#Electronic Circuit Board Assembly

Explore tagged Tumblr posts

Text

Multilayer PCBs (Printed Circuit Boards) offer numerous advantages over their single-layer or double-layer counterparts. These benefits arise from their enhanced design capabilities, improved performance, and greater flexibility. Here are some key advantages of multilayer PCBs:

#PCB#printed circuit board manufacturers#electronic cable assembly#pcb manufacturing#pcb assembly manufacturer#pcb assembly services#pcb board manufacturer#printed circuit board manufacturer in india#circuit board manufacturing#pcb exporters#pcba#pcb manufacturer#pcb design#pcbassembly#multilayer pcb

2 notes

·

View notes

Text

Electronic Manufacturing Services -- Hitechpcba by PCB Assembly Electronic Manufacturing Services Hitech Circuits has always been focused on electronic manufacturing services for over 15 years with much experience for design and production in the PCBA field. We provide one-stop services, including SMT mounting, plug-in (THT), electronic component procurement and sourcing, finished product assembly, testing, and other comprehensive services. From the introduction of new products to the provision of customized components, to stable production, we provide solutions for the entire product lifecycle, enabling our customers to achieve success. Hitech Circuits creates value for customers through advanced value engineering services, customized component solutions, global factory layout, and high-level supply chain management. www.hitechpcba.com/electronic-manufacturing-services

0 notes

Text

The Ultimate Guide to Multi Color PCB Manufacturing

Multi Color PCBs, also known as Printed Circuit Boards, offer a visually stunning way to incorporate multiple colors into electronic devices. These PCBs are designed to enhance the aesthetic appeal of products while maintaining high functionality and performance.

#pcb#pcbassembly#pcbmanufacturer#circuit#electronics#manufacturer#marketing#pcb circuit board near me#Multi Color PCB Manufacturing#manufacturing#pcb circuit#pcb assembly

0 notes

Text

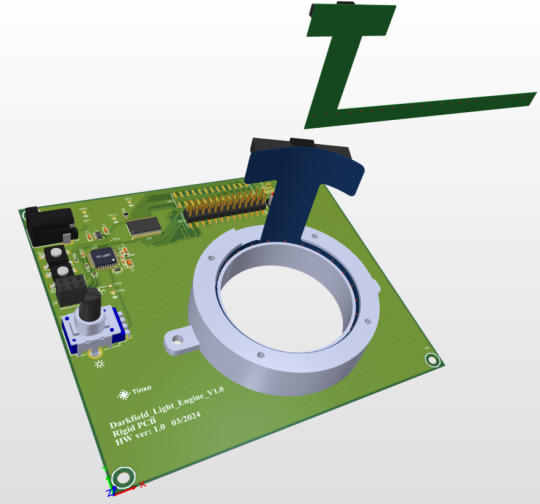

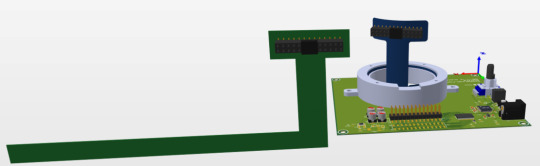

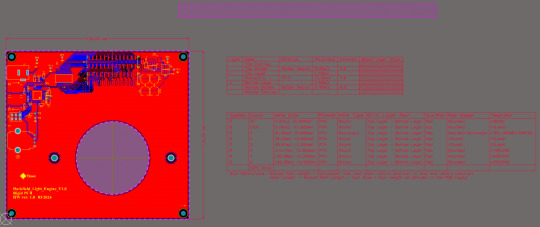

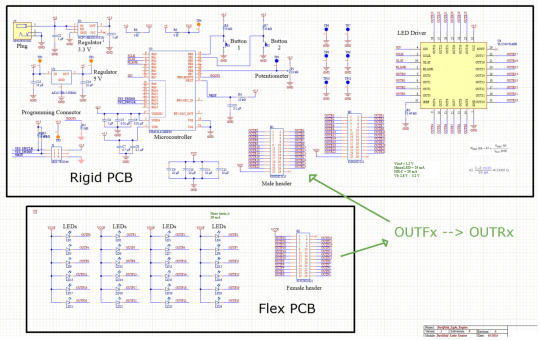

This is another video about the flexible PCB over the rigid PCB without any case.

