#Fire Retardant Rubber Market

Explore tagged Tumblr posts

Text

For two decades, researchers worked to solve a mystery in West Coast streams. Why, when it rained, were large numbers of spawning coho salmon dying? As part of an effort to find out, scientists placed fish in water that contained particles of new and old tires. The salmon died, and the researchers then began testing the hundreds of chemicals that had leached into the water.

A 2020 paper revealed the cause of mortality: a chemical called 6PPD that is added to tires to prevent their cracking and degradation. When 6PPD, which occurs in tire dust, is exposed to ground-level ozone, it’s transformed into multiple other chemicals, including 6PPD-quinone, or 6PPD-q. The compound is acutely toxic to four of 11 tested fish species, including coho salmon.

Mystery solved, but not the problem, for the chemical continues to be used by all major tire manufacturers and is found on roads and in waterways around the world. Though no one has studied the impact of 6PPD-q on human health, it’s also been detected in the urine of children, adults, and pregnant women in South China. The pathways and significance of that contamination are, so far, unknown.

Still, there are now calls for regulatory action. Last month, the legal nonprofit Earthjustice, on behalf of the fishing industry, filed a notice of intent to sue tire manufacturers for violating the Endangered Species Act by using 6PPD. And a coalition of Indian tribes recently called on the EPA to ban use of the chemical. “We have witnessed firsthand the devastation to the salmon species we have always relied upon to nourish our people,” the Puyallup Tribal Council said in a statement. “We have watched as the species have declined to the point of almost certain extinction if nothing is done to protect them.”

The painstaking parsing of 6PPD and 6PPD-q was just the beginning of a global campaign to understand the toxic cocktail of organic chemicals, tiny particles, and heavy metals hiding in tires and, to a lesser extent, brakes. While the acute toxicity of 6PPD-q and its source have strong scientific consensus, tire rubber contains more than 400 chemicals and compounds, many of them carcinogenic, and research is only beginning to show how widespread the problems from tire dust may be.

While the rubber rings beneath your car may seem benign — one advertising campaign used to feature babies cradled in tires — they are, experts say, a significant source of air, soil, and water pollution that may affect humans as well as fish, wildlife, and other organisms. That’s a problem because some 2 billion tires globally are sold each year — enough to reach the moon if stacked on their sides — with the market expected to reach 3.4 billion a year by 2030.

(Researchers weigh a salmon that died after four hours in a tank filled with road runoff.)

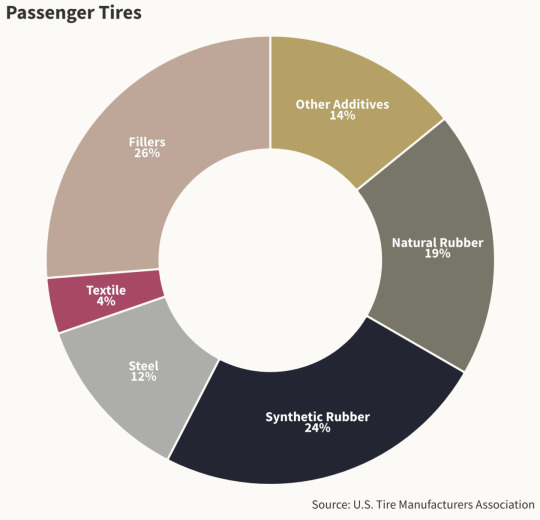

Tires are made from about 20 percent natural rubber and 24 percent synthetic rubber, which requires five gallons of petroleum per tire. Hundreds of other ingredients, including steel, fillers, and heavy metals — including copper, cadmium, lead, and zinc — make up the rest, many of them added to enhance performance, improve durability, and reduce the possibility of fires.

Both natural and synthetic rubber break down in the environment, but synthetic fragments last a lot longer. Seventy-eight percent of ocean microplastics are synthetic tire rubber, according to a report by the Pew Charitable Trust. These fragments are ingested by marine animals — particles have been found in gills and stomachs — and can cause a range of effects, from neurotoxicity to growth retardation and behavioral abnormalities.

“We found extremely high levels of microplastics in our stormwater,” said Rebecca Sutton, an environmental scientist with the San Francisco Estuary Institute who studied runoff. “Our estimated annual discharge of microplastics into San Francisco Bay from stormwater was 7 trillion particles, and half of that was suspected tire particles.”

Tire wear particles, or TWP as they are sometimes known, are emitted continually as vehicles travel. They range in size from visible pieces of rubber or plastic to microparticles, and they comprise one of the products’ most significant environmental impacts, according to the British firm Emissions Analytics, which has spent three years studying tire emissions. The company found that a car’s four tires collectively emit 1 trillion ultrafine particles — of less than 100 nanometers — per kilometer driven. These particles, a growing number of experts say, pose a unique health risk: They are so small they can pass through lung tissue into the bloodstream and cross the blood-brain barrier or be breathed in and travel directly to the brain, causing a range of problems.

According to a recent report issued by researchers at Imperial College London, “There is emerging evidence that tyre wear particles and other particulate matter may contribute to a range of negative health impacts including heart, lung, developmental, reproductive, and cancer outcomes.”

The report says that tires generate 6 million tons of particles a year, globally, of which 200,000 tons end up in oceans. According to Emissions Analytics, cars in the U.S. emit, on average, 5 pounds of tire particles a year, while cars in Europe, where fewer miles are driven, shed 2.5 pounds per year. Moreover, tire emissions from electric vehicles are 20 percent higher than those from fossil-fuel vehicles. EVs weigh more and have greater torque, which wears out tires faster.

Unlike tailpipe exhaust, which has long been studied and regulated, emissions from tires and brakes — which emit significant amounts of metallic particles in addition to organic chemicals — are far harder to measure and control and have therefore escaped regulation. It’s only in the last several years, with the development of new technologies capable of measuring tire emissions and the alarming discovery of 6PPD-q, that the subject is receiving much needed scrutiny.

Recent studies show that the mass of PM 2.5 and PM 10 emissions — which are, along with ozone and ultrafine particles, the world’s primary air pollutants — from tires and brakes far exceeds the mass of emissions from tailpipes, at least in places that have significantly reduced those emissions.

The problem isn’t just rubber in its synthetic and natural form. Government and academic researchers are investigating the transformations produced by tires’ many other ingredients, which could — like 6PPD — form substances more toxic than their parent chemicals as they break down with exposure to sunlight and rain.

“You’ve got a chemical cocktail in these tires that no one really understands and is kept highly confidential by the tire manufacturers,” said Nick Molden, the CEO of Emissions Analytics. “We struggle to think of another consumer product that is so prevalent in the world, and used by virtually everyone, where there is so little known of what is in them.”

“We have known that tires contribute significantly to environmental pollution, but only recently have we begun to uncover the extent of that,” said Cassandra Johannessen, a researcher at Montreal’s Concordia University who is quantifying levels of tire chemicals in urban watersheds and studying how they transform in the environment. The discovery of 6PPD-q has surprised a lot of researchers, she said, because they have learned that “it’s one of the most toxic substances known, and it seems to be everywhere in the world.”

Regulators are playing catch up. In Europe, a standard to be implemented in 2025, known as Euro 7, will regulate not only tailpipe emissions but also emissions from tires and brakes. The California Environmental Protection Agency has passed a rule requiring tire makers to declare an alternative to 6PPD-q by 2024.

(A worker takes apart a tire at a recycling shop in Mit al-Harun, Egypt.)

Tire companies are conducting their own studies of 6PPD, which they have long considered critical for tire safety, and seeking alternatives. In response to new regulations and the emerging research on tire emissions, 10 of the world’s large tire manufacturers have formed the Tire Industry Project to “develop a holistic approach to better understand and promote action on the mitigation” of tire pollution, according to a statement by the project. The group has committed to search for ways to redesign tires to reduce or eliminate emissions.

One critical area of research is how long tire waste, and its breakdown products, persist in the environment. “A five-micron piece of rubber shears off the tire and settles on the soil and sits there a while,” said Molden. “What, over time, is the release of those chemicals, how quickly do they make their way into the water, and are they diluted? At the system level, how big of a problem is this? It is the single biggest knowledge gap.”

