#Cryogenic Control Valve Industry

Explore tagged Tumblr posts

Text

Factors to Consider When Choosing Dewars and Cryogenic Vessels

When selecting Dewars and cryogenic vessels for your business needs, it's important to consider several factors to ensure that you choose the right equipment. Here are some key factors to keep in mind:

Purpose and Application: Determine the specific purpose and application of the vessels you need. Consider the type of materials you will be storing or transporting, their temperature requirements, and any specific handling or safety considerations.

Capacity and Size: Assess your storage or transportation needs in terms of capacity and size. Consider the volume of materials you need to store or transport and choose vessels that can accommodate your requirements. Keep in mind that larger vessels may offer more storage capacity but may also be more challenging to handle and transport.

Material and Construction: Pay attention to the material and construction of the Dewars and cryogenic vessels. Stainless steel and aluminum are commonly used materials as they offer durability and resistance to low temperatures. Glass vessels may be suitable for certain applications but can be more fragile. Choose vessels that are designed to withstand the temperatures and conditions specific to your application.

Insulation: Consider the insulation capabilities of the vessels. Effective insulation is crucial for maintaining the low temperatures required for cryogenic storage. Look for vessels with high-quality insulation materials and designs that minimize heat transfer and provide efficient temperature control.

Safety Features: Ensure that the vessels you choose have appropriate safety features. This may include pressure relief valves, emergency venting systems, and secure closures to prevent leaks or spills. Safety should be a top priority when dealing with cryogenic materials.

Supplier Reputation and Support: Research and choose reputable suppliers or manufacturers with experience in producing high-quality Dewars and cryogenic vessels. Consider factors such as product warranties, technical support, and after-sales service. A reliable supplier will be able to provide guidance and assistance throughout the lifespan of the equipment.

Compliance with Regulations: Verify that the Dewars and cryogenic vessels you choose comply with relevant regulations and standards in your industry. This ensures that the equipment meets safety and performance requirements and can be used legally and responsibly.

Conclusion

Choosing the right Dewars and cryogenic vessels is essential for businesses that require storage or transportation of materials at extremely low temperatures. By considering factors such as purpose, capacity, materials, insulation, safety features, supplier reputation, and compliance with regulations, you can make an informed decision that suits your business needs.

It's recommended to consult with industry experts or suppliers who specialize in cryogenic equipment to get personalized recommendations based on your specific requirements. They can provide valuable insights and guidance to help you choose the most suitable Dewars and cryogenic vessels for your business.

#Liquid nitrogen dewar#cryogenic nitrogen dewars#cryogenic nitrogen tank#cro storage dewars#nitrogen dewar flask

2 notes

·

View notes

Text

Gate Valve supplier in Oman

Middleeast valve is one of the best Gate valve supplier in Oman . We supply to cities like Ibri, Sur, Muscat, and Mutrah.

A gate valve is a type of valve used to control the flow of fluids (liquids or gases) by using a gate or wedge-like disc that moves perpendicular to the flow path to either block or allow the passage of the fluid.

The main function of a gate valve is to provide a tight shutoff, effectively stopping the flow of fluid through the pipeline when the valve is fully closed, and allowing unrestricted flow when the valve is fully open. Gate valves are commonly used in applications where the fluid flow needs to be completely shut off, such as in water supply systems, oil and gas pipelines, industrial processes, and more.

Gate valves consist of several main components, including the body, gate (wedge), stem, actuator, and seats. Here's how they work:

Open Position:

In the open position, the gate (wedge) is fully retracted into the valve body, allowing the fluid to flow through the valve with minimal obstruction. The gate moves perpendicular to the direction of the fluid flow. The valve is opened by turning the valve stem (either manually using a handwheel or with an actuator) which is connected to the gate.

Closing Position:

To close the valve, the stem is turned in the opposite direction, causing the gate to move down into the flow path of the fluid. As the gate descends, it gradually restricts the flow until the valve is completely closed. The gate makes contact with the valve seats located at the bottom of the valve body, forming a tight seal that prevents any further flow.

Middleeast valve is the greatest Gate valve supplier in Oman and are known for their ability to provide a tight seal and low pressure drop when fully open. However, they might require more turns to fully open or close compared to other valve types like ball valves. It's important to use gate valves in appropriate applications and avoid using them for flow regulation where frequent adjustments are necessary.

Description:

Available materials: SS304, SS904, SS904L, SS316, Aluminium Bronze, Monel, Bronze, Brass, Duplex steel, Inconel, Incoloy, Titanium, WCB, CF8, CF8M, CF3, CF3M, WC1, WC6, WC9, Cast iron, super duplex

Size: 1/2″- 64”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Operations: Hand Wheel Gate valve, Gear operated Gate valve, Electric actuated Gate valve and Pneumatic Actuated Gate valve

Ends: Flanged(FF,RF,RTJ), Buttweld, Socket weld, Threaded

Standards: API607, DIN, BS, ANSI, AWWA, ASME, API6D

Gate valve types:

Rising Stem Gate Valve

Non Rising Stem Gate Valve

Bellow Seal Gate Valve

Pressure Seal Gate Valve

Cryogenic Gate Valve

Forged Gate Valve

Gate valve advantages :

They have low fluid resistance.

They have superior sealing capability.

They come with a wide application range.

They have dual flow directions.

Gate valve Industries:

Textiles.

Power generation.

Refineries.

Petrochemical plants.

Shipbuilding

Chemical industry.

Paper factories.

Gate valve parts:

Hand wheel.

Stuffing Box.

Bonnet

Gasket

Stem

Flange

Disk

Body seats

Packing

Body

Visit our website: https://www.middleeastvalve.com/product-category/gate-valve/

2 notes

·

View notes

Text

Nickel Alloys in Extreme Conditions: What You Need to Know

Nickel alloys play an important role in industries subjected to harsh environments such as extreme heat, pressure, and corrosive chemicals. Their great performance in these conditions makes them the backbone of industries like aerospace, chemical processing, and oil and gas. Understanding the technical nuances of nickel alloys will help businesses choose the right material for specific operational needs, making sure long-lasting and cost-effective solutions.

Why Nickel Alloys?

Nickel’s atomic structure, combined with other elements like chromium, molybdenum, and iron, gives rise to unique properties such as:

1. High Melting Point: Nickel alloys remain stable at temperatures reaching 1455°C (2651°F), maintaining their structural integrity even in severe heat.

2. Corrosion Resistance: These alloys resist oxidation, pitting, and stress corrosion cracking, making them ideal for both acidic and alkaline environments.

3. Toughness at Low Temperatures: Nickel alloys do not become brittle in cryogenic conditions, unlike most metals, which makes them ideal for extreme cold applications like LNG (Liquefied Natural Gas) systems.

Key Nickel Alloy Grades and Their Performance:

The following table highlights popular nickel alloy grades, their composition, and their applications, making it easier to identify the right alloy for your industry:

Nickel Alloy Grade, Composition (Key Elements),

Properties, Applications

Nickel 200/201 (UNS N02200/N02201),

Nearly pure nickel (99% Ni),

Excellent resistance to alkalis, good mechanical properties at subzero temperatures,

Chemical processing, caustic soda production, electrical components

Inconel 625 (UNS N06625)

Nickel-Chromium-Molybdenum (58% Ni, 21.5% Cr, 9% Mo),

High strength, excellent weldability, oxidation and corrosion resistance,

Aerospace, offshore platforms, gas turbines,

Monel 400 (UNS N04400)

Nickel-Copper (63% Ni, 28–34% Cu),

Best seawater and chemical resistance, good mechanical strength,

Marine environments, hydrocarbon processing, valves and pumps,

Hastelloy C276 (UNS N10276)

Nickel-Molybdenum-Chromium (57% Ni, 16% Mo, 15.5% Cr),

Excellent corrosion resistance in harsh environments, particularly against acids,

Chemical reactors, pollution control equipment, flue gas desulfurization.