This is the flexible PCB.

This is the Flex PCB in 2D mode.

This is the Rigid PCB.

This is the Rigid PCB in 2D mode.

This is the schematic.

I had to check this project several times before implementing it because I had to be very careful with the corresponding signals.

#electronics#Altium Designer#Altium#flex pcb#pcb assembly#pcb#pcb manufacturer#flexible circuit board

0 notes

Video

Electronic Manufacturing Services -- Hitechpcba by PCB Assembly Via Flickr: Electronic Manufacturing Services Hitech Circuits has always been focused on electronic manufacturing services for over 15 years with much experience for design and production in the PCBA field. We provide one-stop services, including SMT mounting, plug-in (THT), electronic component procurement and sourcing, finished product assembly, testing, and other comprehensive services. From the introduction of new products to the provision of customized components, to stable production, we provide solutions for the entire product lifecycle, enabling our customers to achieve success. Hitech Circuits creates value for customers through advanced value engineering services, customized component solutions, global factory layout, and high-level supply chain management. www.hitechpcba.com/electronic-manufacturing-services

1 note

·

View note

Text

#smart watch assembly#smart watch factory#smart wearable tws assembly#cable wiring harness factory#quality Smart Watch Assembly#affordable Smart Watch Assembly#best Smart Watch Factory#electronics pcba factory#printed circuit board assembly#electronics#smt pcb jobwork#electronics manufacturer

0 notes

Text

What is Heart of Innovation in PCB Assembly and Electronic Manufacturing

Within the walls of a PCB factory, precision is not just a requirement; it's a way of life. These facilities are equipped with state-of-the-art machinery operated by skilled technicians who ensure every minute detail is adhered to. From solder paste application to component placement and reflow soldering, each step demands a meticulous approach. The harmony of man and machine in a PCB factory is the symphony that brings forth technological marvels, fostering innovation in every circuit.

#pcb factory near me#pcb assembly#pcb board manufacturer near me#electronic manufacturing company#printed circuit board assembly near me

0 notes

Text

#pcb assembly services#circuit board assembly#printed circuit assembly#printed circuit board design#electronic pcb#pcb fabrication and assembly#pcb production#pcb design service#pcb fabrication#pcb electronic#oem electronics manufacturing#pcb prototype us

0 notes

Text

Me in February: my awful timing to never get the cool new diy electronic kits that i want. stupid crap always selling out, heartbroken & h8 everything

Me today: *must overcompensate by purchasing every version that ever becomes available from every known seller*

1 note

·

View note

Text

Top 10 PCB Manufacturers in the World: A Comprehensive Guide

Introduction

In today's technologically advanced world, printed circuit boards (PCBs) play a crucial role in powering various electronic devices. From smartphones and laptops to medical equipment and automotive systems, PCBs serve as the backbone of modern technology. With the increasing demand for high-quality PCBs, it's essential to know about the top manufacturers in the world. This comprehensive guide will explore the top 10 PCB manufacturers globally, shedding light on their expertise, capabilities, and contributions to the industry.

PCB Manufacturing Industry: An Overview

Before delving into the top 10 PCB manufacturers, let's first understand the PCB manufacturing industry as a whole. PCBs are vital components that provide electrical connections and mechanical support for various electronic components. They are made by laminating thin layers of copper onto a non-conductive substrate, usually made of fiberglass or composite epoxy materials.

PCBs can have multiple layers, each serving a specific purpose. The manufacturing process involves intricate steps such as designing the PCB layout, etching the copper layers, drilling holes, and applying solder mask and silkscreen for labeling.

