#Copper Aluminium Sheet

Explore tagged Tumblr posts

Text

The Benefits of Copper Composite Panel

Copper composite panel 100% recyclable, sustainable, eco-friendly, fireproof and durable but also uniquely alluring. This is a major USP that makes it stand apart. Equipped with a glossy finish, these sheets have a red-orange tone which allows it to undergo oxidation. To know more, visit here: https://www.quora.com/What-are-the-benefits-of-a-copper-composite-panel/answer/Pradip-152

0 notes

Text

Best company for Copper Brush Aluminium UV Printing Sheet supplier Manufacturer in Pune, Maharashtra, India. Buy Copper Brush Aluminium UV Printing Sheet in Pune, Maharashtra, India at best cost only sublimationsheet in

#copper Brush Aluminium UV Printing Sheet | Copper Brush Aluminum UV Printing Sheet supplier#Manufacturer in Pune#India

0 notes

Text

Bimetal Sheet | Bajeria Industries

Bajeria offer Bimetal Sheet to our valuable clients. we are manufacture, exporter as well as supplier of Bimetallic Sheet. We provide sizes as per your requirement with best delivery. For more information please kindly visit our website https://www.bajeria.com/copal-copper.html

#BIMETAL SHEET#COPPER ALUMINIUM BIMETALLIC STRIP#COPAL BIMETAL#COPAL BONDED SHEET#COPPER ALUMINIUM BONDED SHEET

0 notes

Text

✨Making Galadriel’s Crown✨

Eyyy I’m catching up with Galadriel WIPs again—hope you all don’t mind a little back tracking since she’s already had her official reveal 😜

The crown IMO came out surprisingly well considering I have limited experience with anything jewellery or metal related. So proud of the leaves!!

Re: the brass craft metal—while the cricut CAN cut metal sheets in aluminium or copper, even annealed softer brass is still much too hard for it to handle. That said, etching the outlines still made my my life a lot easier so I’m not mad about it!

Part of me wishes I could have gotten the thibra stems a little thinner and smoother, but it was very fiddly to work in between all the stems and leaves with the hot tool, so I’m content to leave it as-is. 😜

#wip: galadriel lindon gown#lotr#lord of the rings#rings of power#morfydd clarke#trop#tolkien#galadriel#galadriel cosplay

124 notes

·

View notes

Text

What are the Key Mechanical Properties of Solids?

Mechanical properties of solids refer to the characteristics that define how a material responds to external forces, such as stress, strain, and deformation. These properties include elasticity, plasticity, hardness, toughness, strength, and ductility, among others. They are fundamental in determining a material’s suitability for various applications, influencing its behaviour under different conditions.

The significance of mechanical properties spans numerous fields. In engineering, these properties ensure the safety and durability of structures like bridges, buildings, and dams. In construction, they guide the selection of materials for specific purposes, such as load-bearing or flexibility. Material science relies heavily on these properties to develop innovative materials that meet evolving industrial demands.

This article aims to delve into the science behind mechanical properties, their key characteristics, real-world applications, and their indispensable role in innovation and progress.

The Science Behind Mechanical Properties

Stress and Strain: Fundamentals

Stress is the force per unit area exerted on a material. It can be mathematically expressed as:

where is the applied force and is the cross-sectional area of the material. Strain, on the other hand, measures the deformation caused by stress. It is defined as the ratio of the change in length to the original length: where is the change in length and is the original length.

Types of Stress and Strain

Tensile Stress and Strain: Occurs when forces act to stretch a material. Examples include the stretching of rubber bands and cables.

Compressive Stress and Strain: Results from forces that compress or squeeze a material. Concrete in buildings often experiences compressive stress.

Shear Stress and Strain: Arises when forces are applied parallel to a surface. Scissors cutting paper is an example of shear stress in action.

Hooke’s Law and Elasticity

Elasticity is the ability of a material to return to its original shape and size after the removal of stress. Hooke’s Law describes this behaviour:

where is the Young’s modulus, a measure of a material’s stiffness. Elasticity is crucial for applications requiring temporary deformation, such as springs.

Plasticity and Permanent Deformation

When stress exceeds a material’s elastic limit, it undergoes plastic deformation, leading to permanent changes in shape or size. Metals like aluminium and copper exhibit plasticity, making them ideal for moulding and shaping processes.

