#Ethylene Propylene Diene Monomer Rubber Prices

Text

EPDM Rubber Prices | Pricing | Trend | News | Database | Chart | Forecast

Ethylene Propylene Diene Monomer (EPDM) rubber is a synthetic elastomer widely used in various industries due to its exceptional resistance to heat, ozone, and weather conditions, as well as its excellent flexibility and durability. The global market for EPDM rubber has seen significant fluctuations in prices over the years, influenced by a variety of factors such as raw material availability, production costs, demand-supply dynamics, and geopolitical conditions.

The pricing of EPDM rubber is closely tied to the cost of its primary raw materials, ethylene and propylene, which are derived from crude oil and natural gas. Fluctuations in the prices of these feedstocks directly impact the production costs of EPDM. For instance, when crude oil prices rise, the cost of ethylene and propylene typically increases, leading to higher EPDM prices. Conversely, when oil prices fall, EPDM production costs tend to decrease, resulting in lower market prices. This close correlation with the oil industry makes EPDM prices highly sensitive to changes in the global energy markets.

Get Real Time Prices for EPDM Rubber: https://www.chemanalyst.com/Pricing-data/epdm-rubber-1110

Demand for EPDM rubber is another crucial factor influencing its market prices. EPDM is used extensively in the automotive industry for weather seals, hoses, and other components, as well as in the construction industry for roofing membranes and window seals. As these industries grow or contract, the demand for EPDM follows suit. For example, during periods of strong automotive production, demand for EPDM typically increases, driving up prices. On the other hand, when the automotive or construction industries face downturns, demand for EPDM decreases, leading to potential price reductions. The demand from emerging markets, particularly in Asia, has been a significant driver of EPDM consumption, contributing to price increases in recent years.

Supply chain dynamics also play a vital role in determining EPDM rubber prices. The global production of EPDM is concentrated in a few key regions, including North America, Europe, and Asia. Any disruptions in production or supply chain issues in these regions can lead to significant price volatility. For example, natural disasters, plant shutdowns, or logistical challenges can reduce the supply of EPDM, creating shortages in the market and pushing prices higher. Conversely, when production levels are stable and supply chains are efficient, EPDM prices tend to stabilize or even decrease.

Another factor that has increasingly influenced EPDM rubber prices is the growing focus on sustainability and environmental regulations. The production of EPDM involves the use of chemicals that can have environmental impacts, and as governments worldwide implement stricter environmental regulations, the cost of compliance can drive up production costs. Additionally, there is a growing demand for eco-friendly alternatives, which can affect traditional EPDM market dynamics. Manufacturers may need to invest in cleaner technologies or find alternative raw materials, which can further influence the pricing structure of EPDM rubber.

Geopolitical factors also contribute to the fluctuations in EPDM rubber prices. Trade tensions, tariffs, and economic sanctions can disrupt the global supply chain, affecting both the availability and cost of raw materials needed for EPDM production. For example, tariffs on imported ethylene or propylene can increase production costs in countries that rely on these imports, leading to higher EPDM prices in those regions. Similarly, sanctions on key oil-producing countries can impact global oil prices, subsequently affecting the cost of EPDM production. Moreover, political instability in regions where EPDM is produced or where its raw materials are sourced can lead to supply disruptions, further exacerbating price volatility.

Technological advancements and innovations in the EPDM production process can also impact the market prices. Companies that invest in new technologies to improve production efficiency or reduce waste can lower their production costs, which may lead to more competitive pricing in the market. Additionally, the development of new EPDM formulations with enhanced properties can create niche markets with different pricing dynamics. For example, specialized EPDM grades that offer superior heat resistance or extended durability may command higher prices due to their added value in certain applications.

The global economic environment is another overarching factor that influences EPDM rubber prices. Economic growth or recession in major markets can have a profound impact on the demand for EPDM. During times of economic expansion, industries such as automotive and construction typically experience growth, leading to increased demand for EPDM and higher prices. Conversely, during economic downturns, these industries often reduce their output, leading to lower demand and a potential decline in EPDM prices. Currency fluctuations also play a role, as the international nature of the EPDM market means that exchange rates can impact the pricing of imports and exports, further contributing to price variability.

In recent years, the EPDM rubber market has also been affected by the rise of alternative materials and the increasing adoption of bio-based and recycled rubber products. As industries seek to reduce their environmental footprint, there is growing interest in alternatives to traditional EPDM that offer similar performance with lower environmental impact. This shift in demand can influence EPDM prices, particularly if alternative materials gain significant market share. However, EPDM remains a preferred choice for many applications due to its superior performance characteristics, ensuring its continued relevance in the market despite these emerging trends.

Overall, the market for Ethylene Propylene Diene Monomer (EPDM) rubber is shaped by a complex interplay of factors that influence its pricing. From raw material costs and supply chain dynamics to demand trends and geopolitical influences, the EPDM rubber market is subject to significant price fluctuations. Understanding these factors is crucial for industry stakeholders, as it enables them to navigate the challenges of the market and make informed decisions in an increasingly volatile economic environment. As the market continues to evolve, close monitoring of these influences will be essential for anticipating price trends and managing costs effectively.

Get Real Time Prices for EPDM Rubber: https://www.chemanalyst.com/Pricing-data/epdm-rubber-1110

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#EPDM Rubber#EPDM Rubber Price Monitor Ethylene Propylene Diene Monomer Rubber Price#Ethylene Propylene Diene Monomer Rubber Prices

0 notes

Text

Difference between EPDM and Nitrile Rubber

Synthetic rubber is an artificial man-made elastomer that is used in a vast range of domestic as well as industrial applications. There are different types of Synthetic rubbers, each with its different properties.

EPDM Rubber and Nitrile Rubber are two such common synthetic rubber compounds that are used extensively.

While both EPDM and Nitrile rubbers offer a considerable amount of elasticity and durability, they differ in their properties, resistance to certain environmental conditions or mediums, and have their applications.

What is EPDM Rubber?

EPDM Rubber, or Ethylene Propylene Diene Monomer Rubber, was developed in the 1960s.

As rubber as a raw material became widespread in use, manufacturers began to realize that there was a need for synthetic UV-resistant rubber that could withstand exposure to outdoor environments for an extended period without facing degradation like natural rubber. The answer to this was EPDM Rubber.

EPDM is made up of ethylene, propylene, and diene comonomers, and have a saturated polyethylene backbone to their structure, which provides them with a high resistance capability to heat, light, and ozone, as compared to other rubber materials.

This property of endurance outdoor weathering exposure is what sets EPDM Rubbers apart from other rubbers and has earned it industry-wide appeal and acceptance.

Properties of EPDM Rubber

EPDM offers considerable resistance to abrasion, heat, steam, light, UV rays, water, and ozone, giving it a weatherproof quality and high durability, which makes it an excellent choice for outdoor applications.

It is also resilient and flexible, possessing low electrical conductivity, high noise insulation, a maximum elongation of 600%, and a tensile range of 500-2500 P.S.I.

It can function at temperatures as low as -51⁰C and as high as 150°C without air. It is also compatible with mild acids, alcohols, ketones, silicone oils, greases, hot and cold water, detergents, alkalis, fireproof hydraulic fluids, etc.

On the other hand, EPDM is incompatible with most hydrocarbons, such as kerosene, oils, gasoline, halogenated solvents, and some lubricants.

The durability, flexibility, and long life in extreme environments are what make EPDM rubbers a widely-used synthetic material in the industry.

Primary Uses Of EPDM Rubber

EPDM rubbers can be produced in many forms, such as EPDM sheet rubbers as well as adhesives.

Some common applications of the EPDM rubber include :

Seals and Sealants.

Gaskets.

O-Rings.

Tubing.

Washers.

Cooling Systems.

Brake Systems.

Ozone Exposure Applications.

Roofing.

Waterproof Coating.

Custom Moulded Rubber Components.

What is Nitrile Rubber?

Nitrile Rubber, also known as NBR (Nitrile Butadiene Rubber) or Buna-N, was first developed in the 1930s.

