#Data Analytics in Manufacturing Industry

Explore tagged Tumblr posts

Text

#data analytics#data visualization#datainsights#manufacturing industry#Data Analytics in Manufacturing Industry#insights

0 notes

Text

The United States Food and Drug Administration (FDA) | Chemxpert Database

In this case, the FDA plays pivotal roles in the process of approving drugs to enhance safety effectiveness and quality of the drugs used in the market. It starts with the preclinical phase and IND, then clinical trials in three phases. A new drug application (NDA) is filed with FDA following positive results from trial hearings, and the FDA examines all collected data before granting newer drugs approval for common use.

#drug database#active pharmaceutical ingredient manufacturers#FDA website#GMP in pharmaceutical industry#data analytics in pharmaceutical industry#pharma industry trends

1 note

·

View note

Text

0 notes

Text

Business Intelligence (BI) involves gathering, analyzing, and presenting data to inform better business decisions. In the manufacturing industry, BI plays a vital role in enhancing agility and driving performance improvements. Explore our latest blog to discover how BI can help transform manufacturing businesses into data-driven enterprises.

0 notes

Text

Digital Twin in Smart Manufacturing: Unlocking Efficiency and Innovation

In today’s rapidly evolving manufacturing landscape, the integration of digital twin technology has emerged as a game-changer. By creating virtual replicas of physical assets and processes, manufacturers can unlock unprecedented levels of efficiency and innovation. Companies like Web Synergies are at the forefront of this transformation, offering comprehensive solutions that enable businesses to harness the power of digital twins in their operations.

What is a Digital Twin?

A digital twin is a real-time digital replica of a physical object or system, created through the integration of Internet of Things (IoT) sensors, data analytics, and simulation technologies. It allows manufacturers to monitor, analyze, and optimize their production processes remotely. This dynamic representation provides valuable insights that drive data-informed decisions, leading to enhanced operational efficiency and reduced costs.

The Role of Digital Twins in Smart Manufacturing

Streamlining Operations

Digital twins are instrumental in streamlining operations by providing a detailed view of manufacturing processes. With Web Synergies’ Connected Manufacturing solutions, manufacturers can establish a cohesive ecosystem where every component is interconnected. This connectivity facilitates real-time monitoring and analysis, enabling manufacturers to identify bottlenecks and inefficiencies swiftly.

Enhancing Predictive Maintenance

One of the most significant advantages of digital twin technology is its ability to enhance predictive maintenance. By leveraging Intelligent Asset Management solutions from Web Synergies, manufacturers can predict equipment failures before they occur. This proactive approach not only minimizes downtime but also extends the lifespan of machinery, ultimately resulting in substantial cost savings.

Improving Quality Control

Quality control is paramount in manufacturing, and digital twins significantly enhance this aspect. With Web Synergies’ Data and Analytics services, manufacturers can perform simulations and analyses that allow them to fine-tune their production processes. By monitoring performance in real-time, manufacturers can quickly identify defects and implement corrective measures, ensuring that quality standards are consistently met.

Web Synergies’ Digital Twin Solutions

Web Synergies offers a suite of digital twin solutions designed to empower manufacturers on their journey toward Industry 4.0. By leveraging Cloud Services and Data Transformation, Web Synergies ensures that manufacturers have access to the latest technology and insights necessary for optimizing their operations. Their comprehensive approach guarantees seamless integration of digital twin technology into existing manufacturing processes.

Conclusion: Embracing Innovation with Digital Twins

As the manufacturing sector continues to evolve, embracing digital twin technology is no longer an option but a necessity for staying competitive. Companies like Web Synergies are leading the charge, providing innovative solutions that unlock efficiency and drive continuous improvement. By adopting digital twins, manufacturers can not only enhance operational performance but also foster a culture of innovation that propels them into the future.

For more insights into how digital twin technology can transform your manufacturing processes, visit Web Synergies’ blog on smart manufacturing.

#Digital Twin Technology#Smart Manufacturing#Industry 4.0#Connected Manufacturing#Intelligent Asset Management#Data Analytics#Web Synergies

0 notes

Text

ERP Data Analytics in Manufacturing with the ERP Software for manufacturing industry. For growth and sales with ERP Manufacturing Software for Small Business, Precisely for ERP for Manufacturing Company in India.

0 notes

Text

Manufacturing Analytics Services In Hyderabad - Innodatatics

With the help of our manufacturing analytics services, companies can increase operational effectiveness and promote continuous improvement by turning raw production data into useful insights. We assist manufacturers in streamlining their operations, reducing downtime, and improving the quality of their output by utilizing advanced analytics, machine learning, and real-time data visualization

#manufacturing analytics services#manufacturing analytics services in Hyderabad#manufacturing analytics services in Bangalore#manufacturing analytics services in Innodatatics#manufacturing analytics#big data in manufacturing#manufacturing data analysis#predictive manufacturing#big data analytics in manufacturing#analytics in manufacturing industry#predictive analytics manufacturing#big data analytics in manufacturing industry

0 notes

Text

Why These Process Equipment Manufacturers are Dominating the Market?

In the highly competitive industrial landscape, certain process equipment manufacturers have risen to the top, setting benchmarks for quality, innovation, and customer satisfaction. This article explores the reasons behind their dominance in the market, shedding light on their strategies, technologies, and unwavering commitment to excellence.

Commitment to Innovation and R&D

One of the primary reasons these manufacturers lead the market is their relentless focus on innovation and research and development (R&D). Investing heavily in R&D allows them to stay ahead of the technological curve and continuously improve their products.