Key Mechanical Properties

1. Young’s Modulus (Stiffness)

Represents a material’s resistance to deformation under tensile stress.

Example: Steel has a high Young’s modulus, making it ideal for construction.

2. Shear Modulus and Bulk Modulus

Shear Modulus measures resistance to shape changes under shear stress.

Bulk Modulus evaluates a material’s response to uniform compression.

Applications include hydraulic systems and pressure vessels.

3. Poisson’s Ratio

Describes the ratio of lateral strain to longitudinal strain. Materials with low Poisson ratios, like cork, are used for sealing applications.

4. Strength

Includes tensile, compressive, and shear strength. Determines how much load a material can bear without failure.

Example: Carbon fiber composites are used in aerospace for their high strength-to-weight ratio.

5. Ductility and Malleability

Ductility is the ability to be stretched into a wire. Copper’s ductility makes it suitable for electrical wiring.

Malleability is the ability to be hammered into sheets. Gold’s malleability is utilized in jewellery making.

6. Brittleness and Toughness

Brittleness: Materials like glass break without significant deformation.

Toughness: Measures a material’s ability to absorb energy before fracturing. Rubber is an example of a tough material.

7. Hardness

Resistance to indentation or scratching. Hardness tests include the Mohs scale and the Brinell test.

Example: Diamond, the hardest known material, is used in cutting tools.

Applications in Engineering and Design

Civil Engineering

Bridges: Steel and reinforced concrete combine high strength and ductility to withstand loads.

Buildings: Materials like concrete and glass are chosen based on compressive strength and aesthetic appeal.

Aerospace and Automotive Industries

Lightweight yet strong materials like titanium alloys ensure efficiency and safety in aircraft.

Automotive components use materials with high impact resistance, such as advanced polymers.

Manufacturing Tools and Machinery

Machine tools rely on hard materials like tungsten carbide for durability and precision.

Conveyor belts require toughness and flexibility to handle wear and tear.

Product Design and Safety Analysis

Consumer goods, such as smartphones, use materials that balance hardness and toughness.

Safety-critical systems, like helmets and airbags, are designed with energy-absorbing materials.

Material Science and Advancements

Developing New Materials

Nanomaterials and composites offer superior strength and lightweight properties.

Innovations like graphene enhance conductivity and mechanical strength.

Sustainability and Recycling

Recyclable materials, such as aluminium, reduce environmental impact.

Bio-based polymers provide eco-friendly alternatives for packaging and construction.

Future Trends

Smart materials, such as shape-memory alloys, adapt to environmental changes.

Research focuses on enhancing the durability of materials under extreme conditions.

The mechanical properties of solids are the backbone of modern engineering, construction, and material science. They ensure the safety, functionality, and efficiency of structures and products. By understanding and leveraging these properties, we can drive innovation, create sustainable solutions, and meet the challenges of an ever-evolving world.

As we continue to explore new materials and techniques, the importance of mechanical properties will remain at the forefront of progress, shaping a future of resilience and ingenuity.

For more simplified explanations like the one above, visit the physics blogs on the Tutoroot website. Elevate your learning with Tutoroot’s personalised Physics online tuition. Begin your journey with a FREE DEMO session and discover the advantages of online tuitions.

2 notes

·

View notes

Text

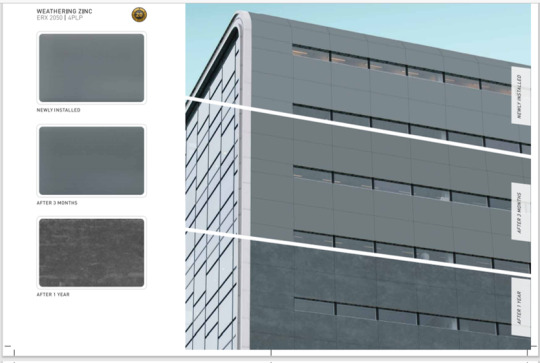

Euramax Interesting Facts about Zinc Finish ACPs

Zinc, Copper, Aluminium and Steel are some of the popularly used metals not only in construction but also in the décor of a building.

Roofing sheets, cladding of exterior & interior walls, false ceilings and decorative wall panels are some of the areas in which metal has replaced wood, stone, and more classic materials.

