#Electronics manufacturing

Explore tagged Tumblr posts

Text

The Unseen Driver: Merck KGaA’s Behind-the-Scenes Impact on the Semiconductor World

Merck KGaA, a venerable company with a history spanning over 350 years, occupies a critical position in the semiconductor industry through its Electronics Business, led by CEO Kai Beckmann. With a background in Computer Science and Microelectronics, Beckmann's over 35 years of leadership within the company have equipped him with a deep understanding of the industry's intricacies. Merck KGaA's role in providing specialized materials and technologies for semiconductor manufacturing is foundational, supporting all top 100 semiconductor companies, including those with fabrication plants and fabless entities, as well as tool companies offering integrated solutions.

The company's contributions are not merely supplementary but constitute the building blocks of semiconductor architecture, including crucial layers on silicon substrates for insulation, conduction, and more. This multifaceted support underscores Merck KGaA's indispensable position in the industry. The current AI-driven surge in demand for sophisticated chips, particularly evident in data center applications and the training of large language models, has significantly boosted the company's growth trajectory. As AI's influence expands beyond data centers to edge devices, such as smartphones, in the form of Edge AI, the demand for Merck KGaA's advanced materials and technologies is expected to escalate further.

Navigating the semiconductor industry's complex dynamics, characterized by a historically cyclical nature now complicated by asynchronous technology cycles, requires foresight and adaptability. Merck KGaA is well-positioned to meet these challenges, leveraging its extensive experience and commitment to innovation. The integration of AI into material science, to accelerate the discovery of new materials, exemplifies the company's proactive approach. This strategic deployment of AI, both as a driver of demand and a tool for innovation, highlights Merck KGaA's pivotal role in shaping the industry's future.

As the industry evolves, with Edge AI poised to potentially redefine production and research paradigms, Merck KGaA's expertise will be crucial in addressing the heightened need for sophisticated materials. The company's ability to balance the stability afforded by its 70% family ownership with the agility of a publicly traded entity, listed on the German DAX index, further enhances its capacity to respond effectively to emerging trends. Through its innovative spirit, deep industry knowledge, and strategic adaptability, Merck KGaA is not only navigating the transformative impact of AI on the semiconductor industry but also playing a defining role in its future trajectory.

Kai Beckmann: Why Next-Gen Chips Are Critical for AI's Future (Eye on AI, December 2024)

youtube

Thursday, December 5, 2024

#semiconductor industry#artificial intelligence#ai applications#technology innovation#material science#electronics manufacturing#industry trends#future tech#corporate leadership#interview#ai assisted writing#machine art#Youtube

5 notes

·

View notes

Text

Article is Very worth reading, don’t let the long section at the beginning about a rug put you off.

#navajo weaving#marilou schultz#intel pentium#national gallery of art#american indian movement#race in the us#race in america#navajo#navajo nation#electronics manufacturing#a bigger history#textiles#rug#native american

20K notes

·

View notes

Text

0 notes

Text

Anzer PCB Assembly Services in Ohio - Trusted Electronics Manufacturing

https://getpocket.com/@9f5T0A7agf9b9ph957db5aMd09pTg070622g41iG1ePd9fQQ7c656O38L36CO6b5?src=navbar

0 notes

Text

vimeo

Comprehensive Electronics Manufacturing Support Solutions by Rhosigma Rhosigma provides top-notch Electronics Manufacturing Support to simplify your production process. From design and prototyping to assembly and testing, we ensure every stage is handled with expertise. Partner with us for innovative solutions, cost savings, and exceptional results, taking your electronics manufacturing to the next level.

0 notes

Text

PCB SMT assembly | Electronic SMT PCB assembly Production Process by China PCB Supplier - Topscom

PCB smt assembly or electronic PCB SMT assembly process by China supplier Topscom. Electronics production and electronics manufacturing - an overview of the electronic PCB SMT assembly process involved in building a surface mount technology (smt) board. https://is.gd/f84IFy

PCB SMT assembly, China printed circuit board assembly, China PCB factory, China PCB fabrication, China PCB manufacturing, China PCB board, China PCB manufacturer, China PCB service, China PCB prototype, China PCB supplier, China PCB, PCB China, China PCB online, PCB board, China PCB assembly, PCBA China, China PCB design, PCB assembly, China PCB quote, PCBA, contract manufacturing China, China contract manufacturing, contract manufacturing, China electronic assembly, China electronic manufacturing, electronics manufacturing, electronic board manufacturers, China OEM manufacturing, OEM manufacturing, China cable wire harness assembly

0 notes

Text

Know Electronics Manufacturing: The Total Guide

Introduction

Electronics manufacturing is defined as the process of bringing electronic products into being, such as product design and assembly, to component integration on circuit boards. It is a backbone industry for companies in automation, robotics, automobiles, and electronics for consumer needs. In this blog post, we will take closer looks at what electronics manufacturing essentially constitutes and the roles that companies playing among their many other roles offer to clients in the creation of their electronic products.