During WW1, rubber was high in demand. The price of natural rubber skyrocketed after the war due to shortages. That sparked a renewed interest in the development of synthetic rubber, paving the way for Nitrile / Buna-N.

Nitrile is composed of acrylonitrile and butadiene monomers. It is highly resistant to oil, gas, diesel fuel, chemicals, and petroleum products.

Today, it is one of the widely used synthetic rubbers, especially in the sealant industry. A huge benefit of Nitrile Rubberis that it is cost-efficient and provides flexibility in applications.

Properties of Nitrile Rubber

One of the most significant advantages that Nitrile offers is its imperviousness to mineral oils, vegetable oils, benzene and petrol, petroleum-based products, diesel fuels, gas, chemicals, diluted acids, and alkaline.

The amount of oil resistance is influenced by the percentage of acrylonitrile in the rubber. The higher the acrylonitrile content, the better the resistance as well as strength and permeability. Lower acrylonitrile means less resistance but more flexibility at lower temperatures.

Nitrile can operate at temperatures ranging from -40°C to 108°C and is also abrasion, tear, and compression set resistant.

It offers three times more puncture resistance than natural rubber and possesses a 600% elongation rate and a 500-2500 P.S.I. tensile range. Nitrile, however, also has drawbacks, with poor resistance to UV rays, ozone, weathering, and extended outdoor exposure.

Primary Uses of Nitrile Rubber

Some common applications of Nitrile rubber include:

Sealants.

Molded Goods.

Gasket.

Hydraulic Hoses.

Conveyor Belting.

Washers.

O-Rings.

Fuel Systems.

Protective Equipment (like Gloves).

Oil Resistant Applications.

It is also ideal for automotive, aeronautical, nuclear, as well as kitchen applications.

EPDM vs Nitrile Rubber – Which is Better?

Both EPDM Rubber and Nitrile Rubber have their advantages and disadvantages.

However, they’re also quite similar in some of their properties. Before we look at their differences, let’s take a look at their similarities.

EPDM and Nitrile rubbers are synthetic elastomers that are both highly durable and flexible. They are similar in their elongation percentage, tensile strength, and impervious abrasion, and compression set. The two are also commonly used for O-rings, gaskets, and other industrial applications.

After understanding how they are similar, let’s go through their core differences.

EPDM’s temperature resistance range is from -51°C to 150°C, while for Nitrile, it is -40°C to 108°C. While both work well in extreme temperatures, EPDM has a slight edge over Nitrile.

EPDM Rubber is great at providing resistance against UV Rays, Ozone, Sunlight, and Weathering Conditions, and can hold well in outdoor environments without facing degrading.

Nitrile has extremely low resistance against UV Rays, Ozone, and weathering effects, and performs poorly in outdoor environments.

On the contrary, Nitrile Rubber provides great resistance to gasoline, diesel fuel, motor oil, non-polar solvents, and petroleum-based products, as compared to EPDM, which is poorly resistant to them. Due to this, while EPDM is used frequently in braking systems in vehicles, Nitrile finds better use in the fuel systems.

Another difference between EPDM and Nitrile is that EPDM is an aromatic polymer but Nitrile, on the other hand, is non-aromatic. And when it comes to cost, Nitrile is the more expensive one out of the two.

Making the Right Choice – EPDM vs Nitrile Rubber.

When you choose between EPDM Rubber and Nitrile Rubber, you need to consider its application and the environment during the decision-making process.

If you want a rubber product that performs well in outdoor environments when exposed to ozone, sunlight, and UV rays, then EPDM Rubber is your best bet.

However, when such exposures are not a concern and fuels are involved, then Nitrile is a more suitable option.

Now that you know the basics of EPDM and Nitrile Rubber, their properties, their applications, and their differences, we hope that you will be able to utilize them to your advantage.

If you need any rubber products, you can rely on R-Tech Rubber Industries. They provide a wide variety of Rubber products in India.

0 notes

Text

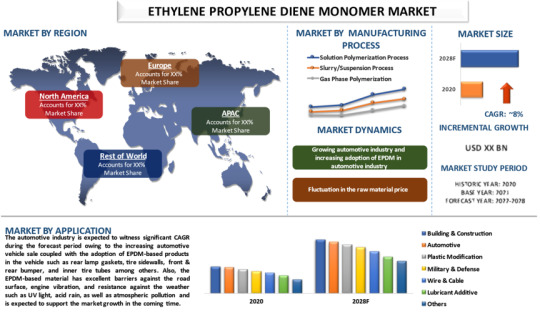

Ethylene Propylene Diene Monomer (EPDM) Market Overview

Introduction

Ethylene Propylene Diene Monomer Market is a type of synthetic rubber known for its excellent resistance to heat, oxidation, ozone, and weathering. EPDM rubber is used in a wide range of applications, including automotive weatherstripping and seals, roofing membranes, and industrial and construction products. The market for EPDM is growing steadily due to its superior properties and the increasing demand from various end-use industries.

Market Drivers

1. Automotive Industry Growth: The automotive sector is one of the largest consumers of EPDM, utilizing it in hoses, seals, and weatherstripping. The continuous growth in vehicle production and the shift towards electric vehicles, which require durable and heat-resistant materials, drive the demand for EPDM.

2. Construction Industry Demand: In the construction industry, EPDM is used in roofing membranes and other applications due to its durability and weather resistance. With increasing infrastructure projects and renovation activities, the demand for EPDM in the construction sector is rising.

3. Rising Industrial Applications: EPDM's properties make it suitable for various industrial applications, such as conveyor belts, gaskets, and hoses. The expansion of the manufacturing sector and the need for reliable and durable materials in industrial processes contribute to the market growth.

Market Challenges

1. Raw Material Price Volatility: The prices of raw materials used in the production of EPDM, such as ethylene and propylene, are subject to fluctuations. This volatility can affect the overall cost of production and impact profit margins for manufacturers.

2. Environmental Regulations: The production and disposal of synthetic rubber are subject to environmental regulations. Compliance with these regulations can increase production costs and pose challenges for manufacturers.

For a comprehensive analysis of the market drivers:- https://univdatos.com/report/ethylene-propylene-diene-monomer-market/

Regional Insights

1. North America: The North American EPDM market is driven by the robust automotive and construction sectors. The region's focus on sustainable and energy-efficient buildings further supports the demand for EPDM in roofing applications.

2. Europe: Europe is a significant market for EPDM due to its strong automotive industry and stringent environmental regulations that promote the use of durable and recyclable materials. The construction sector also contributes to the market growth in this region.

3. Asia-Pacific: The Asia-Pacific region is witnessing rapid growth in the EPDM market, fueled by the booming automotive industry in countries like China and India. Additionally, the expanding construction industry and increasing industrialization are driving the demand for EPDM in this region.

4. Latin America and Middle East & Africa: These regions are experiencing moderate growth in the EPDM market. The increasing automotive production and construction activities are key factors contributing to the market expansion in these regions.

Market Trends

1. Sustainability and Recycling: There is a growing emphasis on sustainability and recycling in the EPDM market. Manufacturers are focusing on developing eco-friendly production processes and recyclable EPDM products to meet the rising demand for sustainable solutions.

2. Technological Advancements: Innovations in production technologies and the development of advanced EPDM formulations are enhancing the performance and applications of EPDM. These advancements are expected to open new opportunities in various end-use industries.

3. Increased Use in Electric Vehicles: The shift towards electric vehicles (EVs) is driving the demand for high-performance materials like EPDM. EVs require materials that can withstand higher temperatures and provide better insulation, making EPDM an ideal choice.

For a sample report, visit:- https://univdatos.com/get-a-free-sample-form-php/?product_id=31683

Competitive Landscape

The EPDM market is highly competitive, with several key players operating globally. Companies are focusing on strategic initiatives such as mergers and acquisitions, collaborations, and new product developments to strengthen their market position. Some of the prominent players in the EPDM market include:

Conclusion

The Ethylene Propylene Diene Monomer (EPDM) market is poised for significant growth in the coming years, driven by the increasing demand from the automotive, construction, and industrial sectors. While challenges such as raw material price volatility and environmental regulations exist, advancements in technology and a focus on sustainability are expected to propel the market forward. The competitive landscape will continue to evolve as companies innovate and adapt to meet the changing demands of the market.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

The Complete Guide to Flat Roofing Materials

Flat roofing refers to a kind of roofing system that has a minimum slope, usually less than 10 ranges, and is normally used in commercial and business homes. It differs from sloped roofs, which have a steeper incline and are extra commonly discovered in residential homes. Some of the most famous flat roofing substances include EPDM, TPO, and PVC, which can be durable and long-lasting.

