#Ductile Iron Pipe

Text

Ductile iron pipes offer numerous benefits, making them the ideal choice for various applications. They are incredibly durable, corrosion-resistant, and have a long lifespan. Additionally, they provide excellent flow characteristics and require minimal maintenance.

Website - https://firstdiamondcc.com/

0 notes

Text

Cohen Industrial Supply Co.

Your trusted partner in Houston, TX, for premium industrial pipes and related products is Cohen Industrial Supply Co. Our specialization in ductile iron pipes allows us to deliver custom solutions tailored to your project's specific needs. Whether you require iron pipes, flow control solutions, spiral-weld pipes, or high-frequency welded pipes, we provide a dependable supply and excellent service in the Houston region. Explore our offerings at cohenpipe.com.

CONTACT US :

Cohen Industrial Supply Co.

11943 Farm to Market Rd 529, Houston, TX 77041

(713) 467-3300

Monday - Friday 7:30AM - 4:30PM,

Saturday & Sunday - Closed

Email: [email protected]

Website: https://cohenpipe.com

External links:

https://wellfound.com/u/cohen-industrial-supply-co

https://www.blogger.com/u/4/profile/09545656226224504423

https://gravatar.com/digitalvilla08

https://artmight.com/user/profile/2841699

https://in.pinterest.com/CohenIndustrialSupplyCo/

https://sites.google.com/view/cohen-industrial-supply-co/home?authuser=4

https://digitalvilla08.wordpress.com/

https://coub.com/dd7befaed808e02d63f1

https://www.buzzfeed.com/cohenindustrialsupplyco

1 note

·

View note

Text

Middle East and Africa Ductile Iron Pipes Market Growth, Forecast 2023-2030

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the Middle East and Africa Ductile Iron Pipes Market size at USD 494.71 million in 2023. During the forecast period between 2024 and 2030, BlueWeave expects the Middle East and Africa Ductile Iron Pipes Market size to grow at a CAGR of 5.59% reaching a value of USD 823.87 million by 2030. The Middle East and Africa Ductile Iron Pipes Market is primarily driven by escalating urbanization, population growth, and infrastructural development projects. Increasing water and wastewater treatment activities, coupled with a rising demand for durable and corrosion-resistant piping systems, fuel the market's growth. Government initiatives for improved water supply and sanitation further stimulate the demand for ductile iron pipes. Additionally, the region's robust industrialization and economic expansion contribute to the market's momentum. Technological advancements and a focus on sustainable water management solutions also play pivotal roles in shaping the market landscape.

Opportunity – Innovative technological advancements

Technological advancements are steering the Middle East and Africa Ductile Iron Pipes market towards unprecedented growth. Integration of state-of-the-art manufacturing processes, such as advanced casting techniques and automation, is enhancing production efficiency and product quality. Additionally, the implementation of smart technologies, like IoT-enabled monitoring systems, is revolutionizing pipeline management and maintenance. These advancements not only address infrastructure challenges but also foster sustainable practices. Therefore, the Middle East and Africa Ductile Iron Pipes market is experiencing a surge in demand, driven by cutting-edge technologies that promise efficiency, durability, and environmental responsibility.

Sample Request @ https://www.blueweaveconsulting.com/report/middle-east-and-africa-ductile-iron-pipes-market/report-sample

Impact of Escalating Geopolitical Tensions on Middle East and Africa Ductile Iron Pipes Market

Escalating geopolitical tensions in the Middle East and Africa have adversely impacted the Ductile Iron Pipes Market. Instabilities in the region disrupt supply chains, leading to increased costs and delays in project timelines. For instance, in 2023, the Yemeni conflict disrupted infrastructure projects, impacting ductile iron pipe demand. Additionally, political uncertainties in Sudan and Libya have hindered market growth, as investors adopt a cautious approach. The regional instability has also affected raw material prices due to supply chain disruptions. In 2022, the Ethiopia-Sudan border dispute further exacerbated challenges for market players, causing a decline in investments. As geopolitical tensions persist, the Middle East and Africa Ductile Iron Pipes Market faces ongoing uncertainties, influencing project execution and market dynamics.

