#Ferrosilicon Industry

Explore tagged Tumblr posts

Text

Ferrosilicon Market Segmented On The Basis Of Application, End-Use, Region And Forecast 2030: Grand View Research Inc.

San Francisco, 12 June 2023: The Report Ferrosilicon Market Size, Share & Trends Analysis Report By Application (Deoxidizer, Inoculants), By End-use (Stainless Steel, Cast Iron), By Region, And Segment Forecasts, 2023 – 2030 The global ferrosilicon market size is expected to reach USD 13.67 billion by 2030, registering a CAGR of 2.5% over the forecast period, according to a new report by Grand…

View On WordPress

#Ferrosilicon Industry#Ferrosilicon Market#Ferrosilicon Market 2030#Ferrosilicon Market Revenue#Ferrosilicon Market Share#Ferrosilicon Market Size

0 notes

Text

Driving Efficiency: Ferro Silicon Market Soars with Deoxidizer and Inoculants Applications

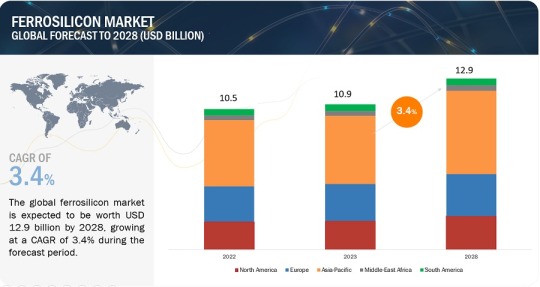

The report “Ferro Silicon Market by Type (Atomized Ferrosilicon, Milled ferrosilicon), Application (Deoxidizer, Inoculants), End-use Industry (Stainless Steel, Cast Iron, Magnesium), and Region (Asia Pacific, Europe, North America, MEA, SA) – Global Forecast to 2028″, is projected to reach USD 12.9 billion by 2028, at a CAGR of 3.4% from USD 10.9 billion in 2023. The ferrosilicon market is…

View On WordPress

#Atomized Ferrosilicon#Deoxidizer#Ferro Silicon#Ferro Silicon Alloy Market#Ferro Silicon Analysis#Ferro Silicon Consumption#Ferro Silicon Demand#Ferro Silicon Export Market#Ferro Silicon Growth#Ferro Silicon Industry#Ferro Silicon Manufacturer#Ferro Silicon Market#Ferro Silicon Market Dynamics#Ferro Silicon Market Forecast#Ferro Silicon Market Graph#Ferro Silicon Market Outlook#Ferro Silicon Market Research#Ferro Silicon Market Segmentations#Ferro Silicon Market Segments#Ferro Silicon Powder Market#Ferro Silicon Pricing#Ferro Silicon Production#Ferro Silicon Regional Growth#Ferro Silicon Supply#Ferro Silicon Trends#Global Ferro Silicon Market#Inoculants#Milled Ferrosilicon

0 notes

Text

Worldwide Ferrosilicon Market Will Reach USD 13.7 Billion By 2030

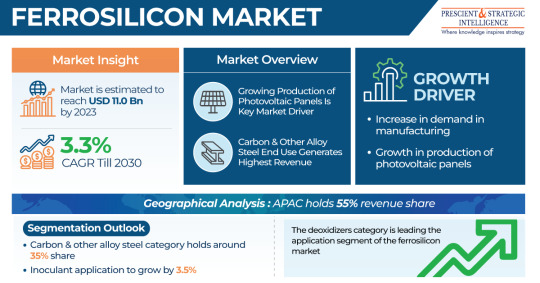

The projected revenue of the worldwide ferrosilicon market is around USD 11.0 billion for 2023, with an anticipated increase to USD 13.7 billion by 2030. This growth is forecasted to occur at a compound annual growth rate (CAGR) of 3.3% between 2024 and 2030. This growth of the market can be credited to the extensive variety of applications of this material in the automotive, construction, and…

View On WordPress

#alloy#challenges#environmental considerations#ferrosilicon#global demand#Growth opportunities#industrial applications#market#market trends#metallurgy#pricing dynamics#regulatory landscapes#steel production#Technological advancements

0 notes

Text

Growing Resistance: Mineral Additives against Rust

Concrete forms a very important element of modern construction due to strength, versatility, and durability. However, one critical problem related to the durability of concrete is the corrosion of the embedded steel reinforcement. Exposure to moisture, chlorides, and other aggressive agents has caused the corrosion. Among several solutions to the mentioned challenge, the incorporation of Mineral admixtures for rust prevention of rust is being practiced effectively, improving the durability of concrete and also enhancing the lifespan of the structure.

What are Mineral Admixtures?

Mineral admixtures are substances that consist of finely milled particles incorporated into concrete to enhance its characteristics. These components, frequently derived from industrial processes, contribute to the improvement of concrete performance through multiple mechanisms, such as decreasing permeability, augmenting strength, and enhancing resistance to external environmental influences. Regarding the prevention of rust, mineral admixtures are vital as they alter the concrete matrix, thereby restricting the penetration of corrosive substances and safeguarding steel reinforcement.

Categories of Mineral Additives for Corrosion Mitigation

Fly Ash

Fly ash is a by-product of coal combustion widely used as a mineral admixture in concrete. It has a pozzolanic property to refine the pore structure, reducing permeability and thereby minimizing penetration of water and chlorides, thus forming a protection layer around the steel reinforcements and preventing rust.

Silica fume

Silica fume, a by-product of silicon and ferrosilicon alloy production, is highly effective in enhancing concrete durability. Its ultrafine particles fill the voids in the concrete matrix, drastically reducing permeability and chloride ion ingress. Silica fume also increases the density of the interfacial transition zone around steel reinforcement, offering superior rust protection.

Ground Granulated Blast Furnace Slag (GGBS).

GGBS is a by-product of iron production and is used as a cementitious material when mixed with concrete. It enhances the sulphate resistance and chloride penetration of concrete, which prevents rust on steel reinforcement. GGBS also reduces the heat of hydration, thus enhancing the durability of concrete in the long run.

Met kaolin being a calcined clay, is known for its high pozzolanic properties and, when added to the concrete, improves strength in conjunction with durability while reducing permeability. Moreover, metakaolin helps in the chemical resistance of concrete, making it very efficient in rust prevention under harsh conditions.

Rice Husk Ash

Rice husk ash is the most readily available source of silica-containing mineral admixture, which is itself a waste product of agricultural operations. Its addition could improve the durability of concrete by removing porosity and chloride ion-diffusion-induced rust into steel reinforcement.

Advantages of Employing Mineral Admixtures for Corrosion Mitigation

Improved durability: It reduces the chances of corrosion, which extends the life of constructions.

