versatile, lightweight, and offers excellent moisture resistance, making it ideal for products that need to stay fresh for longer. Many food packaging suppliers use plastic due to its low cost and ability to be moulded into different shapes and sizes. Plastics like PET, HDPE, and LDPE are common in food packaging design. However, with the rise of environmental awareness, many businesses seek more sustainable options.

2. Glass is a robust, reusable packaging material famous for packaging sauces, jams, and pickles. It keeps food items fresh without reacting chemically, making it a safe option. Although glass is heavier than other materials, its durability and clarity make it a preferred choice for premium food brands. Many people also see glass as a more sustainable packaging material, as it is 100% recyclable.

3. Paper and paperboard are commonly used for packaging dry foods like biscuits, cereals, and snack bars. They are lightweight, affordable, and easily recyclable, making them popular in sustainable packaging. Paperboard is also customisable, so brands often use it to design attractive packaging.

4. Flexible packaging is an umbrella term for materials like pouches, bags, and wraps, often made from plastic, paper, or aluminium combinations. It is ideal for products like chips, chocolates, and powdered items. Flexible packaging allows food packaging suppliers to create unique shapes and sizes, helping brands stand out.

5. Aluminium foil is popular for packaging food items like snacks, ready-to-eat meals, and even dairy products. It protects food from light, moisture, and air, keeping it fresh for longer. Aluminium foil can be used as a standalone material or laminated with other materials for extra durability. This material is lightweight and easy to recycle, adding to its appeal in sustainable packaging.

Sustainable Packaging Options in India

Consumers have become more conscious about the environment. Many brands are now seeking sustainable alternatives to traditional materials. Sustainable packaging is using materials that have less impact on the environment, either biodegradable or recyclable. Here are some popular packaging sustainable options.

Biodegradable Plastics

Biodegradable plastics break down naturally, unlike traditional plastics. They are made from plant-based materials like corn starch, which makes them a good choice for packaging food while minimising waste. Many food packaging suppliers offer these alternatives as they align with global environmental standards.

Compostable Packaging

Compostable materials go further than biodegradable materials, breaking down into natural elements that nourish the soil. Materials like bagasse (a by-product of sugarcane) and other plant fibres are gaining popularity for packaging food sustainably. Compostable packaging is ideal for single-use products, offering an eco-friendly solution.

Recycled Paper and Cardboard

Recycled paper is another sustainable option widely used in India. Using recycled paper reduces the demand for virgin materials, helping conserve resources. This material is best suited for dry goods and products that don’t require much moisture protection.

Conclusion

Partnering with a reliable food packaging supplier in India is important for quality and consistency in your packaging. Look for suppliers who can meet your specific needs and provide high-quality materials. Finding a supplier who offers sustainable options is also helpful, especially if your brand wants to reduce its environmental footprint. A good supplier like Global Parachem can help you create a packaging product that aligns with your brand values and appeals to your target audience.

0 notes

Text

Selecting the Perfect Compostable Packaging for Your Cannabis Products

The cannabis industry faces a significant challenge: waste. With many single-use products and strict packaging regulations requiring tamper-resistant and childproof designs, the industry is often criticized for its environmental impact. These requirements, combined with the need for packaging that ensures product freshness, have resulted in large amounts of disposable waste, raising concerns among environmental advocates.

However, there's good news. Compostable cannabis packaging offers a sustainable alternative that meets regulatory standards, maintains product quality, and supports environmental responsibility—all without breaking the bank. Let’s explore the best compostable packaging options and their benefits to help you make the right choice for your cannabis products.

Popular Compostable Cannabis Packaging Options

Compostable packaging is made from materials that decompose naturally, unlike conventional plastic packaging that can linger in landfills for decades. Here are some top choices:

1. PLA and PHA Bioplastics

Bioplastics, derived from renewable resources, are both compostable and biodegradable, making them ideal for sustainable cannabis packaging.

PLA (Polylactic Acid): Made from renewable resources like corn starch, sugarcane, or cassava, PLA is created through a polymerization process that produces versatile packaging options in various colors and finishes.

PHA (Polyhydroxyalkanoate): Naturally produced by bacteria during the fermentation of sugars and lipids, PHA is a durable, biodegradable polymer. It’s perfect for packaging like tubes and containers.

At The Packaging Tree, we specialize in bioplastic solutions such as PHA for containers and PLA for flexible packaging like pouches. Contact us for free samples to explore these sustainable options for your cannabis brand.

2. Hemp-Based Materials

Hemp is a strong, renewable resource that’s both compostable and biodegradable. It’s increasingly used in cannabis packaging, including boxes, folding cartons, tags, inserts, and more.