Middle East and Africa Ductile Iron Pipes Market

Segmental Coverage

Middle East and Africa Ductile Iron Pipes Market – By Diameter

Based on diameter, Middle East and Africa Ductile Iron Pipes Market is divided into DN up to 300, DN 300–700, DN 700–1000, DN 1000–1200, and DN Above 1200 segments. The DN 700–1000 diameter segment is the largest one in the Middle East and Africa Ductile Iron Pipes Market. The surge is attributed to substantial government investments in building reliable sewerage systems, driving demand for the pipes. The high alumina cement mortar lining enables resistance to high-pressure conditions, particularly in alkaline or acidic water. Further, the pipes' cement mortar coating protects against potential damage during installation, such as rock falls.

Middle East and Africa Ductile Iron Pipes Market – By Joint Type

Based on joint type, Middle East and Africa Ductile Iron Pipes Market is split into Socket & Spigot and Flanged segments. The socket & spigot segment holds a largest market share to the Middle East and Africa Ductile Iron Pipes Market by joint type. The segment’s dominance can be attributed to the segment's widespread usage and versatility in various applications. The socket and spigot segment's popularity is driven by its efficient and reliable jointing system, making it a preferred choice for infrastructure projects across the region. The flanged segment, while significant, doesn't surpass the market share held by socket and spigot, highlighting the latter's prominent position in the Ductile Iron Pipes Market in the Middle East and Africa.

Competitive Landscape

Middle East and Africa Ductile Iron Pipes Market is fiercely competitive. Major companies in the market include National Pipe Company (NPC), Ducast Factory LLC, Arabian Pipes Company, Future Pipe Industries, Bahrain Pipes, Qatar Metal Coating Company, and Saint-Gobain PAM Middle East. These companies use various strategies, including increasing investments in their R&D activities, mergers, and acquisitions, joint ventures, collaborations, licensing agreements, and new product and service releases to further strengthen their position in the Middle East and Africa Ductile Iron Pipes Market.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

The Global Ductile Iron Pipes Market is projected to grow at a considerable CAGR during the forecast period, i.e., 2022-27. The market growth is driven primarily by the increasing number of construction & development projects across different countries worldwide, owing to the growing government focus on infrastructural developments.

#Global Ductile Iron Pipes Market#Global Ductile Iron Pipes Market news#Global Ductile Iron Pipes Market Growth

0 notes

Text

Ironclad Excellence: Leading Ductile Cast Iron Pipe Manufacturers

Elevate your infrastructure with BIC India, renowned ductile cast iron pipe manufacturers. Our precision-engineered pipes ensure durability, reliability, and seamless performance for diverse industrial applications.

#cast iron mould manufacturers#cast iron manhole cover manufacturers#cast iron exporter#gray iron exporter#ductile iron pipe exporter#USA

0 notes

Text

Di Pipes Manufacturers In India | Class K9 Diameter 1100MM | Vedanta Metalbazaar

Browse for di pipes class K9 1100mm from Vedanta Metalbazaar, a leading exporter of di water pipe in India. Using the most recent technologies, they provide di pipes of the highest quality. See here for additional details!

0 notes

Text

Ductile Iron Pipes and Fittings For Irrigation Pumping Station

Ductile Iron pipes and fittings are a preferred choice for many different applications. Due to their exceptional range of characteristics and benefits, they are a popular choice of materials for pipe fittings. The use of ductile iron pipes and fittings for irrigation pumping station contributes majorly in maintaining optimized performance within the irrigation system.

Compared to other materials, ductile iron made pipes and fittings are resilient in nature. Therefore, they can sufficiently withstand extreme weather conditions, natural disasters, soil contaminations and other unforeseen disasters. They are also environmentally friendly which means when you choose pipe and fittings made from ductile iron, you are making a sustainable choice for your project.

