#Corundum Industry

Explore tagged Tumblr posts

Text

Do you guys want more posts about some of the rocks I have?

And why is the answer yes, you really want to learn about pink dolomite?

#anyways I'm having a thought. because brain rot. and obviously techno is sooooo rhodochrosite.#but also he is so corundum. and not in a 'ooh ruby red stone like blood' way. but yeah also that#but in the way that most people think it's a pretty stone to be cut and polished and made by people into jewelry when the primary use is#actually as an industrial material

7 notes

·

View notes

Text

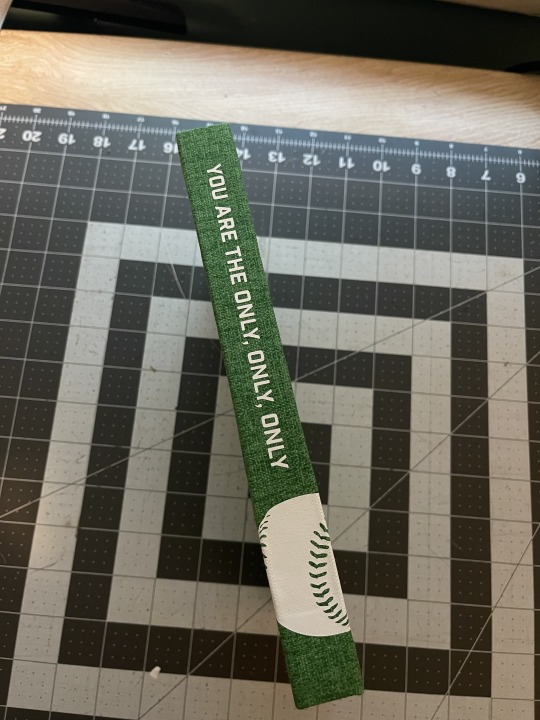

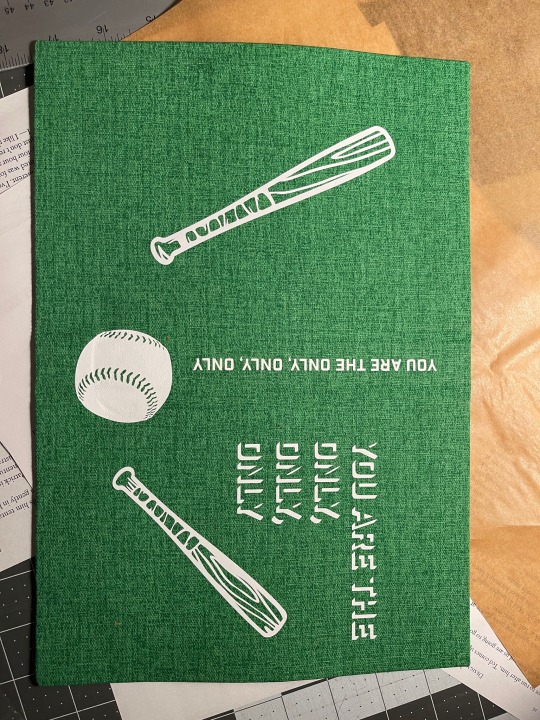

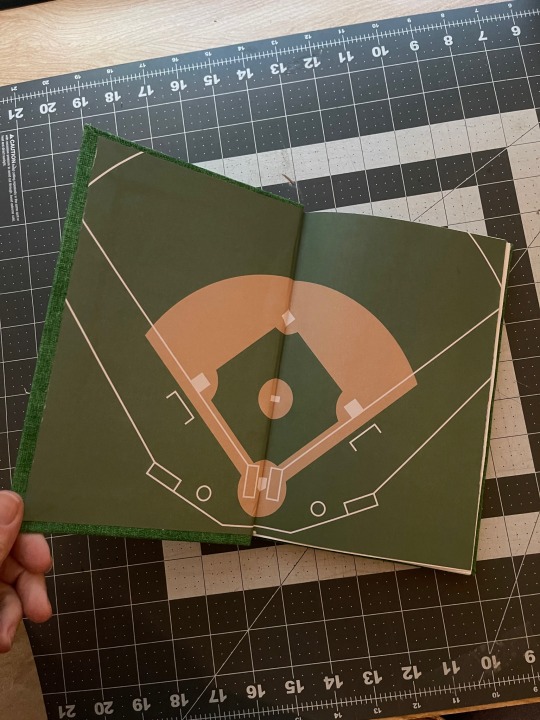

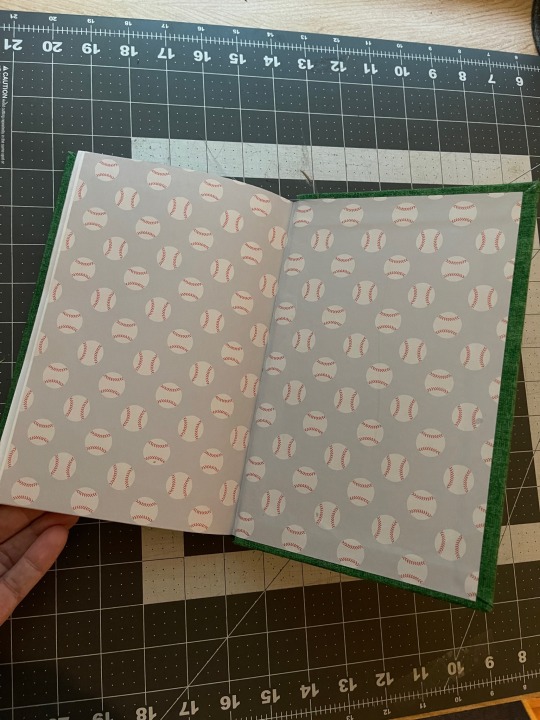

Bound: You Are the Only, Only, Only by DesignatedGrape

This was the second book I ever bound, but I was relying on the kindness of a friend to deliver it, but it made its way into the hands of its intended recipient (the author, the delightful @designatedgrape, who I followed into the Check, Please fandom as well, so I am very grateful for them) this weekend!

The fic is a Schitt's Creek baseball AU, and I had a lot of fun with that when designing it. I used two different baseball-themed endpapers, and chose a grass green fabric for the cover. The chapter headings featured the corresponding number of baseballs.

My favorite little secret surprise, though, is in the endbands. This was made before I ordered premade endbands, so I had to make them out of fabric. And I found the perfect fabric...

