#Flat Belt Conveyor

Explore tagged Tumblr posts

Text

Benefits of Flat Belt Conveyors in Material Handling

A flat belt conveyor is a mechanical system designed for horizontal material transportation within industries. It features a continuous flat belt moving over pulleys or rollers, powered by a motor. Versatile and widely used, flat belt conveyors efficiently transport bulk materials, components in manufacturing, packaged goods in warehouses, and luggage in airports. Their simple design, ease of customization, and cost-effectiveness make them integral to streamlined material handling processes in various sectors.

Uses of Flat Belt Conveyors:

Bulk Material Handling: Flat belt conveyors are widely employed for transporting bulk materials such as grains, ores, and raw materials in industries like agriculture and mining. The continuous surface of the flat belt allows for a smooth and efficient flow of materials over long distances.

Manufacturing and Assembly Lines: In manufacturing processes, especially in industries like electronics and food production, flat belt conveyors play a crucial role in the movement of components along assembly lines. Their flat, unobstructed surface ensures that even delicate items can be conveyed without the risk of damage.

Packaging and Warehousing: Flat belt conveyors are used in packaging lines for the orderly and automated movement of packaged goods. Warehouses also benefit from these conveyors for efficient order picking and sorting of products, optimizing logistical operations.

Airport Baggage Handling: Airports leverage flat belt conveyors in their baggage handling systems, streamlining the journey of passenger luggage from check-in to the aircraft. The flat surface of the belt ensures smooth and reliable transport of bags of varying sizes.

Advantages of Flat Belt Conveyors:

Versatility and Adaptability: Flat belt conveyors are known for their versatility, accommodating a wide range of materials and applications. They can be easily adapted to suit specific industry requirements, making them an ideal choice for diverse material handling needs.

Ease of Maintenance: With a straightforward design comprising a flat surface and pulley system, flat belt conveyors are relatively easy to maintain. This simplicity translates into reduced downtime and lower maintenance costs, contributing to increased operational efficiency.

Cost-Effectiveness: Flat belt conveyors offer a cost-effective solution for material handling, making them an attractive option for businesses aiming to optimize their operational expenses. The initial investment is often offset by long-term savings in maintenance and labor costs.

Quiet and Energy-Efficient Operation: The smooth, continuous motion of flat belt conveyors results in quiet and energy-efficient operation. This not only creates a more conducive work environment but also aligns with the growing emphasis on sustainable and eco-friendly practices in modern industries.

Conclusion:

In the world of material handling, flat belt conveyors stand out as versatile, cost-effective, and efficient solutions. From transporting bulk materials to facilitating the movement of delicate components on assembly lines, these conveyors have proven their worth across diverse industries. As technology continues to advance, flat belt conveyors will likely remain at the forefront, contributing to the ongoing evolution of streamlined and efficient material handling systems.

#flat belt conveyor#flat belt conveyor manufacturer#flat belt conveyor manufacturer in India#flat belt conveyor manufacturer in Delhi NCR#flat belt conveyor supplier#flat belt conveyor supplier in India

1 note

·

View note

Text

Titan material handling pvt. Ltd provide Belt Conveyor at best cost, It Is the best Belt conveyor, Flat Belt Conveyor manufacturers company in Pune, Mumbai, India, Andhra Pradesh, Visakhapatnam, SriCity, Guntur, Goa, Margao, Haryana, Gurugram, Faridabad, Gujarat, Ahmedabad, Ankleshwar, Bharuch, Gandhinagar, Jamnagar, Rajkot, Vadodara, Himachal Pradesh, Baddi, Karnataka, Bangalore, Belagavi, Tumkur, Manglore, Hubli, Maharashtra, Navi Mumbai, Mumbai, Pimpri Chinchwad, Pune, Nashik, Aurangabad, Nagpur, Kolhapur, Rajnangaon, Madhya Pradesh, Pithampur, Indore, Tamil Nadu, Coimbatore, Chennai, Hosur, Uttar Pradesh, Noida, Telangana, Hyderabad, Chakan, Hinjawadi, Pirangut, Baramati, Ranjangaon, shirur

