#Drainage Geocomposite

Explore tagged Tumblr posts

Text

The Role of Geosynthetic Materials in Modern Construction

Learn how important it is to use Geosynthetic Materials, geonets, and geocells while building roads. Explore the uses, advantages, and future of strong, sustainable roads.

#Geosynthetic Companies In India#Geosynthetic Companies In Vadodara#Geosynthetic Products#Salt Barrier#Drainage Geocomposite#Geonet#indonetgroup#indonet#makeinindia#safenetservices

0 notes

Text

Drainage Geocomposite Specifications in Delhi NCR - Underground drainage: They are installed under roads, sports fields, and other structures to collect and channel water away from the surface, preventing stagnation and maintaining stability. Full and containment walls: drainage geocomposites Manufacturers and Suppliers in Delhi, India are used in health filling systems and behind the containment walls to manage leachate and groundwater, reducing hydrostatic pressure and improving the stability of the structures.

0 notes

Text

Global Geocomposites Market: Key Drivers, Challenges, and Opportunities

Rising Infrastructure Development and Environmental Protection Efforts Propel Growth in the Geocomposites Market.

The Geocomposites Market Size was valued at USD 445.3 million in 2023, and is expected to reach USD 776.0 million by 2032, and grow at a CAGR of 6.4% over the forecast period 2024-2032.

The Geocomposites Market is fueled by increasing demand for cost-effective, durable, and sustainable solutions in construction, transportation, and environmental applications. Geocomposites, which are a combination of geotextiles, geogrids, geomembranes, and other geosynthetic materials, provide enhanced drainage, reinforcement, filtration, and barrier functions. With rising investments in infrastructure projects, road construction, and waste management, the demand for high-performance geocomposites is surging globally.

Key Players

ABG Limited

Atarfil

BASF

BOSTD Geosynthetics

Freudenberg Performance Materials

Geomembranes & Geotextiles

Geosynthetics

GSE Environmental

HUESKER

L & M Construction Chemicals

Emerging Trends and Future Scope

The Geocomposites Market is evolving with increased adoption in smart infrastructure projects and sustainable construction. Government regulations promoting environmental protection are driving the use of geocomposites in landfill management, water containment, and erosion control. The demand for lightweight and high-strength geocomposites is also rising in railway stabilization, road widening, and tunneling projects.

Additionally, advancements in bio-based and recyclable geocomposites are gaining momentum as industries seek eco-friendly alternatives to traditional materials. The expansion of geocomposites in offshore and marine applications, such as coastal protection and oil spill containment, further broadens the market scope. With increasing focus on climate-resilient infrastructure, geocomposites are playing a critical role in flood mitigation, stormwater management, and soil stabilization.

Key Market Points

Growing demand for geocomposites in construction, transportation, and waste management

Rising investments in smart infrastructure and climate-resilient projects

Advancements in eco-friendly and recyclable geocomposite materials

Increasing use of geocomposites in railways, roads, and tunneling applications

Government regulations supporting geocomposites for environmental sustainability

Conclusion

The Geocomposites Market is poised for significant expansion as industries and governments prioritize durability, sustainability, and cost-efficiency in infrastructure development. With the increasing adoption of advanced geosynthetics for environmental protection, road stabilization, and water management, the market is expected to grow steadily. Companies investing in innovative, high-performance, and eco-friendly geocomposites will shape the future of civil engineering and sustainable construction.

Read Full Report: https://www.snsinsider.com/reports/geocomposites-market-3057

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Geocomposites Market#Geocomposites Market Size#Geocomposites Market Share#Geocomposites Market Report#Geocomposites Market Forecast

0 notes

Text

Geosynthetics in Mining: Enhancing Safety and Environmental Protection

Mining operations are essential for global industrial growth, but they also pose significant challenges related to safety and environmental sustainability. The extraction of minerals and metals generates massive amounts of waste, soil instability, and water contamination risks. Geosynthetics have emerged as a crucial solution to these challenges, improving mine safety, controlling erosion, and minimizing ecological impact. A trusted geosynthetic manufacturer provides a range of innovative products that enhance the structural integrity of mining infrastructure while protecting the environment.

1. The Role of Geosynthetics in Mining

Mining sites involve extensive land excavation, tailings management, and waste containment, all of which require durable and reliable materials to prevent soil erosion and contamination. Geosynthetics, including geotextiles, geomembranes, geogrids, and geosynthetic clay liners (GCLs), provide reinforcement, filtration, and containment functions critical to mining operations.

By incorporating geosynthetics, mining companies can enhance site stability, improve safety, and comply with environmental regulations, making these materials indispensable for modern mining practices.

2. Key Geosynthetic Applications in Mining

a. Tailings Management and Waste Containment

Mining activities generate large volumes of tailings—fine waste materials left after mineral extraction. Without proper containment, tailings can contaminate water sources and lead to hazardous environmental consequences. Geomembranes and GCLs act as impermeable barriers that prevent leakage, protecting groundwater and surrounding ecosystems.

b. Heap Leach Pads for Metal Recovery

Heap leaching is a widely used process for extracting metals like gold, silver, and copper from ore piles. Geosynthetics such as high-density polyethylene (HDPE) geomembranes create leak-proof barriers that prevent toxic leachate from seeping into the ground. This ensures efficient metal recovery while safeguarding the environment.

c. Slope and Soil Stabilization

Mining operations often involve excavation in unstable terrains, increasing the risk of landslides and erosion. Geogrids and geotextiles reinforce weak soils, providing stability to mining roads, embankments, and tailings dams. These materials enhance load-bearing capacity and prevent ground failure, improving worker safety.

d. Water Management and Drainage Systems

Water accumulation in mining pits and processing facilities can lead to operational disruptions and safety hazards. Drainage geocomposites and geonets facilitate efficient water management by redirecting excess water and preventing soil saturation. This reduces risks related to flooding and structural failures.

e. Dust and Erosion Control

Dust pollution is a major concern in mining areas, affecting air quality and worker health. Geotextiles and erosion control blankets prevent dust dispersion and stabilize exposed soil surfaces, reducing environmental impact and maintaining regulatory compliance.