Another area of research centers on the impacts of aromatic hydrocarbons — including benzene and naphthalene — off-gassed by synthetic rubber or emitted when discarded tires are burned in incinerators for energy recovery. Even at low concentrations, these compounds are toxic to humans. They also react with sunlight to form ozone, or ground-level smog, which causes respiratory harm. “We have shown that the amount of off-gassing volatile organic compounds is 100 times greater than that coming out of a modern tailpipe,” said Molden. “This is from the tire just sitting there.”

When tires reach their end of life, they’re either sent to landfills, incinerated, burned in an energy-intensive process called pyrolysis, or shredded and repurposed for use in artificial turf or in playgrounds or for other surfaces. But as concern about tire pollutants grows, so do concerns about these recycled products and the hydrocarbons they may off-gas. There is ongoing debate over whether crumb rubber, made from tire scraps, poses a health threat when used to fill gaps in artificial turf. Based on several peer-reviewed studies, the European Union is instituting stricter limits on the use of this material. Other studies, however, have shown no health impact.

Besides California’s requirement to study alternatives to 6PPD, there are a number of efforts worldwide to redesign tires to counter the problems they pose. More than a decade ago, tire makers hoped that dandelions, which produce a form of rubber, and soy oil could provide a steady and sustainable supply of rubber. But tires made from those alternatives didn’t live up to expectations: they still required additives. The Continental Tire Company, based in Hanover, Germany, markets a bicycle tire made of dandelion roots. Tested by Emission Analytics, it emitted 25 percent fewer carcinogenic aromatics than conventionally made bike tires, but the plant-powered tire still contained ingredients of concern.

(Rubber made from dandelions.)

Other companies are searching for ways to address the problem of tire emissions. The Tyre Collective, a clean-tech startup based in the U.K., has developed an electrostatic plate that affixes to each of a car’s tires: The plates remove up to 60 percent of particles emitted by both tires and brakes, storing them in a cartridge attached to the device. The particles can be reused in numerous other applications, including in new tires.

In San Francisco, scientists studying the pollutants in storm runoff found a potential solution: Rain gardens, installed in yards to capture stormwater, were also trapping 96 percent of street litter and 100 percent of black rubbery fragments. In Vancouver, B.C. researchers found that rain gardens could prevent more than 90 percent of 6PPD-q from running off roads and entering salmon-bearing streams.

Tire waste particles, says Molden, of Emissions Analytics, are finally getting the attention they deserve, thanks in part to California’s rule requiring a search for alternatives to 6PPD. The legislation “is groundbreaking,” he says, “because it puts the chemical composition [of tires] on the regulatory agenda.” For the first time, he adds, “Tire manufacturers are being exposed to the same regulatory scrutiny that car manufacturers have been for 50 years.”

8 notes

·

View notes

Text

Combating Fire Risks: Analyzing the Global Flame Retardant Market

The global flame retardant market size is expected to reach USD 14.90 billion by 2030, registering a CAGR of 7.1% during the forecast period, according to a new report by Grand View Research, Inc. This growth can be attributed to the growing application scope in key end-use industries including automotive, electrical & electronics, transportation, construction, and others. In addition, increasing demand for these products in applications, such as polyolefin, Engineering Thermoplastics (ETP), epoxy resins, Polyvinyl Chloride (PVC), and rubber, coupled with the presence of favorable government regulations, especially in Asia Pacific, North, America, and Europe, will drive the market in the coming years.

Halogenated products, including brominated, chlorinated, phosphate-based, and antimony trioxide-based, are widely used in various applications, such as printed wiring boards, wires & cables, floorings, flexible polyurethane foams, polyolefins, polyamides, wall sheeting, refrigeration, and others. The demand for environmentally friendly products, such as non-halogenated flame retardants, is growing at a rapid pace. The Asia Pacific, North America, and Europe regions have emerged as the largest consumers owing to the presence of stringent environmental sustainability policies and the rising awareness about fire safety among consumers.

Phosphorus-based flame retardants, both chlorinated and non-halogenated, are extensively used in flexible and rigid polyurethane foams and the demand is anticipated to augment in the coming years. They have wide application prospects, and it is a vital part of inorganic flame retardants. These products can be divided into inorganic and organic phosphorous products. Asia Pacific holds a substantially high share owing to the increasing product penetration in the end-use industries including automotive, electrical & electronics, construction, and others. The markets in Asia Pacific are witnessing high production, especially in countries, such as India, China, Japan, and South Korea, owing to the growing emphasis on eco-labeled fire resistance products.

The COVID-19 pandemic has highly impacted the growth of the automotive and construction, sectors. The halting of manufacturing activities, slowing down of construction projects, and ongoing labor shortages owing to travel restrictions are expected to affect the demand for the products and their derivatives in construction applications over the forecast period. The global market is highly competitive due to the presence of a large number of multinationals that are engaged in constant R&D activities. Companies, such as BASF SE, Clariant, DuPont, DSM, Albemarle Corp., and LANXESS have a global presence and dominate the market due to a wide range of products for each application market. A majority of these companies have integrated their business operations across the value chain.

Flame Retardant Market Report Highlights

Asia Pacific was the dominant regional market in 2022 owing to the increased investments in the end-use industries, such as transportation and construction, especially in developing countries like India

The U.S. accounted for the largest share of the North America regional market in 2022 due to the large-scale production and rapid growth of the electrical & electronics, automotive, and construction sectors in the U.S.

The non-halogenated product segment accounted for the highest revenue as well as volume share in 2022 owing to increased environmental concerns and stringent government regulations

By application, Polyolefins segment accounted for the largest revenue share in 2022. Due to the growing use of polyolefins as plastics in numerous applications.

Flame Retardant Market Segmentation

Grand View Research has segmented the global flame retardant market based on product, application, end-use, and region:

Flame Retardant Product Outlook (Revenue, USD Million; Volume, Kilo Tons, 2018 - 2030)

Halogenated

Brominated

Chlorinated Phosphates

Antimony Trioxide

Others

Non-Halogenated

Aluminum Hydroxide

Magnesium Dihydroxide

Phosphorus Based

Others

Flame Retardant Application Outlook (Revenue, USD Million; Volume, Kilo Tons, 2018 - 2030)

Polyolefins

Epoxy Resins

UPE

PVC

ETP

Rubber

Styrenics

Others

Flame Retardant End-use Outlook (Revenue, USD Million; Volume, Kilo Tons, 2018 - 2030)

Construction

Transportation

Electrical & Electronics

Others

Flame Retardant Regional Outlook (Revenue, USD Million; Volume, Kilo Tons, 2018 - 2030)

North America

US

Canada

Mexico

Europe

UK

Germany

France

Italy

Spain

Norway

Asia Pacific

China

Japan

India

South Korea

Central & South America

Brazil

Argentina

Middle East and Africa

Saudi Arabia

South Africa

List of Key Players

Albemarle Corporation

ICL

LANXESS

CLARIANT

Italmatch Chemicals S.p.A

Huber Engineered Materials

BASF SE

THOR

DSM

FRX Innovations

DuPont

Order a free sample PDF of the Flame Retardant Market Intelligence Study, published by Grand View Research.

0 notes

Text

Top 15 Market Players in Global Zinc Borate (smoke suppression and afterglow reduction) Market

Top 15 Market Players in Global Zinc Borate (smoke suppression and afterglow reduction) Market

Zinc borate plays a vital role as a multifunctional additive in industries such as plastics, rubber, and coatings. Its ability to enhance flame retardancy, suppress smoke, and reduce afterglow has made it a critical component in fire protection. The following 15 companies are driving innovation and market growth in the zinc borate sector:

Borax (part of Rio Tinto Group) A global leader in boron-based chemicals, Borax provides high-quality zinc borate for fire protection and other industrial uses.

Zhejiang Xusen Flame Retardants Co., Ltd. A major supplier in Asia, Xusen focuses on producing cost-effective and high-performance zinc borate for flame retardant applications.

