#Epoxy Adhesives

Explore tagged Tumblr posts

Text

High-Performance Adhesives for Aircraft Manufacturing

In the aerospace industry, the demand for high-performance adhesives has never been greater. As aircraft designs evolve, the need for materials that can withstand extreme conditions while ensuring structural integrity and safety is paramount. High-performance adhesives have become integral to aircraft manufacturing, providing exceptional strength, durability, and reliability.

One of the primary reasons aerospace adhesives are indispensable is their ability to bond various materials such as metals, composites, and plastics. These adhesives offer a seamless bonding solution, reducing the need for mechanical fasteners, which in turn decreases the aircraft's weight and enhances fuel efficiency. Among the various types of adhesives used, epoxy adhesives stand out for their remarkable properties. Epoxy adhesive manufacturers in India are at the forefront of developing formulations that cater specifically to the aerospace sector's rigorous requirements.

In addition to strength, electrically conductive adhesives are gaining traction in aircraft manufacturing. These adhesives ensure reliable electrical conductivity while providing robust mechanical bonding, making them ideal for electronic components within aircraft. The ability to conduct electricity without compromising on bond integrity is a game-changer for the industry, paving the way for more efficient and reliable aerospace systems.

As an adhesive manufacturer in India, Kohesi Bond is dedicated to producing high-quality aerospace adhesives that meet international standards. Our range of epoxy adhesives is designed to endure extreme temperatures, resist environmental degradation, and maintain superior performance under stress. We understand the critical role these adhesives play in ensuring the safety and efficiency of aircraft, and our products reflect this commitment to excellence.

In conclusion, the advancements in aerospace adhesives are revolutionizing aircraft manufacturing. With the expertise of epoxy adhesive manufacturers in India and the innovative solutions provided by companies like Kohesi Bond, the future of aerospace construction is set to soar to new heights.

For more information about our high-performance adhesives, visit Kohesi Bond.

#Aerospace adhesives#Aircraft manufacturing#High-performance adhesives#Epoxy adhesives#Electrically conductive adhesive#Adhesive manufacturer in India#Epoxy adhesive manufacturers in India#Aerospace industry#Structural adhesives for aircraft#Aviation bonding solutions#Lightweight aircraft materials#Kohesi Bond aerospace adhesives#Advanced adhesive technologies

1 note

·

View note

Text

Global Tile Adhesives & Stone Adhesives Market Forecast to 2027: Cementitious and Epoxy Chemistries Drive Growth

The global tile & stone adhesives market size is projected to grow from USD 4.7 billion in 2022 to USD 7.0 billion by 2027, at a CAGR of 8.0%. Tile and stone adhesives are used to create a strong and durable bond between tile/stone and the tiling substrate. These adhesives are used to fix ceramic tiles, porcelain tiles, mosaics, marble, and granite to walls and floors in residential, commercial,…

View On WordPress

#adhesive stone wall tiles#Ceramic tile adhesives#Epoxy adhesives#Global Tile Adhesives & Stone Adhesives Industry#Global Tile Adhesives & Stone Adhesives Market#Grout sealers#marble tile adhesive#Mortar additives#natural stone adhesive#Natural stone adhesives#Polymer-modified adhesives#Stone Adhesives Market#stone tile adhesive#thinset for granite#tile & stone adhesives market#tile adhesive market#Tile Adhesives & Stone Adhesives Applications#Tile Adhesives & Stone Adhesives Ecosystem#Tile Adhesives & Stone Adhesives Industry#Tile Adhesives & Stone Adhesives Industry Forecast#Tile Adhesives & Stone Adhesives Manufacturers#Tile Adhesives & Stone Adhesives Market#Tile Adhesives & Stone Adhesives Producers#Tile Adhesives & Stone Adhesives Products#Tile Adhesives & Stone Adhesives Suppliers#Tile Adhesives & Stone Adhesives Technology#Tile Adhesives & Stone Adhesives Trends#Tile Adhesives Market#tile and stone adhesives market#wall stone adhesive

0 notes

Text

Choosing the right adhesive for industrial applications is essential for project success. Learn about different adhesive types, key selection factors, and best practices to ensure efficiency and durability. Explore A-Gas Electronic Materials' expert advice and high-quality solutions.