Cost Efficiency: Lowers maintenance and repair costs by minimizing rust-related damage.

Sustainability: Uses industrial by-products, hence minimizing environmental degradation.

Strengthened: The mechanical properties of concrete are enhanced.

Adaptability: Suitable for use in diverse applications, including marine structures, industrial facilities, and transportation infrastructure.

Utilization of Mineral Admixtures

Marine Structures: It protects against chloride-induced corrosion from seawater.

Bridges and highways: It reduces the effects of salt de-icing and environmental factors.

Industrial structures: Increase resistance to chemical exposure and heavy loads. Residential and commercial structures: Enhances longevity and diminishes maintenance requirements over time. Conclusion The inclusion of mineral admixtures with the purpose of alleviating rust is one of the most remarkable developments in the concrete technology field. These admixtures contribute to an economical and environmentally friendly solution to the constantly recurring problem of steel reinforcement corrosion by enhancing the durability and strength of concrete infrastructures. Mineral admixtures ensure the continued strength, safety, and durability of reinforced concrete structures for a more extended period in different scenarios, such as coastal locations, industrial zones, or general construction activities.

0 notes

Text

0 notes

Text

Efficient Ferro Silicon Magnesium Production with Magnesium Cored Wire Injection Systems!

Ferro Silicon Magnesium (FeSiMg) is an essential alloy used primarily in the production of ductile iron. It plays a vital role in the nodularization of cast iron, transforming the structure of graphite flakes into spherical nodules that improve the strength, ductility, and overall mechanical properties of the metal. However, the production of FeSiMg comes with challenges, particularly in the efficient and precise addition of magnesium to molten iron. To meet the ever-increasing demand for high-quality ductile iron and reduce material wastage, advanced injection systems have become a game-changer in the FeSiMg production process. These systems improve precision, increase efficiency, and offer environmental benefits that align with the evolving demands of the modern metallurgical industry.

Understanding FeSiMg and Its Importance

FeSiMg plays a crucial role in the production of ductile iron, known for its superior mechanical properties like strength, ductility, and wear resistance. The primary role of FeSiMg in ductile iron production is nodularization—the process of converting graphite flakes into spherical shapes to improve the iron's mechanical properties. This transformation is essential for industries like automotive, construction, and heavy machinery.

However, the production of high-quality FeSiMg is a complex process that requires precise control over alloying elements. Magnesium, being highly reactive, presents unique challenges in its introduction into molten metal. This is where advanced cored wire injection systems come into play.

The Role of Magnesium-Cored Wire Injection Systems

A magnesium cored wire injection system is specialized technology designed to inject magnesium and other alloying elements into molten metal with high precision. These systems consist of long, hollow wires filled with magnesium or magnesium-containing compounds, which are fed directly into the molten iron. The injection process ensures the efficient absorption of magnesium, minimizing wastage and maximizing yield.

Key features of these systems include:

Controlled Feeding: The speed and quantity of magnesium wire can be precisely controlled, ensuring consistent alloy composition.

Enhanced Efficiency: By minimizing the oxidation and loss of magnesium, these systems improve its absorption rate, reducing material costs.

Improved Safety: Magnesium's high reactivity poses safety risks during manual handling, but cored wire systems automate the process, ensuring safer operations.

Advantages of Advanced Cored Wire Systems in FeSiMg Production

1. Higher yield and cost efficiency.

Advanced cored wire injection systems ensure the optimal utilization of magnesium, leading to higher yields. This reduces the need for excessive raw materials, translating into significant cost savings. Additionally, the efficient use of resources aligns with the industry's sustainability goals by minimizing waste.

2. Precision in alloy composition

Consistency is critical in alloy production, especially for applications demanding stringent quality standards. Cored wire systems allow precise control over the magnesium content in ferrosilicon magnesium, ensuring uniformity in the final product.

3. Reduction in Environmental Impact

Traditional methods of magnesium addition often result in higher emissions and waste. Cored wire systems minimize these impacts by optimizing the injection process and reducing magnesium oxidation, contributing to a cleaner production environment.

4. Enhanced Process Control and Flexibility

With advanced automation and control mechanisms, these systems offer real-time monitoring and adjustment capabilities. This flexibility allows manufacturers to adapt quickly to changing production requirements without compromising efficiency.

Applications in Ductile Iron Production

The manufacture of ductile iron is the main use for ferro-silicon magnesium. Nodularisers, Such as magnesium cored wire injection systems play a vital role in this process by enabling precise nodularization. The spherical graphite structures formed in ductile iron significantly enhance its mechanical properties, making it suitable for critical components like crankshafts, gears, and pipes.

Advanced magnesium-cored wire systems ensure that the nodularization process is both efficient and consistent, meeting the high-quality standards required by industries such as automotive and construction.

Innovations Driving the Future of Cored Wire Technology

The ongoing advancements in cored wire injection systems are further enhancing their efficiency and applicability. Some key innovations include:

Smart Injection Systems: Equipped with IoT and AI technologies, these systems offer predictive maintenance, real-time analytics, and automated adjustments for optimal performance.

Eco-Friendly Wire Fillings: Research is underway to develop environmentally friendly wire fillings that reduce emissions and further improve sustainability.

Integration with Industry 4.0: The integration of cored wire systems with Industry 4.0 technologies is revolutionizing the metallurgical industry, enabling seamless data exchange and process optimization.

Challenges and Solutions

Despite their numerous benefits, the implementation of cored wire systems faces some challenges:

Initial Investment: The cost of acquiring and installing advanced systems can be a barrier for smaller foundries. However, the long-term savings in material and operational costs often outweigh the initial investment.

Skill requirements: operating these systems requires specialized training. Manufacturers are addressing this by offering comprehensive training programs and user-friendly interfaces.

Maintenance Needs: Regular maintenance is crucial to ensure consistent performance. Advanced systems now come with predictive maintenance features to minimize downtime.

Conclusion

The production of FeSIMg is a cornerstone of the metallurgical industry, and advancements in advanced magnesium-cored wire injection systems have revolutionized this process. By enhancing efficiency, precision, and sustainability, these systems are not only meeting the current demands of alloy production but also setting the stage for future innovations.

As industries continue to prioritize quality and environmental responsibility, the adoption of advanced cored wire technologies is expected to grow, driving significant improvements in alloy manufacturing and reshaping the future of metallurgical processes.

#MagnesiumcCoredWireInjectionSystem #FerroSiliconMagnesiumIndia #MagnesiumCiredWire

#ferro silicon magnesium#magnesium cored wire injection system#magnesium cored wire feeder#magnesium cored wire#nodularisers#ferro silicon magnesium in india#FeSiMg

0 notes

Text

We do not make magnesium out of the sea salt. Sea salt is 10% magnesium cloride and is on paper the best sorce for magnesium. The most common method to extract magnesium is the least efficient.

