#Depth Micrometers

Explore tagged Tumblr posts

Text

Why Choose Depth Micrometers for Precision Measurements?

In the realm of precision engineering and quality assurance, precise measurements are essential. From production to research and development, confirming that components adhere to precise specifications is essential for performance, safety, and reliability. Depth micrometers are essential for obtaining this degree of precision, delivering the accuracy necessary for intricate tasks across different sectors. These specialized instruments are crafted to gauge the depth of holes, slots, and recesses with unparalleled accuracy, rendering them essential for various uses.

Depth micrometers, commonly known as depth gauges, are accurate tools utilized for measuring the depth of an item, typically from a level surface to the base of a sunken region. In contrast to regular micrometers that mainly gauge thickness or width, depth micrometers specialize solely in measuring depth, guaranteeing precision even in the tiniest dimensions. These instruments offer a range of features to accommodate various measurement situations, such as adjustable anvil sizes, dial indicators, and digital displays for straightforward and accurate readings.

The significance of depth micrometers is in their capacity to provide reliable and consistent measurements in situations where even minor variations can result in major consequences. For sectors including aerospace, automotive, metalworking, and electronics, sustaining this degree of accuracy is crucial. Depth micrometers enable experts to examine and assess components with precision, guaranteeing that each piece adheres to the necessary specifications.

A key reason depth micrometers are preferred is their adaptability. These tools can be utilized in numerous settings, ranging from highly accurate laboratories to tough manufacturing areas. Depth micrometers offer the precision needed for efficient quality control, whether assessing small parts or larger structures. Their ability to adjust to various surfaces and materials guarantees they stay essential tools in sectors where accuracy is crucial.

Depth micrometers are available in both manual and digital formats, addressing the unique requirements of various users. Manual depth micrometers are preferred for their ease of use and dependability, providing a simple method of measurement without requiring electricity or intricate electronics. Conversely, digital depth micrometers offer superior functionalities like improved data retention, simplified documentation, and instantaneous measurements, which make them perfect for contemporary, technology-oriented operations.

In addition, the progression of depth micrometers has consistently advanced alongside technological improvements. Advanced sensors and enhanced materials have resulted in measuring tools that are more accurate, durable, and efficient. These advancements have assisted manufacturers and engineers in attaining higher precision, minimizing the chances of mistakes and enhancing the overall quality of their products.

Depth micrometers are utilized in a variety of applications. In aerospace, they are utilized to assess complex components essential for aircraft performance. In the automotive industry, they guarantee that engine parts and other essential components align perfectly for optimal performance. Likewise, in metal fabrication and machining, depth micrometers are vital for verifying that complex cuts and finishes adhere to stringent standards.

Besides their technical features, depth micrometers aid in minimizing waste and enhancing efficiency. Precise measurements result in fewer defects, reduced rework, and improved overall product quality. For businesses aiming for top-quality manufacturing, utilizing depth micrometers offers a competitive edge, allowing them to achieve strict tolerances with accuracy and efficiency.

AAM Trading is recognized as a trustworthy source of top-notch depth micrometers, serving the varied demands of sectors that need accurate measurements. AAM Trading is dedicated to innovation and customer satisfaction, providing a diverse selection of depth micrometers tailored to fulfill the unique needs of contemporary manufacturing and engineering. Their products are designed with accuracy and resilience, guaranteeing peak performance in every application. At AAM Trading, customers can anticipate not just high-quality depth micrometers but also professional assistance in choosing the ideal tool for their specific requirements. The organization's commitment to delivering advanced measuring solutions, supported by outstanding customer service, positions them as a reliable partner in precision measurement. AAM Trading’s depth micrometers are crafted to provide the precision and dependability needed for success, whether in advanced research, industrial production, or routine quality checks.

0 notes

Text

I was entering data about a drill hole, things like depth and location. Except I was tired and distracted, and accidentally swapped the depth and the northing.

So for a brief moment, we had a hole that went past the centre of the Earth, that we had measured the depth of to the nearest micrometer.

It was a beautiful hole while it lasted (30 seconds, before I realised what i had done).

39 notes

·

View notes

Text

Got motivation and made a little short of my CotL AU.

Now I go sleepy

…

……..

Shamura was sitting in their bedchamber on the floor, ever-so-slightly leaning forward one micrometer a minute. Their expression was as empty as could be, the only sign of the god being alive was their pupils shaking and the rise and fall of their chest with each breath getting slower…

A few books and documents lay in front of them, why did they bring those out again? At some point, they faded away. Soon, everything faded away, and they were left in a void. A void manifested from the depths of their consciousness slipping away from reality.

Laughter rang out, bright and mirthful somewhere in the distance. It stopped and silence floated again for a moment before tiny little taps filled it. The taps were getting closer, and closer, and closer until…

“Hello!”

Shamura looked up but didn't move their head, before them was a young spider, a pretty headpiece made of repurposed cobwebs and obsidian pieces that were shaped like teardrops draped over the young spider’s forehead.

Something about this spiderling felt familiar, in a bittersweet way. A memory that used to hold comfort.

“... Hello, little one.” They straightened their back, their body felt lighter than it should've.

The little one observed Shamura before taking a seat as well, almost perfectly mirroring their pose. It raised a hand, putting another over its chest.

It smiled brightly. “I’m-”

“Shamura Ludovica Kiaaski,” Shamura finished for the spiderling. The crown on its head told them of the puzzle pieces they needed. The crown’s crescent eye staring into theirs, a familiar gaze. A bittersweet memory they're holding onto by half a thread.

“... How'd you know?” The little one giggled, rocking back and forth idly.

“I… just a hunch, per se.”

“What are you doing here?” It rolled its Rs and Ls. They knew the accent well, they lost it sometime after they found Heket.

“I know not anymore.”

It blinked at them before tilting its head. “You forget what you were doing too? It happens to me all the time! The others scold me sometimes ‘cause of that”

They knew. “A lot more than I used to…”

Silence again, lingering just above their heads.

Slowly, they brought a hand up, and it came to rest upon the spiderling’s cheek. It blinked again before it made a click with its fangs and turned into their palm with a smile, just like Shamura thought it would.

Ichor dripped down the side of their face from under the spiderweb headdress they wore. Soft words came out of their mouth before they could think about the question.“... Can you tell me who you are?”