In simple terms, electronics manufacturing refers to the assembling of various forms of parts, like printed circuit boards, integrated circuits, and numerous other forms of electronic components, into electronic devices and systems. It can be small enough to be held in one's hand, a small appliance consumed by a consumer, to something so big that it just fits into a small room, an extremely complicated industrial system, or just about anything in between.

Design and Prototyping: Of course, any given product's electronic design and prototype are always the bases and most often created using computer-aided design.

PCB Assembly: The nucleus or central core of elements in most electronics products is usually constituted of PCBs. Hence, assembling circuit boards often utilizes Surface Mount Technology for an effective and precise implementation.

Component Assembly: As the PCB is assembled, other components, including processors, capacitors, and connectors, among others, make a whole system.

Final Quality Control: The product is put through extreme testing that ensures the final product performs well and within quality standards before it leaves the factory.

Supply Chain Management: Getting and sourcing the component properly is the backbone of constructing it in time and within budget.

After-Market Support: Continuous support and maintenance ensure electronics continue to work long after the initial production.

Looking for a partner to help with electronics manufacturing? We provide custom solutions that fit your needs. Contact us today to learn more.

Why Electronics Manufacturing?

Electronics form the basis of modern technology. Without accuracy and knowledge behind the process of manufacturing electronic devices, car industries such as automotive, automation, and telecommunication would never have reached the level they are today. Efficiently processing all aspects of manufacturing ensures cost-effective productions and faster time-to-market with a greater level of reliability in the finished products.

Varieties of Electronic Manufacturing Services

There are many types of EMS providers, and each has many services in each type:

Design & Engineering: Design services will include custom designs. EMS providers usually collaborate with the clients for creating a prototype, design for manufacturability, and make sure if the designs are manufacturable. This is the most critical design stage for a feasible and scalable product.

PCB Assembly & Surface Mount Technology (SMT): PCB assembly refers to the process of placing electronic components on a PCB. SMT is one of the most extensively practiced techniques in the industry for manufacturing miniaturized components accurately with good productivity.

Procurement & Supply Chain Management: A proper chain of supply will ensure that the parts are procured in due time. Even the deliveries do not come late. In general, it also comprises logistics management so that all the parts get to the production place at due time.

Testing and Quality Control: Testing is one of the most critical parts of making electronic devices long-lasting and reliable, thereby keeping abreast of the demand for electronics. There are several EMS providers who have techniques of testing to ensure that whatever leaves the door meets the standards of quality that their customers expect of them.

After-Sales Support: Once it enters the market, after-sales support for it is a must. Such might include repairs, servicing, or upgrading to extend the life span of that electronic product.

The Future of Electronics Manufacturing

Advances in industry lead to corresponding calls on electronics manufacturing. What has changed are the industry concerns today from automation, precision, and bettering their footprint on the environment. The future of electronics will be made of AI, ML, and IoT technologies, and providers of EMS are more integrated than ever into this emerging scene.

Conclusion

Electronics manufacturing involves the step-by-step process of designing, assembling, testing, and supporting the making of electronic products. An experienced EMS provider can therefore help a company have its electronic products made with the utmost efficiency and quality.

Ready to start your electronics project? We’re here to help you every step of the way. Contact us now for expert manufacturing services.

Also read:

Understanding Electronics Design & Engineering

Firmware Development: Where Software Meets Hardware

The Essentials of PCB Design: Techniques and Best Practices

The Complete Guide to Hardware Development: From Design to Deployment

0 notes

Text

Successful Applications of Ceramic Epoxy Adhesives in Various Industries

Ceramic epoxy adhesives are gaining prominence across multiple industries due to their exceptional strength, durability, and resistance to extreme conditions. These adhesives are engineered to bond ceramics and other materials, providing reliable solutions for demanding applications. Their unique properties make them ideal for high-performance environments, particularly in high-temperature applications.

In the aerospace sector, high temperature ceramic epoxy adhesives are used to assemble engine components and thermal protection systems. These adhesives withstand intense heat and mechanical stress, ensuring the structural integrity of critical components. As a result, they contribute significantly to the overall safety and efficiency of aerospace vehicles.

The automotive industry also benefits from the best ceramic epoxy adhesive for bonding parts that experience high stress and exposure to harsh conditions. Manufacturers utilize these adhesives to secure exhaust systems, engine components, and structural elements, enhancing vehicle performance and longevity. Their superior bonding capabilities help reduce the risk of failure, which is paramount in automotive applications.