Gold, Silver, Zinc, Bronze, Copper and Brass finish in ACPs is even more fascinating with its majestic looks.

But what is Zinc Finish Aluminium Composite Panel?

Zinc ACP is a multilayered panel made up of two aluminium sheets with a composite core. It is 0.5 mm thick and thermo-glued on either side of an LDPE core for optimum reaction to fire.

What are the advantages of using zinc composite panels?

Zinc finish ACP Panels add awe-inspiring looks to both interiors and exteriors instantly.

Zinc finish ACP is flexible, easy to bend, strong and hence is the choice for architects and designers

Zinc finish ACP is weather-resistant

Zinc finish ACP is available in fire-retardant sheets

Zinc finish ACP is very environmentally friendly can be reused and is 100 per cent recyclable metal.

Why should you use zinc composite panels?

Zinc finish aluminium composite panels are aesthetically pleasing

Building facades, building elevation designs, exterior wall panelling, roofing, cladding, etc. are some of the areas for the application of Zinc finish aluminium composite panels

Zinc finish acp sheets are easier to install and manage. It does not require special and expensive machinery that are usually required for cutting and grooving.

It has a low maintenance cost and can be easily done with the help of washing and cleaning

Zinc finish ACP panels are a long-lasting and beneficial alternative for building cladding.

While delivering extraordinary style, these ACP Panels are fire-retardant also. It restricts fire spread and no smoke and toxic fumes are released which is the main cause of death in a fire accident.

The architectural appeal is continually growing for this material. Zinc ACP is more than a piece of the panel; it comes with assurity of adding beauty at a cost-effective price & is environmentally friendly at the same time. Choose your colour and texture in to suit your design and application.

For more details on the product, visit the company website https://www.eurobondacp.com/zinc

2 notes

·

View notes

Text

Using Brass Scrap to Its Full Potential in Contemporary Recycling

In the modern world, recycling is essential to sustainability, and brass scrap is a major contributor to this trend. Brass is a valuable and adaptable material that is highly sought after in many different industries and has enormous potential for recycling and reuse. Effective use of Brass Scrap in Sydney can have a big impact on resource conservation, economic growth, and environmental impact reduction.

Understanding Brass and Its Recycling Potential

Copper and zinc make up the majority of brass, while other metals like lead or aluminium may also be included. Brass is frequently used in plumbing, electrical, musical instrument, and decorative applications because of its strength, resilience to corrosion, and malleability. It is a perfect candidate for recycling because of these qualities. This intrinsic feature lowers the energy consumption related to the manufacturing of primary metals as well as the requirement for virgin raw materials. Therefore, in commercial and industrial applications, Brass Scrap in Sydney offers a viable substitute.

The Recycling Process of Brass Scrap

Recycling brass scrap involves several steps:

Collection and Sorting: Scrap is gathered from a variety of sources and arranged according to its composition and quality. This stage guarantees the removal of impurities such as plastics or iron.

Melting: High temperatures are used in furnaces to melt the graded brass.

Purification: During melting, impurities are eliminated by separating slag or using fluxing agents.

Recasting: To be used again in manufacturing, the purified brass is cast into new forms like bars, sheets, or parts. This method is a more sustainable choice because it uses a lot less energy than mining and processing virgin copper and zinc.

Economic Benefits of Recycling Brass Scrap

Not only is recycling brass trash good for the environment, but it also pays you financially. Important advantages include:

Cost Savings for Industries: Manufacturers save money on materials by using reclaimed brass.

Job Creation: Employment possibilities in collecting, sorting, and processing are created by the recycling sector.

Revenue Generation: Brass scrap can be sold to recycling facilities for a profit by both individuals and businesses.

Brass scrap recycling is a desirable alternative for both individuals and companies due to the financial incentives offered.

Challenges in Brass Scrap Recycling

There are obstacles to overcome even if recycling brass scrap has indisputable advantages:

Contamination: During processing, contaminants such as paint, coatings, or mixed metals that are frequently present in brass scrap must be eliminated.

Sorting Complexity: Different grades of brass must be identified and separated using sophisticated technologies and expert labour.

