#Epoxy floor markings

Explore tagged Tumblr posts

Text

Charlotte Parking Lot Striping Company

Our Services:

Warehouse floor striping Epoxy floor striping Epoxy warehouse striping Epoxy floor markings Safety floor markings Warehouse line striping Forklift floor coating Novolac epoxy installation Large parking lot striping Large parking lot line painting Truck court striping Truck court numbering/stenciling

Visit our online listings:

https://bit.ly/3KfY6Zm

#Warehouse floor striping#Epoxy floor striping#Epoxy floor markings#Parking lot striping Charlotte NC#Parking lot line painting Charlotte NC

0 notes

Text

Line Marking

PM Industries provides professional line marking services for commercial and industrial spaces, including car parks, warehouses, and sporting facilities. Our precision line marking ensures clear, durable markings that enhance safety, organization, and compliance with industry standards. Whether you need parking lot lines, safety zones, or custom markings, our experienced team uses high-quality materials and equipment to deliver crisp, long-lasting results. Trust PM Industries for all your line marking needs across Perth and surrounding areas.

#Epoxy Resin Floors#Industrial Floor Coatings#Food Grade Flooring#Residential Flooring#Decorative Floor Coatings#Line markings#Commercial Floor Coatings#Safety flooring#Chemical resistant coatings

0 notes

Text

Discover premium epoxy flooring materials at Florock India. Our top-quality epoxy solutions are perfect for industrial, commercial, and residential applications, offering durability, aesthetic appeal, and easy maintenance. Transform your floors with our versatile, high-performance products designed to withstand heavy traffic and harsh conditions. Choose Florock India for superior epoxy flooring materials.

0 notes

Text

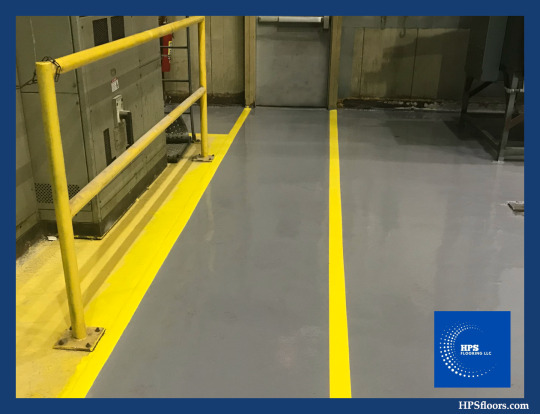

Warehouse Epoxy Flooring: Durable, Safe, and Efficient

When it comes to maintaining a warehouse, the flooring is often an overlooked yet crucial aspect of the facility's infrastructure. The floor must withstand heavy loads, constant foot traffic, and machinery movement while ensuring safety and efficiency. Epoxy flooring is a top choice for warehouses.

What is Epoxy Flooring?

Epoxy flooring is a surface coating created by mixing resin and hardener, forming a durable, seamless layer. This coating bonds exceptionally well to concrete floors, providing an even, resilient surface. The result is a floor that can endure the demanding environment of a warehouse while offering a professional appearance.

Why Choose Epoxy Flooring for Warehouses?

Durability: Warehouses experience high-impact activities, from forklifts carrying heavy loads to constant foot traffic. Epoxy flooring is highly resistant to abrasions, and impacts making it ideal for such environments. Its durability reduces the need for frequent repairs, saving time and costs.

Safety First: Epoxy flooring offers slip-resistant options that can be customized with visible markings for pathways, loading zones, and hazardous areas, improving navigation and reducing accidents.

Easy Maintenance: The seamless nature of epoxy floors makes cleaning and maintenance a breeze. Unlike traditional flooring, there are no cracks or crevices for dirt and debris to accumulate, ensuring a cleaner workspace with minimal effort.

Chemical Resistance: Many warehouses deal with chemicals or materials that can damage conventional flooring. Epoxy floors resist chemical spills, preventing stains and maintaining the floor’s integrity over time.

Cost-Effective: While the upfront cost of epoxy flooring may be higher than some alternatives, its longevity and minimal maintenance requirements make it a cost-effective investment for any warehouse.

Customization Options for Warehouse Needs

Epoxy flooring can be tailored to meet the specific needs of your warehouse. From anti-slip coatings to high-gloss finishes for better lighting, the options are vast. Additionally, color coding and line markings can help organize workflows and improve safety.