The PCB manufacturing industry is highly competitive and driven by innovation. With advancements in technology, manufacturers are constantly pushing the boundaries to produce PCBs that are smaller, more efficient, and capable of supporting complex electronic designs.

Now, let's dive into the top 10 PCB manufacturers in the world and explore their unique strengths and contributions.

ACME Circuits — We are the best-printed circuit board manufacturer and services providers. We provide high-quality PCB assembly, PCB design, PCB fabrication, PCB layout, PCB programming, testing, etc.

2. Foxconn Technology Group

3. TTM Technologies

4. Tripod Technology Corporation

5. Unimicron Technology Corporation

6. Zhen Ding Technology Holding

7. Nippon Mektron

8. Sumitomo Electric Industries

9. Young Poong Electronics

10. Samsung Electro-Mechanics

Conclusion

Choosing the right PCB manufacturer is paramount to the success of any electronic product. The top 10 PCB manufacturers in the world mentioned in this article have demonstrated their expertise, reliability, and commitment to delivering high-quality PCB solutions. Whether you prioritize innovation, customization, sustainability, or scalability, these manufacturers offer a diverse range of options to suit your specific requirements. By partnering with a reputable and trusted PCB manufacturer, you can ensure the seamless integration of PCBs into your electronic devices, ultimately enhancing their performance and reliability.

#Printed Circuit Board Manufacturers#pcb manufacturing#printed circuit board assembly#circuit board manufacturing#pcb board manufacturer#high frequency pcb manufacturing#printed circuit board manufacturers near me#pcb manufacturer#pcb supplier#pcb assembly services#pcb assembly manufacturer#electronic cable assembly#electronic contract services#pcb exporters#printed circuit board manufacturer in india#pcb manufacturing companies in india