Most Common Types of Flat Roofing Materials

The maximum not unusual varieties of flat roofing substances are:

EPDM (Ethylene Propylene Diene Monomer) :

It's a synthetic rubber membrane that is regarded for its sturdiness and versatility. EPDM is immune to UV rays, ozone, and extreme temperatures, making it a wonderful alternative for flat roofs.

TPO (Thermoplastic Olefin) :

A unmarried-ply roofing membrane made from thermoplastic polyolefin. It's a famous choice for flat roofs due to its strength efficiency and potential to mirror UV rays.

PVC (Polyvinyl Chloride) :

It's a thermoplastic fabric that is recognised for its durability and resistance to chemical compounds, fire, and excessive temperatures. PVC is likewise power green and UV resistant.

Built-up Roofing (BUR) :

It's a traditional roofing machine made from a couple of layers of felt or fiberglass, which are lined with tar or asphalt to create a waterproof barrier.

Modified Bitumen:

It's a type of asphalt-based totally roofing this is bolstered with either a polyester or fiberglass mat. It provides properly sturdiness and resistance to punctures and tears.

It's well worth noting that every kind of flat roof material has its personal precise set of benefits and drawbacks. The nice desire in your building will rely upon elements which include region, weather, and finances.

Advantages and Disadvantages of Flat Roofing

Advantages of flat roofing:

Cost-powerful:

Flat roofs are normally much less high priced to install and maintain than sloped roofs. This is because they require much less substances and hard work to construct.

Easy Access:

Flat roofs are easy to get entry to, which makes it handy for protection and maintenance. This can shop money and time in the end.

Space:

Flat roofs may be used as an extra out of doors space, along with for creating a rooftop lawn or terrace.

Energy efficient:

TPO and PVC have reflective properties that can assist to lessen the amount of heat absorbed with the aid of the building, that can lead to lower cooling fees.

Disadvantages of flat roofing:

Drainage:

Flat roofs will have drainage problems: if now not nicely designed and maintained. This can result in water ponding, leaks, and different harm.

Weather Damage:

Flat roofs are extra at risk of harm from heavy rain and snow, in addition to excessive winds.

Not suitable for all climates: Flat roofs are not suitable for areas with heavy snow or frequent heavy rains, because of the threat of water ponding.

Reduced lifespan:

Without right protection, flat roofs generally tend to have a shorter lifespan than sloped roofs.

It's worth noting that with proper design, installation, and upkeep, flat roofs may be a viable alternative for many buildings. It's crucial to seek advice from a professional roofing contractor to determine if a flat roof is the right preference in your precise constructing and vicinity.

Also Read :

Why Are Flat Roofs Used?

WHY SOLID ROOF CONSERVATORIES ARE A GROWING TREND

0 notes

Text

Unveiling the Power of EPDM Rubber Roofing Solutions

Are you in search of a roofing solution that combines durability, versatility, and cost-effectiveness? Look no further than EPDM Rubber Roofing Solutions. In this guide, we'll explore the world of EPDM roofing solutions, uncovering what sets them apart, why they're gaining popularity, and how they can benefit your property. So, let's dive into the realm of EPDM and discover why it's a top choice for savvy property owners.

Unraveling the Mysteries: What is EPDM Rubber Roofing?

1. An Introduction to EPDM

EPDM, or Ethylene Propylene Diene Monomer, is a synthetic rubber roofing membrane known for its exceptional durability and weather resistance. Originally developed in the 1960s, EPDM has since become one of the most popular roofing materials worldwide, favored for its longevity and ease of installation.

2. The Versatility of EPDM

EPDM rubber roofing is available in various forms, including sheets, rolls, and membranes, making it suitable for a wide range of roofing applications. Whether you're installing a flat roof, low-slope roof, or even a pond liner, EPDM offers versatility and flexibility to accommodate diverse roofing needs.

Exploring the Advantages of EPDM Roofing Solutions

1. Exceptional Durability

EPDM rubber roofing is renowned for its durability, with a typical lifespan of 30 years or more when properly installed and maintained. Its resistance to UV radiation, ozone exposure, and extreme temperatures ensures long-term performance and protection for your property.

2. Cost-Effectiveness

In addition to its durability, EPDM roofing solutions are highly cost-effective, offering a competitive price point compared to other roofing materials. Its long lifespan and minimal maintenance requirements translate to significant cost savings over the life of the roof, making it an economical choice for budget-conscious property owners.

3. Easy Installation and Maintenance

EPDM rubber roofing is relatively easy to install compared to other roofing materials, thanks to its lightweight and flexible nature. Additionally, its seamless design minimizes the risk of leaks and simplifies maintenance, reducing the need for costly repairs and upkeep over time.

Overcoming Common Misconceptions

1. Myth: EPDM is Prone to Damage

Contrary to popular belief, EPDM rubber roofing is highly resistant to damage from environmental factors such as hail, wind, and moisture. Its robust construction and flexibility allow it to withstand harsh weather conditions without compromising performance or integrity.

2. Myth: EPDM Requires Frequent Replacement

While some roofing materials may require frequent replacement due to wear and tear, EPDM rubber roofing is designed to last for decades with minimal maintenance. By investing in EPDM, property owners can enjoy long-term peace of mind and protection without the hassle of frequent replacements.

youtube

Conclusion: Embracing the Power of EPDM

EPDM rubber roofing solutions offer a winning combination of durability, versatility, and cost-effectiveness, making them an ideal choice for property owners seeking reliable protection and long-term value. By harnessing the power of EPDM, you can safeguard your property against the elements and enjoy peace of mind for years to come. So why wait? Discover the benefits of EPDM for yourself and elevate your roofing experience today!

#Bitumen Roofing for Flats#Flat Roof Leak Detection Services#Roof Garden Waterproofing Systems#Flat Roof Insulation Techniques#Residential Flat Roof Replacement#Commercial Roofing System Upgrades#Emergency Flat Roof Repairs#Youtube

1 note

·

View note

Text

What are The Different Flat Roofing Material Types?

Masonry Exterior While many homes feature pitched roofs, you might come across some with flat roofs. Flat roofs are not only cost-effective but also require minimal maintenance, making them an ideal choice for contemporary homes. Flat roofs have gained popularity in commercial buildings and modern homes due to their practicality and versatility. They offer usable space that can serve various purposes, including reducing heat absorption through the application of reflective roof coatings (which can lead to significant energy savings), creating outdoor living areas, installing green roofs, and mounting solar panels. However, selecting the right material for your flat roof can be challenging, as different materials come with varying costs, durability levels, and maintenance needs. Several technologies have emerged in recent years and are shaping the future of the roofing industry. In this article, we will explore three types of materials for flat roofing, along with their advantages and disadvantages. Built-Up Roof (BUR) The traditional hot-tar-and-gravel roof consists of three or more layers of waterproof material, which are alternating with hot tar and then ballasted with a layer of smooth river stone. Initially, these roofs were made of tar paper, but nowadays, they are increasingly incorporating more advanced materials such as fiberglass membranes. Pros Gravel serves as an effective fire retardant, making it a desirable choice. It adds an appealing aesthetic for windows and decks with a view of the roof. It’s the cheapest of the roof varieties. Cons Very heavy. Joists sometimes have to be strengthened. It emits strong odors and creates a messy installation process. Installation is not recommended for occupied homes. It’s not suitable for DIY installation and locating leaks can be challenging. Gravel can clog gutters and scuppers. Modified Bitumen Roof A single-ply rolled roof, resembling ice-and-water shield but with a mineral-based wear surface, is commonly used. Torch-down systems require heating the adhesive while unrolling the material. Alternatively, newer peel-and-stick systems are considered safer and simpler to install. Pros Homeowners can install peel-and-stick material themselves. Its light-colored mineral surface reflects heat, leading to reduced energy bills. Its price falls in the middle range compared to other roofing options. Cons Torch-down application is considered a fire hazard and is not recommended for occupied buildings. It lacks the scuff or tear resistance typically found in rubber-membrane roofs. Rubber Membrane Roof EPDM, short for ethylene propylene diene monomer, is a genuine rubber material. This durable single-ply membrane resembles an inner tube but is designed to withstand damage from sunlight. EPDM can be mechanically anchored using fasteners, ballasted with stone, or glued in place. Pros The material is relatively lightweight yet highly resistant to scuffs and tears. Homeowner-friendly installation. Leaks are easy to patch. Cons The standard black material absorbs heat, while light-colored coatings, recommended in warm climates, can increase the cost by 30% or more. It’s more vulnerable to punctures than other choices. Cleaning is essential for maintaining the best appearance and longevity of a building with a masonry exterior, especially when considering restoration efforts. Flat roofs offer a cost-effective, low-maintenance solution for protecting your home. However, it’s crucial to consult with a roofing professional to assess your specific roofing requirements and determine the most suitable material for your flat roof. If you are looking for a roofing contractor for your upcoming home renovation projects at New America Construction we provide roofing estimates for all NJ homeowners. Call us for more information 973-804-9400 Find us in: Facebook, Instagram, Google and Yelp.