The Godling uncovered its face enough to look at them with one eye and answer with “Why should I? Don't you already know? That's the whole point of being the God of Knowledge, right?” It giggled again, still so bright and… genuinely happy. Not a care in the world for what's to come. Suddenly, its smile turned to surprise when it looked behind Shamura, then it stood up and pointed. “Who’s that?”

They looked over it for a moment… they faintly remember the silk dress it wore… crafted by them with the help if someone dear

When did they lose it?

How long ago did they make it?

Why did it matter?

Shamura turned their head and twisted their back to see. It was the Lamb, walking up to them in the nightgown they had made for her recently and holding her two-headed lamb plushie close to her.

She stopped for a moment to close their bedchamber door. After a moment of pause, she hopped over to them and made herself comfortable in their lap.

“... Hello, my dear.” With her arrival, their bedchamber faded back into their awareness, and the light from the small window on their ceiling was gone, replaced with twinkling stars. How long have they been there?

“Hi,” she said, low and tired, definitely woken up sometime in the past hour.

They ran a claw through her wool. “Aren't you supposed to be asleep, Little Lamb?”

“... Yeah, but……”

“‘But’? What's wrong?”

The Lamb pressed her cheek against their chest. “My dreams aren't being nice to me. It started out fine, but something happened and I woke up with tears down my face,” she pouted, annoyed that was how she was woken up.

They lifted up another claw and carefully ran it over her cheek. It did feel dry like tears were there not too long ago. “If it makes you feel any better, my dreams aren't being all that nice to me either…” Would they consider that a dream or a hallucination? Did they fall asleep?

“That makes two of us… can I sleep in here until my forced vacation is over?” Right, Shamura and the others forced her to take it easy for at least a week when they noticed just how many tasks she was handling at the same time.

“If it’ll help you rest, then go ahead, Little Lamb.”

“Thank you ‘Mura” she thanked them as she squeezed her plushie and adjusted her position.

“......... You're welcome, my dear.”

#cotl#cotl shamura#cotl lamb#cotl au#CotL My Happy Ending AU#Was listening to Bad Apple and got inspired#Also threw in some fluff at the end because I couldn't help myself#When you space out so hard you hallucinate your child self from thousands of years ago#/silly#spectator not spectating

6 notes

·

View notes

Text

Holy God This Is All So Boring

i am taking microscope images of the cells i'm studying. the cells were grown on a glass plate before i fixed them (killed & chemically preserved), so by default a microscope image of them is taken from a camera below them, looking up through the glass. they're stained with fluorescent dyes for four different proteins, so every single picture has to be repeated four times with a different laser light illuminating the cells (imagine taking a photo with a red filter, a blue filter, and a green filter, and then composing them all together to get the full picture. it's actually almost exactly the opposite of that, but that's close enough).

i care mostly about how the cells are shaped in three dimensions, and i'm using a laser which is specially shaped so it can collect only a very thin slice of the cells in the Z-direction, without interference from the parts of the cells just above or just below what i'm taking pictures of. as a result, i need to take lots of pictures at different depths in the cells, so i can get slices that i can stack on top of each other and get back a 3D shape. also, because i am using a tiny concentrated beam of light to achieve the above effects, it has to scan across the image to collect each picture, like a scanner; it can't just be collected in a single snapshot like a photo.

the distance between one slice and the next is less than a quarter of a micrometer. i'm using a 63x magnified magnifying lens to magnify the image, and the light detector that picks up the light is specially made to allow the images to be processed even further, so i can resolve structures that are less than 200 nanometers, which is the Abbé limit and is the technical resolution limit of light microscopy (don't worry about this). i care about things that are the size of, like, three proteins stuck together, and therefore maybe 10nm wide, so this is important to me.

all of this is, you know, scientifically great, very useful to me, i'm getting some very interesting results that i am genuinely looking forward to thinking about more, except the upshot of all of this is that just getting a single picture of two cells from the bottom to top of the cells involves 80-100 slices and takes like 27 minutes per image to collect, and i need at least six pictures tonight, and certain bastards in certain other labs habitually pre-book the microscope so i can't use it except at 5-9pm on a friday. no one else is here in the lab and my mother is busy with elder care and my girlfriend is busy with like, groceries, so i can't call either of them even if i weren't too irritable to be good company, and oh my god, i am so bored, i am so so bored, i am bored enough even to type out this whole explanation even though none of you could possibly care because it took most of my current round of waiting for 27 minutes to do

#in theory i should collect seven additional images on top of the six named#but 'fortunately' i stained this plate a while ago and the dye for the other images has kind of faded#so instead of doing it now. i will stain another plate. and do it the next time i can wrestle four hours away from aforementioned bastards#now certain of you who are in the know about microscopes might be wondering something#''glass'' they might say#''don't all modern microscopes come with the ability to pre-select positions and then just wander off and let the microscope run on its own#all night? why stay there and do this instead of setting it up and going home?''#and yes that's correct. but there are two issues#one is that i am obviously using an oil objective and this particular one can only do 2-3 positions before it needs the oil refreshed#so i would rather notice that need prior to taking the image than the next morning#and secondly. i can't figure out where the positions function is in ZenBlue. and the scope core staff only work for a random three hours of#every day. none of which i can get a booking in anyhow. so i have no one to tell me how to find it.#box opener#doctor worm#my life is so much harder than anyone else's ever.

13 notes

·

View notes

Text

Got into an argument with a friend (derogatory) about using chatGPT for answering technical questions. And. He kept using chatGPT to “”””backup”””” his claims. He then proceeded to accuse me of not understanding the underlying technology and made fun of my coding. Not the closest I’ve come to putting a 9mm chunk of lead through that dumbass’s brain but it’s certainly in the top ten.

ChatGPT can answer questions yes, however it only gives you a vague micrometer deep understanding of the topic at hand without any of the nuance or depth that a human written article could provide. It also makes you a big dumb idiot head. Idk. It’s like intelligence loss but it’s not kinky or hot. Just sorta sad and lame. I HATE CHATGPT

ur future nurse is using chapgpt to glide thru school u better take care of urself

132K notes

·

View notes

Text

Precision Calibration Services in UAE

Middle East Calibration Lab L.L.C. is a UAE-based ISO/IEC 17025:2017 accredited calibration laboratory recognized by the Emirates National Accreditation System (ENAS). MIDDLE EAST CALIBRATION LAB L.L.C is one of the leading organizations in the field of calibration and repair of measuring instruments, testing equipment and weighing systems.