3. How Geosynthetics Improve Safety in Mining

Mining sites present various safety hazards, including ground instability, tailings dam failures, and exposure to hazardous materials. Geosynthetics mitigate these risks by:

Preventing soil and slope failures: Geogrids reinforce embankments, reducing landslide risks.

Containing hazardous materials: Geomembranes prevent toxic seepage into the environment.

Reducing dust inhalation: Geotextile covers limit airborne contaminants.

Enhancing road durability: Geosynthetics improve load distribution on haul roads, minimizing wear and tear.

By using geosynthetics, mining companies can create a safer work environment and reduce accident-related liabilities.

4. Environmental Benefits of Geosynthetics in Mining

Environmental sustainability is a growing priority in the mining industry. Geosynthetics help mining companies minimize their ecological footprint through:

Leak-proof containment systems that protect water bodies from toxic waste.

Erosion control measures that preserve surrounding landscapes.

Efficient water management that prevents contamination and wastage.

Reduced reliance on natural resources, as geosynthetics replace traditional construction materials like gravel and clay.

A geosynthetic manufacturer specializing in mining applications provides customized solutions that align with environmental regulations and promote sustainable mining practices.

5. Choosing the Right Geosynthetic Manufacturer for Mining Applications

Selecting a reliable geosynthetic manufacturer is crucial for ensuring high-performance materials that withstand harsh mining conditions. When evaluating manufacturers, consider:

Material quality and certifications to meet industry standards.

Customization options tailored to specific mining site requirements.

Expertise in mining applications to provide proven solutions.

Technical support and consultation for proper material selection and installation.

Investing in high-quality geosynthetics from a trusted manufacturer ensures long-term durability, operational efficiency, and environmental protection.

Conclusion

Geosynthetics have revolutionized the mining industry by enhancing safety, improving waste containment, and promoting environmental sustainability. Whether stabilizing slopes, preventing toxic leaks, or managing water resources, these materials play an essential role in modern mining operations. Partnering with a leading geosynthetic manufacturer ensures access to advanced solutions that optimize mining infrastructure while minimizing ecological impact. As the mining industry continues to evolve, geosynthetics will remain a key component in building a safer and more sustainable future.

0 notes

Text

Understanding the Different Types of Geocells and Their Uses

Geocells are three-dimensional, honeycomb-like structures made from polymer materials, which have become increasingly popular in civil engineering and construction. They are designed to provide soil stabilization, erosion control, and various other geotechnical applications. This article delves into the different types of geocells available in the market and their diverse uses, emphasizing the importance of sourcing from reliable Geocell suppliers in India, particularly those dealing with geocell material in Ahmedabad, as well as prominent geocell manufacturers in India.

Types of Geocells

Geocells can be classified based on material, structure, and application. The most common types include:

1. Polyethylene Geocells

Polyethylene geocells are widely used due to their durability and resistance to environmental factors. These cells can withstand extreme temperatures and are resistant to chemicals, making them suitable for various applications, including road construction and erosion control. They are often manufactured by geocell manufacturers in India, ensuring that local projects can utilize quality materials tailored for specific conditions.

2. Polypropylene Geocells

Polypropylene geocells are known for their flexibility and lightweight nature. These cells are particularly useful in applications requiring easy installation and transportation. Their high tensile strength and resistance to ultraviolet (UV) rays make them suitable for landscaping and erosion control in areas exposed to sunlight. Companies that supply geocell materials in Ahmedabad often offer polypropylene options, catering to regional requirements.

3. Geocomposite Geocells

Geocomposite geocells combine different materials, such as geotextiles or geogrids, with traditional geocell structures. This innovative design enhances the geocell's properties, offering improved drainage and filtration capabilities. They are particularly beneficial in applications involving water management, such as retaining walls and drainage systems. These products are increasingly available through specialized geocell suppliers in India, focusing on composite materials.

4. Heavy-Duty Geocells

Heavy-duty geocells are designed to withstand extreme loads and are typically used in high-traffic areas. These cells can support heavy vehicles and equipment, making them ideal for construction sites, industrial applications, and military uses. They provide excellent stability and can be filled with various materials, including soil, gravel, or concrete. Local geocell manufacturers in India often produce heavy-duty options to meet the demands of various industries.

Applications of Geocells

The versatility of geocells allows them to be used in numerous applications. Below are some common uses that illustrate their significance in modern engineering and construction.

1. Soil Stabilization

One of the primary uses of geocells is soil stabilization. By confining soil within their three-dimensional structure, geocells help prevent erosion and improve load distribution. This application is vital for constructing roads, parking lots, and other surfaces where soil stability is crucial. Geocell suppliers in India often highlight their products’ effectiveness in enhancing soil strength and preventing failure.

2. Erosion Control

Erosion control is another significant application of geocells. They are effective in preventing soil erosion on slopes, riverbanks, and coastlines. When filled with soil or vegetation, geocells promote vegetation growth while protecting the underlying soil from water and wind erosion. This application is particularly relevant in regions prone to heavy rainfall or high winds, where erosion can lead to significant land loss.

3. Retaining Walls

Geocells are increasingly used in constructing retaining walls. Their ability to retain soil while providing structural support makes them an ideal choice for slopes and embankments. The cells can be filled with various materials, allowing for flexibility in design and construction. The use of geocells in retaining walls not only enhances stability but also minimizes the environmental impact of traditional concrete walls.

4. Access Roads and Pavements

Geocells provide an excellent solution for constructing access roads and pavements in areas with unstable soil. By distributing the load evenly, geocells prevent pavement cracking and subsidence, extending the lifespan of the road surface. This application is particularly important in remote or challenging terrains where conventional paving methods may be inadequate. Geocell material in Ahmedabad can be tailored to meet the specific requirements of such projects.

5. Landfill and Waste Management

Geocells play a vital role in landfill and waste management applications. They are used to stabilize waste piles and manage leachate by facilitating drainage. Their three-dimensional structure allows for effective waste containment while minimizing environmental impact. This application is increasingly relevant in regions focused on sustainable waste management practices.

6. Landscaping and Recreation

Geocells are also popular in landscaping and recreational applications. They can be used to create green roofs, permeable pavements, and other sustainable designs that promote drainage and vegetation growth. By incorporating geocells, landscape architects can achieve aesthetic and functional goals while reducing runoff and improving water quality.