Once you know what the fabric is, you can see it but otherwise they just look like normal endbands.

Fonts used: Body: Corundum Text Titles: Industry Inc

81 notes

·

View notes

Note

can you guys chill lmao. just trying to help

Sapphire is a precious gemstone, a variety of the mineral corundum, consisting of aluminium oxide (α-Al2O3) with trace amounts of elements such as iron, titanium, cobalt, lead, chromium, vanadium, magnesium, boron, and silicon. The name sapphire is derived from the Latin word sapphirus, itself from the Greek word sappheiros (σάπφειρος), which referred to lapis lazuli. It is typically blue, but natural "fancy" sapphires also occur in yellow, purple, orange, and green colors; "parti sapphires" show two or more colors. Red corundum stones also occur, but are called rubies rather than sapphires. Pink-colored corundum may be classified either as ruby or sapphire depending on locale. Commonly, natural sapphires are cut and polished into gemstones and worn in jewelry. They also may be created synthetically in laboratories for industrial or decorative purposes in large crystal boules. Because of the remarkable hardness of sapphires – 9 on the Mohs scale (the third hardest mineral, after diamond at 10 and moissanite at 9.5) – sapphires are also used in some non-ornamental applications, such as infrared optical components, high-durability windows, wristwatch crystals and movement bearings, and very thin electronic wafers, which are used as the insulating substrates of special-purpose solid-state electronics such as integrated circuits and GaN-based blue LEDs. Sapphire is the birthstone for September and the gem of the 45th anniversary. A sapphire jubilee occurs after 65 years.

Sapphire is one of the two gem-varieties of corundum, the other being ruby (defined as corundum in a shade of red). Although blue is the best-known sapphire color, they occur in other colors, including gray and black, and also can be colorless. A pinkish orange variety of sapphire is called padparadscha.

Significant sapphire deposits are found in Australia, Afghanistan, Cambodia, Cameroon, China (Shandong), Colombia, Ethiopia, India Jammu and Kashmir (Padder, Kishtwar), Kenya, Laos, Madagascar, Malawi, Mozambique, Myanmar (Burma), Nigeria, Rwanda, Sri Lanka, Tanzania, Thailand, United States (Montana) and Vietnam. Sapphire and rubies are often found in the same geographical settings, but they generally have different geological formations. For example, both ruby and sapphire are found in Myanmar's Mogok Stone Tract, but the rubies form in marble, while the sapphire forms in granitic pegmatites or corundum syenites.

Every sapphire mine produces a wide range of quality, and origin is not a guarantee of quality. For sapphire, Jammu and Kashmir receives the highest premium, although Burma, Sri Lanka, and Madagascar also produce large quantities of fine quality gems.

The cost of natural sapphires varies depending on their color, clarity, size, cut, and overall quality. Sapphires that are completely untreated are worth far more than those that have been treated. Geographical origin also has a major impact on price. For most gems of one carat or more, an independent report from a respected laboratory such as GIA, Lotus Gemology, or SSEF, is often required by buyers before they will make a purchase.

9 notes

·

View notes

Text

Mineral Swag Round 1: Can You Even Tell the Difference?

More information under the cut!

Look, in 2023, natural diamonds are OUT.

I'll be honest, unless you're going to admire the natural shape of a mineral or its raw color and imperfections (for example, garnet in its dodecahedral form), I think natural minerals serve little purpose except education and research! I mean, if you're going to cut up and polish the mineral anyway, why care if it was lab grown (and hundreds of dollars cheaper) or "naturally" formed in the rocks somewhere?

And hopefully most people know by now that natural diamonds are a ethical nightmare! Even conflict free diamonds are not entirely ethical! The prices of diamonds are insanely inflated, many people suffered to get that diamond, and almost no one could tell the difference between a lab-made and natural diamond because they're really the same exact thing.

I suppose I’m not here to rant and rave about natural vs lab-made gems so, onto the specific issue of diamonds vs white sapphires...

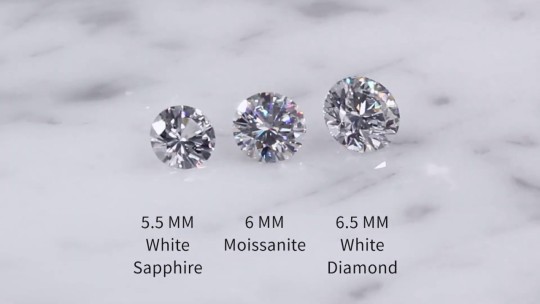

There are a couple differences. First off, among lab-created stones, sapphire is usually cheaper.

Of course, diamond will always be harder than sapphire. Jewelry companies say corundum could show more wear than diamond, but unless you're using a piece of jewelry as an industrial grade sandpaper, it's much more likely that the gold jewelry setting will show signs of wear when compared to either gem (gold is very soft) so I'm inclined to say that's mostly a marketing tactic.

But, if you need an industrial grade sandpaper, or a blade for a rock saw, diamond really IS what you need! Diamonds are very efficient when it comes to cutting hard things (including other diamonds) and they absolutely have their place in SCIENCE and maybe in your jewelry, as long as it’s lab-created.

Bonus: Can you tell the difference between these gems, because I'm pretty practiced at comparing rocks and minerals and it’s pretty difficult to tell.

