#Conveyor for Batch Printing

Explore tagged Tumblr posts

Text

I'm so tired of fast.

Tired of hearing it,

Day in and day out.

So tired of living it,

Between store shelves or conveyor belt rollers.

The urge to push and push and push.

Hurry, hurry, hurry

Wayne was faster-- There's WIP to master--

60 to 100

Process until you drop dead

Please sacrifice your beauty for time.

Sacrifice your quality to earn one less dime.

I've seen the last guy fix the shelves,

Five-- Bottom to top,

But only after three did he stop.

The most top and bottom deprived,

For no toe tipped nor knee delved,

A most embarrassing standard stapled to my side.

We're sending batch in five,

Seconds.

The lanes are probably fine--

Four seconds.

The necessary pieces are off to the--

Three seconds.

There's a queue after the finished run, can't you afford me--

Two seconds.

Just give me a minute!

Or hour!

Or day!

Just do it yourself or get out of my way!

I'm tired of watching you fail and whine!

So, my friend, please step to the side!

It's suddenly okay when the CEO comes all this way,

And ten minutes are forgiven when the print goes astray,

But when we have the chance to do it right,

You can't help but see five minutes as a personal blight.

When I see this speed,

And sit in this collective disappointment,

I worry for the common deed,

While scrolling past an ad for "snake-liver ointment."

We live so fast,

Not allowing our heads to fill with thoughts.

Are you scared of waiting?

Of stillness?

Of echoes?

Will the exposure continue the rot of your lifeless body?

I'm tired of fast

Of haste

Of what's left of today

And I guess we'll all take that to our graves.

1 note

·

View note

Text

How Does an Automatic Pouch Packaging Machine Work?

In today’s fast-paced industrial landscape, packaging plays a crucial role in ensuring product safety, enhancing shelf appeal, and improving overall efficiency. Businesses across various industries rely on Automatic Pouch Packaging Machines to streamline their production lines and maintain product quality. But how do these machines function? Let’s explore the working process of an Automatic Pouch Packaging Machine and why choosing a reliable Automatic Pouch Packaging Machine Manufacturer like Ambika Packaging Solution is essential.

Understanding Automatic Pouch Packaging Machines

An Automatic Pouch Packaging Machine is a high-speed, precision-based equipment designed to fill and seal pouches efficiently. These machines are widely used in industries such as food & beverage, pharmaceuticals, chemicals, cosmetics, and more. By automating the packaging process, businesses can achieve greater consistency, reduce labor costs, and increase productivity.

Step-by-Step Working Process of an Automatic Pouch Packaging Machine

1. Pouch Loading and Feeding

The process starts with pouch loading, where pre-formed pouches are fed into the machine. Some machines come with an automatic feeding system that picks up the pouches from a stack and places them into the designated position for further processing.

2. Pouch Detection and Alignment

Once the pouches are fed into the system, sensors detect their presence and ensure proper alignment. This step is critical to avoid errors such as misaligned sealing or improper filling, which could compromise the packaging quality.

3. Pouch Opening

After alignment, the machine opens the pouch using vacuum suction or mechanical grippers. This step ensures that the pouch is fully open and ready to receive the product without any obstructions.

4. Product Filling

The filling station dispenses the pre-measured product into the open pouch. Different types of filling mechanisms are used depending on the nature of the product:

Auger Fillers – Used for powders like spices, flour, and coffee.

Liquid Fillers – Ideal for juices, oils, and sauces.

Weigh Fillers – Used for granular and solid products like snacks, nuts, and dry fruits.

5. Excess Air Removal (Optional)

In some packaging processes, excess air is removed from the pouch to increase product shelf life and maintain freshness. This is especially important in food packaging.

6. Pouch Sealing

Once the product is filled, the pouch moves to the sealing station. The machine applies heat and pressure to seal the pouch effectively. There are different sealing techniques, such as:

Heat Sealing – Commonly used for plastic and laminated pouches.

Ultrasonic Sealing – Used for delicate packaging materials and provides a strong seal without excessive heat.

7. Coding and Labeling (Optional)

Many Automatic Pouch Packaging Machines integrate a coding system to print batch numbers, manufacturing dates, expiration dates, and barcodes on the pouch. This step ensures compliance with industry regulations and enhances traceability.

8. Pouch Cutting and Discharge

After sealing, the machine cuts the pouch to separate it from the next one (if applicable) and then discharges the finished product onto a conveyor belt or collection area for final inspection and packaging.

9. Quality Check and Sorting

A final quality check ensures that the pouches are properly sealed, labeled, and free from defects. Any defective pouches are rejected automatically to maintain the highest packaging standards.

Benefits of Using an Automatic Pouch Packaging Machine

Increased Efficiency – Automating the packaging process significantly reduces downtime and improves production speed.

Consistent Quality – Ensures uniform filling, sealing, and packaging, eliminating human errors.

Reduced Labor Costs – Minimizes the need for manual intervention, cutting down labor expenses.

Versatility – Can handle a variety of pouch materials, shapes, and sizes.

Enhanced Product Shelf Life – Proper sealing techniques help prevent contamination and spoilage.

Customization Options – Machines can be tailored to suit specific industry requirements.

Choosing the Right Automatic Pouch Packaging Machine Manufacturer

Selecting a reliable Automatic Pouch Packaging Machine Manufacturer is crucial for ensuring durability, efficiency, and quality. Ambika Packaging Solution is a trusted name in the industry, offering state-of-the-art packaging machines tailored to various industrial needs. Here’s why you should choose Ambika Packaging Solution:

Advanced Technology – They use cutting-edge technology to manufacture high-performance packaging machines.

Customization – They provide tailored solutions to meet specific business requirements.

Quality Assurance – Machines undergo rigorous quality checks to ensure reliability and efficiency.

After-Sales Support – Dedicated customer support ensures seamless operation and minimal downtime.

Industry Expertise – Years of experience in the packaging industry make them a preferred choice among businesses.

Conclusion

An Automatic Pouch Packaging Machine is a game-changer for industries looking to enhance efficiency and maintain high packaging standards. By automating the pouch filling and sealing process, businesses can achieve consistent quality, reduce costs, and increase productivity. Choosing a reliable Automatic Pouch Packaging Machine Manufacturer, such as Ambika Packaging Solution, ensures that you get a high-quality machine tailored to your industry needs.

If you’re looking for a trusted partner in packaging automation, Ambika Packaging Solution offers cutting-edge solutions to streamline your packaging operations. Contact them today to learn more about their innovative packaging machines!

#Automatic Pouch Packaging Machine Manufacturer#Packaging Solutions Near Me#Packaging Machine Manufacturer in Haryana#Liquid Packaging Machines Manufacturer

0 notes

Text

Heels clicked against concrete as Chuuya made his way drifting between one warehouse and another, all of his subordinates hard at work shuffling around cargo from one vehicle to another and taking accounting of everything.