Selecting the Right Geocell Supplier

When choosing geocell suppliers in India, it is essential to consider several factors to ensure that the products meet project requirements. Look for suppliers that offer a range of materials, including those made from polyethylene and polypropylene, as well as composite options. Ensure that the supplier has a proven track record in the industry and offers reliable customer support.

Importance of Local Suppliers

Sourcing geocell material in Ahmedabad or other local regions can lead to significant advantages, including reduced transportation costs and quicker delivery times. Local suppliers often have a better understanding of the regional soil conditions and environmental factors, allowing them to recommend the most suitable geocell types for specific projects.

Quality Assurance

Always check for quality assurance certifications from Geocell manufacturers in India. Reputable manufacturers will adhere to industry standards and regulations, ensuring that their products are reliable and effective. Quality assurance also contributes to the longevity and performance of geocells in various applications.

Conclusion

Understanding the different types of geocells and their diverse applications is essential for engineers, contractors, and project managers. From soil stabilization to erosion control, geocells offer a versatile solution to many modern construction challenges. By partnering with reliable geocell suppliers in India and sourcing quality geocell material in Ahmedabad, stakeholders can ensure the success of their projects. As the demand for sustainable and effective construction solutions continues to grow, geocells will remain an integral part of the engineering landscape.

FAQs related to geocells:

1. What are geocells?

Geocells are three-dimensional, honeycomb-like structures made from polymers, such as polyethylene or polypropylene. They are used in various civil engineering applications to provide soil stabilization, erosion control, and load support.

2. What are the main types of geocells?

The main types of geocells include:

Polyethylene Geocells: Known for durability and chemical resistance.

Polypropylene Geocells: Lightweight and flexible, suitable for landscaping.

Geocomposite Geocells: Combine different materials for improved drainage and filtration.

Heavy-Duty Geocells: Designed to withstand extreme loads for high-traffic areas.

3. What are the applications of geocells?

Geocells are used in various applications, including:

Soil Stabilization: Enhancing soil strength for construction projects.

Erosion Control: Preventing soil erosion on slopes and riverbanks.

Retaining Walls: Providing structural support and soil retention.

Access Roads and Pavements: Distributing loads to prevent cracking and subsidence.

Landfill Management: Stabilizing waste and managing drainage.

Landscaping: Promoting vegetation growth in sustainable designs.

0 notes

Text

Masonry Waterproofing Solutions: Protecting Your Investment | Murphy Masonry

Masonry structures, such as walls, foundations, and patios, are susceptible to water damage, which can lead to costly repairs and structural problems. To protect your investment, it's essential to implement effective masonry waterproofing solutions.

Murphy Masonry, a leading provider of masonry services, offers a variety of waterproofing solutions tailored to your specific needs. Here are some common techniques:

Waterproofing Coatings Acrylic-Based Coatings: These coatings form a durable, flexible membrane that repels water and prevents moisture penetration. Silicone-Based Coatings: Silicone coatings are highly resistant to moisture and UV rays, making them ideal for exterior surfaces. Elastomeric Coatings: These coatings expand and contract with temperature changes, ensuring effective waterproofing even in harsh conditions.

Waterproofing Membranes Rubberized Bitumen Membranes: These membranes are highly durable and provide excellent waterproofing protection. PVC Membranes: PVC membranes are lightweight, flexible, and resistant to chemicals and UV rays. Geocomposite Membranes: These membranes combine a geotextile fabric with a waterproofing layer, providing both drainage and waterproofing benefits.

Waterproofing Systems Drain Tile Systems: These systems collect and redirect water away from the foundation, preventing moisture buildup. French Drain Systems: French drains are a type of subsurface drainage system that helps to relieve hydrostatic pressure and prevent water from entering the basement. Foundation Waterproofing: This involves applying waterproofing materials to the exterior or interior of the foundation to prevent water infiltration.

Preventative Measures Proper Grading: Ensure that the grade of your property slopes away from the foundation to prevent water from pooling around the building. Regular Maintenance: Inspect your masonry structures regularly for signs of damage or water infiltration. Avoid Overwatering: Be mindful of overwatering your landscaping, as excess water can lead to moisture problems.

By implementing effective masonry waterproofing solutions and taking preventative measures, you can protect your investment and ensure the longevity of your masonry structures. Murphy Masonry can provide expert advice and services to help you choose the right waterproofing solution for your specific needs.

0 notes

Text

Southern Geosynthetics Supplies (SGS) is a specialist distributor of quality geosynthetic products. SGS represents some of the biggest names in the industry including Huesker soil reinforcement geogrids, DUX geotextiles, ABG drainage geocomposites and Rainsmart stormwater products. Local support in Sydney and Melbourne is provided by our qualified sales professionals backed-up by the full resources of major manufacturers.

0 notes

Text

Geosynthetics Market Overview: Growth Factors and Future Trends (2023-2032)

The geosynthetics market is projected to grow from USD 7,857.78 million in 2023 to USD 13,368.05 million by 2032, at a compound annual growth rate (CAGR) of 5.90%.

The geosynthetics market encompasses a wide range of synthetic materials used in civil engineering, construction, and environmental applications to enhance the performance and durability of infrastructure projects. These materials include geotextiles, geomembranes, geogrids, geonets, geocomposites, and geosynthetic clay liners, each serving specific functions such as separation, filtration, reinforcement, drainage, and containment. The market has witnessed significant growth due to the increasing need for sustainable and cost-effective solutions in infrastructure development, particularly in sectors like transportation, water management, mining, and waste management.

One of the primary drivers of the geosynthetics market is the burgeoning demand for infrastructure development across emerging economies. Rapid urbanization and industrialization in countries like China, India, and Brazil have led to extensive construction activities, necessitating the use of geosynthetics for road construction, railway stabilization, and erosion control. In developed regions, such as North America and Europe, the focus is on the maintenance and upgrade of existing infrastructure, where geosynthetics provide long-term durability and performance enhancements, reducing maintenance costs and extending the life of structures.

Environmental concerns and stringent regulations regarding waste management and pollution control have further propelled the adoption of geosynthetics. These materials play a crucial role in landfill linings, wastewater treatment facilities, and environmental remediation projects by providing effective containment solutions that prevent contamination of soil and groundwater. The growing emphasis on sustainable construction practices and the need for efficient water management systems, especially in arid regions, have also contributed to the increased use of geosynthetics in applications such as reservoirs, canals, and dams.