Market Fluctuations: Trends in the global metal market can affect the value of brass scrap, which can have an effect on profitability. To optimise the potential of recycling brass scrap, these issues must be resolved with creativity and effective methods. Conclusion

Brass Scrap in Sydney holds immense potential in contemporary recycling due to its durability, recyclability, and value. By using brass scrap to its full potential, industries and individuals can contribute to environmental conservation, resource efficiency, and economic growth. Addressing challenges and adopting innovative practices can further enhance the recycling process, ensuring a sustainable future. As the world moves toward a more circular economy, brass scrap serves as a shining example of how waste can be transformed into wealth.

Disclaimer: This is generic Information & post; content about the services can be changed from time to time as per your requirements and contract. This is written for only SEO purposes; we are not claiming it is 100% accurate as it's general content. The images we use in this context have been taken from the official website of Sydney Scrap Metal. To get the latest and updated information, contact us today or visit our website.

0 notes

Text

Channel Letter Bending Machine in Maharashtra

Success Technologies is a Manufacturer, and Supplier of Channel Letter Bending Machine in Maharashtra, India. Our Registered Office and Manufacturing Unit are located in Ahmedabad, Gujarat, India. A Channel Letter Bending Machine is a specialized tool used in the production of channel letters for signage. These machines precisely bend metal strips (usually aluminum or steel) to create the "C," "U," or "L" shapes that form the framework of channel letters. The process involves using hydraulic, pneumatic, or motorized systems to bend the metal into specific forms, ensuring accuracy and efficiency. Businesses can use channel letters for both illuminated and non-illuminated signs, offering flexibility to create custom signage solutions for various applications. How the Channel Letter Bending Machine Works: The working process of a Channel Letter Bending Machine is relatively simple but highly efficient: Material Loading: The operator loads the metal sheet (usually aluminum) onto the machine, which is then fed into the machine for bending. Customization: The operator configures the machine according to the specific dimensions and shape of the desired letter or number. Bending: The machine uses a combination of hydraulic or motorized bending to precisely shape the metal into the correct channel letter form. Cutting and Trimming: After the bending process, the machine cuts the metal at the desired length and trims any excess for a clean and professional finish. Assembly: The manufacturer assembles the channel letters and adds optional illumination components for enhanced visibility. Types of Channel Letter Bending Machine: CNC Aluminium Bending Machine Channel Letter Bending Machine Applications: Architectural Design Automotive Industry Aerospace Sector Retail and Display Fixtures Prototyping and R&D What materials can be bent with a Channel Letter Bending Machine? Manufacturers design Channel Letter Bending Machines to bend aluminum, stainless steel, and galvanized steel. Some models may also be suitable for other materials like brass and copper. How do I choose the right Channel Letter Bending Machine? The choice of machine depends on factors such as the volume of production, the types of signs you need to create, your budget, and the size of your operation. We recommend discussing your specific requirements with our team for personalized advice. Success Technologies is a Supplier of Channel Letter Bending Machine in Maharashtra, india Including Mumbai, Pune, Nagpur, Thane, Pimpri-Chinchwad, Nashik, Kalyan-Dombivli, Vasai-Virar, Aurangabad, Navi Mumbai, Solapur, Mira-Bhayandar, Bhiwandi-Nizampur, Jalgaon, Amravati, Nanded-Waghala, Kolhapur, Ulhasnagar, Sangli, Malegaon, Akola, Latur, Dhule, Ahmednagar, Chandrapur, Parbhani, Ichalkaranji, Jalna, Ambarnath, Bhusawal, Panvel, Badlapur, Beed, Gondia, Satara, Barshi, Yavatmal, Achalpur, Osmanabad, Nandurbar, Wardha, Udgir, Hinganghat. For more information and inquiries, feel free to contact us. View Product: Click Here Read the full article

#Achalpur#Ahmedabad#Ahmednagar#Akola#Ambarnath#Amravati#Aurangabad#Badlapur#Barshi#Beed#Bhiwandi-Nizampur#Bhusawal#Chandrapur#ChannelLetterBendingMachine#ChannelLetterBendingMachineinAhmedabad#ChannelLetterBendingMachineinGujarat#ChannelLetterBendingMachineinIndia#ChannelLetterBendingMachineinMaharashtra#Dhule#Exporter#ExporterofChannelLetterBendingMachine#Gondia#Gujarat#Hinganghat#Ichalkaranji#India#Jalgaon#Jalna#Kalyan-Dombivli#Kolhapur

0 notes

Text

tainless steel, aluminium, and brass

Recycling metals is an essential part of creating a sustainable future. Among the many recyclable materials, stainless steel, aluminium, and brass stand out due to their versatility, durability, and recyclability. By recycling these metals, we conserve natural resources, reduce energy consumption, and minimize environmental impact. Let’s dive into the benefits and processes of recycling these valuable materials and how you can contribute to the cause.