So far, everything was going well. Nothing had been tampered with. The stock of inventory matched the order records. Nothing was unaccounted for. They were expected to make a tidy sale off of most of these goods, except the ones bound for resupplying headquarters with items and ammunition they needed.

There was chatter here and there, but Chuuya didn't typically mind. As long as work got done, he was happy enough to let his workers socialize and keep their spirits and camaraderie up, and they weren't doing anything that they needed to be silent to avoid unwanted attention either.

He made his way to another conveyor belt where his guys were checking through boxes and then repacking them for their final haul onto a delivery truck, idle chatter and laughs drifting past his ear.

"--okay so I got one. Why are elevators jokes so good? Because they work on so many levels."

"What starts with E, ends with E, and has only one letter in it? An envelope."

"Okay, okay. What has a bed you can't sleep on?" You could never go wrong with a good mafia joke. "A river."

"Why were the teacher's eyes crossed? Because she couldn't control her pupils-- Oh. Good day, Nakahara-San."

The men stood at attention respectfully, setting aside what they were doing to fold their hands behind their backs and address him properly.

"How goes the job?"

One of the workers stepped forward and presented him with a clipboard full of various pages of paper between both hands, a mix of print and hand-written numbers and checks, which Chuuya scanned down every item, before flipping to the next page to do the same.

"Here's the inventory report, Sir."

Everyone stood completely still and silent as he read through every page and came away satisfied. Another good shipment with everything accounted for. The Boss would be happy about that. It meant there weren't any little moles chewing at the wires right now, at least not on the business end of things. If there were any infiltrators from a rival company or gang, they were keeping their heads low for the time being.

"Good work. Make sure the records still match when the deliveries reach their destinations. You know what I expect."

"Yes sir," came a chorus of professional voices all at once.

Chuuya started to swivel to move on to the next batch, before one of his guys piped up, "just one moment, sir! Would you like to hear a joke, sir?"

He stopped, turning with a slow blink, but Chuuya didn't explicitly say no, so he took it as an invitation to continue.

"Why do seagulls fly over the sea?" A few beats of pause, to give him a moment to think about it and try to answer (everyone knew Chuuya had beef with seagulls), but when he just stared and waited with an unchanging expression, the man continued. "Because if they flew over the bay, they'd be bagels!"

A few more beats of pause. Nobody moved.

"Oh. Yeah, I guess that's pretty funny." But it came relatively flat, like he'd barely heard what he'd said, where normally he'd at least humor a stupid joke with a snort and a few good-humored chuckles, if nothing else but to keep up a light repertoire among his subordinates. Today, he distractedly turned again and kept walking, his mind clearly somewhere else. "Anyway, keep up the good work."

Still nobody moved, like statues, until Chuuya had gone well out of ear-shot, the workers exchanging slow glances with each other in another stretch of silence.

"What do you think that's about?"

"Dunno," someone shrugged, everyone returning to work loading up the truck with cargo and talking in more hushed whispers. "He did take a few days off recently that weren't on the schedule. You think something might've happened?"

"Nobody died recently, did they? I mean, not anyone in our unit."

"No, not that I can think of."

"Maybe someone outside the Port Mafia? But I don't think Nakahara-san has any family outside the organization. At least no one that he talks about."

"It could be a friend. Or maybe trouble with a lover? It could be a break-up."

"No way. I don't think he'd take sick days for something like that."

"But he was putting in a lot of overtime just before that. Seemed pretty wound up about something."

"Maybe he got sick with something really serious?"

"You think?"

"Yeah. Like something terminal maybe? Not like it's any of our business, but--..."

"Who can say really? Seems like he's just been going through the motions lately."

"Could be burn-out. I imagine the ones at the top don't really get vacations even when they get vacations."

"Yeah, I wouldn't be surprised. Nakahara-san especially works way too hard sometimes."

"Well are you going to tell him to take a break?"

"As if any of us have the authority to."

From there, the hushed speculations only continued to spiral with a more somber mood than before, but no one dared try to question him directly.

#drabble#Main verse#ic#{--when ur muse is like ''nobody will notice anything different. Poker face''#Literally fucking everyone: *notices*--}

2 notes

·

View notes

Text

A Guide to Essential Industrial Machines: Turn Tables, Label Printing Machines, Pouch Packing Machines, and More

In today's fast-paced industrial world, machines like turn tables, label printing machines, pouch packing machines, and labeler machine systems play an integral role in optimizing manufacturing and packaging processes. Below, we’ll delve into the functions, benefits, and key applications of these essential industrial tools.

Turn Tables: Enhancing Material Handling Efficiency

Overview: Turn table are essential for industrial processes that require efficient material handling and smooth workflow transitions. These machines are often used in conjunction with conveyors or packaging systems to facilitate direction changes or accumulation of goods.

Key Features and Benefits:

Compact Design: Fits into tight spaces while maintaining operational efficiency.

Durability: Made from robust materials to withstand heavy loads and repetitive use.

Customizability: Can be tailored to meet specific industrial requirements.

Applications: Turn tables are widely used in industries like food processing, pharmaceuticals, and automotive manufacturing for tasks like product orientation, accumulation, or redirecting items on production lines.

Label Printing Machines: Precision in Product Identification

Overview: Label printing machines play a critical role in product identification and branding. They allow manufacturers to print and apply labels with essential information such as barcodes, batch numbers, and branding elements directly onto products or packaging.

Key Features and Benefits:

High-Speed Printing: Handles large volumes of labels efficiently.

Versatile Design: Accommodates a range of label sizes and materials.

Integration Options: Compatible with other systems, such as conveyors or packaging lines.

Applications: These machines are essential in industries such as retail, logistics, and pharmaceuticals to ensure products are correctly labeled for tracking and compliance purposes.

Example Product: Print and Apply Labeling Machine – A cutting-edge solution designed for automated labeling with precision and speed.

Pouch Packing Machines: Revolutionizing Packaging Solutions

Overview: Pouch packing machines simplify the packaging process by efficiently sealing products into pouches. They are highly versatile and cater to industries like food, pharmaceuticals, and chemicals.

Key Features and Benefits:

Automated Operation: Reduces manual labor while increasing output.

Versatility: Compatible with a wide variety of pouch types, including stand-up pouches and zip-lock bags.

Efficiency: Ensures accurate sealing and reduces material wastage.

Applications: These machines are ideal for packaging powdered goods, liquids, or small items, offering both efficiency and enhanced product protection.

Labelling Machines: Streamlining Product Presentation

Overview: Labeling machines are indispensable in modern manufacturing, providing an automated solution for applying labels to products or packaging. Label machine ensure consistency and accuracy while enhancing the overall appearance of goods.

Key Features and Benefits:

Automation-Friendly: Easily integrates into production lines.

Flexibility: Handles a variety of shapes and sizes, from bottles to boxes.

Precision Application: Ensures labels are applied evenly and securely.