Installation and Maintenance

Professional installation is critical for ensuring the longevity of epoxy flooring. The process involves surface preparation, which may include cleaning, repairing cracks, and applying a primer. Once the epoxy is applied, it cures to form a hard, durable surface.

Regular maintenance involves simple sweeping and occasional mopping with mild detergents. For warehouses dealing with heavy traffic or chemical spills, periodic inspections can help ensure the floor remains in excellent condition.

#epoxyflooring#sherwinwilliams#warehousefloorpainting#epoxy floor contractor nj#epoxy flooring#epoxy warehouse flooring#epoxy contractor nj#warehouse floor painting#warehouse epoxy floor#chemical resistant floor#commercial flooring

3 notes

·

View notes

Text

Top 3 Benefits of Hiring Granite Restoration Services

Granite is one of the preferred choices for kitchen countertops because it is resistant to most acids, durable and easier to maintain. But with time it can become cracked, etched and dull looking. If you are experiencing the same problem and looking for “granite repair near me” on the internet, then you will be glad to know that this article will show you some awesome benefits of hiring a professional for this service.

Let's delve into the three benefits of hiring Professional Granite Restoration Services.

Fixes damage- One of the main benefits of hiring professional restoration services is that they greatly enhance the look of your stone. They have enough expertise to find out the issue and suggest recommendations to fix those damaged areas, giving you a polished-looking granite stone.

Removal of etched marks- Normally granite is acid-resistant, but over the years it can become resistant to acid. And when it comes in contact with acid, it causes etch marks that are usually quite difficult to remove. Professionals make sure to use the top-quality chemical agent and the right tools to remove these hard stains without causing any further damage during the process.

Refinishing and polishing- This is another significant benefit of hiring professionals. They use the Best Quality Polishing Powders to polish the marble and granite stone as per the individual’s choice. They can offer a semi-gloss or matte-finish look and you can get a glass-like Polished-Looking Granite.

Conclusion

If you are searching for “Granite Restoration Services Near Me” on the internet, you will come across a few reputed companies that offer marble and granite restoration services including stone crack repair, epoxy filling, topcoat sealer removal, polishing, grinding, cleaning sanitizing stone and much more. In addition, they have a team of expert professionals who will offer you the best service to increase the durability of your marble or granite flooring.

2 notes

·

View notes

Text

Discover the Benefits of Epoxy Line Solutions for Your Flooring Needs

When it comes to enhancing the look and durability of your floors, there are few materials as effective and versatile as epoxy. Epoxy flooring has become a go-to choice for homeowners and businesses alike, offering a range of benefits that go beyond just aesthetic appeal. From residential spaces to industrial settings, epoxy floor coatings provide a long-lasting and cost-effective solution to floor maintenance. One of the most innovative developments in epoxy flooring is the use of epoxy line solutions, which provide even more advantages for those looking to improve their flooring.

Epoxy is a resin-based material that forms a durable, high-performance coating when applied to floors. It’s composed of two main components – a resin and a hardener – that chemically bond to create a tough, glossy surface. Epoxy flooring is known for its strength, resistance to wear and tear, and ability to withstand heavy traffic. It is often used in garages, basements, commercial kitchens, warehouses, and even hospital settings due to its ability to handle demanding conditions. It provides not only a beautiful finish but also a functional and practical solution for areas that experience regular use.

One of the latest trends in the world of epoxy flooring is the use of epoxy line solutions. These solutions involve the application of epoxy lines to floors for a variety of purposes, ranging from creating designated traffic lanes in industrial spaces to enhancing the visual appeal of a commercial or residential floor. Epoxy line solutions can be used to add clear and precise lines for safety, organization, or simply to improve the aesthetic appeal of the floor. Whether it's for a factory floor that requires clear marking of walkways or a retail space needing a clean, polished look, epoxy lines offer a professional finish.

The benefits of epoxy line solutions are numerous and can be seen in various settings. For starters, they provide superior durability and long-term resistance to chemicals, stains, and abrasions. This makes them ideal for both heavy-duty and high-traffic areas. In industrial environments, for example, floors are often subjected to constant wear and exposure to oils, chemicals, and other harsh substances. With epoxy coatings, these floors remain intact and continue to look new, reducing the need for frequent repairs or replacements. The epoxy lines, which are applied to specific areas of the floor, also offer additional protection against high-impact forces and help to clearly mark different areas within the space.