Some Least Known Mechanical Properties of Nickel Alloys

1. Superplasticity in Manufacturing: Certain nickel alloys, such as Nimonic 90, show superplasticity, meaning they can tolerate extreme deformation without failure at high temperatures. This property allows for easier shaping of complex geometries, like turbine blades, without sacrificing material strength.

2. Creep Resistance: Creep refers to the gradual deformation of a material under constant stress at rising temperatures. Nickel alloys, particularly Inconel 718 and Hastelloy X, are designed to resist creep deformation, maintaining their shape over long periods, even in heater components and jet engines where constant thermal cycling occurs.

3. Fatigue Strength: Nickel alloys also excel in fatigue resistance, which is the ability to withstand repeated stress cycles without cracking. This is critical for industries such as aerospace and automotive, where components like engine valves and turbine discs are subjected to constant cyclic loads at high temperatures.

Nickel Alloy Innovations in Modern Applications

1. 3D Printing with Nickel Alloys: Recent advances in additive manufacturing have enabled the use of nickel alloys like Inconel 718 and Hastelloy X in 3D printing. These alloys, in powder form, are used to create complex, high-performance components for aerospace and defence, offering reduced material waste and increased design flexibility.

2. Nickel-Aluminide Alloys for High-Temperature Industrial Equipment: Nickel-aluminides, a class of nickel alloys, have gained attention for their exceptional strength and oxidation resistance at temperatures exceeding 1200°C. These alloys are now being deployed in combustion chambers for power plants due to their combination of low density and high durability.

3. Nickel-Titanium Shape Memory Alloys: Nickel alloys also have niche applications in shape memory technology. Nickel-titanium (Nitinol) is widely used in the medical field. When damaged, Nitinol can return to its original shape when exposed to heat, offering high fatigue resistance and durability in high-performance environments.

Nickel alloys are essential for industries where extreme conditions are the norm. Selecting the right alloy is crucial for ensuring durability and performance. For instance, understanding the differences between fasteners made from Inconel 600 or Monel can significantly influence your application’s success. By making informed choices, businesses can reduce maintenance costs and guarantee the longevity of their components.

Do not leave your operations to chance, choose the best with Online Fittings! Explore our extensive range of premium nickel alloys today and elevate your industrial performance to new heights!

0 notes

Text

Cryogenic Valve Market Trends and Strategic Insights Analysis 2024 - 2032

The cryogenic valve market is an essential segment of the global industrial landscape, particularly in sectors that require the management of gases and liquids at extremely low temperatures. These valves play a crucial role in the safe and efficient operation of systems involving liquefied gases, such as natural gas, nitrogen, and oxygen. This article provides an in-depth overview of the cryogenic valve market, covering its significance, key players, market trends, regulatory landscape, challenges, and future outlook.

Overview of the Cryogenic Valve Market

What are Cryogenic Valves?

Cryogenic valves are specialized valves designed to control the flow of fluids at cryogenic temperatures, typically below -150°C (-238°F). These valves are used in applications where the handling of liquefied gases is essential. The main types of cryogenic valves include:

Globe Valves

Gate Valves

Ball Valves

Check Valves

Importance of Cryogenic Valves

Cryogenic valves are critical for several reasons:

Safety: They ensure the safe transport and storage of liquefied gases, preventing leaks and accidents.

Efficiency: High-performance cryogenic valves help maintain the integrity of systems, reducing energy losses and operational costs.

Versatility: These valves are essential in various industries, including natural gas, aerospace, healthcare, and chemical processing.

Market Landscape

Key Players

The cryogenic valve market features a mix of global and regional players, including:

Emerson Electric Co.

Flowserve Corporation

Parker Hannifin Corporation

Curtiss-Wright Corporation

Velan Inc.

These companies are involved in the manufacturing and supply of cryogenic valves, offering a range of products tailored to different industry needs.

Market Segmentation

The cryogenic valve market can be segmented based on several criteria:

By Type

Ball Valves

Gate Valves

Globe Valves

Check Valves

By Application

Natural Gas and LNG

Aerospace

Medical and Healthcare

Chemical Processing

Market Size and Growth

The cryogenic valve market is expected to witness substantial growth, driven by the increasing demand for liquefied natural gas (LNG), advancements in cryogenic technology, and the expansion of industrial applications. Market research indicates that the market will continue to grow as industries focus on energy efficiency and safety.

Trends and Innovations

Technological Advancements

Recent innovations in cryogenic valve technology focus on enhancing performance, reliability, and safety. Key developments include:

Smart Valves: Incorporating IoT and digital technologies for real-time monitoring and predictive maintenance.

Advanced Materials: Using high-performance materials that withstand extreme temperatures and pressures, improving durability and longevity.

Automated Systems: Increasing automation in valve operations to enhance efficiency and reduce human error.

Growing Demand for LNG

The global shift towards cleaner energy sources has led to increased demand for LNG, driving the growth of the cryogenic valve market. As LNG becomes a preferred fuel for power generation and transportation, the need for reliable and efficient cryogenic valves becomes more critical.

Regulatory Landscape

Safety and Environmental Standards

The cryogenic valve market is governed by stringent safety and environmental regulations to ensure the safe handling and transportation of liquefied gases. Regulatory bodies, such as the American Society of Mechanical Engineers (ASME) and the American National Standards Institute (ANSI), set standards for valve design and performance.

Recent Legislative Changes

Recent regulations have focused on enhancing safety measures in the transportation and storage of cryogenic materials. These changes emphasize the need for regular inspections and maintenance, increasing the demand for high-quality cryogenic valves.

Challenges in the Market

Supply Chain Disruptions

The cryogenic valve market is susceptible to supply chain disruptions, particularly concerning raw materials and components. Fluctuations in material availability can lead to delays in production and increased costs.

Competition and Pricing Pressure

The market is highly competitive, with numerous manufacturers offering similar products. This competition can result in pricing pressures, affecting profit margins for manufacturers.

Future Outlook

Growth Projections

The cryogenic valve market is anticipated to experience robust growth, driven by the rising demand for LNG, advancements in cryogenic applications, and the expansion of various industrial sectors. As industries increasingly prioritize safety and efficiency, the market for cryogenic valves is expected to expand significantly.

Opportunities for Innovation

The cryogenic valve sector presents significant opportunities for innovation, particularly in developing smart valves and automated systems. Companies that focus on research and development will likely lead the market by offering cutting-edge solutions that enhance performance and reliability.

Conclusion

The cryogenic valve market is poised for significant growth as the demand for liquefied gases and energy-efficient solutions continues to rise. With a focus on technological advancements, regulatory compliance, and sustainability, cryogenic valves will play a vital role in ensuring the safe and efficient handling of liquefied gases across various industries. By embracing innovation and addressing the challenges ahead, the cryogenic valve market can contribute to a more sustainable energy future while optimizing operational performance.