Applications:

Food & Beverage Industry: Labeling bottles, cans, or containers with branding and nutritional information.

Pharmaceuticals: Applying regulatory and safety information to medicines.

Retail: Labeling consumer products for easy identification and branding.

Example Products:

Labelling Machines – Comprehensive solutions for automatic labeling needs.

Print and Apply Labeling Machine – Ideal for high-volume labeling operations.

Packaging Machines: The Backbone of Modern Manufacturing

Overview: Packaging machines streamline the packing process, ensuring products are sealed and protected efficiently. They range from semi-automatic systems to fully automated units designed for mass production.

Key Features and Benefits:

Speed and Accuracy: Handles high-volume packaging with precision.

Energy Efficiency: Modern machines are designed to minimize energy consumption.

Versatility: Supports a variety of packaging formats and materials.

Applications: Packaging machine cater to industries like food, cosmetics, and electronics, offering tailored solutions for different product types.

Example Products:

Packaging Machines – Advanced systems for diverse industrial applications.

Conclusion

From turn tables to labeling and packaging machines, these industrial tools are transforming manufacturing processes by improving efficiency, precision, and scalability. As technology advances, these machines continue to evolve, offering innovative solutions tailored to various industries.

If you’re looking to optimize your operations, investing in these packaging machineries are a step toward enhanced productivity and streamlined processes.

FAQs

What is the primary purpose of turn tables in industrial settings? Turn tables facilitate the efficient movement and orientation of products on production lines, ensuring smooth transitions between processes.

How do label printing machines benefit manufacturers? Label printing machines enable precise and high-speed labeling, ensuring compliance with regulatory standards and improving product traceability.

What industries benefit most from pouch packing machines? Industries like food, pharmaceuticals, and chemicals rely heavily on pouch packing machines for efficient and secure product packaging.

Can labeling machines handle irregularly shaped products? Yes, many labeling machines are designed to accommodate a variety of product shapes and sizes, providing flexibility in application.

Are packaging machines eco-friendly? Modern packaging machines often incorporate energy-saving features and support recyclable materials, making them more eco-friendly.

youtube

0 notes

Text

HZS75 Ready-Mixed Concrete Batching Plant Shipped To Algeria

Recently, Focus Machinery successfully shipped a set of high quality HZS75 ready-mixed concrete batching plant to Algeria, providing advanced concrete production equipment for the local construction industry. The mixing plant is well-equipped and has excellent performance, making it an ideal choice for construction projects in the Algerian market.

The HZS75 ready-mixed concrete batching plant consists of multiple high-performance components, ensuring efficient and stable concrete production. The core equipment is the JS1500 double-shaft concrete mixer, which has a strong mixing capacity and can efficiently mix various types of concrete to ensure uniform and stable quality of each batch of concrete. The PLD2400-4 aggregate batching machine is equipped with four independent weighing hoppers, which can accurately batch ingredients, not only improving production efficiency, but also ensuring the accuracy of concrete proportions.

In addition, the mixing plant is also equipped with two sets of 100-ton bolted cement silos, which, in conjunction with the LSY219-9 screw cement conveyor, ensure the stable supply and transportation of cement, greatly improving the continuity and reliability of production. The fully automatic computer control system makes the operation easier and more efficient. The system is equipped with a dot matrix printer, which can automatically record and print the relevant data of each production, which is convenient for quality monitoring and management.

The successful delivery of this equipment marks the further expansion of Focus Machinery in the Algerian market, and also provides a more efficient and environmentally friendly concrete production solution for the local construction industry. The customer highly appreciated the efficient performance and precision design of the batching plant, and looks forward to achieving greater success in future cooperation.

We FOCUS MECHINERY stand for new product ideas and courageous vision of the future, we stand for our never-stopping dedication and devotion to your construction equipment solutions, we focus on your project needs.If you're looking for a particular supplier or specific configurations, I can provide more details or recommendations!

Whatsapp&Phone:+86 13676986531

#concrete contractors#concrete plant customization#concrete mixer plant#concrete bag breaker#concrete mixer#1000t deck barge#1500t deck barge#concrete plant contractors

0 notes

Text

Packaging Automation Solutions: A Game-Changer for Modern Businesses

Automation is no longer just a buzzword; it’s the lifeblood of industries striving for efficiency and innovation. In the world of packaging, packaging automation solutions are transforming how businesses operate. From small startups to multinational giants, everyone is tapping into the power of automation to streamline processes and boost productivity. Let’s explore what makes these solutions so impactful, and yes, we’ll keep it engaging—because automation doesn’t have to be boring!

What Are Packaging Automation Solutions?

Packaging automation solutions encompass advanced technologies and systems designed to handle various packaging tasks—think filling, sealing, labeling, and palletizing—with minimal human intervention. These solutions use robotics, sensors, and software to deliver precision, speed, and reliability in packaging operations.

Gone are the days of endless manual labor on assembly lines. With packaging automation solutions, businesses can achieve more in less time, ensuring consistent quality while reducing costs.

Why Should Businesses Invest in Packaging Automation Solutions?

Let’s break it down:

Speed: Imagine meeting tight deadlines without breaking a sweat.

Accuracy: Say goodbye to crooked labels and messy seals.

Cost Savings: Less waste and reduced labor costs mean a better bottom line.

Scalability: Whether it’s 100 units or 10,000, automation adapts to your needs.

Happier Teams: Employees can focus on creative, meaningful tasks instead of repetitive grunt work.

The Benefits of Packaging Automation Solutions

1. Supercharged Productivity

With packaging automation solutions, what used to take hours can now be done in minutes. Machines don’t take breaks, and they certainly don’t call in sick. This consistent output ensures you meet production goals, even during peak demand periods.

2. Impeccable Quality Control

Human error is inevitable, but machines? They’re built for precision. Whether it’s filling bottles to the exact milliliter or applying labels perfectly every time, automation ensures your products look and perform their best.

3. Cost Efficiency

While the initial investment might seem steep, the long-term savings are worth it. Automation minimizes waste, optimizes material use, and reduces the need for manual labor. Over time, these savings add up significantly.

4. Enhanced Worker Safety

Let’s face it—packaging tasks can be repetitive and even hazardous. Packaging automation solutions take over the physically demanding jobs, reducing workplace injuries and keeping your team safe.

5. Eco-Friendly Operations

Modern automation systems are designed with sustainability in mind. They optimize resource use, reduce waste, and often integrate with green energy solutions, helping your business stay environmentally responsible.

How Do Packaging Automation Solutions Work?

Step 1: Feeding and Organizing

Products are fed into the system using conveyors and robotic arms. These machines organize and sort items, ensuring a smooth flow through the packaging line.

Step 2: Filling and Sealing

Automated systems precisely measure and fill products into containers, be it liquids, powders, or solids. Once filled, the packages are sealed—tight, secure, and ready to move on.