20 notes

·

View notes

Photo

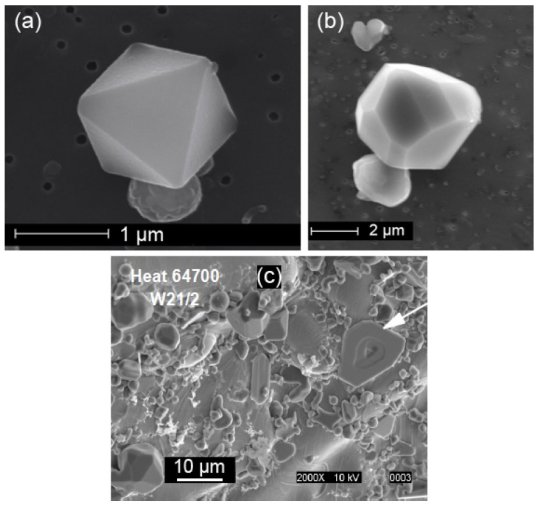

Examples of faceted Al2O3 inclusion in steel

Inclusion name: Alumina Record No.: 1282 Inclusion formula: Al2O3 Inclusion type (Macro/Micro/Nano): Micro Inclusion type (Exogenous/Indigenous): Indigenous Inclusion classification: Oxide Inclusion composition in weight %: No data Sample: Steel Steel composition in weight %: No data Note: Inclusion with well developed facet planes and a three-dimensional character are classified as faceted inclusions (Fig. 1). They are also numerously found in industrial samples. Their size ranges from a few ìm to few tens µm. In the work of Dekkers, faceted inclusions are further classified as octahedral (Fig. 1 (a)) or non-octahedral (Fig. 1 (b)). The reason is the belief that corundum, which cannot develop an octahedral habit, is not the only Al2O3 phase present in liquid steel. Other Al2O3 polymorphs could explain the presence of octahedral inclusions. The facets appear in the crystal habit as a result of slower growth rate, and the subsequent ability of the crystal to arrange the incoming growth units in the configuration that minimises the surface energy. Such growth conditions are obtained at lower supersaturation degree. From that point of view, faceted inclusions cannot be formed during cooling. Also, the size of the polygonal inclusions was found to be independent on the cooling rate of the Fe. As a result of different supersaturation degrees during the growth of the polyhedral crystal, flat, concave or hopper faces (Fig. 1 (c)) on the octahedral inclusions were observed. Large faceted inclusions can also result from the sintering and densification processes of aggregates. Overgrowth of plate-like inclusions or dendrites was occasionally observed on small octahedral inclusions.

Source.

12 notes

·

View notes

Text

Imperial Research Division Technical Report: Advancements in Phrik Alloy Metallurgy

Author: Dr. Jaina Dallows

Abstract: This technical report presents the findings of my research into metallurgy and the subsequent improvements made to Phrik and its alloys, a highly sought-after material renowned for its exceptional durability and lightsaber resistance. Through a comprehensive analysis of existing metallurgical techniques, combined with innovative experimentation and synthesis processes, I have successfully enhanced the structural properties and applicability of Phrik and its alloys, paving the way for enhanced military armaments and defensive systems in the Imperial arsenal.

Introduction: Phrik Alloy has long been revered for its unique properties, most notably its capability to withstand the energy blades of lightsabers. However, its insusceptibility to tooling, brittleness, and limited supply has hindered its widespread use. This research aimed to revolutionize phrik metallurgy by developing novel techniques that enhance its qualities, increase yield, and reduce the production costs associated with its synthesis.

2.1 Material Selection: A range of base metals, including beskar, corundum, vanadium, and tunqstoid, were meticulously examined to determine their suitability for alloying with Phrik. Through a series of trial compositions and evaluations, a combination of corundum and vanadium emerged as the optimal choice, offering improved hardness, thermal stability, and corrosion resistance.

2.2 Synthesis Process: The standard production process for phrik alloys was enhanced by introducing advanced metallurgical methodologies. A proprietary smelting technique involving controlled fusion in an plasma arc furnace was employed to ensure a homogeneous distribution of the constituent elements and minimize impurities. Furthermore, a novel quenching and tempering process was developed to enhance the material's hardness and resilience.

2.3 Nanostructural Modification: To further enhance the material's inherent properties, nanoscale structural modifications were introduced to the Phrik Alloy. Through controlled heat treatment, the alloy's grain boundaries were refined, resulting in increased mechanical strength and improved fracture toughness. This technique also mitigated the risk of crack propagation, rendering the alloy more resistant to catastrophic failure.

Characterization and Analysis: Comprehensive characterization of the improved Phrik Alloy was performed to validate its enhanced properties. Key tests included microstructural analysis using a hyperlight beam emission topographer, Erso hardness measurements, and tensile strength evaluations. The alloy exhibited an increase of 25% in hardness, surpassing its predecessors, while maintaining excellent ductility and resilience. Notably, the modified alloy demonstrated a 30% increase in resistance to ablative shock compared to previous iterations.

Industrial Implementation: The successful advancements in Phrik Alloy metallurgy have profound implications for the Empire's military capabilities. The improved alloy can be seamlessly integrated into various applications, including armored plating, melee weapons, and critical ship components. The increased availability and reduced production costs will allow for wider deployment within the Imperial forces, ensuring superior protection against lightsaber-wielding adversaries.

Conclusion: This research report presents a significant milestone in the development of Phrik Alloy metallurgy. By incorporating advanced techniques and nanostructural modifications, we have successfully improved the material's hardness, resilience, and theoretical lightsaber resistance. The enhanced Phrik Alloy offers the Empire a distinct advantage in combat scenarios, with the potential to revolutionize the defense industry. Further research is underway to explore additional applications and potential synergies with other advanced materials.

Acknowledgments: The author expresses sincere gratitude to the Imperial Research Division for providing the necessary resources and support for this study. Special thanks are extended to the team of researchers involved in the experimental work, and Commodore Fordo, without whom this breakthrough would not have been possible.

Disclaimer: The research findings contained in this report are classified and intended solely for internal distribution within the Imperial Research Division. Unauthorized reproduction or dissemination is strictly prohibited.

2 notes

·

View notes

Text

Why Are Natural Rubies So Expensive?

Natural rubies are highly valued in the jewelry industry, fetching exorbitant prices due to a combination of unique factors. This article aims to provide a detailed, logical, and popular science-style explanation of the reasons behind the high prices of natural rubies.

Rarity and Formation

Natural rubies are among the rarest gemstones in the world. Their scarcity is a primary reason for their high price. Rubies are formed under specific geological conditions, requiring high temperatures and pressures over millions of years. The primary sources of rubies include countries like Myanmar (Burma), Sri Lanka, Thailand, and Brazil, where the geological structures and mineral resources are conducive to their formation.

The process of ruby formation begins with the crystallization of aluminum oxide (corundum) in the presence of chromium, which gives the ruby its iconic red color. The铬 element is crucial as it determines the color intensity and purity of the ruby. The combination of these factors is not only rare but also occurs in limited geological zones, making rubies exceptionally hard to find.

Color and Clarity

The value of a ruby is heavily influenced by its color and clarity. The most sought-after rubies are those with a vivid, pure red color, often described as “pigeon’s blood” red. This color is the most rare and commands the highest prices. Rubies with secondary colors such as pink or purple are also valuable but typically fetch lower prices compared to pure red ones.

Clarity refers to the absence of inclusions or flaws within the gemstone. A ruby with high clarity is more valuable because it allows for better light transmission and reflection, enhancing its overall beauty and brilliance. Natural rubies often contain inclusions, such as rutile silk or fluid inclusions, which can affect their clarity and, consequently, their value. The fewer and less visible these inclusions, the higher the price of the ruby.