More Trending Reports

Carbon Credit Market Analysis

Green Energy Market Analysis

Stationary Energy Storage Market Analysis

Floating Wind Turbine Market Analysis

0 notes

Text

Control Valves Market Size, Share, Trends, Growth Opportunities and Competitive Outlook

"Global Control Valves Market – Industry Trends and Forecast to 2028

Global Control Valves Market, By Component (Valve Body, Actuators, Others), Material (Stainless Steel, Cast Iron, Alloy-Based, Cryogenic, Others), Type (Rotary Valves, Linear Valves), Operation (Hydraulic Control Valve, Pneumatic Control Valve, Electric Control Valve), Size (Less than 1”, Between 1” to 6”, Between 6” to 25”, Between 25” to 50”, More than 50”), End User (Oil and Gas, Energy and Power, Water and Wastewater Treatment, Food and Beverages, Chemicals, Pharmaceuticals, Construction, Pulp and Paper, Others) Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, Italy, U.K., France, Spain, Netherlands, Belgium, Switzerland, Turkey, Russia, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

**Segments**

- **Product Type:** The control valves market can be segmented based on product type into pneumatic control valves, hydraulic control valves, electric control valves, and others. Pneumatic control valves are widely used for applications requiring simple and reliable control mechanisms, while hydraulic control valves are preferred for high-pressure applications. Electric control valves are gaining popularity due to advancements in automation and remote control capabilities.

- **Application:** In terms of application, the market for control valves can be classified into oil and gas, water and wastewater treatment, power generation, chemicals, pharmaceuticals, and others. The oil and gas industry is a major end user of control valves, where they are essential for regulating flow, pressure, and temperature in various processes. Water and wastewater treatment plants also utilize control valves for precise control of water flow and treatment chemicals.

- **End-User Industry:** The market can also be segmented by end-user industry, including oil and gas, energy and power, water and wastewater, chemicals, pharmaceuticals, and others. The oil and gas sector dominates the demand for control valves due to the extensive use of valves in drilling operations, refineries, pipelines, and distribution networks. The energy and power industry follows closely, with control valves being integral to power generation plants for efficient operation and control.

**Market Players**

- **Emerson Electric Co.:** Emerson is a leading player in the global control valves market, offering a wide range of products catering to various industries. The company's innovative technologies and focus on customer needs have solidified its position in the market.

- **Flowserve Corporation:** Flowserve is another key player known for its comprehensive portfolio of control valves designed for critical applications in industries such as oil and gas, power generation, and water treatment. The company's global presence and dedication to quality make it a preferred choice for many customers.

- **Schneider Electric SE:** Schneider Electric is a prominent player that provides integrated solutions including control valves for industrial automation and processEmerson Electric Co., Flowserve Corporation, and Schneider Electric SE are key players in the global control valves market, each contributing significantly to the industry with their innovative solutions and strong market presence. Emerson's wide range of products tailored to various industries underscores its commitment to meeting diverse customer needs. The company's focus on technological advancements and customer-centric approach has enabled it to establish a strong foothold in the market, making it a preferred choice for many organizations across different sectors.

Flowserve Corporation is recognized for its comprehensive portfolio of control valves, specifically designed to address critical requirements in industries such as oil and gas, power generation, and water treatment. The company's global reach and unwavering dedication to quality and reliability have positioned it as a trusted partner for customers seeking high-performance control valve solutions. Flowserve's expertise in providing cutting-edge products for challenging applications further enhances its competitive edge in the market.

Schneider Electric SE stands out as a prominent player offering integrated solutions that encompass control valves for industrial automation and process applications. The company's emphasis on providing holistic solutions that enhance operational efficiency and productivity has earned it a strong reputation in the market. Schneider Electric's commitment to innovation and sustainability aligns with the evolving needs of industries worldwide, positioning it as a frontrunner in the control valves market.

The global control valves market continues to witness growth driven by factors such as increasing automation trends, focus on operational efficiency, and stringent regulations regarding process control and safety. The demand for control valves across various industries, including oil and gas, power generation, water and wastewater treatment, chemicals, and pharmaceuticals, underscores the significance of these components in optimizing industrial processes and ensuring smooth operations.

As industries increasingly adopt advanced technologies and digital solutions, the market for control valves is poised for further expansion. Companies like Emerson Electric Co., Flowserve Corporation, and Schneider Electric SE are at the forefront of driving innovation and setting industry standards in terms of product performance, reliability, and customer satisfaction. With a strong emphasis on research and development, these**Segments**

- **Product Type:** - Pneumatic control valves are preferred for simple and reliable applications. - Hydraulic control valves are suitable for high-pressure applications. - Electric control valves are gaining popularity due to automation advancements.

- **Application:** - Control valves are used across industries like oil and gas, water treatment, power generation, chemicals, and pharmaceuticals. - Essential for regulating flow, pressure, and temperature in various processes. - Water treatment plants rely on control valves for precise water flow control.

- **End-User Industry:** - Oil and gas, energy and power, water and wastewater, chemicals, pharmaceuticals are major users of control valves. - Oil and gas sector dominates demand due to extensive use in drilling, refining, and distribution. - Energy and power industry relies on control valves for efficient plant operation.

**Market Players**

- **Emerson Electric Co.:** - Offers a wide range of products catering to various industries. - Innovative technologies and customer focus strengthen market position.

- **Flowserve Corporation:** - Known for comprehensive control valve portfolio for critical applications. - Global presence and quality focus make it a preferred choice.

- **Schneider Electric SE:** - Provides integrated solutions including control valves for industrial automation. - Strong reputation for enhancing operational efficiency and productivity.

Global Control Valves Market drives growth through automation trends, operational efficiency focus, and stringent regulations. With rising adoption of technology

Highlights of TOC:

Chapter 1: Market overview

Chapter 2: Global Control Valves Market

Chapter 3: Regional analysis of the Global Control Valves Market industry

Chapter 4: Control Valves Market segmentation based on types and applications

Chapter 5: Revenue analysis based on types and applications

Chapter 6: Market share

Chapter 7: Competitive Landscape

Chapter 8: Drivers, Restraints, Challenges, and Opportunities

Chapter 9: Gross Margin and Price Analysis

Key takeaways from the Control Valves Market report:

Detailed considerate of Control Valves Market-particular drivers, Trends, constraints, Restraints, Opportunities and major micro markets.

Comprehensive valuation of all prospects and threat in the

In depth study of industry strategies for growth of the Control Valves Market-leading players.

Control Valves Market latest innovations and major procedures.

Favorable dip inside Vigorous high-tech and market latest trends remarkable the Market.

Conclusive study about the growth conspiracy of Control Valves Market for forthcoming years.

Browse Trending Reports:

Thermal Imaging Cameras Market Baby Food Market Thin Film Encapsulation Market Paper Coating Materials Market Protein Engineering Market Psoriasis Treatment Market Whole Exome Sequencing Market Std Diagnostics Market Medication Delivery Systems Market Lane Keep Assist System Market Liquid Synthetic Rubber Market Mainframe Market Myxoid Round Cell Liposarcoma Drug Market Hematology Analyzer Market Low Differential Pressure Sensor Market Biofuel Enzyme Market Aroma Ingredients Market Coconut Water Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

Cryogenic Valves Market Dynamics: Global Growth and Trends (2023-2032)

The global demand for cryogenic valves was valued at USD 4215.6 million in 2022 and is expected to reach USD 6228.36 million in 2030, growing at a CAGR of 5.00% between 2023 and 2030.

Cryogenic valves are specialized valves designed to control the flow of fluids at extremely low temperatures, typically below -150°C (-238°F). These valves are essential in applications involving cryogenic liquids, such as liquid nitrogen, liquid helium, and liquefied natural gas (LNG). Constructed from materials that can withstand the challenges of low-temperature environments, cryogenic valves are engineered to prevent leakage and ensure reliable operation under pressure and thermal stress. They come in various types, including gate, globe, ball, and check valves, each serving specific functions within cryogenic systems. The design of cryogenic valves incorporates features like extended bonnets, insulation, and sealing technologies to maintain temperature stability and performance. As industries increasingly adopt cryogenic technology for applications in aerospace, medical, and energy sectors, the demand for high-performance cryogenic valves continues to grow, driving innovation and advancements in materials and engineering practices.