U.S. Borax Inc. Known for its premium boron products, U.S. Borax delivers zinc borate solutions that meet stringent industry standards.

Shandong Taixing Advanced Materials Co., Ltd. This Chinese company specializes in zinc borate production for smoke suppression in polymers and coatings.

Chemtura Corporation (now part of Lanxess) A key player in specialty chemicals, Chemtura offers advanced zinc borate formulations tailored for industrial applications.

China Zibo Borate Co., Ltd. Recognized for its high-quality zinc borate products, Zibo Borate serves the growing demand in Asia-Pacific markets.

Borochemie International Pte. Ltd. Headquartered in Singapore, Borochemie delivers specialized borate chemicals, including zinc borate, for global industries.

Shenzhen Jinhongda Flame Retardant Materials Co., Ltd. This company focuses on zinc borate additives for advanced flame-retardant solutions in construction and electronics.

Russian Bor As a leading supplier of boron products in Eastern Europe, Russian Bor provides zinc borate for smoke suppression and fire safety applications.

Yingkou Tanyun Chemical Research Institute Co., Ltd. A pioneer in flame-retardant materials, Tanyun offers zinc borate with applications in rubber, plastics, and textiles.

The Shepherd Chemical Company Known for its expertise in specialty chemicals, Shepherd Chemical develops zinc borate formulations for high-performance applications.

MCC Corporation MCC produces high-quality zinc borate, targeting sectors such as automotive, construction, and consumer electronics.

Quiborax Based in South America, Quiborax is a significant producer of boron-based chemicals, including zinc borate, for industrial applications.

Firebrake ZB by ICL Group A renowned product line under ICL, Firebrake ZB is widely used for smoke suppression and afterglow reduction in flame-retardant systems.

Guangdong Hongkai Flame Retardant Co., Ltd. A key player in the Chinese market, Hongkai focuses on innovative zinc borate solutions for polymers and textiles.

Request report sample at https://datavagyanik.com/reports/global-zinc-borate-smoke-suppression-and-afterglow-reduction-market-size-production-sales-average-product-price-market-share/

Top Winning Strategies in Zinc Borate (smoke suppression and afterglow reduction) Market

To remain competitive, companies in the zinc borate market are adopting innovative and customer-centric approaches. Below are the top strategies propelling growth in the sector:

Focus on Sustainability Companies are developing eco-friendly zinc borate products that comply with global environmental standards.

Expansion in Emerging Markets Targeting high-growth regions, such as Asia-Pacific and Latin America, is helping companies capture new customer bases.

Customization of Products Tailored zinc borate formulations are gaining traction, as industries demand solutions that meet specific performance criteria.

Strengthening Supply Chains Ensuring a steady supply of raw materials and minimizing logistics disruptions is a key priority for market leaders.

Collaborative R&D Companies are partnering with academic institutions and research organizations to develop next-generation zinc borate products.

Integration of Advanced Manufacturing Technologies Automation and AI-driven processes are enabling cost-efficient production while maintaining high product quality.

Regulatory Compliance Adhering to regional and international fire safety standards is essential for gaining customer trust and expanding market reach.

Strategic Partnerships Collaborating with polymer, rubber, and coating manufacturers helps in promoting zinc borate applications across diverse industries.

Expanding Product Portfolios Companies are diversifying their offerings to include zinc borate products with enhanced properties, such as improved thermal stability.

Investment in Marketing and Branding Building brand recognition through strategic marketing efforts is helping companies increase their visibility in the competitive market.

Adoption of Circular Economy Principles Recycling and reusing materials in zinc borate production processes align with global sustainability trends.

Enhancing Technical Support Services Providing robust technical guidance and post-sale support ensures long-term customer relationships.

Leveraging Digital Tools Utilizing data analytics and digital platforms helps in identifying customer needs and predicting market trends.

Competitor Benchmarking Regularly analyzing competitor strategies allows companies to fine-tune their own approaches and stay ahead.

Vertical Integration By integrating raw material extraction and production processes, companies achieve cost savings and ensure consistent quality.

Request a free sample copy at https://datavagyanik.com/reports/global-zinc-borate-smoke-suppression-and-afterglow-reduction-market-size-production-sales-average-product-price-market-share/

#Zinc Borate (smoke suppression and afterglow reduction) Market#Zinc Borate (smoke suppression and afterglow reduction) Production#market players#market size#market share#top trends#revenue#average price

0 notes

Text

Flame Retardants Market Growth and Status Explored in a New Research Report 2034

The flame retardants market is a key component of industries focused on enhancing fire safety. These compounds are added to materials such as plastics, textiles, and coatings to reduce flammability and inhibit the spread of fire. With growing safety regulations and increased awareness about fire prevention, the demand for flame retardants is on a steady rise globally.

The market for flame retardants is expected to increase at a compound annual growth rate (CAGR) of 7.2% between 2024 and 2034, reaching USD 16,462.41 million in 2034 based on an average growth pattern. In 2024, it is projected that the market will be worth USD 9,845.59 million.

Get a Sample Copy of Report, Click Here: https://wemarketresearch.com/reports/request-free-sample-pdf/flame-retardants-market/1589

Market Size and Growth:

The global flame retardants market was valued at approximately USD 8 billion in 2023 and is projected to grow at a CAGR of around 6% from 2024 to 2030.

Growth drivers include stringent fire safety standards, rapid industrialization, and advancements in flame-retardant technologies.

Key Applications:

Building & Construction: Used in insulation materials, structural components, and coatings.

Electronics & Electrical: Applied to circuit boards, cables, and appliances.

Transportation: Essential for automotive, aerospace, and railway materials.

Textiles: Used in furniture upholstery, curtains, and protective clothing.

Types of Flame Retardants:

Halogenated Flame Retardants: Known for effectiveness but facing declining usage due to environmental concerns.

Non-Halogenated Flame Retardants: Includes phosphorous-based, nitrogen-based, and inorganic flame retardants, growing in popularity for their eco-friendliness.

Flame Retardants Market Trends

Rising environmental concerns and health-related issues have led to increased adoption of non-halogenated flame retardants.

Manufacturers are investing in bio-based flame retardants to align with sustainability goals.

Advancements in Technology:

Development of multifunctional flame retardants that enhance fire safety without compromising the physical properties of materials.

Nanotechnology is being integrated to produce more efficient and lightweight solutions.

Stringent Regulations:

Governments worldwide are enforcing strict fire safety standards, boosting demand for flame-retardant materials.

Europe and North America are particularly focused on phasing out hazardous flame retardants.

Flame Retardants Market Opportunities

With the expansion of 5G networks, there’s increased usage of flame retardants in electronic components and infrastructure.

Manufacturers are exploring flame-retardant solutions compatible with recycling processes, especially in the plastic and automotive sectors.

Use of flame-retardant materials in medical devices and hospital furnishings, where fire safety is critical, is opening new avenues for growth.

Key companies profiled in this research study are,

The Flame Retardants Market is dominated by a few large companies, such as

BASF SE

Clariant AG

Huntsman Corporation

Israel Chemicals Limited (ICL)

Albemarle Corporation

·DuPont de Nemours, Inc.

Arkema S.A.

Solvay S.A.

Dow Chemical Company

Ferro Corporation

Nabaltec AG

Shanghai Pret Composites Co., Ltd.

Jiangsu Kuaima Chemical Co., Ltd.

Flame Retardants Market Segmentation,

By Type:

Alumina Trihydrate

Brominated Flame Retardant

Antimony Trioxide

Phosphorous Flame Retardant

Others

By Application:

Unsaturated Polyester Resins

Epoxy Resins

PVC

Rubber

Polyolefins

Others (Engineering Thermoplastics and PET)

By End User Industry:

Construction

Automotive & Transportation

Electronics

Others (Textiles, Aerospace, and Adhesives)

By Region:

North America

Latin America

Europe

East Asia

South Asia

Oceania

Middle East and Africa

Flame Retardants Industry: Regional Analysis

Asia Pacific Market Forecast

Asia Pacific dominates the worldwide flame retardant market, accounting for around 36% of the market in 2023. The Asia-Pacific region is the one with the fastest rate of growth and the highest percentage of flame retardants due to the fast industrialization, urbanization, and rise in construction activity. The growing demand for electronics, textiles, and cars in countries like China and India is largely responsible for the industry's expansion.