The sfift in production has mostly been due to cheaper labour and energy costs in North Central China due to large coal deposites in the region and a large labour force.

It mimics early industrial firms that moved from the country side of GB to the citys, from the free infinate enegry provided by water wells on streams to a more expencive coal powerd production in the citys.

The firms had to adapt to the wims of the market, and coal alowed them to downsvale and upscale production based on the needs, while the countyside industry had a consistent supply, that could not be easily increased.

Discription of the current process for magnesium prod.:

"In this process, closed-end, nickel-chromium-steel alloy retorts are filled with a mixture of calcined dolomite ore and ferrosilicon, which are heated until magnesium crowns form. Each cycle takes about 11 hours, requires manually filling and emptying of the vacuum tubes, and uses about 11 tons of raw materials for every one ton of magnesium produced." - https://www.thoughtco.com/magnesium-production-2339718

"The birth of wings from the sea." Magnesium. Advertising art. 1939-45.

Science History Institute

190 notes

·

View notes

Text

Silica Fume Market

🌍 Exploring the Growing Silica Fume Market! 🚀

The Silica Fume market is witnessing rapid growth, driven by its increasing demand across various industries like construction, concrete, and refractory materials. 🏗️🔍 As a byproduct of silicon and ferrosilicon alloy production, silica fume enhances the durability and strength of concrete, making it a game-changer for infrastructure projects and industrial applications. 🏢⚙️

#SilicaFume#ConstructionMaterials#InfrastructureDevelopment#Sustainability#HighStrengthConcrete#RefractoryMaterials

0 notes

Text

Advantages of Incorporating Supplementary Cementitious Materials (SCMs) in Concrete

As the construction industry seeks more sustainable and high-performance solutions, the use of Supplementary Cementitious Materials (SCMs) has emerged as a game-changer. SCMs, which include ground granulated blast furnace slag (GGBS), Fly Ash, and silica fumes, are increasingly being used to enhance the durability and performance of modern concrete mixes while promoting environmental sustainability. In this article, we will explore the benefits of SCMs and their role in modern construction practices.

Understanding Supplementary Cementitious Materials (SCMs)

SCMs refer to materials derived from industrial byproducts or natural processes that can be added to concrete to improve its properties. At Firstchoice Ready Mix, we highly recommend using SCMs due to their ability to enhance the strength, workability, and durability of concrete. SCMs typically contain compounds such as silica, alumina, and calcium, which react with cement hydration products to form calcium silicate hydrate. This reaction improves the overall structure and strength of concrete, making SCMs a popular choice in modern construction.

By incorporating SCMs, construction companies can reduce their reliance on traditional Portland cement, which is energy-intensive and contributes significantly to carbon emissions. SCMs offer a sustainable alternative that supports environmental goals while enhancing the performance of concrete.

Key Benefits of SCMs in Concrete

1. Ground Granulated Blast Furnace Slag (GGBS)

GGBS is a byproduct of the steel and iron industries, produced by cooling molten iron slag. It is an essential SCM that improves the durability and workability of concrete. At Firstchoice Ready Mix, we use GGBS to create high-strength cement, which is resistant to surface attacks, chloride penetration, and other environmental factors.

GGBS is especially beneficial in harsh conditions, such as marine structures and wastewater treatment plants, where durability is crucial. Additionally, using GGBS reduces the carbon footprint of concrete by minimizing the energy required for cement production, making it an eco-friendly choice.

2. Fly Ash

Fly Ash, produced from coal combustion, is another widely used SCM that enhances concrete properties. It contains silica, alumina, and iron oxide, which contribute to pozzolanic reactions in concrete. Fly Ash improves the workability and pumpability of concrete, making it easier to handle during construction.

At Firstchoice Ready Mix, Fly Ash is used in large-scale projects to produce high-strength concrete mixes. Fly Ash helps refine the pore structure of concrete, improving its density and reducing permeability. This results in concrete that is more resistant to chemical attacks and environmental degradation, extending the lifespan of structures.

3. Silica Fumes

Silica fumes, a byproduct of silicon and ferrosilicon production, is an ultrafine powder that significantly improves the strength and density of concrete. By filling microscopic voids in the cement particles, silica fumes enhance the compressive strength of concrete, making it ideal for high-performance applications such as industrial floors and heavy-duty infrastructure.

The use of silica fumes also increases concrete's resistance to abrasion and aggressive chemical attacks, further improving its durability and longevity.

4. Enhanced Durability and Temperature Control

SCMs are crucial for enhancing the durability of concrete, especially in aggressive environments. GGBS, Fly Ash, and silica fumes improve the resistance of concrete to environmental factors such as chemical exposure and temperature fluctuations. This leads to lower maintenance costs and longer-lasting structures.

SCMs are also effective in controlling the temperature of concrete during the hydration process, which is particularly important in mass concrete applications. By reducing the heat generated during hydration, SCMs help minimize the risk of thermal cracking and other temperature-related issues.

5. Optimized Chemical Compositions

At Firstchoice Ready Mix, we work closely with construction chemical suppliers to develop customized admixtures and additives that optimize the hydration process of concrete. By using SCMs in combination with these additives, we produce high-strength concrete mixes that meet the diverse needs of construction projects.

Conclusion

The use of Supplementary Cementitious Materials (SCMs) offers numerous advantages for modern construction, including improved durability, reduced carbon emissions, and enhanced performance. As a leading provider of high-strength concrete mixes, Firstchoice Ready Mix is committed to promoting sustainable construction practices by incorporating SCMs into our products.

By using SCMs such as GGBS, Fly Ash, and silica fumes, we can help reduce the environmental impact of construction projects while delivering high-performance concrete that meets the demands of today’s infrastructure.

#concrete admixtures market#modern construction#high-performance concrete#construction chemical suppliers

0 notes

Text

Unlocking Industrial Potential with Trusted Ferro Alloys Suppliers

The significance of reliable ferro alloys suppliers in industrial manufacturing cannot be overlooked. These suppliers are essential in providing the key raw materials that support a variety of industries, such as construction, automotive, and aerospace. The quality and consistency of ferro alloys like ferromanganese, ferrosilicon, and ferrochrome play a critical role in determining the performance, strength, and durability of the products made from them. As a result, selecting a dependable supplier is crucial for companies that aim to maintain high standards in their production processes.