As the availability of hemp grows, the potential for its use in cannabis packaging expands. Hemp paper, for example, offers endless customization possibilities, including offset printing, embossing, debossing, and even full-color printing, making it a versatile and eco-friendly choice.

3. Mushroom-Based Materials

Mushroom-based packaging, derived from mycelium (the root-like structure of mushrooms), is a groundbreaking innovation in sustainable packaging. Mycelium grows around agricultural waste like corn stalks or hemp hurds, binding them into solid, lightweight, and compostable packaging materials.

These materials are strong, biodegradable, and moldable, making them a unique substitute for plastic or Styrofoam. For cannabis brands looking to create innovative, eco-friendly designs, mushroom-based materials are a fantastic option.

Benefits of Compostable Packaging for Cannabis Products

Switching to compostable cannabis packaging offers a host of benefits:

1. Reduced Environmental Impact

Compostable materials break down naturally, avoiding the long-term pollution caused by traditional plastics. By using renewable resources, this packaging minimizes the ecological footprint of your products.

2. Meet Consumer Demand for Sustainability

Today’s consumers are increasingly drawn to environmentally responsible brands. Offering products in compostable packaging can help you attract eco-conscious customers and build loyalty within this growing demographic.

3. Compliance with Regulations

Many cannabis regulations now emphasize reducing environmental impact. Compostable packaging ensures compliance while demonstrating your brand’s commitment to sustainability.

4. Enhanced Brand Reputation

Sustainability is more than a trend; it’s a key factor in brand perception. By investing in eco-friendly packaging, your brand can stand out as an industry leader committed to reducing waste and promoting environmental stewardship.

Challenges of Compostable Cannabis Packaging

While the benefits are substantial, it’s important to consider potential challenges:

1. Higher Costs

Compostable packaging can be more expensive than traditional options. However, growing demand and advancements in production are driving prices down, making these materials more accessible over time.

2. Limited Composting Facilities

Many areas still lack industrial composting facilities, making proper disposal challenging. Nevertheless, adopting compostable packaging now positions your brand as forward-thinking and prepared for future sustainability trends.

3. Compatibility Concerns

Not all products are compatible with compostable materials. Partnering with an experienced packaging provider like The Packaging Tree ensures you’ll find the right solutions to maintain product quality and freshness.

4. Consumer Awareness

Educating consumers on proper composting practices is essential. Without proper disposal, compostable packaging may not fully decompose, potentially diminishing its environmental benefits.

Choosing Compostable Cannabis Packaging with The Packaging Tree

Compostable cannabis packaging is a smart, sustainable choice for your products. It supports your brand’s environmental goals, appeals to eco-conscious consumers, and positions your business as an innovative leader in the cannabis industry.

At ThePackagingTree, we offer a wide range of compostable packaging solutions tailored to your brand’s needs. From bioplastics to hemp and mushroom-based materials, we’re here to help you find the perfect packaging to meet regulatory standards and delight your customers.

Contact us today to learn more or request free samples. Together, we can create a greener future for the cannabis industry.

0 notes

Text

Vancouver Die Cutting: Precision Packaging for Every Product

When it comes to creating custom packaging that fits perfectly with your product’s design, Vancouver Die Cutting is an essential process. Die cutting is a technique used to cut paper, cardboard, plastic, and other materials into precise shapes or sizes. Whether you’re packaging a product, creating promotional materials, or looking to add intricate designs to your packaging, die cutting provides precision and versatility. In this blog, we’ll explore the benefits of Vancouver Die Cutting, the importance of Packing Boxes Vancouver, and how Order Boxes Vancouver can meet your packaging needs.

The Power of Vancouver Die Cutting

Vancouver Die Cutting is a process that allows you to create intricate shapes and designs that stand out. Whether it’s a box with unique folds, a decorative cutout, or a product insert, die cutting provides you with the ability to create customized packaging that looks professional and attracts attention.

Key Benefits of Vancouver Die Cutting

Customization and Precision: With die cutting, you can create packaging that fits your products perfectly. Whether it’s custom-shaped boxes, inserts, or labels, this process ensures your packaging is designed to fit your exact specifications, giving your products a polished and tailored look.

Efficiency: Die cutting allows for high-speed production with consistent, precise results. This makes it an efficient process for businesses that need to produce large quantities of custom packaging quickly and cost-effectively.

Unique Designs: If you’re looking to add a unique touch to your packaging, die cutting can help. From custom window shapes to embossed logos, this process allows for a level of creativity that can make your product stand out on the shelves or during shipping.

Versatility: Vancouver die cutting can be used on a variety of materials, including cardboard, paperboard, corrugated cardboard, and plastic. This flexibility makes it an ideal choice for businesses in any industry that needs custom-designed packaging solutions.