The study on the Cryogenic Valves market highlights several key findings that underscore the growth potential and evolving dynamics of this specialized sector. Here are the notable findings:

Growing Demand in LNG Sector: The demand for cryogenic valves is significantly driven by the expanding liquefied natural gas (LNG) market. As countries invest in LNG infrastructure for energy security and cleaner fuel alternatives, the need for reliable cryogenic valves in LNG terminals, storage tanks, and transportation systems is increasing.

Expanding Applications in Various Industries: Cryogenic valves are not limited to the LNG sector; they are increasingly used in diverse industries such as aerospace, medical (for cryopreservation), and industrial gas production. This broadening application base is contributing to market growth as new technologies and processes emerge.

Technological Advancements: Innovations in materials and valve designs are enhancing the performance and reliability of cryogenic valves. Developments such as improved sealing technologies, lightweight materials, and enhanced insulation features are making these valves more efficient and durable in extreme conditions.

Rising Investment in Cryogenic Technologies: Increased investment in cryogenic technology and research is driving the development of advanced valves. Governments and private sectors are focusing on developing cryogenic processes, which necessitates high-quality valves capable of operating under low temperatures and pressures.

Focus on Safety and Compliance: With stringent safety regulations governing cryogenic applications, there is an increasing emphasis on developing valves that meet international safety standards. Manufacturers are investing in testing and certification processes to ensure their products comply with industry regulations, enhancing market credibility.

Emerging Markets as Growth Drivers: Emerging economies, particularly in Asia-Pacific and the Middle East, are witnessing rapid industrialization and infrastructure development, driving demand for cryogenic valves. Investments in energy projects, particularly LNG facilities and petrochemical plants, are creating significant growth opportunities in these regions.

Customization and Specialized Solutions: There is a growing demand for customized cryogenic valves tailored to specific applications and customer requirements. Manufacturers offering specialized solutions, including unique designs and materials, are better positioned to capture niche segments of the market.

Aftermarket Services and Maintenance: The market for cryogenic valves is complemented by a growing focus on aftermarket services, including maintenance, repair, and replacement. Companies providing comprehensive service packages can enhance customer satisfaction and foster long-term relationships.

Increased Competition and Consolidation: The cryogenic valves market is becoming increasingly competitive, with several established players and new entrants. Mergers and acquisitions are expected as companies seek to enhance their technological capabilities, expand their product portfolios, and increase market share.

Sustainability Initiatives: As industries aim to reduce their environmental footprint, the demand for energy-efficient and environmentally friendly solutions is on the rise. Cryogenic valves that facilitate sustainable practices, such as minimizing gas leaks and optimizing energy consumption, are becoming more sought after.

Access Complete Report - https://www.credenceresearch.com/report/cryogenic-valves-market

Key Players

Schlumberger (U.S.)

Flowserve Corp. (U.S.)

Baker Hughes (U.S.)

Emerson Electric Co. (U.S.)

Neles Corp. (Finland)

KITZ Corporation (Japan)

Cryostar GmbH (France)

Bray International (U.S.)

HEROSE GmbH (Germany)

Cryocomp (U.S.)

Velan Inc (Canada)

Phpk Technologies (U.S.)

ACME Cryogenics (U.S.)

The Cryogenic Valves market is experiencing several innovative trends that enhance functionality, safety, and efficiency in cryogenic applications. Here are some of the most notable trends shaping this market:

Advanced Materials Development: Innovations in materials science are leading to the development of advanced alloys and composite materials that can withstand extreme temperatures and pressures. These materials improve the durability and reliability of cryogenic valves, reducing the risk of leakage and failures.

Smart Valve Technologies: The integration of smart technologies into cryogenic valves is gaining traction. Smart valves equipped with sensors and IoT connectivity provide real-time monitoring and data analytics, allowing operators to optimize performance, predict maintenance needs, and improve overall system efficiency.

Enhanced Sealing Technologies: New sealing technologies, such as improved elastomers and metal seals, are being developed to enhance the performance of cryogenic valves. These seals are designed to function effectively at low temperatures and under varying pressure conditions, reducing the risk of leaks and improving safety.

Modular and Customizable Designs: Manufacturers are increasingly offering modular and customizable cryogenic valve solutions that can be tailored to specific applications. This flexibility allows users to adapt valves for various systems and processes, enhancing their usability across different industries.

Focus on Energy Efficiency: As industries become more energy-conscious, there is a growing emphasis on developing energy-efficient cryogenic valves. These valves minimize energy loss during operation and optimize flow control, contributing to reduced operational costs and lower environmental impact.

Sustainable Manufacturing Practices: Companies are adopting sustainable manufacturing practices to reduce their environmental footprint. This includes using eco-friendly materials, optimizing production processes, and implementing waste reduction strategies, aligning with global sustainability initiatives.

Improved Design and Simulation Tools: Advanced computer-aided design (CAD) and simulation tools are enabling manufacturers to optimize the design of cryogenic valves before production. These tools help predict performance under extreme conditions, allowing for better reliability and efficiency.

Increased Focus on Safety Features: The cryogenic industry is placing greater emphasis on safety innovations, such as fail-safe mechanisms and enhanced pressure relief systems in valves. These features ensure that valves operate safely under cryogenic conditions, protecting both equipment and personnel.

Automation and Remote Control Capabilities: The trend toward automation in industrial processes is influencing the cryogenic valves market. Valves that can be remotely controlled and automated contribute to safer operations and reduce the need for manual intervention in potentially hazardous environments.

Collaboration and Partnership Models: Companies are increasingly engaging in partnerships and collaborations to drive innovation in cryogenic valve technology. Collaborations with research institutions, technology providers, and industry stakeholders foster the development of cutting-edge solutions and enhance competitive positioning.

Segmentation

By Valve Type

Globe Valves

Gate Valves

Ball Valves

Check Valves

Butterfly Valves

Others

By Material

Stainless Steel

Brass

Bronze

Plastic

Others

By Application

Industrial Gases

Liquefied Natural Gas (LNG)

Healthcare

Aerospace

Energy

Other Applications

By End-Use Industry

Healthcare

Energy

Industrial Gases

Aerospace and Defense

Oil and Gas

Other Industries

By Valve Size

Small Valves (Up to 2 Inches)

Medium Valves (2 to 8 Inches)

Large Valves (Above 8 Inches)

Browse the full report – https://www.credenceresearch.com/report/cryogenic-valves-market

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Ball Valve in Andhra Pradesh