1 note

·

View note

Text

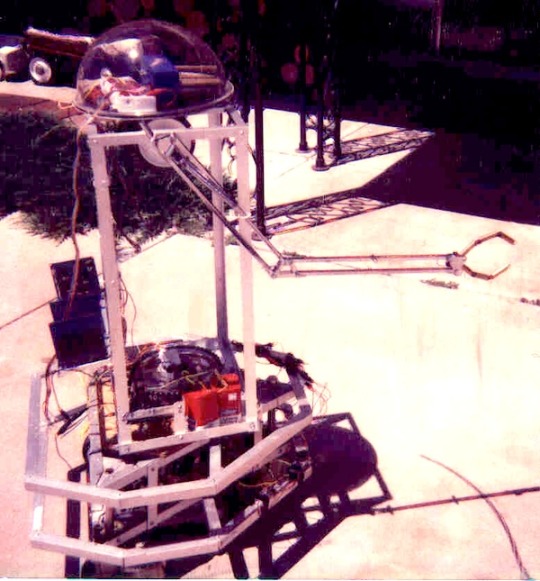

S.A.M by "Bill" (1978). "S.A.M (Short for "Sentient, Autonomous Mechanism" or "Smart Ass Machine", depending on his (and my) mood on a given day, was one of my first real robot projects, started in 1978 when I was around 15. His "brain" was a single-board Z-80 computer (the big square object in the middle of his "back" in this picture), with many bits of TTL I/O, a couple of serial ports, a bunch of counter-timers, and several D/A & A/D channels. The base was taken from the book "How to Build a Computer Controlled Robot" by Todd Loofbourrow - I had built the robot in the book, and had used my KIM-1 to control it. Later, I decided that just a little platform was kind of boring, so I added the upper torso shown here. The torso (mounted on a "lazy-susan" turntable bearing) is rotated by a heavy-duty gear motor driving a chain and sprocket assembly from a bicycle. The base is powered by two of the (apparently no longer available, which is sad) all-metal rubber-tired "motorized wheel" assemblies that Herbach & Rademan used to sell, with a large rubber-tired caster in front. The head platform (mounted on a small "lazy-susan" bearing) was originally rotated by a surplus gearbox from a Mattel "Big Trak" with some rubber-tired wheels mounted on the output shafts. This arrangement was later replaced by a small gear-head motor driving a large gear mounted to the center of the turntable. The device in the head with the tubes sticking out the front is a directional light tracking device. Each tube has a CDS photocell at the bottom, and is painted flat black inside. A comparator circuit tells the computer which direction the brightest light is coming from. This device could also tilt up and down with a small gear-head motor, to track light sources vertically. Most of the circuitry was installed on small plug-boards from Radio Shack, mounted in a card rack below the CPU card. This rack could be tipped back 90 degrees to facilitate easier access for testing. In addition to motor driver circuits, there was a "Sweet Talker" speech synthesizer board so he could talk. Power came from a large "gel-cell" marine battery (for powering trolling motors on boats), which was slung near the ground in the center of the base. Two 6V lantern batteries (later replaced by a 12V motorcycle battery) provided separate power for the electronics. All motors were isolated from the electronics via relays and/or opto-isolators. After these pictures were taken, a set of metal panels was installed on the "facets" of the base, with lever switches behind them for collision sensing. A Polaroid sonar range-finder was also added later. If you check out the other photos of S.A.M., you will notice an "arm" sticking out the front. This was a prototype made from an old swing-arm desk lamp and some "fingers" from a robot hand design using brass tubing, bicycle chain, and 1/16" steel cable to allow natural bending of each finger. It was later replaced with a much heavier duty aluminum framework arm operated by two 12VDC linear actuators." – My Home Robot Projects, by Bill.

24 notes

·

View notes

Text

#pcb#electronics#pcbassembly#pcbmanufacturer#circuit#investing#manufacturer#manufacturing#marketing#top pcb manufacture#pcb design services#pcb manufacturer in ahmedabad#pcb stencil material#pcb fabrication near me#pcb assembly#pcb manufacturer in Gandhinagar#pcb manufacturer in surat#how to cut pcb circuit board#printed circuit board manufacturers near me

0 notes

Text

CC ORIGIN STORY by @lubedoo

Hello! I’ve been following your art for some time and really enjoy it! I especially like the Tails and CC threads and have been mulling just how CC came to be and how she first met Tails, given the brief outlines you’ve published. I scribbled out the first chapter of a fan fiction expanding on CCs origins which I hope you’ll like. Let me know what you think… I can write more if you like it. Hope to see more of Tails and CC soon either way!

Chapter 1: Walter’s Widgets

“No, this won’t work… the gear pitch is misaligned to the functional plane!”

The camera aperture on the small robot’s spindly head focused in and out on the tiny interlocking mechanism as its grouchy furred boss pointed at the offending interface with thin metal pick. Its pincer-like hands reached for the device, but it was quickly snatched away. The robot retreated a few feet on its wheelbase at the sudden movement.

“It has to be at the correct angle or it will bind and fail prematurely!” He looked sternly at the two droids standing in front of him, the second a more squat construction containing a platform and several manipulators. “Assembler, you have the steady table and precision arms. Can’t you work with Gear Placer to match these up?”

Assembler responded in a series of low hums and groan-like noises, while Gear Placer rattled off high-pitched squeals and beeps.

“Wait, whoa��� one at a time.” The old woodchuck removed his glasses and grasped the bridge of his nose. “I can understand both of you but not when you talk over each other. Didn’t the interface chips I installed help with translating your machine languages?”

Gear Placer reached a pincer inside an opening in its head and plucked out a small circuit board, which clearly had been overtaxed. The melted wires and burn marks were testament to its overuse and failure. Assembler groaned about its being in a similar condition, but was unable to remove it given its location.

The woodchuck sighed as he examined the ruined electronics. “I suppose that’s what I get for cobbling you all together from different control boards and drivers. I never expected my Widget business to be so complex.”