Packing Boxes Vancouver: The Essential for Secure and Safe Shipping

When it comes to protecting your products during transit, Packing Boxes Vancouver are indispensable. These boxes are designed to provide strength, durability, and protection for a wide range of products, from fragile items to bulky goods. Whether you’re shipping locally or internationally, the right packing boxes can make all the difference in ensuring your products arrive in perfect condition.

Key Benefits of Packing Boxes Vancouver

Durability: Packing Boxes Vancouver are made from strong, high-quality materials designed to withstand the stresses of shipping and handling. They protect your items from damage caused by bumps, drops, or rough handling during transport.

Variety of Sizes: Packing boxes come in many different sizes and styles to suit various products. From small, lightweight items to large, heavy products, you can find the perfect box to fit your needs. This ensures that your products are not only secure but also well-organized.

Protection Against the Elements: Many packing boxes are designed to provide extra protection against the elements, such as moisture or temperature changes. This makes them ideal for shipping perishable goods, electronics, or fragile items.

Eco-Friendly Options: Many businesses today are looking for sustainable packaging solutions. Vancouver packing boxes are available in eco-friendly materials, such as recycled cardboard or biodegradable packing materials, ensuring that your packaging is as environmentally conscious as it is functional.

Order Boxes Vancouver: Streamline Your Packaging Process

Order Boxes Vancouver offer the perfect solution for businesses and individuals who need high-quality, customizable boxes on demand. Whether you're in the retail, manufacturing, or logistics industry, ordering boxes that meet your specific requirements can streamline your operations and reduce waste.

Key Benefits of Order Boxes Vancouver

On-Demand Customization: Order Boxes Vancouver give you the flexibility to order boxes that meet your exact needs, whether it’s a unique size, color, or material. Whether you're looking for packaging for retail products or bulk shipping, you can ensure that your boxes are tailored for your specific requirements.

Cost-Effective: Ordering in bulk or on demand allows businesses to optimize their packaging costs. By ordering the right quantity of boxes, you can reduce excess inventory and save on storage fees.

Variety of Styles: From standard shipping boxes to decorative boxes, Order Boxes Vancouver come in various styles and designs. Customizable options like branded boxes, window boxes, and specialized boxes for fragile items provide the perfect solutions for all packaging needs.

Convenience: Ordering boxes in Vancouver is easy and efficient, whether you choose to order in-store or online. With quick turnaround times, you can have your packaging delivered when you need it, ensuring your products are always ready for sale or shipment.

Combining Vancouver Die Cutting with Packing and Order Boxes

By combining Vancouver Die Cutting with Packing Boxes Vancouver and Order Boxes Vancouver, businesses can achieve a fully customized and efficient packaging solution. Die cutting allows you to design custom-shaped boxes and inserts, while packing boxes provide the structural integrity needed to protect your products. Order boxes allow for flexibility and cost efficiency, enabling businesses to get the exact packaging they need without overstocking.

Whether you're a business owner looking to create standout packaging or someone looking for reliable boxes for shipping and storage, these packaging solutions work together to ensure your products are protected, presented beautifully, and delivered efficiently.

Where to Find the Best Vancouver Packaging Solutions

If you're looking for high-quality Vancouver Die Cutting, Packing Boxes Vancouver, or Order Boxes Vancouver, visit Racer Boxes. Racer Boxes offers a wide range of customizable packaging solutions for every need, from precision die cutting to bulk-order boxes. They provide durable, efficient, and eco-friendly packaging solutions to help streamline your business or personal packaging needs.

Conclusion

In today’s competitive market, packaging is more than just about function – it’s about presenting your products in the best light possible. With Vancouver Die Cutting, Packing Boxes Vancouver, and Order Boxes Vancouver, you can ensure that your packaging is not only protective but also custom-designed to represent your brand and meet your specific needs. Visit Racer Boxes for all your packaging solutions and create the perfect packaging experience for your business or special project.

0 notes

Text

Your Path to Success: Top Private University in UP for Aspiring Students

Introduction

UP is currently known for its excellent education, particularly in private universities, after formerly being connected to culture and history. These colleges assist students in moving away from traditional education and toward what is relevant to the world and society today.

Now it is time to understand why private universities are becoming so popular in UP, what key characteristics define them, and which university you should attend if you’re planning to study in this Province.

Why Students Should Choose Private University

The top private school in UP has revolutionized the educational landscape by providing students with excellent instruction. Unlike many public colleges, private institutions provide state-of-the-art facilities, flexible scheduling, and efficient teaching methods.