#industrial adhesives#epoxy adhesives#polyurethane adhesives#acrylic adhesives#silicone adhesives#cyanoacrylate adhesives#material compatibility#bonding strength#curing time#adhesive application methods#health and safety in adhesives#A-Gas Electronic Materials#UK industrial adhesives#industrial bonding solutions

0 notes

Text

YQXPOLYMER 0164 as An Alternative of DER 331, was Launched into International Market

YQXPOLYMER Epoxy Resin 0164 is a liquid resin manufactured from bisphenol-A and epichlorohydrin. It is recognized as a standard from which many variations have been developed.

YQXPOLYMER 0164 Key Properties

High bonding strength, wide application.

Mild construction conditions, convenient for operation.

Multiple manufacturing processes, meeting various customer requirements.

Packaging and Storage

Packing: Barrels, tanks, or customization.

Storage: Under certain circumstances, such as low temperature, this product can crystallize after lengthy storage, this can be reversed by warming up to 60-70 °C while stimming. The product should be stored in a cool and dry place in its original closed packaging, and not be stored exposed to direct sunlight.

YQXPOLYMER 0164 exhibits the same performance with DER 331, which is suitable for use in applications such as: adhesives, filament winding, casting and tooling, civil engineering, composites, automotive coatings, can coating, oil coating, marine & protective coatings, potting and Encapsulation, etc.

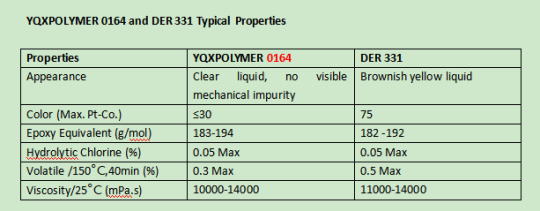

Here is a parameters comparison of the two products:

YQXPOLYMER 0164 and DER 331 Typical Properties

From the chart comparison, it can be seen that YQXPOLYMER 0164 and DER 331 have some identical or similar parameters. In addition to better color transparency than DER 331, YQXPOLYMER 0164 has some other advantages, such as highly cost-effective, short lead time, in-time after-sales service, even OEM service.

YQXPOLYMER is looking for partners, distributors of its epoxy resins products globally.

About YQXPOLYMER

YQXPOLYMER is a leading manufacturer of Epoxy Resin, PBT, Polycarbonate and other chemicals and comprehensive polymer applications provider.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#YQXPOLYMER 0164#DER 331#DER 331 resin#epoxy adhesive#epoxy coating#epoxy resin manufacturer

2 notes

·

View notes

Text

making some absolutely unhinged crafting decisions to avoid buying new materials or gluing anything down and I think it might actually work out.

#I want to be able to take this apart if need be!#I don't trust adhesives or epoxy!#I hate commitment!#your girl

12 notes

·

View notes

Text

something you don't learn until you get really far into the making and tinkering life is that there's no such thing as "glue" really. there are so many kinds of substances that stick other substances together and they are all very different and if you just go look at the adhesives aisle in the hardware store the packaging never actually tells you anything useful. it's like "this is SUPER T-REX POWER GLUE" and the fine print says "good for use on wood metal and plastic". okay. but WHICH PLASTICS MY GOOD BITCH,

because SURPRISE, there's no such thing as "plastic" either. every kind of wood is basically the same on a chemical level, but the only thing every plastic has in common is "some of its molecules are long" and that is NOT a quality that determines how things stick together.

I just ordered some stuff I hope will permanently stick a circuit board to a steel sheet and withstand temperatures up to 150 degrees. by the way circuit boards are made of epoxy-bound woven glass cloth which is cool as hell but what the fuck do you glue that with? can any of the 12 kinds of adhesives I currently own do that? no of course not. if I want to stick two pieces of acrylic together so hard they become watertight to a depth of 3000 metres I have some shit that does that, but it does literally nothing else.

anyway. once you start learning how many kinds of sticking things together there are, the people at 3M start to seem like witches and I don't know if they're the kind we can trust with that level of arcane knowledge

26K notes

·

View notes

Text

Factors to Consider When Choosing Metal Bonding Epoxy Adhesive

When bonding one metal surface to another, the choice of adhesive plays a vital role in ensuring the joint is strong, durable, and complete. Instead of mechanical fasteners, screws or bolts, metal epoxy adhesive provides more muscular bond strength without compromising the toughness of the metal.In this guide, you'll learn what factors to consider when choosing a metal bonding adhesive.