Another significant benefit of epoxy line solutions is their ability to enhance safety within a given space. Epoxy lines are often used to clearly delineate walkways, vehicle lanes, and restricted zones, which can improve the overall flow of movement and prevent accidents. For example, in warehouses or factories, epoxy lines can be used to separate pedestrian walkways from areas where forklifts or heavy machinery operate, reducing the risk of injury. Epoxy lines can also be used in parking lots or garages to direct vehicle traffic and ensure that spaces are utilized efficiently.

One of the most appealing aspects of epoxy line solutions is the ease of maintenance they offer. Once the epoxy has cured and set, it forms a smooth, non-porous surface that is easy to clean and maintain. Spills and dirt can be wiped away quickly, and regular cleaning does not cause any damage to the epoxy or the lines. This makes it an attractive choice for businesses or homeowners who want a low-maintenance flooring solution that remains attractive over time.

The versatility of epoxy line solutions makes them ideal for a wide range of applications. Whether you're installing epoxy flooring in a commercial kitchen, a retail space, or a high-traffic warehouse, the ability to customize the lines to suit the needs of the space is a huge advantage. Epoxy lines can be tailored to the specific layout of the space, whether that means creating designated lanes for equipment, marking areas for storage, or simply adding decorative borders for an aesthetically pleasing finish. The customization options make it easy to integrate epoxy lines into any flooring plan, whether you prefer bold, contrasting lines or more subtle, muted designs.

Epoxy flooring solutions also contribute to energy efficiency. Epoxy coatings can reflect light, helping to brighten up dim or poorly lit areas. This can be particularly useful in commercial settings, where improved lighting can create a more welcoming atmosphere or help workers perform tasks more effectively. The reflective qualities of epoxy flooring can also contribute to reducing energy costs by minimizing the need for artificial lighting during the day.

Additionally, epoxy line solutions are an environmentally friendly choice. Since epoxy coatings are durable and long-lasting, they reduce the need for frequent replacements, which can be wasteful. The materials used in epoxy coatings are also relatively low in volatile organic compounds (VOCs), making them a safer option for indoor environments compared to other types of coatings or paints that may emit harmful gases.

Finally, the installation process of epoxy line solutions is relatively quick and easy. Professional contractors can apply epoxy flooring and lines in a matter of days, minimizing downtime for businesses or disruptions in residential areas. The process involves preparing the floor surface, applying a primer, and then adding the epoxy coating along with the desired lines. Once applied, the floor will be ready for use in a short amount of time, making it a highly efficient flooring option for those with tight timelines.

In conclusion, epoxy line solutions offer a wealth of benefits for anyone looking to improve their flooring. Whether it’s for enhancing safety, improving the appearance of a space, or creating organized, functional areas, epoxy lines provide a durable and cost-effective solution. From industrial spaces to residential homes, the versatility and durability of epoxy make it an ideal choice for flooring needs. Investing in epoxy line solutions not only ensures a long-lasting floor but also adds to the overall aesthetic and functionality of any space.

0 notes

Text

Transform Your Floors with Long-Lasting Epoxy Coatings in Utah

When it comes to upgrading your floors, durability and style are key factors to consider. Whether you're looking to revamp your garage, basement, or commercial space, epoxy floor coating utah provide the perfect solution. In Utah, Hardrock Concrete Coatings stands out as a trusted provider of high-quality, fashionable epoxy flooring that transforms any surface into a stunning masterpiece.

Why Choose Epoxy Floor Coatings?

Epoxy floor coatings are a popular choice for both residential and commercial spaces due to their incredible benefits:

Durability Beyond Compare

Epoxy coatings create a hard, durable surface that withstands heavy traffic, impacts, and abrasions. Perfect for garages, warehouses, and retail spaces, epoxy flooring maintains its integrity even under intense usage.

Aesthetic Appeal

Modern epoxy coatings come in a range of colors, textures, and finishes, allowing for endless customization. Whether you prefer a sleek, glossy surface or a textured, non-slip design, epoxy flooring can match your vision.

Ease of Maintenance

Unlike traditional flooring, epoxy-coated surfaces are resistant to stains, spills, and grime. Cleaning is as simple as wiping or mopping, making them a practical choice for busy households and commercial establishments.

Long-Lasting Investment

With proper installation and care, epoxy flooring can last for years without needing replacement. Its longevity makes it a cost-effective solution for property owners.

Areas That Benefit from Epoxy Coatings

Epoxy flooring isn’t limited to one type of space; it enhances various settings:

Residential Garages: Transform your garage into a showroom-worthy space with sleek, polished epoxy flooring that resists oil and tire marks.

Basements: Add style and protection to your basement with moisture-resistant epoxy coatings that prevent mold and mildew.