1. Cutting-Edge Technologies

Leading manufacturers leverage cutting-edge technologies such as automation, Internet of Things (IoT), and artificial intelligence (AI) to enhance the performance and efficiency of their equipment. For example, IoT-enabled devices provide real-time data and analytics, enabling predictive maintenance and reducing downtime.

2. Sustainable Solutions

In response to global environmental challenges, top manufacturers are also pioneering sustainable solutions. They are developing energy-efficient equipment and integrating eco-friendly practices into their production processes. Innovations like energy-efficient heat exchangers and low-emission burners are just a few examples of how they are making industrial operations greener.

Customer-Centric Approach

Dominant process equipment manufacturers put their customers at the heart of their operations. They understand that meeting and exceeding customer expectations is crucial for long-term success.

(a) Customized Solutions

By offering customized solutions, these manufacturers can address the specific needs of their clients. This flexibility ensures that customers get equipment tailored to their unique operational requirements, enhancing efficiency and productivity.

(b) Exceptional Service and Support

Outstanding customer service and after-sales support further distinguish leading manufacturers. They provide comprehensive training, maintenance services, and technical support to ensure that their equipment performs optimally throughout its lifecycle.

Quality and Reliability

Quality and reliability are non-negotiable for top process equipment manufacturers. They adhere to stringent quality control measures and industry standards to ensure their products are durable and dependable.

(i) High-Quality Materials and Manufacturing Processes

Using high-quality materials and employing advanced manufacturing processes ensures that the equipment can withstand the rigors of industrial use. Rigorous testing and quality assurance protocols help maintain high standards.

(ii) Compliance with Industry Standards

Adherence to international industry standards and certifications, such as ISO 9001 and ASME, guarantees that the equipment meets the highest quality benchmarks. This compliance not only ensures safety and reliability but also boosts customer confidence.

Strategic Partnerships and Collaborations

Forming strategic partnerships and collaborations with other industry leaders and technology providers is another strategy that sets these manufacturers apart. Such alliances enable them to integrate the latest innovations and expand their market reach.

1. Collaborative R&D Projects

Collaborative R&D projects with academic institutions and research organizations help manufacturers stay at the forefront of technological advancements. These collaborations often lead to the development of groundbreaking solutions that address emerging industry challenges.

2. Supply Chain Optimization

Strategic partnerships with suppliers ensure a robust and reliable supply chain. By working closely with their suppliers, manufacturers can maintain consistent quality and timely delivery of components and materials.

Global Reach and Market Penetration

The ability to penetrate global markets is a significant factor in the dominance of these manufacturers. They have established a strong international presence through strategic market expansion and localization efforts.

(a) Local Manufacturing and Service Centers

Setting up local manufacturing and service centers enables manufacturers to cater to regional markets more effectively. This localized approach ensures faster delivery times, better customer support, and a deeper understanding of local market dynamics.

(b) Global Distribution Networks

A robust global distribution network allows these manufacturers to reach customers worldwide. Strategic partnerships with distributors and agents ensure that their products are readily available in key markets.

Emphasis on Training and Development

Investing in the training and development of their workforce is another hallmark of leading process equipment manufacturers. A skilled and knowledgeable workforce is crucial for driving innovation and maintaining high-quality standards.

(i) Employee Training Programs

Comprehensive employee training programs keep the workforce updated on the latest technologies and best practices. These programs enhance the skills of employees, enabling them to contribute effectively to the company's success.

(ii) Talent Acquisition and Retention

Attracting and retaining top talent is a priority for these manufacturers. By offering competitive compensation, career development opportunities, and a positive work environment, they ensure that they have the best minds driving their operations.

Future Outlook and Continuous Improvement

Looking ahead, dominant process equipment manufacturers are committed to continuous improvement and staying ahead of industry trends. Their forward-thinking approach ensures they remain leaders in the market.

1. Adapting to Industry Trends

Manufacturers are closely monitoring industry trends such as digital transformation, Industry 4.0, and sustainability. By adapting to these trends, they can develop innovative solutions that meet future market demands.

2. Continuous Product Development

Ongoing product development efforts ensure that manufacturers can introduce new and improved equipment to the market. Continuous innovation helps them maintain a competitive edge and cater to evolving customer needs.

In conclusion, the dominance of leading process equipment manufacturers is the result of a multifaceted approach that includes a commitment to innovation, customer-centric strategies, uncompromising quality, strategic partnerships, global reach, and a focus on continuous improvement. By excelling in these areas, they set new standards in the industry and remain at the forefront of industrial progress.

If You Want to Discover More About Process Equipment Manufacturers then Visit the Site: Jasmino

#technology#manufacturing#manufacturing industry#manufacturer#process equipment#equipment manufacturer#industry trends#industry standards#innovative technology#technological advancements#strategicpartnerships#quality assurance#data & analytics

0 notes

Text

#pressure sensor#sensors#instrumentation#measurement#engineering#technology#physics#electronics#industrial automation#process control#manufacturing#automation#IoT#smart devices#smart homes#smart cities#data analytics#data science#machine learning#artificial intelligence#automation technology#industrial automation systems#process automation#manufacturing automation#sensor technology#pressure measurement#sensor types#pressure sensor types#diaphragm pressure sensor#strain gauge pressure sensor

0 notes

Text

Power BI integration provides useful insights and improves decision-making for the manufacturing industry. It helps manufacturers enhance performance with data analytics. Read this blog to understand the role of Power BI analytics in the manufacturing industry.