0 notes

Text

#Automatic Packing Machine Manufacturers In Chennai#Auger Packing Machine Manufacturers In Chennai#Weighmetric Packing Machine Manufacturers In Chennai#Multihead Weigher Machine Manufacturers In Chennai#Volumetric Packing Machine Manufacturers In Chennai#Multipurpose Packing Machine Manufacturers In Chennai#Liquid Packing Machine Manufacturers In Chennai#Paste Packing Machine Manufacturers In Chennai#Pharma Packing Machine Manufacturers In Chennai#Oil Packing Machine Manufacturers In Chennai#Mini Doy Pack Machine Manufacturers In Chennai#Horizontal PFS (Pick-Fill-Seal) Machine Manufacturers In Chennai#Ffs - Volumetric Packing Machine Manufacturers In Chennai#FFS TRAY Model Machines Manufacturers In Chennai#Multitrack Packing Machine Manufacturers In Chennai#Flow Wrap Packing Machine Manufacturers In Chennai#Semi – Automatic Machine Manufacturers In Chennai#Semi Automatic Weighmetric Filling Machine Manufacturers In Chennai#Semi Automatic Paste Filling Machine Manufacturers In Chennai#Semi Automatic Volumetric Filling Machine Manufacturers In Chennai#Heavy-Duty Band Sealer Machine Manufacturers In Chennai#Semi Automatic Auger Filling Machine Manufacturers In Chennai#Conveyor Machine manufacturers in Chennai#Z-Conveyor Manufacturers In Chennai#Screw Conveyor Machine Manufacturers In Chennai#Bucket Elevator Machine Manufacturers In Chennai#Roller Conveyor Machine Manufacturers In Chennai#Flat Belt Conveyor Manufacturers In Chennai#Inclined Conveyor Manufacturers In Chennai#Packing machine manufacturers in Chennai

0 notes

Text

Knife roller conveyor Manufacturer in Pune | India

Enhance safety and productivity with our advanced and innovative knife roller conveyor manufacturer in Pune, India with high-quality products which is easy to install, and economical. Knife roller conveyors offer an array of advantages setting them apart as the preferred choice for precision material transport.

#Knife Edge Conveyor Manufacturer Pune#Weighing Conveyor Manufacturer Pune#Flat Belt Conveyor Pune#Activated Roller Belt Conveyor Pune#Flexi Link Conveyor Manufacturer Pune#Modular Conveyor Manufacturer Pune#Automation#Assembly Techniques.

0 notes

Text

Lifting Plough Assembly: Calculations for Conveyor System Loads and Forces

Lifting plough assemblies are a crucial component of conveyor systems that aid in the efficient transfer of bulk materials. These assemblies are used to divert materials from the conveyor belt to various discharge points, ensuring that the materials are delivered to their intended location. The design and calculation of lifting plough assemblies require a thorough understanding of the forces…

View On WordPress

#acceleration load#belt conveyor#conveyor motor#conveyor speed#conveyors#dead load#flat belt conveyor system#friction load#impact load#lifting plough assembly#live load

0 notes

Text

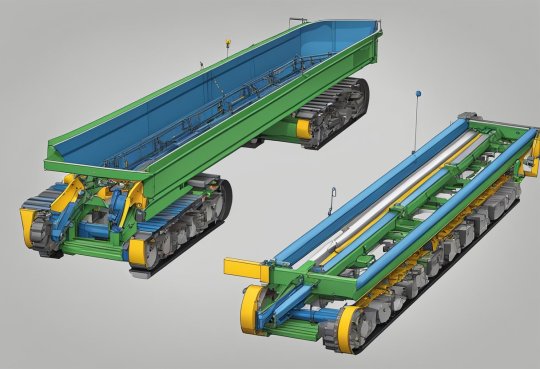

Horizontal Flat Belt Conveyor manufacturer In Faridabad

Parthax stands as a pinnacle in the realm of manufacturing and supplying Horizontal Flat Belt Conveyors manufacturers in Faridabad. Renowned for its commitment to quality, innovation, and reliability, Parthax has established itself as a leader in the industry.