Commercial Spaces: From retail stores to restaurants, epoxy floors create a professional, clean look that stands up to high foot traffic.

Industrial Facilities: Durable epoxy coatings protect against chemicals, abrasions, and heavy equipment, making them ideal for warehouses and factories.

Hardrock Concrete Coatings: Utah’s Flooring Experts

Hardrock Concrete Coatings has established itself as a premier provider of epoxy flooring solutions in Utah. With a focus on quality and customer satisfaction, the company offers a range of services designed to meet diverse flooring needs.

What Sets Us Apart?

Expert Installation Our team of professionals ensures seamless application and flawless finishes. From surface preparation to the final coat, we prioritize every detail to deliver superior results.

Customized Designs At Hardrock Concrete Coatings, we believe your floors should reflect your unique style. Choose from a wide selection of colors, patterns, and finishes to create a look that suits your space.

Eco-Friendly Solutions We use environmentally friendly materials and techniques, ensuring your floors are not only beautiful but also sustainable.

Affordable Pricing High-quality flooring doesn’t have to break the bank. We offer competitive pricing, making epoxy flooring accessible to all property owners in Utah.

Benefits of Partnering with Hardrock Concrete Coatings

When you choose Hardrock Concrete Coatings, you’re investing in:

Enhanced Property Value: Epoxy flooring adds a modern, professional touch to your property, boosting its appeal and resale value.

Improved Safety: Non-slip epoxy coatings reduce the risk of accidents in areas prone to moisture or spills.

Quick Turnaround: Our efficient team ensures minimal disruption to your schedule, completing projects on time and to your satisfaction.

Transform Your Space Today

Epoxy floor coatings utah is more than just a practical choice; it’s a statement of style and sophistication. With Hardrock Concrete Coatings, you can elevate your space while enjoying the benefits of durability and easy maintenance.

Don’t settle for ordinary flooring when you can have extraordinary results. Visit Hardrockconcretecoatings.com today to explore our offerings and schedule a consultation. Let us help you transform your floors into a lasting, fashionable centerpiece of your property.

Experience the perfect blend of functionality and aesthetics with Utah’s trusted epoxy floor specialists. Your dream floor is just a click away!

0 notes

Text

Epoxy floors are a great choice for improving safety in industrial environments. One key benefit is their anti-slip surface, which can be customized to reduce the risk of slips and falls, even in areas exposed to oil, water, or chemicals. This is a big plus for warehouses, factories, and workshops.

Another safety feature is their high visibility. Epoxy floors can be designed with bright colors or markings to highlight safety zones, pathways, or hazardous areas, helping workers move safely.

Additionally, epoxy floors are resistant to chemicals and fire, reducing risks in industries dealing with hazardous materials.

Working with trusted resin manufacturers like MB Enterprises ensures you get high-quality epoxy flooring that boosts safety while offering durability and easy maintenance.

#resin manufacturers#epoxy floor coating manufacturers#epoxy flooring manufacturers#epoxy resin manufacturers in india

0 notes

Text

Epoxy Paint for Garage Floors: Making Maintenance Easy and Stylish

Introduction

When it comes to maintaining a garage, aesthetics and functionality often clash. On one hand, you want a space that looks good; on the other, it needs to withstand the wear and tear that comes from constant use. Enter epoxy paint for garage floors, a game changer in the world of home improvement. This durable coating not only enhances the visual appeal of your garage but also simplifies maintenance, making it an ideal choice for homeowners.

In this article, we’ll delve deep into everything you need to know about epoxy garage floors. From understanding what epoxy is to exploring its benefits, installation process, and maintenance tips—this comprehensive guide has got you covered. So buckle up as we explore how epoxy paint can make your garage floors both easy to maintain and stylish!

What are Epoxy Floors?

Epoxy floors are a type of flooring surface that consists of a mixture of resin and hardener. When these two components Artcrete Designs come together, they create Artcrete designs for homes a chemical reaction that results in a hard, durable surface. This makes epoxy an excellent choice for areas that experience heavy foot traffic or exposure to chemicals—like garages.

The Composition of Epoxy Floors

Epoxy floors typically consist of:

Resin: The primary component that provides the adhesive properties. Hardener: When mixed with resin, it catalyzes the curing process. Additives: These can include color pigments or anti-slip agents depending on your needs.

This combination produces a seamless finish that is both tough and aesthetically pleasing.