Bond Strength:

The required bonding strength varies depending on the application. Components bearing heavy loads and stresses, such as automotive or aerospace components, require high tensile and shear strength adhesives. In contrast, light-stress applications like electronics or decorative objects may use ordinary adhesives to maintain flexibility.

Environment Condition:

Metal has a rigid surface, but metal bonds are often exposed to harsh environments, temperature fluctuations, moisture, and harsh chemicals. Make sure to choose a durable adhesive that can withstand these conditions without compromising the integrity of the bond. Epoxy adhesives can easily withstand heat and chemicals, while polyurethane adhesives withstand moisture.

Metal Variations:

Different metals have different applications and surfaces, affecting the adhesive's performance. The low surface energy of aluminium and stainless steel makes bonding with an adhesive challenging.Surface enhancements such as cleaning or roughening are needed to bond them effectively with an industrial epoxy adhesive.

Curing Time:

Curing time refers to the time it takes for the adhesive to harden and reach its maximum strength fully. On an ideal basis, cyanoacrylates (adhesive) will set in seconds, while epoxy adhesives can take hours or even days to bond to the surface, but they are solid and durable. Consider the curing time required based on your application and whether you need a fast or slow adhesive.

Flexibility and Toughness:

Different bonds require a particular flexibility, especially bonds that involve movement or vibration of the metal. Adhesives such as polyurethane or acrylic are the best choice for these cases as their more flexible bonds allow for precise metal bonding. On the other hand, if the stiffness of the metal is a challenge, epoxy adhesives may be a great choice.

About ITW Performance Polymers:

ITW Performance Polymers is a recognized supplier of durable, flexible, and strong epoxy adhesives for metal objects. Their epoxy solutions are the perfect choice for pipe wrap, coating, or metal bonding.

Discover more at https://itwperformancepolymers.com/

Original Source: https://bit.ly/47Vjz44

0 notes

Text

What is Epoxy.com Product #11

Epoxy.com Product #11 joint material offers several benefits, making it an excellent choice for various applications. Flexibility It is a 100% solids flexible epoxy joint filler, which means it can accommodate slight movements in the concrete without cracking. Durability It absorbs the impact and shock of heavy loads and steel-wheeled traffic, preventing erosion of control joint…

#Epoxy#epoxy adhesive#epoxy instalation#epoxy joint material#epoxy resin#epoxy systems#epoxy.com 100% solids products#Epoxy.com low VOC products#Epoxy.com Zero (0) VOC Products#Low VOC#zero voc epoxy

0 notes

Text

Epoxy adhesives and epoxy resins, though often confused, serve different purposes and have unique characteristics. Understanding these differences can help you choose the right product for your project.

0 notes

Text

Choosing the right tile adhesive is crucial for the success of any tiling project. With a variety of options available on the market, selecting the best adhesive can be overwhelming. Factors such as the type of tile, substrate, and environmental conditions all play a role in determining the most suitable adhesive for your project. In this comprehensive guide, we'll walk you through everything you need to know to choose the right tile adhesive for your specific needs.

1. Understand the Different Types of Tile Adhesives:

There are several types of tile adhesives available, including cement-based adhesives, epoxy adhesives, and acrylic adhesives. Each type has its own unique properties and advantages, so it's essential to understand the differences between them before making a decision.

Cement-Based Adhesives: Cement-based adhesives are the most commonly used type of tile adhesive. They are versatile, easy to use, and suitable for a wide range of tile types and substrates. Cement-based adhesives are available in powder form and require mixing with water before application.

Epoxy Adhesives: Epoxy adhesives are known for their exceptional bonding strength and durability. They are ideal for bonding non-porous tiles, such as porcelain and glass, to difficult substrates like metal and concrete. Epoxy adhesives are available in two-part formulas that require mixing before use.

Acrylic Adhesives: Acrylic adhesives are water-based adhesives that offer excellent flexibility and adhesion. They are suitable for bonding tiles to a variety of substrates, including drywall, plywood, and cement board. Acrylic adhesives are available in ready-to-use formulations and are easy to apply.