But that’s not all, ductile iron pipes and fittings offer many more perks. If you are interested to know more then get in touch with Dutco Tennant LLC experts now.

0 notes

Text

SUPER CENTURION® HYDRANT WITH HYMAX GRIP® RESTRAINT COUPLING

FEATURES:

-easy installation:

-fully factory assembled

-stab-fit design

-easy-to-access top-facing-bolt

-felxibitily

-compatible with many different types of pipes

-compatible with Ductile Iron, Gray Iron, PVC and HDPE

-dynamic deflection up to four degrees

17 notes

·

View notes

Note

hey civ i have some top of the shelf prime facts of echo... somebody died in the mines once! the pipes were made of lead until 2000 something! oh and you should check your left rear tire wink wink ;]

I had heard of the mines thing! But I didn't see any bodies when I was exploring it last time I was here and explored those, though I didn't go too far so maybe I missed it.

Also on lead pipes! They aren't dangerous as long as they don't corrode. Many cities around the US still use lead pipes from old days (modern pipes can't use lead, instead they're typically ductile iron or PVC), you just gotta keep things that corrode lead out of the water and you don't have any issues. Though for Echo, I'm gonna assume they are corroded. Good thing I brought water with me.

Also I'll check my tire in a minute, let me finish my sandwich. It was fine a second ago when I crawled into the bed.

6 notes

·

View notes

Text

Exploring Large Diameter Pipes – Construction Challenges and Solutions

Understanding Large Diameter Pipes

Large diameter (Dia) pipes are essential components in many infrastructure projects, including water supply systems, sewage treatment plants, and oil and gas pipelines. Their size and functionality enable the efficient transport of large volumes of liquids and gases, making them indispensable in modern construction. However, working with large diameter pipes presents unique challenges that require specialized solutions. Tube Trading, a leading large Dia pipe supplier in Vadodara, has extensive experience in addressing these challenges. This article explores the construction challenges associated with large diameter pipes and the solutions provided by industry leaders like Tube Trading, a prominent large Dia pipe dealer in Vadodara and a reliable large Dia pipe distributor in Gujarat.

Large diameter pipes are typically defined as pipes with a diameter of 24 inches (600 mm) or more. They are made from various materials, including steel, ductile iron, concrete, and plastic, each offering specific advantages depending on the application. These pipes are used in a variety of sectors, such as:

Water and Wastewater: For transporting potable water and sewage.

Oil and Gas: For transporting crude oil, natural gas, and refined products.

Industrial Applications: For transporting chemicals, slurry, and other industrial fluids.

Construction: As structural elements in large infrastructure projects.

Construction Challenges of Large Diameter Pipes

The installation and maintenance of large diameter pipes pose several challenges, which include:

1. Transportation and Handling

Transporting and handling large diameter pipes can be logistically complex due to their size and weight. These pipes often require special equipment and careful planning to ensure they are transported safely and efficiently.

Solution: Tube Trading, as a leading large Dia pipe distributor in Gujarat, uses specialized transportation methods and equipment to handle large diameter pipes. This includes flatbed trucks, cranes, and forklifts designed to accommodate the size and weight of these pipes. Their logistics team ensures that transportation complies with all safety regulations and standards.

2. Site Preparation and Trenching

Proper site preparation and trenching are critical for the successful installation of large diameter pipes. This involves clearing the site, excavating trenches, and ensuring that the ground conditions are suitable for pipe laying.

Solution: Tube Trading provides comprehensive site assessment and preparation services. They use advanced geotechnical surveys to analyze soil conditions and design appropriate trenching solutions. This minimizes the risk of ground instability and ensures a solid foundation for the pipes.

3. Jointing and Welding

Joining large diameter pipes securely is essential to prevent leaks and ensure the integrity of the pipeline. This can be particularly challenging with materials like steel, which require precise welding techniques.