Why Choose Epoxy for Garage Floors? Durability and Longevity

One of the most compelling reasons to opt for epoxy for garage floors is durability. Unlike traditional concrete surfaces, which can crack or chip over time, epoxy coatings resist stains, spills, and impacts from heavy objects.

Aesthetic Appeal

With various colors and finishes available—including metallic options—epoxy garage floors can be customized to match your style. Whether you prefer classic gray or bold red hues, there’s an option to fit every taste.

Easy Maintenance

Cleaning epoxy floors is a breeze! Spills can be wiped off effortlessly without leaving behind stains or residue. You won’t have to worry about scrubbing away at stubborn marks or dirt buildup.

Advantages of Using Epoxy Paint for Garage Floors Chemical Resistance

For those who work on their cars or store chemicals in their garages, having a floor resistant to spills is crucial. Epoxy coatings can withstand oils, greases, and other substances without degrading.

Safety Features

Are epoxy floors slippery? Not necessarily! Many manufacturers offer anti-slip additives that can be mixed into the epoxy formula to enhance traction.

Cost-Effectiveness

When considering how much do epoxy floors cost compared to other flooring options like tiles or polished concrete? You'll find that aesthetic appeal combined with longevity often makes it more economical in the long run.

Types of Epoxy Garage Floors Available

1 note

·

View note

Text

Garage Flooring

PM Industries offers premium garage flooring solutions that are designed to withstand the demands of everyday use. From epoxy coatings to durable sealers, our garage flooring services provide a tough, easy-to-clean surface that resists stains, chemicals, and abrasion. Whether you use your garage for parking, storage, or as a workshop, our high-quality garage flooring options will improve its functionality and appearance. Let PM Industries enhance your garage space with long-lasting and stylish flooring solutions.

#Epoxy Resin Floors#Industrial Floor Coatings#Food Grade Flooring#Residential Flooring#Decorative Floor Coatings#Line markings#Commercial Floor Coatings#Safety flooring#Chemical resistant coatings

0 notes

Text

Discover premium epoxy flooring materials at Florock India. Our top-quality epoxy solutions are perfect for industrial, commercial, and residential applications, offering durability, aesthetic appeal, and easy maintenance. Transform your floors with our versatile, high-performance products designed to withstand heavy traffic and harsh conditions. Choose Florock India for superior epoxy flooring materials.

#esd flooring#epoxy and pu flooring coating#epoxy flooring#line marking for car park decks#epoxy flooring materials

0 notes

Text

Types of Garage Floor Coatings

Choosing the right garage floor coating for your space can be difficult. Is an epoxy garage floor coating better for your space or a concrete garage floor coating? What’s the best fit for your budget? What is going to stand the test of time and be the best investment over the years? As one of the premier garage floor epoxy contractors, Resinous Flooring Supply DFW can help you answer those questions.

Epoxy garage floor coating

There are two, main types of epoxy garage floor coatings: consumer-grade and industrial-grade.

Consumer-grade epoxy garage floor coating are the DIY products you see lining the aisles in your favorite hardware store. While they can be a great product for a DIY refresh of your space, they don’t offer the durability of a higher-quality epoxy product.

Industrial-grade epoxy garage floor coatings are made of higher-quality materials than DIY products and, because they are installed by trained professionals, create a more stable bond with your concrete garage floor, making them more durable and longer lasting.

Polyaspartic epoxy floor coating

A polyaspartic epoxy floor coating is considered to be the gold-star garage floor coating. Because it permeates far into your garage floor’s concrete base, it provides a super stable foundational bond that makes it more resistant to damage from impacts and abrasions, chemicals, and permanent markings left on the floor.

Acrylic floor coating

This affordable, long-lasting garage floor coating is available in a range of colors and finishes. Acrylic garage floor coatings are durable and leave your floor looking amazing for years to come.

Polyurethane floor coating

While very similar in appearance to epoxy garage floor coatings, polyurethane coatings do have some very important differences. A polyurethane floor coating cures with a more elastic finish, making it softer to walk on and more impact resistant as the impact load is more easily absorbed.

0 notes

Text

What to Expect During a Cracked Foundation Repair

When facing a cracked foundation repair, you may wonder about the intricacies involved in the process. From the initial assessment to the post-repair maintenance, each step plays a crucial role in ensuring the stability and longevity of your home's foundation. Understanding what to expect during this intricate procedure can provide you with insight into the intricacies of foundation repair and how it can impact the structural integrity of your home.

Initial Assessment

Upon discovering cracks in your foundation, the initial assessment is crucial.

