#Custom Steel Part Manufacturers

Explore tagged Tumblr posts

Text

Get ready to experience Metalman Auto like never before! 🚀

Our new website is set to launch with a UI Experience and immersive 360-degree product views. This fresh digital experience is designed to showcase our strengths, capabilities, and commitment to quality in the automotive and non-automotive sectors. 🔧 What to Expect:

A sleek and modern user interface

Detailed 360-degree views of our top products

Enhanced navigation and a user-friendly experience

Comprehensive insights into our services and expertise

At Metalman Auto, we are constantly innovating to deliver excellence in metal fabrication, tubular solutions, and OEM partnerships. And now, we are bringing that innovation online! Stay tuned as we prepare to unveil a new chapter in Metalman Auto’s digital journey. Be the first to explore our innovations, discover our solutions, and connect with us like never before. 📅 Launch Date: Coming Soon! . #MetalmanAuto #AutomotiveIndustry

#automobile#automotive#car accessories#automotive parts#automotive industry#automotive tools#automotive art#vehicle#oem#oemparts#oem manufacturing#factory#heavy metal#metalman auto#Two-Wheeler Parts Manufacturer#Three-Wheeler Components Supplier#Passenger Vehicle Parts Manufacturer#Automotive Metal Components Supplier#Custom Metal Fabrication for OEM#metal fabrication#steel fabrication#fabricationservices#manufacturer#newport fabrication inc in canada#supplier#Electric Vehicle (EV) Parts Supplier#electric vehicles#hyundai#evs#electric car

3 notes

·

View notes

Text

#stainless-steel-cnc-machining-services#prototype-machining-services#custom-cnc-aluminum-parts#cnc-machining#cnc-components-manufacturers#best-prototype-companies

0 notes

Text

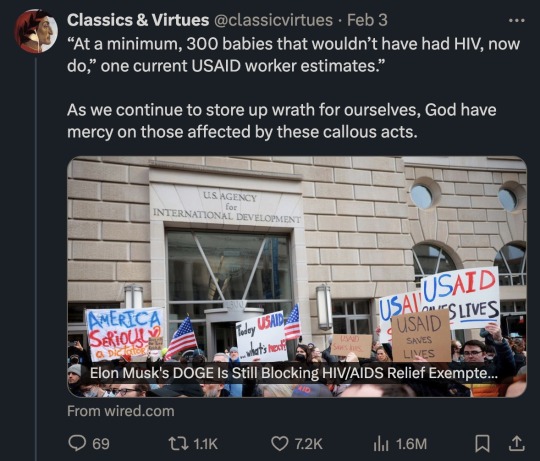

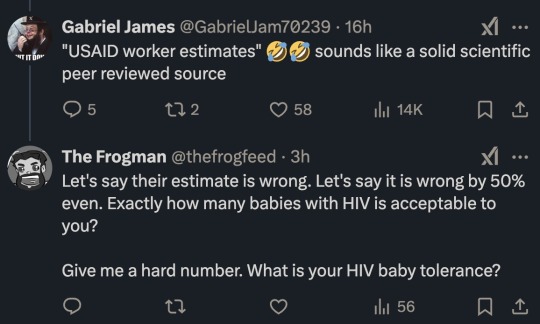

The Price of "Efficiency"

There is a classic story about writing in space. It typically goes something like,

"NASA spent millions of dollars developing an ink pen so they could write in microgravity.

Russia used a pencil."

It became a parable about efficiency and bloated, wasteful budgets and overcomplication.

And without nuance, it feels like a good lesson. It's a simple teaching you can store in your brain and it can help you avoid complication when simplicity will work just as well.

But the parable is a lie.

There is a reason they spent millions of dollars making a space pen. Pencils in space are fucking dangerous. If one splinter or shard or speck gets loose in zero gravity that fucker can float directly into your eyeball.

There is a more modern version of this story. Congress will look over NASA or the military's budget and ask why they need $400 hammers or bolts that cost $50 apiece. They will hold up a bag of bolts and tell the taxpayer they are getting screwed.

But the NASA hammer has the pencil problem. If a shard of steel breaks off that hammer in zero gravity, it's a big problem. It could float into an important electrical system and cause a short. Maybe even a fire.

And those bolts might be for a $50 million fighter jet. They need to be custom manufactured to extreme tolerances. And you'll be glad you paid for those $50 bolts because replacing the fighter jet will end up being much more costly.

This is a concept Elon Musk should understand considering his work at SpaceX. People often deride SpaceX when a rocket blows up. They see it as a giant waste. But that is a normal part of rocket development. If you want to make a better rocket, you cannot avoid blowing a few into smithereens.

Everything needs context.

You have to consider nuance before making huge unilateral decisions about apparent wasteful spending. The folks who run these programs should be allowed to defend their existence. But outside his own interests, Elon can only seem to see space pens when Russian pencils will suffice. He is looking at these programs and making no effort to see the nuance.

They say USAID gives more money to "governance" than they give to "humanitarian aid."

HOW WASTEFUL!

Except a lot of humanitarian aid gets stolen without government infrastructure to secure and deliver said aid.

Waste happens. Fraud happens. I have no doubt.

But figuring out what is *actually* wasteful is a difficult job that takes a lot of research and understanding.