Solution: As a top large Dia pipe dealer in Vadodara, Tube Trading offers expert welding and jointing services. Their team of certified welders uses state-of-the-art welding equipment and techniques to ensure strong, leak-proof joints. For non-metallic pipes, they provide specialized coupling systems that offer reliable connections.

4. Pressure Testing and Quality Assurance

Large diameter pipes used in critical applications, such as water supply and oil and gas transport, must undergo rigorous pressure testing to ensure they can withstand operational pressures without failing.

Solution: Tube Trading conducts thorough pressure testing and quality assurance checks on all pipes before installation. Their testing procedures comply with international standards, ensuring the pipes’ durability and reliability. This includes hydrostatic testing, where pipes are filled with water and pressurized to detect leaks and weaknesses.

5. Corrosion Protection

Corrosion can significantly reduce the lifespan of large diameter pipes, especially those made from metal. Protecting these pipes from corrosion is essential for long-term durability and performance.

Solution: Tube Trading offers a range of corrosion protection solutions, including coatings, linings, and cathodic protection systems. These measures protect the pipes from environmental factors and extend their service life. Their experts recommend the most suitable protection method based on the pipe material and operating conditions.

6. Environmental and Regulatory Compliance

Construction projects involving large diameter pipes must comply with environmental regulations and standards to minimize their impact on the environment.

Solution: Tube Trading is committed to environmentally responsible practices. They ensure all their projects comply with local and international environmental regulations. This includes using environmentally friendly materials and methods, as well as implementing measures to protect natural habitats and water sources during construction.

Innovative Solutions by Tube Trading

Tube Trading’s extensive experience and expertise in handling large diameter pipes make them a trusted partner for construction projects in Vadodara and Gujarat. Here are some innovative solutions they offer:

1. Custom Pipe Fabrication

Tube Trading provides custom fabrication services to meet specific project requirements. This includes custom lengths, bends, and fittings that ensure seamless integration with existing infrastructure. Their fabrication facilities are equipped with the latest technology to deliver high-precision products.

2. Comprehensive Project Management

From initial planning to final installation, Tube Trading offers comprehensive project management services. Their team of experts oversees every aspect of the project, ensuring timely completion and adherence to budget. This integrated approach minimizes disruptions and ensures smooth project execution.

3. Advanced Material Solutions

Tube Trading supplies a variety of pipe materials, including high-density polyethylene (HDPE), polyvinyl chloride (PVC), and ductile iron. Each material is chosen based on the specific needs of the project, offering optimal performance and cost-effectiveness. Their material experts provide guidance on selecting the best material for each application.

4. Technical Support and Training

Tube Trading provides technical support and training to ensure that construction teams are well-equipped to handle large diameter pipes. This includes training on installation techniques, safety procedures, and maintenance practices. Their support services ensure that clients have the knowledge and resources needed for successful project execution.

Why Tube Trading Stands Out

As a premier large Dia pipe supplier in Vadodara, Tube Trading has built a reputation for excellence and reliability. Their commitment to quality, innovation, and customer satisfaction sets them apart in the industry. Here’s why Tube Trading is the preferred choice for large diameter pipe solutions:

1. Extensive Industry Experience

With years of experience in the industry, Tube Trading has developed deep expertise in handling large diameter pipes. Their extensive portfolio of completed projects demonstrates their capability and reliability.

2. Quality Assurance

Tube Trading adheres to the highest quality standards in the industry. Their products undergo rigorous testing and inspection to ensure they meet or exceed client expectations. This commitment to quality ensures that clients receive durable, high-performance pipes for their projects.

3. Customer-Centric Approach

Tube Trading’s customer-centric approach ensures that clients receive personalized solutions tailored to their specific needs. Their team works closely with clients to understand their requirements and provide the most effective solutions.