Technological advancements have significantly improved the quality and functionality of geosynthetic products. Innovations in material science have led to the development of high-performance geosynthetics with enhanced properties such as increased tensile strength, chemical resistance, and UV stability. These advancements have expanded the application scope of geosynthetics, enabling their use in more demanding and specialized projects. Additionally, the integration of geosynthetics with other construction materials and systems has created new opportunities for multifunctional solutions that address complex engineering challenges.

The geosynthetics market dynamics encompass various factors that influence its growth, development, and competitive landscape. These dynamics include market drivers, restraints, opportunities, and trends. Understanding these dynamics is essential for stakeholders to make informed decisions and strategize effectively. Here are the key market dynamics of the geosynthetics industry:

Market Drivers

Infrastructure Development

Rapid urbanization and industrialization in emerging economies drive the demand for new infrastructure projects such as roads, highways, railways, and airports. Geosynthetics are extensively used in these projects for soil stabilization, reinforcement, and erosion control.

Environmental Regulations

Stringent environmental regulations related to waste management, water pollution, and soil contamination are promoting the use of geosynthetics. These materials are crucial in applications like landfill liners, wastewater treatment facilities, and containment systems to prevent environmental degradation.

Sustainable Construction Practices

The growing emphasis on sustainable construction practices and green building initiatives is boosting the adoption of geosynthetics. These materials contribute to sustainability by enhancing the durability and longevity of infrastructure, reducing maintenance costs, and minimizing environmental impact.

Technological Advancements

Innovations in material science and manufacturing processes have led to the development of high-performance geosynthetics with superior properties such as increased tensile strength, chemical resistance, and UV stability. These advancements have expanded the application scope of geosynthetics.

Water Management

The need for efficient water management systems, especially in arid and semi-arid regions, drives the demand for geosynthetics in applications like reservoirs, canals, dams, and drainage systems. Geosynthetics help in water conservation and management, essential for agriculture and urban development.

Market Restraints

Fluctuating Raw Material Prices

The prices of raw materials used in the production of geosynthetics, such as polypropylene and polyethylene, are subject to fluctuations due to market conditions and supply chain disruptions. This can impact production costs and profit margins for manufacturers.

Lack of Standardized Regulations

Inconsistent regulatory standards and quality benchmarks across different regions can lead to variability in product performance and reliability. The lack of standardization poses challenges for manufacturers and users in ensuring consistent quality and compliance.

Market Education and Awareness

Limited awareness and understanding of the benefits and applications of geosynthetics among engineers, contractors, and policymakers can hinder market growth. Educating stakeholders about the advantages and proper usage of geosynthetics is crucial for wider adoption.

Market Opportunities

Emerging Markets

Emerging economies in Asia-Pacific, Latin America, and Africa present significant growth opportunities for the geosynthetics market. Increasing infrastructure development, urbanization, and industrialization in these regions drive the demand for geosynthetics.

Integration with Advanced Technologies

The integration of geosynthetics with advanced technologies, such as smart sensors and monitoring systems, can create new opportunities for multifunctional solutions that address complex engineering challenges. These innovations can enhance the performance and efficiency of geosynthetic applications.

Expansion of Application Areas

The development of new and innovative geosynthetic products tailored for specific applications, such as marine engineering, agriculture, and renewable energy projects, can open new markets and drive growth.

Market Trends

Sustainability Focus

There is a growing trend towards sustainability in the geosynthetics market, with manufacturers adopting eco-friendly practices, such as using recycled materials, reducing carbon footprints, and developing biodegradable geosynthetics.

Rising Demand for Geotextiles

Geotextiles are one of the most widely used geosynthetic products due to their versatility and effectiveness in various applications, including filtration, separation, reinforcement, and drainage. The demand for geotextiles is expected to continue rising, driven by their widespread use in infrastructure projects.

Collaborations and Partnerships

Strategic collaborations and partnerships between geosynthetic manufacturers, research institutions, and industry stakeholders are becoming increasingly common. These collaborations aim to drive innovation, improve product quality, and expand market reach.

Increased Investment in R&D

Companies are investing heavily in research and development to develop advanced geosynthetic products with improved properties and performance. Continuous innovation is key to maintaining a competitive edge in the market.

Key Player-

AGRU Kunststofftechnik GmbH

Low & Bonar PLC

Tensar Corporation

Raven Industries, Inc.

Thrace Group

GSE Environmental Inc.

Officine Maccaferri S.p.A.

Koninklijke Ten Cate B.V.

HUESKER Synthetic GmbH

Solmax International Inc.

Geofabrics Australasia Pty. Ltd.

More About Report- https://www.credenceresearch.com/report/geosynthetics-market

Geosynthetics Market Regional Insights

North America:

Market Characteristics: North America is a mature market for geosynthetics, with a high level of adoption across various applications such as infrastructure, environmental protection, and construction.

Key Drivers: The region's growth is driven by stringent environmental regulations, significant investments in infrastructure rehabilitation, and the presence of major industry players. The demand for sustainable construction materials and technologies also propels the market.

Notable Projects: Large-scale infrastructure projects, such as highway expansions, airport renovations, and waste management initiatives, utilize geosynthetics extensively.

Future Outlook: Continued investment in infrastructure modernization and environmental sustainability initiatives is expected to sustain market growth.

Europe:

Market Characteristics: Europe also represents a significant share of the geosynthetics market, characterized by high regulatory standards and a strong focus on environmental sustainability.

Key Drivers: The European market is driven by the need for advanced waste management solutions, erosion control, and sustainable construction practices. Government regulations mandating the use of environmentally friendly materials further support market growth.

Notable Projects: Prominent applications include landfill liners, road construction, and coastal erosion protection projects.

Future Outlook: With ongoing efforts towards green infrastructure and sustainable urban development, the market is expected to maintain a steady growth trajectory.

Asia-Pacific:

Market Characteristics: Asia-Pacific is the fastest-growing region for geosynthetics, driven by rapid urbanization, industrialization, and infrastructure development in countries like China and India.