Precision Calibration Services in UAE: Trust MECL for Reliable Accuracy

Maintaining accuracy in measurement tools is essential across industries such as manufacturing, engineering, and quality control. At Middle East Calibration Lab LLC (MECL), we specialize in delivering ISO 17025 accredited calibration services across the UAE. With years of experience and a commitment to excellence, MECL ensures your equipment performs with precision. Our core offerings include Outside Micrometer Calibration, Digital Caliper Calibration, and Granite Surface Plate Calibration.

Outside Micrometer Calibration

Outside micrometers are vital instruments used for measuring external dimensions with a high degree of accuracy. Over time, factors such as wear and tear or environmental conditions can lead to deviations in measurement. MECL offers Outside Micrometer Calibration services that adhere to international standards, ensuring each device is verified for accuracy, repeatability, and traceability.

Our calibration process includes zero adjustment, inspection of spindle movement, and verification against certified gauge blocks. All findings are recorded in a detailed calibration certificate, helping clients meet both internal quality standards and regulatory compliance.

Digital Caliper Calibration

In fast-paced industries, digital calipers are a go-to tool for quick and reliable measurements. However, even slight inconsistencies can lead to costly production errors. MECL provides professional Digital Caliper Calibration services using high-precision equipment in a controlled environment.

Our experts inspect the caliper’s internal and external measurement jaws, depth gauge, and display unit. With periodic calibration, clients can ensure the longevity and accuracy of their digital calipers, enhancing both product quality and operational efficiency.

Granite Surface Plate Calibration

A granite surface plate forms the reference base for inspection, layout, and tool setup. Over time, these plates can wear out or become uneven due to constant use, leading to inaccurate measurements. MECL’s Granite Surface Plate Calibration services involve thorough cleaning, visual inspection, and a detailed flatness check using electronic levels and autocollimators.

Whether it’s a small workshop plate or a large industrial slab, we ensure your surface plate meets required specifications and standards, supporting accurate and dependable work every time.

Why Choose MECL?

ISO 17025 Accredited Lab

Highly Trained Technicians

Traceable Calibration Standards

Comprehensive Calibration Reports

Fast Turnaround Times

At MECL, our team understands the importance of reliable tools in maintaining production integrity. Our advanced equipment, combined with our commitment to customer satisfaction, sets us apart in the calibration industry.

Get in Touch

For more details about our calibration services in Dubai, Sharjah, and across the UAE, contact us today. Whether you need Outside Micrometer Calibration, Digital Caliper Calibration, or Granite Surface Plate Calibration, we are ready to help.

📞 Call us: +971 6 524 1472 📧 Email: [email protected]

Ensure precision in every measurement — partner with MECL for trustworthy calibration solutions.

0 notes

Text

Supplying Accuracy: Best Test and Measurement Equipment Providers in Qatar

Measurement instruments play a vital role across numerous professional environments, including laboratories, as well as in everyday applications. They assist in everything from ensuring product consistency to supporting precision in engineering and manufacturing processes. Arabcal, as a trusted supplier, provides these testing and measurement devices, which are key to maintaining accuracy and exactness in various industries.

Understanding Test and Measuring Instruments

Testing and measuring instruments are used to assess, evaluate, and determine physical properties such as length, mass, temperature, and pressure. They play a crucial role in maintaining precision and are essential across various fields including scientific research, construction, medical diagnostics, and the automotive industry. These devices empower users to achieve exceptional and reliable results from simple temperature gauges to advanced analytical spectrometers.

Below is a list of commonly used testing and measurement instruments, along with their respective uses and applications.

1. Thermometer

Use: Determining temperature.

Thermometers are extensively utilized in weather forecasting, scientific research, and the medical field. They come in multiple types, including digital, infrared, and mercury-based models, each tailored for specific purposes—such as measuring body temperature or monitoring the heat levels of industrial equipment.

2. Pressure gauge

Use: Determining the pressure in gases or liquids.

Across various sectors—from gas production to the oil industry—pressure gauges are widely employed to ensure operational effectiveness and safety. They also aid in monitoring equipment such as HVAC units and boilers, helping to prevent breakdowns and system failures.

3. Multimeter

Use: Measures electrical properties like current, voltage, and resistance.

A multimeter is a vital instrument that integrates multiple functionalities into one device, especially useful in electrical and electronic engineering. It helps ensure the safety of equipment and diagnose electrical faults within circuits.

4. Micrometers

Use: Provides highly accurate measurements of small dimensions.

A micrometer is used to determine the thickness, diameter, or depth of components in fields like mechanical engineering, machining, and production. It plays a crucial role in upholding quality assurance during the manufacturing process.

5. Oscilloscope

Use: Continually measures voltage signals.

In the electronics sector, oscilloscopes are used to visualize waveforms. Engineers rely on them to evaluate the performance of electrical devices, design systems, and troubleshoot circuits.

Importance of Test and Measuring Instruments

Testing and measurement devices are crucial across a wide range of industries. They are used to assess the dependability of processes, products, and even entire systems within any sector.

These instruments can detect flaws, enhance design effectiveness, and ensure regulatory adherence. Additionally, mastering the proper use of these tools is vital for maintaining precision, whether you're an engineer, scientist, or enthusiast.

Tips for Choosing the Right Measuring Instruments

Goal: Recognize the particular project requirements to choose the right tool specialized for that work. For instance, vernier calipers can be used for larger dimensions and micrometers for smaller ones.

Accuracy: Verify the precision of the tool for your use case.

Ease of Use: Use tools with digital displays or user-friendly designs to ensure ease of usage.

Durability: To ensure it can be used over a long period, choose equipment made of premium materials.

Calibration: Calibrate your instruments regularly to make them accurate and precise.

Conclusion

Cutting-edge technology is incorporated into contemporary testing and measurement instruments, such as those provided by Arabcal, to deliver real-time data, connectivity, and analysis. By enhancing speed and precision, smart devices, wireless measurement systems, and automated testing tools make businesses safer and more efficient. As a leading test and measurement instruments supplier in Qatar, Arabcal ensures that these tools are essential for achieving excellence across various industries due to their extensive applications and capabilities.