European Market Statistics

Europe's well-known emphasis on environmentally friendly practices and legislation is driving the demand for non-toxic flame retardants. Strict regulations that support the market, such REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), have an impact on the use of particular flame retardants. The building and automotive industries in the region make extensive use of flame retardants.

Market Predictions for North America

North America dominates the flame retardant market due to the region's stringent fire safety regulations, particularly in the building and automobile industries. Due to the existence of major manufacturers and continuous advancements in flame retardant compounds, the market is growing. Non-halogenated flame retardants are becoming more and more popular in the area due to environmental concerns.

Conclusion:

The flame retardants market is poised for sustained growth, driven by advancements in fire safety standards, the rise of eco-friendly alternatives, and expanding applications across industries like construction, electronics, and transportation. As safety and sustainability become global priorities, manufacturers are innovating to meet the dual demands of high performance and environmental compliance.

Looking ahead, the integration of smart flame retardants, bio-based solutions, and recyclable materials will reshape the market, making it more dynamic and sustainable. With stringent regulations and growing consumer awareness, the market is set to play a pivotal role in enhancing fire safety while supporting global environmental goals.

0 notes

Text

Everything You Need to Know About PVC Tape and Bijli Tape for Electrical Insulation

When it comes to electrical work, choosing the right type of tape is essential for safety, efficiency, and long-lasting results. PVC tape, commonly known in India as Bijli tape, is a staple for electricians and DIY enthusiasts alike. Made of polyvinyl chloride (PVC), these tapes provide essential insulation, protection, and durability in various electrical applications. In this blog, we’ll explore what PVC tape and Bijli tape are, their benefits, and why selecting high-quality products from reliable PVC tape manufacturers is crucial. We’ll also discuss the versatility and types of PVC tape rolls available in the market.

What is Bijli Tape?

"Bijli tape" is a colloquial term used in India for PVC electrical insulation tape. Popularly known as Bijli tapes, these are essentially PVC tapes specifically tailored for the Indian market and are widely used by electricians across the country. These tapes are crucial for ensuring secure, insulated, and damage-free electrical connections in various environments, including homes, offices, and industrial settings.

Key Benefits of Using PVC and Bijli Tape

PVC tape and Bijli tapes are essential for any electrical project due to their unique features and advantages:

High Insulation: PVC tape rolls are designed to provide superior electrical insulation. They help prevent electrical shorts, shocks, and potential fires.

Flexibility and Stretchability: PVC tapes are known for their flexibility, which makes them easy to use even around tight corners and bends.

Durability: PVC tapes are highly resistant to wear, abrasion, and moisture. This makes them a long-lasting solution for electrical insulation.

Temperature and Flame Resistance: Good-quality PVC and Bijli tapes are designed to withstand varying temperatures and are often flame retardant, adding an extra layer of safety to electrical setups.

Versatile Application: Available in different colors, PVC tape rolls can be used to identify wires, mark circuits, and create easy-to-recognize electrical systems.

Choosing High-Quality PVC Tape Manufacturers

With the market flooded with PVC and Bijli tapes, it’s essential to choose reliable and reputable PVC tape manufacturers to ensure quality and durability. Here are some factors to consider:

Material Quality: High-quality PVC tape is made from durable polyvinyl chloride with a strong adhesive that lasts for a long time without peeling.

Adhesion Strength: Look for PVC tape that adheres well to various surfaces, including metal, plastic, and rubber.

Thermal and Electrical Insulation Properties: Manufacturers should provide product details, including resistance to heat, voltage rating, and insulation thickness.

Certifications and Standards: Choose manufacturers who comply with safety and quality standards, ensuring their products are certified and meet industry benchmarks.

Some well-known PVC tape manufacturers offer a wide range of products, including specialized electric tape rolls designed for various applications, from industrial machinery to household wiring.

Types of PVC Tape Rolls and Applications

There are several types of PVC tape rolls available, each designed for specific applications. Here’s a look at some common types:

Standard PVC Electrical Tape Rolls: These are general-purpose tapes commonly used for insulating electrical wires. They are often available in various colors to help differentiate between wires.

High-Voltage PVC Tape Rolls: Used in heavy-duty industrial applications, high-voltage PVC tapes provide enhanced insulation and protection in high-voltage environments.

Weather-Resistant PVC Tapes: Designed for outdoor applications, these tapes are UV-resistant and moisture-resistant, making them ideal for use in harsh weather conditions.

Flame-Retardant PVC Tapes: Often used in environments where safety is paramount, flame-retardant PVC tapes minimize the risk of fire in case of electrical faults.

Bijli Tape: Specifically popular in India, Bijli tapes are widely used in household and commercial electrical projects for their reliability and insulation quality.

How to Use PVC Tape Effectively

Using PVC tape effectively can extend the life of your electrical work and ensure safety. Here are some best practices:

Clean the Surface: Ensure the surface is dry and clean before applying the tape to guarantee strong adhesion.

Apply with Tension: Stretch the tape slightly as you wrap it around wires to ensure a secure fit without any gaps.

Layering: For additional protection, especially in high-voltage applications, consider layering PVC tape by wrapping it multiple times around the wires.

Color Coding: Use different colors of PVC tape to organize wires, mark phases, or distinguish between circuits.

PVC and Bijli Tape in Electrical Safety

When dealing with electricity, safety is paramount. Using high-quality PVC tape rolls is an essential part of securing electrical connections and avoiding hazards. PVC tapes, particularly those sourced from reputable manufacturers, are tested to ensure they withstand the electrical and thermal demands of modern electrical systems. Insufficient or low-quality insulation can lead to short circuits, fire hazards, or electric shocks, making the choice of PVC and Bijli tape an important safety decision.

Conclusion

PVC tape and Bijli tapes are essential tools in the electrician’s toolkit, providing insulation, protection, and durability for a wide range of applications. From general-purpose electric tape rolls to weather-resistant and flame-retardant variants, choosing the right tape is crucial for ensuring safe and long-lasting electrical setups. By sourcing your PVC tape rolls from trusted manufacturers, you can ensure high quality, better insulation, and a longer lifespan for your electrical work.

#electrical insulation tape#pvc electrical tape#pvc tape manufacturers in delhi#pvc insulation tape in delhi#pvc tape#pvc insulation tape#pvc electrical insulation tape#pvc tape roll#bijli electrical tape#insulation tape roll#bijli tapes#bijli tape

0 notes

Text

Aluminium Trihydrate Price | Prices | Pricing | News | Database | Chart | ChemAnalyst

Aluminium Trihydrate Prices commonly known as ATH, is a crucial mineral compound used across a variety of industries, including the manufacturing of flame retardants, fillers, and in the production of aluminum. The price of Aluminium Trihydrate is influenced by multiple factors, including raw material costs, demand in key industries, and market conditions in the mining and chemicals sectors. Understanding the pricing trends of ATH is essential for businesses and manufacturers to navigate cost fluctuations and optimize their operations.

The global demand for Aluminium Trihydrate has been steadily rising due to its extensive applications. ATH is primarily used in the production of flame retardants, where it acts as an effective non-toxic fire retardant. Its use in plastic, rubber, and coatings industries for this purpose has been a major driver of its price movements. As safety regulations become stricter across various regions, particularly in construction and automotive sectors, the demand for flame retardants, and consequently ATH, continues to increase. Additionally, ATH serves as a critical raw material in the production of aluminum metal, where it acts as a precursor in the Bayer process. These varied applications contribute to the overall demand for Aluminium Trihydrate, which in turn impacts its price.