Size and Cut

Size is another critical factor determining the price of a ruby. Larger rubies are rare and, therefore, more expensive. The larger the gemstone, the more difficult it is to find one with good color, clarity, and cut. Carat weight is a significant factor in pricing rubies, and the price per carat typically increases exponentially with size.

The cut of a ruby is crucial for maximizing its beauty and value. A well-cut ruby will have a balanced proportion between its depth, width, and table size, ensuring optimal light performance. The cutter must strike a balance between retaining carat weight and achieving an attractive appearance. Poorly cut rubies may appear dull or lack brilliance, reducing their value despite their potential color and clarity.

Demand and Supply

The demand for natural rubies far exceeds their supply, driving up prices. Rubies have held cultural and symbolic significance across various civilizations, making them highly sought-after for jewelry and investment purposes. In many cultures, rubies symbolize love, passion, and power, making them ideal for engagement rings, anniversary gifts, and other significant occasions.

The increasing demand for rubies, coupled with their limited availability, creates a supply-demand imbalance. This imbalance results in high prices and strong market demand, even for smaller and less perfect rubies. As economies grow and disposable income increases, more people can afford to buy luxury items like natural rubies, further pushing up prices.

Cultural Significance

Rubies have a rich history and cultural significance that adds to their value. For centuries, rubies have been associated with royalty, power, and love. In ancient times, they were believed to possess magical powers and were used in talismans and religious artifacts. This historical and cultural association has made rubies highly valuable and sought-after, particularly in cultures where they hold special significance.

In many Asian countries, rubies are considered auspicious and are often given as gifts during significant life events like weddings and births. Their cultural significance and traditional value have helped maintain a strong demand for rubies, even during economic downturns.

Investment Potential

Rubies are considered a valuable investment due to their scarcity, beauty, and cultural significance. Over the long term, the value of natural rubies has generally appreciated, making them a sound investment option. Unlike some other investments, rubies are tangible assets that can be enjoyed and worn while appreciating in value.

Investors often look for high-quality rubies with excellent color, clarity, and cut, as these are likely to retain their value and appreciate over time. The limited supply of high-quality rubies ensures that demand will continue to outstrip supply, supporting price growth.

Difficulty in Mining and Production

Mining natural rubies is a challenging and labor-intensive process. Ruby deposits are often located in remote and inaccessible areas, making extraction difficult and costly. Additionally, the extraction process can be environmentally destructive, leading to increased regulatory scrutiny and costs.

Once extracted, rubies require skilled cutting and polishing to bring out their beauty and maximize their value. The cutting and polishing process is labor-intensive and requires highly skilled craftsmen. The combination of mining difficulties, environmental concerns, and the need for skilled labor contributes to the high cost of producing natural rubies.

Conclusion

Natural rubies are exceptionally valuable due to their rarity, unique color, clarity, size, cultural significance, investment potential, mining and production difficulties, and the need for quality assurance and certification. These factors combined make natural rubies a highly sought-after gemstone with a strong market demand and high prices. Understanding these reasons helps explain why natural rubies continue to be a cornerstone of the jewelry industry and a cherished possession for many collectors and enthusiasts.

0 notes

Text

A-99 Aluminium Oxide High-Purity Corundum Thermal Storage Balls

Corundum thermal storage balls have remarkable features such as low reheat line shrinkage, high softening temperature under high-temperature load, corrosion resistance, high strength, large heat storage and release, good thermal shock stability, good thermal conductivity, and small thermal expansion coefficient. They have a longer service life and better energy-saving effect.

Compared with the current commonly used alumina heat storage balls, high purity corundum (AL203>99.5%) heat storage balls are better in thermal shock resistance, slag resistance, corrosion resistance, longer service life, and better energy-saving effect.

+86-18501518842 / +86-13587222672

+86-0572-2926332 / 2926337

+86-0572-2926335

No.11 Building, South Taihu High-tech Intelligent Manufacturing Industrial Park, Wuxing District, Huzhou City, Zhejiang, China

0 notes

Text

White Grinding Wheels Manufacturer: Precision and Performance in Every Wheel

In the world of grinding, the choice of the right wheel is crucial to achieving the desired finish and precision. White grinding wheels, known for their versatility and efficiency, are widely used in various industrial applications, especially in precision grinding and sharpening tasks. These wheels are made from high-grade aluminum oxide, which provides a combination of hardness, sharpness, and wear resistance. As a leading white grinding wheel manufacturer, the focus is on delivering superior quality and performance that meet the demands of various industries.

Material Quality and Manufacturing Excellence

White grinding wheels are typically made from pure aluminum oxide, also known as white corundum. This material is prized for its sharp cutting edges and ability to maintain cool grinding temperatures, which helps in preventing overheating of the workpiece. The manufacturing process involves carefully selecting and blending the raw materials to achieve the right balance of hardness and friability, ensuring that the wheel remains sharp while minimizing the risk of loading or glazing.

Manufacturers use advanced techniques such as vitrification to bond the abrasive grains together. This process creates a strong, durable wheel that maintains its shape White Grinding Wheels Manufacturer and cutting efficiency over time. The consistency in grain size and distribution is critical, as it directly affects the wheel’s grinding performance and the quality of the finish on the workpiece.

Customization and Quality Control

A reputable white grinding wheel manufacturer offers a range of customization options to meet specific customer requirements. This can include adjusting the wheel’s size, grit, and bonding type to suit particular applications, whether it’s for precision sharpening, surface grinding, or tool sharpening.

Quality control is a top priority for manufacturers, with each wheel undergoing rigorous testing to ensure it meets industry standards. This includes checks for balance, durability, and cutting performance. The goal is to produce wheels that deliver consistent results, minimizing downtime and maximizing productivity for users.

Conclusion

White grinding wheels are a staple in precision grinding operations, known for their ability to produce fine finishes and maintain sharpness under demanding conditions. As a manufacturer, the commitment to quality, innovation, and customer satisfaction ensures that these wheels continue to meet the evolving needs of the industry. Whether used in tool rooms, production lines, or custom applications, white grinding wheels offer reliability and performance that professionals can trust.

0 notes

Text

Various types of ceramic crucibles: quartz, alumina, boron nitride, zirconia

As an important component of chemical instruments, crucibles are containers for melting and refining metal liquids, as well as solid-liquid heating and reaction. They are the basis for ensuring the smooth progress of chemical reactions. Historically, crucibles were originally made of clay, and one of the earliest uses of platinum was also for preparing crucibles. However, with the development of preparation technology, crucibles can now be made of any material that can melt or change its contents.