4. Comprehensive Solutions

From supply and fabrication to installation and maintenance, Tube Trading offers end-to-end solutions for large diameter pipes. This comprehensive approach simplifies project management and ensures seamless execution.

Conclusion

Large diameter pipes are critical components in many infrastructure projects, but they come with unique construction challenges. Addressing these challenges requires specialized expertise and innovative solutions. Tube Trading, a leading large Dia pipe supplier in Vadodara, excels in providing comprehensive solutions that ensure successful project execution. Their commitment to quality, innovation, and customer satisfaction makes them a trusted partner for large diameter pipe projects in Vadodara and Gujarat. Whether you need custom fabrication, technical support, or comprehensive project management, Tube Trading is your go-to large Dia pipe dealer in Vadodara and a reliable large Dia pipe distributor in Gujarat.

#Large dia pipe distributor in Gujarat#Large dia pipe supplier in Vadodara#Large dia pipe dealer in Vadodara

4 notes

·

View notes

Text

Ironclad Excellence: Leading Cast Iron Fittings Manufacturers

BIC India, renowned among cast iron fittings manufacturers, crafts premium-quality solutions. Unparalleled durability and precision define their products, setting a standard in the industry.

#ductile iron pipes and fittings manufacturers#iron pipe manufacturers#cast iron drain cover manufacturers#cast iron manufacturer#cast iron casting manufacturers#USA

0 notes

Text

Civil engineer: density won’t break Atlanta’s infrastructure

FEB 5, 2023

One of the biggest fears Atlantans voice about urban density is that it will cause too much of a strain on our infrastructure systems. It’s a claim that pops up often in public comments — whenever we discuss allowing apartments and duplexes into single-family home districts that currently exclude density, neighbors push back with warnings that the water, electricity, and sewage systems will be strained to a breaking point.

To get some facts, we turned to Griffin Wasdin, a licensed Civil Engineer.

Is urban density in Atlanta a danger to our infrastructure systems?

[Wasdin]: “Honestly, density is the best thing for infrastructure, especially LINEAR infrastructure. Infrastructure is designed for long term durability in 15 to 100 year replacement cycles. Remember how your parents used to check that your shoes had room to grow in? Civil engineers do that with sewers and power lines too. Each urban block requires a minimum investment in asphalt, piping, sidewalks, power lines, transformers, telecom, etc, so each block is (almost) a fixed cost. More residents on a block just means more efficient utilization of this expensive upfront investment.”

“It is also important to remember that City of Atlanta’s population density is about 50% of the population density in the middle of the 20th Century when the majority of our modern infrastructure system was developed, so in many cases, today’s ‘increased urban density’ is simply returning to the infrastructure system’s original design conditions.”

ABOVE: The under-construction Front Porch project on Auburn Avenue will add density (formerly this was an empty property), and it’ll do so without putting a strain on infrastructure. It’s an efficient utilization of the expensive upfront investment in infrastructure that’s already been made in our neighborhoods.

Some people claim the old pipes in their neighborhoods can’t handle more stress; is it true?

“Strong Towns estimates that the typical North American urban neighborhoods could increase density by a factor of ten without impacting the existing sewer lines.”

“Fun fact: the Ductile Iron Pipe Research Association (formerly the Cast Iron Pipe Research Association) gives out an award for water mains that provide service for 100 years. They started giving out the award in the 1940’s and in the 1990’s the added a sesquicentennial award. Augusta, GA has at least one pipe still in service from 1859. Infrastructure done right is durable and resilient.”

What about our water and sewage infrastructure – can they handle increased density?

“A recent Strong Towns podcast touched on the issue of water supply versus demand, versus capacity. Modern pressurized water systems are designed to deliver high volume water service for fire fighting which is far, far greater than what is required for drinking water; yet another example of how existing infrastructure can easily accommodate infill development and higher density.”