Key Drivers: The region's growth is fueled by massive infrastructure projects, including road and railway construction, water management systems, and urban development. The increasing awareness of environmental protection and the benefits of geosynthetics also contribute to market expansion.

Notable Projects: Significant projects include large-scale dam constructions, coastal protection works, and urban infrastructure upgrades.

Future Outlook: The region is expected to witness continued robust growth due to ongoing urbanization, government initiatives, and increasing investments in infrastructure and environmental projects.

Latin America:

Market Characteristics: The Latin American market is growing, albeit at a slower pace compared to Asia-Pacific, driven by infrastructure development and environmental protection efforts.

Key Drivers: Economic development, urbanization, and the need for improved infrastructure and environmental management are the primary drivers. Countries like Brazil and Mexico are leading the regional market.

Notable Projects: Key applications include mining operations, road construction, and waste management projects.

Future Outlook: Growth is expected to continue as governments and private sectors invest in infrastructure and environmental sustainability, though economic and political challenges may pose occasional hindrances.

Middle East and Africa:

Market Characteristics: The Middle East and Africa region is an emerging market for geosynthetics, with significant potential for growth due to ongoing infrastructure development and environmental challenges.

Key Drivers: The market is driven by large-scale infrastructure projects, including roads, railways, water management systems, and oil and gas industry applications. Environmental protection and the need for sustainable construction materials also support market growth.

Notable Projects: Major projects include desert reclamation, coastal protection, and infrastructure development in urban areas.

Future Outlook: The market is expected to grow as countries in the region invest in modernizing infrastructure and addressing environmental concerns, though geopolitical instability and economic variability may impact growth rates.

Segments:

Based on Product Type:

Geotextile

Geomembrane

Geogrid

Geonet

Geocomposite

Geosynthetics Clay Liner

Others

Based on Material Type:

Polyethylene (HDPE/LLDPE)

Polypropylene (PP)

Polyester

Natural fibers

Others

Based on Primary Application:

Separation

Drainage & Filtration

Reinforcement

Containment

Browse the full report – https://www.credenceresearch.com/report/geosynthetics-market

Browse Our Blog: https://www.linkedin.com/pulse/geosynthetics-market-analysis-global-industry-ocoef

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

10 Ways for Slope Protection & Stabilization

Slopes, whether natural or man-made, are a ubiquitous feature of our landscapes. However, they can be susceptible to erosion, landslides, and other failures. This can create safety hazards, damage infrastructure, and disrupt natural ecosystems.

Fortunately, a variety of Slope Stabilization Solutions exist to ensure the stability and longevity of slopes.

Let's explore ten effective methods:

1. Vegetation and Bioengineering: Planting native grasses, shrubs, and trees on slopes helps bind soil particles together, reducing erosion. This natural approach also promotes habitat creation and aesthetics.

2. Geosynthetic Reinforcements: These include geotextiles, geogrids, and geocomposites – synthetic materials placed within the soil to increase its strength and stability.

3. Terracing and Grading: Creating terraces (stepped sections) or modifying the slope's angle reduces the overall inclination and gravitational forces, enhancing stability.

4. Retaining Walls: Constructed walls made of concrete, masonry, or steel can physically support and retain soil on steep slopes.

5. Soil Nailing: This technique involves installing closely spaced grouted nails into the slope to reinforce the soil and prevent movement.

6. Shotcrete: A sprayable concrete applied to the slope face creates a protective layer that binds soil particles and strengthens the surface.

7. Gabion Walls: Flexible and robust walls constructed from interlocking wire mesh baskets filled with stones offer strong erosion and slope protection. Explore companies like gabion wire mesh manufacturers in India like Shrisai for high-quality options.

8. Drainage Systems: Proper drainage controls are crucial. Ditches, channels, and perforated pipes help divert excess water away from slopes, preventing saturation and potential landslides.

9. Biodegradable Mats: These temporary biodegradable mats made from natural materials like jute or coir help hold soil in place during the initial establishment of vegetation on slopes.

10. Ground Improvement Techniques: Techniques like compaction, grouting, or chemical stabilization can improve the properties of weak soils and enhance their overall stability.

Choosing the Right Slope Stabilization Solution

The optimal slope stabilization method depends on various factors: slope angle, soil type, budget, and environmental considerations. Consulting a qualified geotechnical engineer helps determine the most effective and sustainable solution for your specific needs.

The Importance of Slope Stabilization

Implementing Slope Stabilization Solutions offers numerous benefits:

Safety: Reduces the risk of landslides and protects infrastructure and property from damage.

Erosion Control: Minimizes soil erosion, maintaining land integrity and preventing sedimentation in waterways.

Aesthetics: Stabilized slopes can be visually appealing, especially when incorporating natural elements like vegetation.

Environmental Benefits: Slope stabilization contributes to healthy ecosystems by promoting vegetation growth and preventing soil loss.

Slope stabilization is crucial for ensuring the safety and integrity of our landscapes. By understanding the various methods available and consulting with professionals, you can find the most effective solution to secure your slopes and promote a healthy environment.

#gabion manufacturer#gabion exporters#gabion walls#Rockfall Protection & Mitigation#Slope Stabilization Solutions#Shri Sai Eco Solutions

0 notes

Text

Geosynthetics Market Analysis: Trends Shaping the Future

In the rapidly evolving world of civil engineering and infrastructure development, the Geosynthetics Market plays a pivotal role in enhancing the sustainability, durability, and cost-effectiveness of construction projects. Geosynthetics are engineered materials that offer a wide range of applications, from soil stabilization to erosion control, and they have been instrumental in reshaping the way we build and maintain our infrastructure. In this blog, we'll delve into the world of geosynthetics, exploring their various applications, the market trends, and their role in creating more sustainable construction practices. Geosynthetics Market is anticipated to reach a valuation of USD 19,677.2 million and will grow at 6% CAGR from 2023 to 2033.

The Geosynthetics Revolution

Geosynthetics are synthetic materials made from polymers such as polypropylene, polyethylene, and polyester. They come in various forms, including geotextiles, geogrids, geomembranes, and geocomposites. These materials are designed to enhance the mechanical and hydraulic properties of soils, creating a stronger and more durable foundation for construction projects. The applications of geosynthetics are vast and varied, making them an integral part of modern infrastructure development.