There are many types, models, and specifications of crucibles, which can be selected at will, with strong applicability, and can ensure the purity of the smelted material. Among them, ceramic crucibles are an important component of crucibles, and ceramic crucibles can be divided into quartz crucibles, corundum crucibles, boron nitride crucibles, zirconia crucibles, etc. according to the raw materials, and are used in different occasions according to their respective properties.

1. Quartz Ceramic Crucible

Quartz ceramic crucible, full name high-purity fused quartz ceramic crucible (silicon dioxide content ≥ 99.9%), is a ceramic crucible made of high-purity fused quartz as raw material. It has the characteristics of fine structure, low thermal conductivity, small thermal expansion coefficient, good thermal shock stability, good electrical properties, good chemical corrosion resistance, etc. Therefore, quartz ceramic crucible is widely used in the glass deep processing industry, metallurgical industry, electronics industry, chemical industry, aerospace, and other fields. Generally speaking, its shapes are mainly square and cylindrical.

With the attention and development of environmentally friendly energy, solar energy as a green energy has been widely valued by countries around the world. The use of polysilicon for solar energy conversion has increased dramatically, which has promoted the rapid development of polysilicon production. Therefore, the use of large-sized thin-walled square fused quartz ceramic crucibles has also increased dramatically, and the international market prospects are very optimistic about it.

2. Alumina crucible

Corundum crucible, scientific name alumina crucible, people usually call crucibles with an alumina content of more than 95% corundum crucibles. Corundum crucibles are hard and resistant to melting, high-temperature resistance, acid and alkali resistance, rapid cooling, and extreme heat resistance, chemical corrosion resistance, suitable for using anhydrous Na2CO3 and other weak alkaline substances as a flux to melt samples, but not suitable for using Na2O2, NaOH and other strong alkaline substances and acidic substances as a flux to melt samples.

99.70% corundum crucibles have good high-temperature insulation and mechanical strength in an oxidizing and reducing atmosphere of 1650℃-1700℃, and the short-term use temperature can reach up to 1800℃. According to the application conditions, alumina crucibles are available in a variety of sizes and shapes, such as arc crucibles, round bottom crucibles, straight crucibles, square crucibles, etc.

3. Boron nitride crucible

The common types of boron nitride are cubic boron nitride (C-BN) and hexagonal boron nitride (h-BN). Among them, boron nitride crucibles are usually made of h-BN. h-BN ceramics have good heat resistance, thermal stability, thermal conductivity, and high-temperature dielectric strength. They are ideal heat dissipation materials and high-temperature insulation materials.

Due to the excellent chemical stability of h-BN, it can resist the erosion of most molten metals. Because of the above-mentioned high-temperature insulation properties, high thermal conductivity, and low thermal expansion, it is most suitable as a material used in strict environmental conditions such as semiconductor processes. h-BN crucibles are often used for melting metals and semiconductors. Its operating temperature under vacuum is as high as 1800 degrees, and its operating temperature under atmosphere protection can reach up to 2100℃. It is generally protected by nitrogen or argon (atmosphere protection is to prevent the crucible from oxidation).

4. Zirconia crucible

The melting point of zirconia is higher than that of zirconium, reaching 2700℃. It is one of the materials with the best refractory performance in nature. Even if it is heated to 1900℃, it will not react with molten aluminum, iron, nickel, platinum, and other metals, silicates, and acidic slags. Therefore, Zirconia crucibles can successfully melt platinum, palladium, ruthenium, cesium, and other platinum group precious metals and their alloys.

It is worth noting that although zirconia is more expensive than alumina, it is a special oxide refractory material that cannot be replaced by other oxide materials when used in high-temperature furnaces above 2000℃.

0 notes

Text

"September Birthstone: The Timeless Beauty and Power of Sapphire"

Embrace Your September Birthstone: Sapphire

Hey, September born! Each month has its own special gem, and for those born in September, it's the enchanting Sapphire. Bestowing a piece of jewelry with this birthstone is believed to bring the wearer good luck and protection. Birthstones symbolize the month of birth according to the Gregorian calendar.

What Makes Sapphire Special

The Sapphire, associated with truth, sincerity, and consistency, is the birthstone for September. Traditionally, Sapphires are believed to possess mystical properties that enhance vision, understanding, and interpretation. They are reputed to be effective in treating medical issues like lowering fevers, reducing inflammation, and aiding with hearing problems. Sapphires are also thought to amplify the effects of Venus and banish negative thoughts.

The Historical Significance of Sapphire

The word "Sapphire" is derived from the Greek word for blue. Since ancient times, blue sapphires have symbolized honesty, loyalty, purity, and trust. They are one of the most popular engagement gemstones today. While sapphires are found in many parts of the world, the most prized ones come from Myanmar, Kashmir, and Sri Lanka. The most sought-after sapphires are those with a deeply saturated violet-blue color and a silky transparency. Among the rarest and most beautiful varieties is the pink-orange corundum, reminiscent of a tropical sunset.

Fun Facts About Sapphires

Sapphires have been cherished as precious gemstones for thousands of years, popular in ancient Rome, Persia, and throughout the Middle Ages. Thanks to their hardness, sapphires are used in various industrial applications. For example, the Apple Watch Series 3 features lab-created sapphire crystals in its screen to make it more scratch-resistant. On the Mohs scale of hardness, only diamonds, with a rating of 10, can scratch sapphires, which score a 9.

The Many Colors of Sapphires

While sapphires are typically thought of as rich blue, they actually come in nearly every color of the rainbow, including pink, peach, orange, yellow, green, aqua, and purple. Red sapphires are known as rubies. The rarest sapphire is the pinkish-orange variety called Padparadscha, named after the Sinhalese word for lotus blossom. These gemstones are traditionally found in Sri Lankan rivers.

The Durability of Sapphires

Sapphires are among the most durable natural elements on Earth. They are rated on their ability to withstand scratching based on the Mohs scale of hardness, scoring a 9 out of 10. Their colors are derived from trace elements within the mineral corundum. Blue sapphires contain iron and titanium, while chromium can turn corundum pink or red, the latter being classified as ruby.

Famous Sapphires

One of the most famous royal sapphires today is the engagement ring given by Britain's Prince Charles to Lady Diana Spencer in 1981, now worn by Princess Catherine. It features a 12-carat oval blue sapphire surrounded by diamonds.