The post What are The Different Flat Roofing Material Types? first appeared on Exterior Contractor Company.

from https://newamericaconstructionco.com/roofing/what-are-the-different-flat-roofing-material-types/?utm_source=rss&utm_medium=rss&utm_campaign=what-are-the-different-flat-roofing-material-types

0 notes

Text

Synthetic rubber Market Revolution: A Market Overview

The global synthetic rubber market size is expected to reach USD 36.15 billion by 2032, according to a new study by Polaris Market Research. The report “Synthetic Rubber Market Share, Size, Trends, Industry Analysis Report, By Product Type (SBR, IIR, EPDM, IR, NBR, & Others), By Application, By Industry Vertical, By Regions, Segments & Forecast, 2019 – 2032” gives a detailed insight into current market dynamics and provides analysis on future market growth.

Synthetic Rubber Market is expected to grow at a quickest rate over the forecast period owing to wider applications of Synthetic rubbers in tire and non-tire segments of automobile industry. Adoption of synthetic rubber from industry such as industrial goods, fmcg and medical sector in various applications coupled with rising prices of natural rubber are some of other factors behind the growth of the market in the coming years.

Synthetic rubbers are artificially produced materials that mimic natural rubber's desirable properties. Petrochemical feedstocks are the primary raw materials for manufacturing of synthetic rubber. The major development of synthetic rubber can be attributed to one factor during the World War II period when the United States was cut off from all of its sources of natural rubber. To meet the country's needs, the government built synthetic rubber plants and sold the plants to industries in the post-war period, which gave a kick-start to commercializing synthetic rubber.

The synthetic rubber are widely adopted in a variety of applications for some of its beneficial characteristics such as better abrasion resistance, superior elasticity, heat and aging resistance, flame retardant, and flexibility at low temperatures. Some of the most common varieties of synthetic rubber used by end-use industry butyl rubber (IIR), polybutadiene rubber, styrene-butadiene (SBR) rubber, chloroprene rubber, Ethylene propylene diene monomer rubber (EPDM) rubber, nitrile rubber.

For instance, as per the European Automobile Manufacturer's Association (ACEA), world vehicle production has increased by 1.3% from 2020 to 2021, with a value of 79.1 million motor vehicles. Moreover, global car and commercial vehicle production grew by 0.03% and 4% from 2020 to 2021. In addition, the aggregate value for cars and commercial vehicles production in 2021 was 80.14 million, which was 3% higher than the 2020 production number of 77.71 million per the International Organization of Motor Vehicle Manufacturers.

Various inhibiting factor for the Synthetic Rubber market can be attributed to the price fluctuation of Petrochemical feedstock (Crude Oil) raw materials in the last few years. Since crude oil prices largely depend on various factors, such as demand-supply and other geo-political relations between trading countries, it greatly affects the price structure and profit margins of synthetic rubber producers. In addition, the high manufacturing and rising transportation costs also impact the end-price of synthetic rubber products, further decreasing the demand from buyers end to some extent.

Have Questions? Request a sample or make an Inquiry before buying this report by clicking the link below: https://www.polarismarketresearch.com/industry-analysis/synthetic-rubber-market/request-for-sample

The COVID-19 pandemic has negatively impacted the Synthetic Rubber market across all regions. Various countries' governments have imposed certain measures to control the virus to further spread among the people. The temporary shutdown of multiple shops and production units had led to the decrease in demand and supply of products constituting synthetic rubber. In the pandemic period, the consumer demand was remained insignificant as consumers preferred spending money on their health and essential goods. The declining demand for various end-use industries has lowered the synthetic rubber market during pandemic period.

Synthetic Rubber Market Report Highlights:

The Styrene Butadiene Rubber (SBR) is anticipated to dominate the synthetic rubber market owing to its properties including high abrasion resistance, high tensile strength, and good aging stability, favor styrene butadiene rubber.

While, Nitrile Butadiene Rubber (NBR) has been anticipated to witness the fastest growth rate in the forecast period. The major factors for segment growth can be ascribed to its benefits, such as fuel and oil resistance, abrasion resistance, and good temperature properties.

The Tire segment is anticipated to account for a major share of the Synthetic Rubber market. The major factors can be attributed to various advantages such as better aging and heat resistance, abrasion resistant, excellent electrical insulation material, and others. For instance, as per the USA Tire Manufacturers Association, both passenger and truck tires use 24% and 11% synthetic polymers for their contribution to the life of a tire.

Asia-Pacific Region is accounted for the largest market share in 2022 due to presence of major tire producing countries in the region such as India, China, Japan, South Korea, Thailand, and Indonesia. For instance, as per European Automobile Manufacturer's Association (ACEA), Greater China accounted for around 33% of world car production in 2021 and 31% of commercial vehicle production in the same period.

Polaris Market Research has segmented the Synthetic Rubber Computing Market report based on product type, application, industry vertical, and region:

Synthetic Rubber Computing Market, Product Type Outlook (Revenue - USD Billion, 2019 - 2032)

Styrene-butadiene Rubber (SBR)

Butyl Rubber (IIR)

Ethylene-propylene-diene Rubber (EPDM)

Isoprene Rubber (IR)

Acrylonitrile-butadiene Rubber (NBR)

Others

Synthetic Rubber Computing Market, Application Outlook (Revenue - USD Billion, 2019 - 2032)

Tire

Non-Tire Automobile Applications

Footwear

Industrial Goods

Sporting Goods

Other Applications

Synthetic Rubber Computing Market, Industry Vertical Outlook (Revenue - USD Billion, 2019- 2032)

Automotive

Industrial Goods

Chemical Industry

Medical Industry

Paper & Pulp

Others

Synthetic Rubber Computing Market, Regional Outlook (Revenue - USD Billion, 2019 - 2032)

North America

U.S.

Canada

Europe

Germany

UK

France

Italy

Spain

Russia

Netherlands

Asia Pacific

China

India

Japan

South Korea

Indonesia

Malaysia

Latin America

Argentina

Brazil

Mexico

Middle East & Africa

UAE

Saudi Arabia

Israel

South Africa

Purchase the Report for Key Insights:@ https://www.polarismarketresearch.com/industry-analysis/synthetic-rubber-market

Bottom of FormAbout Us:

Polaris Market Research is a worldwide market research and consulting organization. We give unmatched nature of offering to our customers present all around the globe across industry verticals. Polaris Market Research has expertise in giving deep-dive market insight along with market intelligence to our customers spread crosswise over various undertakings. We at Polaris are obliged to serve our different client base present over the enterprises of medicinal services, healthcare, innovation, next-gen technologies, semi-conductors, chemicals, automotive, and aerospace & defense, among different ventures, present globally.