Get Real Time Prices for Aluminium Trihydrate: https://www.chemanalyst.com/Pricing-data/aluminium-trihydrate-1621

Another key factor influencing ATH pricing is the cost of raw materials and energy. Aluminium Trihydrate is primarily derived from bauxite, a naturally occurring mineral. Fluctuations in the global supply of bauxite can have a significant impact on the availability and price of ATH. The extraction and processing of bauxite require substantial energy inputs, and any shifts in energy costs, especially those related to fuel and electricity, can influence the production cost of ATH. As energy prices fluctuate, manufacturers may adjust the price of ATH to reflect these changes. Additionally, labor costs, transportation expenses, and mining regulations in major bauxite-producing countries can all contribute to price volatility.

The geographical distribution of ATH production also plays a role in its pricing. Major producers of Aluminium Trihydrate include countries such as China, the United States, and Australia, where large-scale bauxite mining and processing facilities are located. Transportation costs and supply chain disruptions in these regions can cause short-term fluctuations in ATH prices. For example, natural disasters, geopolitical tensions, or logistic challenges can lead to delays in the supply of bauxite, causing a ripple effect on the availability of ATH. Additionally, the COVID-19 pandemic highlighted the vulnerability of global supply chains, leading to production halts and price surges in several commodities, including ATH.

Environmental regulations and sustainability trends are also shaping the Aluminium Trihydrate market. As environmental awareness grows, companies are increasingly looking for eco-friendly alternatives to traditional flame retardants, such as halogenated compounds. This has spurred innovation in the ATH market, with manufacturers focusing on producing more sustainable and high-performance grades of Aluminium Trihydrate. The implementation of stricter environmental policies in various countries may result in higher production costs for ATH manufacturers who need to comply with these regulations. However, these changes also offer opportunities for producers who can align their products with eco-friendly certifications and industry standards.

Demand from the construction and automotive sectors is another major driver of ATH prices. In construction, Aluminium Trihydrate is used in the production of non-combustible materials such as building facades and fire-resistant coatings. With the growing emphasis on safety standards and fire prevention in both residential and commercial buildings, ATH demand is expected to remain strong. The automotive industry also contributes to ATH demand, as flame retardants are used in vehicle interiors, wiring, and insulation materials to comply with fire safety regulations. As the demand for electric vehicles (EVs) grows, ATH is likely to see an uptick in use, as EV batteries and components require high standards of fire protection.

The price of Aluminium Trihydrate also experiences periodic fluctuations driven by market speculation, as is the case with many other industrial commodities. Financial traders and investors often speculate on future price movements of ATH based on anticipated supply shortages, demand forecasts, or geopolitical developments. These speculative activities can amplify price volatility, especially in the short term. For example, if a major producer experiences a strike or supply chain interruption, market participants may drive up prices in anticipation of a supply shortage.

The growth of emerging economies, particularly in Asia, has been another key factor in shaping the demand and pricing for Aluminium Trihydrate. Countries like China, India, and Southeast Asian nations have seen rapid urbanization and industrialization in recent years, driving the demand for construction materials, automotive components, and consumer goods. ATH plays a significant role in these sectors, particularly in the production of flame retardants and coatings. As these economies continue to expand, the demand for Aluminium Trihydrate is expected to grow, further influencing its market price.

Looking ahead, the price of Aluminium Trihydrate is expected to remain subject to fluctuations driven by a combination of supply-side and demand-side factors. Raw material costs, energy prices, labor conditions, and environmental regulations will continue to influence production costs, while end-user industries such as construction, automotive, and electronics will drive demand. As businesses navigate these challenges, it will be crucial for manufacturers to remain adaptable, leveraging advances in technology and sustainability practices to maintain profitability while responding to market dynamics. Furthermore, geopolitical factors, trade policies, and international economic conditions will continue to shape the global Aluminium Trihydrate market. Ultimately, the future pricing of ATH will reflect a balance of these diverse elements, making it essential for industry stakeholders to stay informed and agile in managing their operations and cost structures.

Our Related News for Aluminium Trihydrate: https://www.chemanalyst.com/NewsAndDeals/NewsDetails/aluminium-trihydrate-prices-improves-in-august-in-india-and-saudi-arabia-30137

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Aluminium Trihydrate#Aluminium Trihydrate Price#Aluminium Trihydrate Prices#Aluminium Trihydrate Pricing#Aluminium Trihydrate News

0 notes

Text

Top Insulation Tape Manufacturers: A Comparative Review

Insulation tape is a vital component in electrical work, ensuring safety and stability in wiring and circuit installations. It protects wires from external elements such as moisture, heat, and electrical currents, making it an indispensable tool for electricians and industries alike. With so many insulation tape manufacturers on the market, choosing the right brand can be a daunting task. This blog aims to provide a comparative review of some of the top manufacturers, focusing on key factors such as durability, safety standards, and product variety. We will also take a look at the innovations from companies like Asio Electricals, which not only excel in insulation tape but also as a circuit breakers manufacturer.

Why is Insulation Tape Important?

Before diving into the review, it’s essential to understand why insulation tape plays such a critical role in electrical work. Its primary function is to insulate electrical wires, preventing the risk of short circuits, electric shocks, and fires. The tape must be durable, flame-retardant, and resistant to wear and tear, making the choice of manufacturer crucial.

1. 3M: A Global Leader in Electrical Solutions

When discussing insulation tape manufacturers, one of the first names that comes to mind is 3M. Known for its wide range of industrial and consumer products, 3M offers high-quality insulation tapes designed for various electrical applications.

Product Range: 3M offers a variety of insulation tapes, including general-purpose vinyl electrical tapes, high-temperature tapes, and rubber splicing tapes. Their tapes are highly regarded for their durability and resistance to UV rays, which makes them suitable for both indoor and outdoor applications.

Safety Standards: 3M ensures that all their tapes meet global safety standards, making them a preferred choice for industrial electricians. Their tapes are flame-retardant, providing an extra layer of safety in wiring installations.

While 3M tapes are among the most expensive on the market, their proven track record of reliability justifies the investment. They are a solid choice for large-scale industrial projects.

2. Asio Electricals: Excellence in Innovation

Asio Electricals has quickly gained recognition in the market for its range of electrical products, including insulation tapes. Though Asio is primarily known as a circuit breakers manufacturer, their insulation tapes have been making waves due to their affordability and high quality.

Product Range: Asio’s insulation tapes are designed to meet the needs of both professional electricians and DIY enthusiasts. Their products are known for their flexibility, which allows for easier wrapping around cables, ensuring a tighter, more secure fit.

Affordability: What sets Asio apart from competitors like 3M is its affordability without compromising on quality. This makes Asio tapes an excellent choice for smaller electrical projects where cost efficiency is a priority.

Innovation: Asio is committed to staying ahead of industry trends by continually innovating its products. Their focus on high safety standards, combined with their reputation as a reliable circuit breaker manufacturer, makes them a trusted brand in the electrical sector.

3. Nitto Denko: Durability and Specialisation

Nitto Denko is another renowned name in the field of insulation tape manufacturers. This Japan-based company offers specialized tapes that cater to niche industries, such as automotive and electronics.

Product Range: Nitto Denko’s tapes are designed for more specific applications, such as high-temperature environments, making them ideal for use in automotive wiring or industrial machinery.

Specialisation: Nitto Denko is a leader when it comes to specialized tapes that go beyond traditional insulation needs. They offer options that provide not only electrical insulation but also heat resistance and chemical protection.

Price Point: Due to their specialised nature, Nitto Denko products are often priced higher than competitors like Asio Electricals. However, for highly specific use cases, their durability and performance are unmatched.

4. Tesa: The All-Rounder

Tesa is a European brand that produces a wide range of tapes for various industries, including electrical, automotive, and industrial. Known for its adhesive technologies, Tesa offers versatile insulation tapes suitable for different environments.

Product Range: Tesa’s insulation tapes are known for their versatility. They offer tapes that provide excellent adhesion even in low-temperature conditions, making them ideal for outdoor applications.

Durability: Tesa tapes are built to last, withstanding both heat and moisture, making them suitable for long-term electrical installations.

Tesa’s products are priced competitively, offering a good balance between performance and cost, making them a popular choice in the European market.