ABOVE: From northgeorgiawater.org, Metro Atlanta’s per-capita water usage is declining

“As for modern urban households, they use dramatically less water and energy per person, which means our aging systems are actually increasing excess capacity through efficiency. According to the Metropolitan North Georgia Water District, per-person water usage today (99 gallons per day) is down 50% from 2000. Our current Metro region’s wastewater treatment capacity (697 million gallons per day) exceeds the 2050 projected capacity needs (667 million gallons per day).”

And electricity? Can our grid support new density in Single Family Home districts?

“Electric utility service operates similar to the principles described above but with some caveats and nuances. Like water and sewer, intown Atlanta’s power delivery infrastructure was originally built back when our neighborhoods were 50% denser, so there’s some built-in capacity as we crawl back to historic population levels. Power-delivery equipment is installed in 20-40 year replacement cycles, so system planning engineers often oversize new equipment to leave a healthy margin for growth.”

“Unlike water and sewer, household power consumption doesn’t follow a clear downward trend. Downward consumption trends from increasingly efficient fixtures and appliances can be counterbalanced by new energy hogging technology like electric cars that system planners in the 1950’s would never have anticipated. Efficiency gains from modern heat pump AC systems and triple pane windows is offset by a long term change in consumers’ preference for increasingly colder indoor air temperatures.”

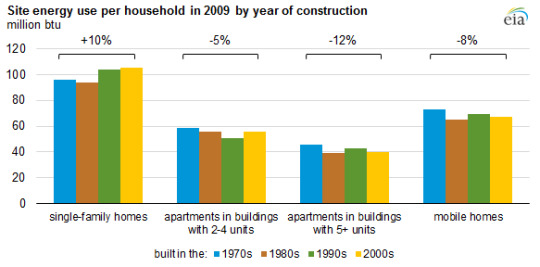

ABOVE: From the U.S. Energy Information Administration, multifamily homes are more energy efficient.

“The one ‘trend’ that is certain in residential power consumption is that multifamily homes will always be more energy efficient that single family homes, and really, it’s not so much a trend as physics.”

“Multifamily homes tend to be more compact which results in a smaller space to heat or cool, and the presence of one or several party walls shared between units results in a lower heat exchange surface area with the hot or cold outdoor temperature extremes. Multifamily homes tend to be newer and built to a higher quality standard than single family homes, so their scant exterior walls tend to be better insulated (“better” here carrying a lot of water considering many historic Craftsmen and Victorian-era homes are completely uninsulated).”

-------

This was reposted from our ThreadATL.org site

8 notes

·

View notes

Text

What is the difference between steel alloy and cast iron?

To begin with, steel alloy and cast iron are both types of metal alloys that are widely used in various industries. Although they share some similarities, there are significant differences that set them apart. Steel alloy is made by combining iron with other elements such as carbon, manganese, and chromium. Steel typically contains less carbon than cast iron, making it more ductile and malleable. Its tensile strength is higher, and it's more resistant to corrosion, making it ideal for use in building structures, machinery, and automobiles.

Cast iron, on the other hand, is formed by melting iron and adding carbon, silicon, and other elements. Cast iron contains a higher percentage of carbon, making it harder and more brittle. It is generally used in applications where high compressive strength is required, such as in the production of engine blocks, cookware, and pipes. Cast iron is also more prone to cracking under pressure or impact than steel alloy.

In conclusion, the differences between steel alloy and cast iron are based on their composition and properties. Both materials have distinct advantages and disadvantages, and their suitability depends on the specific application. By the way, after talking about it, only one company name comes to my mind that is Datre Corporation Ltd, is a leading manufacturer of high-quality steel casting products that meet the highest industry standards in Eastern India. So you can confidently utilise their products for your industrial needs.