Contact Us:

Polaris Market Research

Email: [email protected]

Phone: +1-929-297-9727

0 notes

Text

EPDM (ethylene propylene diene monomer) rubber roofing has emerged as a popular choice for flat roofs due to its durability, longevity, and ease of installation. This versatile roofing material offers a host of advantages over traditional options, making it a favorite among architects, contractors, and homeowners alike.

Understanding EPDM

EPDM is a synthetic rubber roofing membrane known for its exceptional weather resistance, thermal stability, and resistance to ozone and ultraviolet (UV) radiation. These characteristics make it an ideal material for flat roofs, where exposure to the elements is constant. EPDM comes in large rolls, and its installation involves adhering the sheets to the roof substrate, creating a seamless and durable waterproof barrier.

Cost of EPDM Flat Roof

The cost of EPDM flat roofing can vary based on several factors, including the size of the roof, labor costs in the region, and any additional materials or features required. Here's a breakdown of the primary cost considerations:

Material Cost:

EPDM is typically priced per square foot. The cost can range from $0.80 to $3.50 per square foot, depending on the thickness of the membrane and whether it is black or white (with white EPDM reflecting more sunlight and potentially reducing cooling costs).

Labour Cost:

Professional installation is recommended for EPDM flat roofs, and labor costs can vary. On average, expect to pay between $3 to $7 per square foot for installation. Factors such as roof complexity, accessibility, and local labor rates can influence the final labor cost.

Read more

0 notes

Text

The Economics of EPDM Rubber Production: Understanding the Cost Factors

The latest report titled EPDM Rubber Production Cost by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of EPDM Rubber.

Procurement Resource study is based on the latest prices and other economic data available. It also offers additional analysis of the report with detailed breakdown of all cost components (capital investment details, production cost details, economics for another plant location, dynamic cost model). In addition, the report incorporates the production process with detailed process and material flow, capital investment, operating costs along with financial expenses and depreciation charges.

Request For Free Sample: https://procurementresource.com/production-cost-report-store/epdm-rubber/request-sample

Procurement Resource’s detailed report describes the stepwise consumption of material and utilities along with a detailed process flow diagram. Furthermore, the study assesses the latest developments within the industry that might influence EPDM Rubber production cost, looking into capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

Procurement Resource Assessment of EPDM Rubber Production Process:

1. EPDM Rubber Production Cost From Suspension Polymerization: This report provides an overview of the production process of and expense evaluation of EPDM Rubber industrial production across EPDM Rubber manufacturing plant. To produce EPDM rubber, the first polymerization of propylene (polymer-grade) and ethylene takes place using a catalyst. The catalyst is then separated using an emulsifier, and the resulting substance is purified, dried, and moulded into rubber forms.

Request For Free Sample: https://procurementresource.com/cost-analysis/epdm-rubber-production-from-suspension-polymerization/requestsample

Product Definition:

EPDM rubber is a special synthetic rubber that is composed of propylene, ethylene, as well as diene monomers. This resilient material boasts a unique molecular structure that imparts an exceptional degree of resistance to outdoor elements. It is also highly resistant to abrasion and aging, due to which it is widely used as a waterproof material for various purposes. Moreover, it has a long lifespan if it is properly maintained, but it is vulnerable to be damaged from solvents, hydrocarbon oils, and some lubricants. EPDM roofing can last up to 30-50 years, while liners can last up to 20 years. However, EPDM is not flame resistant like silicone and should not be used for food applications.

Market Drivers:

EPDM is a cost-effective alternative to silicone rubber that is widely used for parts exposed to moisture or outdoor conditions, as well as for electrical insulation. It has multiple applications in the automotive industry, where its flexibility, resilience, and weather resistance make it ideal for weather stripping, seals, and brake systems. In addition, it is used in industrial applications for its insulating and waterproof properties, as well as its ability to withstand harsh conditions. It is also used for roofing, sealant, expansion joints, garage door seals, pool and tank liners, and waterproof coating for bitumen roofs. In the construction industry, it is widely used for insulation, weatherproofing, and waterproofing. These wide ranges of applications in different sectors increase its demand. Therefore, the growth in the construction and automobile industries play a major role in raising its market growth.

Looking for an exhaustive and personalised report that could significantly substantiate your business?

Although Procurement Resource leaves no page unfurled in terms of the rigorous research for the commodities that make the heftiest base of your business, we incline more towards tailoring the reports per your specificities. All you need is one-to-one consulting with our seasoned consultants to comprehend the prime parameters you are looking to pin your research on.

Some of the common requests we receive from our clients include:

Adapting the report to the country/region where you intend to establish your plant.

Adjusting the manufacturing capacity of the plant according to your needs

Customizing machinery suppliers and costs to meet your requirements.

Providing additional information to the existing scope based on your needs.

About Us:

Procurement Resource ensures that our clients remain at the vanguard of their industries by providing actionable procurement intelligence with the help of our expert analysts, researchers, and domain experts. Our team of highly seasoned analysts undertakes extensive research to provide our customers with the latest and up-to-date market reports, cost models, price analysis, benchmarking, and category insights, which aid in simplifying the procurement process for our clientele.

Procurement Resource work with a diverse range of procurement teams across industries to get real-time data and insights that can be effectively implemented by our customers. As a team of experts, we also track the prices and production costs of an extensive range of goods and commodities, thus, providing you with updated and reliable data.

We, at Procurement Resource, with the help of the latest and cutting-edge techniques in the industry, help our clients understand the supply chain, procurement, and industry climate so that they can form strategies that ensure their optimum growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Chris Byrd

Email: [email protected]

Toll-Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA

1 note

·

View note

Text

Revolutionizing the Rubber Realm: A Deep Dive into the Thriving EPDM Market Landscape

In the ever-evolving landscape of the global market, the Ethylene Propylene Diene Monomer (EPDM) industry is poised for significant growth. According to the latest report, the EPDM Market is estimated to be USD 3.6 billion in 2022 and is projected to reach USD 4.8 billion by 2027, reflecting a noteworthy Compound Annual Growth Rate (CAGR) of 5.9% during the forecast period from 2022 to 2027.

EPDM Market Overview

EPDM, a versatile synthetic rubber, finds its applications across diverse sectors, including Automotive, Building & Construction, Plastic Modification, Tires & Tubes, Wires & Cables, and Lubricant Additives. Automotive, in particular, emerges as the major driver of the EPDM market, contributing significantly to its growth. As the automotive sector experiences a robust recovery in the Asia-Pacific (APAC) region, the demand for EPDM is expected to surge.

Key Insights and Opportunities

The automotive application holds the largest share in the EPDM market, with China playing a pivotal role. The country's focus on developing new energy vehicles (NEVs), encompassing Fuel Cell Electric Vehicles (FCVs), Plug-in Hybrid Electric Vehicles (PHEVs), and Battery Electric Vehicles (BEVs), is a key catalyst for the increased usage of EPDM in the automotive industry. According to the China Association of Automobile Manufacturers (CAAM), the total production of cars in 2021 witnessed a 3% year-on-year increase.

Additionally, the growing demand for electric and hybrid vehicles presents new opportunities in the EPDM market. The development of eco-friendly technologies for EPDM production aligns with the global shift towards sustainable practices in the automotive sector.

Manufacturing Processes and Market Dynamics

EPDM can be manufactured through various processes, and the Solution Polymerization Process currently dominates the market. This process is highly versatile, allowing for the production of a wide range of polymers. Polymerization and catalyst technologies play a crucial role in tailoring EPDM to meet specific application and processing needs.

Regional Market Dynamics

The Asia-Pacific region emerged as the frontrunner in the global EPDM market in 2021, with China being a key player in both production and consumption. The region's dominance is attributed to the concentration of EPDM producers and the flourishing automotive and construction sectors. New construction projects and sustained growth in the automotive industry are propelling the EPDM market in Asia Pacific.