Get Free Sample Copy of This Report: https://www.chemviewconsulting.com/request-sample/geosynthetics-market

Applications of Geosynthetics

Soil Stabilization: Geosynthetics are used to improve the load-bearing capacity of soils. They are often employed in road construction to reduce settlement, increase bearing capacity, and extend the lifespan of pavement.

Erosion Control: Geotextiles, in particular, are used to prevent soil erosion in areas prone to heavy rainfall and runoff. They can be used in coastal protection, riverbank stabilization, and other applications where soil needs to be protected from erosion.

Waste Containment: Geomembranes are critical components of waste containment systems, such as landfills and wastewater treatment plants. They prevent the leakage of hazardous materials into the environment, safeguarding public health and the ecosystem.

Geogrids for Reinforcement: Geogrids are used to reinforce soils and provide structural stability in applications like retaining walls, embankments, and steep slopes.

Drainage Systems: Geocomposites are used in drainage systems to manage excess water in various infrastructure projects, including roads, sports fields, and airport runways.

Market Trends and Growth

The geosynthetics market has been experiencing significant growth in recent years, driven by several key factors:

Infrastructure Investment: Governments and private sectors worldwide are investing heavily in infrastructure development. Geosynthetics are being increasingly adopted to ensure the longevity and cost-efficiency of these projects.

Environmental Concerns: Geosynthetics help reduce the environmental impact of construction activities by minimizing soil erosion, pollution, and waste. This aligns with the growing global emphasis on sustainability.

Technological Advancements: Ongoing research and development have led to the creation of more advanced and effective geosynthetic materials, expanding their range of applications.

Urbanization: The increasing urbanization trend worldwide has created a demand for efficient construction methods that make the most of available space. Geosynthetics contribute to this by enabling the construction of reliable and long-lasting infrastructure in urban environments.

Creating Sustainable Infrastructure

One of the most significant contributions of geosynthetics to the construction industry is their role in sustainable development. These materials allow engineers and builders to design and construct infrastructure that is more environmentally friendly and economically viable. Here's how geosynthetics contribute to sustainability:

Reduced Environmental Impact: Geosynthetics minimize soil erosion and the need for large quantities of natural resources, leading to a reduced environmental footprint in construction projects.

Extended Lifespan: Infrastructure built with geosynthetics often has a longer lifespan due to improved soil stabilization and erosion control. This reduces the need for frequent repairs and replacements.

Cost Savings: By reducing maintenance and repair costs, geosynthetics contribute to cost-effective construction practices.

Versatility: Geosynthetics can be used in a wide variety of projects, from road construction to water management, making them a versatile solution for sustainable infrastructure development.

Request for Customization: https://www.chemviewconsulting.com/request-customization/geosynthetics-market

The geosynthetics market is a driving force behind the transformation of the construction and infrastructure industry. As our world faces growing environmental challenges and a need for efficient and cost-effective construction practices, geosynthetics offer a versatile and sustainable solution. By preventing soil erosion, stabilizing foundations, and safeguarding against environmental hazards, these engineered materials are shaping a brighter and more sustainable future for our infrastructure.

As governments and industries continue to prioritize sustainability, the geosynthetics market is poised for even greater growth and innovation, leading the way to a more resilient and eco-friendly built environment. With their ever-expanding applications and benefits, geosynthetics are proving to be an essential component of modern construction practices.

#Geosynthetics Market#Geosynthetics Market Size#Geosynthetics Market Share#Geosynthetics Market Demand

0 notes

Text

Geocomposites Market Outlook: Geotechnical Engineering and Environmental Stewardship

Geocomposites Market Full Information:

Geocomposites are advanced materials designed to address various challenges in geotechnical and civil engineering applications. These materials typically consist of a combination of geotextiles, geogrids, and/or geomembranes, which are layered or combined to provide improved mechanical and hydraulic properties. Geocomposites play a crucial role in various construction and environmental projects, contributing to their durability and effectiveness.

In the market overview and scope, geocomposites have witnessed significant growth due to their versatile applications across multiple industries. They are extensively used in soil stabilization, erosion control, drainage systems, and landfill engineering, among other applications. The market scope extends to infrastructure development, environmental protection, and geotechnical engineering, making it a dynamic and evolving sector.

Geocomposites market growth in the industry is driven by several factors. Increasing infrastructure development, particularly in emerging economies, has heightened the demand for geocomposites. Their use in road construction, railways, and hydraulic engineering projects has surged, promoting market expansion. Additionally, growing environmental concerns and the need for sustainable solutions have further fueled the adoption of geocomposites in landfills, wastewater treatment, and erosion control initiatives.

The geocomposites industry comprises various players, including manufacturers, suppliers, and distributors. Competition in this sector is intense, with companies continuously innovating to improve the performance and sustainability of their products. Market players often focus on developing custom geocomposites to cater to the specific needs of different projects, enhancing their market presence and reputation.

In terms of trends, the geocomposites market is witnessing a shift towards eco-friendly and recyclable materials. Sustainability has become a key driver, with consumers and project developers preferring environmentally responsible solutions. This has led to the development of geocomposites that use recycled materials and are designed for easy disposal or reuse, aligning with circular economy principles.

Furthermore, the integration of advanced technologies, such as geosynthetics with monitoring systems, is gaining prominence. These smart geocomposites can provide real-time data on structural integrity and environmental conditions, offering a new dimension to project management and maintenance. Such innovative solutions are likely to reshape the geocomposites market in the coming years.

In conclusion, the geocomposites market is a thriving industry that plays a crucial role in the fields of geotechnical and civil engineering. It offers versatile solutions for infrastructure development, environmental protection, and sustainability. As the industry continues to evolve, we can expect to see further advancements in material composition and technology integration to meet the growing demands of modern construction and environmental projects.

0 notes

Text

Geosynthetic Materials in Modern Construction: Modern Uses & Benefits

In today's dynamic world of construction, geosynthetic materials have proven to be invaluable resources. Engineered to enhance the performance and longevity of various construction applications, these materials have brought about significant advancements in the industry. This article explores the multifaceted uses and advantages of geosynthetics, with a particular focus on their role in road construction and building projects.

Introduction to Geosynthetics

What are Geosynthetics?