Company name: Datre Corporation

Address: Falta Industrial Growth Center (F.I.G.C), Sector — III South 24 Parganas, Pin — 743 504, West Bengal, India

Phone No: 7605087010, 7605087007, 7605087008

Landline No: +91 7605087008

#stainless steel#cast iron#steel alloy#carbon#steel casting manufacturer#manufacturing industry#manufacturing company#aluminium manufacturer#manufacturer

3 notes

·

View notes

Text

Get Ductile Iron Pipes Class K9 Diameter 1000MM Leading Supplier | Vedanta Metalbazaar

Discover an extensive selection of 1000mm diameter class K7 ductile iron pipes from Vedanta Metalbazaar, a top supplier of them in India, at a competitive price. Get more information!

0 notes

Text

Carbon Steel Flanges VS Stainless Steel Flanges

Generally speaking, a flange is a forged or cast ring of steel that is used to connect or join sections of pipe. It also includes flanges that are integral to pressure vessels, pumps, or any other element that utilizes flanges. Bolts connect flanges together and threaded or welded them to the piping system. There are a variety of types of flanges available, including stainless steel flanges (SS flanges), alloy steel flanges, carbon steel flanges, slip-on flanges, blind flanges, weld neck flanges, threaded flanges, lap joints, and orifice flanges. This article discusses stainless steel vs carbon steel.

What are carbon steel flanges?

A flange connects two ends of a pipe or ends a pipe. Various materials are available for them. Flanges made from carbon steel are one such type. This material provides excellent durability, corrosion resistance, and finishing properties. There are several types of them. It is common to use Carbon Steel Blind Flanges to terminate pipes. The raw materials used in the manufacture of these flanges are of high quality. Between 0.25 and 0.60 percent of their carbon content is carbon. In addition to being highly ductile, the product is also excellently fabricated due to its high carbon and manganese content.

What are Stainless steel flanges?

In residential, commercial, and industrial piping systems, stainless steel flanges and fittings are used. Stainless steel is widely used for the transportation of gases or liquids, chemical processing, maritime applications, sanitary applications, and areas requiring corrosion resistance because of its strength, corrosion resistance, and ability to withstand high temperatures, pressures, and flows.

To determine the right stainless steel grade and flange type for your application, refer to the appropriate standards or contact us. To determine the right stainless steel grade and flange type for your application, refer to the appropriate standards or contact us.

Carbon Steel vs Stainless Steel

Stainless steel has a higher melting point and a lower carbon content than iron-carbon alloys. In appearance and properties, carbon steel is similar to stainless steel, but it contains a higher percentage of carbon.

A common application of engineering and construction materials like carbon steel is in large-scale industrial processes like telecommunications, transportation, chemical processing, and petroleum extraction and refining.

The process used in making Stainless Steel 304 Flanges is essentially two steps consisting mostly of iron and carbon. There are many types of steel that can be called stainless steel 304 flanges. Corrosion resistance can be achieved by adding nickel and chromium to stainless steel.

Flanges in detail:

Pipe Flanges are most often manufactured from forgings produced in grades A-105. There are two grades of A-350 material: LF2 for applications requiring lower temperatures and F42-F70 for applications requiring high yields. It is widely accepted that pipeline service is carried out with high-yield materials due to their increased strength.

Besides having a greater amount of chrome and molybdenum than carbon steel flanges, alloy steel flanges are able to withstand temperatures and pressures that are higher than those of carbon steel flanges. In contrast to conventional carbon steel flanges, they have a higher Chromium content, which makes them more corrosion resistant.

Flanges are commonly manufactured from stainless steel containing Nickel, Chromium, and Molybdenum. Flanges are commonly manufactured from stainless steel containing Nickel, Chromium, and Molybdenum. Forgings classes can be serviced with trace elements during melting. Aside from this, the 300 Series is not magnetic, whereas the 400 Series is magnetic, as well as has weakened corrosion resistance.

Read More About This Article On Our Website For More information: https://thesteelexporter.com/carbon-steel-flanges-vs-stainless-steel-flanges/

#design#architecture#interiordesign#steel#art#garden#gardendesign#rust#gardening#sculpture#metal#welding

2 notes

·

View notes