#Cuttingtools

Explore tagged Tumblr posts

Text

Essential Cutting Tools for Perfect Precision in Interior Design!

Discover the best cutting tools used in interior design and renovation projects! From precision cutters for detailed work to heavy-duty tools for large materials, these are must-haves for any project. Whether you're working with wood, metal, or tiles, the right tools ensure flawless results and smooth finishes. Let Qube Interiors show you how to choose the perfect tools for your next design venture!

#CuttingTools#InteriorDesign#QubeInteriors#DIYTools#PrecisionCutting#HomeRenovation#ToolTips#Craftsmanship#Woodworking#DesignTools#InteriorSolutions#interiorcompany#interiordesignerhyderabad#HomeInterior#HomeStyle#interiordesignideas#interiordesigninspiration#dreamhome#designwithqube#homedecor#hometransformation#falseceiling#falseceilingdesign

3 notes

·

View notes

Text

Paper Cutting Machines In UAE

Unlock precision and efficiency with the best Paper Cutting Machines in UAE! At TradersFind, connect with top suppliers offering robust, high-precision machines tailored for your business needs. 📈🚀 Find your perfect match today!

Connect with us on WhatsApp at +971 56 977 3623 to discuss your Paper Cutting Machines requirements.

Visit our website and browse our Paper Cutting Machines category today! https://www.tradersfind.com/category/paper-cutting-machine

#papercuttingmachine#precisioncutting#businesssolutions#officeequipment#industrialmachinery#efficiency#productivity#qualitycut#cuttingedge#topsuppliers#tradersfind#b2buae#businessgrowth#supplierconnection#uaebusiness#machinerymarket#innovation#technology#officetools#cuttingtools#businessneeds

2 notes

·

View notes

Text

High Speed Steels Market — Forecast(2025–2031)

𝐇𝐢𝐠𝐡 𝐒𝐩𝐞𝐞𝐝 𝐒𝐭𝐞𝐞𝐥𝐬 𝐌𝐚𝐫𝐤𝐞𝐭: 𝐔𝐧𝐜𝐨𝐯𝐞𝐫𝐢𝐧𝐠 𝐭𝐡𝐞 𝐅𝐮𝐭𝐮𝐫𝐞 𝐨𝐟 𝐌𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐢𝐧𝐠 𝐄𝐱𝐜𝐞𝐥𝐥𝐞𝐧𝐜𝐞 | IndustryARC™

High-Speed Steels Market size is expected to reach a value of US$4.2 billion by the end of the year 2027 after growing at a CAGR of 5.1% during the forecast period from 2022–2027.

👉 𝑫𝒐𝒘𝒏𝒍𝒐𝒂𝒅 𝑺𝒂𝒎𝒑𝒍𝒆 𝑹𝒆𝒑𝒐𝒓𝒕

The #High #Speed #Steels (#HSS) Market refers to the global market for high-performance steels used in #manufacturing and #toolmaking, where high wear resistance and the ability to retain hardness at elevated temperatures are crucial. High-speed steels are primarily used for #cuttingtools, drills, mills, and various industrial applications that require precision and high durability.

𝐊𝐞𝐲 𝐅𝐞𝐚𝐭𝐮𝐫𝐞𝐬 :

🔹High Wear Resistance: They are designed to withstand high friction and wear, making them ideal for high-speed cutting applications.

🔹Heat Resistance: HSS maintains hardness even at high temperatures, making them suitable for tools that work at high speeds and generate significant heat.

🔹Alloying Elements: They contain a variety of alloying elements such as tungsten, molybdenum, chromium, and vanadium, which enhance their hardness and performance.

👉 𝑭𝒐𝒓 𝑴𝒐𝒓𝒆 𝑰𝒏𝒇𝒐𝒓𝒎𝒂𝒕𝒊𝒐𝒏

𝐀𝐩𝐩𝐥𝐢𝐜𝐚𝐭𝐢𝐨𝐧𝐬:

👉Cutting Tools: Widely used in the production of cutting tools like drills, mills, and lathe tools.

👉Manufacturing: Essential in high-speed machining and manufacturing processes such as drilling, milling, and turning.