Step 3: Labeling and Coding

Labels are applied flawlessly, and any necessary information—like barcodes, batch numbers, or expiry dates—is printed with laser-sharp clarity.

Step 4: Quality Checks

AI-powered cameras and sensors inspect every package to ensure it meets quality standards. Defective products are flagged and removed from the line.

Step 5: Palletizing and Shipping

Finally, robotic arms stack the packaged goods onto pallets, optimizing them for storage or transport. Some systems even integrate with logistics software for seamless shipping.

Real-World Success Stories

Case Study 1: A Craft Brewery’s Leap to Automation

A small craft brewery struggling with demand spikes turned to packaging automation solutions. The result? Their production tripled, labor costs halved, and they finally had time to focus on brewing award-winning beers.

Case Study 2: A Global Retailer’s Packaging Overhaul

A retail giant adopted fully automated packaging systems across their distribution centers. Not only did this cut processing times by 60%, but it also reduced packaging waste by 30%, aligning with their sustainability goals.

Challenges in Adopting Packaging Automation Solutions

Initial Costs

Let’s be honest—automation isn’t cheap. Investment if often important as long-term benefits often outweigh the initial expenses.

Skill Gaps

Operating and maintaining automated systems require skilled workers. Investing in training is crucial.

Integration

Adapting new systems to existing operations can be tricky. Partnering with experienced providers ensures a smoother transition.

The Future of Packaging Automation Solutions

The future is bright, and it’s automated! Innovations in AI, machine learning, and IoT are making packaging systems smarter and more adaptable. Picture this: machines that predict maintenance needs, adapt to new packaging designs on the fly, and optimize energy use—all while keeping your operations running smoothly.

Conclusion

Packaging automation solutions are the secret sauce for businesses aiming to stay competitive in today’s fast-paced world. They enhance efficiency, improve quality, and save costs—all while making operations safer and more sustainable. Whether you’re a small startup or a global powerhouse, automation can revolutionize your packaging game. So, what are you waiting for? It’s time to let the robots take the reins—and maybe crack a joke or two along the way!

FAQs

1. What industries benefit the most from packaging automation solutions?

Virtually all industries—from food and beverages to pharmaceuticals, cosmetics, and e-commerce—can benefit from automation.

2. How long does it take to see ROI on automation?

Depending on the scale of implementation, most businesses see ROI within 1-3 years.

3. Is automation suitable for small businesses?

Absolutely! Scalable solutions mean even small businesses can adopt automation without breaking the bank.

4. Do automated systems require a lot of maintenance?

Regular maintenance is necessary but manageable, especially with modern systems designed for durability and self-diagnosis.

5. Can automation help with sustainability?

Yes! Many systems are designed to optimize resources and reduce waste, making your operations greener.

1 note

·

View note

Text

A Comparative Analysis for Variable Data Printing vs. Traditional Printing

The printing industry has seen significant advancements over the years, particularly with the introduction of variable data printing (VDP). This technology allows for the printing of individualized information on each sheet, such as alphanumeric characters, addresses, barcodes, QR codes, and logos.

What is Variable Data Printing?

Variable data printing (VDP) involves printing unique data on each sheet, which is crucial for applications requiring personalized information. This technology supports high-speed printing on various substrates like Colour Wove, Maplitho, Art Paper, Duplex Board up to 350 gsm, and NCR Sheet. The Autoprint Reckoner VDP65 is an example of a machine that leverages HP Inkjet Technology to offer efficient numbering, barcoding, mail addressing, and online perforation.

Traditional Printing

Traditional printing methods, such as offset and digital printing, produce identical copies of a print job. These methods are cost-effective for large volumes of the same print material but do not offer the flexibility of VDP. Traditional printing is best suited for mass production where the content remains consistent across all copies.

Advantages of Variable Data Printing

1. Personalization: VDP allows for the customization of each printed piece, making it ideal for direct mail, marketing materials, and personalized invitations.

2. Efficiency: By printing variable information directly, VDP eliminates the need for pre-printed stock and separate personalization steps, reducing production time.

3. Cost-Effectiveness: Although the initial setup cost may be higher, VDP can be more cost-effective in the long run by reducing waste and inventory costs.

4. Versatility: VDP can be applied to various substrates and formats, offering flexibility for different applications.

Autoprint Reckoner VDP65

The Autoprint Reckoner VDP65 is an offline sheetfed variable data printing machine using HP Inkjet Technology. It is designed for high-speed, accurate printing of variable data such as numbers, barcodes, and addresses. As an authorized oil-free air compressor dealer, AS Equipment ensures that customers receive top-quality products along with exceptional support and service, maximizing the performance and reliability of their compressed air systems.

Batch Coding Systems

A batch coding system is crucial for marking products with unique codes or batch numbers, ensuring traceability throughout the supply chain. These systems are vital for industries like food and beverage, pharmaceuticals, and cosmetics, where product safety and quality are paramount. Batch coding can be integrated with VDP machines to streamline processes and ensure accurate, consistent coding.

Steps Involved in Batch Coding

1. Prepare the Design: Create the design for the batch code, including relevant information such as the date of manufacture and product batch number.

2. Set Up the Machine: Calibrate the batch coding machine and load the necessary ink or ribbon.

3. Load the Product: Position the product or packaging correctly on the machine’s conveyor.

4. Set Parameters: Configure printing speed, number of copies, and other settings.

5. Start Coding: Activate the machine to print the batch code.

6. Verify Codes: Check the printed codes for accuracy and legibility.

Both variable data printing and traditional printing have their unique advantages and are suited to different applications. VDP offers unparalleled flexibility and efficiency for personalized printing needs, while traditional printing remains the best choice for large-scale, uniform print jobs. By understanding the strengths of each method, businesses can choose the right technology to optimize their production processes. For high-quality VDP solutions, the Autoprint Reckoner VDP65 stands out as a reliable choice, supported by AS Equipment’s excellent service as an authorized dealer.

Read more posts Maximizing Efficiency with Automatic UV Coating Machines: Tips and Best Practices Role of prepress in offset printing

0 notes

Text

The Automatic Rotary Labeling Machine streamlines your labeling process with precision. Containers are fed onto a rotary star plate, where they are smoothly transported to the labeling point. An electronic sensor releases the label, which is then pressed onto the bottle with the help of a roller. If equipped, the batch printing device prints necessary details like batch numbers while the label is stationary. Once the labeling is complete, the starwheel efficiently transfers the bottle to the next operation on the conveyor.

