#Dry Vacuum Pumps

Explore tagged Tumblr posts

Text

Top 5 Reasons Why Dry Vacuum Pumps Are Essential for Modern Industrial Processes

In today’s competitive industrial landscape, the efficiency and reliability of equipment are most crucial. One critical component that has significantly enhanced industrial operations is the dry vacuum pump. These advanced devices have become indispensable due to their unique advantages. Explore this blog to know about the top 5 reasons why dry vacuum pumps are essential for modern industrial processes. https://bit.ly/4d7lymI

0 notes

Text

Efficient Dry Vacuum Pumps by Tekman: Innovating Vacuum Solutions

Discover unparalleled vacuum solutions with Tekman, a leading dry vacuum pump manufacturer. Tekman's cutting-edge technology ensures efficient and reliable performance for various industrial applications. With a commitment to innovation and quality, Tekman's dry vacuum pumps deliver superior performance, durability, and cost-effectiveness. Trust Tekman for your vacuum needs and experience unmatched reliability and efficiency in your operations.

0 notes

Text

Dry vacuum pumps offer numerous advantages over traditional wet pumps, such as oil-free operation, reduced contamination risk, and lower maintenance costs. They are ideal for applications where clean, dry vacuum is crucial, like semiconductor manufacturing and laboratory research. However, considerations include initial investment and potential limitations in handling certain gases or particles. Choosing dry vacuum pumps ensures efficiency, reliability, and environmental friendliness.

0 notes

Text

Unleashing the Power of Dry Vacuum Pumps for Enhanced Industrial Efficiency

Dry Vacuum Pump stand as stalwart companions in the realm of industrial operations, revolutionizing processes with their unparalleled efficiency and reliability. As stalwarts of industrial ingenuity, dry vacuum pumps have emerged as indispensable assets across a myriad of sectors, ranging from semiconductor manufacturing to pharmaceutical production. In this comprehensive guide, we delve into the intricacies of dry vacuum pumps, uncovering their inner workings, applications, and the myriad benefits they bestow upon industries worldwide.

Understanding the Mechanism Behind Dry Vacuum Pumps

At the heart of every dry vacuum pump lies a sophisticated mechanism designed to achieve optimal performance and durability. Unlike traditional vacuum pumps, which utilize oil for lubrication, dry vacuum pumps eschew such lubricants, thus eliminating the risk of oil contamination in sensitive applications. Instead, these pumps rely on innovative sealing mechanisms and advanced materials to maintain peak efficiency while operating in diverse environments.

Applications Across Diverse Industries

The versatility of dry vacuum pumps transcends industry boundaries, finding application in a plethora of sectors where precise vacuum control is paramount. In the realm of semiconductor manufacturing, these pumps play a pivotal role in processes such as chemical vapor deposition (CVD), physical vapor deposition (PVD), and ion implantation, ensuring the integrity of delicate substrates and enhancing yields.

Moreover, the pharmaceutical industry relies heavily on dry vacuum pumps for aseptic processing, freeze-drying, and solvent recovery, where stringent quality standards necessitate the use of contaminant-free vacuum solutions. Additionally, the automotive, aerospace, and energy sectors leverage these pumps for applications ranging from vacuum coating to composite curing, underscoring their indispensable nature in modern industrial settings.

Advantages Over Conventional Vacuum Pumping Solutions

The adoption of dry vacuum pumps heralds a paradigm shift in vacuum technology, offering a plethora of advantages over conventional pumping solutions. By eliminating the need for oil lubrication, these pumps mitigate the risk of oil contamination, ensuring product purity and operational integrity in sensitive applications.

Furthermore, dry vacuum pumps boast enhanced reliability and reduced maintenance requirements, translating into significant cost savings and uninterrupted production cycles for industries worldwide. Their robust construction and minimal downtime make them ideal choices for high-throughput operations where efficiency and uptime are paramount.

Factors Influencing Pump Selection and Performance

When selecting a dry vacuum pump for specific applications, several factors come into play to ensure optimal performance and efficiency. Factors such as ultimate vacuum level, pumping speed, gas compatibility, and footprint must be carefully considered to align the pump’s capabilities with the unique requirements of the application.

Additionally, factors like power consumption, noise levels, and environmental considerations play a crucial role in determining the suitability of a dry vacuum pump for a particular industrial setting. By conducting a comprehensive assessment of these factors, industries can make informed decisions that maximize productivity and minimize operational costs.

Future Trends and Innovations in Dry Vacuum Pump Technology

As industries evolve and demand for more efficient vacuum solutions grows, dry vacuum pumps continue to undergo rapid advancements and innovations. Emerging trends such as the integration of IoT technology for remote monitoring and predictive maintenance promise to further enhance the reliability and performance of these pumps.

Moreover, the advent of eco-friendly materials and energy-efficient designs underscores a commitment to sustainability and environmental stewardship in the realm of vacuum technology. By embracing these trends and fostering a culture of innovation, manufacturers can stay ahead of the curve and address the evolving needs of industries worldwide.

In conclusion, dry vacuum pumps stand as indispensable assets in the modern industrial landscape, offering unparalleled efficiency, reliability, and versatility across a myriad of applications. By understanding their inner workings, applications, and benefits, industries can harness the full potential of these pumps to drive innovation, productivity, and sustainability in the years to come.

Read More : https://www.becker-international.com/in/1888/rotary-vane-vacuum-pumps-oil-free.htm

0 notes

Link

In conclusion, dry vacuum pumps are an essential tool for several industries and applications, providing a reliable and cost-effective solution for creating a vacuum. The non-contact technology used in dry vacuum pumps eliminates the need for oil, making them environmentally friendly and requiring less maintenance. The three types of dry vacuum pumps - claw, screw, and scroll - provide a range of options to suit different applications.

0 notes

Text

#Rotary Vane Vacuum pump#Dry Vacuum Pump#Helium Leak Detector#Helium Leak Testing Machine#Helium Recovery System

0 notes

Text

Revolutionizing Everyday Tasks with Advanced Tools

When it comes to tackling agricultural and cleaning challenges, having the right tools can make all the difference. Advanced machinery like water pumps, power tillers, floor pressure washers and wet and dry vacuum cleaners are transforming the way we handle daily tasks, offering efficiency and reliability. Companies like STIHL, a global leader in innovative tools and equipment, are setting the benchmark for quality and performance in these categories.

Efficient Solutions for Agriculture and Irrigation

Water Pumps: Whether for agricultural irrigation or draining waterlogged areas, water pumps are indispensable. With their ability to transport large volumes of water efficiently, these machines ensure that fields remain hydrated and flood risks are minimized. STIHL's range of durable and high-performance water pumps is designed to meet diverse irrigation needs, making them an ideal choice for farmers and gardeners.

Power Tillers: Preparing the soil for planting is no longer a tedious task, thanks to power tillers. These machines help break up and aerate the soil, boosting crop productivity. STIHL offers compact yet powerful power tillers that are perfect for small and medium-sized farms, enabling users to complete their fieldwork faster and with less physical effort.

Transforming Cleaning with Advanced Tools

Floor Pressure Washer: When it comes to cleaning stubborn dirt and grime, a floor pressure washer is your best ally. This equipment uses high-pressure water jets to effectively clean surfaces like driveways, patios and industrial floors. STIHL's floor pressure washers are designed with robust motors and adjustable pressure settings, providing versatility for both residential and commercial cleaning tasks.

Wet and Dry Vacuum Cleaner: A clean environment is essential for both health and productivity. A wet and dry vacuum cleaner is a versatile tool that handles liquid spills and solid debris with ease. STIHL’s models are known for their powerful suction, large capacity and durable design, making them a must-have for homes, offices and industrial spaces.

Why Choose STIHL?

STIHL is synonymous with innovation, quality and durability. With a legacy of providing world-class equipment for forestry, agriculture and cleaning, STIHL ensures that its tools are built to last and perform under the toughest conditions. Their user-friendly designs, energy efficiency and advanced technology make them a preferred choice for professionals and homeowners alike.

Benefits of Using Advanced Equipment

Efficiency: Tools like water pumps, power tillers, floor pressure washers and wet and dry vacuum cleaners save time and effort, allowing you to focus on other important tasks.

Cost-Effectiveness: Investing in high-quality equipment reduces long-term maintenance costs and enhances productivity.

Environmental Care: Many of STIHL’s products are designed to minimize emissions and energy consumption, contributing to sustainability.

Conclusion

From efficient irrigation solutions to powerful cleaning tools, advanced equipment has become a necessity in modern agriculture and maintenance. With brands like STIHL offering reliable and innovative products, users can tackle challenges with ease and confidence. Whether you need a water pump for irrigation, a power tiller for farming, or cleaning equipment like a floor pressure washer and wet and dry vacuum cleaner, STIHL has you covered with tools designed to deliver unmatched performance and durability.

0 notes

Text

Durable Dry Running Rotary Vane Vacuum Pumps Australia

Get low-maintenance and reliable vacuum solutions with Vacuum Pumps. Our dry running rotary vane vacuum pumps offer oil-free operation and durable efficiency.

#Dry running rotary vane vacuum pump#industrial vacuum pumps#vacuum pumps#industrial equipment supplier#vacuum pumps australia#vacuum pumps suppliers

0 notes

Text

Huge Savings! Get Upto 25% Off On Our Top Selling Industrial Air Blowers & Vacuum Pumps.

🌐 www.yashblower.com ☎️ +91 9971006400

#yashblowers#air blower#industrial equipment#dry vacuum pump#discount#ringblower#sale#offer#dryvacuumpump#airblowers#centrifugalblowers#hugesavings#deals#vacuumpump

0 notes

Text

Global Top 14 Companies Accounted for 94% of total Semiconductor Dry Vacuum Pump market (QYResearch, 2021)

A vacuum pump is a device used to generate, improve and maintain a vacuum environment according to a certain working principle. It is an indispensable product that directly affects the performance and quality of vacuum complete equipment. Dry vacuum pumps are non-contact vacuum pumps that do not use oil or seals.

In order to control the manufacturing process to smaller dimensions, it is increasingly necessary to perform more semiconductor manufacturing process steps with greater precision and uniformity. To achieve this, semiconductor processes must operate in an extremely controlled vacuum environment. At present, vacuum pumps have been widely used in many process links of semiconductor manufacturing, including etching, coating, diffusion and so on.

According to the new market research report “Global Semiconductor Dry Vacuum Pump Market Report 2023-2029”, published by QYResearch, the global Semiconductor Dry Vacuum Pump market size is projected to reach USD 2.24 billion by 2029, at a CAGR of 8.9% during the forecast period.

Figure. Global Semiconductor Dry Vacuum Pump Market Size (US$ Million), 2018-2029

Figure. Global Semiconductor Dry Vacuum Pump Top 14 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Semiconductor Dry Vacuum Pump include Atlas Copco (Edwards Vacuum), Ebara Corporation, Pfeiffer Vacuum GmbH, LOTVACUUM, Kashiyama Industries, Hanbell Precise Machinery, Busch Vacuum, SKY Technology Development, ULVAC, Inc, Osaka Vacuum, Ltd, etc. In 2022, the global top five players had a share approximately 94.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Revolutionizing Industrial Efficiency: How Dry Vacuum Pumps are Transforming Critical Processes Across Various Sectors

In today’s fast-paced industrial landscape, efficiency and reliability are key drivers of success. As industries strive to optimize operations and reduce costs, the adoption of advanced technologies like Dry vacuum pumps is playing a crucial role in transforming critical processes across various sectors. Check out this interesting blog to know about the revolutionizing industrial efficiency and how dry vacuum pumps are transforming critical processes across various sectors. https://bit.ly/4dPC2RA

0 notes

Text

Explore Tekman's High-Performance Dry Vacuum Pumps for Efficient and Eco-Friendly Industrial Solution

Tekman is a prominent manufacturer of Dry Vacuum Pumps, known for their exceptional performance and efficiency in various industrial settings. Designed to provide a clean and reliable vacuum source, Tekman's Dry Vacuum Pumps eliminate the need for oil lubrication, reducing maintenance costs and environmental impact. With advanced engineering and robust construction, these pumps ensure consistent operation and longevity, making them the ideal choice for laboratories, packaging, and pharmaceutical applications.

0 notes

Text

Explore the transformative power of dry vacuum pumps in 'Beyond the Oil Barrier,' a compelling journey through industries reshaped by cutting-edge technology. This enlightening narrative delves into the innovative applications and environmental benefits of Dry Vacuum Pumps, unraveling their pivotal role in revolutionizing manufacturing, healthcare, and more. Witness the evolution beyond traditional oil-based systems, unlocking new frontiers in efficiency and sustainability.

#dry vacuum pump#dry vacuum pump manufacturers#dry vacuum pump manufacturers in india#dry vacuum pumps#dry vacuum pumps manufacturers#dry vacuum pump working principle

0 notes

Text

0 notes

Text

https://mullenequipment.com/dry-vacuum-pumps/

Dry Vacuum Pumps Distributor

Flowserve/ SIHI Dry Vacuum Pumps are more forgiving to process upsets, they have better handling of solids and liquid carryover, no lubricants needed, energy efficient with low noise and vibration with the patented double pitch twin screw design.

0 notes

Text

Exploring Advanced Vacuum and Helium Leak Detection Solutions

In industries ranging from manufacturing to research, vacuum systems play a pivotal role in ensuring operational efficiency and product quality. Among the various technologies available, rotary vane vacuum pumps, dry vacuum pumps, helium leak detectors, helium leak testing machines, and helium recovery systems have become essential tools. Let’s dive into the functionalities and applications of these systems to better understand their impact.

Rotary Vane Vacuum Pump: Reliable Performance in a Compact Design

The rotary vane vacuum pump is one of the most commonly used types of vacuum pumps. Its compact design, reliability, and versatility make it suitable for various applications. The pump operates by using vanes that rotate inside a cylindrical chamber, creating a vacuum by displacing air or other gases.

Applications:

Medical and Laboratory Equipment: Rotary vane vacuum pumps are used in medical applications such as vacuum-assisted wound closure systems and laboratory vacuum systems.

Packaging Industry: These pumps are integral to vacuum packaging machines, ensuring products remain fresh by eliminating air from packaging.

HVAC Systems: In heating, ventilation, and air conditioning systems, rotary vane pumps help in refrigerant recovery and evacuation processes.

Key benefits of rotary vane vacuum pumps include their durability, low noise operation, and ease of maintenance.

Dry Vacuum Pump: Oil-Free Efficiency for Sensitive Processes

Unlike rotary vane pumps, dry vacuum pump operate without the use of oil or any other sealing liquid. This makes them ideal for processes where contamination must be avoided.

Advantages of Dry Vacuum Pumps:

Clean Operation: With no oil involved, these pumps prevent contamination of the pumped gases or the environment.

Energy Efficiency: Many dry vacuum pumps are designed to consume less energy, reducing operational costs.

Low Maintenance: Without oil changes or sealing fluid replacement, maintenance requirements are minimal.

Common Applications:

Pharmaceutical Industry: Dry vacuum pumps are used in tablet coating and other sensitive pharmaceutical processes.

Semiconductor Manufacturing: These pumps play a critical role in processes like chemical vapor deposition and etching, where cleanliness is paramount.

Food Processing: Dry vacuum pumps are used in freeze-drying and vacuum cooling applications.