But also, sometimes the fraud and the waste are worth it. Large companies will actually factor theft and fraud into their budget because it would be more costly to try and prevent it. They consider it "the cost of doing business."

But it seems no fraud or waste is acceptable to a conservative when the goal is helping people. 100% efficiency is required. You can't give all kids school lunches because some of those kids have rich parents. You can't give people disability income because some will take advantage.

Apparently if you can help millions of people but you have to absorb 10% of the cost due to fraud... well that is just unacceptable.

It's better to help no one at all.

Oftentimes Republicans will create anti-fraud programs that end up costing more than the actual fraud happening. And all the anti-fraud programs end up doing is making deserving people jump through extra hoops.

Get a lawyer. See an approved doctor. Gather 20 years of evidence that you've been disabled. Whoops, they didn't request the proper records. Start over.

That was basically my disability case. I was already on disability. They had already determined I was disabled 20 years ago. But I had to prove that I was disabled all over again to get the better kind of disability. They couldn't take their own word that I was disabled.

Those hoops were created because catching fraud is more important than helping people.

Not terribly efficient.

And then there is the "not our problem" approach.

Taxpayer money is "wasted" helping people in other countries. "We have homeless veterans! Why are we helping African babies?"

Giving out free condoms is one of the easiest and cheapest ways to stop the spread of disease. Sickness cares very little for imaginary borders. Saving lives in another country also saves lives here. It's mutually beneficial. We probably even prevented some of those homeless vets from getting infected.

No thought is being put into this scorched earth shit show.

As always... get fucked, Elon.

883 notes

·

View notes

Text

Virat Special Steels, INDIA! Your Trusted Partner in Special Steels

VIRAT SPECIAL STEELS PVT. LIMITED , INDIA., we are proud to be one of the largest importers, exporters, and stockists of Die Blocks, Tool Steels, Die Steels, Special Steels, and Alloy Steels.

With over five decades of experience, we maintain the biggest steel yards and a high level of inventory from the world’s leading manufacturers like Swiss Steel DEW, NLMK Verona, Vitkovice, Somers Forge, and Villares Metals.

We are in this business for the last about more than Five Decades, and have been dealing with large number of forging units. The products, we deal in are specifically engineered to extend life service, save time and provide optimal performance to our customers.

Product List

DIE STEEL ( HH 370 - 410 BHN ) DIN-1.2714 / AISI L6 )

HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

ALLOY STEELS, EN-SERIES ETC.

Our products are specifically engineered to extend service life, save time, and provide optimal performance. You can rely on us for accurate and timely service on our part to process and execute your orders to match your satisfaction.

Virat Special Steels, INDIA! https://www.viratsteels.com/

📞 Contact us today to learn more about how we can support your business! https://www.viratsteel.in/special-steel-supply-networks/

Any further queries feel free to contact us : 🌐https://www.viratsteels.com/ 📬 [email protected] ☎+91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#db6 steel#h13steel#h11steel#h13steelbarexporter#p20ni#hot work steels#cold work steel#plasticmouldsteels

2 notes

·

View notes

Text

Metal Welding Services in Miami: What to Know

Metal Welding Services in Miami: What to Know

If you’re searching for top-notch metal welding services near me in Miami, finding a professional and reliable service provider is key. Miami’s booming construction, automotive, and marine industries demand high-quality welding solutions for various projects. Let’s explore what makes metal welding services in Miami stand out and what you should look for when selecting a provider.

What Are Metal Welding Services?

Metal welding involves joining two or more metal parts through heat, pressure, or both. Welding is an essential process in industries like construction, automotive, manufacturing, and shipbuilding. Miami is home to a range of experienced welding professionals who cater to diverse project needs, including:

Structural welding: For buildings and bridges.

Automotive welding: For vehicle repairs and customization.

Marine welding: Specializing in ships and boats.

Custom metal fabrication: Tailored designs for unique projects.

Why Choose Professional Metal Welding Services in Miami?

Miami is a hub for skilled welders offering precision, durability, and expertise. Here are some key benefits of choosing local welding services:

Expertise in Various Techniques: Certified professionals in Miami use advanced techniques such as TIG, MIG, and stick welding for high-quality results.

Access to High-Quality Materials: Miami welding shops have access to durable metals like aluminum, stainless steel, and carbon steel.

Compliance with Local Regulations: Professionals ensure projects adhere to Miami’s building and safety codes.

Fast Turnaround Times: Local services minimize delays, ensuring your project is completed on time.

Types of Metal Welding Services Offered in Miami

Whether you’re working on a large-scale construction project or need small repairs, Miami’s welding professionals provide a range of services:

Residential Welding: Gates, fences, and railings.

Commercial Welding: Storefronts, signs, and structural supports.

Industrial Welding: Heavy machinery, pipelines, and tanks.

Repair Services: Fixing broken metal parts for boats, vehicles, or equipment.

How to Find the Best Metal Welding Services Near You

Finding the right welding service in Miami can be overwhelming. Here are some tips to help you choose the best provider:

Check for Certifications: Look for welders certified by organizations like the American Welding Society (AWS).

Read Reviews and Testimonials: Online reviews on platforms like Google and Yelp can give insights into the quality of service.

Compare Pricing: Request quotes from multiple providers to ensure competitive pricing without compromising quality.

Ask About Experience: Providers with extensive experience in your specific project type are likely to deliver better results.

Inspect Their Equipment: Modern, well-maintained equipment indicates a commitment to quality.

Top-Rated Welding Companies in Miami

Here are some highly recommended welding services in Miami to consider:

Miami Welding & Fabrication: Specializing in custom designs and structural welding.

South Florida Marine Welding: Experts in marine welding and aluminum fabrication.

Elite Welding Services: Known for precision welding and on-site services.

Benefits of Choosing Local Welding Services

Opting for a local welding service in Miami comes with several advantages:

Quick Response Times: Local businesses can provide on-site services faster.

Knowledge of Miami’s Environment: Welders understand the impact of Miami’s humid climate on metal structures.

Supporting Local Economy: Working with local providers strengthens the community.

Common Metals Used in Welding Projects

Miami welding services work with a variety of metals depending on the project requirements. Common metals include:

Aluminum: Lightweight and corrosion-resistant, ideal for marine and automotive projects.

Stainless Steel: Strong and resistant to rust, perfect for construction and decorative purposes.

Carbon Steel: Durable and cost-effective, suitable for heavy-duty industrial applications.

Copper: Used for electrical and plumbing applications.

How Much Do Metal Welding Services Cost in Miami?

The cost of metal welding services in Miami varies based on factors like:

Type of Project: Custom designs or large-scale industrial jobs may cost more.

Materials Used: Exotic metals like titanium are more expensive.

Complexity of Work: Intricate designs or repairs require more time and expertise.

On average, welding services in Miami range from $75 to $150 per hour, but it’s best to request a detailed quote for accurate pricing.

Tips for Maintaining Welded Metal Structures

To ensure the longevity of your welded metal structures, follow these maintenance tips:

Regular Inspections: Check for signs of wear, rust, or cracks.

Cleaning: Use appropriate cleaners to remove dirt and prevent corrosion.

Apply Protective Coatings: Paint or galvanize metal surfaces to enhance durability.

Avoid Overloading: Prevent excessive stress on welded joints.

Why Miami’s Climate Matters for Welding Projects

Miami’s coastal location and humid climate can affect metal structures over time. Professional welders in Miami understand these challenges and take necessary precautions, such as:

Using corrosion-resistant materials.

Applying protective coatings to combat rust.

Ensuring proper welding techniques to withstand environmental stressors.

Conclusion

When searching for metal welding services near me in Miami, it’s important to choose a provider with expertise, modern equipment, and a proven track record. Whether you need custom fabrication, industrial repairs, or marine welding, Miami’s professionals offer reliable solutions to meet your needs. By selecting a trusted local welding service, you can ensure your project is completed efficiently and to the highest standard.

2 notes

·

View notes

Text

In U.S. President Donald Trump’s avalanche of day-one executive orders, he did not drop the gauntlet on the start of the next trade war, much to the temporary relief of markets and currency traders, as well as Canada and Mexico, which received almost an eight-hour reprieve before he threatened them, too.

But his sweeping executive order on trade did lay the groundwork for all and more that he promised on the campaign trail, prompting agency reviews and investigations that are the necessary precursor for the broad tariffs on China and the rest of the world. With an April 1 deadline for nearly all the reviews and investigations, the clock is already ticking for early administration action on Trump’s punitive trade agenda.

The executive order basically breaks down into China and the rest of the world. But there’s one interesting difference from many of the other actions Trump took that explicitly rolled back Biden-era rules, regulations, and mandates: Some of the planned trade measures maintain and build upon trade actions that the Biden administration took, including to combat China’s unfair trade practices and bolster U.S. export controls.

Parts of the executive order go after a particular obsession that Trump and his trade braintrust have: searching for a problem for which they already have the solution (more tariffs, of course).

First, Trump directed his administration to figure out why the U.S. trade deficit in goods just keeps getting bigger and to come up with some convincing reason why that is a national security risk, since economists and trade experts are blasé about what is essentially an accounting metric. That review opens the door to global tariffs—i.e., import duties on every other country—through the Carter-era International Emergency Economic Powers Act.

Second, Trump ordered a root-and-branch review of the U.S. industrial and manufacturing base to determine which imports might possibly affect national security and could thus be subject to their own punitive tariffs under Section 232 of the 1962 Trade Expansion Act. (Trump used that exact tool to hike tariffs on steel and aluminum on national security grounds in his first term, but he’s thinking bigger this time.)

The other not-entirely-about-China elements in the trade executive order are other usual suspects, including ordering further investigations into countries that may manipulate their currencies for trade advantage and a review of arcane de minimis customs rules that create a loophole for lots of small-value trade to sneak past his tariff dragnet. Trump also promised a review and perhaps expansion of Biden-era restrictions on technology exports and opened the door to further restrictions on Chinese “connected” technology, such as electric vehicles, which the Biden administration already flagged as a potential national security risk.

But much of the executive order goes specifically after China, the world’s second-biggest economy and the United States’ third-biggest trade partner. Cherishing hope over experience, Trump ordered an appraisal of his underwhelming Phase One trade deal with China to find out if Beijing complied with its terms (it did not), and he raised the specter of punitive tariffs.

Trump also builds on the Biden administration’s latest investigation into China’s unfair trade practices under the authorities of Section 301 of the 1974 Trade Act, promising to look at the entire industrial supply chain and especially third countries who offer Beijing a way to sidestep China-specific tariffs. (That’s bad news for countries such as Vietnam and Malaysia, not to mention Mexico, which rerouted a lot of China-U.S. bound trade and are now in the crosshairs.)

He also ordered the Office of the U.S. Trade Representative (USTR) to take its own look at China’s unfair trade practices—that means, in practice, a cheap yuan, industrial subsidies, dumping, intellectual property theft, market discrimination, and the like—and to use its own sweeping authority to impose—you guessed it—tariffs. Just for good measure, the executive order vowed to assess ongoing legislative efforts to strip China of its current preferential trade relations with the United States, a step that would automatically open the door to higher tariffs.

Trump campaigned on raising taxes on U.S. businesses and consumers through import levies as a way to rebalance what he and his trade advisors see as an unbalanced trade relationship with the world. What he did on his first day in office sets that process in motion, leaving just enough time for talks with targeted countries that could deliver the deals of a lifetime—or herald a new threat to global trade and growth.

3 notes

·

View notes

Text

Do you have HMS1 and HMS2 steel scrap?

EDELSTAHL VIRAT IBERICA is an emerging importer - exporter, supplier of tool steels, mold steels from various countries. We are also engaged in the trade of ferrous, alloy steel, etc., with a network of partners all over the world, we are able to quickly meet customer needs.

HMS-1, HMS-2, and ferrous scrap are terms commonly used in the scrap industry to classify and describe different types of steel and iron scrap.

Here's what each of these terms means:

HMS-1 (Heavy Fusion Scrap 1):

HMS-1 is a designation for heavy, bulky scrap, composed primarily of wrought iron and steel.

It typically includes scrap metal from a variety of sources, such as demolished buildings, old machinery, and industrial equipment.

HMS-1 is relatively clean and free of excessive contaminants, making it suitable for recycling into new steel products.

It usually consists of thick and heavy items such as beams, pipes, and plates.

HMS-2 (heavy melt scrap 2):

HMS-2 is another scrap category, but it may contain a slightly higher percentage of contaminants compared to HMS-1.

Includes items such as smaller structural steel parts, miscellaneous steel parts, and lighter gauge materials.

While still suitable for recycling, HMS-2 may require further processing to remove impurities and contaminants before it can be used in steel production.

We are looking for all wholesale scrap metal manufacturers and suppliers such as #HMS1, #HMS2, ferrous scrap, electronic motor scrap and shredded scrap in #Portugal…

Learn more: https://moldsteel.eu/recycling-products/

WhatsApp Chat: +351-920016150 E-mail: [email protected]

#europe#porto#portugal#din2738#edelstashlviratibrica#viratsteels#b2b#oportunidades#empresas#agricultura

2 notes

·

View notes

Text

The Commonly Used Metal 3D Printing Materials

Metal 3D printing uses a variety of metal powders, wires, and even liquid resins infused with metal. Almost any metal can be 3D printed, from stainless steel to nickel-based alloys, and in practice, about 8 are most commonly used. The most common question about metal 3D printing is: Will the final part have the same mechanical properties as a machined, moulded or forged metal part? The answer is yes, and sometimes even better mechanical quality, but it depends a lot on the metal 3D printing technology you use, the type of feedstock used, post-processing and the shape of the part. In addition, the comparison depends on the aspects you are concerned about: for example, tensile strength, static load strength, high cycle fatigue, and so on.

In general, the material properties of metal parts made by metal bond jetting are equivalent to those of metal parts produced by metal injection moulding, and it is one of the most widely used manufacturing methods for the mass production of metal parts. These 8 metal alloys below are just the beginning of what is possible today as metal material producers continue to push the boundaries and customize metal alloys for specific needs using specific metal 3D printing technologies.

1.Stainless Steel Feature: All-round Stainless steel is not the material most commonly used in 3D printing, but many alloy varieties. The first two are 316L and 17-4 PH, but also 304L, 15-5 PH, 420, 254, PH1, GP1, 630, and 410 can be printed, as well as custom blends produced by material manufacturer. These steels are specifically designed to resist corrosion. They are a lightweight and affordable metal that is ideal for 3D printing. This is because it is faster and cheaper than traditional methods and can print small batches and complex parts. 3D printing is the preferred option for companies that need a single tool or several replacement parts. Stainless steel can be used in almost any type of 3D printing, from economical wire for extruded 3D printing on benchtop machines to powder for binder jetting and laser powder bed fusion, and even resin.

2.Tool Steel Feature: High hardness, good wear resistance Tool steels, like stainless steels, come in different varieties with different tensile strengths, ductility, hardness and other properties. Tool steels are a variety of alloy steels designed specifically for the manufacture of tools. They are known for their hardness, wear resistance and ability to hold a cutting edge at high temperatures. This 3D printing steel is commonly used in the manufacture of injection mould inserts, aerospace components, military applications, manufacturing tools, as well as construction and architecture. The main advantage of 3D printed tool steel is not only its strength, but also its unique ability to create parts with internal channels (e.g. cooling channels in moulding tools) and lattice fillings that cannot be manufactured by traditional methods.

3.Low-Alloy Steel All 3D printing steels are alloys, but this category includes steels with low or less than 5 per cent of other elements. These low alloy steels are designed to have higher mechanical properties and greater resistance to wear and corrosion than other steels which are commonly used in automotive, aerospace and structural applications.

4.Aluminum Feature: Lightweight and corrosion resistant For aerospace, automotive and industry, the design freedom and cost efficiency of 3D printing further enhances the lightweight and chemical resistance of aluminum components. The use of aluminum and aluminum alloys in 3D printing is surging because the metal is economical and easy to 3D print. Like most metals, aluminum can be used as wire or powder for a variety of 3D printing techniques. Aluminium has good chemical resistance, is very light and has one of the best strength-to-weight ratios of any metal. Combined with silicon and magnesium, it is the choice of many in the aerospace and automotive industries because of its ability to withstand harsh conditions.

5.Titanium Feature: Lightweight and biocompatible As strong as steel but half the weight, titanium is a complex metal that is practically made for 3D printing. Titanium has become one of the most commonly used metals in additive manufacturing, with a wide range of applications in aerospace, joint replacement and surgical tools, racing car and bicycle frames, electronics and other high-performance products. Titanium and titanium-based alloys offer high mechanical strength, high strength-to-weight ratios and better corrosion resistance than stainless steel. It makes rockets and aircraft lighter, thus saving fuel and increasing payload capacity. In the medical industry, 3D printed titanium implants have been successfully used in the spine, hips, knees and extremities due to the inherent biocompatibility and good mechanical properties of the metal, coupled with the ability to customize porous structures with 3D printing, allowing for osseointegration and mass customization for better patient outcomes.

6.Copper Feature: Electrical and thermal conductivity 3D printing using pure copper and space-age copper alloys is available with a range of metal 3D printers and services. You can create rapid copper prototypes using copper filament on an FDM 3D printer and large copper rocket boosters using copper alloys on a laser powder bed fusion 3D printer. There is also copper wire and copper resin for micro 3D printing. In fact, copper plays a huge role in the global sustainable development goals as a key component of electric motors, charging infrastructure, solar energy and batteries.

7.Nickel Alloy Feature: Extreme environments resistant Nickel-based alloys and "high-temperature alloys" are known for their excellent high-temperature strength, corrosion and oxidation resistance. These alloys retain their strength and mechanical properties at high temperatures. They are commonly used in demanding applications such as aerospace, gas turbines, chemical processing and marine environments. In recent years, these alloys have also become increasingly popular in 3D printing, especially in the aerospace and automotive industries. When referring to nickel alloys, you may hear the term inconel. Inconel is the trade name for a range of nickel-chromium-based high-temperature alloys, including IN625, IN718 and IN939. Nickel alloys are generally more expensive than other materials such as steel and aluminium and may not be suitable for low temperature applications.

8.Cobalt Chrome Feature: High temperature and corrosion resistance 3D printed cobalt chrome has a high strength-to-weight ratio and excellent corrosion resistance, making it a good material choice for aerospace components and industrial machinery. It is also biocompatible and is often used in orthopaedic implants, dental prosthetics and medical devices that require long-term contact with biological tissue. Cobalt-chromium alloys can be processed using additive manufacturing techniques such as selective laser melting (SLM) or electron beam melting (EBM). This allows complex geometries and customized parts to be produced with minimal material waste, making it attractive to industries adopting advanced manufacturing techniques.

To sum up, metal 3D printing uses a wide range of metal powders and wires, including stainless steel, tool steel, etc. to print complex parts with superior mechanical properties. Commonly used metals in 3D printing include aluminum, titanium, copper, nickel alloys, tool steel, cobalt-chromium alloys, stainless steel for aerospace, medical and jewellery applications and more.

#design#business#autos#prototype#prototyping#prototype machining#rapid prototyping#3d printed#3d printing#3d printing services#sls#slm

2 notes

·

View notes

Text

Elevating Precision Manufacturing: The Role of Mekalite’s CNC Machining Service

In today’s competitive manufacturing landscape, precision, efficiency, and adaptability are key to staying ahead. CNC machining has emerged as a vital technology, enabling manufacturers to produce complex and high-precision parts consistently. At Mekalite, we are redefining excellence in CNC machining services by combining advanced technology, a skilled workforce, and a commitment to quality.

https://mekalite.com/

What is CNC Machining?

CNC (Computer Numerical Control) machining is a process that uses computerized controls to operate machinery and tools with high accuracy. This enables the production of intricate parts from a variety of materials, including metals and plastics, while maintaining tight tolerances. CNC machining is critical in industries such as aerospace, automotive, medical devices, and electronics.

Why Choose Mekalite for CNC Machining?

Mekalite sets itself apart by offering a comprehensive approach to CNC machining, ensuring every project is handled with precision and care.

Advanced Machinery and Capabilities Our cutting-edge, multi-axis CNC machines allow us to handle even the most complex designs with precision and consistency. Whether you need rapid prototyping, low-volume manufacturing, or full-scale production, Mekalite’s technology enables us to meet your unique needs.