#test and measurement equipment market#instrument and equipment supplier in uae#tester equipment supplier uae

0 notes

Text

Integration of ISO 17020 Consultants into Dimensional Checks Explained

When it comes to inspection and conformity assessment, specificity and uniformity are critical. This is especially the case with industries such as manufacturing, aerospace, automotive, and heavy engineering, where even the tiniest variance in dimensions can result in significant issues with quality or product failure. Dimensional checks and systematic evaluations to ensure that components meet predetermined specifications play a critical role in mitigating these risks.

Also, significant is compliance with ISO 17020, a widely-used global standard defining the competence of inspection bodies. It specifies requirements for deciding the competence of bodies performing inspection and for the impartiality and consistency of their inspection activities. However, it can be difficult to execute this standard effectively, in particular when dealing with technical domains, such as dimensional inspection. This is where the ISO 17020 Consultants come into play.

ISO consultants in UAE are the guiding stars who help manufacturing businesses to set the best dimensional inspection process that is compliant, accurate, and contributes towards operational excellence.

Understanding ISO 17020

What is ISO 17020?

ISO/IEC 17020:2012 is an international standard that specifies the criteria for the operation of different types of bodies performing inspections. It guarantees these bodies are disinterested, technically skilled, and systematic in their inspections.

Scope and Applicability

The standard applies to organizations that are engaging in:

In-process and final product inspection

First-article inspections

Client/regulatory third-party inspections

It is a yardstick of quality and assurance in inspection activities, designated applicable to all sectors.

Standard Key Requirements

Independence and Impartiality: Inspection bodies must not be subject to commercial, financial, or other pressures that may compromise their objectivity;

Technical Competence: However, inspectors need to have the right skills, training, and experience in dimensional checks and other checks.

Inspection Approach and Reporting: Each type of inspection requires adherence to clear procedures and methods, and results need to be reported consistently and transparently.

Quality Management Systems (QMS): Document control, internal audits, and corrective actions are essential parts of a QMS to ensure continuous improvement.

What Are Dimensional Checks?

Definition and Importance

K Dimensional checks are specific measurements taken of physical components to determine if the component is built to engineering specifications. These inspections are important for:

Ensuring product quality

Maintaining tolerance levels

Preventing rework and warranty claims

Back up compliance with rules and regulations

Dimensional Inspection Common Tools

Calipers, Micrometers, and Gauges: For manual measurements of lengths, diameters, and depths.

Coordinate Measuring Machines (CMMs): For 3D dimensional measurement with high accuracy.

Laser Measuring and Vision Systems: Used for non-contact inspections in an automated environment.

Role in Product Conformance

Dimensional checks work as a gatekeeper for quality (mainly in the case of mass production). They pick up deviations early and prevent defective goods from getting out to customers or causing downstream defects.

Why Are ISO 17020 Certification Consultants Responsible?

What do ISO 17020 Consultants Do?

These experts help organizations navigate the ISO 17020 Certification in UAE process. They are well versed at interpreting the clauses of the standard and a variety of technical environments where they can be applied, such as dimensional inspections.

Services Offered

Gap Analysis and Readiness Assessment: How current inspection practices compare to the requirements of the standard.

Documentation Support: Writing up inspection written procedures, quality manuals, and compliance reports.

Training and Competency Development: Staff training related to the principles and technical inspection methods.

Internal Audits and Mock Inspections: These involve aides with an internal audit system preparing for the audits that must be performed before each certification cycle to rectify issues and make necessary improvements.

Accreditation Assistance: Working with governing bodies to maintain accreditations and assist in formal audits.

Advantages of Getting a Consultant Involved

Knowledge: The ISO 17020 Certification Consultants in Dubai understand how the standard looks in practice.

Recognizing Change: They assist in the construction of systematic, repeatable, and standardized checking systems.

Improved Compliance: Their expertise reduces the chance of non-conformities during audits.

Risk Mitigation: Consultants spot deficiencies before they result in certification delays or failures.

Incorporating Consultants in Dimensional Inspection Processes

ISO 17020 Based Fitted Plan for Dimensional Checks

Note, however, that the certification does not prescribe how to perform inspections, only that those methods be validated, repeatable, and appropriate. Dimensional inspection practice is aligned with these principles by the consultants.

At a minimum, this has to go hand in hand with accreditation requirements

ISO 17020 Certification Consultants help to write SOPs (Standard Operating Procedures) that are well-defined, consistent, and traceable. They also make sure that records of inspections, calibration, and training are well-maintained, all of which are of key importance for successful accreditation.

Developing Traceable Systems

Traceability is required with the use of tools like CMMs or laser systems. Consultants help implement:

Calibration schedules

Evaluating uncertainty measurements

Standardized reporting formats.

Equipment calibration and operator competence

A dimensional check is only as good as the tool that is being used and the person performing the check. ISO 17020 Consultants in Abu Dhabi verify:

All measuring tools are traceable and properly calibrated to national/international standards

The competency of operators is trained and tested

Challenges and Solutions

Dimensional Inspections — Common Issues

Document Shortcomings: Inadequate processes and absent checks.

Neglecting Measurement Uncertainty: Failing to properly compute or report measurement uncertainty.

Inconsistent Reporting: Different formats or auntency of results that makes it difficult to provide clarity to clients or auditors.

How Do Consultants Overcome These?

Structured Training Programs: They educate teams on the tenets of best practices, QMS requirements, and the principles of ISO 17020 Certification in UAE.

Process Optimization: Consultants tailor processes to best ensure efficiency and consistency by implementing a lean approach and process improvements through quality inspection steps.

Audit Preparation: Mock audits, as well as root cause analysis, aid in preempting external certification or surveillance visits.

Corrective Actions: Advice on finding root causes of non-conformities, making permanent corrections

The Main Point!!

When dimensional accuracy is mission-critical, precision inspections are vital to product quality. Without the guidance of ISO 17020 Consultants in UAE, organizations may struggle and take unnecessary measures in the process for effective dimensional checks. They may benefit from the guidance of ISO consultants to help organizations increase inspection outcomes more efficiently, reduce technical errors, and achieve accreditation effectively.