Meghmani Metal Industries is a Manufacturer and Ball Valve Supplier in Andhra Pradesh, India. Our Registered Office and Manufacturing Unit is in Ahmedabad, Gujarat, India. A ball valve is a quarter-turn valve that utilizes a spherical disc (the "ball") to control the flow of fluid through a pipeline. The hole or port through the center of the ball allows fluid to flow when the valve is open and prevents flow when the valve is closed. Various industries widely use ball valves because they offer durability, reliability, and ease of operation. Technical Specifications: Size Range: Typically available from 1/4 inch to 12 inches and larger, depending on the application. Flow Coefficient (Cv): Varies by size and design, indicating the valve's flow capacity. Leakage Class: Designed to meet various leakage standards (e.g., ISO 5208) depending on the application requirements. Actuation Options: Can be manually operated or automated using electric, pneumatic, or hydraulic actuators for remote control. Features: Body types available in two-piece, three-piece, and welded designs, catering to various installation needs. Commonly made from materials such as stainless steel, brass, PVC, and others, depending on the application and fluid type. Offers various end connections, including threaded, flanged, and socket weld, to suit different piping systems. Can handle operating pressures ranging from low to high, with some models designed for extreme conditions. Suitable for a wide temperature range, from cryogenic conditions to high-temperature applications. Meghmani Metal Industries is Manufacturer and Ball Valve Supplier in Andhra Pradesh, India Including Anantapur, Chittoor, East Godavari, Guntur, Krishna, Kurnool, Prakasam, Srikakulam, Sri Potti Sriramulu Nellore, Visakhapatnam, Vizianagaram, West Godavari, Kadapa, Visakhapatnam, Vijayawada, Nellore, Kurnool, Rajamahendravaram, Tirupati, Kakinada, Srikakulam, Yemmiganur, Nagarjunakoṇḍa, Rajahmundry, Adoni, Amaravati, Chandragiri, Dowlaiswaram, Eluru, Guntur, Kadapa, Kakinada. For inquiries, quotes, or to discuss your specific needs, contact us today. View Product: Click Here Read the full article

0 notes

Text

Global Ball Valve Market Set to Expand Amid Growing Demand in Oil & Gas and Water Treatment Sectors

The Ball Valve Market focuses on manufacturing and supplying valves that regulate the flow of liquids and gases through a spherical closure mechanism. These ball valves are essential in controlling the flow in a variety of industries, such as oil and gas, water treatment, power generation, pharmaceuticals, and chemical processing. What makes ball valves highly valuable is their ability to provide reliable sealing and control, even in high-pressure environments. They are known for their durability, simple design, and ability to handle both high temperatures and pressures. By using a rotating ball with a hole in the center, ball valves offer a quick and easy way to start or stop fluid flow with a simple turn of a handle.

Before ball valves became widely used, flow control systems in industries often relied on more complex and less efficient mechanisms that could wear out quickly and were prone to leakage. This led to frequent maintenance issues and operational inefficiencies. Today, ball valves have dramatically improved the way industries manage fluid systems, offering a reliable, low-maintenance solution that ensures precision, safety, and efficiency in various applications. Consumers benefit from reduced downtime, increased safety, and lower operational costs due to the improved performance and durability of ball valves compared to earlier alternatives.

Ball Valve Market Size and Growth in 2023-2030

The Ball Valve Market was valued at approximately USD 12.5 billion in 2023 and is projected to reach around USD 18.3 billion by 2030, growing at a CAGR of 5.3% during the forecast period. This growth is driven by increasing demand in industries such as oil and gas, water treatment, and power generation, where efficient flow control is critical. Additionally, the rise of automation and smart valve technology is further accelerating the market's expansion as industries seek more reliable and cost-effective solutions.

Ball Valve Market Segmentation by Type

In the Ball Valve Market, segmentation by type can be illustrated using the analogy of Low Viscosity Cements, Medium Viscosity Cements, and High Viscosity Cements to represent different types of ball valves based on their application and design features.

Low Viscosity Cements can be compared to standard or floating ball valves, which are commonly used in low-pressure systems and general industrial applications. These valves are cost-effective and ideal for controlling the flow of fluids in non-critical operations, such as in water treatment plants and HVAC systems. Their simple design offers quick shut-off capabilities and requires minimal maintenance.

Medium Viscosity Cements represent trunnion-mounted ball valves, which are designed for higher-pressure systems where more robust flow control is required. These valves are typically used in industries like oil and gas, where maintaining control under higher pressures is essential. The trunnion design reduces the torque required to operate the valve, making it suitable for large-diameter pipelines and more demanding environments.

High Viscosity Cements align with multi-port and cryogenic ball valves, which are designed for specialized applications in sectors such as pharmaceuticals, chemicals, and cryogenics. These valves are engineered to handle extreme temperatures and more complex flow management, offering enhanced precision and durability in critical systems. Their ability to handle challenging environments makes them indispensable in sectors that require specialized solutions.

Ball Valve Market Applications on the Global Stage

The Ball Valve Market plays a pivotal role in several key industries worldwide, providing reliable solutions for controlling the flow of liquids and gases in various systems. The versatility of ball valves, which range from basic to highly specialized types, allows them to be used across diverse applications, from oil and gas pipelines to water treatment plants and power generation facilities. Let’s explore how the ball valve market impacts different industries globally.

1. Oil and Gas Industry: Ensuring Safe and Efficient Flow Control

In the oil and gas sector, ball valves are essential for controlling the flow of crude oil, natural gas, and other hydrocarbons through pipelines and processing plants. Companies like Schlumberger and Emerson Electric manufacture high-performance ball valves designed to withstand the high pressures and temperatures common in upstream and downstream oil and gas applications. These valves ensure operational safety, prevent leakage, and help control the flow in offshore rigs, refineries, and distribution networks. As energy demand increases, the oil and gas sector’s reliance on ball valves for critical flow control solutions is expected to grow steadily.

2. Water and Wastewater Treatment: Managing Flow in Critical Infrastructure

In the water and wastewater treatment industry, ball valves are used to regulate the flow of water through treatment facilities and distribution systems. Ball valves help manage the clean water supply and control the flow of wastewater in urban infrastructure. Municipalities rely on these valves for precise flow control to ensure water treatment processes are efficient, reduce water loss, and maintain safe water quality. Companies like Pentair and Flowserve manufacture ball valves specifically designed to handle the corrosive environments of wastewater systems, ensuring long-term durability and reliability.

3. Power Generation: Enhancing Operational Efficiency and Safety

The power generation sector, including nuclear, coal, and renewable energy plants, relies on ball valves to control the flow of steam, water, and gas in high-temperature and high-pressure environments. These valves play a crucial role in maintaining the operational efficiency of power plants, regulating critical systems, and preventing failures that could lead to costly shutdowns. Ball valves help ensure safe, smooth operations in systems that require precise flow management, such as steam turbines and cooling systems. Companies like Velan and KITZ Corporation provide advanced ball valve solutions tailored to the stringent demands of the power generation industry.

4. Chemical and Pharmaceutical Industry: Ensuring Process Control and Safety

In the chemical and pharmaceutical industries, ball valves are widely used to control the flow of highly corrosive or hazardous fluids. These industries require valves that can provide reliable sealing and precise flow control to ensure the safety and accuracy of production processes. For example, in pharmaceutical manufacturing, ball valves control the flow of ingredients and chemicals in the production of medicines. Emerson and Crane Co. produce specialized ball valves designed to handle aggressive chemicals and maintain high levels of sterility, contributing to the safe and efficient production of chemical products and pharmaceuticals.

5. HVAC and Building Systems: Improving Energy Efficiency

Ball valves are extensively used in HVAC (Heating, Ventilation, and Air Conditioning) systems to regulate the flow of refrigerants, water, and air in commercial and residential buildings. These valves help improve energy efficiency by controlling the flow of fluids within heating and cooling systems, ensuring that buildings maintain optimal temperatures with minimal energy waste. By utilizing ball valves in HVAC systems, companies can reduce energy consumption, leading to lower operational costs and environmental impact. Manufacturers like Honeywell and Johnson Controls supply ball valves that are crucial in optimizing the performance of building systems globally.

Legal Constraints and Limitations of the Ball Valve Market: A Global Perspective

The Ball Valve Market operates under a range of regulatory challenges and legal constraints that vary from country to country. These constraints often revolve around product standards, environmental regulations, and safety requirements, which can impact how manufacturers design, produce, and distribute ball valves globally. Let’s explore the key legal challenges faced by the ball valve industry in different regions.