A reliable ferro alloys supplier does more than just supply materials; they serve as a strategic partner in enhancing your business's success. By offering high-quality, precisely formulated alloys, they help manufacturers optimize their production processes, ensuring that the final products meet the rigorous standards required by their industries. Whether it’s improving the corrosion resistance of stainless steel or increasing the hardness of construction-grade steel, the right supplier ensures that the materials provided are perfectly suited to your specific requirements.

In addition, partnering with a reputable ferro alloys supplier ensures a reliable supply chain, which is vital for preventing production delays and interruptions. In industries where timing is crucial, such as automotive or aerospace, having a supplier who consistently meets delivery deadlines is invaluable. This reliability allows manufacturers to maintain smooth operations, meet their production goals, and deliver on their promises to customers.

Furthermore, ferro alloys suppliers bring valuable technical expertise to the table. With their deep knowledge of alloy compositions and industrial applications, they can offer expert guidance on the most effective ways to use the materials, helping manufacturers achieve the best possible results. This collaboration can lead to innovations in product development and enhancements in manufacturing efficiency, giving companies a competitive edge.

In summary, choosing a ferro alloys supplier is not just about sourcing raw materials; it’s about forming a partnership that supports long-term growth and success. By opting for a supplier that prioritizes quality, reliability, and sustainability, companies can unlock greater industrial potential, driving innovation and progress in their fields.

0 notes

Text

Manganese Alloys Market: Current Analysis and Forecast (2022-2028)

According to a new report published by UnivDatos Markets Insights, the Manganese Alloys Marketwas valued at more than USD 23 billion in 2020 and is expected to grow at a CAGR of around 6% from 2022-2028. The analysis has been segmented into Type (Silicomanganese, High-Carbon Ferromanganese, Medium & Low-Carbon (MLC) Ferromanganese, and Others); Application (Steel Manufacturing, Welding Accessories, Foundry, and Others); Region/Country.

The manganese alloys market report has been aggregated by collecting informative data on various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the manganese alloys market. The manganese alloys market report offers a detailed analysis of the latest industry developments and trending factors in the market that are influencing the market growth. Furthermore, this statistical market research repository examines and estimates the manganese alloys market at the global and regional levels.

Market Overview

Manganese alloy is an alloy steel containing an average of around 13% manganese. Manganese alloys are majorly known for their high-impact strength and resistance to abrasion once in their work-hardened state. In recent years, manganese alloys are used in the production of aluminum and copper alloys, special grades of stainless steel, and other special steels. Manganese alloys are also used for both cast and forged components. In addition, manganese alloy is used as a hardening agent in some steels, mixing manganese with gold, silver, bismuth, etc., to produce alloys that are used for very specific applications, generally related to the electronic industry.

Factors such as increasing demand in the construction sector coupled with the growing adoption of manganese steels in the automotive sector, increasing adoption, and product launches in the market are some of the prominent factors that are positively influencing the market growth globally.

Some of the major players operating in the market include Eramet, Ferroglobe PLC, Maithan Alloys Ltd., Monnet Ispat and Energy Limited, South32, Nippon Denko Co. Ltd., Vale S.A., Transalloys (PTY) Ltd., Marubeni Tetsugen Co. Ltd, Pertama Ferroalloys Sdn. Bhd.

COVID-19 Impact

The recent covid-19 pandemic has disrupted the world and has brought a state of shock to the global economy. The global pandemic has impacted industries and has transformed the way industries are delivered. Covid-19 affected the entire business ecosystem, especially the marginal stakeholders like small vendors/contractors, contract laborers, downstream and ancillary businesses, etc. The manganese alloys market has been significantly affected during these times owing to the disruption in mining industries which in turn affected the extraction of manganese alloys coupled with the halts in the construction of new projects across the globe also negatively impacted the market.

The global manganese alloys market report is studied thoroughly with several aspects that would help stakeholders in making their decisions more curated.

Based on type, the market is segmented into silicomanganese, high-carbon ferromanganese, medium & low-carbon (MLC) ferromanganese, and others. The silicomanganese category is to witness the highest CAGR during the forecast period owing to the high need for manganese steel production. The addition of silicon manganese during the steel-making process aids in obtaining low-carbon steels, which further increases the purity and strength of such alloy steels. Furthermore, the entry of global players into emerging markets adds to the growth of the market. For instance, Aug 2022, Arab Alloys launched EGP 1bn industrial complexes in SCZone. The company aimed to produce 48,000 tonnes of ferrosilicon and silicon manganese, to use in the iron, aluminum, and steel industries.

On the basis of application, the market is categorized into steel manufacturing, welding accessories, foundry, and others. Among these, steel manufacturing to hold a significant share of the market in 2020. This is because steel possesses some properties such as increased hardenability gains toughness, achieving better wear resistance, and others. Owing to these factors, manganese steel is used in offshore oil rigs, bridges, civil engineering and construction machines, pressure vessels, power plants, and hydroelectric plants. Thus, steel manufacturing is expected to grow during the forecasted period.

Manganese Alloys Market Geographical Segmentation Includes:

North America (U.S, Canada, and the Rest of North America)

Europe (Germany, U.K., France, Italy, Spain, and the Rest of Europe)

Asia-Pacific (China, Japan, India, and the Rest of Asia-Pacific)

Rest of the World

APAC is anticipated to grow at a substantial CAGR during the forecast period. This is mainly because of the investments in new construction projects, the rising adoption of high-carbon ferromanganese in the steel industry, and rapid urbanization in developing countries such as China, India, and Japan are driving the growth of the market. Moreover, the wide expanse of manufacturing businesses, the constant development of transportation, and other fields along with growth in expanding public-private cooperation for steel-related investments within the region coupled with supportive government initiatives for the ferrous metals industry are accelerating the growth of the market.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=31054

The major players targeting the market include

Eramet

Ferroglobe PLC

Maithan Alloys Ltd.

Monnet Ispat and Energy Limited

South32

Nippon Denko Co. Ltd.

Vale S.A.

Transalloys (PTY) Ltd.

Marubeni Tetsugen Co. Ltd

Pertama Ferroalloys Sdn. Bhd

Competitive Landscape

The degree of competition among prominent global companies has been elaborated by analyzing several leading key players operating worldwide. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the manganese alloys market. The major players have been analyzed by using research methodologies for getting insight views on global competition.

Key questions resolved through this analytical market research report include:

• What are the latest trends, new patterns, and technological advancements in the manganese alloys market?

• Which factors are influencing the manganese alloys market over the forecast period?

• What are the global challenges, threats, and risks in the manganese alloys market?

• Which factors are propelling and restraining the manganese alloys market?

• What are the demanding global regions of the manganese alloys market?

• What will be the global market size in the upcoming years?

• What are the crucial market acquisition strategies and policies applied by global companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature and geography. Please let us know If you have any custom needs.