Consultants provide the blueprint of success from documentation to jobs, calibration to training, and compliance. They ensure that dimensional inspections are technically competent but also adhere to international quality standards.

If your organization is aiming to enhance inspection credibility, minimize errors, and ensure long-lasting quality improvements, enlist a consultant.

0 notes

Text

OKAY SO

like you've yourself mentioned in the tags! Males can't sting since a stinger is a modified ovipostor. However, some species can't really sting at all (or only very poorly), because their ovipostor is simply not a stinger! A great example would be many species of woodwasps, which, despite their fearsome looks, can't do much stinging-wise with that big ol' thing. And, if you take a look at them, you might actually confuse the ovipostor with the source of their other, lovely namesake: horntail! Now, they use this spine-like structure to drill through bark and wood so that they can insert their ovipositor into the fashioned hole and lay their eggs inside! Fun!

On the other uh. Side we have, well. A wasp that truly needs no introducing, right? The one and only Cazadore, the Orange and Blue Menace, the Tarantula Hawk. Now, as funny as its latin name - Pepsis Grossa is, (I get it dude, you prefer Coca-Cola) this beauty is no thing to laugh at. It is a parasitoid wasp, the likes of which use their sting to paralyse their prey, and then use their ovipositor-stinger to lay their eggs inside of them. (Or of they're less dramaric right next to them but, well, I'm all about the drama queens of the entomological world.) And, judging by its name, I'm sure you can figure out its favoured prey. Yes indeed, they hunt tarantulas, laying their eggs inside of their still-alive, paralysed bodies, before sragging them into their own nests. Many species of parasitoid wasp brood, once they hatch, actually know to devour the vital organs very last, so that the flesh is fresh the longest. Yum.

Some other fun ovipositor weilding wasps are fig wasps, which, if pollinating, enter the fig themselves and die inside too, alongside their brood, while if parasitoid, simply lay their eggs inside using their ovipositor. I will not continue further along their life-cycle and gladly avoid the in-depth explanation of incestuous mating of non-hatched brood and mature individuals, in what is truly a pregnancy any% speedrun.

Another great ovipositor-er is the fariryfly. It's a parasitoid and nothing about that it too special, aside from, I guess, the fact that they can be smaller than the eggs they are parasitoids of. I mean, come on, they can be as small as 100 micrometers!! That is about the average size of a human cell!!!! They're eenie meenie teeny tiny!! They're even considered as a sort of pest removal thanks to the species they parasitoid off of! Imagine that!! An army of tiny wasps to fight the pests!

*stares pointedly at mud dauber wasp* you know what you did. Airplane accidents aside...! Great wasp! They're the kinda parasitoid wasp that lays its eggs merely next to their unmoving-but-alive prey, but they do the fun thing of sealing them inside a mud tube/nest. That's fun!! Seal em inside the catacomb queen!! Really Jigsaw of you.

Anyway I'm sorry if I missed any interesting ones but these are all that immediately came to mind. Love 'em.

mm fulled of eggs

#ask and you shall receive#sorry if you knew all this tho#anyway I should get an insect rambling tag#this has happened often enough#ant talks ants#yeah sure sounds good