Customized Solutions We understand that every project is different. Mekalite works closely with each client to understand their specific requirements, delivering tailored solutions that align with their design and functionality goals.

Strict Quality Assurance At Mekalite, quality is our top priority. Our rigorous quality control protocols cover every step of the production process, from material selection to final inspection. This commitment ensures every part meets the industry’s highest standards.

Industries Served by Mekalite

Mekalite’s CNC machining services support a diverse range of industries, including:

Aerospace: High-precision components for engines, structural parts, and aircraft interiors.

Automotive: Custom engine parts, suspension components, and detailed bodywork.

Medical: Surgical instruments, implants, and diagnostic equipment requiring tight tolerances.

Electronics: Housing frames, connectors, and precision parts for delicate devices.

Benefits of Partnering with Mekalite

Choosing Mekalite as your CNC machining service provider offers numerous advantages:

High Precision and Accuracy Our state-of-the-art CNC machines, combined with skilled operators, enable us to achieve exceptional accuracy and repeatability across all projects.

Wide Range of Materials Mekalite’s expertise spans across various materials, from metals like stainless steel and aluminum to specialized plastics. This flexibility allows for innovative product designs and customized applications.

Cost Efficiency and Scalability With automated processes and minimal manual intervention, CNC machining reduces labor costs while enhancing efficiency. Whether you need a single prototype or a large production run, Mekalite’s scalable services can adapt to your requirements.

Timely Deliveries Time is crucial in manufacturing. Our efficient workflows and commitment to meeting deadlines ensure that your projects are completed on schedule, every time.

Looking Ahead: Mekalite’s Commitment to Innovation

Mekalite is committed to staying ahead of industry trends and technological advancements. By continually investing in the latest CNC machinery and refining our processes, we aim to provide even more innovative and reliable solutions to our clients. Our vision is to be a trusted partner in helping businesses achieve new levels of success through precision manufacturing.

Conclusion

CNC machining is revolutionizing the manufacturing industry, and Mekalite is at the forefront of this transformation. Our combination of cutting-edge technology, tailored solutions, and a dedication to quality makes us a preferred partner for businesses across various sectors.

If you’re looking for a reliable CNC machining service provider that delivers precision and value, Mekalite is here to help. Contact us today to discuss your next project!

https://mekalite.com/

2 notes

·

View notes

Text

MS Eccentric Reducer Manufacturer in Delhi, India: Udhhyog

In industrial piping systems, proper flow control is essential for efficient operations. An MS eccentric reducer plays a critical role in this, ensuring smooth transitions between different pipe sizes while preventing fluid buildup. If you're looking for a reliable MS eccentric reducer manufacturer in Delhi, India, Udhhyog is the trusted name you can count on. We specialize in manufacturing high-quality MS eccentric reducers at competitive prices, making us the go-to supplier for businesses across various industries.

What is an MS Eccentric Reducer?

An MS eccentric reducer is a pipe fitting used to connect pipes of different diameters while maintaining an offset alignment. Unlike concentric reducers, where the centerlines of both pipes are aligned, an eccentric reducer has one side flat, which helps avoid fluid accumulation at the lower part of the pipe. This feature is especially useful in applications where liquid buildup could create blockages or inefficiencies.

Key Features and Benefits of MS Eccentric Reducers

Optimized Fluid Flow: By maintaining an offset alignment, MS eccentric reducers ensure smooth transitions between pipes while preventing fluid or gas pooling at the bottom of the pipeline.

Cost-Efficient Solution: Made from mild steel, these reducers offer a budget-friendly solution for industries that need reliable and durable pipe fittings.

Durability: MS eccentric reducers are highly durable, capable of withstanding high pressure, extreme temperatures, and corrosion when coated properly.

Ideal for Horizontal Piping Systems: The eccentric design is particularly beneficial in horizontal piping systems, as it prevents liquid from settling at the pipe's lowest point.

Versatile Applications: MS eccentric reducers are widely used across several industries, including oil and gas, water treatment, chemical processing, and HVAC systems.

Applications of MS Eccentric Reducers

Oil and Gas Pipelines: In industries where fluid buildup can cause issues, MS eccentric reducers are essential for maintaining efficient fluid flow.

Water Treatment Systems: These reducers ensure that water flows smoothly without pooling in pipelines, reducing the chances of blockages.

Chemical Processing: In chemical industries, MS eccentric reducers are crucial for preventing unwanted fluid accumulation in pipelines.

HVAC Systems: MS eccentric reducers play a vital role in balancing airflow in heating, ventilation, and air conditioning systems by ensuring a steady flow in ducts of different sizes.

Why Choose Udhhyog as Your MS Eccentric Reducer Manufacturer?

At Udhhyog, we take pride in being one of the leading MS eccentric reducer manufacturers in Delhi, India. Here’s why businesses trust us for their industrial steel product needs:

Top-Notch Manufacturing Process: We use advanced manufacturing techniques to ensure that all our products, including MS eccentric reducers, meet industry standards for durability and performance.

Competitive Pricing: As a leading manufacturer, we provide high-quality products at the lowest prices in the market, helping businesses reduce their procurement costs.

Customized Solutions: At Udhhyog, we offer customized solutions tailored to meet the specific needs of our clients, ensuring the perfect fit for your piping system.

Extensive Product Range: Apart from MS eccentric reducers, we offer a wide range of other pipe fittings, flanges, and valves, making Udhhyog a one-stop shop for all your industrial steel needs.

Timely Delivery Across India: Based in Delhi, we cater to businesses all over India, ensuring quick and reliable delivery of products to industrial hubs and MSMEs alike.

Buy MS Eccentric Reducers from Udhhyog

Whether you're in need of MS eccentric reducers for oil and gas, water treatment, or HVAC applications, Udhhyog offers the best quality at the lowest prices. Our dedication to quality manufacturing, combined with our customer-first approach, ensures that you get the best value for your investment. Contact Udhhyog today for more information on our MS eccentric reducers and other pipe fittings.

#MSEccentricReducer#MSReducerManufacturer#IndustrialFittings#DelhiManufacturer#Udhhyog#BestPriceIndia#PipeFittings#SteelReducer#B2BManufacturer#EccentricReducerIndia

2 notes

·

View notes

Text

Top 5 Auto Parts Manufacturers | Metalman Auto Ltd.

Metalman Auto Ltd. is proud to be ranked among the top 5 auto parts manufacturers in India, a testament to our dedication to quality and innovation. We specialize in producing a diverse range of metal components, including body panels, chassis parts, and assemblies for various automotive applications. Our cutting-edge facilities and experienced workforce enable us to deliver products that meet the stringent requirements of global automotive standards. We are continuously expanding our capabilities to include new technologies and materials, ensuring that we remain at the forefront of the industry. Our partnerships with leading OEMs and suppliers demonstrate our ability to deliver reliable, high-performance components that enhance vehicle safety and efficiency. With a focus on sustainability and technological advancement, Metalman Auto is setting new benchmarks in automotive component manufacturing.

#electric vehicles#metal fabrication#fabricationservices#oemparts#steel fabrication#supplier#oem manufacturing#manufacturer#stainless steel#vehicle transport#transportation#transport for london#ipo news#ipo alert#transport technology#transport service#stocks#business magazines#business standard#manufacturing#automotive parts#High-Volume Automotive Parts Manufacturing#markets#metalman auto#automotive industry#parts Manufacturin#automotive#car accessories#oem#custom metal parts manufacturer for oems

0 notes

Text

#stainless-steel-cnc-machining-services#cnc-components-manufacturers#cnc-machining#custom-cnc-aluminum-parts#cnc-machining-companies-near-me

0 notes

Text

[In front of Paint 2!]

MY DREAM!!!!

AT LONG LAST and multiple thwarted attempts (pandemic and chip shortage) I have finally managed a successful field trip to Subaru of Indiana for their manufacturing tour!!!!

17 years ago, my baby car was born right there!!

We got to see—EVERYTHING, from the steel and aluminum coils to them being stamped into thin sheets to the tool and die process to the welding to the drivetrain, suspension assemblies, brakes, front consoles, trim and finish, paint, quality testing (various points), tires on conveyor belts like little doughnuts, cars on doing brake tests, cars on dynos, cars being pressure-tested for leaks… And also Subaru NICU, where all the cars that don’t pass their tests go for diagnosis and repair (ope).

You weren’t allowed to bring anything into the plant, so my highlights from memory:

One of the transfer presses that stamps out body pieces was, when the plant was constructed in the 1980s, the largest piece of industrial machinery ever imported into the United States. It came via the Panama Canal, up the Mississippi, up the Ohio River, and then they had to built an entire port in order to get it out of the water. It then took three days to drive all the pieces up to Lafayette, Indiana. We got to see it punching out interior door panels!

There are various buffer zones in line production so that if one part of the process gets slowed down it won’t automatically cause a slowdown in the entire plant. The place where extra engines are stored when they’re in buffer status is called an “engine hotel.”

The USDM 2.0 and 2.5L engines are built at SIA, though transmissions come from Japan fully-assembled.

There are different musical chimes for each part of the line, and it chimes when there’s a slowdown in a particular area so people can keep track of what’s going on and where the bottlenecks are.

SIA currently manufactures USDM Legacy, Outback, Ascent, and Crosstrek models. USDM Forester, Impreza, WRX, BRZ, and Solterra are built in Japan and shipped.

The SIA test tack is the second largest oval track in the state of Indiana, second only to the Indianapolis Motor Speedway—SIA also has an off-road test track.

The paint process interacts poorly with silicone-based products, so painters cannot use a long list of shampoos, soaps, chapsticks, lotions, etc. They also can’t eat popcorn, because the oils stay on human fingers for 2-3 days?!

They don’t batch paint—so instead of painting 20 red cars, say, you’ll see different colors coming out right after each other. All the Subarus they built are made to order, which means each already has a customer who triggered the construction of this vehicle.

20 notes

·

View notes

Text

China metal parts manufacturer Custom CNC turned parts for World customers, competitive CNC turning steel turned parts Customize Service. mxmparts.com

#china metal parts#cnc turning#mxmparts#turned parts#custom parts#china steel parts#china turned parts#cnc turned parts#china cnc turning#steel parts manufacturer#steel turned parts#china supplier

0 notes

Text

Leading the way in Special Steels!

VIRAT SPECIAL STEELS PVT. LIMITED , INDIA., we are proud to be one of the largest importers, exporters, and stockists of Die Blocks, Tool Steels, Die Steels, Special Steels, and Alloy Steels.

With over five decades of experience, we maintain the biggest steel yards and a high level of inventory from the world’s leading manufacturers like Swiss Steels DEW, NLMK Verona, Hyundai Steel, Vitkovice, Somers Forge, and Villares Metals.

We are in this business for the last about more than Five Decades, and have been dealing with large number of forging units. The products, we deal in are specifically engineered to extend life service, save time and provide optimal performance to our customers.

You can rely on us for accurate and timely service on our part to process and execute your orders to match your satisfaction.

We are in this business for the last about more than Five Decades, and have been dealing with large number of forging units as well as these Industries:

Our Serving Industries:

Forging Industry

Pressure Die Casting

Aluminum Extrusion

Automotive Industry

Oil and Gas

Mining and many more..

Our products are specifically engineered to extend service life, save time, and provide optimal performance. Trust us for accurate and timely service to meet your needs.

Virat Special Steels, INDIA! https://www.viratsteels.com/

📞 Contact us today to learn more about how we can support your business! https://www.viratsteel.in/special-steel-supply-networks/

Watch now: https://www.youtube.com/watch?v=c4h5KqyzVd0

youtube

Any further queries feel free to contact us : 🌐https://www.viratsteels.com/ 📬 [email protected] ☎+91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#tool steel suppliers#tool steels#diesteel#forging#db6 steel#h13toolsteels#h13steel#h11steel#Youtube

2 notes

·

View notes

Text

Buy MS Seamless Pipe from Leading Manufacturers in Delhi

When it comes to purchasing MS seamless pipes in Delhi, finding a reliable and trusted supplier is essential for ensuring quality and performance. Mild Steel (MS) seamless pipes are widely used in various industries, such as construction, oil and gas, plumbing, and manufacturing, due to their strength, durability, and resistance to corrosion.

In this article, we’ll explore why MS seamless pipes are important, their applications, and how you can find the best suppliers in Delhi.

What Are MS Seamless Pipes?

MS seamless pipes are made from mild steel, a low-carbon steel known for its flexibility and weldability. These pipes are manufactured without any seams or joints, providing a smoother finish and superior strength compared to welded pipes. The seamless construction ensures that the pipe can withstand high pressure and temperature without weakening, making it ideal for demanding applications.

Applications of MS Seamless Pipes

MS seamless pipes have a variety of uses across multiple industries, such as:

Construction: Used for building frames, scaffolding, and structural support due to their high tensile strength.

Oil & Gas Industry: Perfect for transporting fluids and gases under high pressure, ensuring safety and efficiency.

Water Supply: MS seamless pipes are used in water distribution systems as they prevent leakage and can handle large volumes of water.

Automotive: Employed in making parts for vehicles due to their strength and lightweight properties.

The versatility of MS seamless pipes makes them essential in industries where strength and reliability are paramount.

Why Buy MS Seamless Pipes from Leading Manufacturers?

Purchasing MS seamless pipes from leading manufacturers offers several advantages:

Guaranteed Quality: Leading manufacturers ensure that the pipes meet international standards, providing high durability and strength.

Wide Range of Sizes: Established suppliers offer a variety of sizes and specifications to cater to different industrial needs.

Competitive Pricing: Leading suppliers often provide the most competitive prices due to their ability to source materials and manufacture in bulk.

After-Sales Support: Trusted manufacturers provide excellent customer service, helping you with installation, maintenance, and any other post-purchase concerns.

Where to Buy MS Seamless Pipes in Delhi?

If you’re looking for the best MS seamless pipe supplier in Delhi, Udhhyog is a top choice. Udhhyog is known for its wide selection of MS seamless pipes at the lowest prices in India. They cater to both large industrial needs and small business requirements, ensuring that every customer finds the right solution.

Why Choose Udhhyog?

High-Quality Products: Udhhyog ensures that their pipes meet stringent quality standards, making them durable and efficient for various uses.

Competitive Pricing: By leveraging their strong supply chain, Udhhyog offers MS seamless pipes at highly competitive rates, helping businesses cut costs without compromising on quality.

Wide Availability: As one of the leading suppliers in Delhi, Udhhyog ensures that you can easily get the sizes and specifications you need for your project.

Reliable Service: Udhhyog prides itself on excellent customer service, offering prompt delivery and responsive after-sales support.

How to Order from Udhhyog?

Ordering MS seamless pipes from Udhhyog is straightforward. You can visit their website to explore their product range, check specifications, and place an order. You can also contact their sales team for any specific inquiries or bulk orders. Udhhyog offers flexible payment options and ensures timely delivery across India, making procurement easier for businesses

#MSSeamlessPipes#MSPipes#SeamlessPipes#PipeFittings#IndustrialPipes#SteelPipes#DelhiSuppliers#DelhiManufacturers#DelhiBusiness#ConstructionMaterials#OilAndGas#WaterSupplyPipes#AutomotiveParts#BuyMSSeamlessPipes#SteelAtLowestPrices#Udhhyog#MSSeamlessPipeSupplier#MSSteelPipesIndia#PipeSuppliersIndia#SteelManufacturersDelhi

5 notes

·

View notes