Another significant application of ceramic epoxy adhesives is in the electronics industry. With the increasing demand for lightweight and durable materials, epoxy bonding adhesives are essential for assembling electronic components. These adhesives provide excellent insulation and thermal stability, making them suitable for circuit boards and other critical electronics, ensuring functionality even under extreme conditions.

In addition to these applications, the construction industry relies on high temperature ceramic adhesives for bonding tiles, stones, and other building materials. Their ability to withstand environmental factors, such as moisture and temperature fluctuations, makes them a preferred choice among builders and contractors.

As an adhesive manufacturer in India, Kohesi Bond offers a range of ceramic epoxy adhesives designed for diverse applications. Our products are formulated to meet the highest industry standards, ensuring reliability and performance. With our commitment to quality and innovation, we provide the right solutions for your adhesive needs, helping you achieve successful outcomes in your projects.

#Ceramic Epoxy Adhesive#High Temperature Adhesives#Industrial Adhesives#Epoxy Bonding#Adhesive Solutions#Aerospace Adhesives#Automotive Adhesives#Electronics Manufacturing#Construction Adhesives#Adhesive Manufacturer in India#High Performance Adhesives#Durable Bonding Solutions#Ceramic Adhesive Applications#Epoxy Adhesive Properties#Advanced Adhesives

1 note

·

View note

Text

Explore our ultimate guide to the electronics manufacturing process. Learn about key stages, technologies, and best practices in the production of electronic components with Viasion. In this article, steps involved in electronics manufacturing process will be written in sequential order.

0 notes

Text

Starting an Electronics Trading Business in Dubai: A Step-by-Step Guide

Navigating the Process of Starting an Electronics Trading Company in Dubai

When considering the establishment of an electronics trading company in Dubai, it’s crucial to consult with experts who can navigate you through the complex process and pinpoint subtle details you might overlook.

Private Wolf is your go-to resource for a seamless acquisition of an Electronics Trading License in Dubai, enabling you to kickstart your business promptly.

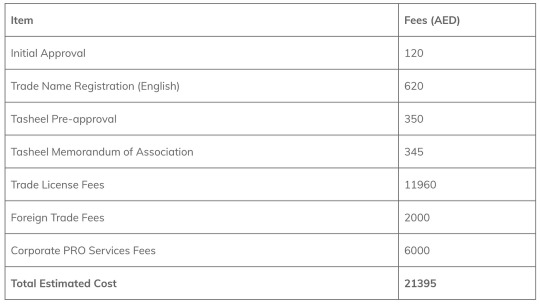

Investment Required for an Electronics Trading License in Dubai

The investment for an electronics trading license in Dubai typically starts at AED 20,000. However, this amount can fluctuate based on various factors that impact the total cost, such as business size and type, jurisdiction, the specific business license required, and more.

To avoid pitfalls and ensure accuracy in cost estimation, it’s highly recommended to engage a team of skilled professionals like those at Private Wolf. They offer expertise in licensing and tax matters, providing precise cost assessments for establishing an electronics trading company in Dubai.

Breakdown of Electronics Trading License Cost in Dubai

Government Charges and Fees (in AED)

Essential Documentation for Electronics Trading License

To initiate your electronics trading business in Dubai, several key documents are required, such as:

Multiple options for company name reservation

Passport with previous UAE visas or entry stamps

NOC from current sponsor (if applicable)

License application form

Memorandum of Association

Tenancy contract (actual or virtual office)

Please note that this list is not exhaustive, and additional documents may be required based on your specific business requirements, jurisdiction, and scale.

Let the experts at Private Wolf handle the intricacies of this process, ensuring a hassle-free experience in obtaining your Electronics trading license swiftly.

Choosing the Right Location for Your Electronics Trading Company in Dubai

When establishing an electronics trading company in Dubai, you have three primary location options:

Mainland: While more costly than free zones, the Mainland offers significant advantages like enhanced growth opportunities, prime locations, broader market access, and convenient transportation. Overseen by the DED, a Mainland license grants complete business control and unrestricted trading capabilities.

DAFZA (Dubai Airport Freezone Authority): This government-established Freezone offers tax exemptions, repatriation of profits, and ownership rights. Renowned for being one of the fastest-growing economic Freezones in the MENA region, DAFZA provides an attractive option for businesses with its strategic airport-adjacent location and dedicated logistics center.

Other UAE Freezones: With over 40 specialized Freezones, these offer complete foreign ownership and are known for their efficient infrastructure and streamlined operations. Selecting the appropriate Freezone depends on various factors, including startup costs and available resources.

For a well-informed decision on the best Freezone for your business, consider consulting with the experts at Private Wolf.

Advantages of Launching an Electronics Trading Business in Dubai

Starting an electronics trading enterprise in Dubai comes with multiple benefits:

Trade Advantages: Enjoy tax exemptions and a selection of Freezones, offering potential for both local and international trade success.