Industry Players and Strategies

Leading players in the EPDM market include ARLANXEO, DOW Inc., Exxon Mobil Corporation, JSR Corporation (Kumho Polychem Co. Ltd.), PetroChina Company Limited, Versalis S.p. A., SK Global Chemical Co., Ltd., Sumitomo Chemical Co., Ltd., and Mitsui Chemicals, Inc. These industry giants are actively shaping the market through strategic initiatives, ensuring competitiveness and sustainability.

Download PDF Report :

Navigating the Future

As the EPDM market continues to evolve, keeping an eye on ethylene propylene diene monomer prices, EPDM market trends, and the EPDM price trend for 2023 will be critical. Stakeholders should remain vigilant about the dynamic market forces, ensuring they are well-positioned to capitalize on emerging opportunities and navigate challenges.

The EPDM market's growth trajectory is marked by resilience and adaptability, making it a key player in the global rubber market. Stay tuned for more updates on the EPDM market, where innovation meets opportunity in this dynamic industry landscape.

0 notes

Text

Your Guide to Choosing the Right Commercial Roofing Company in Albany, NY

Your commercial roof is one of the most important assets of your business. It protects your employees, inventory, and equipment from the elements. That's why it's so important to choose the right commercial roofing company for all of your roofing needs.

In this blog post, we'll discuss the factors to consider when choosing a commercial roofing company in Albany, NY. We'll also provide a list of tips for hiring a reliable and reputable contractor.

Factors to Consider When Choosing a Commercial Roofing Company

Here are some of the most important factors to consider when choosing a commercial roofing company in Albany, NY:

Experience: Choose a company with extensive experience in commercial roofing. This will ensure that they have the knowledge and expertise to handle your specific needs.

Reputation: Ask for references and read online reviews to get a sense of the company's reputation.

Licensing and insurance: Make sure the company is licensed and insured in the state of New York. This will protect you in case of any problems down the road.

Warranty: Choose a company that offers a warranty on their work. This will protect you in case of any defects in the materials or workmanship.

Tips for Hiring a Reliable and Trustworthy Commercial Roofing Contractor

Here are some tips for hiring a reliable and trustworthy commercial roofing contractor:

Get multiple estimates: Be sure to get estimates from multiple contractors before making a decision. This will help you compare prices and services.

Ask about their experience: Ask the contractors about their experience with commercial roofing projects similar to yours. Be sure to find out what types of roofs they have worked on and how many years of experience they have.

Check their references: Ask the contractors for references from previous customers. Contact the references and ask about their experience with the company.

Get everything in writing: Once you have chosen a contractor, be sure to get everything in writing. This includes the contract, warranty, and estimated price.

Why Choose National Commercial Roofing and Construction?

National Commercial Roofing and Construction is a leading commercial roofing company in Albany, NY. We have over 20 years of experience in the industry and have worked on a wide variety of commercial roofing projects.

We are committed to providing our customers with the highest quality workmanship and customer service.

We offer a variety of commercial roofing services, including:

New roof installation

Roof repair

Roof replacement

Roof maintenance

We also offer a variety of commercial roofing materials, including:

TPO

EPDM

Modified bitumen

Metal roofing

Contact Us Today

If you are looking for a reliable and trustworthy commercial roofing company in Albany, NY, contact National Commercial Roofing and Construction today. We offer free estimates and consultations.

FAQ

Q: What are the different types of commercial roofing materials?

A: The most common types of commercial roofing materials are TPO, EPDM, modified bitumen, and metal roofing.

TPO roofing: TPO roofing is a type of thermoplastic roofing membrane that is made from a blend of ethylene propylene diene monomer (EPDM) and polypropylene (PP). It is a durable and lightweight roofing material that is resistant to UV rays, ozone, and fire.

EPDM roofing: EPDM roofing is a type of synthetic rubber roofing membrane that is made from ethylene propylene diene monomer (EPDM). It is a durable and flexible roofing material that is resistant to UV rays, ozone, and chemicals.

Modified bitumen roofing: Modified bitumen roofing is a type of asphalt roofing material that has been modified with polymers to improve its performance. It is a durable and waterproof roofing material that is resistant to UV rays, ozone, and fire.

Metal roofing: Metal roofing is a type of roofing material that is made from metal, such as steel or aluminum. It is a durable and long-lasting roofing material that is resistant to fire, hail, and wind.

Q: How often should I have my commercial roof inspected?

A: You should have your commercial roof inspected at least once a year by a qualified roofing contractor. This will help to identify any potential problems early on, before they cause major damage.

#roofing company albany#metal roofing albany#commercial roofers albany#commercial roofing company albany#ny#roofing

0 notes

Text

EPDM Rubber Prices, Price, Trend, Supply & Demand and Forecast | ChemAnalyst

EPDM Rubber Prices, a versatile synthetic rubber known for its excellent weather resistance, durability, and thermal stability, has become a cornerstone material in various industries, including automotive, construction, and manufacturing. As with any commodity, its pricing dynamics are subject to a multitude of factors, influencing its market value and availability. Understanding these factors is crucial for businesses relying on EPDM rubber to navigate market fluctuations effectively.

One of the primary determinants of EPDM rubber prices is the cost of raw materials. EPDM is produced from ethylene, propylene, and a small amount of diene monomer. Thus, any fluctuations in the prices of these feedstocks significantly impact the overall production cost of EPDM. For instance, changes in crude oil prices, as ethylene and propylene are derived from petroleum, directly influence the cost of EPDM production. Additionally, factors such as supply chain disruptions, geopolitical tensions, and natural disasters can disrupt the availability of raw materials, further impacting prices.

Market demand and supply dynamics play a pivotal role in shaping EPDM rubber prices. As industries like automotive, construction, and electrical continue to grow, the demand for EPDM rubber escalates. Conversely, during economic downturns or periods of reduced industrial activity, demand may decrease, leading to a surplus in supply and subsequent price drops. Moreover, shifts in consumer preferences towards sustainable and eco-friendly products have prompted manufacturers to invest in EPDM rubber as a viable alternative, potentially driving prices higher due to increased demand.

Get Real Time Prices of EPDM Rubber: https://www.chemanalyst.com/Pricing-data/epdm-rubber-1110

Global economic conditions and currency fluctuations exert significant influence on EPDM rubber pricing. EPDM is a globally traded commodity, and its pricing is susceptible to macroeconomic factors such as inflation rates, exchange rates, and interest rates. For example, a stronger US dollar can make EPDM imports cheaper for countries with weaker currencies, boosting demand and prices in those markets. Conversely, a weaker dollar may lead to higher import costs, impacting pricing dynamics differently across regions.

Technological advancements and innovations in EPDM production processes also impact pricing. Manufacturers constantly strive to enhance production efficiency, reduce energy consumption, and minimize environmental impact. Investments in research and development (R&D) aimed at developing novel production techniques or improving product quality can affect production costs and, consequently, prices. Moreover, breakthroughs in recycling technologies enable the reuse of EPDM scrap and waste, mitigating supply constraints and potentially stabilizing prices.

Regulatory policies and environmental standards significantly influence the EPDM market. Stringent regulations aimed at reducing carbon emissions and promoting sustainable practices drive the demand for eco-friendly materials like EPDM rubber. Compliance with regulatory requirements often entails additional production costs, which may translate to higher prices for end consumers. Conversely, lax regulations or non-compliance penalties in certain regions can create price differentials, affecting global trade dynamics and price competitiveness.

Geopolitical factors, including trade agreements, tariffs, and sanctions, can disrupt EPDM rubber supply chains and pricing structures. Trade tensions between major EPDM-producing countries may lead to tariffs or trade barriers, affecting import/export volumes and prices. Political instability or conflicts in key EPDM-producing regions can disrupt production and transportation, leading to supply shortages and price volatility. Therefore, geopolitical risks are essential considerations for businesses reliant on EPDM rubber to assess market uncertainties and develop robust risk mitigation strategies.

In conclusion, EPDM rubber prices are influenced by a myriad of interconnected factors, ranging from raw material costs and market demand to technological innovations and regulatory policies. Businesses operating in industries dependent on EPDM rubber must closely monitor these factors and adapt their strategies accordingly to navigate market fluctuations effectively. By understanding the underlying dynamics shaping EPDM rubber prices, businesses can make informed decisions to optimize procurement, manage costs, and maintain competitiveness in the global marketplace.