5. Anchor by Panasonic: Affordable and Reliable

Anchor by Panasonic is well-known in India for producing affordable yet reliable electrical products. Their insulation tapes are designed with the Indian market in mind, focusing on delivering durability at a low price point.

Product Range: Anchor offers general-purpose insulation tapes that are perfect for small to medium-scale electrical projects. While they may not offer the advanced features of tapes from brands like Nitto Denko, they are highly reliable for basic insulation needs.

Affordability: Anchor is one of the most budget-friendly options on the market, making it a go-to choice for everyday electrical repairs and installations in India.

Conclusion: Which Manufacturer Should You Choose?

When it comes to choosing the right insulation tape manufacturers, your decision will largely depend on the scope and specific needs of your project. For large-scale industrial projects, brands like 3M and Nitto Denko provide the durability and specialized features required to meet demanding standards. If you’re looking for cost-effective yet reliable insulation tapes, Asio Electricals is an excellent choice, especially when you factor in their innovation in other electrical products like circuit breakers.

For those seeking a balance between performance and cost, Tesa offers a versatile range of tapes suitable for both indoor and outdoor use. Meanwhile, Anchor by Panasonic provides an affordable solution for basic electrical needs.

Ultimately, the right insulation tape should provide long-lasting protection, be easy to apply, and meet the specific demands of your project. With brands like Asio Electricals continuing to innovate, finding a reliable and affordable option has never been easier.

Also Read:

Exploring Global Markets for Wire and Cable Manufacturers

The Importance of an Electric Switch Manufacturing Company

Originally published at https://asioworld.blogspot.com

0 notes

Text

Elevating Your Mercedes V-Class with Stylish and Durable Car Mats

When it comes to maintaining the pristine condition of your Mercedes V-Class, investing in high-quality car mats is a must. Simply Car Mats, a leading provider of custom-fit car accessories, offers a range of Mercedes V-Class car mats that combine style, durability, and unparalleled protection for your vehicle's interior.

****Tailored Fit for Your Mercedes V-Class****

The Mercedes V-Class is a versatile and spacious MPV that demands a level of care and attention to detail. Simply Car Mats' Mercedes V-Class car mats are designed specifically to fit your vehicle, ensuring a seamless and secure installation. Our mats are crafted to perfectly contour the floor of your V-Class, providing a snug and custom-like fit that prevents slipping and sliding.

****Durable Materials for Long-Lasting Protection****

Crafted from high-quality materials, the Mercedes V-Class car mats from Simply Car Mats are built to withstand the rigors of daily use. The mats are available in both carpet and rubber options, catering to your specific needs and preferences. The carpet mats feature a fire-retardant and waterproof backing, ensuring your vehicle's floors are protected from spills and mud, while the rubber mats offer exceptional resistance to wear and tear.

****Personalize Your V-Class with Custom Branding****

In addition to their functional benefits, Simply Car Mats' Mercedes V-Class car mats can be personalized to reflect your unique style. You can choose from a range of carpet colors and opt for custom text or logo embroidery, allowing you to seamlessly integrate your car mats with the overall aesthetic of your V-Class. This personalization option adds a touch of individuality to your vehicle, making it truly your own.

****Elevate Your Driving Experience****

By investing in high-quality Mercedes V-Class car mats from Simply Car Mats, you can elevate the overall driving experience in your vehicle. These mats not only protect your car's floors but also contribute to a more comfortable and refined interior. With our precise fit and durable construction, you can enjoy the peace of mind that comes with knowing your V-Class is well-protected.

Whether you're a proud owner of a Mercedes V-Class or are in the market for a new set of car mats, Simply Car Mats' offerings are a must-consider. Elevate the style and functionality of your V-Class with their tailored, durable, and customizable car mats, and enjoy the ultimate in automotive interior protection.

<Click Here> to buy this product.

0 notes

Text

Roofing Materials Market: Exploring Emerging Trends

Different Types of Roofing Materials Asphalt Shingles

Asphalt shingles are the most commonly used roofing material for residential properties. They are made from fiberglass or organic materials that are covered with asphalt. Asphalt shingles are a cost-effective option that is durable and comes in a variety of styles and colors. However, they have a shorter lifespan than other materials, only lasting around 15-25 years. Homeowners need to replace asphalt shingles more frequently. They are also not a sustainable option as they contain asphalt and fiberglass. Concrete and Clay Tile

Concrete and clay tile roofs have a very stylish and elegant look, but they also provide excellent durability and protection for the home. Clay and concrete roof tiles can last 50 years or longer with proper installation and maintenance. They are resistant to fire, wind damage, and harsh weather conditions. The tiles are very durable. However, concrete and clay roofs are much heavier and more expensive to install compared to asphalt shingles or metal roofs. They require a sturdier roof structure to support the extra weight. Repairs may also be more complicated with tile roofs. Metal Roofing

Metal roofing such as steel, copper, titanium and aluminum is a long-lasting, sustainable option. Metal roofs have a lifespan of 50-100 years and come with strong warranties. They do not burn, rot or deteriorate like other materials. Metal is very durable against extremes in weather, high winds, hail damage, and fire. While upfront costs are higher than asphalt shingles, metal roofing offers increased energy efficiency and savings over time. Metal roofs are also 100% recyclable at the end of their lifespan. Some types like standing seam metal roofs have a modern, sleek look. Wood Shakes and Shingles

Cedar roofing made from shakes and shingles has a beautiful natural appearance. The wood weathers to a silvery gray tone. Wood roofing is a heavy, long-lasting choice that can last 50-100 years if properly maintained. It has natural insulating properties. However, wood is very flammable and not suitable for homes in wildfire-prone areas without proper fire-retardant treatment and regular maintenance. Wood roofs are also vulnerable to damage from humidity, insects, and rot if not properly ventilated. The upfront costs and specialized installation make wood roofing an expensive option. Green Roofing Materials

Sustainable, green roofing options are becoming more popular choices. Some eco-friendly alternatives include recycled rubber, terra cotta, and solar roof tiles. Solar roofing integrates functional photovoltaic panels to generate electricity from sunlight. Rubber roofing made from recycled tires provides stability and noise reduction, while terra cotta tiles have heritage charm with lower embodied energy than concrete. Green roofing helps property owners reduce their environmental footprint in materials selection while gaining energy efficiency. Higher costs remain a barrier to mass adoption of these innovative roofing solutions currently. Understanding the Durability Factor

When choosing roofing materials, it's important to consider lifespan as a key factor. A material's durability directly impacts the maintenance needs and replacement schedule over time. High-performance options like metal and tile roofs last 50+ years but require greater investment. Asphalt shingles are inexpensive initially but more frequent replacement bumps lifetime costs. Wood demands skilled installation to maintain moisture protection. Understanding the true lifetime expenses before buying helps determine the most suitable choice for both budget and sustainability objectives in the long run. Materials like metal reward homeowners for their resilience and stand-the-test-of-time performance. Other Important Considerations

Aside from lifespan, roof type suitability depends on several climate and structural factors: Weather resistance appropriate for a region's temperature extremes and precipitation levels Wind loads - heavier materials withstand high winds best Roof pitch - steep slopes support tile/shingle options, low pitches may require single-ply membrane Snow load capacity in snow-prone areas Attic ventilation for wood roofs Fire ratings in fire-risk regions Budget for materials, installation, and future replacement costs Personal aesthetic preferences for style and color Consulting with a professional roofer is advised to select a material well-matched to the specific home, its architecture, and environmental conditions. A qualified roofing assessment weighs all considerations for a custom recommendation. Often multiple quality materials suitably fulfill requirements, so personal choice matters most. With the right material choice based on thorough research, homeowners gain maximum long-term protection for their roof investment. Conclusion

By understanding the traits of popular roofing materials, homeowners can make an informed selection best for their individual home and budget needs now and over the coming decades. While initial price usually favors asphalt, more durable metal and tile options provide better long-term value and sustainability due to their 50+ year lifespans with proper care. Locating the optimal balance of longevity, weather protection, and lifetime costs aligned with the specific property results in the smartest roofing decision. Consulting an expert roofer's specialized guidance creates confidence in finding the right quality material for any home.