Stainless Steel Recycling: Durable and Eco-Friendly

Stainless steel recycling is a key component in promoting environmental sustainability. This robust material is widely used in construction, automotive, and household applications due to its resistance to corrosion and strength.

Why recycle stainless steel?

100% Recyclable: Stainless steel can be recycled indefinitely without losing its quality or properties.

Resource Conservation: Recycling stainless steel reduces the need for raw materials like iron ore, nickel, and chromium, preserving these finite resources.

Energy Efficiency: The recycling process consumes far less energy compared to producing new stainless steel from raw materials.

Recycling stainless steel not only reduces waste but also supports the circular economy. To learn more about how to recycle stainless steel, visit Adelaide Metal Recycling.

Aluminium Recycling: Endless Possibilities

Aluminium recycling is one of the most energy-efficient recycling processes, making it an environmentally and economically viable choice. Aluminium is widely used in packaging, transportation, and construction, and its unique properties make it a valuable resource.

Benefits of aluminium recycling:

Energy Savings: Recycling aluminium uses only 5% of the energy required to produce new aluminium from bauxite.

Infinite Recyclability: Unlike many materials, aluminium doesn’t degrade during the recycling process, allowing it to be reused indefinitely.

Landfill Reduction: Recycling aluminium keeps cans, sheets, and other waste out of landfills, reducing environmental pollution.

Recycling aluminium is a small step that can make a big impact. Learn how you can contribute to a sustainable future with aluminium recycling.

Brass Recycling: Maximizing Value and Sustainability

Brass recycling is another critical part of reducing waste and conserving resources. Brass is commonly used in plumbing fixtures, musical instruments, and decorative items due to its durability and aesthetic appeal.

Why should you recycle brass?

High Value: Brass is a high-value material, making it economically beneficial to recycle.

Resource Conservation: Recycling brass reduces the need for mining copper and zinc, the primary components of brass.

Energy Efficiency: The recycling process consumes less energy than producing new brass, making it an eco-friendly option.

Recycling brass is a win-win for the environment and your wallet. Discover the benefits of recycling brass at Adelaide Metal Recycling.

Website :

Scrap Metal Recycling Adelaide | Adelaide Metal Recycling

Scrap Metal Recycling Adelaide: Adelaide Metal Recycling are the best scrap metal recyclers in adelaide, we pay cash for array of metals like copper, steel, aluminium, brass & etc.

Email : [email protected]

Address : 183 Eastern Parade, Gillman, South Australia 5013

Phone number : 08 8123 4113

0 notes

Text

Durability Meets Design: Why Cladding Suppliers in Melbourne Are Industry Leaders

Because they increase a building's durability and aesthetic appeal, roofing and cladding services are essential. Leading cladding suppliers in Melbourne guarantee fire safety, weather resistance, insulation, and a sleek, modern look with their superior architectural cladding. These days, cladding is made of innovative materials like copper and zinc for both functionality and aesthetics. The metals used for cladding are so durable that they last a long time and improve the home's energy efficiency.

An Overview of the Modern Cladding Industry for Residential Buildings

Zinc wall cladding has become more and more popular among cladding installers for use in both residential and commercial buildings because to its exceptional flexibility, durability, and environmental advantages. Zinc resists weathering and corrosion because it naturally develops a platina over time to protect it and hence the inner layers of zinc remain protected. Additionally, zinc wall coating provides excellent insulation, boosting the building's energy efficiency. Zinc may aid in ecologically responsible building design as it is a sustainable and recyclable material.

Copper Cladding: Over time, copper naturally develops a patina, which serves as the metal's outermost layer and a barrier against further corrosion. It is possible to cut copper cladding into cladding sheets or wall panels. It is an environmentally friendly choice since it can be recycled, requiring fewer fresh resources or metal ores.