👉Automotive and Aerospace: Used in the production of precision components for the automotive, aerospace, and other heavy industries.

Get this Report on discount of $1000 on purchase of Credit Card

🌍𝐌𝐚𝐫𝐤𝐞𝐭 𝐃𝐲𝐧𝐚𝐦𝐢𝐜𝐬:

🔹Demand for Precision Tools: The increasing demand for precision in industries such as #automotive, #aerospace, and #electronics is driving the growth of the HSS market.

🔹Technological Advancements: Innovations in HSS alloys, coatings, and manufacturing processes are enhancing the performance of tools, contributing to market growth.

➡️ 𝐤𝐞𝐲 𝐏𝐥��𝐲𝐞𝐫𝐬 : voestalpine Railway Systems | Nippon Steel Corporation | Jiangsu Hengli Hydraulic Co., Ltd. | Daido Steel Co., Ltd. | Graphite | ArcelorMittal | Heye International GmbH | Hudson Tool Steel Corporation | West Yorkshire Steel Co Ltd | Sandvik | Erasteel | Friedr. Lohmann GmbH | Kennametal | voestalpine | ArcelorMittal | thyssenkrupp | thyssenkrupp Uhde | RUKO GmbH Präzisionswerkzeuge | Walter Tools | Proterial Cable America | Proterial, Ltd. | OSG Corporation |

#HighSpeedSteels#ManufacturingExcellence#Toolmaking#CuttingTools#IndustrialMaterials#PrecisionEngineering#SteelMarket#HeatResistantMaterials#HSS#SteelIndustry#SteelManufacturing

0 notes

Text

The Impact of Pipe Threading Taps on System Leak Prevention

When it comes to plumbing systems, preventing leaks is a top priority. You might not think about the tools that make it all possible, but pipe threading taps play an important role in ensuring a tight seal. Understanding how these taps work can change your approach to plumbing projects.

Importance of Leak Prevention

Preventing leaks in your plumbing system is important for maintaining efficiency and saving money. By addressing potential issues before they become problems, you protect your home and avoid costly repairs.

Common Causes of Leaks

Leaks often stem from several sources. Corroded pipes can develop holes over time. Loose fittings create gaps that allow water to escape. Poorly installed joints also lead to leaks, especially if pipe threading taps are not used correctly. Even temperature changes can cause pipes to expand and contract, resulting in cracks.

Consequences of System Leaks

Ignoring leaks can lead to serious consequences. Water damage can weaken your home's structure and promote mold growth. Increased water bills from unnoticed leaks can drain your finances. In severe cases, leaks can damage appliances or lead to complete plumbing failure, resulting in expensive repairs and disruptions.

The Role of Pipe Threading Taps

Pipe threading taps play an important role in creating secure connections in plumbing systems. They help prevent leaks by carving exact threads on the ends of pipes, ensuring that pipes and fittings fit tightly together.

How Taps Work in Threading

Pipe threading taps work by cutting threads into the pipes. You insert the tap into the end of a pipe and twist it, allowing the tap to carve out spiral grooves. These grooves create a thread pattern that perfectly matches the threading on the fittings. When you connect the fittings to the threaded pipes, the secure fit reduces the chances of leaks.

Quality of Threading and Leak Prevention

The quality of the threads made using pipe threading taps significantly affects leak prevention. High-quality taps create clean, exact threads that allow fittings to seal tightly. If the threads are rough or uneven, the connection might weaken over time, leading to potential leaks. Opting for reliable, well-made tapping tools helps you maintain leak-free plumbing systems.

Conclusion

Using high-quality pipe threading taps can make a world of variation in preventing leaks in your plumbing systems. When you ensure exact threading, you’re more than avoiding annoying leaks but also saving yourself from potentially costly repairs down the line.

0 notes

Text

High-Performance Abrasives and Cutting Tools

Take your operations to the next level with premium abrasives and cutting tools from Supra Industries. Built for precision, reliability, and efficiency, our products are designed to deliver top-tier performance in any industry. Shop now for unmatched quality!