For more information, visit - https://www.parthec.com/product/automatic-rotary-labeling-machine

#Parthec#AutomaticBottleLabelingMachine#RotaryLabelingMachine#BottleLabelingMachine#BatchLabelingMachine#ContainerLablingMachine

0 notes

Text

Automatic Ampoule Sticker Labeling Machine in Nigeria

Laxmi Pharma Equipment is a Manufacturer, Supplier, and Exporter of Automatic Ampoule Sticker Labeling Machine in Nigeria. Our Headquartered in Ahmedabad, Gujarat, India. An automatic ampoule sticker labeling machine is designed to apply self-adhesive labels on cylindrical ampoules efficiently and accurately. The machine ensures high-speed labeling, reduces manual intervention, and maintains consistency, making it a valuable tool for production lines that handle small vials or ampoules. Types of Automatic Ampoule Sticker Labeling Machine: Vertical Ampoule Sticker Labeling Machine Horizontal Ampoule Sticker Labeling Machine High-Speed Ampoule Sticker Labeling Machine Customized Ampoule Labeling Machine Features of Automatic Ampoule Sticker Labeling Machines: High Precision Labeling: Ensures accurate placement of labels with minimal errors. User-Friendly Interface: Equipped with a touchscreen or PLC controls for ease of operation. Durable Build: Constructed from stainless steel to ensure longevity and hygiene. Versatile Compatibility: Suitable for various sizes and types of ampoules. Zero Downtime Mechanism: Features like automatic label roll replacement reduce production interruptions. Print and Apply Options: Can integrate with printers for batch numbers, barcodes, or other details. How does an automatic ampoule sticker labeling machine work? The machine uses a conveyor to feed ampoules into the labeling unit. Sensors detect the ampoule’s position, and the labeling head applies the sticker precisely. Advanced models may also print additional details like batch numbers. What is the maximum speed of these machines? High-speed models can label up to 400 ampoules per minute, depending on the machine and label size. Can the machine handle different ampoule sizes? Yes, most machines are compatible with various ampoule diameters and heights. Adjustable settings allow for easy customization. Laxmi Pharma Equipment is an Exporter of Automatic Ampoule Sticker Labeling Machine in Nigeria Including locations like Lagos, Abuja, Port Harcourt, Kano, Ibadan, Benin City, Maiduguri, Aba, Jos, Kaduna, Ilorin, Zaria, Yola, Oyo, Birnin Kebbi, Enugu, Buguma, Mokwa, Bosso, Ikorodu, Gombe, Nasarawa, Onitsha, Oron, Ikot Abasi, Deba Habe, Jemaa, Ibi, Brass, Jamaare, Degema, Minna, Ilesa, Owerri, Sokoto, Awka, Sagamu, Bida, Nnewi. For more information, please feel free to contact us. View Product: Click Here Read the full article

#Aba#Abuja#AutomaticAmpouleStickerLabelingMachineinAhmedabad#AutomaticAmpouleStickerLabelingMachineinGujarat#AutomaticAmpouleStickerLabelingMachineinNigeria#AutomaticAmpouleStickerLabellingMachine#Awka#BeninCity#Bida#BirninKebbi#Bosso#Brass#Buguma#DebaHabe#Degema#Enugu#Exporter#ExporterofAutomaticAmpouleStickerLabelingMachine#Gombe#Ibadan#Ibi#Ikorodu#IkotAbasi#Ilesa#Ilorin#Jamaare#Jemaa#Jos#Kaduna#Kano

0 notes

Text

Applications of PCB Conveyor Systems in Electronics Manufacturing

PCB conveyor systems are indispensable in electronics manufacturing, serving as the backbone of automated production lines. These systems are designed to transport printed circuit boards (PCBs) between various stages of assembly and inspection, ensuring smooth operations and enhancing efficiency. Their versatility and reliability make them crucial in a wide range of applications across the electronics industry.

1. Integration in SMT Assembly Lines

PCB conveyor systems are heavily used in Surface Mount Technology (SMT) assembly lines, where they link critical processes such as solder paste printing, pick-and-place assembly, reflow soldering, and inspection. By automating the transfer of PCBs, conveyor systems maintain consistent production flow, reducing bottlenecks and optimizing throughput. Their precision ensures that PCBs are positioned accurately for each stage of the assembly process.

2. Buffering and Accumulation

In high-volume production environments, PCB conveyors are used for buffering and accumulation to manage variations in processing times between machines. For instance, if a pick-and-place machine temporarily slows down, the conveyor can hold PCBs without disrupting the upstream processes. This buffering capability ensures a balanced workflow and reduces downtime.

3. Quality Inspection and Testing

Conveyor systems facilitate the integration of Automated Optical Inspection (AOI), X-ray inspection, and functional testing equipment. As PCBs are transported, inspection systems can analyze solder joints, component placement, and overall assembly quality. This ensures defects are identified early, minimizing the risk of defective products reaching the market.

4. Multi-Layer PCB Manufacturing

In multi-layer PCB assembly, conveyors support intricate processes like layer alignment and lamination. Their stability and precision help manufacturers handle complex designs and ensure that each layer aligns correctly, which is essential for the functionality of advanced electronics.

5. Prototyping and Small Batch Production

PCB conveyors are also valuable in prototyping and small-batch production. They allow manufacturers to test new designs efficiently by seamlessly integrating with flexible production setups.

6. Diverse Applications Across Industries

Beyond consumer electronics, PCB conveyor systems are utilized in industries such as automotive, aerospace, and medical devices, where high-quality and reliable PCBs are essential for critical applications.

In conclusion, PCB conveyor systems are foundational to electronics manufacturing, enabling streamlined workflows, precision handling, and enhanced quality control. Their diverse applications highlight their importance in meeting the demands of modern electronics production.

related articles:

Future Trends in PCB Conveyor Systems Introduction to PCB Conveyor Systems Key Features of Modern PCB Conveyor Systems

0 notes

Text

Ampoule Filling Line

Ampoule manufacturing line and ampoule filling line (also known as ampoule compact line) are cGMP injectable lines that include washing, filling, sealing, inspecting, and labeling processes. For both closed-mouth and open-mouth ampoules, we offer liquid injection ampoule lines. We provide both fully automatic and semi-automatic ampoule filling lines, which are suitable for smaller ampoule filling lines. All of the equipment in automatic filling lines is integrated so that it functions as a single, cohesive system. For cGMP compliance, all contact parts are constructed from FDA-approved materials or stainless steel 316L.

Automatic Ampoule Filling Line

Automatic Ampoule Filling Lines are made up of machines for labeling, filling, sealing, and washing. Every machine is connected to function as a single, cohesive system. Automation is used in operations to remove human intervention. These lines are also known as Production Scale Ampoule Filling Lines or High-Speed Ampoule Production Lines. The equipment in this kind of filling line is listed below:

Automatic Ampoule Washing Machine

The purpose of an automatic ampoule washer, also known as an automatic ampoule washing machine, is to clean ampoules while minimizing machine parts’ contact with the ampoules in order to comply with cGMP regulations. Positive ampoule washing is ensured by a machine with a specially developed Gripper system that grabs the ampoule from the neck and inverts it until the washing process is finished. The ampoule is then released on the outfeed feedworm system in a vertical position after washing. Using replacement parts, the machine can clean ampoules ranging from 1 to 20 milliliters.

youtube

Sterilization Tunnel

Glass ampoules and vials that have been cleaned are sterilized and depyrogenated online using a sterilization and depyrogenation tunnel, also known as a pharma sterilizing tunnel. Glass ampoules and vials are moved from automatic washing machines (non-sterile) to the outlet filing line (sterile region) in the tunnel via a stainless-steel wire conveyor.