#Role of Power BI in manufacturing#Power BI in manufacturing industry#Power BI in data analytics operations

0 notes

Text

Leading Global Pharma Partners with Chemxpert Database

Chemxpert Database offers access to the top 10 pharmaceutical third-party manufacturing companies in India, along with key pharmaceutical companies in Ireland, Italy, and across Europe. This comprehensive platform helps businesses connect with trusted global pharma partners for efficient production and distribution. Whether you're sourcing from India's manufacturing giants or Europe's established pharmaceutical companies, Chemxpert provides reliable data to streamline operations and ensure compliance in today's competitive market.

#pharmaceutical equipment manufacturers#analytical method development#pharmaceutical companies in France#current trends in pharmaceutical industry#pharma data analytics

1 note

·

View note

Text

AI & IT'S IMPACT

Unleashing the Power: The Impact of AI Across Industries and Future Frontiers

Artificial Intelligence (AI), once confined to the realm of science fiction, has rapidly become a transformative force across diverse industries. Its influence is reshaping the landscape of how businesses operate, innovate, and interact with their stakeholders. As we navigate the current impact of AI and peer into the future, it's evident that the capabilities of this technology are poised to reach unprecedented heights.

1. Healthcare:

In the healthcare sector, AI is a game-changer, revolutionizing diagnostics, treatment plans, and patient care. Machine learning algorithms analyze vast datasets to identify patterns, aiding in early disease detection. AI-driven robotic surgery is enhancing precision, reducing recovery times, and minimizing risks. Personalized medicine, powered by AI, tailors treatments based on an individual's genetic makeup, optimizing therapeutic outcomes.

2. Finance:

AI is reshaping the financial industry by enhancing efficiency, risk management, and customer experiences. Algorithms analyze market trends, enabling quicker and more accurate investment decisions. Chatbots and virtual assistants powered by AI streamline customer interactions, providing real-time assistance. Fraud detection algorithms work tirelessly to identify suspicious activities, bolstering security measures in online transactions.

3. Manufacturing:

In manufacturing, AI is optimizing production processes through predictive maintenance and quality control. Smart factories leverage AI to monitor equipment health, reducing downtime by predicting potential failures. Robots and autonomous systems, guided by AI, enhance precision and efficiency in tasks ranging from assembly lines to logistics. This not only increases productivity but also contributes to safer working environments.

4. Education:

AI is reshaping the educational landscape by personalizing learning experiences. Adaptive learning platforms use AI algorithms to tailor educational content to individual student needs, fostering better comprehension and engagement. AI-driven tools also assist educators in grading, administrative tasks, and provide insights into student performance, allowing for more effective teaching strategies.

5. Retail:

In the retail sector, AI is transforming customer experiences through personalized recommendations and efficient supply chain management. Recommendation engines analyze customer preferences, providing targeted product suggestions. AI-powered chatbots handle customer queries, offering real-time assistance. Inventory management is optimized through predictive analytics, reducing waste and ensuring products are readily available.

6. Future Frontiers:

A. Autonomous Vehicles: The future of transportation lies in AI-driven autonomous vehicles. From self-driving cars to automated drones, AI algorithms navigate and respond to dynamic environments, ensuring safer and more efficient transportation. This technology holds the promise of reducing accidents, alleviating traffic congestion, and redefining mobility.

B. Quantum Computing: As AI algorithms become more complex, the need for advanced computing capabilities grows. Quantucm omputing, with its ability to process vast amounts of data at unprecedented speeds, holds the potential to revolutionize AI. This synergy could unlock new possibilities in solving complex problems, ranging from drug discovery to climate modeling.

C. AI in Creativity: AI is not limited to data-driven tasks; it's also making inroads into the realm of creativity. AI-generated art, music, and content are gaining recognition. Future developments may see AI collaborating with human creators, pushing the boundaries of what is possible in fields traditionally associated with human ingenuity.

In conclusion, the impact of AI across industries is profound and multifaceted. From enhancing efficiency and precision to revolutionizing how we approach complex challenges, AI is at the forefront of innovation. The future capabilities of AI hold the promise of even greater advancements, ushering in an era where the boundaries of what is achievable continue to expand. As businesses and industries continue to embrace and adapt to these transformative technologies, the synergy between human intelligence and artificial intelligence will undoubtedly shape a future defined by unprecedented possibilities.

19 notes

·

View notes

Text

Deep Dives into Tech and Digital Growth Strategies

In an era of rapid technological advancements and evolving business landscapes, understanding the nuances of tech-driven strategies is essential for sustained growth. Companies today must leverage cutting-edge technologies and innovative digital growth strategies to stay competitive. This article takes a deep dive into the world of technology and digital strategies, highlighting how businesses can harness them to achieve their full potential.

Tech Innovation: The Catalyst for Business Evolution

Innovation in technology is reshaping industries, from manufacturing and healthcare to retail and financial services. Businesses that embrace tech innovations can unlock new opportunities and create unique competitive advantages.

Automation and AI: Automation tools and artificial intelligence (AI) are driving efficiency, reducing human errors, and freeing up resources for more strategic tasks. Companies that adopt AI-driven decision-making processes gain valuable insights and predictive analytics.

Cloud Computing: Cloud-based solutions offer businesses scalable, cost-effective options for data storage and software deployment. Cloud technologies facilitate remote work, enhance collaboration, and provide data accessibility from any location.

Internet of Things (IoT): IoT is transforming industries by connecting devices and enabling real-time data collection and analysis. Businesses can leverage IoT to monitor operations, optimize workflows, and improve customer experiences.

5G Connectivity: The rollout of 5G networks is enabling faster communication and data transfer. This enhanced connectivity paves the way for innovations in areas like telemedicine, augmented reality, and autonomous vehicles.