0 notes

Text

AAC Block Adhesive Prices

Discover superior bonding solutions with crts aac block adhesive. Our premium grade adhesive is specially formulated for aac blocks ensuring strong and durable bonds.Say goodbye to worries about stability and longevity with our reliable product.Plus with competitive aac block adhesive prices you get exceptional value for your investment.Trust crts for all your construction needs and experience the difference quality makes.Choose the adhesive trusted by professionals and builders alike.Elevate your projects with crts best adhesive for wall tiles today.

aac block adhesive,best epoxy for tiles,aac block adhesive price, bathroom tile epoxy,best adhesive for wall tiles,best epoxy grout for tiles in india,best adhesive for tiles in india,best epoxy tile grout in india,best epoxy grout for bath room tiles,bathroom epoxy coating, best adhesive for ceramic tiles,best adhesive for slate floor tiles,

#aac block adhesive price#best epoxy grout for bathroom tiles#best epoxy for tiles#best adhesive for wall tiles#best adhesive for tiles in india#best adhesive for slate floor tiles#best adhesive for ceramic tiles#bathroom tile epoxy#bathroom epoxy coating#aac block adhesive

0 notes

Text

Successful Applications of Ceramic Epoxy Adhesives in Various Industries

Ceramic epoxy adhesives are gaining prominence across multiple industries due to their exceptional strength, durability, and resistance to extreme conditions. These adhesives are engineered to bond ceramics and other materials, providing reliable solutions for demanding applications. Their unique properties make them ideal for high-performance environments, particularly in high-temperature applications.

In the aerospace sector, high temperature ceramic epoxy adhesives are used to assemble engine components and thermal protection systems. These adhesives withstand intense heat and mechanical stress, ensuring the structural integrity of critical components. As a result, they contribute significantly to the overall safety and efficiency of aerospace vehicles.

The automotive industry also benefits from the best ceramic epoxy adhesive for bonding parts that experience high stress and exposure to harsh conditions. Manufacturers utilize these adhesives to secure exhaust systems, engine components, and structural elements, enhancing vehicle performance and longevity. Their superior bonding capabilities help reduce the risk of failure, which is paramount in automotive applications.

Another significant application of ceramic epoxy adhesives is in the electronics industry. With the increasing demand for lightweight and durable materials, epoxy bonding adhesives are essential for assembling electronic components. These adhesives provide excellent insulation and thermal stability, making them suitable for circuit boards and other critical electronics, ensuring functionality even under extreme conditions.

In addition to these applications, the construction industry relies on high temperature ceramic adhesives for bonding tiles, stones, and other building materials. Their ability to withstand environmental factors, such as moisture and temperature fluctuations, makes them a preferred choice among builders and contractors.

As an adhesive manufacturer in India, Kohesi Bond offers a range of ceramic epoxy adhesives designed for diverse applications. Our products are formulated to meet the highest industry standards, ensuring reliability and performance. With our commitment to quality and innovation, we provide the right solutions for your adhesive needs, helping you achieve successful outcomes in your projects.

#Ceramic Epoxy Adhesive#High Temperature Adhesives#Industrial Adhesives#Epoxy Bonding#Adhesive Solutions#Aerospace Adhesives#Automotive Adhesives#Electronics Manufacturing#Construction Adhesives#Adhesive Manufacturer in India#High Performance Adhesives#Durable Bonding Solutions#Ceramic Adhesive Applications#Epoxy Adhesive Properties#Advanced Adhesives

1 note

·

View note

Text

ACIDIC CLEANERS’ VS. ALKALINE CLEANERS

For the purpose of cleaning cementitious grout acidic based tile and grout cleaners are extremely effective. By reacting with the cement in the grout, it removes the dirt present in it. It also removes a small top layer of the grout to expose the lower clean layer. Acidic based grout cleaners are particularly effective at cleaning and whitening..... Read More

0 notes

Text

#Epoxy Coating#epoxy floor coatings#epoxycoating#adhesives and sealants market#industrial lubricants#adhesives#automotive sector#electronic vehicle#aftermarket parts#ev#sealants

0 notes

Text

High Toughness Epoxy Resin 9821A/B for Carbon Fiber High-pressure Gas Cylinders

launched 9821A/B high-toughness epoxy resin for winding molding. This product is a two-component epoxy resin system with the characteristics of moderate viscosity, long pot life and good operability. Its cast body has excellent mechanical properties, high elongation at break and good impact resistance.

9821A/B epoxy resin has excellent wettability to both carbon fiber and glass fiber, and is suitable for the production of high-toughness composite products wound with various types of fibers, such as carbon fiber high-pressure gas cylinders.

Carbon fiber composite high-pressure gas cylinders are made of carbon fiber materials and epoxy resin bodies through winding and high-temperature curing processes. Compared with metal gas cylinders, the carbon fiber material itself has better performance.

What are the advantages of high-pressure gas cylinders made of carbon fiber compared with metal gas cylinders?