Get Real Time Prices of EPDM Rubber: https://www.chemanalyst.com/Pricing-data/epdm-rubber-1110

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

Difference between EPDM and Nitrile Rubber

Synthetic rubber is an artificial man-made elastomer that is used in a vast range of domestic as well as industrial applications. There are different types of Synthetic rubbers, each with its different properties.

EPDM Rubber and Nitrile Rubber are two such common synthetic rubber compounds that are used extensively.

While both EPDM and Nitrile rubbers offer a considerable amount of elasticity and durability, they differ in their properties, resistance to certain environmental conditions or mediums, and have their applications.

What is EPDM Rubber?

EPDM Rubber, or Ethylene Propylene Diene Monomer Rubber, was developed in the 1960s.

As rubber as a raw material became widespread in use, manufacturers began to realize that there was a need for synthetic UV-resistant rubber that could withstand exposure to outdoor environments for an extended period without facing degradation like natural rubber. The answer to this was EPDM Rubber.

EPDM is made up of ethylene, propylene, and diene comonomers, and have a saturated polyethylene backbone to their structure, which provides them with a high resistance capability to heat, light, and ozone, as compared to other rubber materials.

This property of endurance outdoor weathering exposure is what sets EPDM Rubbers apart from other rubbers and has earned it industry-wide appeal and acceptance.

Properties of EPDM Rubber

EPDM offers considerable resistance to abrasion, heat, steam, light, UV rays, water, and ozone, giving it a weatherproof quality and high durability, which makes it an excellent choice for outdoor applications.

It is also resilient and flexible, possessing low electrical conductivity, high noise insulation, a maximum elongation of 600%, and a tensile range of 500-2500 P.S.I.

It can function at temperatures as low as -51⁰C and as high as 150°C without air. It is also compatible with mild acids, alcohols, ketones, silicone oils, greases, hot and cold water, detergents, alkalis, fireproof hydraulic fluids, etc.

On the other hand, EPDM is incompatible with most hydrocarbons, such as kerosene, oils, gasoline, halogenated solvents, and some lubricants.

The durability, flexibility, and long life in extreme environments are what make EPDM rubbers a widely-used synthetic material in the industry.

Primary Uses Of EPDM Rubber

EPDM rubbers can be produced in many forms, such as EPDM sheet rubbers as well as adhesives.

Some common applications of the EPDM rubber include :

Seals and Sealants.

Gaskets.

O-Rings.

Tubing.

Washers.

Cooling Systems.

Brake Systems.

Ozone Exposure Applications.

Roofing.

Waterproof Coating.

Custom Moulded Rubber Components.

What is Nitrile Rubber?

Nitrile Rubber, also known as NBR (Nitrile Butadiene Rubber) or Buna-N, was first developed in the 1930s.

During WW1, rubber was high in demand. The price of natural rubber skyrocketed after the war due to shortages. That sparked a renewed interest in the development of synthetic rubber, paving the way for Nitrile / Buna-N.

Nitrile is composed of acrylonitrile and butadiene monomers. It is highly resistant to oil, gas, diesel fuel, chemicals, and petroleum products.

Today, it is one of the widely used synthetic rubbers, especially in the sealant industry. A huge benefit of Nitrile Rubberis that it is cost-efficient and provides flexibility in applications.

Properties of Nitrile Rubber

One of the most significant advantages that Nitrile offers is its imperviousness to mineral oils, vegetable oils, benzene and petrol, petroleum-based products, diesel fuels, gas, chemicals, diluted acids, and alkaline.

The amount of oil resistance is influenced by the percentage of acrylonitrile in the rubber. The higher the acrylonitrile content, the better the resistance as well as strength and permeability. Lower acrylonitrile means less resistance but more flexibility at lower temperatures.

Nitrile can operate at temperatures ranging from -40°C to 108°C and is also abrasion, tear, and compression set resistant.

It offers three times more puncture resistance than natural rubber and possesses a 600% elongation rate and a 500-2500 P.S.I. tensile range. Nitrile, however, also has drawbacks, with poor resistance to UV rays, ozone, weathering, and extended outdoor exposure.

Primary Uses of Nitrile Rubber

Some common applications of Nitrile rubber include:

Sealants.

Molded Goods.

Gasket.

Hydraulic Hoses.

Conveyor Belting.

Washers.

O-Rings.

Fuel Systems.

Protective Equipment (like Gloves).

Oil Resistant Applications.

It is also ideal for automotive, aeronautical, nuclear, as well as kitchen applications.

EPDM vs Nitrile Rubber – Which is Better?

Both EPDM Rubber and Nitrile Rubber have their advantages and disadvantages.

However, they’re also quite similar in some of their properties. Before we look at their differences, let’s take a look at their similarities.

EPDM and Nitrile rubbers are synthetic elastomers that are both highly durable and flexible. They are similar in their elongation percentage, tensile strength, and impervious abrasion, and compression set. The two are also commonly used for O-rings, gaskets, and other industrial applications.

After understanding how they are similar, let’s go through their core differences.

EPDM’s temperature resistance range is from -51°C to 150°C, while for Nitrile, it is -40°C to 108°C. While both work well in extreme temperatures, EPDM has a slight edge over Nitrile.

EPDM Rubber is great at providing resistance against UV Rays, Ozone, Sunlight, and Weathering Conditions, and can hold well in outdoor environments without facing degrading.

Nitrile has extremely low resistance against UV Rays, Ozone, and weathering effects, and performs poorly in outdoor environments.

On the contrary, Nitrile Rubber provides great resistance to gasoline, diesel fuel, motor oil, non-polar solvents, and petroleum-based products, as compared to EPDM, which is poorly resistant to them. Due to this, while EPDM is used frequently in braking systems in vehicles, Nitrile finds better use in the fuel systems.

Another difference between EPDM and Nitrile is that EPDM is an aromatic polymer but Nitrile, on the other hand, is non-aromatic. And when it comes to cost, Nitrile is the more expensive one out of the two.

Making the Right Choice – EPDM vs Nitrile Rubber.

When you choose between EPDM Rubber and Nitrile Rubber, you need to consider its application and the environment during the decision-making process.

If you want a rubber product that performs well in outdoor environments when exposed to ozone, sunlight, and UV rays, then EPDM Rubber is your best bet.

However, when such exposures are not a concern and fuels are involved, then Nitrile is a more suitable option.

Now that you know the basics of EPDM and Nitrile Rubber, their properties, their applications, and their differences, we hope that you will be able to utilize them to your advantage.

If you need any rubber products, you can rely on R-Tech Rubber Industries. They provide a wide variety of Rubber products in India.

0 notes

Text

Rubber Coated Fabric Market Share, Trends, Report 2022-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the global rubber coated fabric market size at USD 6.14 billion in 2022. During the forecast period between 2023 and 2029, BlueWeave expects the global rubber coated fabric market size to grow at a significant CAGR of 4.3% reaching a value of USD 8.25 billion by 2029. Major growth drivers for the global rubber coated fabric market include an increasing adoption of rubber-coated fabrics in the production of military and protective apparel. In the automotive sector, original equipment manufacturing (OEM), particularly in airbags, represents the primary application for these coated fabrics. Notably, they find uses in automotive interiors, headliners, convertible tops, pickup truck bed covers, heavy-duty truck covers, and various protective covers. The expansion of global rubber coated fabric market is also attributed to the growing utilization of these materials in industrial products like conveyor belts and PTFE tapes. Additionally, there's an expected boost from the rising acceptance of coated fabrics as cost-effective alternatives to leather in upholstery and trim applications. Market growth is further driven by fluctuating raw material prices, strict environmental regulations, and ongoing technological innovations aimed at cost reduction and production efficiency enhancement. However, availability of low cost substitute and release of pollutant during manufacturing process are anticipated to restrain the overall market growth during the period in analysis.