Browse Related Newsletter from UnivDatos Market Insights

Phytogenic Feed Additives Market - SWOT Analysis [2023-2028]

Titanium Dioxide Market - SWOT Analysis [2023-2028]

About Us:

UnivDatos Market Insights: Your Partner in Data-Driven Market Strategies. Unlock growth opportunities and make smart decisions with our expert research and insights.

Contact us:

UnivDatos Market Insights (UMI)

Email: [email protected]

Web: https://univdatos.com

LinkedIn: www.linkedin.com/company/univ-datos-market-insight/

Ph: +91 7838604911

0 notes

Text

Silica Fume in Concrete: Enhancing Strength and Durability

https://krct.ac.in/blog/2024/05/30/silica-fume-in-concrete-enhancing-strength-and-durability/

In modern construction, innovations that enhance material performance while promoting sustainability are highly valued. One such innovation is the use of silica fume in concrete, a game-changer in the field of civil engineering. Silica fume is derived as a byproduct from the production of silicon and ferrosilicon alloys. Silica fume has found an important role in advancing concrete technology. In this blog post, we will explore how silica fume in concrete enhances its strength and durability; its benefits, and its contribution to sustainable building practices.

What is Silica Fume?

Silica fume, also known as micro silica, consists of ultra-fine particles approximately 100 times smaller than the average cement particle. These micro-sized particles have a significant impact on the properties of concrete when added to the mix. The high silicon dioxide content of silica fume contributes to its effectiveness as a pozzolanic material, meaning it reacts with calcium hydroxide in concrete to form additional cementitious compounds.

Compressive and Flexural Strength

One of the primary benefits of incorporating silica fume in concrete is the substantial increase in both compressive and flexural strength. The tiny particles fill the voids between cement particles, creating a denser and more cohesive mix. This increased density translates to higher strength, making silica fume an indispensable component in high-performance concrete applications, such as bridges, high-rise buildings, and industrial floors.

Pozzolanic Reaction

Silica fume's pozzolanic reaction with calcium hydroxide in concrete produces additional calcium silicate hydrate (C-S-H), the compound responsible for the strength and durability of concrete. This reaction not only enhances strength but also improves the overall microstructure of the concrete, making it more robust and long-lasting.

Chemical Resistance

The pozzolanic reaction also leads to the formation of additional binding compounds, which increase the concrete's resistance to chemical attacks. This makes silica fume-enhanced concrete particularly suitable for environments exposed to harsh chemicals, such as wastewater treatment plants, industrial facilities, and coastal structures.

Reduced Permeability

Silica fume significantly refines the pore structure of concrete, reducing its permeability. This refined pore structure minimizes the ingress of water and harmful chemicals, thereby enhancing the durability of the concrete. It also makes the concrete more resistant to freeze-thaw cycles, which can cause cracking and deterioration in colder climates.

Sustainability and Eco-Friendly Practices

As the construction industry increasingly focuses on sustainability, the use of silica fume in concrete aligns well with eco-friendly practices. By repurposing an industrial by-product, silica fume enhances concrete performance and also reduces waste and promotes recycling. This contributes to a more sustainable building practice, supporting the development of resilient infrastructure with a lower environmental footprint.

Conclusion

Thus, as we look towards the future of construction, silica fume stands out as a key ingredient in building robust and resilient infrastructure. By leveraging the advantages of silica fume in concrete, we can create structures that not only meet the demands of today but also stand the test of time. Whether for high-performance applications or sustainable building practices, silica fume proves to be an invaluable addition to modern concrete technology.

https://krct.ac.in/blog/2024/05/30/silica-fume-in-concrete-enhancing-strength-and-durability/

#Silica Fume in Concrete: Enhancing Strength and Durability#Silica Fume in Concrete#government job after civil engineering#the best engineering college in trichy tamilnadu india#the best civil ai ds ece eee placement college in trichy tamilnadu india

0 notes

Text

Comprehensive Analysis of "Quartz for Ferroalloys Market" Dynamics, Growth Drivers, and Future Prospects

The Quartz for Ferroalloys Market is Valued at USD 28.1 billion in 2024 and is projected to reach USD XX billion by 2030, growing at a CAGR of 5.9% During the Forecast period of 2024–2032.

Introduction: Quartz, a mineral composed of silicon and oxygen, is a crucial raw material in the production of ferroalloys. Ferroalloys, which include ferrochrome, ferromanganese, and ferrosilicon, are essential in the manufacturing of various steel and alloy products. The unique properties of quartz, such as high purity, stability at high temperatures, and its role as a fluxing agent, make it indispensable in the ferroalloys industry. This report delves into the global market trends, key drivers, and future outlook of quartz for ferroalloys, providing a comprehensive understanding of its significance and applications.

Download a Free Sample Copy of the Report: https://www.marketdigits.com/request/sample/1028

Major Companies: ✤ Imerys S.A., ✤ Sibelco, ✤ Saint-Gobain, ✤ Kakatiya Minerals Pvt Ltd., ✤ Jiangsu Pacific Quartz Co., Ltd., ✤ Shilpa Enterprises, ✤ Australian Silica Quartz Group Ltd, ✤ Elkem ASA, ✤ DuPont, China Minmetals, ✤ Shin-Etsu Quartz Products Co., Ltd., ✤ Donghai Shihu Quartz Co., Ltd., ✤ and Others.

Why Should Access to This Report? ➥ In-Depth Market Insights: Gain detailed knowledge about the current market scenario, emerging trends, and growth drivers shaping the quartz for ferroalloys market. ➥ Strategic Analysis: Understand the competitive landscape, key players, and their strategies to stay ahead in the market. ➥ Market Forecasts: Access accurate and reliable market forecasts to make informed business decisions and identify potential investment opportunities. ➥ Tailored Solutions: Benefit from tailored insights and recommendations to address specific business needs and challenges.

Inquire Before Buying at - https://www.marketdigits.com/request/enquiry-before-buying/1028

Research Methodology: The research methodology adopted for this report involves a blend of primary and secondary research. Primary research includes interviews with industry experts, key stakeholders, and decision-makers, while secondary research involves the analysis of industry reports, company publications, and reputable databases. The data collected is meticulously analyzed to provide a comprehensive and accurate representation of the market.