0 notes

Text

Discover the benefits of using Tetrahydrofuran ZL-439 Supplement

As a commonly used additive, Tetrahydrofuran ZL-439 has advantages in all walks of life. Let’s learn about it with the editor. If you are interested in our Tetrahydrofuran ZL-439, you can directly click to learn more

Improve solubility:

Tetrahydrofuran ZL-439 has good solubility and is compatible with many different types of substances. It can be quickly dissolved and dispersed in the matrix material, thus improving the uniformity and stability of the material. This makes the additive widely used in the fields of coatings, adhesives and resins to improve the handling performance and coating quality of products.

Improve adhesive performance:

Tetrahydrofuran ZL-439 exhibits excellent performance in bonding applications. It enhances the adhesion between the base material and the adhesive, and improves bond strength and durability. This makes the additive widely used in automotive manufacturing, aerospace and construction to ensure reliable joining of components and structures.

Provides Antioxidant Protection:

Tetrahydrofuran ZL-439 can effectively prevent the occurrence of oxidation reactions. It can form a protective layer on the surface of the base material to block the erosion of the material by air and other oxidants. This antioxidant protection helps prolong the life of products, especially in areas such as plastics, rubber and coated materials.

Improve flame retardant properties:

Tetrahydrofuran ZL-439 also plays an important role in improving the flame retardancy of the material. It improves the flame retardancy of the material and reduces the risk of fire. Therefore, in the fields of electrical and electronic equipment, furniture and building materials, this additive is widely used to meet safety standards and regulatory requirements.

Adjustable performance:

Tetrahydrofuran ZL-439 has the advantage of adjustable properties. By adjusting the ratio of additives or using them in combination with other compounds, the characteristics of the product can be changed according to the needs and requirements of different applications. This flexibility makes Tetrahydrofuran ZL-439 an ideal choice during product development and optimization.

It can be seen that Tetrahydrofuran ZL-439 additive has significant advantages in improving product performance.

It improves solubility, provides antioxidant protection, enhances adhesion properties, improves flame retardancy, and has the advantage of tunable properties. Tetrahydrofuran ZL-439 provides long-lasting support for the function and performance of products, whether in the coatings industry, in the construction sector or in the manufacture of electrical and electronic equipment. By fully exploiting the advantages of this additive, companies can gain a competitive advantage and meet the market demand for high-performance products.

Welcome to contact us for more content about Tetrahydrofuran ZL-439 additive

0 notes

Text

Indoor Flooring Forecast to 2031 with Key Companies Profile, Supply, Demand and SWOT Analysis

The global indoor flooring market size was valued at $133.3 billion in 2021, and is projected to reach $226.3 billion by 2031, growing at a CAGR of 5.4% from 2022 to 2031.The indoor flooring market size was valued at $1,33,288.0 million in 2021, and is projected to reach $2,26,305.0 million by 2031, registering a CAGR of 5.4% from 2022 to 2031. Building materials used to construct floors in residential, commercial, and industrial buildings are known as indoor flooring items. Indoor flooring is put when a new building or an old structure is being renovated. Interior infrastructure benefits from indoor flooring. Indoor flooring is available in a variety of materials, colors, and designs. Expansionary fiscal policy on infrastructure construction is likely to boost demand for flooring. The flooring market has seen an increase in insulation demand, as a well-insulated floor creates a better sound environment because of increased need for comfort and privacy as a result of noisier surroundings. As a result, demand for insulation is increasing, resulting in market development. Consumer preferences for aesthetically better designs, textures, and colors, as well as low-maintenance and easy-to-install floorings, are expected to propel market growth.

In addition, increase in urban population increases the commercial construction activity. The global urban population is rapidly increasing, according to World Bank data. New commercial construction projects, such as business complexes, hospitals, housing facilities, and shopping malls, are being prompted by rise in urban population. Consumers are investing their hard-earned money in high-quality residential complexes with exquisite flooring finishes, which boosts flooring activity.

The indoor flooring market is segmented on the basis of material type, construction type, end user, and region. On the basis of type, the market is divided into ceramic tiles, carpet, vinyl, linoleum, & rubber, wood laminate, and others. On the basis of construction type, the market is divided into new construction and renovation. On the basis of end user, the market is divided into residential and industrial & commercial. Region-wise, the global market analysis is conducted across North America (the U.S., Canada, and Mexico), Europe (UK, France, Germany, Russia, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, and Rest of Asia-Pacific), and LAMEA (Latin America, the Middle East, and Africa).

On the basis of material type, the ceramic tiles segment generated largest revenue in 2021, due to their unique appearance and fire-retardant properties, which increased the use of indoor ceramic tiles. These panels are also scratch-resistant and waterproof, and are made to be lightweight and durable. Rise in urbanization leads to increase in residential infrastructure construction, and thus, countries such as the U.S., China, and India have increased the demand for ceramic tiles, further driving the indoor flooring market growth.

On the basis of region, Asia-Pacific registered highest revenue in 2021 in indoor flooring market, owing to rise in investment in commercial and residential constructions. Furthermore, the region’s market expansion is predicted to be fueled by a large increase in the trend of home improvement and repair. As a result, the increase in number of new building and infrastructure projects is likely to provide profitable prospects for industry participants.

On the basis of construction type, the new construction segment accounted for highest revenue in the global indoor flooring market in 2021 owning to rise in investment in residential and commercial construction around the globe.

Competition Analysis

The key players that operating in the indoor flooring market are Armstrong Flooring, Inc., Beaulieu International Group, Ecore International, Forbo International SA, Interface, Inc., Mats Inc., Mohawk Industries, Inc., Shaw Industries Group, Inc., Tarkett, and Toli Corporation.

Full Report With TOC:-https://www.alliedmarketresearch.com/indoor-flooring-market-A08630

0 notes

Text

How to judge the fire performance of led display

Today, with the rapid development of science and technology, the LED display industry is also developing rapidly. In China's LED display industry, industry scale and technology content. And market share have made certain breakthroughs. In particular, the market share increased by an average of 40% annually. His rapid development will also be technically unsound. The sudden fire incident at the Yijunchuo Hotel in Hong Kong on April 2, 2012 sounded an alarm bell for the entire LED industry. The standardization and standardization of LED products has been put on the agenda again. In particular, LED display screen has become a major focus in fire safety application technology. What are the factors that affect the safety of the display screen? Teach you the waterproof and moisture-proof methods of three LED displays.

How to judge the fire resistance of led display?

The fire prevention technology of LED display mainly depends on the fire prevention raw materials and box technology of LED display.

The fireproof raw materials mainly include the wires and power supplies used inside the display LED screen, the fireproof materials of the external protective structure and the plastic kit. So how to ask?

First of all, requirements for wire rod. Because in most LED display applications, the power consumption is proportional to the area of the display. In this way, the larger the area of the display screen, the greater its power consumption. It also has higher requirements for the electrification stability of the wire. This requires strict requirements on material selection. There are three requirements for wire rod conforming to the requirements of the national standard:

1. The wire core is the conductive carrier of copper wire, the tolerance of wire core sectional area is within the standard range, and the insulation and flame resistance of the rubber covering the wire core meet the standard.

2. Compared with the general copper clad aluminum wire core, the wire core has a smaller sectional area and the insulation rubber grade is not enough.

3. Power-on performance is more stable, and short circuit is not easy to occur;

Secondly, the best choice is to pass the UL certification of power supply products. In this way, it can work normally even when the external temperature is very high.

Moreover, in the selection of materials for external protection of LED display. The general outdoor display screen on the market is made of aluminum-plastic panel, which is aging rapidly with high temperature, rain, cold and hot impact, and the rain is easy to penetrate into the screen body, resulting in short circuit of electronic components and fire; Most of the display screen products with higher fire rating are made of fire-resistant aluminum-plastic panels, which have excellent fire resistance, strong fire resistance and flame retardancy, and strong oxygen aging performance of the special core material. The melting point temperature is 135 ℃, the decomposition temperature is ≥ 300 ℃, environmental protection performance, low smoke and halogen-free, SGS compliance, flame retardance B-S1, d0, t0, reference standards UL94, GB/8624-2006.