1. United States: Compliance with Industry Standards and Safety Regulations

In the United States, ball valve manufacturers must comply with strict industry standards and safety regulations set by organizations like the American National Standards Institute (ANSI) and the American Petroleum Institute (API). These standards ensure that ball valves used in sectors such as oil and gas, water treatment, and chemicals meet safety and performance benchmarks. Additionally, ball valves used in infrastructure and energy applications must meet regulations imposed by the Occupational Safety and Health Administration (OSHA) and Environmental Protection Agency (EPA), which govern the safety and environmental impact of these products. Non-compliance with these standards can lead to costly penalties and product recalls, affecting market performance.

2. European Union: Adherence to CE Marking and Environmental Directives

In the European Union (EU), ball valves must meet the CE marking requirements, which ensure compliance with EU safety, health, and environmental protection regulations. Additionally, ball valve manufacturers must adhere to the Restriction of Hazardous Substances (RoHS) directive, which restricts the use of specific hazardous materials in the production of ball valves. The Pressure Equipment Directive (PED) also applies, particularly in industries like energy and chemicals, where ball valves are subject to strict safety and operational guidelines. Non-compliance with these regulations can lead to fines, restricted market access, and reputational damage.

3. China: Material Standards and Quality Control Regulations

In China, the ball valve market is governed by the China Compulsory Certification (CCC), which ensures that products meet national quality and safety standards. Ball valves used in high-risk industries like oil and gas or chemical manufacturing must meet rigorous safety certifications. Additionally, China's environmental policies are becoming increasingly stringent, particularly under the country’s efforts to reduce pollution and improve industrial sustainability. This has led to a growing demand for eco-friendly materials and manufacturing practices. Non-compliance with these national regulations can lead to market restrictions and disrupt supply chains in the region.

4. India: Evolving Industry Standards and Sustainability Challenges

In India, the regulatory landscape for ball valves is evolving, particularly as the country focuses on boosting local manufacturing through initiatives like Make in India. Indian regulations, such as those imposed by the Bureau of Indian Standards (BIS), set safety and performance standards for ball valves used in sectors like water management and oil and gas. Additionally, India is tightening its environmental regulations, requiring ball valve manufacturers to adopt greener manufacturing processes and meet emission control standards. Non-compliance with these regulations can result in limited market access and barriers to trade with international markets.

5. Middle East: Safety and Certification Standards in Oil and Gas

The Middle East, particularly in countries like Saudi Arabia and the United Arab Emirates, has stringent certification standards for ball valves used in the oil and gas sector, which dominates the region's economy. Compliance with certifications from organizations like Saudi Aramco or ADNOC (Abu Dhabi National Oil Company) is essential for manufacturers looking to operate in the region. These certifications ensure that ball valves can withstand the harsh environmental conditions and high pressures present in oil and gas operations. Failure to meet these certifications can result in being excluded from contracts and projects, limiting market opportunities in this critical region.

Conclusion

Over the next five years, the Ball Valve Market is expected to experience steady growth driven by the increasing demand from sectors such as oil and gas, water treatment, and power generation. Key developments will likely focus on smart valve technology, automation, and sustainable manufacturing, with advancements in materials like composite and corrosion-resistant alloys becoming more prominent. Leading companies like Emerson Electric and Flowserve will likely continue their dominance, but emerging players such as Crane Co. and Velan could challenge their position with innovative, cost-effective solutions. Ongoing R&D efforts are centered on enhancing valve durability, improving sealing technologies, and integrating IoT for real-time monitoring and predictive maintenance. Investors and professionals are optimistic about the growth of this market, as the push for more efficient, automated systems in critical industries creates significant opportunities for innovation and long-term profitability.

Browse For More Reports :

Biofuels Market Growth Biostimulants Market Forecast Blood Pressure Cuffs Market Scope Botulinum Toxin Market Trends Brain Computer Interface Market Overview

0 notes

Text

Cryogenic Valves Market Size, Trends, Research Report - 2032 | Reports and Insights

The Reports and Insights, a leading market research company, has recently releases report titled “Cryogenic Valves Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Cryogenic Valves Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Cryogenic Valves Market?

The global cryogenic valves market size reached US$ 3.8 billion in 2023. Looking forward, Reports and Insights expects the market to reach US$ 6.5 billion in 2032, exhibiting a growth rate (CAGR) of 6.2% during 2024-2032.

What are Cryogenic Valves?

Cryogenic valves are specifically designed to control the flow of extremely cold gases and liquids, typically at temperatures below -150°C (-238°F). They are crucial for managing cryogenic substances such as liquid nitrogen, helium, oxygen, and natural gas in industries like aerospace, energy, medical, and chemical processing. Built to maintain secure seals and provide effective insulation, these valves prevent leaks and reduce thermal loss even under extreme cold conditions. Their construction materials and design enable them to endure the expansion and contraction caused by low temperatures, ensuring safe and reliable performance in demanding applications.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1931

What are the growth prospects and trends in the Cryogenic Valves industry?

The cryogenic valves market growth is driven by various factors and trends. Cryogenic valves are designed to manage the flow of extremely cold liquids and gases, typically at temperatures below -150°C (-238°F), such as liquid nitrogen, helium, and oxygen. Essential for sectors like aerospace, energy, medical, and chemical processing, these valves ensure precise control and safe handling of cryogenic fluids. Built to endure the harsh conditions of low temperatures, cryogenic valves are constructed with materials and insulation methods that prevent leakage and reduce thermal loss. Their design accommodates the expansion and contraction of materials due to temperature changes, providing reliable and efficient performance in demanding environments. Hence, all these factors contribute to cryogenic valves market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Paper Type:

Matte Paper

Glossy Paper

Semi-gloss Paper

By Application:

Universal Files Copy Application

Advertisement Making Application

Graphic Design Application

Market Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Emerson Electric Co.

Flowserve Corporation

Schlumberger Limited

Parker Hannifin Corporation

Velan Inc.

Herose GmbH

Chart Industries, Inc.

Cryogenic Limited

L&T Valves Limited

Bray International, Inc.

Powell Valves

Habonim Industrial Valves & Actuators

Valco Group

Samson AG

Valvesco AG

View Full Report: https://www.reportsandinsights.com/report/Cryogenic Valves-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

Cryogenic Equipment Market to Witness Comprehensive Growth by 2030

The Cryogenic Equipment Market was valued at USD 11.3 billion in 2023-e and will surpass USD 17.5 billion by 2030; growing at a CAGR of 6.4% during 2024 - 2030. The report focuses on estimating the current market potential in terms of the total addressable market for all the segments, sub-segments, and regions. In the process, all the high-growth and upcoming technologies were identified and analyzed to measure their impact on the current and future market. The report also identifies the key stakeholders, their business gaps, and their purchasing behavior. This information is essential for developing effective marketing strategies and creating products or services that meet the needs of the target market.

Cryogenic equipment refers to devices used to generate, maintain, and apply extremely low temperatures. This equipment includes cryogenic storage tanks, valves, vaporizers, pumps, and other components that handle cryogenic liquids like liquid nitrogen, helium, oxygen, and hydrogen. These substances are vital in various industries, including healthcare, aerospace, electronics, and energy.

Read More about Sample Report: https://intentmarketresearch.com/request-sample/cryogenic-equipment-market-3387.html

Current Market Trends

Increased Demand in Healthcare: The healthcare sector's growing reliance on cryogenic equipment for the storage and transportation of biological samples, vaccines, and other temperature-sensitive materials has significantly boosted the market. The COVID-19 pandemic highlighted the critical need for reliable cryogenic storage solutions for vaccine distribution.