Major Segmentation:

By Product ✦ Ferrochrome ✦ Ferromanganese ✦ Ferro Silico Manganese ✦ Ferrosilicon

By Quartz Grain Size ✦ Coarse ✦ Medium ✦ Fine

By Quartz Grade ✦ High Purity Quartz ✦ Standard Purity Quartz

By Application ✦ Electrical Porcelain ✦ Sanitary ware ✦ Art ware ✦ Carbon Steel ✦ Stainless Steel ✦ Alloy Steel ✦ Cast Iron ✦ Others

By End-Use Industry ✦ Automotive ✦ Aerospace & Defense ✦ Construction ✦ Machinery & Equipment ✦ Electronics ✦ Others

Click to Request Free 10% Customization on this Report @ https://www.marketdigits.com/request/customization/1028

Mostly Asked Questions: ➽ What are the key factors driving the growth of the quartz for ferroalloys market? ➽ Which regions are expected to witness significant growth in the market? ➽ Who are the major players in the market, and what are their strategies? ➽ What are the primary applications of quartz in the ferroalloys industry? ➽ How is the competitive landscape evolving in the market? ➽ What are the challenges faced by the market, and how can they be addressed? ➽ What are the potential opportunities for new entrants in the market?

Summary of this Research Report: This research report provides a comprehensive analysis of the global quartz for ferroalloys market, highlighting the key trends, growth drivers, and prospects. It offers valuable insights into the competitive landscape, market segments, and regional dynamics. By accessing this report, businesses can make informed decisions, identify potential opportunities, and develop effective strategies to thrive in the dynamic market environment.

Request for Discount @ https://www.marketdigits.com/request/discount/1028

0 notes

Text

Magnesium Alloy Ingot Prices Trend, Database, Chart, Index, Forecast

Magnesium Alloy Ingot prices have been subject to significant fluctuations due to various market dynamics. As a vital material in numerous industries, including automotive, aerospace, and electronics, magnesium alloys are highly sought after for their lightweight and high-strength properties. The cost of magnesium alloy ingots is influenced by several key factors, including raw material availability, production costs, demand from end-use sectors, and geopolitical considerations. In recent years, the global supply chain has faced disruptions due to trade tensions and environmental regulations, particularly in major producing countries like China, which has historically dominated the magnesium market. These disruptions have led to supply shortages, thereby pushing up prices.

The automotive industry's increasing focus on fuel efficiency and emission reductions has bolstered the demand for magnesium alloys, further impacting ingot prices. With the rise of electric vehicles (EVs), manufacturers are keen on using lightweight materials to extend battery life and improve vehicle performance. This surge in demand from the automotive sector has put additional pressure on magnesium alloy suppliers, contributing to higher prices. Moreover, the aerospace industry, which requires materials that offer high strength-to-weight ratios, has also seen increased consumption of magnesium alloys. As airlines and aircraft manufacturers strive to enhance fuel efficiency and reduce carbon footprints, the reliance on lightweight materials like magnesium alloys has intensified.

Get Real Time Prices of Magnesium Alloy Ingot: https://www.chemanalyst.com/Pricing-data/magnesium-alloy-ingot-1337

Environmental regulations have also played a crucial role in shaping the magnesium alloy ingot market. In an effort to curb pollution, several countries have implemented stringent regulations on the extraction and processing of magnesium. China, for instance, has enforced strict environmental policies that have led to the closure of many small and inefficient magnesium smelters. This reduction in production capacity has caused supply constraints, contributing to the rising prices of magnesium alloy ingots. Additionally, energy costs, which constitute a significant portion of the production expenses, have seen an upward trend, further exacerbating the cost pressures on magnesium alloy producers.

Another factor influencing magnesium alloy ingot prices is the fluctuation in the prices of raw materials, such as dolomite and ferrosilicon, which are essential in the production process. The cost of these raw materials is subject to market volatility, driven by factors like mining conditions, transportation costs, and global demand. When the prices of these raw materials increase, the production costs for magnesium alloy ingots also rise, leading to higher market prices. Conversely, a decrease in raw material prices can provide some relief to manufacturers, potentially stabilizing or reducing the prices of magnesium alloy ingots.

The geopolitical landscape significantly affects the global magnesium alloy market. Trade policies, tariffs, and international relations can create uncertainties and disrupt the supply chain. For example, the trade war between the United States and China has had repercussions on the availability and pricing of magnesium alloys. Tariffs and trade barriers can lead to increased costs for importers and exporters, which are often passed on to the end consumers. Such geopolitical tensions can create volatility in the market, making it challenging for businesses to forecast and manage their costs effectively.

Technological advancements in production techniques have also played a role in influencing magnesium alloy ingot prices. Innovations aimed at improving extraction and processing efficiencies can reduce production costs, thereby potentially lowering ingot prices. However, the initial investment required for adopting new technologies can be substantial, and these costs are often reflected in the prices of the final product. As more producers invest in advanced technologies, the long-term outlook for magnesium alloy ingot prices might see some stabilization or even a decline, assuming other market factors remain constant.

In summary, magnesium alloy ingot prices are shaped by a complex interplay of factors including raw material costs, production expenses, demand from key industries, environmental regulations, geopolitical dynamics, and technological advancements. The growing demand from the automotive and aerospace sectors, coupled with supply constraints due to environmental regulations and geopolitical tensions, has contributed to the upward trend in prices. Fluctuations in raw material prices and advancements in production technologies add further layers of complexity to the pricing dynamics. As industries continue to prioritize lightweight and high-strength materials, the market for magnesium alloy ingots is likely to remain robust, with prices reflecting the ongoing challenges and developments in the global supply chain.

Get Real Time Prices of Magnesium Alloy Ingot: https://www.chemanalyst.com/Pricing-data/magnesium-alloy-ingot-1337

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

Boosting Steel Production Efficiency: Exploring the Benefits of Cored Wire Injection

Cored Wire Injection into steel production processes, manufacturers can achieve accurate and consistent alloy feeding. This not only reduces material waste but also enhances the steel's mechanical properties and performance. Moreover, cored wire injection offers flexibility in adjusting the composition of the steel, enabling manufacturers to meet specific customer requirements with ease.

Understanding the Basics of Cored Wire and Its Composition

Cored wire consists of a metal sheath surrounding a core material, typically a powdered alloy or a blend of minerals. The core material is carefully selected based on the desired properties of the steel being produced. When the cored wire is injected into the molten steel, the metal sheath melts, releasing the core material into the liquid metal. This process enables controlled alloy addition, leading to improved steel quality and performance. Cored wire composition can vary depending on the specific requirements of the steel manufacturer, offering flexibility in achieving desired metallurgical outcomes.

Cored wire technology has evolved to encompass a wide range of alloys and elements, including but not limited to ferroalloys such as ferrosilicon, ferromanganese, and ferrochrome. These alloy additions serve various purposes, such as deoxidation, desulfurization, and alloying, contributing to the enhancement of steel properties. The precise composition and size of the cored wire play a critical role in determining the effectiveness of the alloy addition process and its impact on the final steel product.