Standing Seam Wall Cladding: Standing seam cladding is commonly made of materials including titanium, copper, zinc, aluminium, and stainless steel. One may utilise these products in their projects anyway they see fit because they are available in a wide range of sizes, forms, colours, and finishes. The panels are attached using raised seams, which gives the structure a sleek, seamless appearance. In addition to increasing the structure's visual appeal, raised seams increase its resistance to weathering.

Re-Roofing: A roof must always be in outstanding condition for the house's general safety and structural integrity; thus, installation, repair, and painting services are necessary when the roof has deteriorated.

The leading suppliers of roofing and related services are also active in the building insulation sector. Get an estimate from the leading companies offering modern cladding services to improve the energy efficiency of your building.

Source: https://cladding-companies.blogspot.com/2025/01/durability-meets-design-why-cladding.html

0 notes

Text

Copper cladding refers to the process of covering a surface with a layer of copper. It's commonly used in architecture and construction to provide both aesthetic appeal and functional benefits.

0 notes

Text

What are the different types of aluminium sheet metal?

Aluminium sheet metal is a versatile material that has become a staple in various industries due to its remarkable combination of strength, lightweight nature, and corrosion resistance. As demand for precision-engineered components and structures continues to rise, understanding the different types of aluminium sheets becomes crucial for professionals across diverse sectors.

Plain aluminium sheets The most fundamental type of aluminium sheet metal is the plain variety, available in various thicknesses. These sheets are ideal for general applications where structural integrity is essential, ranging from automotive panels to aerospace components.

Aluminium alloy sheets An alloy sheet made of aluminium is created by combining aluminium with one or more other chemical components to improve the qualities of metals, such as silicon, magnesium, copper, chromium, zinc, etc. As a result of the diverse composition of aluminium alloys, aluminium plates, and aluminium alloy plates will have distinct properties, including differences in density and strength.

Perforated aluminium sheets For applications requiring ventilation or filtration, perforated aluminium sheets is the go-to choice. Architectural uses for perforated aluminum sheets include facades, fences, and sunscreens. They offer structures a sleek, contemporary appearance while permitting ventilation and shade. This kind of aluminium sheet is made by making patterns in the surface using a punch or drill.

Embossed aluminium sheets Aluminium stucco sheets are far more resilient than one that isn’t. The surface polish helps to conceal dings and other wear indicators. Additionally, stucco embossing lessens the metal’s capacity to reflect light. This is because, after properly finished, it has a surface that resembles pebbles.

Anodized aluminium sheets Anodized aluminium sheets are metal sheets that undergo a process called anodization. This makes them more resistant to rust and scratches, and they can come in different colors. They are often used in buildings and products where a durable and colorful surface is needed, like in architectural designs and consumer electronics.

Clad aluminium sheets To maximize the benefits of each metal, cladding consists of layering multiple metals together. Clad aluminium sheets are made by gluing a thin layer of aluminium to a core material, such as stainless steel or copper. Applications such as cookware and architectural panels benefit from this overall performance enhancement.

The world of aluminium sheets is vast and diverse, catering to a myriad of applications across industries. From basic plain sheets to specialized varieties like perforated, embossed, anodized, and clad sheets, each type serves a unique purpose, showcasing the adaptability and versatility of this remarkable material

0 notes

Text

Bimetal Sheet | Bajeria Industries

Bajeria offer Bimetal Sheet to our valuable clients. we are manufacture, exporter as well as supplier of Bimetallic Sheet. We provide sizes as per your requirement with best delivery. For more information please kindly visit our website https://www.bajeria.com/copal-copper.html

0 notes

Text

Another news year.