The Horizontal Flat Belt Conveyors crafted by Parthax boast superior design, engineered for seamless performance and longevity. With meticulous attention to detail, these conveyors are tailored to meet the diverse needs of various industries, from manufacturing to logistics and beyond.

read more:https://www.parthax.com/faridabad/horizontal-flat-belt-conveyor

0 notes

Text

#Belt Conveyor System#conveyor belt system for sale#conveyor belt types#flat belt conveyor system#conveyor belt manufacturer#conveyor belt monitoring system#Belt Conveyor System manufacturer India

0 notes

Text

Special Purpose Sprockets Manufacturer in Pune | Maharashtra

Welcome to infinity engineering solutions, your trusted partner for top-quality Special Purpose Sprockets and Special Purpose Conveyor Chains. If you're in search of a reliable manufacturer in Pune, Maharashtra, look no further. We are a leading manufacturer and exporter of specialized conveyor solutions designed to meet your unique requirements. Our Special Purpose Sprockets and Conveyor Chains are engineered with precision and are known for their exceptional reliability and durability. We understand the importance of these critical components in various industrial processes, and that's why we are committed to delivering the highest quality products.

#Special Purpose Sprockets Manufacturer#Special Purpose Conveyor Chain#Heavy Duty Elevator Chains#Flat Top Chain#Special Purpose Conveyor Chains Manufacturer#Hallow Pin Conveyor Chain#Hallow Pin Conveyor Chain Manufaturer Slat Conveyor#Conveyor Chain#Conveyor Chain Manufacturer#Slat Conveyor Manufacturer#Slat Conveyor#Enrober Belt#Honeycomb#Elevator Chains#Wire Mesh Conveyor Belt

0 notes

Text

Storage Solution Providers in India - Bhupati Engineering

Bhupati Engineering is committed to providing high-quality products and services to its customers at competitive prices. The company's products and services are used by a wide range of industries in India, including agriculture, food processing, chemicals, and storage solution providers. Bhupati Engineering is dedicated to providing sustainable solutions that meet the needs of its customers and the environment.

#Storage Solution Providers#Agricultural Storage Tanks#Material Handling Equipment Manufacturers & Suppliers#Grain Storage Silo Manufacturers#Industrial Material Handling Equipment#Conveyor Manufacturing Companies#Conveyor Belt Manufacturers In India#Vertical Bucket Elevator Manufacturers#Liquid Storage Tank Manufacturers#Storage Solutions Companies In India#Flat Bottom Silos#Grain Storage System Equipment#Turnkey Project Solutions#Water Storage Solutions#Flat Bottom Silos Manufacturers#Hopper Bottom Silos Manufacturers#Zincalume Water Storage Tank Manufacturers#Underground Water Tank Manufacturers#Underground Tank Exporters#Agricultural Water Tank Manufacturers & Suppliers#Irrigation Water Tank Manufacturers#Overhead Water Tank Manufacturers & Exporters#Storage Tank Manufacturers & Suppliers#Water Storage Tanks Manufacturers#Exporters#Drinking Water Storage Tank Exporters#Rain Water Storage Tank Manufacturers#Rain Water Harvesting Tanks Exporters#Zincalume Water Tank Manufacturers#Zincalume Water Storage Tanks Exporters

1 note

·

View note

Text

Enhance your PCB assembly process with the advanced Wave Soldering Machine designed for precision and efficiency. Ideal for high-volume production, it ensures uniform soldering with minimal defects. Featuring automated controls and energy-efficient operation, this machine is perfect for delivering high-quality results. Choose Yontro for reliable and cutting-edge soldering solutions!

#reflow soldering machine#conveyor belt manufacturers in india#yontro mechatronic systech#wave soldering machine#conveyor belt#flat belt conveyor#inclined conveyor belt#yontro#cleated belt conveyor#industrial work station

1 note

·

View note

Text

Exploring the History of the Conveyor Belt!