Flexibility and Modern Approach: Private universities have an understanding that appreciable levels of knowledge can best be imparted alongside practice.

Industry Partnerships: These schools frequently collaborate with industry leaders to give students access to training, internships, and placement opportunities.

Global Exposure: Today many tie-up arrangements with foreign universities provide students with a chance to do exchange programs or internships at foreign universities.

Research and Clinical Excellence

The university has a research and practice orientation. Students can participate in research projects that encourage critical and creative thinking in the field of medical science with the help of qualified professors. The clinical part of the preparation is also very developed, so students are ready to work with patients during various practical experiences and rotations. Extensive investigation and analysis are always necessary to determine the demands and learning preferences of the learner.

Features That Define the Best Private Universities

Academic Excellence and Innovation

A few private institutions in Uttar Pradesh take pride in having well-designed courses that meet international standards.

Innovations are conducted and reinforced; students are encouraged to solve meaningful assignments during such projects.

Modern Facilities

The facilities and infrastructure in private universities comprise high-tech classrooms, laboratories, computerized libraries and even sports facilities.

Such amenities help provide the required atmosphere for learning and co-curricular activities.

Diverse Course Offerings

Private institutions in Uttar Pradesh provide courses in MBBS and BSc, GNM, and BAMS.

Such programs enable the learner to follow diverse interests within the course duration.

Expert Faculty

Quality private universities use competent and qualified staff who guide the student through to the end of their course.

Factors to Consider While Choosing a Private University

Before finalizing your choice, keep these aspects in mind:

Accreditation and Ranking

Be sure to check with Universities whether they are recognized by UGC, AICTE NAAC etc.

Agencies such as NIRF can provide insights into the rankings.

Placement Records

Take the time to research the university's placement history, the proposed compensation package, and the list of recruiters.

Campus Culture

A wide, mixed student body benefits the learning process making graduates fit for international organizations.

Alumni Network

Large alumni bases give evidence of the institution’s engagement and accomplishment in a variety of sectors.

Private Education: Issues and Options

This paper compares private Universities with numerous benefits nevertheless; issues such as affordability and quality still arise. However, the regulating body, financial aid programs, and scholarships adequately include tuition costs, living expenses, and quality concerns.

Helpful Advice to Help You Choose the Best Private University

Research: To avoid being misled by unauthentic sources, it is important to cross-check information on universities.

Campus Visits: Visiting the campus proves more useful in determining the facilities and the surrounding conditions.

Engage with Alumni: First-hand information can be created by interviewing alumni.

Conclusion

Selecting the right university is one of the most important decisions that determine the kind of job one will get. Being centered on quality education, and the latest infrastructural facilities along the industry interface, best private university in Uttar Pradesh offer unparalleled opportunities. Thus, choosing something that suits the student’s needs and learning preferences always becomes possible after extensive research and analysis.

1 note

·

View note

Text

Why Flexographic Printing is Revolutionizing the Packaging Industry?

In the fast-growing world of printing, flexography stands as a testament to human ingenuity – a perfect blend of artistic finesse and technical precision. If you've ever admired the crisp graphics on your favorite snack packaging or marveled at the vibrant colors on a shopping bag, you've witnessed the magic of flexographic printing firsthand.

Looking for “flexographic printing Kansas City US” and want to know more about it? This versatile printing method has become the cornerstone of packaging and label production, touching countless aspects of our lives without most of us even realizing it.

What Makes Flexography Special?

At its heart, flexographic printing uses flexible relief plates mounted on high-speed rotary presses. These plates, made from rubber or photopolymer materials, are like sophisticated rubber stamps that can transfer ink onto virtually any surface, from paper and plastic to metallic films and corrugated boards.

But what truly sets flexography apart is its remarkable ability to adapt. Need to print on that tricky plastic film for food packaging? Flexography can handle it. Looking to add that perfect finish to corrugated boxes? Flexographic printing got you covered. This adaptability, combined with cost-effectiveness in the long run, makes it the go-to choice for many printing needs.

The Environmental Edge

In today's environmentally conscious world, flexography shines even brighter. Modern flexo presses use water-based and solvent-free inks, significantly reducing environmental impact. The printing process itself is becoming increasingly efficient, minimizing waste and energy consumption – a win-win for both businesses and our planet.

Innovation at Every Turn

The flexographic industry never stands still. Recent technological advances have brought:

HD plate technology for sharper images and more vivid colors

Computer-to-plate systems for superior precision

Automated registration systems for consistent quality

LED curing for energy efficiency

Extended color gamut printing for broader color possibilities

The Human Element

Behind every successful flexographic print job stands a team of skilled professional artists, plate makers, press operators, and quality control experts. PlateCrafters is also one of them. These dedicated individuals combine their expertise with cutting-edge technology to deliver the exceptional print quality that brands and consumer’s demand.