Ampoule Filling and Sealing Machine

Pharmaceutical glass ampoules are filled and packaged using an ampoule filling and sealing machine, also known as an ampoule filler. Liquid is poured into ampoules, which are subsequently evacuated using nitrogen gas and sealed with combustible gasses. The machine has a filling pump that was specifically made to fill liquid precisely while centering the neck during the filling process. As soon as the liquid is filled, the ampoule is sealed to prevent contamination. Made in compliance with cGMP regulations using premium stainless steel 316L components.

youtube

Ampoule Inspection Machine

Glass ampoules that can be injected can be inspected using an automatic ampoule examination machine. The four tracks of the Ampoule Inspection Machine are made of nylon-6 roller chain, and they come with a spinning assembly that includes A.C. Drive Rejection Units and 24V DC wiring. Additionally, the ability to modify speed was made possible with a variable AC frequency drive. All of the machine’s contact parts are composed of authorized engineered polymers and stainless steel, in compliance with cGMP regulations.

Ampoule Labeling Machine

High-end equipment, known as an ampoule labeling machine or ampoule labeler, is used to label glass ampoules, vials, and eye drop bottles. To print batch number, manufacturing date, and other information on labels, install a printer on your computer. Pharmacy businesses have the option to add barcode scanning and camera-based vision systems. There are various label types that can be used, including paper labels, transparent labels, and BOPP labels with self-adhesive sticker types.

youtube

Semi-Automatic Ampoule Filling Line

Machines for labeling, filling, sealing, and washing make up a semi-automated ampoule filling line. These devices operate autonomously and integrate with one another. These lines are also known as small-scale ampoule filling lines or low-cost ampoule production lines. The equipment in this kind of filling line is listed below:

Semi-Automatic Ampoule Washing Machine

The ampoule jet washer, also known as the semi-automatic ampoule washing machine, is a dependable, portable, and semi-automatic ampoule and vial washer that complies with cGMP regulations. With the aid of appropriate replacement components, the Multijet Ampoule & Vial Washing Machine can wash glass vial sizes ranging from 2 to 100 milliliters and ampoule sizes between 1 and 20 milliliters. Its stainless steel construction ensures durability. FDA-approved materials or stainless steel 316L are used to make all contact parts.

youtube

Dry Heat Sterilizer

Bottles, vials, and ampoules that have been cleaned can be sterilized using an ampoule sterilizer or dry heat sterilizer. It is constructed from MS heavy angles with an exterior wall composed of stainless steel 304 and an inner wall made of stainless steel 316. Our double door DHS is manufactured in compliance with cGMP requirements that are authorized in injectable pharmaceutical factories that uphold a class 100 environment. For cGMP compliance, all contact parts are constructed from FDA-approved materials or stainless steel 316L.

Ampoule Filling and Sealing Machine

Pharmaceutical glass ampoules are filled and packaged using an ampoule filling and sealing machine, also known as an ampoule filler. Liquid is poured into ampoules, which are subsequently evacuated using nitrogen gas and sealed with combustible gasses. The machine has a filling pump that was specifically made to fill liquid precisely while centering the neck during the filling process. As soon as the liquid is filled, the ampoule is sealed to prevent contamination. Made in compliance with cGMP regulations using premium stainless steel 316L components.

youtube

Ampoule Inspection Machine

Glass ampoules that can be injected can be inspected using an automatic ampoule examination machine. The four tracks of the Ampoule Inspection Machine are made of nylon-6 roller chain, and they come with a spinning assembly that includes A.C. Drive Rejection Units and 24V DC wiring. Additionally, the ability to modify speed was made possible with a variable AC frequency drive. All of the machine’s contact parts are composed of authorized engineered polymers and stainless steel, in compliance with cGMP regulations.

Ampoule Labeling Machine

High-end equipment, known as an ampoule labeling machine or ampoule labeler, is used to label glass ampoules, vials, and eye drop bottles. To print batch number, manufacturing date, and other information on labels, install a printer on your computer. In pharmacies, installing camera-based vision systems for printing and barcode scanning is an alternative. There are various label types that can be used, including paper labels, transparent labels, and BOPP labels with self-adhesive sticker types.

youtube

#ampoule compact line#liquid injection ampoule lines#semi-automatic ampoule filling lines#smaller ampoule filling lines#Automatic Ampoule Washing Machine#Sterilization Tunnel#Ampoule Filling and Sealing Machine#Ampoule Inspection Machine#Ampoule Labeling Machine#Semi-Automatic Ampoule Washing Machine#Youtube

0 notes

Text

A.T.E. Group : Open-width wet processing for knit fabric – a fast-emerging trend

Sustainability has emerged as a pivotal concern globally and the textile industry is no exception. Ecology and energy conservation are now focal points as much as quality and price.

Presently, knit textiles are predominantly processed in a tubular form. However, the demand for open-width processing is on the rise. The Indian knit processing industry is increasingly recognising the significant advantages of open-width knit fabric processing with respect to quality and savings of water and energy. This is clear from the ongoing trend wherein several processors have integrated open-width knit processing into their existing tubular knit processing setups.

Challenges faced with tubular knit fabric processing:

Inconsistent results due to batch process

Poor fabric surface quality due to aggressive handling

High weight loss

High chemical and dye consumption

High effluent loads

High fabric handling necessitates increased dependency on labor

A.T.E. offers complete solutions for Goller open-width knit fabric wet processing machines from Fong’s National Engineering Co., Ltd.: German technology made in China. Goller offers spun oil washing ranges, bleaching ranges, mercerizing ranges, cold pad batch dyeing, and washing ranges for dyed and printed knit fabrics in open form. Goller has established itself as a world leader for knit open-width wet processing with hundreds of successful installations worldwide. Goller’s success with open-width knit fabric processing stems from their modular design tailored to meet specific customer requirements that result in optimum results for the application.