Are you finding the History of the Conveyor Belt? We provide all information on conveyor Belts and the primary material details that are used to create belt fabric. Nowadays, the conveyor belts supplier uses various techniques, materials, and designs to make it. To know more about belt fabric manufacturers, visit our blog!

#belt fabric#belt fabric manufacturers#belt fabric supplier#conveyor belts supplier#flat belts supplier#conveyor belts

0 notes

Photo

Flat Flex Wire Mesh Belt

Flat Flex Wire Mesh Belt is also named flat flex conveyor belt. The belt is designed for conveying a wide range of products. This wire mesh belt is customizable options for specific requirements.

1. Construction: (1) Interlocking wire design for strength. (2) High-grade stainless steel construction. (3) Precision welding for enhanced stability. (4) Open mesh structure facilitates easy cleaning. (5) Smooth edges prevent product damage. (6) Resistant to wear and tear for prolonged use. (7) Lightweight yet robust for efficient operation. (8) Designed to minimize belt stretch. (9) Options for reinforced edges for added strength. (10) Available in various belt widths for versatility.

2. Applications: (1) Food processing for hygienic material handling. (2) Heat treatment processes in industrial ovens. (3) Packaging lines for smooth product transition. (4) Automotive manufacturing for assembly lines. (5) Chemical processing for corrosive environments. (6) Electronics industry for delicate component handling. (7) Textile industry for seamless material flow. (8) Pharmaceutical production for hygiene compliance. (9) Agricultural processing for bulk material handling. (10) Mining operations for efficient ore transportation.

3. Performance Benefits: (1) Minimized downtime for increased productivity. (2) Consistent and reliable material conveying. (3) Low friction design for energy efficiency. (4) Easy to clean, ensuring hygienic standards. (5) Reduces product waste with smooth transitions. (6) Resistant to adverse environmental conditions. (7) Customizable for specific operational needs. (8) Improved worker safety with reliable operation. (9) Long-lasting performance for a solid ROI. (10) Adaptable to various speed and load requirements.

4. Customization Options: (1) Custom belt lengths for diverse Conveyor Systems. (2) Specialized mesh configurations for unique materials. (3) Color-coding for easy visual identification. (4) Variable wire thickness for enhanced strength. (5) Optional coatings for additional corrosion resistance. (6) Attachment options for specialized handling. (7) Integration of tracking systems for precision. (8) Perforations for liquid drainage applications. (9) Adjustable belt tension for optimal performance. (10) Collaboration with engineers for tailored solutions.

The product Flat Flex Wire Mesh Belt appeared first on Alex Wire Mesh.

#Conveyor Belt#Flat Flex Belt#Flat Flex Belting#Flat Flex Conveyor Belt#Flat Flex Mesh Belt#Flat Flex Metal Belt#Flat Flex Steel Belt#Flat Flex Transport Belt#Flat Flex Wire Belt#Flat Flex Wire Mesh Belt#Mesh Conveyor Belt#Metal Conveyor Belt#Steel Conveyor Belt#Wire Belt#Wire Conveyor Belt#Wire Mesh Belt#Wire Mesh Conveyor Belt

0 notes

Text

Titan material handling pvt. Ltd provide Belt Conveyor at best cost, It Is the bestBelt conveyor, Flat Belt Conveyor manufacturers company in Pune, Mumbai, India, Andhra Pradesh, Visakhapatnam, SriCity, Guntur, Goa, Margao, Haryana, Gurugram, Faridabad, Gujarat, Ahmedabad, Ankleshwar, Bharuch, Gandhinagar, Jamnagar, Rajkot, Vadodara, Himachal Pradesh, Baddi, Karnataka, Bangalore, Belagavi, Tumkur, Manglore, Hubli, Maharashtra, Navi Mumbai, Mumbai, Pimpri Chinchwad, Pune, Nashik, Aurangabad, Nagpur, Kolhapur, Rajnangaon, Madhya Pradesh, Pithampur, Indore, Tamil Nadu, Coimbatore, Chennai, Hosur, Uttar Pradesh, Noida, Telangana, Hyderabad, Chakan, Hinjawadi, Pirangut, Baramati, Ranjangaon, shirur

0 notes

Text

Gravity spiral conveyor Manufacturer in Pune | India

In this world of material transport and handling, finding a suitable gravity spiral conveyor manufacturer is quite tough to find. Hence, Rothe Packtech offers a pioneering gravity spiral conveyor manufacturer in Pune, India.