Begin by examining the size, location, and pattern of the cracks. Measure their width and length to determine the severity of the damage. Look for any signs of water infiltration or structural issues that may have caused the cracks.

Take note of any uneven floors or sticking doors and windows, as these could indicate a more serious problem.

Next, consider the environmental factors that could have contributed to the foundation damage.

Evaluate the soil composition around your home and the presence of any trees or roots that may be affecting the stability of the foundation. Additionally, check for any plumbing leaks or drainage issues that could be exacerbating the problem.

After completing the visual inspection, consult with a professional foundation repair specialist to assess the best course of action.

They'll provide recommendations based on the extent of the damage and develop a repair plan tailored to your specific needs. Remember, addressing foundation cracks promptly can prevent further structural issues down the line.

Excavation Process

To initiate the excavation process for repairing your cracked foundation, the first step is to mark out the area that needs to be excavated.

This crucial step ensures that only the necessary sections are disturbed, minimizing disruptions to the surrounding area. Once the area is marked, excavation equipment will be brought in to dig out the soil and expose the foundation in need of repair.

The excavation process may vary depending on the severity of the damage and the accessibility of the site. In some cases, hand tools may be used for precision digging in tight spaces, while larger machinery may be necessary for larger areas.

During the excavation process, it's important to ensure the safety of the workers and the structural integrity of the surrounding buildings.

Proper shoring and bracing techniques may be employed to prevent collapses and accidents. Additionally, measures will be taken to manage any excess soil and debris generated during the excavation, keeping the work site organized and safe.

Repair Techniques

As you delve into the realm of cracked foundation repair, understanding the essential repair techniques becomes paramount.

When it comes to addressing foundation cracks, various methods are employed to ensure structural integrity.

Epoxy Injection: This technique involves injecting epoxy into the cracks to bond and seal them, preventing further water infiltration.

Polyurethane Foam Injection: In this method, expanding polyurethane foam is injected into the cracks to fill voids and stabilize the foundation.

Carbon Fiber Straps: Carbon fiber straps are used to reinforce and stabilize cracked foundation walls, providing additional strength.

Underpinning: Underpinning involves strengthening the foundation by extending its depth or breadth, usually through installing additional supports or footings.

Foundation Reinforcement

Foundation reinforcement serves as a crucial aspect of maintaining the structural integrity of buildings and homes.

When dealing with a cracked foundation, reinforcement methods are often employed to provide additional strength and stability to the structure.

This process typically involves installing various materials such as steel beams, carbon fiber strips, or concrete piers to help support and strengthen the foundation.

Steel beams are commonly used in foundation reinforcement to distribute the weight of the building more evenly and prevent further cracking or shifting.

Carbon fiber strips offer a lightweight but durable solution for strengthening foundations without adding excessive weight.

Concrete piers are another popular choice for foundation reinforcement, providing strong support for the existing foundation.

Post-Repair Maintenance

After completing the necessary repairs on your cracked foundation, it's essential to prioritize post-repair maintenance to ensure the longevity and stability of your structure.

There are some crucial tasks to keep in mind:

Monitor Moisture Levels: Regularly check for any signs of water seepage or moisture buildup around the foundation. Addressing these issues promptly can prevent further damage.

Inspect Foundation Regularly: Conduct visual inspections of the repaired areas and the surrounding foundation to detect any new cracks or shifts. Early identification can help in taking timely action.

Maintain Proper Drainage: Ensure that your property has adequate drainage systems in place to redirect water away from the foundation. Proper drainage can prevent water-related issues.

Consult Professionals: If you notice any concerning changes or have doubts about the stability of your foundation, don't hesitate to consult foundation repair experts for guidance and assistance. Professional advice can help you address potential problems before they escalate.

Conclusion

Overall, during a cracked foundation repair, you can expect a thorough assessment of the damage, excavation to expose the affected area, various repair techniques like epoxy injection, and foundation reinforcement with steel beams or concrete piers. Post-repair maintenance is essential to monitor moisture levels and address any issues promptly. By following these steps, you can ensure a stable and strong foundation for your property.

0 notes

Text

Durable and Safe Epoxy Flooring for Food and Beverage Industry

The Benefits of Epoxy Flooring in the Food and Beverage Industry

The food and beverage industry demands flooring that can withstand heavy foot traffic, chemical exposure, and frequent cleaning while ensuring safety and hygiene. Epoxy flooring Orlando is an excellent solution, offering durability, low maintenance, and compliance with strict industry standards. Here's a comprehensive guide to the benefits of epoxy flooring for food and beverage facilities.