Walter Woodchuck had built WW Widgets into a local phenomenon. It started as a hobby business, building little devices for himself and his friends in his garage workshop. But word spread about his clever and unique designs, and suddenly customers were sending in requests from as far as Reclusivia. It provided him with a nice retirement income and kept him busy for sure, but he knew he needed help if he was to keep building these devices to his exacting standards.

And Walter was by no means a “people person.” He tried hiring a few Mobian assistants but none lasted very long. He was very particular in how he wanted things done, and few of his hired help was willing (or able) to keep up with his demands. Even his nephew William could only last for short stints in the WW manufacturing area before needing a periodic “sabbatical.”

So Walter decided with the size and scope of his business to move out of the tiny garage and into a “Fabratory” he had built towards the back corner of his property. It was a moderately sized but impressive facility that functioned as a device development lab, a manufacturing floor, a warehouse, and a store front. The store was more of an Automat, with remote payment devices and clear-doored cubbies where his customers could pay for and retrieve their items. It was very rare that any of them met with or even saw Walter… and he liked it that way. There was even a small living space so he could spend as much time as he wanted in his own little world. He would send one of the robots for supplies as needed, and the store owners in town knew Walter was good for payment.

But as with Walter and the outside world, communication among his robots was severely lacking. He built them as the need arose, from Circuit Solderer to Chip Mounter and Metal Stamper to Test Aligner. Their names were childish but functional, as Walter didn’t see the need to personalize his creations, only to have them do their job as they were told. And since they were constructed over time, the parts available to build them varied as did their internal machine languages, resulting in a maddening (to Walter) Production Line of Babel. The robots understood everything Walter told them but little of what the others twittered and beeped. They were still effective in producing wonderful Widgets, but frequently also manufactured a lot of stress for Walter.

Walter turned back to Gear Placer and Assembler, impatiently explaining to each what needed to be fixed on the device they had presented. They both excitedly responded in their own languages and raced off to fix their mistake.

“There has to be an easier way,” the tired woodchuck grumbled. “Maybe if I built another robot, one that could understand all their code and interpret for them… and me…” His voice trailed off as he turned to his drafting table and began drawing up yet another design.

After a few hours of intense thought and technical sketching (and with a few interruptions from the Production floor), he looked at his newest blueprint. “Yes, this should do nicely. I’m sure Oscar has the proper processors, auditory inputs, and servo impellers to make this happen. It will be my most advanced creation yet. I’ll need it to be able to learn, accept and provide feedback, and adapt to our design changes.” His brow furrowed. “This is going to be somewhat expensive, but that latest Widget order from Spagonia should cover the cost. Well worth it.”

He looked over the plans again and leaned back in his chair. Walter crossed his arms, smiled, and relaxed a bit. “Yes, you will be a great help to me… Code Compiler.”

-----

Evay: Wow, this is amazing! Oh I sincerely hope you do write more! I know I've been neglectful in all of the details of CC's origin. I promise I do have a script written for a comic for her, but I love when you all take the initiative and interpret how you think things went. It's an absolute delight for me 🥰 I really enjoyed this read and I look forward to more. Thank you so much!

38 notes

·

View notes

Text

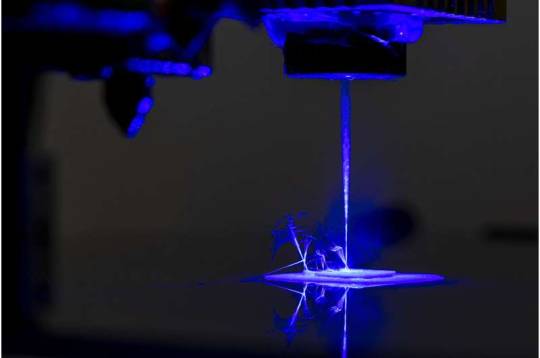

No assembly required: Innovative 3D printing method streamlines multi-materials manufacturing

University of Missouri researchers have developed a way to create complex devices with multiple materials—including plastics, metals and semiconductors—all with a single machine. The research, which was recently published in Nature Communications, outlines a novel 3D printing and laser process to manufacture multi-material, multi-layered sensors, circuit boards and even textiles with electronic components. It's called the Freeform Multi-material Assembly Process, and it promises to revolutionize the fabrication of new products. By printing sensors embedded within a structure, the machine can make things that can sense environmental conditions, including temperature and pressure. For other researchers, that could mean having a natural-looking object such as a rock or seashell that could measure the movement of ocean water. For the public, applications could include wearable devices that monitor blood pressure and other vital signs.