94K notes

·

View notes

Text

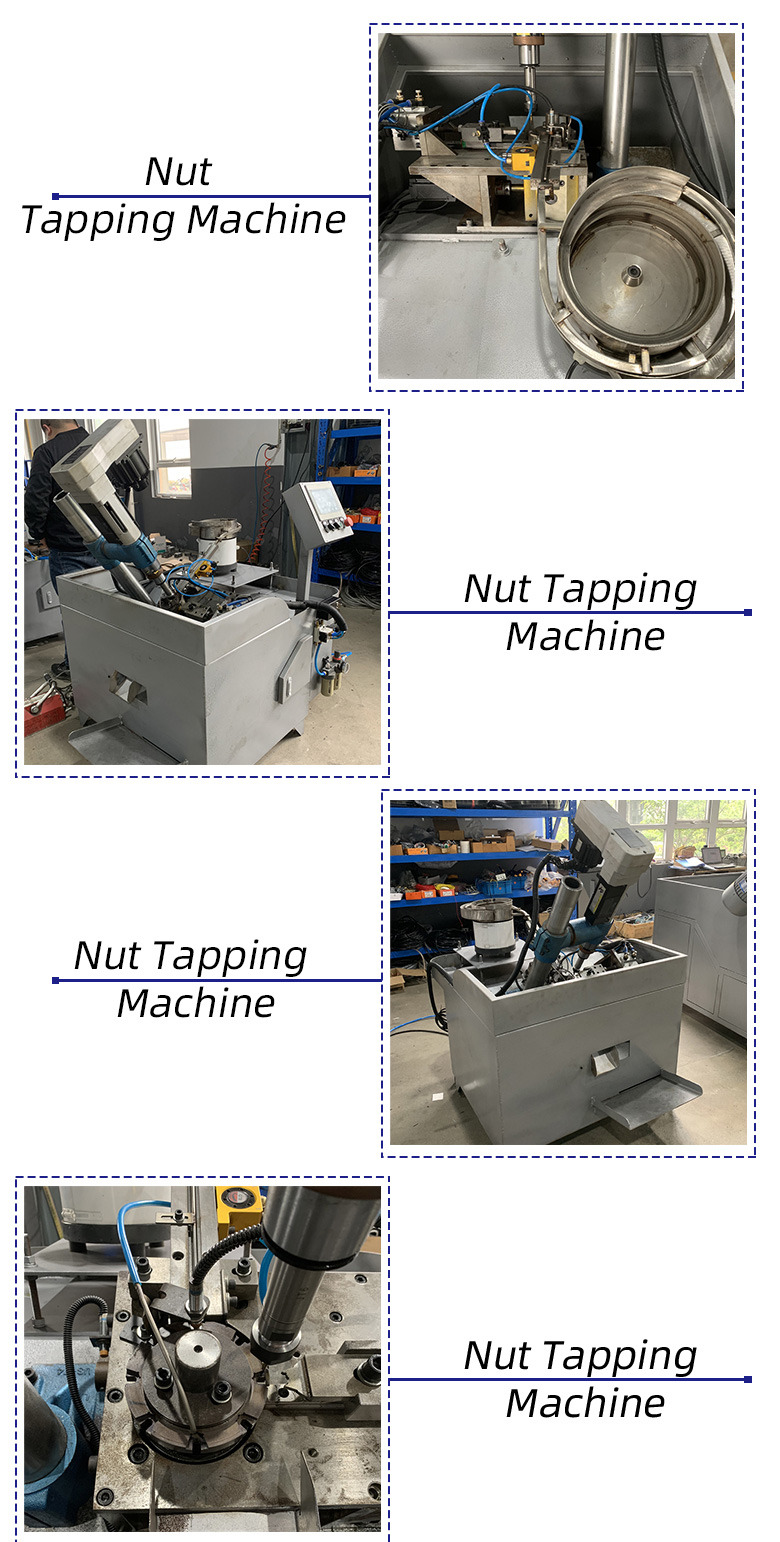

Automatic Non-Standard Nut Tapping Machine: Precision Meets Speed

For manufacturers requiring high-speed, high-precision solutions for non-standard nut production, the Automatic Non-Standard Nut Tapping Machine redefines efficiency and reliability. Designed for industrial workshops and OEM facilities, this advanced system integrates automatic loading, tapping, and unloading into a seamless workflow, ensuring consistent quality while slashing production costs and cycle times.

Why Choose Our High-Speed Tapping Machine?

End-to-End Automation Achieve uninterrupted production with fully automated loading, tapping, and unloading processes—ideal for high-volume runs of non-standard nuts with complex geometries.

Ratchet-Driven Precision A patented ratchet mechanism ensures micrometer-level positioning accuracy (±0.003mm), guaranteeing uniform thread depth and pitch across thousands of cycles.

Multi-Directional Chip Management Vertical, slant, or horizontal tapping orientations prevent chip accumulation, reducing downtime and tool wear in demanding environments.

Smart Fault Detection Infrared sensors instantly detect tap breakage or thread irregularities, halting operations to minimize material waste and costly rework.

Customizable Scalability Adapt to diverse nut sizes (M3–M24) and materials (stainless steel, titanium, and alloys) with modular tooling and bespoke configurations.

Technical Excellence for Industrial Demands

High-Speed Tapping: 5,000 RPM capability with adaptive torque control for hard-to-machine materials.

Flexible Orientation: Optimize chip evacuation for blind holes or intricate designs.

Safety Compliance: Optional safety covers and CE-certified emergency stops ensure operator protection.

Energy Efficiency: Regenerative braking reduces power consumption by 20% vs. conventional systems.

Ideal Applications

Automotive suspension nuts and custom fasteners

Aerospace titanium fittings and hydraulic connectors

Heavy machinery bolts and marine-grade components

Electronics enclosures and specialty hardware

Elevate Your Production Capabilities Today The Automatic Non-Standard Nut Tapping Machine isn’t just equipment—it’s a strategic asset for manufacturers tackling tight tolerances, exotic materials, or bespoke designs. By combining speed, precision, and adaptability, our solution empowers you to meet evolving market demands without compromise.

Contact Our Engineering Team for a Customized Production Analysis!

Limited Availability—Request a Demo or Quote Now!

0 notes

Text

video measuring cmm malaysia

The Importance of Precision Measuring Instruments in Malaysia’s Manufacturing Industry

In the fast-evolving world of manufacturing and engineering, accuracy and precision are crucial factors that determine the success of production processes. In Malaysia, industries such as automotive, aerospace, and electronics rely heavily on precision measuring instruments Malaysia to ensure the quality and reliability of their products. These tools help maintain consistency, enhance efficiency, and reduce errors, making them indispensable in high-precision manufacturing sectors.

What Are Precision Measuring Instruments?

Precision measuring instruments are specialized tools used to measure various physical dimensions, such as length, width, height, depth, and angles, with extreme accuracy. These instruments play a vital role in ensuring components meet exact specifications, which is particularly important in industries where even minor deviations can lead to significant defects or operational failures.

Types of Precision Measuring Tools

The need for high accuracy has led to the development of various precision measuring tools Malaysia, including micrometers, calipers, gauges, dial indicators, and height gauges. These tools come in different designs and functionalities, catering to different measurement needs across multiple industries. By utilizing these tools, manufacturers can maintain stringent quality control standards and ensure that their products meet the required specifications.

The Role of Coordinate Measuring Machines (CMM) in Quality Control

One of the most advanced and widely used precision measurement devices is the coordinate measuring machine Malaysia (CMM). A CMM is an essential tool in high-precision manufacturing that helps verify the dimensional accuracy of machined parts. It uses a probing system to measure the physical geometrical characteristics of an object, providing highly accurate data that helps manufacturers detect defects and maintain quality standards.

CMMs are available in different types, including bridge, gantry, and portable versions, each serving specific industrial applications. The ability to automate measurement processes makes CMMs highly efficient in ensuring consistency and repeatability in manufacturing operations.

Advancements in Hexagon Measuring CMM Technology

Technological advancements have further enhanced the capabilities of CMMs, with companies now adopting Hexagon measuring CMM Malaysia for improved accuracy and efficiency. Hexagon CMMs are renowned for their superior design and high-performance measurement capabilities. These machines use advanced software and sensor technology to deliver precise measurements, helping manufacturers optimize their quality control processes.

Hexagon CMMs are widely used in sectors that demand exceptional accuracy, such as aerospace, automotive, and medical device manufacturing. With real-time data analysis and automation features, these machines enable businesses to maintain superior quality control, reduce inspection time, and enhance overall productivity.

The Benefits of Video Measuring CMM Systems

Another cutting-edge technology making waves in the manufacturing industry is the video measuring CMM Malaysia. This advanced measurement system utilizes high-resolution cameras and digital imaging techniques to provide non-contact precision measurements. Video measuring systems are particularly useful for inspecting delicate or complex components that may be challenging to measure using traditional contact-based methods.

Industries that deal with small, intricate parts, such as semiconductor manufacturing and precision engineering, benefit significantly from video measuring CMMs. These machines offer high-speed inspections, improved accuracy, and the ability to measure components without causing any damage, making them a preferred choice for many modern manufacturing applications.