1. Durability and Longevity

Epoxy flooring is engineered to endure heavy machinery, forklifts, and constant foot traffic. Its exceptional resilience makes it a cost-effective choice, reducing the need for frequent repairs or replacements.

Resistant to wear and tear from daily operations

Long-lasting solution for high-traffic areas

Withstands temperature variations and chemical exposure

2. Enhanced Hygiene and Safety

Maintaining cleanliness in food and beverage facilities is crucial to meet health and safety regulations. Epoxy flooring provides a seamless surface that minimizes dirt and bacteria accumulation.

Easy-to-clean, non-porous surface

Resistant to mold, mildew, and microbial growth

Slip-resistant options improve worker safety

3. Chemical Resistance

Food and beverage production often involves exposure to harsh chemicals, cleaning agents, and spills. Epoxy flooring is highly resistant to these substances, ensuring a safe and stable environment.

Protects against chemical damage

Maintains structural integrity despite frequent cleaning

Ideal for areas with exposure to acids, oils, and greases

4. Aesthetic Appeal and Customization

Beyond its functionality, epoxy flooring enhances the aesthetic appeal of industrial spaces. Facilities in Orlando can choose designs that reflect their brand identity.

Available in a variety of colors and patterns

Option to include safety markings or designated zones

Creates a polished, professional appearance

5. Cost-Effectiveness

Epoxy flooring offers significant cost advantages over time. Its durability and low maintenance requirements reduce operational costs.

Minimal need for repairs or replacement

Energy-efficient reflective surface reduces lighting costs

Quick installation minimizes downtime

Applications of Epoxy Flooring in Food and Beverage Facilities

Epoxy flooring suits various areas in the food and beverage industry, including:

Production Areas: Handles high impact and chemical exposure.

Storage Facilities: Protects against moisture and ensures cleanliness.

Packaging Zones: Offers a non-slip surface for worker safety.

Commercial Kitchens: Withstands heat, grease, and frequent cleaning.

Why Choose Sealwell- No#1 Epoxy Flooring Installer in Orlando?

For food and beverage businesses in Orlando, epoxy flooring provides the ideal balance of performance and compliance. With the expertise of Sealwell Inc., you can ensure your flooring meets the highest industry standards.

Benefits of choosing Sealwell for epoxy flooring:

Expertise in food and beverage flooring requirements

High-quality materials tailored to your facility

Professional installation for seamless results

Conclusion

Epoxy flooring is a durable, hygienic, and cost-effective solution for the food and beverage industry. From ensuring safety to maintaining regulatory compliance, it checks all the boxes for flooring that stands up to rigorous demands.

Transform your facility with Epoxy Flooring Orlando from Sealwell Inc. Visit Sealwell Inc. to explore tailored solutions for your flooring needs.

0 notes

Text

Choosing the Right Car Park Paint: A Guide to Durable and Safe Marking Solutions

Car parks are more than just spaces to park vehicles; they are meticulously designed areas that require careful planning to ensure safety, durability, and efficient traffic management. An essential element in this design is the choice of car park paint, which must withstand heavy traffic and environmental conditions and provide clear visibility. Selecting the right paint ensures not only the longevity of the markings but also contributes to a safer and more organized parking environment.

Understanding the Needs of a Car Park

The unique requirements of car parks demand specialized marking solutions. The paint used must be durable enough to resist wear and tear caused by constant vehicle movement and environmental factors like UV rays, rain, and temperature fluctuations. Additionally, markings must be vibrant and clear to guide drivers, prevent accidents, and ensure compliance with parking regulations.

Types of Paint for Car Parks

There are several types of paints commonly used for marking car parks, each with specific benefits:

Thermoplastic Paint: Known for its longevity and high reflectivity, thermoplastic paint is ideal for outdoor car parks. It offers excellent resistance to weather and wear, making it a preferred choice for high-traffic areas.

Acrylic Paint: Acrylic-based road marking paints are versatile and quick-drying. They are suitable for both indoor and outdoor applications and provide a smooth finish. However, their durability may be lower than that of thermoplastics in areas with heavy traffic.

Epoxy Paint: This paint is highly durable and chemical-resistant, making it perfect for indoor car parks. Its robust nature ensures that it remains intact even under harsh conditions.

Water-Based Paint: Environmentally friendly and low in volatile organic compounds (VOCs), water-based paints are a safer option for both users and the environment. However, they may require additional maintenance in high-traffic zones.