Healing Properties of Sapphire

Though sapphire typically refers to the rich blue gemstone variety of corundum, this royal gemstone occurs in every color except red, which is classified as ruby. Historically, it has been used to treat eye infections and improve vision. Blue sapphire is also used to alleviate headaches, fever, nosebleeds, and ear issues, including hearing problems, infections, and vertigo.

Emotional and Spiritual Benefits

Sapphire frees us from our "inner prisons" and psychic suffering, which can cause emotional shutdown. It is an effective aid in treating anxieties or even psychosis, releasing depression and enhancing mood. Sapphire brings calm and focus to the mind and restores balance within the body. It is a stone of spiritual power and wisdom, bringing prosperity and sustaining the blessings of life. Sapphire helps express what we think and feel, allowing us to convey our truths and generate our own realities.

Chakra and Energy Alignment

Blue sapphire ranges in color from light blue to indigo. If your birthday falls within specific periods, a sapphire of the corresponding color can serve as a valuable channel to your guardian angel. Sapphire ensures a smooth flow of energy within the body and spirit, facilitating the expression of thoughts, truths, and compassion.

In conclusion, the September birthstone, sapphire, is not only a symbol of loyalty and truth but also a powerful gemstone with numerous healing and spiritual benefits. Whether you wear it for its beauty, its historical significance, or its mystical properties, sapphire remains a timeless and cherished gem.

For More Information Visit Our Site

0 notes

Text

Tungsten Carbide: A Marvel of Material Science

Tungsten Carbide: A Marvel of Material Science Tungsten Carbide, often simply referred to as carbide, is a compound that has revolutionized many industries due to its unique properties. It is a chemical compound that contains equal parts of tungsten and carbon atoms.Get more news about Tungsten Carbide,you can vist our website!

In its most basic form, tungsten carbide is a fine gray powder. However, it can be pressed and formed into shapes through a process known as sintering. This makes it incredibly versatile and useful in a variety of applications.

One of the most notable properties of tungsten carbide is its hardness. It is approximately twice as stiff as steel and is comparable with corundum in hardness. This makes it an excellent material for use in cutting tools, chisels, and abrasives.

Another significant application of tungsten carbide is in the production of armor-piercing shells. Its hardness and density make it an ideal material for penetrating cores.

Tungsten carbide is also used in the production of industrial machinery. Its resistance to wear and ability to withstand high temperatures make it a preferred material for various components in heavy machinery.

In addition to its hardness, tungsten carbide also has a high melting point and is a good conductor of heat and electricity. These properties make it a valuable material in the production of furnace structure materials and jet engine parts.

Despite its many advantages, tungsten carbide is not without its challenges. Pure tungsten carbide is brittle and can crack under stress. However, this brittleness can be reduced by adding small amounts of other metals such as titanium and cobalt.

In conclusion, tungsten carbide is a marvel of material science. Its unique properties have made it an invaluable resource in various industries. As research continues, it is likely that new applications for this remarkable compound will continue to be discovered.

0 notes

Text

What is an Emery Cloth: Ultimate Guide

An Emery Cloth is a type of abrasive cloth used for sanding metal surfaces. It is durable and suitable for aggressive sanding tasks, reducing the risk of leaving small fragments on the prepared surface. Emery cloth is specifically designed for metal sanding jobs, offering durability and a flexible cloth backing. This abrasive cloth is ideal for pre-finishing metal surfaces and sanding, making it a popular choice for professionals and DIY enthusiasts alike. With its ability to withstand aggressive sanding and provide a smooth finish, Emery Cloth is an essential tool for metalworking and various industrial applications.

Introduction To Emery Cloth

What Is Emery Cloth? Emery cloth is a fabric coated with abrasive particles, commonly used for metal sanding. It offers durability and prevents shredding during aggressive sanding. History Of Emery Cloth Emery cloth, made of corundum, a hard stone for cutting metal, differs from sandpaper made of softer stones like garnet and quartz.

Emery Cloth Vs Sandpaper

When it comes to working with different materials, it's important to understand the differences between emery cloth and sandpaper. While both are abrasive materials, they serve different purposes and have distinct characteristics that make them suitable for specific applications. Differences Between Emery Cloth And Sandpaper Emery cloth is a fabric coated with abrasive particles, typically made from corundum, a hard stone ideal for cutting metal. On the other hand, sandpaper is made of softer materials such as garnet, quartz, or aluminum oxide, and is commonly used for sanding wood and plastic surfaces. Which Is Better For Metal Surfaces? Emery cloth is specifically designed for sanding metal surfaces due to its durable backing that prevents shredding during aggressive sanding. Its ability to maintain integrity under pressure makes it the preferred choice for metal finishing tasks. Emery Cloth Vs Crocus Cloth Crocus cloth, similar to sandpaper and emery cloth, is coated with fine loose iron oxide particles, intended for final metal and gemstone finishing. Unlike emery cloth, crocus cloth provides a smooth finish and is available in various grades for different polishing needs.

Uses Of Emery Cloth

Emery cloth is a versatile abrasive material that finds application in various industries due to its durability and effectiveness. It is used in a wide range of tasks, including metalworking, woodworking, jewelry making, and drywall sanding. Let's explore the specific uses of emery cloth in these different fields. Metalworking Emery cloth is extensively used in metalworking for tasks such as polishing, deburring, and removing rust or corrosion from metal surfaces. Its abrasive nature allows for efficient material removal while providing a smooth finish, making it an essential tool in metal fabrication and repair processes. Woodworking In woodworking, emery cloth is utilized for shaping, smoothing, and finishing wooden surfaces. It is particularly effective in removing imperfections, refining edges, and preparing wood for painting or staining. Woodworkers rely on emery cloth to achieve precise and uniform results in their projects. Jewelry Making Emery cloth plays a crucial role in jewelry making by enabling artisans to refine and polish metal components, such as intricate designs, settings, and clasps. Its abrasive properties allow for meticulous detailing and finishing touches, ensuring the creation of high-quality and visually appealing jewelry pieces. Drywall Sanding When it comes to drywall sanding, emery cloth is utilized for smoothing and leveling joint compound or spackling on walls and ceilings. Its flexibility and durability make it suitable for addressing imperfections and achieving a seamless surface, contributing to the overall quality of drywall finishing.