Following are the various modules offered by Goller:

Oxidator washer a drum washer module with driven fabric transport and power spray for sensitive fabrics which requires dwell time for swelling and shrinkage

Sintensa washer a drum washer module with an inner propeller for effective washing with high turbulence

Universa conveyors compartment with bath separation and circulation spraying system for maintaining dwell time

Variety of chemical dosing systems based on application along with flow control

45° angle intermittent squeezer with scroll roll opening to prevent edge curling thereby avoiding crease formation or pressing

Auto filtering systems

Elastodip chemical applicator, with a long dwelling time of 2-3 minutes for good chemical exchange before bleaching steamer

Special S–wrap mangle for higher pickup of chemicals

A fabric reaction steamer with a built-in indirect steam generation system manages saturated steam conditions and a 100 degrees C+/-1 temperature. It includes tension-controlled drums for fabric preheating, roller or conveyor bed transport for dwell time, E+L centering, and double scroll roll at exit

In mercerising, specially designed roller section as impregnation compartment for dry on wet or wet on wet, room/hot mercerisation, auto caustic concentration control +/-0.5Be, st. upper roller and bottom rollers with load cell tension control in each section, pin chain with 4-5 sections (12-15m), width adjustment at each section, followed by tension-controlled washing and PH neutralisation results in best quality mercerisation

All the washers, except dwell time zones, have thermplate heating systems for effective and efficient heat transfer for energy conservation and reducing the water level in the compartment

Advantages of open-width knit processing over tubular fabric processing:

Improved surface quality

Reduced loss of weight and tensile strength

Less pilling

Excellent colour appearance

Less shrinking

Lower production costs

Less effluent loads

Clean department

Consistency in results

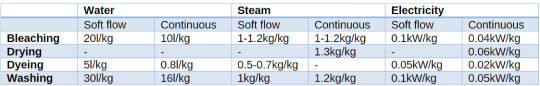

Comparison of utility consumption: Soft flow and continuous ranges

Source – data from Goller’s end users

Soft flow machine material to liquor ratio: 1:5, fabric width 2.2 m

Though the mercerising process has been an integral part of woven fabric processing to produce high-quality fabric, this was not available for knits in open-width form due to the challenges involved in handling knit fabrics in open form. Goller stands out as the pioneer in developing open-width knit fabric mercerising ranges and till date, they have installed 15 machines worldwide, including the one in India at PC Colours, Kolkata.

Mercerising helps to improve dye affinity which invariably leads to 15 to 20% dye savings, provides a deeper shade and more lustrous appearance, achieves excellent colour especially medium dark or dark, and improves the brightness after printing

Similarly, the cold pad batch dyeing method for reactive dyeing of cotton fabrics yields good dyeing results with lower effluent loads. Colour fixation in CPB dyeing is better compared to the exhaust method, requires less water for washing, reduced TDS of the effluent as no salt is used, and consumes no steam for dye fixation.

Open-width knit fabric process flow and a package of machinery from A.T.E.:

A.T.E.: a perfect partner for you

A.T.E. has always been dedicated to offering state-of-the-art, efficient, and eco-friendly equipment that helps customers gain a competitive advantage. The concepts of responsibility and technology are part of the values of A.T.E.

Apart from supplying a complete package of machinery for the processing industry, A.T.E. offers after-sales services, technological support, AMCs, machine audits, etc. A.T.E. has also successfully executed many green-field projects.

A.T.E. is a one-window solution provider in textile engineering across the textile value chain, backed by 80+ years of experience and deep domain knowledge. That is why in addition to textile machinery, we also offer state-of-the-art effluent treatment plants with IoT monitoring, sludge handling solutions and ZLD.

0 notes

Text

Frequently Asked Questions(FAQs) about Ink Pumps for Continuous Inkjet Printers(CIJ)

You will find the following information here:

What is CIJ?

What is the primary application of continuous inkjet printers?

How does continuous inkjet printing work?

How is a continuous inkjet system formed?

Common issues with ink pumps in continuous inkjet printers

TOPSFLO CIJ ink pumps Solution

How to Get in Touch with TOPSFLO for Expert Assistance?

What is CIJ?

CIJ stands for Continuous Inkjet, CIJ is a small character inkjet printing technology that uses a single inkjet nozzle to rapidly spray ink into tiny droplets, forming printed images or text. CIJ printers are widely used worldwide and are a non-contact printing method, making them suitable for marking on both flat and curved surfaces. They are primarily used in industrial applications for product packaging, labeling, and coding.

What are the Main Applications of Continuous Inkjet Printers?

Continuous inkjet printers are primarily used to mark production dates, batch numbers, barcodes, and other information on the surfaces of various materials such as plastic, metal, glass, cardboard, and wood. Typical applications include beverage cartons, cans, and bags, pharmaceuticals, small cardboard boxes, cables, and components. Virtually any product or packaging that moves on a conveyor belt or extrusion machine is suitable for continuous inkjet printing.

How does Continuous Inkjet Printers Work?

Continuous inkjet printers create a continuous stream of ink, which is broken down into numerous ink droplets through high-frequency vibrations. Once the ink droplets are formed, the selected ones are charged by electrodes and then directed by a deflection plate that generates an electrostatic field.

Charged ink droplets pass through the deflection plate, causing them to deviate at a specific angle before being sprayed from the print head onto the product to create the desired printed information. Uncharged ink droplets remain unaffected and return directly to the CIJ ink system.

During this printing process, the solvent base of the ink evaporates, and the viscosity of the ink changes accordingly. To ensure the optimal droplet formulation, viscosity must be strictly controlled within specified values.

How is a Continuous Inkjet System Formed?

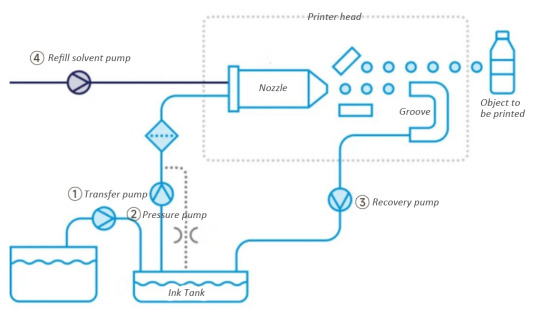

In continuous inkjet (CIJ) printing, ink circulates continuously throughout the printer, from the fluid system to the printhead, and then back to the fluid system. The entire ink path system involves several pumps working in coordination.

Initially, ink is transported from a large container to an ink reservoir using a transfer pump (①).

Subsequently, the ink is pressurized and transferred to the printhead using a pressure pump (②). Inside the printhead, the ink flows through nozzles, forming a continuous array of small ink droplets, each of which can be individually charged. Charged droplets are deflected by electrodes and hit the object to be printed.

Additionally, uncharged ink droplets fly in a straight line into a gutter, and excess ink is recirculated from this point back to the ink reservoir using a recirculation/suction/recovery pump (③).

To prevent the ink from drying and damaging the system when the printer is not in use, a refill solvent pump (④) is typically included in the continuous inkjet system. This pump delivers solvent to the nozzles to flush out any residual ink.

Through these steps, a continuous inkjet system can continuously supply ink and achieve high-speed, efficient inkjet printing.

Common Issues with Ink Pumps in Continuous Inkjet Printers

1. In the current market, there is a wide variety of ink types used in CIJ printers, each with different viscosities. These different ink compositions may contain additives, some of which can be corrosive, leading to compatibility issues with pump materials that can cause malfunctions or a very short lifespan.