Finally, the plastic kit is also an important part of the fireproof raw materials of the display screen. The material used in the bottom shell of the unit module face shield not only has the flame-retardant function, but also can not deform and become brittle and cracked under high and low temperature and long-term use. At the same time, it can be used in combination with the glue with good sealing performance, which can effectively prevent the rainwater from the external environment from penetrating into the interior, thus causing short circuit and fire.

The box technology is another important factor that determines the quality of the fire protection technology of LED display. Fan and air conditioner should be configured to cool the interior while the display is working. However, if the air conditioner or exhaust fan is not properly configured, the heat dissipation treatment will be uneven, which will easily lead to potential safety hazards inside the screen due to temperature rise. Another important reason is that many LED lighting enterprises simply simulate the waterproof test when testing their products, and the durability and strength of the waterproof effect still need further research. This leads to water seepage of some products after use for a period of time, resulting in short circuit and danger. Therefore, product waterproof test is also very important. Another reason is that there is no screen arrester installed. In thunderstorm weather, the internal components of the screen body will be burnt by lightning strike, which will cause danger. Therefore, the screen arrester is a necessary tool, which can directly lead lightning to the ground without affecting the screen.

Of course, besides the product itself, there are also human factors that cause fire accidents. Therefore, in the later maintenance work, the staff must work according to the correct process. The exact cause of the fire at the Hong Kong hotel has yet to be investigated. However, we should not take a negative attitude towards the application of LED display products in Hong Kong because of this incident. Although the entire industry standard has not been established, there are still many LED enterprises doing well in the industry. For example, Shenzhen Bright Color Technology has been very perfect in the fire protection system. We should demand ourselves with high quality and strict specifications to guide the healthy development of the industry, so as to enhance the competitiveness of the entire industry in the world and move towards internationalization.

Thank you for watching. I hope we can solve your problems. Sostron is a professional LED display manufacturer. We provide all kinds of displays, display leasing and display solutions around the world. If you want to know:Acceptance guide for led display. Please click read.

0 notes

Text

Fire Retardant Rubber Market Opportunity and Industry Revenue Analysis by Major Players, 2021-2027

In the latest report, with a graph of the Fire Retardant Rubber market, the assessment bases fundamentally available examples, demand reach, and future odds of this territory over the gauge time period. Besides, the report gives a nitty gritty measurable outline as far as patterns portraying the geographic chances and ventures of driving business investors.

A definite outline of the worldwide market size, territorial and nation market size, market development division, piece of the overall industry, serious climate, stock levels, homegrown and worldwide market player sway, store network streamlining, import requirements, most recent patterns, opportunity examination, and vital market development is introduced in the market report on Fire Retardant Rubber.

Free Sample Report + All Related Graphs & Charts (Including COVID19 Impact Analysis) @:https://www.crystalmarketresearch.com/report-sample/CM0114677

Some of the key players in the Global Fire Retardant Rubber market are:

Elasto Proxy

Shin-Etsu

Polycomp

PAR

Ronfell

MacLellan Rubber

Hebei Shida Seal

OHJI RUBBER?CHEMICAL

Simon FKM

CC Rubber

Fire Retardant Rubber Market

Continue...

TOC of Fire Retardant Rubber Market Report:

Industry Overview of Fire Retardant Rubber Market.

Accumulation Cost Structure Analysis of Fire Retardant Rubber Market.

Specific Information and Manufacturing Plants Analysis of Fire Retardant Rubber Market.

Limit, Production, and Revenue Analysis.

Worth, Cost, Gross and Gross Margin Analysis of Fire Retardant Rubber Market by Regions, Types, and Manufacturers.

Use Volume, Consumption Value, and Sale Price Analysis of Fire Retardant Rubber Market industry by Regions, Types, and Applications.

Supply, Import, Export, and Consumption Analysis of Fire Retardant Rubber Market.

Huge Manufacturers Analysis of Fire Retardant Rubber Market industry.

Publicizing Trader or Distributor Analysis of Fire Retardant Rubber Market.

Industry Chain Analysis of Fire Retardant Rubber Market.

Progression Trend Analysis of Fire Retardant Rubber Market.

New Project Investment Feasibility Analysis of Fire Retardant Rubber Market.

Request Discount on this Report @https://www.crystalmarketresearch.com/check-discount/CM0114677

Prominent Points in Fire Retardant Rubber Market Businesses Segmentation:

Fire Retardant Rubber Market, By Product Type, Estimates and Forecast, 2016-2027 ($Million)

Neoprene Rubber

Viton Rubber

Silicone Rubber

Others

Fire Retardant Rubber Market, By Application, Estimates and Forecast, 2016-2027 ($Million)

Automobile Industry

Electronics Industry

Transportation Industry

Building Industry

Others

Fire Retardant Rubber Market

Regions & Countries Mentioned In The Global Fire Retardant Rubber Market Report::

North America Region

Europe Region

Asia-Pacific Region

South America Region

The Middle East & Africa Region

Motivations to buy the exploration report:

Gives inside and out research examination of the general Fire Retardant Rubber market. which can help save time for business people hoping to begin business in regards to the Fire Retardant Rubber Market.

Different moving news, gauge examination and key contenders of the market are effectively accessible with all the vital data.

Whole market extension and data can be accessible at the fingertips for any business person or organization that buys the report which can help a new business or a contender comprehend the Fire Retardant Rubber Market in detail with every one of the important components.

Diagrams, pie outlines and different portrayals that can assist the peruser with understanding the data at a solitary look.

All vital data with respect to the market that can assist a maker with understanding the purchaser conduct, business sections and sell items dependent on the examination data.

Most moving Coronavirus pandemic effect available and industry with all the important recuperation examination.

Fire Retardant Rubber Research Report Inspects:

Item Type and Applications

Coronavirus Impact investigation

Vital participants/organizations of Fire Retardant Rubber Market all around the world

You can Buy This Report from Here @https://www.crystalmarketresearch.com/send-an-enquiry/CM0114677

Contacts Us:

Crystal Market Research

Sherry | APAC Marketing Division: Level 23-1

Premier Suite, Mont Kiara, 50480 Kuala

Lumpur, Malaysia

E-mail: [email protected]

0 notes

Text

Flame Retardants Market Challenges and Opportunities Share Growth Forecast (2024-2034)

The global Flame Retardants market is experiencing significant growth due to increased demand for fire-resistant materials in sectors such as construction, electronics, transportation, and textiles.Flame retardants are added to materials to prevent or delay combustion, helping reduce the risk of fire-related damage and loss.

The market for flame retardants is expected to increase at a compound annual growth rate (CAGR) of 7.2% between 2024 and 2034, reaching USD 16,462.41 million in 2034 based on an average growth pattern. In 2024, it is projected that the market will be worth USD 9,845.59 million.

Get a Sample Copy of Report, Click Here: https://wemarketresearch.com/reports/request-free-sample-pdf/flame-retardants-market/1589

Types of Flame Retardants

Halogenated Flame Retardants: These contain chlorine or bromine and are widely used but face environmental concerns due to toxic byproducts.

Non-Halogenated Flame Retardants: More environmentally friendly alternatives, often made from phosphorous or nitrogen compounds.

Mineral Flame Retardants: Include substances like aluminum hydroxide and magnesium hydroxide, known for their thermal stability and eco-friendliness.

Challenges in the Flame Retardants Market

Environmental Impact and Regulations: The environmental impact of flame retardants, especially halogenated ones, has led to regulatory restrictions in several regions, affecting their usage.

R&D and Innovation Costs: Developing safer, efficient, and eco-friendly flame retardants involves high R&D costs, which can be a barrier for some manufacturers.

Fluctuating Raw Material Prices: Variability in raw material prices can impact production costs and profitability for flame retardant manufacturers.

Flame Retardants Marketr Driver: