#Dry Laminating Adhesives Manufacturers

Explore tagged Tumblr posts

Text

What Is Dry Lamination Adhesive?

In terms of lamination techniques, Dry Lamination adhesive is unmatched for its exceptional qualities, which allow high-speed lamination machines to produce at a faster pace and with perfect bonding results. Empowera, a market leader in adhesives, is proud to offer you the best Dry Lamination glue available, hand-selected to satisfy your stringent standards and produce top-notch outcomes.

The choice of adhesive is essential to the success of lamination processes, particularly in high-speed settings where effectiveness and efficiency are crucial. Empowera's Dry Lamination Adhesive is designed to function well in these difficult circumstances, facilitating easy integration into your production process and allowing your gear to perform at its best.

One of Dry Lamination adhesive's standout benefits is its quick curing capabilities, which allow for quick bonding and reduce production pauses. This quick bonding procedure creates a strong, long-lasting connection between the materials, improving the general quality of your laminated goods while also increasing efficiency.

Every part of Empowera's Dry Lamination adhesive reflects its dedication to perfection. This adhesive has undergone meticulous testing and is expertly developed to maximize its compatibility with a variety of substrates, guaranteeing versatility and adaptability to various lamination applications.

Empowera also recognizes the value of upholding stringent industry standards and practicing environmental responsibility. You can be confident that their Dry Lamination adhesive is a model of efficiency and abides by eco-friendly practices, reducing its impact on the environment while retaining its remarkable adhesive capabilities.

Having the top Dry Lamination Services in a busy and competitive sector Having dry lamination glue on hand may make a huge impact. The committed support staff at Empowera is here to help you select the best adhesive for your unique needs, providing a smooth and effective lamination procedure.

In conclusion, Dry laminating adhesive is the preferred choice for high-speed laminating machines looking for improved bonding abilities and speedier output. Empowera takes great satisfaction in offering the greatest Dry Lamination adhesive, designed to take your lamination operations to new levels of effectiveness and superiority. Count on Empowera to provide you with a dependable, high-performance adhesive that optimizes your laminating procedures.

#Dry Lamination Adhesive#Dry Lamination Adhesives#Dry Laminating Adhesive#Dry Laminating Adhesives Manufacturers#Dry Lamination Adhesive Manufacturers in India#Dry Lamination Adhesive Suppliers#Water Based Dry Lamination Adhesive

0 notes

Link

Introducing Dry Lamination Adhesives which are high-speed laminators used for faster output and better bonding of Printed or plain Paper/Board to Lamination film.

0 notes

Text

How Do You Repair and Protect the Bottom of Your Boat?

The bottom of your boat is constantly exposed to harsh elements, from saltwater and marine life to debris and impacts. Over time, this exposure can cause wear and tear, leading to damage such as cracks, chips, and hull degradation. Repairing and protecting the bottom of your boat is essential not only for its longevity but also for its performance and safety on the water. Here’s a guide to help you understand how to repair and protect your boat’s hull to keep it in top condition.

1. Inspect the Hull Regularly

The first step in maintaining the bottom of your boat is regular inspection. A thorough check will help you catch small issues before they become major problems. Look for:

Scrapes, gouges, or deep scratches.

Cracks, especially around seams and joints.

Faded or peeling paint or gel coat.

Growth of marine life (barnacles, algae, etc.).

Any signs of corrosion (especially on metal parts like trim tabs or outdrives).

After inspecting, make a note of any areas that require attention and prioritize repairs based on severity.

2. Clean the Bottom of Your Boat

Before you can repair or protect the hull, it’s essential to clean it thoroughly. Regular cleaning will remove dirt, salt buildup, and marine growth that can damage the bottom over time. Use a marine-grade cleaner that is safe for your boat’s material (fiberglass, aluminum, or wood) to scrub the hull. If you notice barnacles or other hard growths, use a scraper to gently remove them. Be careful not to scratch or damage the surface.

For boats that are kept in saltwater, cleaning the hull after each outing will help prevent the buildup of corrosive salt deposits.

3. Repairing Damage to the Hull

If you find cracks, chips, or gouges in the hull, timely repair is crucial to prevent further damage. Here's how to handle common repairs:

Minor Scratches and Chips:

For small cosmetic damage, you can typically use a boat-specific gel coat repair kit. Clean the area first, then apply the gel coat according to the manufacturer’s instructions. Sand it smooth once it dries and buff it to restore the shine.

Cracks or Larger Gouges:

For deeper cracks or gouges that expose the fiberglass beneath the surface, you will need a more substantial repair. First, clean the damaged area and allow it to dry thoroughly. For fiberglass boats, mix a fiberglass resin and hardener, apply it to the crack or gouge, and then smooth it out with a putty knife. Once it has cured, sand the surface smooth and apply a layer of gel coat to match the surrounding hull. If you’re not familiar with fiberglass repair, it might be wise to hire a professional for larger damage.

Hull Leaks:

If the boat has developed a leak, it’s crucial to pinpoint its source and repair it immediately. Leaks in the bottom of the hull can be caused by damaged fiberglass, corroded seams, or failing seals. Small leaks can be patched with marine sealant or epoxy resin, but more severe damage may require professional repair or re-lamination.

4. Applying Bottom Paint for Protection

To protect the hull from future damage and deterioration, applying bottom paint is a key step. Bottom paint helps prevent the growth of marine organisms like algae and barnacles, which can damage the hull and reduce performance. It also creates a protective barrier against the harsh elements of the water.

Steps to Apply Bottom Paint:

Clean the hull thoroughly: Before applying bottom paint, ensure the hull is free of dirt, oil, or any old paint.

Sand the surface: Lightly sand the hull to create a rough surface for better paint adhesion.

Choose the right type of bottom paint: There are different types of bottom paint, including antifouling paints that prevent marine growth and hard paints for boats that are frequently in dry dock. Make sure to select the appropriate paint based on the type of boat, your location, and how often you use your boat.

Apply paint in layers: Use a roller or brush to apply the first coat of paint. Allow it to dry, and then apply a second coat. Follow the manufacturer’s instructions for drying times and the number of coats needed.

5. Protecting Against Corrosion

Corrosion, especially in metal components of the boat like the propeller, drive shaft, and trim tabs, is a common issue for boats in saltwater environments. Regularly inspect metal parts for signs of rust or corrosion and take steps to prevent it.

Use corrosion inhibitors: Apply marine corrosion inhibitors to metal parts, especially those below the waterline. These products help protect against saltwater exposure.

Consider sacrificial anodes: Install sacrificial anodes (zinc or aluminum) on the boat’s metal components. These anodes corrode instead of your boat’s more valuable metal parts, protecting them from rust and degradation.

Regular cleaning and maintenance: Rinse metal parts with fresh water after every use to remove salt deposits that can accelerate corrosion.

6. Maintain Your Boat’s Trailer and Lift

If you use a trailer or lift system to transport your boat, don’t forget to maintain the equipment that keeps your boat above water when it’s not in use. Check the trailer for any rust, wear on the rollers, or faulty brakes. Inspect the lift system for signs of wear or damage and make necessary repairs before putting the boat back in the water.

7. Consider Professional Help for Complex Issues

While many boat owners can handle basic cleaning, maintenance, and small repairs, some hull issues may require professional expertise. If you’re dealing with extensive damage, complex repairs, or if you simply want peace of mind, hiring a professional boat repair technician can ensure the job is done correctly.

Conclusion Proper care and maintenance of the bottom of your boat are essential to keeping it in good condition and maximizing its lifespan. Regular inspections, cleaning, and repairs will protect the hull from wear, marine growth, and environmental damage. By applying bottom paint, addressing minor repairs promptly, and taking steps to prevent corrosion, you can enjoy a safe and smooth ride for years to come. Whether you’re handling repairs yourself or enlisting the help of a professional, taking the time to care for your boat’s bottom is an investment in its long-term performance and durability.

0 notes

Text

5 Common Mistakes to Avoid When Using PVC Laminate Sheets

PVC laminate sheets are an excellent choice for both residential and commercial spaces due to their durability, aesthetic appeal, and easy maintenance. However, when it comes to installation or use, many people make common mistakes that can reduce the lifespan or aesthetic quality of the laminate. In this blog, we will highlight the 5 common mistakes to avoid when using PVC laminate sheets, ensuring you get the best results for your space. As one of the leading suppliers of premium laminates in India, Amulya Mica offers a variety of high-pressure laminate sheets and more to elevate your interior design projects.

1. Ignoring Proper Surface Preparation

Mistake: Installing PVC laminate sheets on an uneven or dirty surface

When applying PVC laminate sheets to furniture or walls, one of the most common mistakes is ignoring surface preparation. If the surface is uneven, dirty, or not smooth enough, the laminate sheets may not adhere properly, leading to bubbling, peeling, or discoloration.

Solution: Always ensure that the surface is clean, dry, and free from dust, grease, or any other impurities. Smooth out any uneven spots and use a high-quality adhesive to secure the laminate properly.

Tip: Consider using HPL laminate sheets (High-Pressure Laminates) for areas that require more robust durability and smooth finishes. You can find a variety of finishes in our Amulya Mica catalogue, tailored for different applications.

2. Choosing the Wrong Thickness of PVC Laminate Sheets

Mistake: Using thin PVC laminate sheets for high-traffic areas

Not all PVC laminate sheets are created equal, and selecting the wrong thickness for the specific application can lead to issues down the line. For high-traffic areas, using thin laminate sheets may cause premature wear and tear.

Solution: Choose thicker premium laminates for areas that experience constant use. For kitchens, offices, or commercial spaces, we recommend our high-pressure laminate sheets that are specifically designed for high durability and scratch resistance.

Tip: If you're unsure about which thickness to choose, consult our Amulya Mica catalogue for guidance on the best laminate options for your needs.

3. Not Accounting for Expansion and Contraction

Mistake: Failing to leave gaps for expansion

PVC laminate sheets can expand and contract due to changes in temperature and humidity. This is especially important in areas with varying climates, like India, where extreme temperature fluctuations can cause the laminate to warp if not installed properly.

Solution: Always leave a small gap (1–2mm) around the edges of the laminate sheets during installation. This will allow for any natural expansion and contraction without causing damage.

Tip: Using high-pressure laminate sheets can help manage expansion better, as they are more resistant to environmental changes compared to standard laminates.

4. Improper Cutting and Measuring

Mistake: Incorrectly cutting or measuring the laminate sheets

One of the biggest challenges with PVC laminate sheets is ensuring precise cutting and measuring. Mistakes in measuring can lead to ill-fitting panels or excess waste, both of which are avoidable.

Solution: Take accurate measurements before cutting and always use the proper cutting tools. A fine-tooth saw or a laminate cutter can help achieve clean edges. Mark your cuts carefully and avoid over-cutting to ensure a neat finish.

Tip: If you're unsure of your cutting skills, consider professional installation services or refer to the detailed step-by-step guides in our Amulya Mica catalogue for expert advice on cutting and fitting premium laminates.

5. Not Following Manufacturer Instructions

Mistake: Overlooking installation instructions and guidelines

Whether you're installing PVC laminate sheets for furniture, walls, or countertops, it's essential to follow the manufacturer's instructions for best results. Neglecting these guidelines can lead to mistakes in adhesive application, cutting techniques, and even the curing time for the laminate.

Solution: Always read the installation instructions provided with the high-pressure laminate sheets or premium laminates you purchase. Adhering to these instructions ensures proper adhesion, longevity, and optimal aesthetic appeal.

Tip: At Amulya Mica, we provide clear guidelines and tips for our customers in our Amulya Mica catalogue to ensure smooth, hassle-free installation. Our team is also available to answer any installation-related questions you may have.

Conclusion

When it comes to enhancing your interiors with PVC laminate sheets, avoiding these common mistakes can make all the difference in ensuring a long-lasting, stylish, and durable finish. By choosing the best laminates in India and following proper installation techniques, you can enjoy beautiful spaces that stand the test of time.

At Amulya Mica, we offer a wide range of premium laminates and high-pressure laminate sheets designed to elevate your design projects. Explore our Amulya Mica catalogue to find the perfect laminate for your needs.

For more expert tips, design ideas, or to browse our collection, visit Amulya Mica.

#pvc laminate sheet#Best Laminates in India#premium laminates#hpl laminate sheet#amulya mica catalogue#laminate designs#pvc laminate#latest laminates design#latest mica design#advance pvc laminate#buy laminates online#0.8 mm laminate#1 mm laminate

0 notes

Text

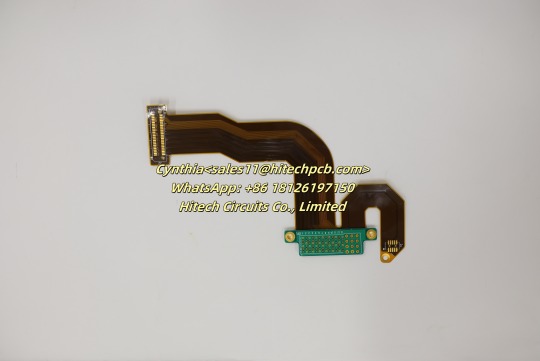

Hitech rigid flex pcb manufacturing process

After the production of FPC flexible boards is completed, the production of Hitech rigid flex pcb boards can be completed through the following processes.

1. Punching

Drill holes on FR4 and PP film, and the design on the alignment hole is not the same as the general through hole. After the punching is completed, browning is required.

2. Riveting

Laminate copper clad laminates, PP adhesives, and FPC circuit boards and place them neatly. The original old process is to laminate and pressing step by step, but it is a waste of time. After many attempts, we found that the stacking process can be completed once.

3. Laminate

This is a relatively complete step in the production of rigid-flex pcb board. Most of the materials are integrated for the first time. First, the bottom layer is copper clad laminate and PP film, above are the FPC flexible board produced in the previous process, and a PP film is placed on the FPC flexible board, then place the last layer of copper clad laminate. All materials to be laminated are placed in order and pressed together.

4. Trimming

That is to remove the part of the circuit board where there is no circuit at the edge of the circuit board currently and in the future. Afterwards, it is necessary to measure whether the material has excessive expansion and contraction. Because the PI used in the production of flexible boards is also expansion and contraction, this has a very large impact on the production of circuit boards.

5. Drilling

This step is the first step to turn on the entire circuit board, and the production parameters should be produced according to the design parameters.

6. Desmear

First, remove the scum generated by the drilling of the circuit board, and then use plasma cleaning to clean the through holes and the board surface.

7. Immersion copper

This step is the process of electroplating through holes, also known as hole metallization. Realize through-hole power conduction.

8. Plate plating

Partially electroplating copper on the upper surface of the electroplating hole makes the copper thickness above the through hole exceed a certain height of the copper clad board surface.

9. Outer dry film positive film production

The same as the production process of the anti-corrosion dry film of the FPC board, the circuit to be etched on the copper clad board is made. After the development is completed, check the circuit.

10. Graphic plating

After the initial copper sinking, pattern electroplating is performed, and the current time and copper plating wire are used according to the design requirements to reach a certain electroplating area.

11. Alkaline etching

12. Print solder mask

This step has the same effect as the FPC board protective film. We see that the PCB rigid board is generally green. This step is generally called green oil printing. After the printing is completed, the inspection is carried out.

13. Open the cover

Cover opening, which is the area where the FPC board is located, but the area not needed by the rigid board is laser cut to expose the FPC board.

14. Curing

It is also a baking process.

15. Surface treatment

Generally, at this time, a rigid-flex PCB board has been manufactured, and only the metallization treatment is required on the surface of the circuit board, which can play a role in preventing wear and oxidation. Generally, this process is to soak the circuit board in a chemical solution, and the metal elements in the solution are densely distributed on the circuit board circuit.

16. Characters printing

The positions of the parts to be assembled and some basic product information are printed on the rigid-flex board in the form of characters.

17. Test

This is a process of checking whether the circuit board is qualified. The test items are tested for electrical properties according to customer requirements. The tests generally include impedance test, open and short circuit test and so on.

18. Final inspection

19. Packaging and shipping

There are many ways to package circuit boards. Generally, Hitech use packaging bags to separate them, and then use a vacuum packaging machine to vacuum package the rigid-flex PCB boards .

If you have an inquiry for our service, please contact us, Cynthia<[email protected]>, thank you.

0 notes

Text

Solvent Base Inks

Solvent-based inks are manufactured by several reputable companies in India, offering a wide range of products tailored to various printing needs. These inks are specifically formulated to dissolve in solvents and are commonly used in printing applications where fast drying and durability are essential.In India, manufacturers of solvent-based inks adhere to stringent quality standards to ensure optimal performance and reliability. These companies employ advanced technology and expertise to produce inks that deliver vibrant colors, excellent adhesion, and resistance to fading and abrasion.

0 notes

Text

What Flooring Installation Solutions Are Available in Singapore?

There are numerous options available in Singapore for flooring installation solutions to suit various requirements and tastes. Services like expert installation, which guarantees a smooth and superior finish, are available to companies and homeowners. Numerous providers streamline the process by providing all-inclusive packages that cover advice, material selection, and installation. Underlayment and moisture barriers are examples of specialist solutions that can improve the flooring's performance and longevity. There are a number of equipment and preparation supplies available for do-it-yourselfers to help them achieve a professional outcome. Every flooring need is successfully satisfied thanks to this wide variety of alternatives.

The Finest Flooring Options in Singapore It's critical to take into account the range of options accessible although looking for the Best Flooring Supplier in Singapore. Trustworthy sellers provide a wide variety of flooring options for both housing and marketable applications, such as hardwood, laminate, vinyl, and tiles. In addition to improving a space's visual appeal, these flooring varieties also increase its longevity and practicality.

Crucial Flooring Items and Supplies for Setup Buy Flooring Essentials in Singapore is key to achieving the ideal flooring installation. This covers things like finishing materials, adhesives, and underlayment’s that guarantee a durable installation. It's also critical to Buy Flooring Preparation Materials. These supplies assist in getting the subfloor ready, making sure it is dry, clean, and level, which is fundamental for any flooring project.

Expert Flooring Installation Services Your flooring project's ultimate success might be greatly impacted by your choice of Flooring Installation Essential Provider in Singapore. Professional installers are equipped with the know-how to manage different kinds of flooring and guarantee that the installation satisfies industry requirements. Using skilled professionals can ensure a perfect finish and save time, whether the project is for a residential or commercial building.

Premium Flooring Installation Supplies for PurchaseNumerous vendors Flooring Installation Material for Sale that are made to facilitate a seamless installation procedure. These supplies, which range from moisture barriers to premium adhesives, are essential for guaranteeing the flooring's lifespan. Respectable suppliers also frequently provide advice on the best materials to use depending on the type of flooring and the surrounding environment.

Complete Flooring Installation Services An excellent choice for individuals seeking a comprehensive bundle is to investigate Flooring Installation Solution in Singapore. This could involve expert installation services, delivery, material selection, and consulting. These all-inclusive solutions are provided by numerous businesses, which facilitates clients' management of flooring projects from inception to completion.

Producers of Flooring Materials

When looking for a flooring materials manufacturer in Singapore, it's critical to recognize the significance of buying from trustworthy sources. Long-lasting, fashionable, and environmentally friendly flooring alternatives that satisfy consumer demands are the main emphasis of quality manufacturers. By selecting goods from reliable producers, you can be sure that the materials you choose will improve the look of your room and last.

Reliable Provider of Flooring Products Finally, while searching to Flooring Products Supplier in Singapore, make sure you pick a reliable seller. Outstanding customer service, competitive price, and high-quality items are all hallmarks of a dependable supplier. You will have gorgeous, useful flooring for many years to come if you can locate the proper supplies and assistance to finish your flooring project.

0 notes

Text

Innovative Uses of Carboxylated SB Latex in Adhesives and Sealants

The adhesive and sealant industry has evolved significantly over the years, driven by the demand for higher performance, flexibility, and eco-friendliness in products. One material that has gained prominence in this field is Carboxylated Styrene Butadiene (SB) Latex. Known for its excellent adhesive properties, flexibility, and cost-effectiveness, Carboxylated SB Latex is finding innovative applications across various industries, from construction to packaging.

In this article, we will explore the unique properties of Carboxylated SB Latex and how its versatility makes it an ideal choice for adhesives and sealants. We will also highlight some key applications and the benefits it offers to manufacturers and end-users.

1. What is Carboxylated SB Latex?

Carboxylated SB Latex is a water-based copolymer made from styrene and butadiene, with carboxylic groups added to its structure. The addition of carboxyl groups improves the polymer's adhesive strength, flexibility, water resistance, and overall performance. This material is widely used in various industrial applications due to its ability to form strong, flexible films and its compatibility with other materials.

In the adhesives and sealants industry, Carboxylated SB Latex stands out because it can bond a wide range of surfaces, including wood, paper, plastic, and textiles. Its water-based nature also makes it environmentally friendly, as it reduces the reliance on volatile organic compounds (VOCs), which are harmful to both the environment and human health.

2. Superior Bonding Strength and Flexibility

One of the key reasons Carboxylated SB Latex is favored in adhesives and sealants is its superior bonding strength. When used in adhesive formulations, it provides strong adhesion to various substrates, making it ideal for applications where durable bonds are required. Whether it's binding paper, laminating plastic films, or adhering textiles, Carboxylated SB Latex delivers reliable performance.

In addition to its bonding strength, Carboxylated SB Latex offers excellent flexibility. This property is crucial for applications where the bonded materials need to withstand movement, stretching, or changes in temperature without the adhesive cracking or breaking. For example, in packaging applications where materials are frequently handled or bent, the flexibility of Carboxylated SB Latex ensures that the bond remains intact over time.

3. Water Resistance and Durability

Another significant advantage of Carboxylated SB Latex is its water resistance. This property makes it suitable for applications where the adhesive or sealant is exposed to moisture or humidity. For instance, in construction, where adhesives and sealants are used to bond building materials, water resistance ensures that the adhesive maintains its integrity even in wet or humid environments.

The durability of Carboxylated SB Latex also extends to its resistance to chemicals and aging. This means that adhesives and sealants made from Carboxylated SB Latex can perform well in harsh environments, including exposure to UV light, chemicals, and fluctuating temperatures. This durability makes it a preferred choice for long-lasting applications in industries such as automotive, construction, and consumer goods.

4. Cost-Effectiveness and Ease of Use

One of the most attractive features of Carboxylated SB Latex is its cost-effectiveness. Being a water-based material, it is easier and cheaper to produce compared to solvent-based adhesives and sealants. Manufacturers benefit from lower production costs while also complying with stringent environmental regulations, which are increasingly pushing for reduced VOC emissions.

Moreover, Carboxylated SB Latex adhesives are easy to apply, as they can be formulated into various consistencies to suit different application methods, such as spraying, brushing, or rolling. This ease of application, combined with its fast drying time, allows for more efficient production processes and faster turnaround times.

5. Innovative Applications in Adhesives and Sealants

Carboxylated SB Latex has found innovative applications in several industries due to its versatile properties:

Packaging Industry: In the packaging industry, Carboxylated SB Latex is used in adhesives for carton sealing, paper laminations, and label applications. Its strong bonding strength ensures that packaging materials stay securely attached, while its water resistance helps maintain the integrity of the package in various environments.

Construction: The construction industry benefits from Carboxylated SB Latex in sealants used for windows, doors, and other structural elements. Its flexibility allows it to accommodate movement and expansion in building materials, while its water resistance ensures that the seals remain effective in preventing leaks.

Textile and Upholstery: Carboxylated SB Latex is also used in adhesives for bonding fabrics and foam in the production of furniture and upholstery. Its flexibility and durability make it an ideal choice for ensuring that fabrics adhere securely to foam without losing strength over time.

Automotive Industry: In the automotive sector, Carboxylated SB Latex is used in adhesives and coatings for interior components like door panels and seats. Its strong adhesion and ability to withstand temperature changes and chemical exposure make it suitable for these demanding applications.

Conclusion

Carboxylated SB Latex has emerged as a versatile and innovative material in the adhesives and sealants industry. Its superior bonding strength, flexibility, water resistance, and cost-effectiveness make it an ideal choice for a wide range of applications, from packaging and construction to textiles and automotive. As industries continue to prioritize sustainability and performance, Carboxylated SB Latex offers a solution that meets these demands while contributing to the development of more efficient and environmentally friendly products.

With its wide range of applications and benefits, Carboxylated SB Latex is poised to play an even more significant role in the future of adhesives and sealants, driving innovation and improving the performance of products across industries.

0 notes

Text

Wood Glue: Essential Adhesive for a Wide Range of Industries

Wood glue is a vital adhesive that plays a key role in various industries, from furniture manufacturing to DIY home projects. Its strength, versatility, and ease of use make it the go-to choice for woodworking professionals, carpenters, and hobbyists alike. Oxcol wood glue, a leading product in this sector, is widely recognized for its superior bonding properties, making it indispensable in sectors where the demand for durable wood joints is critical. This article explores the various industries where wood glue is supplied, who needs it, and why Oxcol wood glue stands out in the marketplace.

What is Wood Glue and Why is it Important? Wood glue, also known as carpenter’s glue, is a specialized adhesive designed to bond wood and wooden materials. Its formula creates a strong, long-lasting bond that ensures the structural integrity of wooden joints. This makes it crucial for applications that involve wood construction, repair, or assembly. One of the most trusted products in this category is Oxcol wood glue, known for its superior adhesion and versatility.

Oxcol Wood Glue: The Choice of Professionals Oxcol wood glue has become the preferred adhesive for professionals in the woodworking and carpentry industries due to its unmatched bonding capabilities. This product not only offers a strong bond but also withstands environmental factors like heat and moisture, ensuring the longevity of the bond even under strenuous conditions.

Where is Wood Glue Supplied? Wood glue, particularly Oxcol wood glue, is supplied to various industries that rely on woodworking for their operations. These include:

Furniture Manufacturing Wood glue is a staple in furniture production, where it is used for assembling everything from chairs to cabinets. High-quality glues like Oxcol ensure that the joints are sturdy and can bear the weight and wear of regular use. Furniture makers rely on wood glue for bonding table legs, chair frames, and drawer panels.

Carpentry and Woodworking Whether it’s a custom cabinetry project or general carpentry work, wood glue is essential for creating strong joints between pieces of wood. Carpenters, woodworkers, and DIY enthusiasts use Oxcol wood glue for projects involving wooden doors, window frames, shelving, and more. Its quick-drying nature and reliable bond allow professionals to complete their projects efficiently without compromising on quality.

Construction Industry In construction, wood is often a key material used for building frames, floors, and roofs. Wood glue is frequently supplied to construction companies for tasks that involve bonding timber materials, particularly for structural elements where nails and screws alone won’t suffice. Oxcol wood glue provides the strong and durable bond needed for load-bearing wood elements, ensuring safety and stability.

Flooring and Paneling Wood flooring and paneling require a secure bond to prevent movement and warping over time. Wood glue is used extensively in the installation of parquet, laminate, and hardwood floors. Oxcol wood glue is known for its superior adhesive properties that can hold flooring panels in place, providing a seamless finish that lasts.

Craft and DIY Projects Hobbyists and DIY enthusiasts also rely on wood glue for small projects and repairs. From building birdhouses to restoring old furniture, wood glue is often the adhesive of choice. Its ability to bond a variety of wooden surfaces makes it versatile for use in different types of projects. Oxcol wood glue is favored for its easy application and strong hold, even for amateurs working on personal projects.

Who Needs Wood Glue? The versatility of wood glue makes it essential for a wide range of individuals and businesses, including:

Woodworking Professionals Wood glue is a staple in the toolkit of every professional woodworker. Whether constructing furniture, crafting cabinetry, or working on decorative wood projects, these professionals need a reliable adhesive that ensures strong joints. Oxcol wood glue is particularly favored for its fast-drying formula and durability, making it ideal for both small and large-scale woodworking jobs.

Construction Companies Construction companies use wood glue in various structural applications. For them, it’s critical that the glue can provide a lasting bond in conditions where temperature, moisture, and stress levels fluctuate. Oxcol wood glue, with its weather-resistant qualities, is a top choice for such needs, ensuring that structural elements remain intact over time.

Furniture Manufacturers Furniture manufacturers are heavy users of wood glue, relying on it for assembling different types of wood pieces into finished products. They need glue that offers both a strong bond and flexibility during assembly. Oxcol wood glue meets these requirements by offering high-strength adhesion, enabling manufacturers to produce sturdy and long-lasting furniture.

DIY Enthusiasts Hobbyists and DIY enthusiasts often turn to wood glue for home improvement and crafting projects. They value its ease of use and ability to form strong bonds between wooden parts. Oxcol wood glue is popular among this group due to its simplicity in application and the professional-quality results it delivers, even for non-experts.

Advantages of Using Oxcol Wood Glue Wood glue, particularly Oxcol wood glue, offers several advantages over other types of adhesives:

Strong Bonding The primary advantage of Oxcol wood glue is its ability to create a strong and durable bond. Whether it’s a large-scale construction project or a small DIY task, Oxcol’s formula ensures that the pieces remain firmly connected over time.

Water and Heat Resistance Wood projects are often exposed to moisture, temperature fluctuations, and wear and tear. Oxcol wood glue stands out because it maintains its bond even in humid or hot environments. This makes it ideal for both indoor and outdoor use.

Quick Drying Time Oxcol wood glue’s quick-drying properties enable users to complete their projects more efficiently. In industries like furniture manufacturing or carpentry, where time is of the essence, this feature is highly valued.

Versatility Oxcol wood glue can be used on a variety of wood types, making it a versatile choice for different applications. Whether working with softwoods, hardwoods, or engineered woods, this glue ensures a reliable bond.

Conclusion Wood glue plays an essential role across various industries, offering the strength and durability required for bonding wood in both professional and DIY applications. Oxcol wood glue, with its high-performance formula, stands out as the adhesive of choice for furniture manufacturers, carpenters, construction companies, and hobbyists alike. Its ability to provide a strong bond, resist environmental factors, and dry quickly makes it an invaluable tool in woodworking. With Oxcol wood glue, professionals and enthusiasts can confidently create durable, high-quality wood products that stand the test of time.

0 notes

Text

What Is Dry Lamination Adhesive?

In terms of lamination techniques, Dry Lamination adhesive is unmatched for its exceptional qualities, which allow high-speed lamination machines to produce at a faster pace and with perfect bonding results. Empowera, a market leader in adhesives, is proud to offer you the best Dry Lamination glue available, hand-selected to satisfy your stringent standards and produce top-notch outcomes.

The choice of adhesive is essential to the success of lamination processes, particularly in high-speed settings where effectiveness and efficiency are crucial. Empowera's Dry Lamination Adhesive is designed to function well in these difficult circumstances, facilitating easy integration into your production process and allowing your gear to perform at its best.

One of Dry Lamination adhesive's standout benefits is its quick curing capabilities, which allow for quick bonding and reduce production pauses. This quick bonding procedure creates a strong, long-lasting connection between the materials, improving the general quality of your laminated goods while also increasing efficiency.

Every part of Empowera's Dry Lamination adhesive reflects its dedication to perfection. This adhesive has undergone meticulous testing and is expertly developed to maximize its compatibility with a variety of substrates, guaranteeing versatility and adaptability to various lamination applications.

Empowera also recognizes the value of upholding stringent industry standards and practicing environmental responsibility. You can be confident that their Dry Lamination adhesive is a model of efficiency and abides by eco-friendly practices, reducing its impact on the environment while retaining its remarkable adhesive capabilities.

Having the top Dry Lamination Services in a busy and competitive sector Having dry lamination glue on hand may make a huge impact. The committed support staff at Empowera is here to help you select the best adhesive for your unique needs, providing a smooth and effective lamination procedure.

In conclusion, Dry laminating adhesive is the preferred choice for high-speed laminating machines looking for improved bonding abilities and speedier output. Empowera takes great satisfaction in offering the greatest Dry Lamination adhesive, designed to take your lamination operations to new levels of effectiveness and superiority. Count on Empowera to provide you with a dependable, high-performance adhesive that optimizes your laminating procedures.

#Dry Lamination Adhesive#Dry Lamination Adhesives#Dry Laminating Adhesive#Dry Laminating Adhesives Manufacturers#Dry Lamination Adhesive Manufacturers in India#Dry Lamination Adhesive Suppliers#Water Based Dry Lamination Adhesive

0 notes

Text

Self-Leveling: The Ideal Flooring Solution for Smooth, Even Surfaces

Self-leveling is a process of applying a compound designed to create a smooth and even surface on a floor. Whether it's for residential, commercial, or industrial spaces, self-leveling compounds provide an efficient way to correct uneven flooring, filling in gaps, dips, and cracks. This method is often used as a base layer for installing various types of flooring like tiles, vinyl, laminate, or hardwood. In this blog, we will explore what self-leveling is, its benefits, how the process works, and the common applications of self-leveling compounds.

1. What is Self-Leveling?

Self Leveling involves the use of a cementitious or polymer-modified compound that is poured onto a floor to correct unevenness. These compounds spread easily, leveling themselves out to create a flat, smooth surface without requiring extensive manual intervention.

Once poured, the compound flows and sets quickly, usually within a few hours, forming a solid, level surface that can be used as a base for various types of flooring or even left as is, depending on the project.

2. Benefits of Self-Leveling Compounds

Self-leveling offers numerous advantages over traditional leveling techniques, making it a popular choice for professionals and DIY enthusiasts alike:

Creates a Perfectly Flat Surface: Self-leveling compounds are ideal for correcting uneven floors, leaving a perfectly smooth and level surface ready for any type of flooring installation. This ensures a flawless finish for your final flooring material.

Quick Drying: Most self-leveling compounds dry quickly, typically within a few hours. This allows for faster project completion, minimizing downtime for residential or commercial spaces.

Easy Application: The self-leveling compound is easy to apply and requires minimal manual effort to achieve a smooth surface. It’s designed to flow and level out on its own, making the process quick and efficient.

Durability: Once set, the compound forms a hard, durable surface that can withstand high traffic and heavy loads, making it ideal for areas that see a lot of foot traffic or require a strong foundation for other flooring materials.

Cost-Effective: Self-leveling is a cost-efficient solution to fixing uneven floors without having to remove the existing flooring. It helps save on labor and material costs by providing a reliable base layer in a short time.

Versatility: Self-leveling compounds can be used on a variety of subfloors, including concrete, wood, or tile. Whether it's for a small residential room or a large commercial space, these compounds offer flexibility in application.

3. The Self-Leveling Process

Self-leveling compounds are typically mixed with water to create a slurry-like mixture, which is then poured onto the floor. Here’s a step-by-step guide on how the self-leveling process works:

Surface Preparation: Before applying the self-leveling compound, it’s essential to clean and prepare the existing floor surface. Any dust, dirt, or debris should be removed, and cracks or holes should be repaired to ensure proper adhesion.

Priming: Depending on the subfloor material, a primer may be applied to improve the bond between the self-leveling compound and the surface. The primer helps ensure even distribution and prevents the compound from soaking into the floor too quickly.

Mixing the Compound: The self-leveling compound is mixed with water in a bucket according to the manufacturer’s instructions. It’s crucial to achieve the right consistency to ensure the compound flows smoothly and levels out properly.

Application: Once mixed, the compound is poured onto the floor, spreading it evenly across the surface. For larger areas, a spreader or rake may be used to distribute the compound, but it generally requires little manual effort to achieve a flat surface.

Drying and Curing: After the compound has been applied, it dries and sets quickly. Depending on the product used, the floor may be ready for light foot traffic in a few hours, with full curing typically occurring within 24 to 48 hours.

4. Common Applications of Self-Leveling Compounds

Self-leveling compounds can be used in various applications, making them a versatile choice for different flooring projects. Here are some common areas where self-leveling compounds are used:

Preparing Subfloors for Flooring Installation: One of the primary uses of self-leveling compounds is to create a smooth base for installing flooring materials such as tiles, vinyl, laminate, or hardwood. This ensures the finished floor looks perfect and remains durable over time.

Restoring Damaged or Uneven Concrete Floors: Over time, concrete floors may develop cracks, dips, or uneven surfaces. Self-leveling compounds are an excellent solution for repairing and restoring these floors to a smooth, level finish.

Garage and Basement Floors: Self-leveling is often used in garages and basements where the floor may have significant unevenness or cracks. The compound creates a durable surface that can withstand heavy loads, making it ideal for these spaces.

Commercial and Industrial Spaces: In commercial and industrial environments where floors endure heavy foot traffic or machinery use, self-leveling compounds provide a strong, flat base. They ensure the floor is durable enough to handle the stress while maintaining a smooth appearance.

5. Conclusion

Self-leveling is a highly effective and efficient way to correct uneven floors, providing a smooth, level surface that is ready for any type of flooring installation. Its ease of application, durability, and quick-drying properties make it a go-to choice for both residential and commercial projects. Whether you’re dealing with a damaged concrete floor, preparing a subfloor for new flooring, or fixing uneven surfaces, self-leveling compounds offer a reliable, cost-effective solution that ensures long-lasting results.

0 notes

Text

Should I Glue Vinyl Sheet Flooring?

Vinyl sheet flooring installed using adhesive can be stable and long-lasting, holding up against wear and tear over time. This technique provides stability and lowers the chance of shifting over time, making it perfect for locations with a lot of foot traffic or wetness. However, in order to produce a smooth, even application, sufficient surface preparation is essential. Adhesion procedures and adhesive choices must be done according to manufacturer instructions for a successful and long-lasting installation. Vinyl sheet flooring is a suitable option for both home and business areas since glue can improve its performance and longevity. If you want to buy sheet vinyl flooring UK, bathroom waterproof flooring, etc visit Vinyl Flooring UK!

Glue Down Vinyl Flooring:

As the name implies, glue is needed to install glue-down vinyl flooring. Although this installation process is not as quick and easy as click-lock vinyl flooring, it may be less expensive. Each board must be adhered to the subfloor with adhesive. Glue-down planks are a suitable choice in situations where the subfloor may not be exactly even because they can be utilized with both plywood and concrete subfloors.

The advantages of glue-down vinyl:

There are a few reasons as to why glue-down vinyl is preferable to the other choices. Glue-down flooring is a common choice for big and commercial settings since it requires less expansion than floating flooring. A floating floor also requires transitions, which a glue-down alternative eliminates.

In places where the substrate may not be completely level, glue-down vinyl flooring can also be utilized. With glue-down vinyl flooring, an underlayment is also not necessary.

How to install vinyl:

1. Prior to anything else, you must measure the space in order to install new vinyl flooring. Recall that we will figure this out when you submit your drawings and measurements, so don't include any wiggle room in your measurements. Include any fixtures you may have in your space, such as a washbasin or toilet, in the overall measures of the space, as these will need to have the vinyl sheet removed.

2. Next, make an effort to remove as much furniture as you can from the space. Eliminating any potential obstructions will make the process of placing the large sheet of vinyl into place a little bit easier.

3. You can draw the shape of the room onto your new vinyl by using the old vinyl floor you're removing as a template. Very useful if you have a small room because you may cut it to fit in a place where you have more room.

4. Ensure that your subfloor is clear of dirt, dry, smooth, and structurally sound. If you've torn off old vinyl or laminate, you may need to scrape off the old adhesive.

5. To enable the vinyl to get to room temperature, move the roll into the designated room at least 24 to 48 hours before installation.

6. When unrolling your vinyl, align the longest side of the sheet with the longest accessible wall and place it around 25 mm from the skirting board.

7. Since your rooms' skirting boards are frequently not perfectly straight, a scribing gauge will aid in the vinyl's ability to sit flush against the wall. Find an off-cut piece of wood, then hammer a nail into it approximately 30 mm from one end until the tip just protrudes from the opposite side to create a scribing gauge.

8. To softly score the skirting's outline onto the vinyl, move the gauge carefully along the skirting with the nail. After cutting along this line with your Stanley knife, slide the vinyl up against the skirting board.

9. To make the vinyl lie flat on interior corners, cut a tiny triangle out of each corner.

10. To create a distinct crease, press the vinyl between the skirting and the floor with the bolster chisel.

11. Holding the knife at a small angle, cut along the seam with your straight edge and knife.

12. If there are any external corners, cut the vinyl exactly where it meets the floor, then trim away any extra, leaving 50–100 mm of excess vinyl at the skirting boards.

13. With a bolster chisel, press into the angle formed by the skirting and the floor. Using an angled knife to achieve a clean finish, hold your straight edge against the crease and cut along it.

14. The vinyl sheet needs to be adhered to the floor once it has been laid completely. Lift the vinyl's edges, apply glue around the room's perimeter, and then press down to apply loose-lay vinyl. Roll half of the vinyl back before spreading glue across the floor to ensure it is fully adhered. Replacing the vinyl, move to the opposite side of the room, and continue the process there. After repositioning the entire vinyl floor, use a soft broom to press it flat.

15. It's a good idea to use silicone to cover the floor's borders when installing vinyl in a bathroom to make sure the surface is totally waterproof.

Vinyl Installation Around Door Frames:

Cut down to where the vinyl meets the floor with your Stanley knife, then continue cutting at equally spaced intervals around the door frame. Remove any surplus material by cutting, but leave about 50 to 100 mm of tail at the bottom so that you may trim more precisely. Press the vinyl into the angle formed by the door frame and the floor with the bolster chisel to create a crease, and then cut along it. Install a door bar to secure the vinyl flooring in place after making a straight cut across the doorway to finish it about halfway beneath it.

Putting Vinyl Around A Radiator Pipe:

Using your knife, cut a straight line from the vinyl's edge to the pipe. Next, repeatedly make small cuts around the pipe's base until the vinyl is flat. For a tidy, expert finish, trim off any excess.

Installing Vinyl At Exterior Corners:

To trim excess vinyl from external corners, cut straight down the vinyl's edge to the floor, leaving 50–100 mm of extra vinyl turned up at the skirting. Press into the angle where the skirting meets the floor with a bolster chisel. To achieve a clean finish, hold the knife at a small angle and cut along each crease with the straightedge pressed against it.

0 notes

Text

Durable Laminate Flooring in India: The Ultimate Choice for Modern Homes

In today’s fast-paced world, homeowners are constantly looking for flooring solutions that offer both style and durability. One option that stands out, especially in India’s diverse climate, is durable laminate flooring. Known for its resilience, affordability, and aesthetic appeal, laminate flooring has become a popular choice for residential as well as commercial spaces.

Why Choose Laminate Flooring?

Durability: Laminate flooring is built to withstand high traffic, making it ideal for busy households and commercial areas. Its multi-layer construction includes a wear layer that protects against scratches, stains, and fading, ensuring longevity even under harsh conditions.

Easy Maintenance: One of the key benefits of laminate flooring is its low maintenance. Regular sweeping and occasional damp mopping are usually sufficient to keep the floor looking as good as new. It doesn’t require the specialized cleaning that natural wood or marble might need.

Affordability: Compared to traditional hardwood or stone flooring, laminate flooring is far more budget-friendly. This makes it an excellent option for homeowners who want the look of luxury without the hefty price tag.

Variety of Designs: Laminate flooring comes in a wide range of designs, including realistic wood and stone finishes. Whether you're aiming for a classic oak look or a contemporary marble design, you can find laminate flooring that fits your aesthetic.

Environmental Impact: Laminate flooring is often made from recycled materials, and many manufacturers are committed to sustainable production practices. This makes it an eco-friendly choice for conscious consumers.

Laminate Flooring in Indian Homes

India’s climate varies dramatically from region to region, ranging from humid coastal areas to dry, hot interiors. One of the best features of laminate flooring is its adaptability to different environments. In humid areas, its water-resistant properties ensure that the flooring doesn’t warp or swell, while in dry areas, it resists cracking and shrinking.

Furthermore, laminate flooring is well-suited for Indian homes that face high foot traffic, especially in urban settings where space is often maximized with multi-purpose rooms.

Installation: A Quick and Easy Process

Laminate flooring is relatively easy to install, often using a click-lock system that doesn’t require adhesives or nails. This not only reduces the time and cost of installation but also allows for easy replacement if necessary. Many homeowners opt for DIY installation, but professional help can guarantee perfect results, especially for large spaces.

Find the Best Laminate Flooring in India

When it comes to durable laminate flooring in India, quality is paramount. A trusted supplier can offer products that are not only beautiful but also long-lasting, ensuring value for money. One such reputable name in the laminate flooring industry is Kronotex, known for its premium products that blend cutting-edge technology with timeless design.

Whether you are renovating your home or designing a new space, choosing durable laminate flooring can elevate the look and feel of your interiors while providing a sturdy foundation for everyday life. Explore the options available at Kronotex to find the perfect fit for your home.

1 note

·

View note

Text

Glues adhesive Manufacturers | Chemline Global

CHEMICRYL Dry Lamination Adhesive performs well on all kind of Dry lamination sheet fed machine like Wen Chyuan, YiiLee, Paper Plast, Billhofer, Zhonke etc.

Excellent performance over all kind of lamination film, i.e. — PET, MET PET, BOPP, MET BOPP, BOPP MATT, (PEARL Finish), Holographic Films etc

CHEMLINE Manufacturers a full range of Hot Melts for Book Binding Adhesives with a brand name of QUIKLOCK in both granules & pillows form. There different grades for A rt Paper Books, Maplitho Pa per (Wood Free Paper) books for high speed multi clamp machines etc. like KOLBUS, MILLER• MARTLNI etc. Our products gives better lab test like Page Pull Test, Flex Test. It gives good adhesive layer for proper spine.

The products have been designed to be Odour free with Good Thermal Stability and reduced charring characteristics. These are special grades suitable for extreme climates conditions.

0 notes

Text

Wondering How Long DTF Transfers Last? A Guide to DTF Durability

Introduction

Direct to Film (DTF) printing has grown in popularity because to its ability to generate colourful and detailed transfers on a variety of surfaces. However, one common concern among supporters is, "How long do DTF transfers last?" Understanding the longevity of DTF prints is critical for those wanting long-term and high-quality outcomes. In this tutorial, we'll look at the elements that influence the duration of DTF transfers, as well as methods for increasing their longevity.

Quality of Materials:

The endurance of DTF transfers is greatly dependant on the quality of the materials utilised. Invest in high-quality DTF film, inks, and adhesives that are particularly engineered for longevity. High-quality materials improve adhesion, colour retention, and resistance to fading over time.

Proper Printing Technique:

Achieving a long-lasting DTF transfer begins with suitable printing processes. Make sure your DTF printer is properly set up, and use the suggested settings for both the printer and the DTF film. Proper curing and drying durations are also important for the print's lifespan.

Substrate Selection:

The type of material to which the DTF transfer is done may affect its longevity. Different fabrics, such as cotton, polyester, or mixes, may necessitate special ink formulas or pre-treatments for effective adherence. Additionally, choosing substrates with correct cleaning and maintenance instructions might help to ensure a longer-lasting print.

Post-Processing and Curing:

After applying the DTF transfer to the base, follow the post-processing and curing instructions specified by the ink and film manufacturers. Curing the print properly helps to fix the ink, making it more resistant to washing, abrasion, and environmental exposure.

Washing and Care Instructions:

Proper care and maintenance are vital for extending the life of DTF transfers. Encourage end users to follow particular cleaning guidelines, such as using gentle detergents, washing inside out, and avoiding high-temperature wash cycles. Providing explicit maintenance directions will allow people to enjoy the prints for a longer amount of time.

UV and Environmental Exposure:

Exposure to ultraviolet (UV) radiation and extreme climatic conditions might shorten the life of DTF transfers. Consider the printed item's intended purpose and if it will be exposed to sunshine, rain, or other factors. UV-resistant inks and laminates are recommended for outdoor applications.

Testing and Quality Assurance:

DTF transfers should be tested on a regular basis using simulated wear and washing conditions. This helps to discover possible concerns early on and enables for changes to the printing process or material choices. Quality assurance procedures help to achieve sturdy and long-lasting prints.

Conclusion

DTF transfers have transformed the world of custom printing by providing detailed and bright graphics on a variety of substrates. Maximising the lifetime of these prints necessitates meticulous attention to detail throughout the printing process, from material selection to post-processing and maintenance recommendations. By investing in high-quality materials, adhering to best procedures, and teaching end-users on correct maintenance, you can ensure that DTF transfers endure a long time, offering long-term delight for individuals who value the beauty of personalised prints.

Check out our Facebook Page and Community Group for offers and more updates.

0 notes

Text

Solvent Base Inks

Solvent-based inks are manufactured by several reputable companies in India, offering a wide range of products tailored to various printing needs. These inks are specifically formulated to dissolve in solvents and are commonly used in printing applications where fast drying and durability are essential.In India, manufacturers of solvent-based inks adhere to stringent quality standards to ensure optimal performance and reliability. These companies employ advanced technology and expertise to produce inks that deliver vibrant colors, excellent adhesion, and resistance to fading and abrasion.

0 notes