2. Instability in the liquid circuit pressure and ink flow during the operation of the inkjet printer can affect the printing results.

Continuous inkjet printing requires prolonged periods of operation. Over time, continuous use may result in wear and tear, potentially leading to a decline in performance or malfunctions, thus compromising the printer's lifespan.

TOPSFLO CIJ ink pumps Solution

Diverse Pump Materials

Topsflo printer ink pumps offer a variety of pump material configurations to accommodate common CIJ ink types, such as MEK, dye-based inks, pigment inks, and soft pigment inks. The pump head materials for diaphragm pumps can be selected from PA, PPS, or PP, while membrane materials can be chosen from EPDM or PTFE. For valve materials, options include EPDM, FKM, or FFKM. YT alloy gear pumps are mainly used for pigment inks, while PEEK gears can be used for dye-based inks.

Carefully Selected Pump Types for Precise Applications

Topsflo offers two pump options tailored for printer applications: diaphragm pumps and gear pumps.

- Diaphragm liquid pumps, especially those designed for low-flow rates, provide relatively stable flow and pressure output. They are more suitable for handling liquids containing solid particles or particulate matter because their design is better suited for handling suspended particles. However, in high-flow applications, diaphragm pumps may produce larger pulses, which could lead to vibration or noise issues.

- Gear pumps are suitable for printers that require a large volume of ink. They offer stable flow and pressure output with lower pulsation. Compared to ordinary gear pumps on the market, TOPSFLO gear pumps use high-precision gears and component control to ensure smooth flow, minimal pulsation, and adjustable output pressure stability.

TOPSFLO engineers can determine which pump is better suited for your application based on your printing requirements, including the desired flow rate, accuracy, pulsation, noise level, ink properties, and whether they contain solid particles, among other factors.

Long-lasting Lifetime for Stable Printing Assurance

Both Topsflo diaphragm pumps and gear pumps are equipped with high-performance brushless motors developed in-house.

The coreless brushless motor in the diaphragm pump boasts a lifespan of up to 15,000 hours, while the gear pump utilizes a high-performance, in-house designed and manufactured brushless three-phase motor with a lifespan exceeding 30,000 hours, requiring no maintenance.

These brushless motors do not produce sparks, static electricity, or electromagnetic interference during operation, ensuring safety and allowing the pumps to run continuously in high-demand inkjet printing tasks.

How to Get in Touch with TOPSFLO for Expert Assistance?

Maintaining a consistently stable flow and using ink fluids with the appropriate viscosity are crucial for overall printing quality. Any abnormalities in the ink supply system can lead to poor printing quality, error messages, and even costly product recalls. Therefore, choosing the right ink pump for your continuous inkjet printer is of utmost importance.

TOPSFLO specializes in the development and production of various micro pumps for printers. They have extensive experience and pump solutions, and they offer customized services to meet different customer needs. Please contact their sales engineers for printer pump application cases and pump information! Email: [email protected] or [email protected]

youtube

0 notes

Text

The Benefits and Advancements of Curing Machines for Pigment Printing

Curing machines play a crucial role in the pigment printing and textile industries. Curing Machines are specialized machines that are designed to cure or dry inks, coatings, and other substances applied to fabrics. In this blog, we’ll be focusing on the two main types of curing machines used in the pigment printing and textile industries: curing machines for pigment printing and textile curing machines.

Curing Machine for Pigment Printing:

Pigment printing is a popular method of printing on fabrics that involves the use of pigments instead of dyes. Pigments are insoluble particles that adhere to the surface of the fabric. They require curing to become permanently fixed to the fabric. The curing process involves heating the fabric to a specific temperature for a set amount of time, which allows the pigments to bind to the fibers.

A curing machine for pigment printing is designed to provide precise temperature control and consistent heating to ensure that the pigments are cured properly. These machines typically use infrared radiation or hot air to heat the fabric. They can be either conveyor or batch type machines, depending on the production requirements

Textile Curing Machine:

Textile curing machines are used to cure various substances applied to fabrics, including inks, coatings, and adhesives. These machines are essential in the textile industry as they ensure that the final product has the desired properties such as colorfastness, durability, and resistance to chemicals and heat.

Textile curing machines come in various sizes and designs, and they can be either conveyor or batch type machines. Conveyor type machines are used for continuous production while batch type machines are used for smaller production runs. The most common types of curing machines for textiles are hot air ovens, infrared dryers, and microwave ovens.

curing machines are a crucial part of the pigment printing and textile industries. They ensure that the final product meets the desired quality standards by providing precise temperature control and consistent heating. Choosing the right curing machine for your production needs is essential for achieving the best results.

#large format printing#printing machines#printing technology#curing machines#Dryer for Digital Printing#Dryer for Digital Printing machine

1 note

·

View note

Text

A detailed guide to Servo voltage stabilizer

The fluctuations in current supply from the electric pole to the household mainline are a common issue across India. Such fluctuations can have a major impact on the performance and the life of electrical appliances in both households as well as in industries. To overcome such challenges an automatic voltage stabilizer is used that can ensure a constant flow of current.

However, in industries, the common voltage stabilizer used in households can not be installed. Hence, a servo voltage stabilizer is used to serve the purpose. This blog will cover the discussion and use cases of a servo voltage stabilizer.

What is a servo voltage stabilizer?

Servo Voltage stabilizers are installed to manage the voltage fluctuations within the industrial units. It acts out every case whether there is a high voltage, low voltage, or unbalanced voltage between the range of +/- 0.5 to 1%.

It is named a servo voltage stabilizer because of its dependency on the servo motor installed. Servo stabilizers are available in both single as well as three-phase models depending upon the need of the industrial unit. Installing such voltage stabilizers allows a 95%+ energy efficiency at improves the performance of the unit.

Where is Servo Voltage Stabilizers required?

Automobile Industry: In such industry, the manufacturers rely on the effective functioning of machines and conveyors. Hence, it is important to ensure a proper flow of current so that an uninterrupted production process can be ensured.

Printing Industry: The machines used in such industries require a constant flow of current to ensure appropriate heat levels. Any fluctuation in the current would result in having an impact on the complete batch of products being printed.

Packaging Industry: Servo voltage stabilizers are used in such an industry to ensure a constant voltage supply. Such is important to ensure the achievement of the required production level and to maintain the supply chain.

CNC Machines: The machines that are independently controlled through computer systems. Hence, it is important to provide them with a continuous flow of current to keep them in operation.

Other Factories: Other units requiring the mandatory need of servo voltage stabilizers include cold storage, food processing plants, and manufacturing units.

Conclusion

A servo voltage stabilizer is an important component preferred by an industrial unit to ensure smooth operations and maximize its output. You can get a best-in-class servo voltage stabilizer for industries as well as an automatic voltage stabilizer for homes at Aulten Digital. We are a leading manufacturer and supplier of a range of stabilizers for your different needs.

1 note

·

View note