Why Choose Takumi Precision for Precision Measuring Solutions?

For businesses looking to invest in high-quality precision measuring solutions in Malaysia, Takumi Precision is a trusted provider of state-of-the-art measurement technologies. With years of experience in the industry, Takumi Precision offers a wide range of precision measuring instruments, including coordinate measuring machines, Hexagon CMMs, and video measuring systems.

By leveraging the latest advancements in measurement technology, Takumi Precision ensures that clients receive top-tier solutions tailored to their specific needs. Their expertise in providing comprehensive measurement solutions helps businesses enhance their quality control processes, minimize errors, and achieve greater efficiency in their production lines.

Conclusion

Precision measuring instruments are vital in maintaining accuracy, improving efficiency, and ensuring the highest quality standards in manufacturing processes. As industries continue to demand greater precision, adopting advanced measurement solutions such as coordinate measuring machines, Hexagon measuring CMMs, and video measuring CMMs becomes increasingly essential.

For companies in Malaysia seeking reliable precision measurement tools, Takumi Precision provides industry-leading solutions designed to meet diverse industrial requirements. By investing in cutting-edge measurement technology, businesses can optimize their quality control efforts, reduce operational costs, and stay competitive in today’s fast-paced manufacturing landscape.

Contact Us

Head Office - No. 41-G, Jalan Sierra 10/2, Bandar 16 Sierra, 47120 Puchong, Selangor, Malaysia

Email: [email protected]

Tag - video measuring cmm malaysia

1 note

·

View note

Text

AAM Trading, based in Doha, Qatar, is a trusted name in industrial and scientific solutions, offering products like Air Quality Meters, Depth Micrometers, Power Quality Analyzers, High Voltage Detectors, Thermal Imaging Cameras, Pneumatic Pumps, Sound Level Meters, Ultrasonic Thickness Gauges, pH Meters, and Heat Stress Meters. Our high-quality instruments ensure precision and reliability for diverse applications.

0 notes

Text

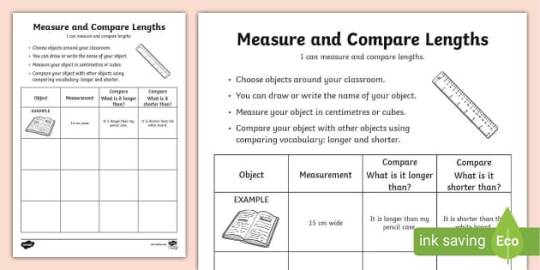

Measuring and Comparing Length: A Comprehensive Guide

Measuring and comparing length is a fundamental skill used in various fields, from science and engineering to everyday activities like cooking or home improvement. This article will provide an in-depth understanding of how to measure and compare length, the tools involved, and how to apply these skills in real-life situations. Whether you're a student, a teacher, or someone looking to improve practical knowledge, this guide will help you master the art of measurement.

Understanding Length and Its Importance

Length refers to the Measuring and comparing length worksheet from one point to another. It is one of the most basic and essential quantities in mathematics, physics, and engineering. The ability to measure length accurately is vital in many professional and daily tasks. Whether you're building a house, sewing clothes, or analyzing scientific data, the precision in measuring length can make a huge difference in outcomes.

Units of Measurement for Length

Before diving into the tools and techniques of measuring length, it's essential to understand the different units used for length.

Metric System

The metric system is the most widely used system for measuring length. The basic units include:

Millimeter (mm): 1 mm equals 0.001 meters.

Centimeter (cm): 1 cm equals 0.01 meters.

Meter (m): The standard unit of length.

Kilometer (km): 1 km equals 1000 meters.

Imperial System

In some countries like the United States, the imperial system is commonly used. The basic units in the imperial system include:

Inches (in): A small unit often used to measure short lengths.

Feet (ft): 1 foot equals 12 inches.

Yards (yd): 1 yard equals 3 feet.

Miles (mi): 1 mile equals 5280 feet.

Tools for Measuring Length

Various tools are used to measure length accurately. Some of the most common ones include:

Ruler or Measuring Tape

A ruler or measuring tape is the most basic and widely used tool for measuring length, whether in the metric or imperial system. Rulers are typically used for small objects or short distances, while measuring tapes are used for longer lengths, such as measuring a room or a building.

Calipers

For more precise measurements, calipers (such as vernier calipers or digital calipers) are used. They can measure internal and external dimensions, as well as depths, with high accuracy.

Micrometer

A micrometer is another precision instrument, mainly used in mechanical engineering to measure very small objects or thin materials, down to thousandths of a millimeter.

Measuring Wheel

For measuring large outdoor distances, such as the length of a road or a field, a measuring wheel is often used. It is rolled along the surface, and the measurement is recorded based on the number of rotations.

How to Measure Length Accurately

Accurate measurement of length requires proper technique and attention to detail. Here are some steps to follow:

Choose the Correct Tool: Select the right instrument depending on the object's size and the required precision.

Align Properly: Make sure the tool is aligned correctly with the object you are measuring. This ensures an accurate reading.

Use the Right Units: Be clear about the units you're using and convert them if necessary to maintain consistency.

Record the Measurement: Always record the measurement at the nearest millimeter or inch, depending on the tool used.

Comparing Lengths

Comparing lengths is often an essential skill, especially in fields like construction, design, or engineering. To compare lengths, you need to follow these steps:

Convert Units If Necessary: Ensure both lengths are in the same unit before comparing. For example, you cannot directly compare 10 cm and 5 inches unless you convert one to the other.

Align Objects for Comparison: Place both objects side by side or measure them from the same starting point to get a clear visual comparison.

Use a Precision Tool for More Accuracy: When comparing smaller lengths, use tools like calipers or micrometers for greater precision.

Common Mistakes to Avoid While Measuring Length

While measuring length may seem straightforward, it’s easy to make mistakes that affect the accuracy of the result. Here are some common errors to avoid:

Not Using a Level Surface

Measuring an object on an uneven surface can lead to inaccurate measurements, especially when using a tape measure or measuring wheel. Always measure on a flat, stable surface.

Incorrect Unit Conversion

Mixing up units or forgetting to convert them properly can lead to incorrect comparisons. For instance, not converting inches to centimeters when comparing two different units will give an incorrect result.