Cored wire manufacturers employ advanced production techniques to ensure the quality and consistency of their products. Through meticulous control of alloy content and wire dimensions, cored wire suppliers can meet the stringent requirements of steel producers seeking reliable and efficient alloy feeding solutions. The continuous development of cored wire formulations and manufacturing processes reflects the industry's commitment to innovation and excellence in steel production.

Advantages of Cored Wire Injection in Steel Production

The utilization of cored wire injection in steel production offers a multitude of benefits that contribute to enhanced efficiency and productivity. One of the primary advantages is the precise control over alloy addition, allowing for accurate and consistent metallurgical outcomes. By introducing cored wire into the molten steel, manufacturers can tailor the composition of the metal to meet specific requirements, thereby optimizing steel quality and performance.

In addition to improving alloy recovery rates, cored wire injection minimizes material waste during the steelmaking process. The targeted delivery of alloys through cored wire technology ensures that the desired elements are efficiently incorporated into the steel melt, maximizing the utilization of expensive alloying materials. This results in cost savings for steel producers and enhances overall operational efficiency.

Furthermore, cored wire injection enables steel manufacturers to adjust the chemical composition of the steel in real-time, offering greater flexibility in meeting customer demands and industry standards. Whether it involves fine-tuning the steel's microstructure or enhancing its mechanical properties, cored wire technology ensures that the desired elements are efficiently incorporated into the steel melt, maximizing the utilization of expensive alloying materials. This results in cost savings for steel producers and enhances overall operational efficiency.

Increased Efficiency and Productivity in Steel Manufacturing

The integration of cored wire injection into steel manufacturing processes brings about a significant improvement in efficiency and productivity. By streamlining the alloy feeding process, cored wire technology enhances the overall operational efficiency of steel plants, leading to increased output and reduced production costs. The precise control over alloy addition not only improves the quality steel production process, ultimately enhancing the competitiveness of steel manufacturers in the global market.

By optimizing alloy utilization and minimizing material wastage, cored wire injection plays a crucial role in improving resource efficiency and sustainability in steel manufacturing. The targeted delivery of alloys directly into the molten steel minimizes the environmental impact associated with traditional alloy addition methods, such as bulk alloy additions or wire feeding systems. As the industry continues to prioritize sustainability and environmental responsibility, it emerges as a sustainable solution for enhancing efficiency while reducing the carbon footprint of steel production.

Cost Savings Through Cored Wire Injection

One of the key advantages of cored wire injection in steel production is the significant cost savings it offers to manufacturers. By enhancing alloy recovery rates and reducing material waste, cored wire technology helps optimize the utilization of expensive alloying materials, thereby lowering production costs and increasing operational efficiency. The precision and efficiency of cored wire injection result in minimal alloy losses, ensuring that valuable elements are fully utilized in the steelmaking process.

Furthermore, the controlled and targeted delivery of alloys through cored wire technology eliminates overfeeding or underfeeding issues commonly associated with traditional alloy addition methods. This precise alloy distribution not only improves the quality of the steel but also prevents unnecessary expenditures on excess alloy usage. As a result, steel manufacturers can achieve cost savings while maintaining high-quality standards, enhancing their competitiveness in the market and maximizing profitability.

In addition to direct cost savings, cored wire injection contributes to indirect savings by streamlining steel production processes and reducing operational complexities. The automation and precision offered by cored wire technology minimize the need for manual labor and oversight, enabling steel plants to operate more efficiently and effectively. This efficiency translates into reduced downtime, optimized resource utilization, and overall cost-effectiveness, making cored wire injection a valuable investment for steel manufacturers seeking to enhance their bottom line.

Improving Steel Quality with Cored Wire Injection

The introduction of cored wire injection into steel production processes has a profound impact on the quality and performance of the final steel product. By enabling precise control over alloy addition, cored wire technology enhances the metallurgical properties of the steel, resulting in improved mechanical strength, durability, and corrosion resistance. The targeted delivery of alloys ensures uniform distribution throughout the steel melt, leading to a homogenous and high-quality steel product.

Moreover, cored wire injection facilitates the removal of impurities and non-metallic inclusions from the steel melt, enhancing the cleanliness and purity of the final product. This purification process results in steel with superior surface finish and enhanced machinability, meeting the stringent quality standards required for various industrial applications. The ability to customize the composition of the steel through cored wire technology enables manufacturers to produce steel grades that meet specific performance criteria and customer preferences.

Incorporating cored wire injection in steel production not only improves the quality of the steel but also enhances its consistency and repeatability. The precise control over alloy addition ensures that each batch of steel meets the desired specifications and performance requirements, reducing variability in material properties and enhancing product reliability. By consistently delivering high-quality steel products, manufacturers can build a reputation for excellence and reliability in the market, attracting customers and driving business growth.

Environmental Benefits of Cored Wire Injection

Beyond its economic and performance benefits, cored wire injection offers significant environmental advantages that align with the steel industry's sustainability goals. By optimizing alloy utilization and reducing material waste, cored wire technology minimizes the environmental impact associated with steel production processes. The targeted delivery of alloys directly into the molten steel reduces the need for excess alloy additions, resulting in lower energy consumption and reduced greenhouse gas emissions.

Furthermore, the precision and efficiency of cored wire injection contribute to resource conservation by maximizing the utilization of valuable alloying materials. The controlled alloy addition process minimizes the generation of by-products and waste, promoting a more sustainable and environmentally friendly approach to steel manufacturing. As the industry continues to prioritize environmental responsibility and sustainable practices, cored wire injection emerges as a key technology for reducing the carbon footprint of steel production and enhancing overall resource efficiency.

In addition to reducing material waste and environmental impact, It also improves workplace safety and reduces occupational hazards associated with traditional alloy addition methods. The automation and precision of cored wire technology minimize the need for manual handling of alloys, reducing the risk of accidents and injuries in steel plants. By creating a safer and healthier work environment, It enhances employee well-being and contributes to the overall sustainability of steel manufacturing operations.

Implementing Cored Wire Injection in Steel Production Processes

The successful implementation of cored wire injection in steel production requires a comprehensive understanding of the technology and its applications. Steel manufacturers looking to adopt cored wire technology should collaborate with experienced suppliers and consultants to tailor solutions that meet their specific production requirements. From selecting the appropriate cored wire compositions to optimizing injection parameters, careful planning and execution are essential for maximizing the benefits of cored wire injection.

Training and upskilling employees on cored wire injection techniques and best practices are critical for ensuring smooth integration and operation of the technology in steel plants. By providing comprehensive training programs and technical support, manufacturers can empower their workforce to effectively utilize cored wire technology and optimize its performance. Continuous monitoring and evaluation of this processes are essential for identifying opportunities for improvement and fine-tuning production parameters to achieve optimal results.