0 notes

Text

Learn How to Sharpen Knives with Expert Techniques

Check out the Bearded Sharpener and his channel for expert tips on knife sharpening tools and blade maintenance!

At The Bearded Sharpener, we focus on quality, offering the best sharpening tools backed by top-notch customer service.

Whether you're learning how to sharpen knives or refining your knife sharpening techniques, we’ve got you covered with tools we trust ourselves.

Our channel is perfect for knife sharpening beginners looking to elevate their skills.

Follow us to see the complete sharpening process and keep your blades in top shape!

Connect with us & Follow our journey on social media for the latest updates and more!

#cuttingtools#ductwork#engineer#engineers#fab101#fabrication#fabricator#fabshop#homemachineshop#hvachacks#hvacr#instamachining#instamachinist#machineshop#machinetools#machining#machinist#machinistsofinstagram#manualmachining#manualmachinist#mechanicalengineer#mechanicalengineering#metalwork#metalworker#metalworking#sheetmetalfab#sheetmetalworker#steelfab

0 notes

Text

𝐋𝐨𝐨𝐤𝐢𝐧𝐠 𝐟𝐨𝐫 𝐭𝐨𝐩-𝐪𝐮𝐚𝐥𝐢𝐭𝐲 𝐜𝐮𝐭𝐭𝐢𝐧𝐠 𝐦𝐚𝐜𝐡𝐢𝐧𝐞 𝐩𝐚𝐫𝐭𝐬 𝐢𝐧 𝐋𝐮𝐝𝐡𝐢𝐚𝐧𝐚? 🛠️

𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐫𝐞𝐥𝐢𝐚𝐛𝐥𝐞 𝐝𝐞𝐚𝐥𝐞𝐫𝐬 offering durable and 𝐞𝐟𝐟𝐢𝐜𝐢𝐞𝐧𝐭 𝐩𝐚𝐫𝐭𝐬 𝐭𝐚𝐢𝐥𝐨𝐫𝐞𝐝 for your needs. 𝐅𝐢𝐧𝐝 the 𝐛𝐞𝐬𝐭 𝐬𝐮𝐩𝐩𝐥𝐢𝐞𝐫𝐬 at www.indianyellowpages.com and keep 𝐲𝐨𝐮𝐫 𝐦𝐚𝐜𝐡𝐢𝐧𝐞𝐫𝐲 𝐫𝐮𝐧𝐧𝐢𝐧𝐠 𝐬𝐦𝐨𝐨𝐭𝐡𝐥𝐲! 🚀

#CuttingMachineParts#LudhianaDealers#MachinerySupplies#MachinePartsIndia#IndustrialSolutions#MachineMaintenance#QualityMachineParts#IndianYellowPages#MachineryMarket#CuttingTools#IndustrialEquipment#PrecisionParts#EngineeringSupplies#ReliableDealers#LudhianaIndustry

0 notes

Text

How to Choose the Best Jigsaw Power Tool for Your Projects

Discover essential tips for selecting the best jigsaw power tool for your projects, considering features, blade types, ergonomics, and user reviews to ensure optimal performance.

Read on https://safatcotrading.com/how-to-choose-the-best-jigsaw-power-tool-for-your-projects/

0 notes

Text

Top Multi Boring Bits Manufacturer in Ahmedabad, India

A Leading manufacturer and supplier of “Multi Boring Bits ” from Ahmedabad, India.

Buy Multi Boring Bits at Best Price in Ahmedabad, Gujarat By Perfect Tools Industries. #1 Trusted Multi Boring Bits Manufacturer and Pan India Supplier.

📎 For Further Information, Please Contact Us 👇

📱 Call : +91 93282 03494, +91 78744 31679

💬 Whatsapp : https://wa.me/919328203494

🌐 Web : https://www.perfecttoolsindustries.com/service/multi-boring-bits/

#MultiBoringBits#MultiBoring#BuyMultiBoringBits#MultiBoringBitsManufacturer#cuttingtools#Perfect#tools#woodworkingtools#woodworkingbits#Ahmedabad#Gujarat

0 notes

Text

#TileBlade#TileCutting#DIYHomeProjects#TileTools#TileInstallation#HomeRenovation#CuttingTools#DIYTips#HomeImprovement#RenovationTools#TileWork#PowerTools#HomeRenovationTips#TileCutter#HandyTools#HomeDIY#ToolTalk#CuttingEdge#TileSaw#usa#canada

0 notes

Text

🔺 Stavya Spine, MISSAB & SAG presenting

🔰 Cutting Tools & Simulation / AR in Spine Surgery 🔰 Hands-On Workshop

🗓 Date: Sunday, July 14th 2024

⏰Time: 9:00 am to 5:00 pm

🏟 Venue: Stavya Annexe Conference Room, Nr. Nagari Hospital, Opp. Carrefour Hotel, Mithakhali, Ellisbridge, Ahmedabad

🔗 Click here to register: https://tinyurl.com/OrthoTV-SpineTech-Workshop

🔺 Conference Fees: Rs. 2000/- 🔺 Workshop Fee: Rs. 5000/- to Rs. 15000/-

❇ Topics & Speakers:

Practical Training in Spine Surgery & Futuristic Simulations AR/VR

Advanced Techniques and Cutting Tools (Porcine Cadavers, Bone Scalpel, Burr, Endoscopy)

Vote of Thanks & Overview of Workshop:

Hands-On Workshop:

👨⚕ Organising Secretary: Dr. Raviranjan Rai, Dr. Ajay Krishnan

👨⚕ Course Convener: Dr. Bharat R. Dave, Dr. Amit C. Jhala

👨⚕ Course Chairman: Dr. Niraj Vasavada, Dr. Bharat R. Dave, Dr. Amit C. Jhala

👨⚕ Course Advisors: Dr. Devanand Degulmadi, Dr. Shivanand Mayi, Dr. Mirant B. Dave

▶️ Media Partner: OrthoTV Global

🤝 OrthoTV Team: Dr. Ashok Shyam, Dr. Neeraj Bijlani

🔗 Discover more at www.orthotvonline.com

🔗 Join OrthoTV - https://linktr.ee/OrthoTV

#SpineSurgery#MISSAB#SAG#ARinSurgery#SpineWorkshop#OrthopedicTraining#OrthoTV#CuttingTools#SimulationInSurgery#MedicalEducation#AdvancedTechniques#OrthopedicInnovation#JoinOrthoTV#StavyaSpine

0 notes

Text

Precision Drilling and Cutting Tools: Achieving Excellence in Precision Machining

Precision drilling and cutting tools play a crucial role in achieving excellence in precision machining. By investing in high-quality tools that offer accuracy, durability, versatility, and efficiency, you can elevate the quality of your work and stay ahead of the competition. Choose precision tools that are tailored to your specific needs and watch your machining projects reach new levels of success.

0 notes

Text

The Advantages of Using 1.2379 Cold Work Steel

The advantages of using 1.2379 Cold Work Steel make it a preferred material for manufacturing high-quality tools and components that require exceptional wear resistance, toughness, and dimensional stability. The advantages are as follows:

High Wear Resistance: 1.2379 Cold Work Steel offers excellent wear resistance, making it suitable for applications where tools are subjected to abrasive wear or high levels of friction.

Good Toughness: Despite its high hardness, 1.2379 steel also possesses good toughness, which is crucial for preventing cracking or chipping during use. This toughness enhances the durability and longevity of tools made from this material.

Excellent Edge Retention: Tools made from 1.2379 Steel can maintain a sharp cutting edge for extended periods, reducing the need for frequent sharpening or replacement. This feature is particularly advantageous in industries where precision and efficiency are critical.

High Compressive Strength: The compressive strength of 1.2379 Steel allows it to withstand heavy loads and resist deformation under pressure. This property is essential for tools that are subjected to intense working conditions or heavy-duty applications.

Ease of Machinability: While it is a high-performance steel, 1.2379 can be machined relatively easily, allowing for the production of intricate tool designs with precision and accuracy.

Versatility: 1.2379 Steel is versatile and can be used to manufacture a wide range of tools and components for various industries, including blanking dies, forming tools, punches, shear blades, and more.

Good Dimensional Stability: The dimensional stability of 1.2379 Steel ensures that tools maintain their shape and size over time, minimizing the risk of dimensional inaccuracies or distortions during use.

Heat Treatable: 1.2379 Steel is heat treatable, allowing manufacturers to adjust its hardness and other mechanical properties to suit specific application requirements. This flexibility in heat treatment enables the customization of tools for optimal performance in different operating conditions.

Corrosion Resistance: While not as corrosion-resistant as stainless steels, 1.2379 Steel exhibits reasonable resistance to corrosion, particularly when compared to other types of carbon steels. Proper maintenance and surface treatments can further enhance its corrosion resistance.

Cost-Effectiveness: Despite its high-performance characteristics, 1.2379 Steel offers good value for money due to its long service life, reduced maintenance requirements, and excellent performance under demanding operating conditions. This makes it a cost-effective choice for many industrial applications.

Sandeep Enterprises stands as a reputable entity in the Steel Industry, renowned for its commitment to excellence, quality, and customer satisfaction. With a comprehensive portfolio spanning a wide range of high-quality steel products and services, Sandeep Enterprises caters to the diverse needs of clients across various sectors. Our Company prides itself on understanding the unique requirements of the steel industry and delivering tailored solutions that meet and exceed expectations.

#SandeepEnterprises#12379ColdWorkSteel#ToolSteel#ColdWorkApplications#HighHardness#WearResistance#Toughness#Machinability#CompressiveStrength#PrecisionEngineering#ToolingExcellence#IndustrialMaterials#Metalworking#CuttingTools#FormingDies#ToolAndDieMaking#Manufacturing#EngineeringMaterials#ColdWorkAlloy#PrecisionMachining#SteelPerformance

1 note

·

View note

Text

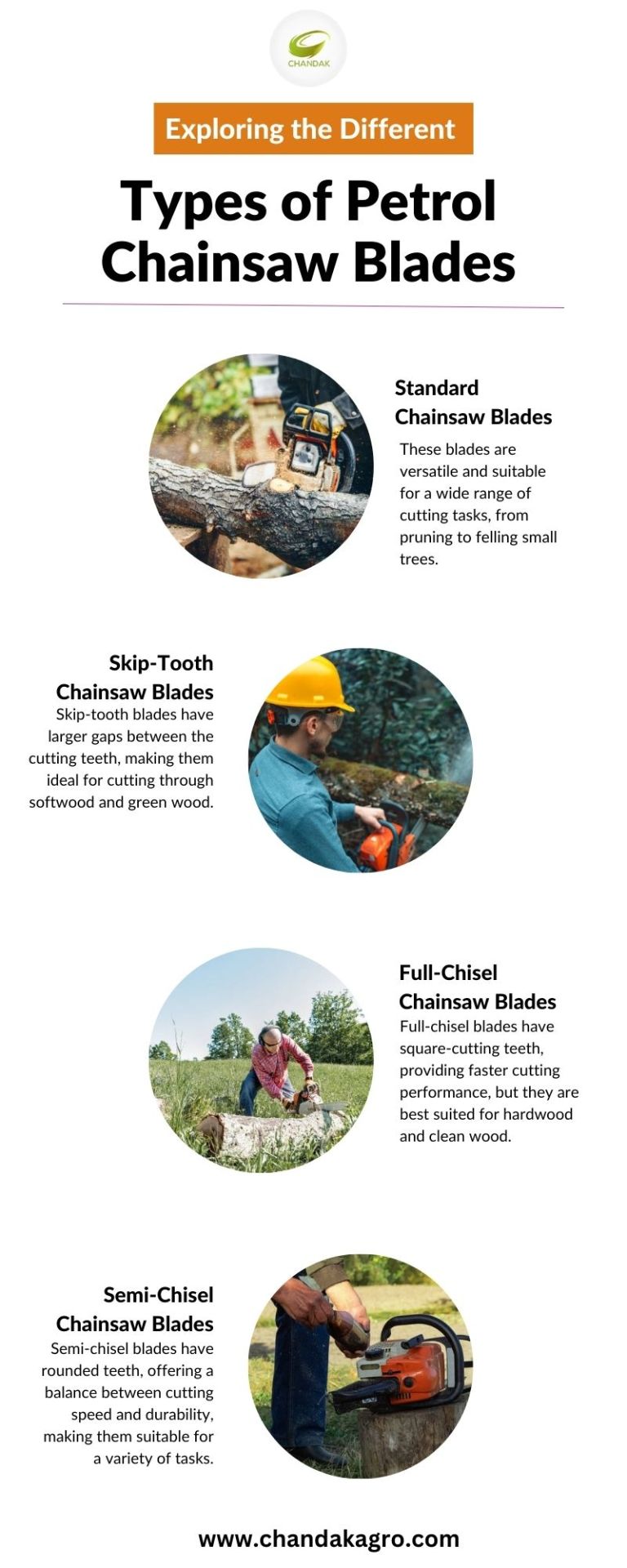

Exploring the Different Types of Petrol Chainsaw Blades

Explore the world of petrol chainsaw blades and find the right one for your cutting tasks. From general-purpose blades for cutting firewood to specialized ones for felling trees, these blades offer versatility and power for all your outdoor cutting needs.

#Petrolchainsaw#Chainsawblades#Outdoorcutting#Firewood#Cuttingtools#Gardenequipment#Chainsawaccessories#chandakagro

0 notes

Text

What To Consider When Choosing A Hacksaw For My Projects

When it comes to selecting the right hacksaw for your projects, there are several factors you need to consider. From the type and size of the blade to handle design, material, price, portability, and ease of use, it's important to make sure you get a saw with all the features you need. Additionally, you should check if it's compatible with other tools in your arsenal as well as any safety features that might come in handy when tackling challenging projects. With these tips, you can ensure that your new hacksaw is up for any job!

Key Takeaways

- Types of hacksaws include standard, mini, and ones specifically designed for cutting metal - Blade length affects the type of cuts that can be made, with shorter blades allowing for tighter turns and longer blades better for cutting straight lines - Coarse tooth patterns are better for wood and plastic, while fine tooth patterns are better for metal cutting - Handle design should provide a comfortable grip and enough leverage, with considerations for handle length, weight, and material for optimal comfort and grip support

Type of Hacksaw

When selecting a hacksaw, it's important to consider the type you'll need - whether it's a standard or mini hacksaw, or maybe even one specifically designed for cutting metal. A standard hacksaw has a fixed blade length and can be used for general-purpose sawing of wood and plastic. Mini hacksaws are great for precise cuts in tight spaces and come with blades that are shorter than those on standard models. For tougher materials such as metals, look for ones with higher tooth count and special blades designed to cut through hard materials. Make sure to check the blade types available before making your purchase so you get the right one for your project. Considering these factors will ensure that you get the perfect hack saw for whatever job you have in mind. Moving onto the size of the blade...

Size of the Blade

Choose a hacksaw blade that's the right size for your job; it'll make the work easier and faster. Blade length is important to consider when selecting a hacksaw, as it affects the type of cuts you can make. A shorter blade allows for tighter turns, while longer blades are better suited for cutting straight lines. Consider the thickness of materials you plan to cut when choosing blade length; thicker materials require longer blades. Additionally, pay attention to tooth pattern - coarser tooth patterns (more teeth per inch) will cut through materials like wood and plastic more quickly than fine-toothed blades which are better suited for metal cutting. Blade Length Tooth Pattern Short Coarse Long Fine Your handle design should provide a comfortable grip and enough leverage—you'll thank yourself later!