Not Considering Tool Precision

Using a tool that lacks precision for the task can lead to errors. For example, using a standard ruler for highly detailed measurements could result in a loss of accuracy.

Practical Applications of Measuring and Comparing Length

In Construction

In construction, precise measurement is crucial. Whether it's measuring the length of a beam or determining how much material is needed, accurate length measurement ensures that buildings and structures are built correctly and safely.

In Manufacturing

In manufacturing, measurements of parts or products must be exact to ensure they fit together perfectly. This is where tools like calipers and micrometers come in handy.

In Everyday Life

Even in everyday life, we measure and compare length constantly. From measuring fabric for sewing to determining the length of furniture for a room, these skills help us make decisions that fit our needs.

Conclusion

Mastering the skill of measuring and comparing length is essential for success in many areas of life. Whether you're measuring for a home improvement project, designing a new product, or simply comparing the length of two objects, having the right tools and understanding the proper techniques can make all the difference. By using accurate measurement tools, choosing the correct units, and avoiding common mistakes, you can achieve precision and accuracy in all your length-related tasks.

1 note

·

View note

Text

AAM Trading, based in Doha, Qatar, is a trusted name in industrial and scientific solutions, offering products like Air Quality Meters, Depth Micrometers, Power Quality Analyzers, High Voltage Detectors, Thermal Imaging Cameras, Pneumatic Pumps, Sound Level Meters, Ultrasonic Thickness Gauges, pH Meters, and Heat Stress Meters. Our high-quality instruments ensure precision and reliability for diverse applications.

0 notes

Text

Filtration Sterilization: (1- Depth Filter, 2- Membrane Filter, 3- Air Filter) to trap and reduce microorganisms cells from liquid solutions using 0.22 micrometer for bacteria or 10 millimeters for viruses #geneticteacher

0 notes

Text

Unleashing the Potential of Machine Vision Systems in Robotics

Introduction to Machine Vision Systems in Robotics

In the ever-evolving landscape of technology, machine vision systems in robotics have emerged as a cornerstone of modern innovation. From industrial automation to autonomous vehicles, these systems are revolutionizing how machines perceive and interact with the world. But what exactly are machine vision systems, and why are they so crucial in robotics?

What is a Machine Vision System in Robotics?

A machine vision system in robotics refers to the integration of cameras, sensors, and processing algorithms that allow robots to "see" and interpret their environment. Unlike human vision, these systems can detect details beyond the visible spectrum, enabling tasks such as object recognition, quality inspection, and spatial navigation. By mimicking the human visual system, they enhance a robot's ability to perform complex, dynamic tasks with precision.

Core Components of a Machine Vision System in Robotics

Cameras and Sensors

At the heart of any machine vision system in robotics lies its imaging hardware. High-resolution cameras, infrared sensors, and depth-sensing devices capture visual data from the environment. Advanced systems even include multi-spectral imaging to identify details invisible to the human eye.

Image Processing Algorithms

Image processing is critical in transforming raw visual data into actionable insights. These algorithms include:

Edge detection: To outline shapes and objects.

Pattern recognition: To identify specific objects or symbols.

3D mapping: To understand spatial relationships.

Artificial Intelligence and Machine Learning

AI-powered algorithms enhance the capability of machine vision systems in robotics by enabling:

Adaptive learning: Systems improve over time by learning from new data.

Real-time decision-making: Immediate analysis and response to dynamic scenarios.

Communication Interfaces

Machine vision systems rely on robust communication protocols to send data to robotic control units. Protocols like Ethernet, USB, and wireless networks ensure seamless integration into robotic ecosystems.

Applications of Machine Vision Systems in Robotics

Industrial Automation

In manufacturing, machine vision systems in robotics are indispensable for quality control and assembly line automation. Robots equipped with these systems can:

Detect product defects.

Assemble components with micrometer precision.

Reduce human error and increase efficiency.

Autonomous Vehicles

Self-driving cars are a prime example of machine vision systems in robotics at work. These systems enable vehicles to:

Recognize road signs and signals.

Avoid obstacles.

Navigate complex traffic scenarios.

Healthcare Robotics

In the medical field, robotic systems use vision technology for:

Assisting in surgeries with unparalleled precision.

Analyzing medical images for diagnostic purposes.

Handling delicate laboratory tasks.

Agricultural Robotics

Agriculture is being transformed by machine vision systems in robotics. Applications include:

Monitoring crop health using spectral imaging.

Automating harvesting processes.

Sorting and grading produce based on quality.

Challenges and Future of Machine Vision Systems in Robotics

Challenges

Despite their potential, machine vision systems face several hurdles:

High cost: Advanced hardware and software increase expenses.

Processing limitations: Real-time processing of high-resolution data requires significant computational power.

Environmental variability: Changes in lighting, weather, or object appearance can affect performance.

The Future

The future of machine vision systems in robotics is bright, driven by advancements in AI, edge computing, and sensor technologies. Emerging trends include:

Use of neuromorphic cameras for faster, energy-efficient processing.

Greater integration of machine learning to improve adaptability.

Enhanced miniaturization for portable and wearable robotic applications.

Conclusion

Machine vision systems in robotics are undeniably reshaping industries and paving the way for smarter, more autonomous machines. By enabling robots to perceive and analyze their environment, these systems unlock capabilities once thought impossible. As technology continues to evolve, the scope and impact of machine vision in robotics will only expand, driving efficiency, safety, and innovation across the globe.

FAQs on Machine Vision Systems in Robotics

What are machine vision systems in robotics?

A machine vision system in robotics is a technology that enables robots to interpret visual data from their environment using cameras, sensors, and processing algorithms.

Why are machine vision systems important in robotics?

These systems are crucial for enabling robots to perform tasks such as object recognition, navigation, and quality inspection with precision and efficiency.

What industries use machine vision systems in robotics?

Industries like manufacturing, healthcare, agriculture, and automotive heavily rely on machine vision systems for automation and innovation.

What are the challenges in implementing machine vision systems in robotics?

Key challenges include high costs, processing limitations, and environmental variability affecting system performance.

What is the future of machine vision systems in robotics?

The future involves advancements in AI, sensor technologies, and edge computing, making machine vision systems more adaptive, efficient, and accessible for a wide range of applications.

0 notes