Geosynthetics are synthetic materials specially manufactured for use in civil engineering, environmental, and construction projects. These engineered materials offer a wide range of properties and applications that contribute to the strength, stability, and sustainability of construction projects.

Geosynthetics in Road Construction

Overview and Applications

In road construction, geosynthetics have become indispensable for enhancing performance and durability. They are used for soil stabilization, base reinforcement, erosion control, and drainage, among other applications.

Geocells in Road Construction

Geocells are three-dimensional honeycomb-like structures that provide soil stabilization and load support. They are particularly effective in road construction over weak subgrades, reducing the risk of road deformation and failure.

Geogrid for Road Construction

Geogrids, with their grid-like structure, are used for soil reinforcement. They are essential in reinforcing the road base, improving load-carrying capacity, and extending the lifespan of roads.

Use of Geosynthetics in Road Construction

The use of geosynthetics in road construction enhances soil properties and aids in overcoming challenges like unstable soil, poor drainage, and high maintenance costs.

Benefits of Geosynthetic Materials in Construction

Enhanced Durability and Strength

Geosynthetic materials significantly increase the durability and load-bearing capacity of roads. This leads to a reduction in road damage and extends the overall lifespan of the construction.

Cost-Effectiveness

By improving soil stability and strength, geosynthetics reduce the need for traditional, more expensive construction materials like aggregates. This results in cost savings both in the short and long term.

Environmental Sustainability

Geosynthetics offer an environmentally friendly solution in construction. Their use minimizes the disturbance of natural soil layers and reduces the need for non-renewable resources.

Adaptability and Versatility

These materials are adaptable to a variety of soil types and construction conditions. Their versatility makes them suitable for a wide range of applications beyond road construction, including railways, landfills, and water containment systems.

Challenges and Considerations

Technical Expertise

The installation and utilization of geosynthetic materials require specialized knowledge and technical expertise. Proper installation is crucial for maximizing their effectiveness.

Quality and Standards

Maintaining high quality and adherence to standards is essential for the optimal performance of geosynthetic materials. This underscores the importance of choosing reliable and experienced manufacturers.

The Future of Geosynthetics in Construction

Innovations and Developments

The future of geosynthetics in construction is bright, with ongoing research and development. Innovations in material science and technology are continuously enhancing the capabilities and applications of geosynthetic materials.

In conclusion, geosynthetic materials have played a pivotal role in revolutionizing modern construction practices. As the industry continues to evolve, these engineered materials will remain at the forefront of innovation and sustainability.

Introducing Indonet Group

As a leading geosynthetics manufacturer based in Vadodara, India, Indonet Group offers a comprehensive product lineup that includes Indodrin geocomposites, Indian Geocell, Indo Drain geonets, and more. With a commitment to quality and innovation, Indonet Group continues to contribute to the advancement of the construction industry through the use of geosynthetic materials.

#Geotextiles#geosynthetic materials#indonetgroup#indonet#Geocell#geonets#Geocomposite#Salt Barriers#Dimple Boards

0 notes

Text

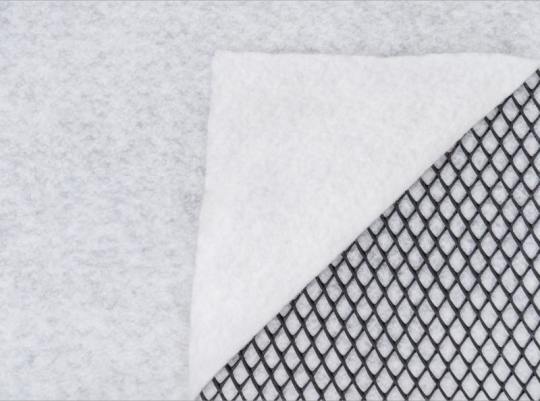

Drainage filtration using geocomposites to prevent silt and soil particles from clogging pipes or raising friction levels. Geocomposites are made up of a geonet and a synthetic needle-punched geotextile that are joined together with heat.

0 notes

Text

Patented Blue Roof Design - ABG Geosynthetics

ABG blueroof restrictor chamber – unique design features

Along with the attenuation void formers, the stormwater restrictor chamber is one of the key components of a Blue Roof SuDS system design. The chambers are fitted above each rainwater outlet (or to the side when close to parapet walls), and are designed to restrict rainfall outflow during key design storm events. When it comes to choosing a Blue Roof system, not all designs are equal however, and ABG’s patented ABG blueroof design includes some specific features to provide additional safeguards against blockages and debris entering the water network.

During typical rainfall events the water simply flows through the chamber’s orifices and drains into the rainwater outlets as it would on a normal roof drainage design (for over 84% of the year). During the high intensity or long duration rainfall of the key design storm events however, the chambers begin to restrict outflow.

Currently in the UK the key design storm event is the 1-in-100 year design storm event, plus 40% allowance for the effects of climatic change. This is either based on the Flood Studies Report (FSR) or Flood Estimation Handbook (FEH) rainfall data for the location. During the key storm events the water flow is reduced to the maximum discharge rate, as agreed with the project engineer at design stage, via sized orifices in the vertical wall of the restrictor chamber.

The ABG blue roof restrictor chamber also features an integral internal overflow weir, which is set at the maximum depth of the Blue Roof system and only comes into effect in the case of an exceedance event or any blockages on the surrounding roof area. The ABG design is different to most competitor systems that feature a flat restrictor plate placed horizontally over the RWO to limit discharge. The limitations of this type of flat plate design is that they can potentially become more easily blocked with debris, or simply be damaged / removed and not replaced correctly. They also cannot be used for parapet outlet positions, unlike the ABG blue roof system.

As part of the ABG system design, the chamber’s control orifices are protected by an additional filter strip in order to prevent blockages and maintain the required maximum flow rates. These filters are then checked as part of the six-monthly maintenance checks.

The filter strips form part of a triple layer of rainwater filtration provided throughout the system build up, with the attenuation void formers being fully wrapped in a filter / separation geotextile, in addition to a perforated geocomposite drainage board layer with bonded geotextile installed on top of the void formers. All these geotextile layers serve to provide added protection and security to prevent debris from entering the system whilst filtering pollutants from the rainfall.