Unmatched Quality

In packaging and label printing, quality isn't just about looking good; it's about maintaining brand integrity and meeting regulatory requirements. Flexography delivers the consistency and reliability that modern businesses need, whether printing simple text or complex graphics.

The Bottom Line:

As we move forward, flexography continues to evolve. Digital integration, sustainable practices, and automation are shaping the future of this dynamic industry. Yet, at its core, flexographic printing remains what it has always been – a reliable, versatile, and efficient printing method that helps bring products to life. Whether you're a brand owner looking to make your product stand out on the shelf or a printer seeking to expand your capabilities, we are one of the best print brokers providing flexographic printing that offers you a world of possibilities.

#Print Brokers#flexographic plates#flexographic printing plates#Flexographic Pre-Press#flexographic printing companies Kansas city usa

0 notes

Text

Gravure Printing Machines: Precision for High-Quality, Large-Scale Printing

Gravure printing, or rotogravure printing, is the practice of high-speed print technique. It brings out high-quality printed products with an excellent precision level. It is mainly used for mass production of items like packaging, labels, and magazines. Gravure printing machines ensure that the images are clear and sharp with well-saturated colors and good quality. The technique of this printing is very suitable for any long run because it guarantees high quality in any plastic, paper, or even foil.

How Gravure Printing Works

In gravure printing, actually the design or image is engraved into the cylinder. These engraved cells are filled up with ink, and when pressed on the substrate, ink transfers accurately to create a good quality print. The color density and details of the image depend on the depth and size of the cells on the cylinder, thus enabling gravure printing machines to create rich and consistent tones. The gradations that gravure printing machines produce are very smooth and feature good details, hence very photo-realistic, mainly for highly color-intensive projects.

Advantages of Gravure Printing Machines

Gravure printing machines have several unique advantages. Its engraved cylinders provide a long-lasting image quality, hence graver is very well suitable for massive production. They are used at very high speeds with thousands of impressions per hour and do not lose the consistency. Gravure printing is well applicable for large works with intricate designs because of extraordinary image reproduction and fine details.

Applications of Gravure Printing Machines

Gravure printing is widely used for various products. These include flexible packaging, labels, gift wrap, wallpapers, and magazines. With the accuracies and quality of gravure printing machines, brands and manufacturers can actually guarantee visually pleasing yet sturdy objects. With gravure printing, in businesses, effectiveness and quality go along with meeting actual production demands on an impressive standard for print.

The company specializes in providing advanced gravure printing machines that suit different industrial applications for companies seeking reliable solutions for high quality printing and large scales.

#Gravure Printing Machines Manufacturer#UV Coating Machines Manufacturer#Flexo Printing Machines Manufacturer

0 notes

Text

RealSoft Packaging Material ERP

RealSoft Packaging Material ERP is designed specifically for the packaging materials industry, offering seamless control over production, inventory, and order management. Known as one of the best ERP solutions in UAE for manufacturing, RealSoft ensures precise stock tracking, efficient resource allocation, and accurate cost management, all essential to meeting high-volume demands.

As the #1 ERP for packaging materials, RealSoft helps businesses increase efficiency, reduce waste, and maintain profitability while delivering quality products to market faster.

0 notes

Text

Enhance Your Business Operations with Megatop’s Industrial Label Printers

In the fast-paced world of modern business, efficiency and accuracy are key drivers of success. Whether you're in manufacturing, logistics, or retail, industrial label printers are a crucial part of your operations. These printers are designed to meet the demanding needs of industries that require high-quality, durable labels for products, packaging, and shipments. Megatop’s industrial label printers offer a powerful solution to streamline your labeling processes and boost productivity.

Why Do You Need an Industrial Label Printer?

Industrial label printers are essential for high-volume printing needs. Unlike consumer-grade printers, industrial models are designed to handle continuous operation and produce labels quickly, accurately, and in large quantities. From inventory management to regulatory compliance, these printers ensure that your labeling processes run smoothly and efficiently.

Here are some of the core benefits of using an industrial label printer:

High-Quality Labels Megatop’s industrial label printers produce sharp, clear, and durable labels that can withstand harsh conditions. Whether you need barcodes for inventory tracking, product identification labels, or safety and compliance labels, these printers ensure that your labels remain legible and intact through various environmental conditions.

Increased Efficiency Speed and volume are often critical in industrial environments. Megatop’s printers can print thousands of labels per day, reducing bottlenecks in production. The quick turnaround time allows your business to stay on schedule and meet tight deadlines.