Digital Marketing Strategies for Sustainable Growth

Digital marketing is at the heart of modern business strategies. To stand out in a crowded market, businesses must adopt targeted and innovative marketing tactics.

Search Engine Optimization (SEO): SEO is critical for improving online visibility and driving organic traffic. Businesses should focus on creating high-quality content, optimizing for keywords, and building authoritative backlinks to enhance search engine rankings.

Content Marketing: Content is king when it comes to building brand authority and engaging audiences. Businesses should invest in creating informative, relevant content that addresses customer pain points and provides solutions.

Social Media Engagement: Social media platforms are powerful tools for building brand awareness and fostering community engagement. Consistent posting, audience interaction, and strategic advertising can amplify a brand’s reach.

Data-Driven Marketing: Analyzing marketing performance data allows businesses to make informed decisions and refine strategies. By leveraging analytics tools, businesses can identify trends, understand customer behaviors, and optimize campaigns for better results.

Personalization: Today’s consumers expect personalized experiences. Businesses that use data to tailor their offerings and communication to individual preferences are more likely to build lasting relationships with customers.

Cybersecurity: Protecting Digital Assets

As businesses become more reliant on digital technologies, cybersecurity is paramount. Cyber threats can compromise sensitive data, disrupt operations, and damage reputations. To safeguard digital assets, businesses must implement robust cybersecurity measures.

Multi-Layered Security: Implementing multi-layered security protocols ensures that businesses are protected from various attack vectors. This includes firewalls, intrusion detection systems, and endpoint protection.

Data Encryption: Encrypting sensitive data both in transit and at rest protects it from unauthorized access.

Regular Audits: Conducting regular security audits helps identify vulnerabilities and ensures that security measures are up-to-date.

Employee Training: Human error is a common cause of data breaches. Educating employees on cybersecurity best practices can reduce the risk of phishing attacks and other social engineering tactics.

Customer-Centric Tech Solutions

Understanding and prioritizing customer needs is key to business growth. Tech innovations can enhance customer experiences and build long-term loyalty.

Customer Relationship Management (CRM) Systems: CRM systems help businesses manage customer interactions and provide personalized experiences. By analyzing customer data, businesses can tailor their offerings and improve satisfaction.

Chatbots and Virtual Assistants: AI-powered chatbots offer 24/7 customer support, answering queries and resolving issues in real-time. These tools enhance customer service while reducing operational costs.

Omnichannel Experiences: Today’s consumers interact with businesses across multiple channels. Providing a seamless, consistent experience across all touchpoints—whether online, in-store, or on mobile—is essential for customer satisfaction.

Tech Integration for Operational Efficiency

Integrating technology into core business processes can streamline operations, reduce costs, and improve overall efficiency.

Enterprise Resource Planning (ERP) Systems: ERP systems integrate various business functions into a unified platform, improving visibility and coordination across departments.

Project Management Tools: Digital project management platforms enable teams to collaborate, track progress, and meet deadlines efficiently.

Supply Chain Optimization: Advanced technologies like IoT and blockchain can enhance supply chain transparency, improve inventory management, and reduce delays.

Sustainable Growth with Tech Partnerships

Partnering with tech solution providers can accelerate business transformation and growth. Collaborating with experts allows businesses to access specialized knowledge and cutting-edge technologies without investing heavily in in-house resources.

Scalability: Tech partnerships enable businesses to scale operations as needed, adapting to market demands without significant disruptions.

Innovation: Partnering with tech innovators ensures that businesses stay ahead of industry trends and adopt new technologies as they emerge.

Looking Ahead: Future Trends in Tech and Digital Growth

The tech landscape is constantly evolving, and businesses must stay agile to remain competitive. Emerging trends like artificial intelligence, quantum computing, and edge computing are set to redefine industries. By staying informed and embracing change, businesses can position themselves for long-term success.

Conclusion

Tech4Biz Solutions is committed to empowering businesses with innovative tech solutions and digital growth strategies. Whether it’s leveraging advanced technologies, optimizing marketing efforts, or enhancing customer experiences, Tech4Biz helps businesses unlock new possibilities. By diving deep into the world of tech and digital strategies, companies can fuel growth, drive innovation, and stay ahead of the curve in an ever-changing business landscape. Visit Tech4Biz Solutions to learn more about how we can help transform your business.

5 notes

·

View notes

Text

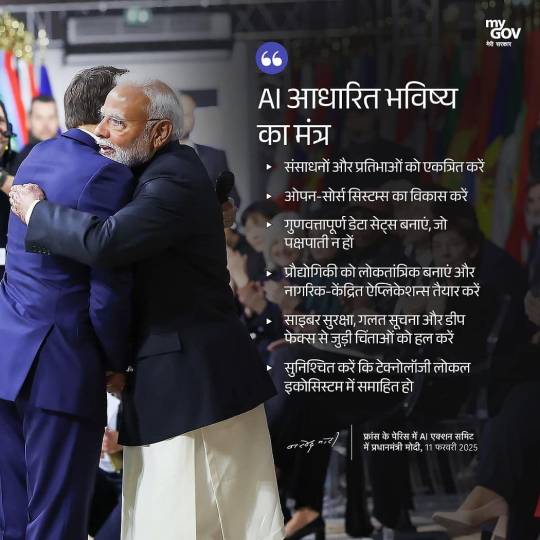

AI-Based Future Mantra: Col Rajyavardhan Rathore’s Vision for Innovation & Growth 🤖🚀

In an era where Artificial Intelligence (AI) is reshaping industries, economies, and societies, Col Rajyavardhan Singh Rathore envisions a future-driven, innovation-led India that embraces AI to power growth, governance, and global competitiveness. His AI-based Future Mantra focuses on leveraging AI for digital transformation, job creation, industry modernization, and national security, ensuring India emerges as a leader in the AI revolution.