Handle Design

When selecting a hacksaw for your projects, it's important to consider the handle design. Ergonomics are critical in terms of comfort and ease of use - you want to ensure that the grip fits comfortably in your hand and is easy to control. Additionally, many hacksaw handles have rubber or plastic grips which provide more cushioning when sawing materials with increased force. Paying attention to these details can help ensure that you're getting a quality tool for your project needs. Ergonomics Make sure you select a hacksaw that feels comfortable in your hands; it'll make the job go smoother and be more enjoyable. Ergonomics plays an important role in selecting a saw, as having the correct grip when cutting is essential for comfort and safety. Consider these 3 factors when choosing: - Handle length - ensure it fits comfortably in your hand without being overly bulky or too short. - Weight - opt for a lightweight design to reduce fatigue during lengthy projects. - Material - choose a soft rubber coating for extra comfort and grip support while cutting. Grips can help improve accuracy and control, so making sure you have the right fit is key to getting the job done quickly and efficiently. Grips Grips can be a crucial element in providing comfort and control when cutting with a hacksaw, allowing you to easily work for extended periods. When considering grips, there are two primary features to look for: blade types and tooth count. Blade types include coarse-toothed blades for metal and fine-toothed blades for wood or plastic. Tooth count ranges from 14 teeth per inch (TPI) up to 32 TPI, depending on the material you're cutting. To maximize cutting control, select a saw that offers adjustable tension settings, as well as an ergonomic handle design that fits your hand comfortably. With these considerations in mind, you'll be able to confidently choose the perfect hacksaw for any project. Moving on to materials...

Material

When it comes to selecting a hacksaw, you should consider the material of both the blade and the handle. Steel blades are a popular choice as they're strong and durable. Aluminum handles provide excellent grip and comfort during use, allowing you to work more efficiently with less fatigue. Choosing the right material for your project is essential to getting an optimal result. Steel blades Steel blades on hacksaws come in various sizes and thicknesses, so it's important to determine which type is best suited for your project. When selecting a blade, consider the following: - Hand sharpening - Is the blade already razor-sharp or will you need to sharpen it? - Blade Thickness - How thick should your blade be to get the job done? - Length of Cut - The longer the cut, the thicker and stronger the blade should be. - Intended Use - Will you be cutting hard materials like metal or soft materials like plastic? No matter the size of your project, understanding these key factors can help ensure you select a steel blade that is up to the task. Additionally, aluminum handles provide excellent stability and control when cutting; these factors are just as important as choosing an appropriate steel blade. Aluminum handles The strength and stability of an aluminum handle can make all the difference when cutting with a hacksaw, providing you with improved control and precision. Consider the blade length of your hacksaw, as well as the tooth design of the saw's blade, as there'll determine how effectively you can cut through the material. Additionally, look for a handle that's made from a lightweight alloy such as aluminum to ensure durability and longevity while also being comfortable to use. The ergonomic design of many aluminum handles makes them easier to grip and reduces fatigue so you can work longer without tiring. When selecting an aluminum-handled saw, be sure it has a secure locking mechanism that prevents slipping while in use. Finally, consider any additional features that may be beneficial, such as vibration dampening or anti-slip texture on the handle for extra comfort and safety. With these factors in mind, you'll have the ideal tool for completing any project quickly and accurately.

Price

You'll want to consider your budget when choosing a hacksaw, so think about how much you're willing to pay. Here are three things to keep in mind: - Cost of the saw itself - Replacement blades and their sharpness - The durability of the materials used in construction. Price is important, but it shouldn't be the only factor taken into account when making a purchase; the quality of construction is also essential for optimal performance and longevity.

Quality of Construction

When choosing a hacksaw, pay close attention to the quality of construction for optimal performance and lasting results. A hacksaw's blade sharpness and tension should be checked before purchase, as they have a huge impact on the saw's cutting power. Look for models with hardened steel blades that are securely fastened in place; otherwise, you'll be faced with poor cuts and potential safety hazards. Additionally, check the handle design and materials used to ensure a good grip when using the saw. If it's too loose or loosely constructed, it could lead to fatigue or even injury. Finally, look for models with an adjustable blade angle for more precise cuts in awkward positions. This way, you can avoid unnecessary strain while still achieving accurate results. With quality construction at its core, your hacksaw will provide reliable performance time after time - making portability a priority as well.