Durability Industrial label printers from Megatop are built to last. They are designed to operate continuously under tough conditions, from extreme temperatures to exposure to dust, moisture, and chemicals. These durable printers can handle high-volume operations without compromising performance, which helps reduce maintenance costs and downtime.

Cost Savings With an industrial label printer, you eliminate the need for outsourcing label printing or dealing with the high cost of manual labor. Megatop’s printers reduce errors, which can save your business time and money. The high efficiency and durability of these printers also translate into lower long-term operational costs, making them a great investment for any business.

Key Features of Megatop’s Industrial Label Printers

Megatop’s industrial label printers come equipped with a range of features that make them ideal for a variety of business applications. Here are some of the standout features of Megatop’s printers:

High-Speed Printing Megatop’s industrial label printers are engineered for speed. Whether you're printing barcode labels, shipping labels, or safety labels, you can count on these printers to produce large volumes quickly and efficiently. This makes them perfect for businesses with high production needs.

Flexible Labeling Options Megatop’s industrial label printers are versatile and capable of printing on a wide range of label materials, including paper, synthetic, and adhesive labels. They can also handle various sizes and shapes, offering flexibility to meet your unique labeling needs. This feature is particularly valuable in industries where products come in different sizes or require specialized labels.

Advanced Connectivity In today’s connected world, the ability to integrate printers into a network is essential. Megatop’s industrial label printers come with multiple connectivity options, including USB, Ethernet, and wireless capabilities. This makes it easy to manage print jobs remotely, integrate the printer into your existing IT infrastructure, and connect with other devices in your production line.

User-Friendly Design Ease of use is critical when selecting industrial equipment. Megatop’s printers feature intuitive control panels and simple interfaces that make it easy for your team to get up and running. Even with minimal training, your employees can operate these printers efficiently, reducing the chances of mistakes and boosting overall productivity.

Durability for Harsh Environments Megatop’s industrial label printers are built with durability in mind. They are constructed to withstand the rigors of industrial environments, including exposure to moisture, dust, and extreme temperatures. Whether you’re printing labels in a factory, warehouse, or on the production floor, these printers are designed to handle the demands of the job.

Low Maintenance and Long Lifespan Megatop’s label printers are designed for long-term performance. These machines require minimal maintenance and are built to last, making them a great investment for any business. With proper care, Megatop’s printers can continue to perform at their best for years, minimizing downtime and reducing the need for frequent repairs.

Industries That Benefit from Megatop’s Industrial Label Printers

Megatop’s industrial label printers are designed to meet the needs of various industries. Here are just a few examples of sectors that benefit from using Megatop printers:

Manufacturing In manufacturing, labeling plays a critical role in identifying raw materials, finished goods, and packaging. Industrial label printers from Megatop ensure that products are clearly labeled for quality control, inventory tracking, and shipping. Barcode and QR code labels help streamline the manufacturing process and improve traceability.

Logistics and Shipping The logistics industry depends on accurate labeling for inventory tracking, order fulfillment, and shipment handling. With Megatop’s industrial label printers, you can quickly print shipping labels, tracking codes, and product identifiers that help keep your logistics operation running smoothly.

Retail Retailers use industrial label printers to create price tags, barcodes, and product labels. These printers help retailers streamline stock management, maintain pricing accuracy, and reduce labeling errors, ensuring that products are correctly labeled and easy to scan at the checkout.

Healthcare and Pharmaceuticals In the healthcare and pharmaceutical industries, product labeling is essential for patient safety and regulatory compliance. Megatop’s printers produce labels with clear, accurate information, including dosage instructions, expiration dates, and batch numbers. These printers are built to meet the stringent regulatory requirements of these industries.

Food and Beverage Accurate labeling is a regulatory requirement in the food and beverage industry. Megatop’s industrial label printers help produce labels with essential product information, including ingredients, allergens, nutritional facts, and expiration dates. These printers ensure that your business stays compliant while improving product traceability.

Why Choose Megatop’s Industrial Label Printers?

Megatop stands out in the industrial printer market for several reasons:

Reliability Megatop’s industrial label printers are known for their reliability and durability. With robust construction and advanced technology, they can handle high-volume printing without compromising quality.

Cost-Effective With their long lifespan and low maintenance requirements, Megatop printers offer great value for money. They help reduce operational costs by increasing efficiency and minimizing errors.

Customer Support Megatop is dedicated to providing excellent customer service. Their knowledgeable team is available to assist with installation, troubleshooting, and technical support, ensuring your label printers continue to perform at their best.

Customization Megatop offers a wide range of industrial label printers that can be tailored to meet your specific business needs. Whether you need specialized labels or additional features, Megatop has the solution to fit your requirements.