🌟 Key Pillars of Col Rathore’s AI Vision

1️⃣ AI-Driven Digital India: Transforming Governance & Public Services

✅ AI-powered e-Governance — Enhancing efficiency, transparency & citizen services. ✅ Smart City Development — AI-based urban planning, traffic management & waste control. ✅ Predictive Analytics for Policy Making — Data-driven decision-making for better governance.

“AI is the key to revolutionizing governance and making citizen services more efficient, accessible, and transparent.”

2️⃣ AI for Industry & Economic Growth: Powering Smart Enterprises

✅ AI in Manufacturing & MSMEs — Enhancing productivity & automation. ✅ AI-powered Startups & Innovation Hubs — Supporting entrepreneurs with next-gen AI solutions. ✅ Boosting IT, Fintech & Smart Commerce — Strengthening India’s global digital economy presence.

“AI is not about replacing jobs; it’s about creating new opportunities, industries, and careers.”

3️⃣ AI in Agriculture: Revolutionizing Rural Economy 🌾🤖

✅ Smart Farming with AI — Precision agriculture & automated irrigation. ✅ AI-based Crop Monitoring & Forecasting — Reducing farmer losses & improving productivity. ✅ Digital Marketplaces for Farmers — Connecting rural producers to global markets.

“AI can empower farmers with knowledge, tools, and predictive analytics to revolutionize Indian agriculture.”

4️⃣ AI in Education & Skill Development: Empowering Youth for Future Jobs 🎓💡

✅ AI-driven Personalized Learning — Smart classrooms & adaptive learning systems. ✅ AI Upskilling Programs — Training youth in AI, robotics & machine learning. ✅ AI-Powered Job Market Platforms — Connecting talent with industries using AI analytics.

“The future belongs to those who master AI. We must equip our youth with the skills to lead in the AI economy.”

5️⃣ AI in National Security & Defense: A Smarter, Safer India 🛡️🚀

✅ AI in Cybersecurity — Advanced threat detection & prevention. ✅ AI-powered Surveillance & Defense Tech — Strengthening India’s armed forces. ✅ AI in Disaster Management — Early warning systems & crisis response automation.

“AI is the force multiplier for India’s defense and security strategy in the 21st century.”

🚀 The Road Ahead: Col Rathore’s Action Plan for AI-Driven Growth

🔹 AI Policy & Infrastructure Development — Strengthening India’s AI ecosystem. 🔹 Public-Private Partnerships for AI Innovation — Encouraging global collaborations. 🔹 AI Talent & Research Investments — Making India a global hub for AI development. 🔹 Ethical AI & Responsible Innovation — Ensuring AI benefits all sections of society.

“AI is India’s gateway to a smarter, more efficient, and innovative future. Let’s lead the way!” 🚀

🌍 India’s AI Future: Leading the Global Innovation Wave

✅ AI-powered industries, smart cities, and a digital economy. ✅ Next-gen job creation & future-ready workforce. ✅ Stronger governance, national security, and agriculture. ✅ A global AI leader driving innovation & inclusivity.

🔥 “AI is not just a tool — it’s the future. And India will lead it!” 🤖 Jai Hind! Jai Innovation! 🇮🇳🚀

4 notes

·

View notes

Text

Data Analytics in ERP Software for Manufacturing Industry

Leveraging ERP Data Analytics in the Manufacturing Industry

Understanding Data Analytics with ERP Software for Manufacturing Industry

What is ERP Data Analytics?

Manufacturing companies have likened their ERP systems to the quiet workers, unnoticeable in the background yet provide critical support. Now when we discuss ERP data analytics, we’re raising the stakes. ERP data analytics refers to the process of leveraging large amounts of data that is accumulated in the ERP systems to make efficient decisions. In other words, it is all about the transformation of a mere number into something useful.

One might think of ERP Software for Manufacturing Industry as a personal manufacturing oracle. It derives from various areas of operations such as the inventory, schedule of production and the supply chain, and aids in interpretation of the figures. Unlike traditional business intelligence that compels data to be hidden in spreadsheets decipherable only by an expert analyst, ERP data analytics provides it with easy to comprehend tools, such as dashboards, graphs, and reports bringing meaningful and timely information.

How ERP Data Analytics Transforms Manufacturing Operations

ERP data analytics doesn't just capture data; it transforms it to revolutionize the way manufacturers operate. Here’s how it can shake things up in your manufacturing operations:

- Streamlining Production Processes: Manufacturing data analysis allows manufacturers to identify strengths and inefficiencies in their manufacturing processes. This means you can tune your production line, speed up production and reduce waste.

- Optimizing Inventory Management: With ERP data analytics, you can get a clear idea of inventory levels, forecast demand, and avoid stock outs or overstocking. It’s like having a crystal ball that tells you when to pull on supply.

- Enhancing Quality Control: By carefully analyzing data collected during development, research can help identify deficiencies and quality issues. This ensures you maintain high standards and avoid costly recalls or rework.

- Boosting Supplier Relationship Management: Having detailed analysis of supplier performance will allow you to manage your supply chain more effectively. It helps you choose the best vendors and negotiate the best terms.

Remember, data alone can’t solve problems. It is the insights from ERP analytics that empower managers, engineers, and operators to streamline operations and increase productivity.