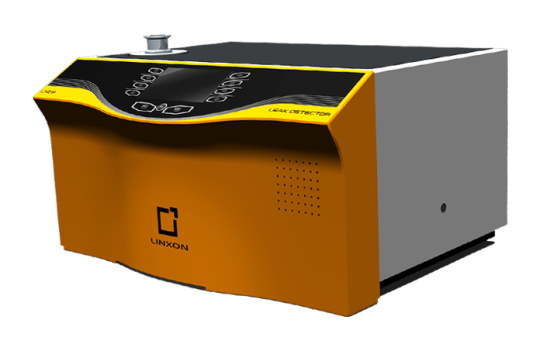

Helium Leak Detector: Precision in Leak Detection

Helium leak detector are essential tools for identifying and quantifying leaks in sealed systems. Helium is an ideal tracer gas due to its small molecular size and inert properties, making it capable of detecting even the tiniest leaks.

Working Principle:

A helium leak detector typically consists of a mass spectrometer that senses the presence of helium within a system. When helium is introduced into the system under test, the detector identifies any escaping helium, pinpointing leaks with high accuracy.

Key Applications:

Automotive Industry: Helium leak detectors are used to ensure the integrity of fuel systems, air conditioning systems, and exhaust systems.

Aerospace Sector: Ensuring leak-tight components in critical aerospace systems, such as fuel tanks and propulsion systems.

Medical Devices: Used in testing the hermeticity of medical implants and diagnostic equipment.

The precision and reliability of helium leak detectors make them indispensable for maintaining safety and quality standards.

Helium Leak Testing Machine: Comprehensive Leak Testing Solutions

A helium leak testing machine is a complete system that incorporates a helium leak detector, pumping systems, and control units to automate the leak testing process. These machines are tailored to meet the specific requirements of various industries.

Features and Benefits:

Automation: Automated testing reduces human error and increases throughput.

Customizability: Machines can be designed for specific applications, such as testing automotive radiators, batteries, or high-pressure vessels.

High Sensitivity: These systems can detect leaks at the micro-level, ensuring the highest standards of quality control.

Industrial Applications:

Energy Sector: Used for testing high-pressure gas cylinders and pipelines.

Electronics Manufacturing: Ensures the integrity of sealed electronic components such as sensors and displays.

Vacuum Technology: Essential in testing vacuum chambers and components for scientific and industrial applications.

Helium Recovery System: Sustainability in Leak Detection

As the demand for helium increases and its availability decreases, helium recovery system have become a critical component of modern leak detection setups. These systems capture and recycle helium, reducing operational costs and environmental impact.

How Helium Recovery Systems Work:

Capture: Helium used in the testing process is captured from the test environment.

Purification: The captured helium is purified to remove contaminants.

Storage: The purified helium is stored for reuse in subsequent tests.

Advantages:

Cost Savings: Reducing the need for new helium purchases can significantly cut costs.

Environmental Benefits: Minimizing helium waste supports sustainable operations.

Enhanced Efficiency: Continuously recycled helium ensures a steady supply for testing operations.

Applications:

Manufacturing Plants: Ideal for large-scale operations where helium usage is high.

Research Facilities: Ensures a sustainable supply of helium for experiments and testing.

Aerospace Industry: Critical for testing and maintaining expensive and sensitive components.

The Future of Vacuum and Leak Detection Technologies

With advancements in technology, vacuum systems and helium leak detection solutions are evolving to meet the growing demands of precision, efficiency, and sustainability. Integration with IoT and smart systems enables real-time monitoring and diagnostics, reducing downtime and increasing productivity. Moreover, the push toward eco-friendly solutions is driving the adoption of oil-free and helium recovery systems.

Final Thoughts:

Whether it’s a rotary vane vacuum pump ensuring efficient vacuum creation, a dry vacuum pump delivering oil-free operation, or a helium leak detector safeguarding the integrity of critical systems, these technologies are indispensable. Helium leak testing machines and helium recovery systems further enhance efficiency and sustainability, making them vital in today’s industrial landscape.

By understanding and implementing these advanced systems, industries can achieve higher standards of quality, safety, and environmental responsibility.

#Rotary Vane Vacuum pump#Dry Vacuum Pump#Helium Leak Detector#Helium Leak Testing Machine#Helium Recovery System

0 notes