Factors to Consider When Choosing Paint

When selecting marking solutions, consider the following factors:

Durability: High-traffic areas need floor coatings that can withstand constant use and environmental exposure.

Visibility: Bright, reflective markings improve safety by providing clear guidance to drivers and pedestrians, especially at night or in low-light conditions.

Environmental Impact: Opt for paints with low VOC content to reduce environmental harm.

Ease of Application and Maintenance: Quick-drying and easy-to-apply paints minimize disruptions during application and maintenance.

Importance of Professional Application

Even the highest-quality paint can only succeed if applied correctly. Engaging professional contractors ensures proper surface preparation, accurate application, and optimal curing. This results in markings that last longer and perform better under varying conditions.

Innovations in Car Park Marking Solutions

Recent advancements in paint technology have introduced solutions like anti-skid and reflective paints, which enhance safety by reducing the risk of skidding and improving visibility. These innovations are becoming increasingly popular in modern car parks, reflecting a commitment to safety and sustainability.

Choosing the right marking solution is pivotal to maintaining a safe and efficient car park. By understanding the specific requirements and evaluating the available options, you can ensure the longevity and effectiveness of the markings. Investing in durable and safe floor paint is essential, and With Caparol's advanced formulations, you can achieve vibrant, long-lasting markings that resist wear and environmental stress. Opting for Caparol not only enhances the user experience but also minimizes maintenance costs, making it the ideal choice for car park owners and operators.

0 notes

Text

Epoxy Garage Floor

Why Homeowners Are Choosing Resin Garage Floors: Benefits You Should Know

In recent years, resin garage floors have become famous for homeowners looking to enhance their garage space. Known for their durability, ease of maintenance, and sleek aesthetic appeal, resin floors offer many benefits that make them attractive.

If you're considering upgrading your garage flooring, resin might be the perfect choice.

vimeo

Enhanced Durability for Heavy Use

One of the standout features of resin garage floor is their impressive durability. Resin flooring, typically made from epoxy or polyurethane resin, creates a tough, protective layer over concrete.

This surface can withstand heavy vehicle traffic, dropped tools, and other impacts without cracking or chipping. Resin floors are also resistant to abrasions, which helps them maintain their appearance over time.

For homeowners who use their garage not just for parking but also as a workspace or storage area, a resin floor provides peace of mind that it will withstand daily wear and tear.

Low-Maintenance and easy-to-clean

Garage floors can quickly become dirty from tire marks, oil spills, and other substances. One key benefit of a resin Epoxy garage floor is its non-porous surface, which repels dirt, dust, and liquids makeing it incredibly easy to clean and maintain.

Most spills can be wiped up with a damp cloth or mop, and regular sweeping will keep it looking fresh.

Resin’s resistance to stains from oil, gasoline, and other chemicals commonly found in garages means less time spent on cleaning and maintenance.

Additionally, unlike unfinished concrete floors that produce dust, resin floors help keep the entire garage cleaner, making them an ideal choice for homeowners looking for a low-maintenance solution. Stylish and Customizable Appearance

A significant advantage of resin garage floors is their ability to transform the look of the space. Resin flooring is available in various colors, finishes, and textures, allowing homeowners to customize the appearance to fit their style.

High-gloss and metallic finishes provide a modern, polished look, while anti-slip textures add safety without compromising aesthetics. Whether you want a clean, minimalist look or something more unique, resin flooring offers flexibility in design. Many homeowners add decorative flakes or quartz granules to create a textured appearance that adds depth and interest.

Improved Safety and Longevity

Beyond aesthetics and ease of maintenance, resin garage floors offer safety and long-lasting performance. Resin coatings can be customized with anti-slip additives, making the surface safer to walk on, especially when wet. This added traction is beneficial in garages where water or oil may accumulate.

Moreover, resin's durable and moisture-resistant properties prevent cracking and other damage caused by temperature fluctuations and moisture.

This longevity reduces the need for costly repairs or replacements, making resin an economical choice in the long run.

Final Thoughts

Resin garage floors are an ideal solution for homeowners looking to enhance their garage with a durable, stylish, and easy-to-maintain surface.

From durability and low maintenance to aesthetic appeal and safety, resin floors offer a range of benefits that make them a worthwhile investment.

If you're considering an upgrade, a resin floor may be the perfect way to transform your Polyurea Garage Floor Coating into a functional and attractive space that stands the test of time.

0 notes