Benefits of ERP Data Analytics for Manufacturing

Improved Operational Efficiency

Operational efficiency is a key ingredient for success in manufacturing, and ERP data analytics can significantly enhance it. Here's how it boosts efficiency:

- Automated Reporting: Manual reporting is often laborious and takes up valuable time. ERP data analytics automated report generation, minimizing human error and allowing your team to concentrate on more important tasks.

- Predictive Maintenance: Analytics can predict when machines are likely to fail, allowing you to conduct maintenance before issues arise. This means less downtime and more production time.

- Resource Optimization: By analyzing demand patterns, ERP analytics assist in allocating resources to where they are most needed, ensuring that every tool and team member is utilized effectively.

- Just-in-Time Production: Minimize waste and enhance cash flow by producing only what's necessary, exactly when it's needed—enabled by precise forecasting through data analytics.

Enhanced Strategic Planning

With ERP data analytics, you can avoid guesswork in planning your next move. Here's how it enhances strategic planning:

- Informed Decision Making: Data analytics provide historical trends and forecast future demands, allowing you to make informed, data-driven decisions rather than relying on gut feelings or instinct alone.

- Trend Analysis: By spotting patterns in the data, you can anticipate market trends and adjust your production processes accordingly. Whether you are increasing or decreasing production or moving into new markets, smart insights guide you.

- Financial Planning: Data analysis helps us understand the cost structure and benefits of various products and processes, enabling better budget allocation and financial forecasting.

- Competitive Advantage:By adopting a data- and insight-driven approach, manufacturers can stay ahead of the competition, keep innovating and adapt to changes in the marketplace

Real-time Decision Making

In a fast-paced world, timing is everything. The real-time decision-making capabilities of ERP data analytics help you stay agile:

- Instant Data Access: Managers and team leaders can access real-time data from anywhere, using dashboards on laptops, tablets, or smartphones. This ensures that they have the most current information at their fingertips.

- Quick Response to Issues: With real-time alerts and notifications, you can manage production issues, supply chain problems, or equipment failures as they occur, reducing delays and keep the connecting cables in operation

- Flexible Production Scheduling: Real-time analytics enable dynamic adaptation of manufacturing processes based on current demand and unforeseen conditions, ensuring efficient use of time and resources

- Enhanced Collaboration: When your team has access to the same up-to-date data, it increases communication and planning, leading to better teamwork and decision-making.

By using ERP data analytics, manufacturers can ride the wave of the fourth industrial revolution. Not only keeping up with technology but using it to turn insights into action, and improve productivity in the workplace. In today’s world where data-driven methodologies rule the roost, ERP data analytics is your ticket to not only survive but thrive in the crowded manufacturing industry

Key Features of ERP for Manufacturing Industry in India

The manufacturing industry is wide and diverse, hence, an appropriate enterprise resource planning (ERP) is needed to ensure that the operations run efficiently. This implies that manufacturers should be familiar with the pivotal characteristics of the ERP for Manufacturing Industry in India To maximize the use of this software, for example, when it is used for data analytics.

Data Integration and Automation

ERP software for manufacturing brings several benefits and among them is the capability to connect and create a flow of data from different organizations’ departments. The ERP system prevents the existence of data silos by bringing together all the business processes such as inventory and finance, within one system. Therefore, stakeholders are provided with the same data in real-time which promotes communication and collaboration within the organization.

Automation is another critical capability. Even though the system has a high need for management skill and leadership, people should engage in error missions. It further assists them in reducing human errors because it helps the ERP system allow reprocessing activities that do not require human engagement of humans through information technology. In so doing, enhancement of operational performance becomes achievable as employees free up time spent on routine tasks to more value adding activities.

Predictive Maintenance and Forecasting

Predictive maintenance is changing the way manufacturers treat their equipment. Due to the importance of predictive analytics incorporated inside an ERP solution, manufacturers are able to detect machine failures before they actually occur; therefore, maintenance operations can be performed in a more effective manner. This predictive capability helps reduce downtime greatly and maximize the useful life of the machine, thereby achieving continuous processes of production.

Equally, forecasting is another equally important aspect for planning what would be needed for a future production. ERP program, with the aid of data analytics, obtains and analyzes past and present information in order to make credible demand predictions. Such projection helps the manufacturers to properly organize production schedules and manage inventory systems, thereby eliminating unnecessary stock and ensuring products are ready when required. Consequently, manufacturers can meet customer expectations at less cost.

Supply Chain Management Optimization

Supply chain management is critical in today’s manufacturing organizations in their efforts to minimize costs. An integrated paperless environment, with strong data analysis features as part of an ERP system, yields understanding of supply chain activities, on multiple levels. With access to real-time data, manufacturers are in a position to control procurement, administer suppliers, and be informed of shipping and logistics.

ERP analytics also assist in recognising some of the challenges surrounding supply chain processes hence enabling businesses to take corrective actions seamlessly. Moreover, by analyzing these trends and patterns, the manufacturers can identify areas that might cause disruption and take the necessary steps to reduce such risk.

Implementing Data Analytics in Manufacturing Software for Small Business

Choosing the Right ERP System

Choosing the right ERP system is critical. Businesses should evaluate their unique requirements and then select the right ERP software that fits their plans. Some of the things to look for are scaling, ease of use, and built-in industry-specific features. Another consideration critically needed when it comes to assessing potential ERP vendors is the quality of their customer support and the degree of flexibility they offer for customization.

It would be helpful for businesses to conduct numerous needs assessment analyses and to take into account the various ideas of the stakeholders in different departments before making their decision. Thus, this collaborative approach guarantees the selection of an ERP solution that will address current and future demands and facilitate innovative development.