Custom Benefits: Dubai customs provide numerous advantages such as lower shipment and customs charges, faster clearance times, and reduced demurrage and storage costs.

Port Benefits: Dubai’s ports facilitate affordable and efficient international trade with lower duties and global access.

Import-Export Policies: Dubai’s lenient policies are conducive to starting an electronics trading business.

Taxation: The tax exemptions, especially in Freezones, create an ideal environment for budding businesses.

How Private Wolf Assists in Establishing Your Electronics Trading Business in Dubai

Embarking on an electronics trading venture in Dubai requires significant professional guidance. Private Wolf stands ready to offer trustworthy and reliable support, ensuring your successful establishment in the electronics trading market.

M.Hussnain Private Wolf | facebook | Instagram | Twitter | Linkedin

#trade license in dubai#cost of electronics business in dubai#electronics business in dubai#business setup in dubai#dubai#business#business setup#cost calculator#business in dubai#private wolf#electronics store#electronics manufacturing#computer

0 notes

Text

Comprehensive Electronics Manufacturing Support Solutions by Rhosigma

Rhosigma provides top-notch Electronics Manufacturing Support to simplify your production process. From design and prototyping to assembly and testing, we ensure every stage is handled with expertise. Partner with us for innovative solutions, cost savings, and exceptional results, taking your electronics manufacturing to the next level.

0 notes

Text

Teledyne To Acquire Xena Networks

Teledyne Technologies Incorporated (NYSE: TDY) has recently announced its acquisition of Xena Networks ApS, a prominent provider of high-speed Terabit Ethernet validation, quality assurance, and production test solutions. This strategic move is aimed at strengthening Teledyne's position in the protocol test market and expanding its offerings in Ethernet system validation, quality assurance, and production line testing of Ethernet components and systems.

Teledyne's Chairman, President, and Chief Executive Officer, Robert Mehrabian, expressed enthusiasm for the acquisition, highlighting how it would reinforce the company's presence in the protocol test market. This expansion is expected to benefit Ethernet system validation engineers, quality assurance labs, and production lines involved in testing, evaluating, and accepting Ethernet components and systems. Mehrabian emphasized that this move builds upon Teledyne's previous acquisitions, such as LeCroy in 2012, which added valuable protocol test businesses, including PCI Express, USB, storage, and networking technologies.

The acquisition of Xena Networks is seen as a strategic addition to Teledyne's existing protocol test portfolio. Teledyne LeCroy's protocol test business has grown over the years through various acquisitions, encompassing Quantum Data for video, Frontline for Bluetooth and WiFi, and OakGate for storage device testing solutions. With Xena Networks now in the fold, Teledyne aims to further strengthen its position as a comprehensive provider of protocol test solutions.

Read More - https://bit.ly/45hLKqX

0 notes

Text

Indoor and outdoor LED walls

In the ever-evolving world of visual communication, LED walls have emerged as transformative technologies that are changing the way we experience information, entertainment, and art. From dazzling outdoor displays that light up cityscapes to indoor screens that enhance presentations, LED walls have become an integral part of modern displays.

indoor and outdoor LED walls are powerful tools that redefine visual engagement. From indoor presentations that captivate audiences to outdoor displays that transform cityscapes, these walls offer unparalleled possibilities. Their adaptability, image quality, and durability make them indispensable in a world where effective communication heavily relies on visual impact. As these technologies continue to evolve, we can only anticipate even more awe-inspiring applications on the horizon.

0 notes

Text

#Semiconductors#Flat Flex Cable#Flexible Electronics#Electrical Connectors#Electronics Manufacturing#High Density Interconnects#Flat Flex Cable Market

0 notes

Text

Radiant Appliances & Electronics Pvt. Ltd in Hyderabad

Radiant extends complete support to its clients with regards to managing customer field returns/market complaints. Our team is on standby to support the customer with repair/re-work solutions as required. We also manage all the spares requirements for our OEM customers through a dedicated team.

Radiant Appliance and Electronics is a premier manufacturing company that caters to the consumer electronics and home appliances industry. In fact, it is the first company from Hyderabad to manufacture LED TVs for global market leaders and well-known MNCs from a state-of-the-art facility at E-City. We are one of the largest manufactures of televisions in India and manufacture TVs for OEMs that cater to more than 40% of the Indian television market.

#led tv manufacturers in india#Home appliances manufacturers in India#Smart LED Televisions#Electronics manufacturing#Radiant Appliances & Electronics#Appliances and Electronics#Supply Chain Management#Manufacturing#TV Manufacturing Company in india#TV Manufacturing Company#Radiant Appliances leverages#Manufacturing Company in india

1 note

·

View note