Beryllium copper strip C17200 0.01mm 0.02mm 0.03 0.04mm 0.05mm 0.06mm 0.07mm 0.075mm 0.08mm 0.09mm 0.1mm 0.12mm 0.15mm 0.2-0.5mm

Beryllium copper Ring C17200 OD200xID100mmxlength300mm

Beryllium copper bar rod C17200 D1mm D2mm D3mm D6mm D8mm D10mm D15mm D20mm D25mm D30mm D35mm D40mm D50mm D60mm D70mm D80mm D90mm D100mm

Beryllium copper strip C17200 T 0.01mm 0.02mm 0.03 0.04mm 0.05mm 0.06mm 0.07mm 0.075mm 0.08mm 0.09mm 0.1mm 0.12mm 0.15mm 0.2-0.5mm

Beryllium copper plate sheet C17200 200x500mm 300x500mm 100x300mm

Beryllium copper wire C17200 D0.01mm 0.02mm 0.03 0.04mm 0.05mm 0.06mm 0.07mm 0.075mm 0.08mm 0.09mm 0.1mm 0.12mm 0.15mm 0.2-0.5mm

Wonder metal main products list:

Beryllium copper plate / strip(C17200/25), beryllium copper rod/wire (C17200/25, C17300/M25, C17500/10, C17510/3), beryllium copper casting mould material (275C) and beryllium copper forging mould material (C17200/25, C17500/10);

Beryllium cobalt copper electrode material (BeCoCu) and beryllium aluminium alloy (BeAl3--4);

Copper-nickel alloy plate / strip (C7701/C7521);

Phosphor copper strip/rod/wire (C5441/C5440/C5100);

Brass alloy strip/plate/rod/profile;

Aluminum bronze alloy materials C86300/C95400.

Tungsten copper alloy materials. 80W-Cu ,75W-Cu,70W-Cu

Mold steel, Tungsten steel, Mold accessories.

Titanium bar/tube/ Plate.

Molybdenum rod/wire.

Stainless steel tube/bar/ Plate.

Plastic materials, anti-static materials, insulating materials, High-temperature engineering plastics. Any question about copper alloys or metal alloy, please feel free to contact us! Contact us by Whatsapp directly: https://wa.me/+8613712198704 Alan Lan Shenzhen Wonder Industrial company limited Whatsapp/Wechat/Line/Tel: +86-13712198704 Skype:saint2938 Email: [email protected] / [email protected] www.berylliumcopperalloys.com

berylliumcopper #copperandberyllium #cuberyllium

c17200 #berylliumcopperprice #c17510 #berylliumcopperalloy

berylliumcoppertube #c17200tube #c17510berylliumcopper #unsc17510 #alloyc17200

c17200alloy #c17200berylliumcopper #becuberylliumcopper #berylliumcopperfoil

c17300 #c17500 #berylliumalloy #berylliumforsale

berylliumcopper172 #berylliumcopper25 #c172berylliumcopper

berylliummachining #berylliumcoppersprings #berylliumcoppersheets #berylliumcoppermachining

berylliumcopperalloyc17200 #copperberylliumalloyc17200

moldmaxberylliumcopper

#c17200#berylliumcopper#bronze#becu#copper#youtube#berylliumcopperbar#berylliumcopperplate#berylliumcopperstrip

0 notes

Text

Why Does Understanding These Properties Matters?

Mechanical properties of solids refer to the characteristics that define how a material responds to external forces, such as stress, strain, and deformation. These properties include elasticity, plasticity, hardness, toughness, strength, and ductility, among others. They are fundamental in determining a material’s suitability for various applications, influencing its behaviours under different conditions.

The significance of mechanical properties spans numerous fields. In engineering, these properties ensure the safety and durability of structures like bridges, buildings, and dams. In construction, they guide the selection of materials for specific purposes, such as load-bearing or flexibility. Material science relies heavily on these properties to develop innovative materials that meet evolving industrial demands.

This article aims to delve into the science behind mechanical properties, their key characteristics, real-world applications, and their indispensable role in innovation and progress.

The Science Behind Mechanical Properties

Stress and Strain: Fundamentals

Stress is the force per unit area exerted on a material. It can be mathematically expressed as:

where is the applied force and is the cross-sectional area of the material. Strain, on the other hand, measures the deformation caused by stress. It is defined as the ratio of the change in length to the original length: where is the change in length and is the original length.

Types of Stress and Strain

Tensile Stress and Strain: Occurs when forces act to stretch a material. Examples include the stretching of rubber bands and cables.

Compressive Stress and Strain: Results from forces that compress or squeeze a material. Concrete in buildings often experiences compressive stress.

Shear Stress and Strain: Arises when forces are applied parallel to a surface. Scissors cutting paper is an example of shear stress in action.