The ABG restrictor chambers are available in different formats and for different roof build-ups i.e. inverted, warm or un-insulated roof areas. Different designs are also available to suit the roof’s final surface finish or use, for example whether the roof is for maintenance access only, amenity pedestrian access or fire engine / traffic loading on an accessed podium deck.

0 notes

Text

Innovations in Geosynthetics: What Manufacturers Are Bringing to the Market

Geosynthetics have transformed modern engineering and construction practices, offering solutions for challenges such as soil stabilization, erosion control, and environmental sustainability. As the demand for advanced materials grows, geosynthetic manufacturers are continuously innovating to develop products that meet the evolving needs of infrastructure, environmental, and geotechnical projects. This article explores the latest innovations in geosynthetics and how manufacturers are driving advancements in this dynamic field.

Understanding Geosynthetics

Geosynthetics are synthetic materials used in geotechnical applications. These include geotextiles, geogrids, geomembranes, geocells, geonets, and geo-composites. Their primary functions include reinforcement, separation, filtration, drainage, and containment, making them indispensable for projects ranging from roads and railways to landfills and coastal protection.

As industries demand more efficient, sustainable, and durable solutions, geosynthetic manufacturers are rising to the challenge by introducing cutting-edge materials and technologies.

Innovations in Geosynthetics

Here are some of the most significant innovations brought to the market by geosynthetic manufacturers:

1. Advanced Polymer Technologies

Modern geosynthetics leverage advanced polymers that enhance strength, durability, and flexibility. Innovations in polymer science have led to geosynthetics that are resistant to chemical exposure, UV radiation, and extreme temperatures, making them ideal for diverse environments.

Impact: Longer lifespans and reduced maintenance costs.

2. Biodegradable Geosynthetics

Sustainability is a top priority for industries worldwide. Manufacturers are now producing biodegradable geosynthetics, which decompose naturally after fulfilling their purpose, such as temporary erosion control.

Impact: Reduced environmental footprint, aligning with green construction practices.

3. Multi-Functional Geocomposites

Geocomposites combine two or more geosynthetic materials to perform multiple functions simultaneously, such as drainage and reinforcement. These products offer enhanced efficiency and reduce the need for additional materials.

Impact: Cost savings and simplified installation processes.

4. Smart Geosynthetics

The integration of sensors and smart technology into geosynthetics is a game-changer. Smart geosynthetics can monitor stress, strain, moisture levels, and temperature in real-time, providing critical data for infrastructure health monitoring.

Impact: Improved maintenance strategies and early detection of potential failures.

5. Recycled Geosynthetics

In response to environmental concerns, manufacturers are creating geosynthetics from recycled materials without compromising performance. These products support sustainable construction practices and contribute to circular economies.

Impact: Lower carbon footprint and reduced waste in production.

6. High-Strength Geogrids

Recent advancements in geogrid technology have resulted in products with exceptional tensile strength and load-bearing capacity. These high-strength geogrids are particularly useful for large-scale infrastructure projects such as highways and railways.

Impact: Enhanced structural stability and extended project lifespans.

7. Innovative Installation Techniques

Manufacturers are designing geosynthetics that are easier and faster to install. Pre-cut panels, adhesive-backed membranes, and modular systems reduce labor time and costs while improving project efficiency.

Impact: Faster project completion and reduced installation errors.

8. Hydraulic Geosynthetics

Hydraulic geosynthetics, such as improved geomembranes and geonets, are designed to manage water flow more effectively. These products are particularly valuable in water reservoirs, canals, and landfill applications.

Impact: Enhanced water management and reduced leakage risks.

9. Anti-Microbial Geotextiles

In applications where contamination is a concern, such as landfill covers or wastewater treatment, manufacturers are introducing anti-microbial geotextiles to inhibit the growth of harmful microorganisms.

Impact: Improved safety and longevity in critical projects.

10. Carbon Footprint Analysis in Manufacturing

Leading geosynthetic manufacturers are integrating carbon footprint analysis into their production processes. By optimizing material use and energy consumption, they aim to create eco-friendly products with a reduced environmental impact.

Impact: Support for sustainable development goals and green certifications.

Benefits of Innovations in Geosynthetics

The advancements in geosynthetics are providing numerous benefits to construction and engineering projects:

Cost Efficiency: Multi-functional and durable products reduce material and maintenance costs.

Sustainability: Eco-friendly solutions align with global environmental standards.

Enhanced Performance: Smart and high-strength geosynthetics offer superior functionality.

Project Flexibility: Innovative designs cater to a wide range of geotechnical challenges.

The Future of Geosynthetics

As the construction and engineering industries face increasing challenges such as urbanization, climate change, and resource scarcity, geosynthetic manufacturers will continue to innovate. Future developments may include:

Wider adoption of AI-driven smart geosynthetics.

Enhanced recycling and reuse of geosynthetic materials.

New composites tailored for specific environments and industries.

These advancements will further cement geosynthetics as an essential component of modern infrastructure development.

Conclusion

The relentless innovation by geosynthetic manufacturers is reshaping the way construction and engineering projects address challenges like soil stability, erosion control, and environmental protection. With advancements ranging from biodegradable materials to smart geosynthetics, these products are not only improving project efficiency but also contributing to sustainability goals. As industries demand smarter, greener, and more cost-effective solutions, geosynthetics are poised to remain at the forefront of modern engineering innovation. By adopting these advanced materials, businesses can ensure durable and environmentally responsible infrastructure for the future.

0 notes

Text

LRK Geotech Geosynthetic Manufacturer in India

LRK Geotech Pvt Ltd is one of the leading suppliers of a broad variety of Geotextiles, HDPE Geomembranes, Geosynthetic Clay Liners, Geobags, Geogrids, Geonets, Geocomposites, Geotubes, Geocells, Geofoams, and Gabions. Further, we have expanded our business horizons providing turnkey solutions to our clients. We have carved a position in the market by offering outstanding services right from the designing, commissioning, installing and servicing to our customers.

#enviromental#landfill#waste management#soil management#aqua culture#geosynthetics#geomembrane#geotextile#geosynthetic clay liner#storage blocks#geocells#geobags#drainage cell#geogrid#geonet#geotube#geocomposite#geopipe#pvd#geomat

2 notes

·

View notes