Grades Of Emery Cloth

An emery cloth is a fabric coated with abrasive materials of varying grades, each suitable for specific applications. Understanding the different grades of emery cloth is essential to achieve optimal results in your sanding projects. Coarse Grade The coarse grade emery cloth is ideal for heavy-duty sanding tasks, such as removing rust, paint, or corrosion from metal surfaces. It is best suited for initial rough sanding to quickly eliminate imperfections. Medium Grade The medium-grade emery cloth strikes a balance between aggressive sanding and finer finishing. It is suitable for smoothing out rough surfaces, preparing them for a more refined touch, and achieving a moderate level of abrasion. Fine Grade The fine-grade emery cloth is perfect for achieving a smooth and polished finish on metal surfaces. It is great for final touches, removing minor imperfections, and creating a refined surface ready for painting or coating. Which Grade To Use For Specific Applications: - Coarse Grade: Use for heavy-duty tasks like removing rust and corrosion. - Medium Grade: Ideal for smoothing out surfaces before finer finishing. - Fine Grade: Perfect for achieving a polished finish and removing minor imperfections.

How To Use Emery Cloth

Emery cloth is a durable abrasive material with a flexible cloth backing. It is designed for sanding metal surfaces and is ideal for pre-finishing metal surfaces by hand. To use emery cloth, wrap it around a file when finishing metal to achieve a good finish, working through grades from coarse to fine and alternating the direction of the file regularly to remove scratches. Emery cloth is a type of abrasive material that is commonly used for sanding metal surfaces. Unlike traditional sandpaper, it has a durable cloth backing that won't come apart or shred during aggressive sanding, which helps to reduce the possibility of small fragments being left on the prepared surface. To use emery cloth effectively, it's important to follow proper preparation techniques and use the right tools. Preparation for Sanding Before using emery cloth, it's important to prepare the surface to be sanded. This involves cleaning the surface thoroughly to remove any dirt, grease, or other debris that could interfere with the sanding process. Once the surface is clean, it's important to choose the right grade of emery cloth for the job. Coarse grits are best for removing paint, rust, and other stubborn materials, while finer grits are better for smoothing and polishing. Wrapping Emery Cloth around a File When finishing metal by hand, pieces of emery cloth can be wrapped around a file. To do this, simply place the emery cloth on a flat surface with the abrasive side facing up. Place the file on top of the emery cloth and wrap it around the file, making sure to leave enough excess cloth to hold onto while sanding. Alternating the Direction of the File To get a good finish, it's important to work through grades from coarse to fine and regularly alternate the direction of the file to remove scratches by polishing across them. This helps to ensure that the surface is sanded evenly and that all scratches are removed. When using emery cloth, it's important to work slowly and carefully, applying even pressure and taking breaks as needed to avoid overheating the metal. In conclusion, emery cloth is a versatile and durable abrasive material that is ideal for sanding metal surfaces. By following proper preparation techniques and using the right tools, you can achieve a smooth and polished finish that will last for years to come.

Types Of Emery Cloth

Emery cloth is a specialized abrasive material used for sanding metal surfaces. Unlike sandpaper, it has a durable cloth backing that prevents shredding during aggressive sanding, making it ideal for metal finishing and shaping. It is designed for tasks that require durability and precision, such as pre-finishing metal surfaces and removing deep scratches. Aluminum Oxide Emery Cloth Aluminum oxide Emery Cloth is known for its versatility and durability. It is commonly used for sanding and polishing metal surfaces due to its abrasive nature. Silicon Carbide Emery Cloth Silicon carbide Emery Cloth is ideal for applications where a finer finish is required. It is effective for smoothing and refining metal surfaces with precision. Zirconia Alumina Emery Cloth Zirconia alumina Emery Cloth is recognized for its high-performance capabilities. It is suitable for heavy-duty tasks and provides excellent results on tough metal surfaces. Emery cloth comes in various types tailored to specific needs, each offering unique benefits for different metalworking applications.

Brands Of Emery Cloth

Emery cloth is an essential abrasive tool for smoothing and polishing metal surfaces. Various brands offer high-quality emery cloth for different applications. Let's explore some reputable brands below: 3m Emery Cloth 3M is a renowned brand known for its top-notch abrasives, including emery cloth. Their emery cloth products are durable, effective, and suitable for a wide range of metalworking tasks. Bulldog Abrasives Emery Cloth Bulldog Abrasives is a trusted name in the industry, providing high-performance emery cloth designed for heavy-duty metal sanding and polishing. Their emery cloth sheets and rolls are known for their reliability and efficiency. Benchmark Abrasives Emery Cloth Benchmark Abrasives offers a premium selection of emery cloth that delivers exceptional results in metal finishing applications. Their emery cloth is designed to withstand rigorous use and provide consistent performance.

Frequently Asked Questions

Is Emery Cloth The Same As Sandpaper? Emery cloth is not the same as sandpaper. Sandpaper is for wood and plastic, while emery cloth is for metal. It's more durable but may contaminate wood. Emery cloth is used for metal sanding jobs requiring durability. It has a cloth backing and is suitable for pre-finishing metal surfaces. What Is The Purpose Of Emery Cloth? Emery cloth is used for sanding metal surfaces, providing durability and reducing the risk of small fragments. It is specifically designed for metal sanding jobs requiring durability and can be used for pre-finishing metal surfaces. Additionally, it is suitable for polishing all metals, including mild carbon steel and cast iron. How To Use An Emery Cloth? To use an emery cloth, wrap around a file for metal finishing. Work through coarse to fine grades, polish in different directions to remove scratches. What Is The Difference Between Crocus Cloth And Emery Cloth? Crocus cloth has loose iron oxide particles for final metal and gemstone finishing, while emery cloth has bound abrasive grains.

Conclusion

Emery cloth is a durable abrasive material specifically designed for sanding metal surfaces. Its cloth backing prevents shredding, reducing the risk of leaving fragments on the surface. Emery cloth is best suited for metal sanding jobs, providing a reliable and effective solution for achieving smooth and polished finishes. https://www.youtube.com/watch?v=npeQMODKdb8 Read the full article

0 notes

Text

Which celebrities wear yellow sapphires?

Yellow sapphire is well known. It is a corundum. It is also known as the Pukhraj stone. Jupiter, which is in charge of your mind, is in charge of the yellow diamond. The Original Yellow Sapphire can help you do well at work or in your business. It can also make you famous, rich, smart, and provide you with money. Women can find a good partner and get married quickly if they wear yellow sapphire. This is because Jupiter rules their horoscopes as a mate. Additionally, pukhraj can help you stay healthy and avoid getting sick. The Pukhraj Stone of the major blog delves into the reasons why the biggest players in the Bollywood industry have embraced this powerful gemstone.