Conclusion

In a world where accuracy and speed are essential, Megatop’s industrial label printers are a must-have for businesses looking to streamline their labeling processes. With their high-quality output, durability, and versatility, these printers help businesses of all sizes improve efficiency and reduce costs. Whether you're in manufacturing, logistics, retail, or healthcare, Megatop’s industrial label printers are the perfect solution to keep your operations running smoothly.

Take your business to the next level with Megatop’s industrial label printers and experience the difference that quality, speed, and reliability can make!

0 notes

Text

Buy Disposable Food Containers in India

In today’s international, where convenience meets sustainability, disposable food bins have come to be essential for various industries, particularly in food and beverage. With the demand for exceptional disposable food packaging growing, the Indian market offers diverse alternatives, starting from food boxes online to chocolate packaging. Triace, a main call in the Indian packaging enterprise, has specialized in delivering pinnacle-notch disposable food boxes that cater to diverse needs, from restaurant takeaways to high-end chocolate packaging boxes.

Why Disposable Food Containers Are a Game-Changer

Disposable food boxes offer a suitable answer for those looking for easy, hygienic, and reliable packaging. They dispose of the trouble of washing and returning containers, making them best for the modern on-the-pass way of life. Notably, these packing containers cater to more than one function, which includes storing leftovers, serving takeaway food, or packaging unique objects like sweets and treats.

Disposable food containers also make an impact on the presentation and branding of a product. Businesses use these boxes to create a long-lasting impression on customers by way of offering their food gadgets attractively and securely. Moreover, with sustainability at the forefront, many corporations are choosing green disposable food packaging packing containers close to me to lessen their environmental footprint.

Types of Disposable Food Containers

India’s disposable food packaging market offers a whole lot of boxes, each tailor-made to different desires:

Paper Food Boxes: Eco-pleasant and flexible, paper foodie bins are perfect for takeout, snacks, and dry gadgets. They are lightweight, compostable, and appropriate for branding.

Plastic Containers: These packing containers are long-lasting and come in numerous styles and sizes. Though now not as green, they continue to be famous for their resilience and price-effectiveness.

Aluminum Foil Containers: Ideal for warm food objects, foil boxes retain warmth and preserve food clean. They are often used by restaurants for packing food for transport.

Eco-Friendly Containers: Made from biodegradable materials, those boxes are best for corporations aiming to decrease their environmental effect. There is an increasing number of celebrities in the organic food and health sectors.

Chocolate Packaging Boxes: A special category of food bins, chocolate packaging containers are used by chocolatiers and confectioners to package delicate and comforting objects. The layout and material of these bins are important for preserving candies and are secure and visually appealing.

Choosing the Right Disposable Food Container for Your Business

When choosing disposable food packaging containers, agencies should keep in mind various factors, including the form of food, temperature retention, and branding capability. If you’re strolling a café, foodie containers and disposable food packaging packing containers near me are notable options for their portability and capability to preserve food excellently at some point of transport.

For confectionery manufacturers, chocolate packaging is an art. Triace, with over 50 years within the packaging and printing commercial enterprise, is familiar with the intricacies concerned in creating a chocolate packaging box that complements the product’s appeal and continues its quality. Their award-prevailing group has been celebrated for revolutionary packaging answers that raise brand presentation and upload cost to the final product.

Benefits of Using High-Quality Disposable Food Containers

Convenience and Portability: Disposable food bins make it smooth for clients to move food without annoying approximately spillage. They are lightweight, making them ideal for takeaways and home deliveries.

Sustainability Options: With the upward thrust in eco-conscious purchasers, disposable containers made from sustainable materials are an excessive call for. By deciding on compostable or biodegradable disposable food containers, businesses contribute to environmental conservation.

Food Safety and Freshness: High-quality food packaging protects food from infection and maintains it fresh. For example, chocolate packaging bins through Triace make sure that candies are saved cool, and free from moisture, enhancing the patron's experience.

Enhanced Brand Image: Customizable disposable food packaging bins near me offer branding opportunities, as emblems, designs, and colors can be tailor-made to represent an emblem’s identification. This provides the general to enjoy and make the emblem memorable.

Affordable Solutions: Disposable bins are price-powerful, especially for agencies that depend upon bulk packaging. This affordability allows small and medium corporations to maintain excellent packaging without stretching their finances.

Triace: Your Trusted Partner in Disposable Food Packaging

Triace has set the usual in the packaging enterprise with its modern and incredible disposable food packaging solutions. The enterprise has been identified with multiple awards for excellence in packaging, especially in disposable food packaging containers and chocolate packaging. From custom foodie boxes to specialized chocolate packaging container designs, Triace is devoted to providing customized providers and brilliant first-rate to meet all of your packaging wishes.