Global Rubber Coated Fabric Market – Overview

The global rubber coated fabric market refers to the worldwide industry involved in the production, distribution, and utilization of textile materials that have been coated or laminated with rubber or rubber-like compounds. These coated fabrics offer enhanced properties, such as durability, resistance to abrasion, weatherproofing, and flexibility, making them suitable for various applications in automotive, military, industrial, and other sectors. The market encompasses the manufacturing, supply chain, and demand for rubber-coated fabrics used in a wide range of products, including protective clothing, conveyor belts, PTFE tapes, automotive components, and various industrial applications.

Sample Request @ https://www.blueweaveconsulting.com/report/rubber-coated-fabric-market/report-sample

Impact of COVID-19 on Global Rubber Coated Fabric Market

COVID-19 pandemic adversely affected the global rubber coated fabric market. Various end-use industries, including aerospace, automotive, and marine, witnessed a negative influence on demand. Original equipment manufacturers (OEMs) faced operational challenges, operating at reduced or zero capacity, primarily due to disruptions in the supply chain. These disruptions encompassed delays or non-arrival of raw materials, disruptions in financial transactions, and an increase in absenteeism among production line personnel, consequently leading to diminished demand for rubber coated fabric products. Also, the automotive industry, a significant consumer of rubber coated fabrics, witnessed substantial repercussions as non-essential businesses were compelled to close during the pandemic outbreak. With a dwindling demand for automobiles, production came to an abrupt standstill. As reported by the International Organization of Motor Vehicle Manufacturers, global automotive production plummeted by 16% in 2020.

Global Rubber Coated Fabric Market – By Type

Based on type, the global rubber coated fabric market is bifurcated into Natural and Synthetic segments. The synthetic segment holds a higher share in the global rubber coated fabric market by type. Synthetic rubbers, such as polychloroprene, ethylene propylene diene monomer (EPDM), and butyl rubber, exhibit superior performance compared to natural rubbers in two significant aspects: thermal stability and resistance to oils and related substances. Synthetic rubber surpasses natural rubber in several key properties, including resistance to abrasion, chemicals, fluids, ozone, electrical heat, and the effects of aging. Also, many synthetic rubber variants, including polychloroprene, EPDM, and butyl rubber, possess flame-resistant qualities, rendering them suitable for insulation in electrical devices. Consequently, the combination of these advantageous properties in synthetic rubber makes it a highly effective choice for coated fabrics, thereby driving growth within the market.

Competitive Landscape

Major players operating in the global rubber coated fabric market include Trelleborg AB, GUMOTEX Coating, Continental (ContiTech), RAVASCO (Indus Belts), Zenith Rubber, Fairprene (Alpha Engineered Composites), Chemprene, White Cross Rubber Products, Arville, Kurwa Rubber & Valves, Bobet, Fabri Cote, Vikamshi, and Colmant Coated Fabrics. To further enhance their market share, these companies employ various strategies, including mergers and acquisitions, partnerships, joint ventures, license agreements, and new product launches.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

Ethylene Propylene Diene Monomer (EPDM) Rubber Market Forecast 2022-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimates global ethylene propylene diene monomer (EPDM) rubber market size at USD 4.98 billion in 2022. During the forecast period between 2023 and 2029, BlueWeave expects global ethylene propylene diene monomer (EPDM) rubber market size to grow at a CAGR of 5.52% reaching a value of USD 7.22 billion by 2029. Major factors for the expansion of global EPDM rubber market include rising financial support for the automotive sector in emerging nations like China, India, and others. Throughout the forecast period, there is expected to be a significant rise in demand for ethylene propylene diene monomer (EPDM) rubber due to the rapid expansion of application sectors like automotive and building & construction. Rapid growth in the U.S. construction and automotive industries has resulted in a sharp increase in the demand for EPDM in the North American region. However, high cost associated with market is anticipated to restrain the overall market expansion.

Global Ethylene Propylene Diene Monomer (EPDM) Rubber Market – Overview

EPDM is also known as ethylene propylene diene monomer (M-class) rubber. To produce cross-linking sites that allow for vulcanization, ethylene, propylene, and a small amount of non-conjugated diene monomers (between 3 and 9 percent) are copolymerized. It is an elastic material with a wide variety of uses. The majority of applications for EPDM include electrical insulation, lamination, and gaskets. This is due to its high resistance to tearing, solvents, abrasives, and temperatures. It has excellent low- and high-temperature elasticity as well as good resistance to common dilute acids, ketones, and alkalis. It also exhibits good electrical insulating properties.

Sample @ https://www.blueweaveconsulting.com/report/ethylene-propylene-diene-monomer-rubber-market/report-sample

Opportunity: Expanding government spending

The demand for ethylene propylene diene monomer is expected to rise as a result of the projected increase in government spending on the healthcare industry (EPDM). Because they are waterproof, ethylene propylene diene monomer (EPDM) coatings are increasingly used on medical equipment. This is a significant factor that, over the forecast period, is expected to greatly expand the ethylene propylene diene monomer (EPDM) market's potential.

Challenge: High Market Prices

Global ethylene propylene diene monomer (EPDM) rubber market is expected to grow more slowly as a result of the process' high cost. Given the presence of other market alternatives, ownership is expensive. These are some of the key elements preventing the ethylene propylene diene monomer (EPDM) rubber market from expanding over the anticipated time frame. One of the main factors holding back market expansion is the rise in environmental concerns brought on by VOC emissions during EPDM manufacturing.

Impact of COVID-19 on Global Ethylene Propylene Diene Monomer (EPDM) Rubber Market

The COVID-19 pandemic had a detrimental impact on global market for ethylene propylene diene monomer (EPDM) rubber market. Due to the closure of manufacturing facilities, manufacturing companies are dealing with the disruption of the demand and product supply chains caused by the pandemic. In the post-pandemic era, expansion in the medical and healthcare industries is expected to support the global market for ethylene propylene diene monomer (EPDM) rubber, as it helps to improve the efficiency of the equipment. Therefore, coronavirus is significantly affecting the growth of the ethylene propylene diene monomer market (EPDM).

Global Ethylene Propylene Diene Monomer (EPDM) Rubber Market – By End User

Global ethylene diene monomer (EPDM) rubber market is segmented by end-user into Automotive, Aerospace and Defense, Consumer Goods, Building and Construction, and Others. EPDM is a high-density synthetic rubber with properties that make it superior to natural and synthetic alternatives for automotive applications. Furthermore, due to its flexibility, resiliency, and excellent weather resistance, EPDM is the most commonly used material in the automotive industry. It's used in weather stripping, seals, sealant, wire and cable harnesses, and vehicle brake systems.

Competitive Landscape

Global ethylene diene monomer (EPDM) rubber market is fiercely competitive, with DuPont, Exxon Mobil Corporation, Lanxess, Mitsui Chemicals, Inc, Sumitomo chemical co. Ltd, SK geo centric Co., Ltd., China Petrochemical Corporation, Johns Manville., Berkshire Hathaway Inc., JSR Corporation, KUMHO POLYCHEM, Lion Elastomers, PJSC "Nizhnekamskneftekhim’’, American Rubber, Rotadyne Tools Pvt. Ltd., American Urethane, Argonics, Inc., Griffith Rubber Mills, and HINDUSTAN RUBBER INDUSTRIES. companies use various strategies, including increasing investments in their R&D activities, mergers, and acquisitions, joint ventures, collaborations, licensing agreements, and new product and service releases to further strengthen their position in the global ethylene diene monomer (EPDM) market.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

Top 3 Unique Flat Roofs And Their Pros/Cons

Today, new flat roofing contractors in Pennsylvania. Well, to be honest, whether they are better than older material or not we will get to know in a moment. Currently, homeowners are looking at three different kinds of flat roofs. Keep reading to find out three unique flat roof variants and their pros and cons.

All three materials have different price tags, although each on would last around 20-25 years.

Here we go…

1. Modified Bitumen Roof: First one first, it is a single-ply rolled roof which is somewhat similar to an ice-and-water shield. In its new peel-and-stick system; it is safe and easier to use.

Pro’s

a. Easy to DIY (do it yourself) installation because of peel-and-stick material.

b. It will contribute to saving more on energy bills.

c. It is affordable

Cons

a. Not recommended for occupied buildings

b. Not much of tear-resistant