Integrating ERP with Existing Systems

Implementation of a new ERP system always involves working with other technologies in place, and this process can be complicated. Several factors that manufacturers should consider include how to properly integrate the ERP system with the other conventional systems or other specific software customarily used in its production processes. It might require developing a B2B solution from the ground up or employing middleware software to link the two.

Integration causes the creation of a seamless system in which information moves back and forth with ease between the different systems, underpinning the quality of information and time-saving on the entry of the same information into two or more systems. Having compatible systems in place means that losses are prevented during transition and keeps the productivity constant.

Training and Change Management

The transition process in implementing of new ERP system involves causing major transformation to the organization. This is why training and change management efforts are critical interventions to employ. Approximately, some of the possible suggestions are, employees require knowledge on how best to use the new system. User manuals and comprehensive training programs can help facilitate this process.

Training is also a part of change management but in addition to the training other forms of management include; overcoming staff resistance consists of the provision of information regarding the benefits as well as change that is expected to accompany the new ERP system. Promoting a positive culture that encourages people to embrace the change and making them feel important would be of great help.

Manufacturers should also identify and deploy ‘ERP champions’ to the organization, specialists ‘for’ who the product is expert and will steer those around him in the proper use of the technology. Having these knowledgeable internal resources in place can reduce the difficulties associated with the implementation process and promote an organizational environment that embraces technology solutions.

Ongoing Evaluation and Adaptation

While ERP systems have been successfully implemented in organisations, constant checks and assessments are crucial. Companies should periodically assess the effectiveness of the system and solicit responses from the end-users to increase the chances of the adopted ERP solution providing optimal value for the manufacturers. This ensures that adjustments can be made in response to changes in trends and technology within the industry.

Thus, taking these strategic steps, manufacturers can provide care for ERP data analytics, which converts the raw data into the valuable information that helps to make right decisions when it is necessary to improve the company’s performance, optimize its processes, and maintain competitive advantage in the changing market environment.

Success Stories in the Manufacturing Sector

Large Manufacturing Enterprises

As the world turns into a digital and growing data-center, large manufacturing enterprises are exploring ERP data analytics possibilities with astonishing advancements. Let's look at some successful scenarios where manufacturing giants have revolutionized their processes:Let's look at some successful scenarios where manufacturing giants have revolutionized their processes:

1. Automotive Manufacturer: For instance, one of the large automotive manufacturing firms used (ERP) enterprise resource planning data analysis to enhance supply chain operations. Introduced from order points, production schedules and suppliers, they were able to cut down inventories by $15% and delivery times by $20%. These analytics provided them with more understanding on their supply chain patterns to allow them to detect disruptions and correct production schedules in real- time.

2. Consumer Electronics Firm: Another electronics manufacturing giant introduced change in the quality assurance mechanism through ERP analytics. It was used in tracking the performance of the production line, and defects as well as returned products. Therefore, they achieved a defector reduction of between 25% and minimized the warranty claims. Not only that, it contributed positively to customer satisfaction as well as to the branding of their products.

3. Industrial Equipment Producer: This company suffered some issues mainly in the maintenance and time wastage which impacted their production goals. Due to applying the ERP data analysis, they were able to assume equipment failures before they occurred. By studying the previous records of their maintenance activities as well as sensor measurements they were able to be more aggressive in their maintenance approach and reduce the downtime to 30 percent and save millions of dollars.

Small and Medium-sized Manufacturers

ERP data analytics isn't just for the giants of the industry. Small and medium-sized manufacturers (SMEs) can also reap remarkable benefits from harnessing their ERP systems:

1. Craft Brewery: A small craft brewery used ERP analytics to optimize their production and sales strategies. By analyzing customer preferences and seasonal demand patterns, they were able to refine their brewing schedules and focus on popular products. This approach led to a 40% increase in sales and enhanced their market presence.

2. Textile Manufacturer: A medium-sized textile company utilized ERP data analytics to streamline their inventory management. By closely monitoring stock levels and sales trends, they eliminated overproduction and reduced waste. This improved their cash flow and increased their profitability by 25%.

3. Metal Fabrication Business: This SMB faced challenges with inefficient production routing which impacted delivery times. By adopting ERP analytics, they analyzed their manufacturing processes and identified bottlenecks. As a result, they restructured their workflows, leading to a 35% reduction in production time and a much quicker turnaround for customer orders.

These stories highlight how both large enterprises and SMEs can thrive by integrating ERP data analytics into their operations, driving innovation, efficiency, and profitability.

Challenges and Solutions in ERP Data Analytics Adoption

However, the idea of adopting ERP data analytics in the manufacturing industry has its own problems. Knowing these and the respective solutions can make the process of adoption easier and more enriched.

Data privacy and security concerns

Since huge quantities of data are processed, data privacy and security issues continue to be critical challenges for manufacturers implementing ERP solutions. undefined

- Implement Robust Security Measures: Encryption and firewall and secure user authentication are indispensable to prevent leakage of data.

- Regular Security Audits and Training: Security audits and briefings for all personnel can play a vital role in protecting data and associated information.

- Compliance with Regulations: Real-world compliance with rules like GDPR and CCPA helps firms to observe a proper level of data protection and does not result in expensive penalties.

In this way, companies can successfully protect themselves from possible data breaches and continue to garner the trust of their consumers and business associates.

Managing Data Complexity

This is because the amount and types of data generated makes it difficult for the manufacturers to make use of the information. undefined

- Use Data Integration Tools: Sometimes these tools can assist in the data accumulation by incorporating data from various sources into a single system for analysis.