Carbon fiber itself is lighter than aluminum, only about 1/4 of steel. Therefore, carbon fiber high-pressure gas cylinders weigh about 50% less than metal gas cylinders of the same volume, making them lighter to use.

The carbon fiber material itself has high strength and the compressive strength can reach more than 3000mpa, which can fully ensure the pressure stability of the carbon fiber high-pressure gas cylinder, making it safer and more reliable.

Carbon fiber high-pressure gas cylinders have excellent corrosion resistance and are resistant to acid, alkali, salt and atmospheric corrosion, making them safer to use.

During the processing of carbon fiber high-pressure gas cylinders, the carbon fiber winding process is mostly used. Under the action of tension, the carbon fiber bundles are impregnated with epoxy resin and continuously wrapped around the rotating mandrel, gradually forming a cylindrical structure. Most of the winding processes used are wet winding, in which the carbon fiber bundles are first processed in a specific dipping device, then directly wound onto the mandrel under tension control, and finally formed through curing and other processes.

The most commonly used wet winding method in the carbon fiber winding molding process has lower cost and good craftsmanship. Wet winding equipment mainly includes fiber frame, tension control equipment, dipping tank, spinning nozzle and rotating mandrel structure. The most advanced six-dimensional winding technology in the world can well control the fiber direction and realize the combination of hoop winding, spiral winding and plane winding. In actual production, a combination of helical winding and circumferential winding is often used. Circular winding can eliminate the hoop stress caused by the internal pressure of the gas cylinder, and helical winding can provide longitudinal stress and improve the overall performance of the gas cylinder.

The resin matrix of carbon fiber high-pressure gas cylinders not only needs to meet the mechanical strength and toughness requirements of the cylinder, but also because the matrix is prone to fatigue damage in a long-term inflation and deflation environment, a high-strength, fatigue-resistant resin system is needed to protect the cylinder service life. In addition to meeting the corresponding properties, the resin matrix used in wet winding molding is also required to have a lower initial viscosity at the operating temperature and a longer pot life at this temperature. Epoxy resin has the advantages of high bonding strength, small curing shrinkage, no small molecule volatiles, good process formability, heat resistance, good chemical stability, and low cost. It also has a large space for modification, is widely available in sources, is reasonably priced, and is suitable for wet winding process systems.

The resin in the composite material layer of high-pressure gas cylinders mainly uses epoxy resin. Epoxy resin is one of the commonly used thermosetting resin matrices in resin-based composite materials. It has the advantages of high bonding strength, small curing shrinkage, no small molecule volatiles, good process formability, heat resistance, good chemical stability, and low cost, and is widely used in fiber winding processes.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#epoxy resin manufacturer#bisphenol a type epoxy resin#epoxy resin supplier#epoxy adhesive#high toughness epoxy resin#carbon fiber#filament winding#filament winding process#carbon fiber winding#carbon fiber filament winding

0 notes

Text

Honoring Strength, Courage, and Hope

On World Cancer Day, CAPA stands with warriors, survivors, and caregivers around the globe. Let's unite in the fight against cancer, spreading awareness, supporting research, and offering love and compassion to those affected.

Together, we can make a difference. Together, we can bring light to the darkness. Join us in honoring the resilience and determination of cancer fighters everywhere. #WorldCancerDay #CAPACares #StrengthInUnity

To know more tile adhesives and waterproofing floors, epoxy grouts visit: https://capaindia.in/product/capa-flex/, https://capaindia.in/product/capaproof-hybrid-w/

#best tile adhesive in india#top tile adhesive brands in india#top building materials companies in india#tile adhesive manufacturers#tile adhesives for fixing natural stones#high strength flooring mortars#tile adhesive companies in india#floor repairs mortars in india#tile adhesives for vitrified tiles#block jointing mortar manufacturers in india#Flooring mortar#Tile and stone adhesive#Industrial Grouts#floor repairs mortars#epoxy grouts#Powder grouts#Ready mix plaster manufacturers#Machine sprayable plaster#Thin joint mortars#Thin joint mortars for AAC blocks#Waterproofing mortar#Waterproofing system#floor repairs mortars in India#best flooring solutions in india#best waterproofing mineral mortars in india#aliphatic polyurethane waterproofing coating#elastomeric waterproofing coating#flexible waterproofing mortar for crack bridging#waterproofing solutions for crack bridging#affordable waterproofing solutions

0 notes