Hooke’s Law and Elasticity

Elasticity is the ability of a material to return to its original shape and size after the removal of stress. Hooke’s Law describes this behaviour:

where is the Young’s modulus, a measure of a material’s stiffness. Elasticity is crucial for applications requiring temporary deformation, such as springs.

Plasticity and Permanent Deformation

When stress exceeds a material’s elastic limit, it undergoes plastic deformation, leading to permanent changes in shape or size. Metals like aluminium and copper exhibit plasticity, making them ideal for moulding and shaping processes.

Key Mechanical Properties

1. Young’s Modulus (Stiffness)

Represents a material’s resistance to deformation under tensile stress.

Example: Steel has a high Young’s modulus, making it ideal for construction.

2. Shear Modulus and Bulk Modulus

Shear Modulus measures resistance to shape changes under shear stress.

Bulk Modulus evaluates a material’s response to uniform compression.

Applications include hydraulic systems and pressure vessels.

3. Poisson’s Ratio

Describes the ratio of lateral strain to longitudinal strain. Materials with low Poisson ratios, like cork, are used for sealing applications.

4. Strength

Includes tensile, compressive, and shear strength. Determines how much load a material can bear without failure.

Example: Carbon fiber composites are used in aerospace for their high strength-to-weight ratio.

5. Ductility and Malleability

Ductility is the ability to be stretched into a wire. Copper’s ductility makes it suitable for electrical wiring.

Malleability is the ability to be hammered into sheets. Gold’s malleability is utilized in jewellery making.

6. Brittleness and Toughness

Brittleness: Materials like glass break without significant deformation.

Toughness: Measures a material’s ability to absorb energy before fracturing. Rubber is an example of a tough material.

7. Hardness

Resistance to indentation or scratching. Hardness tests include the Mohs scale and the Brinell test.

Example: Diamond, the hardest known material, is used in cutting tools.

Applications in Engineering and Design

Civil Engineering

Bridges: Steel and reinforced concrete combine high strength and ductility to withstand loads.

Buildings: Materials like concrete and glass are chosen based on compressive strength and aesthetic appeal.

Aerospace and Automotive Industries

Lightweight yet strong materials like titanium alloys ensure efficiency and safety in aircraft.

Automotive components use materials with high impact resistance, such as advanced polymers.

Manufacturing Tools and Machinery

Machine tools rely on hard materials like tungsten carbide for durability and precision.

Conveyor belts require toughness and flexibility to handle wear and tear.

Product Design and Safety Analysis

Consumer goods, such as smartphones, use materials that balance hardness and toughness.

Safety-critical systems, like helmets and airbags, are designed with energy-absorbing materials.

Material Science and Advancements

Developing New Materials

Nanomaterials and composites offer superior strength and lightweight properties.

Innovations like graphene enhance conductivity and mechanical strength.

Sustainability and Recycling

Recyclable materials, such as aluminium, reduce environmental impact.

Bio-based polymers provide eco-friendly alternatives for packaging and construction.

Future Trends

Smart materials, such as shape-memory alloys, adapt to environmental changes.

Research focuses on enhancing the durability of materials under extreme conditions.

The mechanical properties of solids are the backbone of modern engineering, construction, and material science. They ensure the safety, functionality, and efficiency of structures and products. By understanding and leveraging these properties, we can drive innovation, create sustainable solutions, and meet the challenges of an ever-evolving world.

As we continue to explore new materials and techniques, the importance of mechanical properties will remain at the forefront of progress, shaping a future of resilience and ingenuity.

For more simplified explanations like the one above, visit the physics blogs on the Tutoroot website. Elevate your learning with Tutoroot’s personalised Physics online tuition. Begin your journey with a FREE DEMO session and discover the advantages of online tuitions.

1 note

·

View note

Text

Sign Board

Signboards and Billboard, Neon Signs, Nameplates, Vinyl Inkjet Frosted Glass Sticker Print, Car Branding, Letter Signage, Panaflex Profile Signboard, Aluminium Composite Panel and PVC Sheet, Bell Signs and Round Signs, 3D Frontlight Backlight Sidelight Lettering, LED Moving Display and Digital Display Screen, Digital Billboard, Copper Golden Mirror Letter, Fairstalls, CNC Jali Cutting. Digital LED Signboard Billboard Nameplate Shop BD.

1 note

·

View note