0 notes

Text

AUNIT OF SALASAR JI GEMS LLP

Natural White Sapphire Gemstone

White Sapphire Stone Benefits : Natural White Sapphire Stone is a precious gemstone that belongs to the mineral species corundum, which also includes ruby. It is a type of sapphire that is colorless or white in appearance due to the absence of any impurities or trace elements that would give it color. White sapphire is often used as a diamond substitute in jewelry because of its similar color and brilliance.

White sapphires are durable and have a hardness of 9 on the Mohs scale, making them suitable for everyday wear. They are also relatively affordable compared to other colorless gemstones such as diamonds. However, it is important to note that some white sapphires may have a slightly grayish or yellowish tint, and they may require careful selection to ensure their quality.

In terms of metaphysical properties, white sapphire is believed to promote clarity, focus, and wisdom. It is also thought to enhance communication skills and mental agility. However, it is important to note that these beliefs are not supported by scientific evidence and should be taken with a grain of salt.

Benefits of white sapphire gemstone White sapphire is a gemstone that is becoming increasingly popular in the jewelry industry. Here are some of the benefits of white sapphire gemstone: Durability: White sapphire is a very hard gemstone, second only to diamond in terms of hardness. This makes it a durable gemstone that can withstand daily wear and tear. Beauty: White sapphire has a brilliant white color and a high level of clarity, which makes it a popular choice for engagement rings and other jewelry. Affordability: White sapphire is generally less expensive than diamond, making it a more affordable option for those who want a white gemstone in their jewelry. Symbolism: White sapphire is often associated with purity and wisdom, and is said to enhance spiritual insight and intuition. Versatility: White sapphire is a versatile gemstone that can be used in a variety of jewelry designs, from classic to contemporary. Healing properties: Some people believe that white sapphire has healing properties and can help with conditions such as headaches, fever, and insomnia. Overall, white sapphire is a beautiful and durable gemstone that is a great choice for those looking for a white gemstone with excellent value and symbolism

Do white sapphires occur naturally? Is white sapphire expensive? What are the benefits of natural white sapphire? Buy Natural White Sapphire Stone (Safed Pukhraj) Online Buy White Sapphire (Safed Pukhraj) Stone Online White Sapphire - Buy Safed Pukhraj Stone at Best Price in delhi white sapphire stone price Natural white sapphire gemstone benefits Natural white sapphire gemstone price Natural white sapphire gemstone for which planet Natural white sapphire gemstone in india Natural white sapphire gemstone price in india Natural White Sapphires for Sale Online

Address: 1185-87, Shop No. 9 Gems Plaza Chhatta Madan Gopal, Maliwara, Chandni Chowk, New Delhi, Delhi 110006

Mob No. 9971391757

0 notes

Text

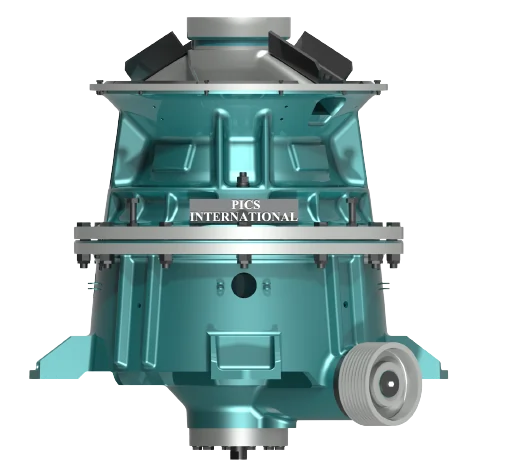

Cone Crusher Manufacturer -Picson

PICS INTERNATIONAL introduces the latest technology Hydro Cone Crusher Manufacturer. PICS INTERNATIONAL cone crushers are suitable for a wide range of applications to get excellently shaped product in polyhydric shape.

GC Series:-

The high crushing ratio of the PICS INTERNATIONAL Hydro Cone Crusher Manufacturer In India makes it ideal for secondary and tertiary stage crushing of hard rocks, perlite, corundum, bauxite, basalt, iron ores, etc. With the PICS INTERNATIONAL Hydro-cone series, you can run your crusher at its peak efficiency under varying feed conditions without worrying about overloading the cone crusher. Its design promotes maximum productivity and performance with high outputs, dependability, and low operating costs.

HP Series:-

A standard jaw crusher combined with an HP Series Cone crusher from PICS International is a great secondary crusher option. They reduce your investment cost and save energy by producing finer goods through fewer crushing processes. Greater product form, a high reduction ratio, and a high capacity are the outcomes of improved inter-particle crushing action in the crushing chamber, which is caused by increased density and pressure.

Maximizing Efficiency and Productivity: The Benefits of Choosing a Cone Crusher Manufacture

1. Quality Assurance: Selecting an experienced cone crusher manufacturer is like making an investment in quality control. Through the production process, reputable manufacturers maintain strict quality control procedures to guarantee that every component satisfies or exceeds industry requirements.

2. Customization and Innovation: cone crusher manufacturer that welcomes innovation and provides customizing choices. Prominent producers allocate resources towards research and development in order to continually improve their product's quality and modify it to suit changing market demands.

3. Comprehensive Support and Service: Choosing to buy a cone crusher is more than just the money spent on it initially. Maintaining uninterrupted operations and reducing downtime requires constant support and maintenance.

4. Access to Expertise: When you work with a respectable cone crusher manufacturer, you may benefit from their extensive experience and industry understanding. Technicians educated by the manufacturer are highly acquainted with their equipment, which allows them to offer insightful advice, help with investigating, and proactive maintenance suggestions.

In conclusion, the benefits of choosing a reputable cone crusher manufacturer extend far beyond the equipment itself. From quality assurance and customization to comprehensive support and long-term value, the advantages are clear. When selecting a cone crusher manufacturer, prioritize reliability, innovation, and expertise to unlock the full potential of your crushing operations. By making an informed decision today, you're laying the groundwork for success tomorrow and beyond.

Contact: - +919081777945 , [email protected]

Address: - 986, 986/1, Near Getco Substation, GIDC, Por Ramangamdi, Por, Vadodara - 391243, Gujarat

Visit for More Information: - https://www.picsinternational.com/cone-crusher

0 notes