- Invest in User-Friendly Analytics Software: Ensuring that the software that is selected has a minimum of complex settings that a non-technical user can comprehend.

- Implement Data Governance Protocols: Effective data management practices that include adoptions of data governance policies to provide quality and accurate data promotes best decisions.

Addressing data complexity directly allows manufacturers to get the most out of their ERP analytics solutions.

Ensuring User Adoption

Therefore, for the use of ERP data analytics to be successful, the workforce must adopt it fully. This is often easier said than done given the resistance to change or lack of capability in people. undefined

- Provide Comprehensive Training: Training sessions and instructions provide employees with the feeling of competent use of new analytics tools, which in turn makes them more engaged and productive.

- Highlight Success Stories: Proposing how analytics have been beneficial within the company motivates others to embrace the change and observe the advantages firsthand.

- Create Champions: Select a few champions that will hold the responsibility of explaining the functionality of the new system to the users.

Manufacturers ought to encourage the company culture of making analytic use of the ERP; with this, manufacturers have a guarantee of successful ERP analytics outcomes.

Altogether, the concept of using ERP data analytics in manufacturing is wrought with challenges, yet recognizing them and finding solutions can open up the path for growth, innovation, and success. The benefits of integrating ERP data analytics are enormous, especially for manufacturers who are ready to address these issues in the early stages.

Future Trends in ERP Data Analytics for Manufacturing

The manufacturing sector is never a static one, and it is quite enjoyable to wait and see how changes, especially the advancement of ERP Data Analytics for Manufacturing, are going to take place. In as much as several organizations seek to sustain their operations a shift towards the use of data is being witnessed. Here are some of the future trends in ERP data analytics in manufacturing and how they are likely to transform the market:

Integration with IoT (Internet of Things)

Another trend that has emerged is the integration of ERP systems with the IoT. Internet of Things is no more a hype – it has stopped being a fad, but is instead, gradually becoming real & reality in the manufacturing sectors. What this essentially implies is through interconnecting the internet of things to machines, manufacturers of machines and equipment get real-time data of everything including the operation of machinery and consumption of energy.

- Predictive Maintenance: Real-time data is useful when predicting when a particular machine is likely to be faulty, and then doing some repair work before a complete breakdown.

- Efficiency Optimization: Based on the data collected by the different IoTs, decisions can be made on the machines while also ascertaining that they are in the best condition at any one time.

Enhanced AI and Machine Learning Capabilities

AI and machine learning are gradually integrating into ERP systems to provide data analysis functions that were once seen in futuristic movies. These technologies can perform calculations on these large data sets much faster than a human and identify patterns that can really help the manufacturing process.

- Demand Forecasting: AI can be used to accurately anticipate customer demand, so manufacturers are able to order the necessary parts and materials in the correct quantities to save on production costs.

- Quality Control: Failure in products can be detected using the M-learning algorithms through features that are uniquely present in production lines that can be analyzed to determine if it contains defects without necessarily calling the attention of a quality inspector.

Advanced Data Visualization

Another emerging trend is the continued build-out of data visualization capabilities within ERP systems. These tools help the manufacturers in processing various data sets and making decisions quickly.

- Real-Time Dashboards: Real-time dashboards are useful to stakeholders since they allow them to monitor indicators at a glance and make adjustments.

- Customizable Reports: It also allows users to make special request reports meeting his or her needs well enough especially in following the performance of the various strategies.

Cloud-Based Solutions

A growing number of organizations are implementing cloud-based solutions for improved flexibility and scalability of ERP systems. Manufacturers can make their data analytics cloud-based, thus updating the necessary systems without the need for costly on-premise hardware.

- Scalability: With the establishment of the business, it has been seen that without nearly as considerable an investment in new frameworks, they can be expanded to accommodate more licenses.

- Remote Access: From this, it is clear that not only can employees access data and analytics from any location, but also it enhances collaboration and decision making across different locations.

In conclusion, it can be seen that the future of ERP data analytics in the manufacturing industry is even more promising and intriguing. These trends therefore if adopted help manufacturers cut expenses, improve their efficiency and hence come up with new ways of producing their products hence making them relevant in the ever evolving production Industry.

In today’s environment, using ERP data analytics is not a luxury for the manufacturing industry, but rather a necessity. By increasing efficiency, improving the productivity rate, and performing business intelligence tasks, ERP systems enable organizations to thrive. Whether the business in question owns a huge factory or a small shop, the knowledge gained through ERP analytics can help cut expenses and increase output. Maximize your manufacturing operations through ERP data analytics!

0 notes

Text

Manufacturing Analytics Services in Hyderabad - Innodatatics

Services for manufacturing analytics provide a thorough strategy to improve operational effectiveness, streamline production processes, and drive corporate expansion. These services assist manufacturers in extracting meaningful insights from massive volumes of production data by utilizing advanced data analytics. This includes monitoring machinery performance, anticipating maintenance requirements, enhancing product quality, and reducing downtime.

#manufacturing analytics services#manufacturing analytics services in Hyderabad#manufacturing analytics services in Bangalore#manufacturing analytics services in Innodatatics#manufacturing analytics#big data in manufacturing#manufacturing data analysis#predictive manufacturing#big data analytics in manufacturing#+#analytics in manufacturing industry#predictive analytics manufacturing#big data analytics in manufacturing industry#Manufacturing analytics services in Innodatatics#Manufacturing analytics solutions#Manufacturing sector#Manufacturing services#Innodatatics analytics services#Innodatatics internship#Innodatatics services in Hyderabad

0 notes