#Gravity Roller Conveyor Manufacturer Pune#Pallet Conveyor Manufacturer Pune#Power Roller Conveyor Manufacturer Pune#Telescopic Conveyor Manufacturer Pune#Take Up Conveyor Manufacturer Pune#Knife Edge Conveyor Manufacturer Pune#Flat Belt Conveyor Pune.

0 notes

Text

Take that, warnings and regulations! >: ]

from Hi-Fi Rush

#hi fi rush#chai hi fi rush#808 hi fi rush#absolute nonsense#why yes thank you I did play through this track up to the conveyor belts specifically to take this photo#half an hour well spent!#gonna get squashed flat any second now

40 notes

·

View notes

Text

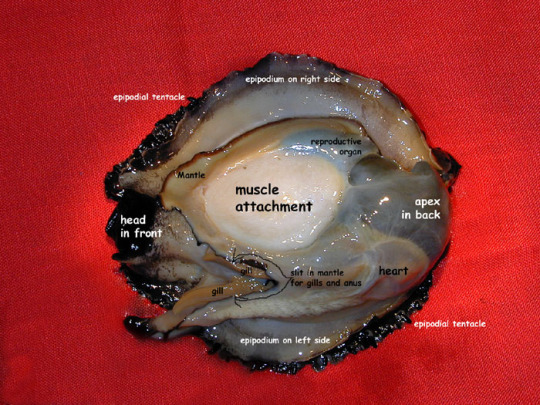

Wet Beast Wednesday: abalone

This is a Wet Beast Wednesday post, but it would also be applicable for Mollusk Monday and maybe even Flat Fuck Friday. Today I'll be introducing you to the abalone. The squat snails have some strange features that set them apart from their fellows in the shell squad. Unfortunately, over harvesting of abalone for their meat and shells have put many abalone species in danger.

(Image: an abalone attached to a rock. It is a snail with a large, broad, and flat brown shell. A muscular foot attaches the animal to the rock. Around the body is a membrane covered in tentacles that reach out around the body. End ID)

Abalone are marine snails of the genus Haliotis (not to be confused with halitosis) that can range in shell diameter from 20 mm (0.8 in) to 300 mm (12 in). The number of species is a matter of some debate. There's a lot of variation in morphology within species which led to many species being incorrectly classified as multiple species. The most accepted number appears to be 56 species and 18 subspecies. Abalone shells are highly flattened and the spiral can be hard to see, making them look like large limpets. They have no operculum and cannot withdraw into their shells like other snails can. Instead, when threatened they suction as hard as possible to an object. The shells have holes in them on one side which are used for respiration, waste disposal, and release of gametes. As abalone grow, the number of holes will change with some being filled in and new ones forming. The interior of the shell is covered in nacre. This substance, also called mother-of-pearl is valuable for its polished, iridescent appearance. Abalone use the nacre to make claw-shaped pearls. The shell is composed of microscopic bricks of calcium carbonate glued together by a protein structure. When pressure is applied to the structure, the bricks slide against each other and the protein glue stretches. This helps absorb the energy of blows and makes the shells very resistant to cracking. The shell structure of abalone has been studied to make sturdier body armor and ceramics.