Moreover, collaboration with cored wire suppliers and industry experts can provide valuable insights and guidance on implementing cored wire injection in steel production processes. By leveraging the expertise and experience of cored wire manufacturers, steel producers can access cutting-edge solutions and innovative technologies that drive efficiency, quality, and competitiveness in the industry. Embracing it as a strategic tool for enhancing steel production processes positions manufacturers for success in an increasingly competitive and dynamic market.

Case Studies and Success Stories of Cored Wire Injection

Numerous steel manufacturers across the globe have successfully implemented cored wire injection in their production processes, realizing tangible benefits in terms of efficiency, quality, and cost savings. Case studies and success stories highlight the transformative impact of cored wire technology on steel production operations, showcasing real-world examples of improved alloy feeding, enhanced steel quality, and streamlined production processes.

One such case study involves a steel plant that adopted cored wire injection to optimize the composition of its high-strength steel grades. By introducing cored wire technology, the manufacturer achieved precise control over alloy addition, resulting in steel products with superior mechanical properties and enhanced performance characteristics. The targeted delivery of alloys through this enabled the plant to meet stringent customer requirements while reducing production costs and improving overall operational efficiency.

In another success story, a steel producer implemented cored wire injection to enhance the cleanliness and purity of its specialty steels. By leveraging cored wire technology for deoxidation and desulfurization, the manufacturer achieved significant improvements in steel quality, leading to enhanced surface finish and machinability. The adoption of cored wire injection not only elevated the performance of the steel products but also reduced environmental impact and enhanced workplace safety, positioning the company as a leader in sustainable steel manufacturing.

These case studies and success stories underscore the transformative potential of cored wire injection in steel production, demonstrating the tangible benefits that manufacturers can achieve by embracing innovative technologies and practices. By leveraging the efficiency, precision, and flexibility of cored wire technology, steel producers can enhance their competitive edge, drive operational excellence, and meet the evolving demands of the global steel market.

Conclusion: Embracing Cored Wire Injection for a Competitive Edge in Steel Manufacturing

In conclusion, It stands out as a game-changing technology that offers a myriad of benefits for boosting steel production efficiency and quality. By enabling precise control over alloy addition, cored wire technology enhances the metallurgical properties of steel, resulting in superior quality, performance, and consistency. The cost savings, environmental benefits, and operational efficiencies associated with It make it a compelling solution for steel manufacturers seeking to optimize their production processes and gain a competitive edge in the market.

As the steel industry continues to evolve and innovate, embracing cored wire injection represents a strategic investment in efficiency, sustainability, and performance. By integrating cored wire technology into their production processes, manufacturers can achieve enhanced alloy feeding, improved steel quality, and streamlined operations, positioning themselves for success in a dynamic and competitive market landscape. It is not just a technological advancement; it is a transformative solution that paves the way for a more efficient, sustainable, and profitable future for the steel industry.

For more info: https://www.ferrosiliconmagnesium.com/

#cored wire injection#bb inoculant#fesimg cored wires#ferro silicon magnesium#ferrosilicon#nodularisers#inoculants#ferrosiliconmagnesium#barium inoculant#ferro silicon magnesium cored wire

0 notes

Text

Ferrosilicon Sector: In-Depth Analysis of Leading Players and Emerging Startups

The ferrosilicon market size is expected to reach USD 512.8 million by 2030, according to a new report by Grand View Research, Inc, expanding at a CAGR of 5.0% over the forecast period. Positive government policies to boost steel production is anticipated to augment the demand for Ferrosilicon (FeSi) in the country.For instance, in 2017, the government of India approved the National Steel Policy (NSP) 2017. The policy set a target to have a crude steel capacity of 300 million tons and seeks to rise the per capita steel consumption to 160 kg by 2030.The product is used as a deoxidizer in steel manufacturing. Thus, rising demand for steel is expected to propel the consumption of FeSi.

India Ferrosilicon Market Report Highlights

Due to the Russia - Ukraine war, the prices of various commodities increased, which impacted the production activities in India in the first half of 2022. For instance, according to the Institute of Indian Foundrymen, despite the growing demand for foundries in India, Kolhapur, Belgaum, and Rajkot, their foundry production reduced by 50%. This affected the demand for ferrosilicon in the country

Due to the increasing production of steel, the deoxidizer segment held the largest revenue share in 2022 and is anticipated to continue growing over the forecast period

Based on region, South India is expected to register a significant growth rate over the forecast period. The governments in the region are trying to boost the manufacturing sector in their states, which is expected to increase the consumption of steel and cast iron in the region

For More Details or Sample Copy please visit link @: India Ferrosilicon Market Report

Based on end-uses, the stainless-steel segment held the largest revenue share in 2022. The consumption of FeSi in the stainless-steel industry is around 5 to 10 times higher than that of regular carbon steel. Therefore, the overall growth of the segment is expected to have a positive effect on the industry growth over the forecast period

Based on application, the inoculant segment is expected to grow at a steady CAGR, in terms of volume, over the forecast period. Inoculant is used widely in cast iron manufacturing and its growing demand in various industries, such as energy, railways, and pipes, is propelling the product consumption. For instance, in February 2023, the Indian government announced a project for South Central Railways. The region received a sanction amount of INR 13,786 crore (USD 1,665.4 million), of which INR 4,418 crore (USD 533.7 million) is for rail projects in Telangana. This type of upgradation and investment in railway is anticipated to propel the use of cast iron over the forecast period. Based on end-use, the electric segment is expected to register significant growth over the forecast period.

Electric steel reduces core losses in motors used in electric vehicles (EVs) and thus improves their performance. Owing to this rising investment in EV manufacturing the consumption of FeSi will increase over the forecast period. For instance, in Feb 2023, Ola Electric signed an MOU with the Tamil Nadu government to set up an electric vehicle hub. According to the agreement, this EV hub is anticipated to include an advanced EV and cell manufacturing facility. The company is expected to invest around INR 7,600 crore (USD 918.1 million) for the same. Market participants are expanding their production capacity to stay ahead of their competition. For instance, in 2022, Berry Alloys Ltd. completed the expansion of its ferroalloy unit by installing a 2 x 12MVA Furnace and a 4 x 7.5MVA Furnace. The total production capacity of ferroalloys increased to 2,96,000 TPA.

#Ferrosilicon#FerrosiliconMarket#Metallurgy#SteelIndustry#AlloyProduction#IndustrialMaterials#SiliconAlloys#MetalMarket#SteelManufacturing#FoundryIndustry#FerrosiliconDemand#SteelProduction#MetalAlloys#IndustrialMetals#MineralsAndMetals

0 notes