Portability

When selecting a hacksaw, portability is key. The saw type and blade material are important to consider - lighter materials such as aluminum or plastic will be more portable than heavier metals like steel. Look for a handle with a comfortable grip that fits your hand size, and if you're going to be bringing the saw with you regularly, make sure it has a case or bag that's easy to store in small spaces. You should also look for features like collapsible blades so the saw can fit into smaller places when not in use. A lightweight hacksaw is essential for any DIY project that requires moving around often, so don't skimp on portability! Consider these points before making your purchase to make sure you get the most out of your new tool. And remember: ease of use should be taken into account too!

Ease of Use

Your hacksaw must be easy to use, as a fuss-free experience makes DIY work a breeze. To ensure ease of use, consider the following: - Blade sharpness: Selecting a hacksaw with an easily sharpenable blade will save time and effort in keeping it ready for use. - Handle design: Choose a handle that fits comfortably in your hand and won't get slippery while you work. - Blade durability: A well-made blade should be able to withstand frequent usage without breaking or bending. - Weight balance: Look for one with good weight balance so you don't tire out quickly when sawing. For smooth transitions between projects, compatibility with other tools is also important.

Compatibility with Other Tools

Making sure your hacksaw is compatible with other tools can make DIY jobs go faster and smoother. When selecting a hacksaw, consider the material of the blade and how well it works with other saw types. For instance, if you're using a jigsaw for some details but need to finish off with a hacksaw, opt for one that has interchangeable blades so you don't get stuck with just one type of blade material. Blade Material Saw Types Compatible? Steel Jigsaw Yes Carbon Steel Coping Yes High Speed Circular No Having this flexibility can help you ensure that all your projects are completed quickly and accurately. Keep in mind that safety features should also be considered when selecting a hacksaw.

Safety Features

Safety is key when tackling DIY projects, so it's essential to pick a hacksaw with safety features. Make sure the model you choose has been tested and given an adequate safety rating; this will give you peace of mind when using it. Additionally, look for a saw with teeth that aren't too fine or too coarse; the blade should be able to cut through material without snagging or slipping. Check for secure handles that won't come off in your hands while cutting and make sure there's an appropriate guard to prevent any kickback. Finally, make sure the blade can be easily replaced when necessary. With these factors in mind, you'll have all the safety features you need for successful projects!

Frequently Asked Questions

Does the hacksaw come with a blade? Yes, the hacksaw comes with a blade. Consider its size and shape to ensure it meets your project needs. A larger, flatter blade is ideal for cutting thicker materials, while a smaller, curved blade works well for thinner items. Is it easy to replace the blade? Yes, it's easy to replace the blade. Consider the blade size and handle design for a comfortable grip that makes replacing blades simpler. Is the hacksaw suitable for a variety of materials? Yes, you should consider if the hacksaw is suitable for a variety of materials. Different blades are designed for different types of material, so look for one that has multiple blade options to suit your needs. Are there any additional accessories included? When selecting a hacksaw, check for available sizes, grip size, and blade type. Consider accessories included like extra blades or handles for comfort and convenience. What is the warranty policy for the hacksaw? When selecting a hacksaw, consider the warranty policy. Find out how long it covers blade longevity and cutting speed. Doing so will ensure you get the most from your investment.

Conclusion

When selecting a hacksaw, there are many factors to consider. Make sure the type of saw fits your project needs, and that the blade size is appropriate for the job at hand. Look for a handle that feels comfortable in your hand and is made from durable material. Consider price and portability when making your decision. Additionally, look for features such as ease of use and compatibility with other tools. Finally, make sure it has all the necessary safety features you need to get the job done safely and efficiently. By taking into account these important considerations, you can pick out the perfect hacksaw for any project! Read the full article

0 notes

Text

Ceramic Inserts Suppliers

Our premium ceramic grades ensure higher productivity. All of the grades show superior high temperature hardness, heat resistance and chemical stability. We offer many types of ceramic cutting tool materials (silicon nitride-based, alumina-based and whisker-based) in a variety of geometries to meet customer demands.

#Machenzzo#ceramics#cbn#carbide#Cuttingtools#cutting#ceramic#metalwork#tool#drill bits#grinder#2023#metal#distributor#cnctools#removals#deburring#grinding#shaping#automotive#aerospace#foundary#engineering#suppliers

1 note

·

View note