(Image: an empty and polished abalone shell, seen from below. The shell is lined with shiny and iridescent nacre. The nacre color varies with species, but in this case is blue-green. A line of holes are on one side of the shell. End ID)

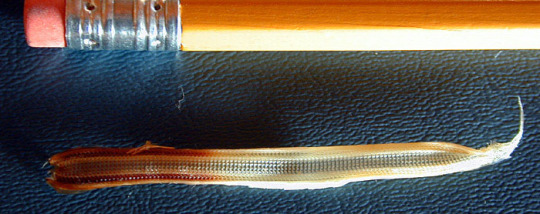

The majority of the shell's interior is filled with the muscular foot, which the abalone uses for locomotion. The foot is attached to the shell in the center. Around the edge of the foot is a structure called the epipodium. This is a frilled membrane lined with sensory tentacles. When an abalone is relaxed, it will extend the tentacles to examine its surrounding. When threatened, the tentacles retract for safety. Along the edge of the shell is the mantle, which produced the material for the shell. Abalone will grow larger throughout their lives, with the mantle continuously making new shell. At the front is the head, which has sensory tentacles and a mouth that contains a pair of oral tentacles use for finding food and the radula. The radula is a tongue-like structure lines with sharp teeth. The teeth scrape algae off of rocks and into the mouth. The teeth are arranged in rows that move forward like a conveyor belt, allowing worn out teeth to fall out and be replaced by fresh ones. The head is near the newest-formed hole and the anus is next to the rearmost hole.

(Image: an abalone seen from below, with the foor removed and anatomy labeled. The organs circle around a central muscle that the foot attaches to. A small head is in the front while the epipodium rings the body. Source. End ID)

(Image: an abalone's radula, removed and next to a pencil for scale. It is a long, thin structure lined with rows of tiny teeth. The front end is stained brown with algae. End ID)

Abalone live on coasts worldwide, with the exception of the North American Atlantic coast, South American Pacific Coast, and the poles. Most species live in cold water, but tropical species are known. They spend their times feeding on algae. Abalone shells are usually covered with life, including algae and sessile animals like tunicates, sponges, and tube worms. The hitchhikers combined with the upper shell's dull appearances serves as effective camouflage. During mating season, males and females release gametes into the water. The number of eggs a female can produce increases with size and can be up to 11 million per season. The larvae start out in a swimming form before metamorphosing into non-swimming juveniles called spat. Abalone reach sexual maturity young and at a small size.

(Iamge: dozens of abalone spat in a tank. They are miniature versions of the adults, but have nacre on the outside of the shell as well, giving them a shiny turquoise color. End ID)

Abalone have been hunted by huamns for millennia, with the oldest evidence of use being a 100,000 year old "workshop" found in Blombos Cave, South Africa, where abalone shells were used as storage for ochre mixtures. Throughout their native ranges, abalone have been harvested for their meat, nacre, and pearls. The shells are often used for jewelry, as decorative inlay, and, in some cultures, as currency. The foot is edible and considered a delicacy in some cultures and a staple in others. The value of abalone has led to worldwide overfishing, resulting in many species being endangered. Captive farming has become a major industry in many places to meet the abalone demands. Farming began in China and Japan in the 1950s and 60s and the majority of abalone farms are still in east Asia. Because of overfishing, the majority of the world's abalone supply now comes from farms. Sport fishing is legal in many parts of the world, with 25% of the wild harvest coming from Tasmania. Many places require permits and have catch limits, but poaching remains a major industry. Collection of abalone is usually done with a blunt scoop called an abalone iron that can pop the animal off of rocks. It has to be blunt because abalone blood does not clot and any cut will lead to the animal bleeding to death. Overharvesting and increasing ocean acidification are the largest threats to abalone. Places where abalone are reintroduced to the wild have seen increased biodiversity and environmental health.

(Image: a carving made by the Haida people of British Columbia, Canada. It reselbles a face with a tall hat or head with a small body carved on it. Abalone shells are used for inlay,, cut into rectangles with the nacre facing out. End ID)

#wet beast wednesday#abalone#snail#snails#sea snail#mollusk#molluscs#marine biology#marine life#biology#ecology#zoology#animal facts#informative#educational#image described

166 notes

·

View notes