Advancements in Technology: Technological innovations are driving the development of more efficient and reliable cryogenic equipment. Modern cryogenic systems are designed to minimize energy consumption and reduce operational costs, making them more attractive to various industries.

Expansion in the LNG Industry: The liquefied natural gas (LNG) industry is one of the primary consumers of cryogenic equipment. With the global shift towards cleaner energy sources, LNG production and transport have surged, necessitating advanced cryogenic solutions.

Rising Aerospace and Electronics Applications: Cryogenic equipment plays a critical role in aerospace and electronics manufacturing. The need for precise temperature control in these industries has spurred the adoption of cryogenic technology.

Growth Factors

Environmental Regulations: Stringent environmental regulations are pushing industries to adopt cleaner and more efficient technologies. Cryogenic equipment is essential for reducing emissions and improving energy efficiency, thus aligning with global environmental goals.

Industrialization and Urbanization: Rapid industrialization and urbanization in developing countries are fueling the demand for cryogenic equipment. As industries expand and infrastructure develops, the need for advanced cooling and storage solutions rises.

Increased Research and Development: Continuous R&D efforts in cryogenic technology are leading to the introduction of innovative products and solutions. Companies are investing in research to develop cryogenic equipment that meets the evolving needs of various industries.

Economic Growth: Economic growth in emerging markets is driving the demand for advanced industrial equipment, including cryogenic systems. As these economies grow, their industrial sectors require more sophisticated technologies to maintain competitiveness.

Ask for Customization Report: https://intentmarketresearch.com/ask-for-customization/cryogenic-equipment-market-3387.html

Future Prospects

The future of the cryogenic equipment market looks promising, with several factors indicating sustained growth:

Emerging Applications: New applications for cryogenic equipment are emerging across various sectors. For instance, the growing interest in space exploration and quantum computing is expected to drive the demand for advanced cryogenic solutions.

Technological Advancements: Ongoing advancements in cryogenic technology will likely lead to more efficient and cost-effective solutions. Innovations such as superconducting materials and improved insulation techniques are set to revolutionize the market.

Sustainable Energy Solutions: The global focus on sustainable energy solutions will continue to boost the demand for cryogenic equipment. Hydrogen energy, for instance, requires advanced cryogenic storage and transportation solutions, presenting significant opportunities for market growth.

Strategic Collaborations and Partnerships: Collaborations between key industry players and research institutions are expected to drive innovation and market expansion. These partnerships will facilitate the development of cutting-edge cryogenic technologies and enhance their adoption across various industries.

Conclusion

The cryogenic equipment market is on a trajectory of significant growth, driven by technological advancements, increasing demand in key industries, and the global push towards sustainability. As new applications emerge and existing technologies evolve, the market is poised to offer exciting opportunities for businesses and investors alike. Keeping an eye on these trends and developments will be crucial for stakeholders aiming to capitalize on the growth of the cryogenic equipment market.

#Cryogenic Equipment#Cryogenic Equipment Size#Cryogenic Equipment Forecast#Cryogenic Equipment Growth

0 notes

Text

Stainless Steel Gate Valve Manufacturer in Germany

Stainless Steel Gate Valve Manufacturer in Germany

Valvesonly Europe is a rapidly growing Stainless Steel Gate Valve Manufacturer in Germany. Gate valves made of stainless steel are preferred because of their durability and minimal maintenance needs. The durability and reliability of these valves are enhanced by the stainless steel construction, ensuring resistance to rust and chemical corrosion. They are crucial in scenarios where precise flow control and effective shut-off are vital due to their straightforward design. When a tight seal is required, these valves are frequently employed to make sure that liquids or gases do not seep through the valve when it is closed. In various industries, stainless steel gate valves present a reliable choice when longevity, resistance to corrosion, and durability are essential considerations.

Special Features

Stainless steel gate valves, known for corrosion resistance, cater to diverse needs with features like elastomer seating and knife gate designs. Adaptable to cryogenic applications and meeting API/ANSI standards, they offer safety features such as fire-safe design and resilient wedge gates. With low maintenance and diverse configurations, including through-conduit designs, these valves are reliable and certified for quality in various industrial applications.

Types:

l Wedge Stainless Steel gate valve

l Pressure seal Stainless Steel gate valve

l Bellow seal Stainless Steel gate valve

l Rising stem gate Stainless Steel Gate Valve

l Non rising stem Stainless Steel Gate Valve

l Electric Stainless Steel Gate Valve

l Pneumatic Stainless Steel Gate Valve

Advantages:

l Corrosion Resistance

l Durability

l Tight Shut-off

l Versatility

l Low Maintenance

l Precise Flow Control

l Reliability

l Compatibility

l Safety

Working Principle:

The working principle of a Stainless Steel Gate Valve revolves around a straightforward yet effective mechanism designed to control the flow of fluids. The gate creates a seal when lowered, stopping the flow. Lifting the gate allows fluid to pass. These valves are versatile, corrosion-resistant, and operate manually or with actuators for precise control in diverse industrial settings.

Industry:

Chemical

Petrochemical

Power Generation

Pulp and Paper

Oil and Gas

Oil Refineries

Mining

In conclusion, Germany's Stainless Steel Gate Valve epitomises precision and reliability in fluid control systems. Adhering to high-quality standards, these valves excel across industries, offering robust construction and adaptability for optimal performance.

Description:

Available materials: Aluminium Bronze, Monel, Bronze, Brass, Duplex steel, Inconel, Incoloy, Titanium, WCB, CF8, CF8M, CF3, CF3M, WC1, WC6, WC9, Cast iron, Super Duplex, SS304, SS904, SS904L, SS316.

Size: 1/2″- 64”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Operations: Hand Wheel, Gear operated, Electric actuated and Pneumatic Actuated

Ends: Buttweld, Socket weld, Threaded, Flanged (FF, RF, RTJ)

Visit us : https://www.valvesonlyeurope.com/product-category/bs-stainless-steel-gate-valve/

0 notes

Text

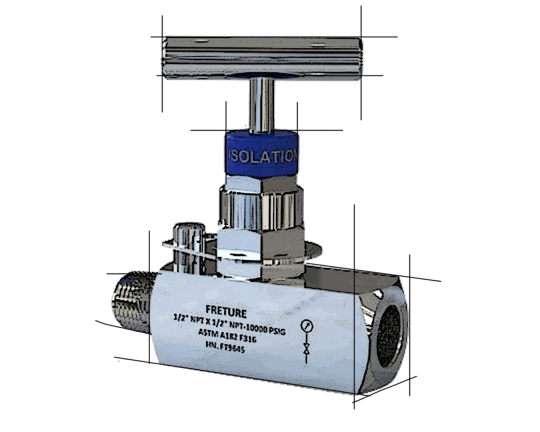

High Pressure Needle Valves: Precision Flow Control in Demanding Applications

In the realm of fluid control systems, high pressure needle valves stand out as indispensable components, offering precise regulation of flow in some of the most challenging industrial environments. These valves, characterized by their ability to withstand extreme pressures while providing accurate flow control, play a crucial role across various sectors, from oil and gas to chemical processing and hydraulic systems.

Understanding High Pressure Needle Valves

A high pressure needle valve is a type of linear motion valve designed to regulate flow with high precision, particularly in systems operating under significant pressure. The valve's name derives from its key component: a slender, tapered pin (the "needle") that moves in and out of a small orifice to control flow. This design allows for extremely fine adjustments, making needle valves ideal for applications requiring meticulous flow regulation.