Read more.

17 notes

·

View notes

Text

#SMT PCB Jobwork#Printed Circuit Board Assembly#Electronics PCBA factory#Cable wiring harness factory#Plastic Moulding jobwork#Power cord factory

0 notes

Text

The Heart of Electronics Manufacturing: Exploring PCB Factories in China

In today's tech-driven world, printed circuit boards (PCBs) are the unsung heroes that power our devices, from smartphones to space shuttles. Behind the scenes, PCB factories in China play a pivotal role in the production of these intricate electronic components. In this blog post, we'll take a closer look at the fascinating world of PCB manufacturing and delve into why China has emerged as a global hub for this critical industry.

The PCB Manufacturing Process

Before we dive into the Chinese PCB factory, let's briefly understand the PCB manufacturing process. PCBs are the backbone of electronic devices, providing the connectivity and functionality required for seamless operation. The manufacturing process can be summarized in a few key steps:

Design: Engineers meticulously design the PCB layout, specifying the arrangement of components and electrical connections.

Prototyping: A prototype PCB is created to validate the design and functionality.

Production: Once the prototype is approved, production begins. This involves etching copper layers, drilling holes, and adding solder mask and silkscreen for component placement.

Assembly: Components such as microchips, resistors, and capacitors are soldered onto the PCB.

Quality Control: Rigorous testing ensures that each PCB meets industry standards and functions flawlessly.

Why China for PCB Manufacturing?

China has become synonymous with PCB China manufacturing for several compelling reasons:

Cost Efficiency: Chinese factories offer competitive pricing due to lower labor and material costs.

Advanced Technology: Many Chinese PCB factories are equipped with state-of-the-art machinery and automated production lines, ensuring precision and efficiency.

Vast Experience: China's PCB industry has decades of experience, making them experts in handling complex projects.

Global Reach: China's strategic location facilitates efficient global distribution, a critical factor for electronics manufacturers.

Environmental Concerns and Solutions

It's crucial to address environmental concerns associated with PCB manufacturing. While the industry has made significant strides in minimizing its environmental footprint, challenges remain. Chinese PCB factories are increasingly adopting eco-friendly practices, such as recycling and waste reduction, to mitigate these concerns.

Conclusion

In the world of electronics, PCBs are the unsung heroes that make our gadgets tick. Chinese PCB factories have played a pivotal role in the growth of this industry, thanks to their cost efficiency, technological prowess, and global reach.

FAQs on PCB Factories and Manufacturing in China

1.What is a PCB Factory?

A PCB factory produces printed circuit boards used in electronic devices.

2.Why choose a Chinese PCB Factory?

Chinese PCB manufacturers offer cost-effectiveness and advanced technology.

3.How can I find a reliable Chinese PCB Factory?

Research online, seek recommendations, check certifications, and visit the factory if possible.

4.What types of PCBs are available in China?

Chinese factories offer single, double, multi-layer, rigid, flexible, and rigid-flex PCBs with various materials and finishes.

5.Is sharing design files safe?

Sign NDAs and ensure security measures are in place.

6.How can I track my PCB order?

Use order tracking systems or communicate with customer support.

7.Are there import/export regulations or tariffs?

Consult with the factory and customs experts as needed.

8.What payment methods are accepted?

Common methods include bank transfers, PayPal, and credit cards. Clarify terms and currency beforehand.

#pcb china#pcb factory#china pcb manufacturer#pcb assembly china#electronic manufacturing services#pcb assembly near me#printed circuit board assembly

0 notes