With a focal point on value-added printing and packaging, Triace gives a wide spectrum of packaging solutions. Whether you want disposable food packaging bins near me or are searching out the correct food container online, their group is dedicated to handing over pinnacle-best products promptly and professionally.

Buying Disposable Food Containers Online

The convenience of buying disposable food boxes online has made it less difficult for companies and individuals alike to discover the proper packaging. Online platforms allow clients to discover a huge style of alternatives, from basic foodie boxes to complex chocolate packaging container designs. With only a few clicks, you may compare sizes, materials, and charges, ensuring that you find precisely what you want for your commercial enterprise.

Whether you’re a restaurant owner, a bakery, or a confectionery logo, shopping for a food container online is the most effective manner to make certain you have got nice packaging on hand. Their significant online catalog consists of an array of packaging products, making it easy to locate the whole lot, from disposable food boxes to specialized chocolate packaging alternatives.

Final Thoughts on Disposable Food Containers

In today’s rapid-paced market, making an investment in high-quality disposable food bins is critical for groups trying to stand out and offer comfort to their customers. These packing containers now not only assist in maintaining food safety and freshness but also enhance emblem image through pleasant packaging.

For premium disposable food packaging answers, Triace is a reliable choice, offering a complete variety of products to shape diverse commercial enterprise wishes. With a long time of experience, awards for innovation, and a determination to be great, Triace is a great partner for businesses trying to make a long-lasting impact with their packaging. From foodie bins to chocolate packaging bins, their services ensure your brand is represented with excellence and attention to detail.

In conclusion, whether you’re attempting to find disposable food packaging boxes near me or need a food field online for your business, the proper preference for a disposable food field can extensively impact consumer pleasure and logo loyalty. With their professional understanding, you can be confident that your food packaging will be practical, sustainable, and appealing, helping your commercial enterprise thrive in an aggressive market.

0 notes

Text

The Role Of Gravure Printing Ink In Modern Packaging

Gravure printing, a popular and highly efficient printing method, plays a vital role in the packaging industry. This technique uses an intaglio process, where images are engraved onto a cylinder. Gravure printing ink is specifically formulated to meet the unique demands of this method, contributing to high-quality prints and effective packaging solutions. This article explores the importance of gravure printing ink in modern packaging, highlighting its characteristics, benefits, and applications.

Characteristics of Gravure Printing Ink

Gravure printing inks are known for their fluid consistency, allowing them to flow smoothly onto the engraved cylinder during the printing process. The inks can be classified into different types based on their solvent content, such as solvent-based, water-based, and UV-curable inks.

Solvent-Based Inks: These inks are commonly used in gravure printing due to their excellent adhesion and vibrant colors. They are suitable for various substrates, including flexible films and paper. However, concerns about volatile organic compounds (VOCs) have led to increased interest in alternative formulations.

Water-Based Inks: With a focus on sustainability, water-based gravure inks have gained popularity. These inks are less harmful to the environment, as they contain fewer VOCs. They offer good adhesion and print quality on various substrates, making them a suitable choice for food packaging.

UV-Curable Inks: These inks cure instantly when exposed to ultraviolet light, providing a quick-drying solution that enhances productivity. UV-curable inks are known for their durability and resistance to abrasion, making them ideal for high-performance packaging applications.

Benefits of Gravure Printing Ink in Packaging

High Print Quality: Gravure printing inks deliver exceptional image clarity and color vibrancy, which are essential for appealing packaging design. The intaglio process allows for fine details and smooth gradients, enhancing the visual impact of packaging.

Versatility: Gravure inks can be used on a wide range of substrates, including plastic films, paper, and metallic materials. This versatility makes gravure printing suitable for various packaging applications, from food and beverage to consumer goods and pharmaceuticals.

Durability: Gravure printing inks are designed to withstand harsh conditions, such as moisture, heat, and chemicals. This durability ensures that packaging remains intact and visually appealing throughout its lifecycle, from production to transportation and retail.

Efficient Production: The gravure printing process is highly efficient, enabling large print runs with consistent quality. This efficiency is crucial in the fast-paced packaging industry, where speed and precision are essential for meeting market demands.

Applications of Gravure Printing Ink

Gravure printing inks are widely used in packaging applications, including:

Flexible Packaging: Used for snack foods, pet foods, and processed meats, gravure inks provide vibrant graphics and necessary barrier properties to preserve freshness.

Laminated Packaging: Gravure printing is common in the production of laminated pouches and bags, which often require multiple layers for added strength and protection.