Key Features and Advantages

Precise Flow Control: The gradual taper of the needle and its fine-threaded stem allow for minute adjustments, enabling operators to achieve exact flow rates.

High Pressure Capability: Engineered to withstand pressures ranging from several hundred to thousands of bar, these valves maintain their integrity in extreme conditions.

Tight Shut-off: When fully closed, the needle forms a metal-to-metal seal with the seat, ensuring minimal to zero leakage.

Durability: Constructed from high-strength materials, these valves offer long service life even in harsh operating environments.

Compact Design: Despite their high pressure capabilities, needle valves are relatively small, making them suitable for installations with space constraints.

Versatility: Available in various configurations to suit different mounting requirements and flow directions.

Construction and Materials

The effectiveness of a high pressure needle valve largely depends on its construction and the materials used:

Body: Typically made from forged steel, stainless steel, or special alloys like Monel or Hastelloy for corrosive applications.

Needle (Stem): Usually constructed from hardened stainless steel or other wear-resistant alloys to ensure longevity and maintain a tight seal.

Seat: Often integrated into the valve body, but may be replaceable in some designs. Material choice depends on the application but is generally a hardened alloy compatible with the body material.

Packing: High-quality packing materials like PTFE or graphite are used to prevent leakage around the stem while allowing smooth operation.

Bonnet: Secures the packing and guides the stem. In high pressure applications, a bolted bonnet design is common for added strength.

The choice of materials is critical and depends on factors such as operating pressure, temperature, media compatibility, and environmental conditions.

Types of High Pressure Needle Valves

Several variations of high pressure needle valves exist, each designed to meet specific application requirements:

Standard Needle Valves: The most common type, suitable for a wide range of general applications.

Micro-Metering Valves: Feature an exceptionally fine needle taper for ultra-precise flow control, often used in laboratory or analytical equipment.

Multi-Port Needle Valves: Incorporate multiple inlets or outlets for complex flow control scenarios.

Angle Pattern Needle Valves: Designed with the inlet and outlet at right angles, useful in certain piping configurations.

Bar Stock Needle Valves: Machined from solid bar stock for maximum pressure handling capability.

Cryogenic Needle Valves: Specially designed to maintain functionality at extremely low temperatures.

Applications Across Industries

The versatility and precision of high pressure needle valves make them indispensable in numerous industrial applications:

Oil and Gas: Used in wellhead control panels, sampling systems, and pressure reduction stations.

Chemical Processing: Crucial for precise chemical injection and reactor feed control.

Hydraulic Systems: Employed in pressure control and hydraulic test benches.

Power Generation: Found in steam sampling systems and turbine control.

Aerospace: Used in fuel systems and hydraulic controls of aircraft.

Research and Development: Essential in high pressure testing equipment and experimental setups.

Water Jet Cutting: Control water flow in high pressure cutting systems.

Considerations for Selection and Installation

Choosing the right high pressure needle valve requires careful consideration of several factors:

Pressure Rating: Must exceed the maximum system pressure with an appropriate safety margin.

Temperature Range: Ensure compatibility with both the minimum and maximum expected temperatures.

Flow Coefficient (Cv): Select a valve with an appropriate Cv for the required flow rate and pressure drop.

Material Compatibility: Choose materials resistant to corrosion and degradation by the process media.

Connection Type: Consider the existing piping system (e.g., NPT threads, tube fittings, welded connections).

Actuation Method: Determine if manual operation is sufficient or if automated control is necessary.

Maintenance and Safety Considerations: Evaluate accessibility for maintenance and incorporate necessary safety features.

Installation best practices include proper alignment, use of appropriate thread sealants or gaskets, and adherence to torque specifications. In high pressure systems, it's crucial to follow proper start-up and shutdown procedures to prevent sudden pressure surges that could damage the valve or connected equipment.

Maintenance and Safety

Proper maintenance is essential to ensure the longevity and safe operation of high pressure needle valves:

Regular Inspection: Check for signs of wear, leakage, or damage, particularly around the stem and seat area.

Lubrication: Periodically lubricate the stem threads to ensure smooth operation, using lubricants compatible with the process media.

Packing Adjustment: Tighten or replace packing as needed to prevent leakage around the stem.

Cleaning: Remove any debris or buildup that could affect valve performance or cause uneven wear.

Testing: Regularly verify proper operation and shut-off capability, especially in critical applications.

Safety is paramount when working with high pressure systems. Always follow proper lockout/tagout procedures before performing maintenance. When opening a high pressure needle valve, do so gradually to prevent sudden pressure release. Training personnel in the proper operation and maintenance of these valves is crucial to prevent accidents and ensure optimal performance.

Innovations and Future Trends

The field of high pressure needle valve technology continues to evolve, driven by industry demands for greater efficiency, safety, and control:

Advanced Materials: Development of new alloys and composites to enhance pressure capabilities and corrosion resistance.

Smart Valves: Integration of sensors and digital controls for real-time monitoring and remote operation.

Improved Sealing Technologies: Innovations in seat and stem designs to enhance shut-off capabilities and reduce wear.

Additive Manufacturing: Exploration of 3D printing techniques for producing complex valve geometries or custom solutions.

Miniaturization: Development of smaller, high-performance valves for space-constrained applications.

Enhanced Ergonomics: Redesigned handles and actuation mechanisms for improved operator comfort and precision.

As industries push the boundaries of pressure and flow control, high pressure needle valves will undoubtedly continue to play a critical role. Ongoing research and development efforts focus on expanding the operational limits of these valves while improving their longevity, ease of use, and integration with modern control systems.

Conclusion

High pressure needle valves represent a pinnacle of precision flow control technology, capable of operating under extreme conditions while providing the fine adjustments necessary for critical processes. Their importance across various industries underscores the need for continued innovation and refinement in valve design and materials.

For engineers and system designers working with high pressure applications, a thorough understanding of needle valve principles, selection criteria, and maintenance requirements is essential. By choosing the right valve and implementing proper care and operation procedures, industries can ensure safe, efficient, and reliable flow control in even the most demanding environments.

As we look to the future, high pressure needle valves will undoubtedly continue to evolve, incorporating new technologies and materials to meet the ever-increasing demands of modern industrial processes. Their role in ensuring precise, safe, and efficient fluid control remains as critical as ever, making them an indispensable component in the landscape of high pressure fluid systems.

0 notes

Text

Control Valves - A Comprehensive Analysis of the Current and Future Demand Get Free Sample PDF -https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=534&utm_source=organic&utm_medium=organic Control valve is a power-operated device used to regulate or manipulate the flow of fluids, such as gas, oil, water, and steam. It plays a crucial role in a control loop and serves as a control element in industrial applications. The primary purpose of a control valve is to adjust the flow, pressure, temperature, or level of a fluid within a piping system. Electric control valves respond to signals from a control system, using an actuator and a positioner. The control valve receives information from various sensors and transmitters to manage fluid parameters. Valve body subassembly, actuating device, and valve positioner are major components of control valves. Ball valves, butterfly valves, cryogenic valves, and globe valves are some of the common types of control valves. Key Players -AVK Holding A/S, Bürkert Fluid Control Systems, Emerson Electric Co., Flowserve Corporation, General Electric Company, Goodwin International Ltd, Honeywell International Inc., KITZ Corporation, Rotork Plc, and Schlumberger Limited

0 notes

Text

Control Valves Market Size, Share, Trends, Growth and Competitive Outlook

"Global Control Valves Market – Industry Trends and Forecast to 2028