#Automatic Ampoule Washing Machine

Explore tagged Tumblr posts

Text

Rotary Ampoule Washer

youtube

Rotary Ampoule Washer or automatic ampoule washing machine is specially designed to wash ampoules with minimum contact of machine parts with the ampoules compiling cGMP standards. Machine with specially designed Gripper system holds the Ampoule from Neck and invert the Ampoule till the washing operation completed and again after washing release the ampoule on outfeed feedworm system in vertical position ensures positive wash of ampoules. Machine is suitable to wash 1ml to 20 ml ampoules with the help of change parts,

Absolute cleanliness and hygiene is paramount in pharmaceutical filling and packaging processes and this becomes of even more importance when you consider injectables filled into glass ampoules. Each ampoule must be absolutely sterile before it goes into the sterile filling area. Adinath, the leader in high technology pharmaceutical machinery offers a high precision ampoule washing machine that meets today’s high standards of sterility and hygiene.

Ampoule feeds through feedworm to infeed Star Wheel and specially designed Gripper hold the Ampoule from neck and invert the Ampoule and move it further on rotary moving system for washing process. Ampoules traveling in neck down position above washing needles and moves along with the Needle bar ensures maximum time for washing once the needle enter in the Ampoule neck. Machine with Standard Six Different Washing Stations each of 6 Needle for optimum Washing and the sequence can be change as per customer’s requirement. Machine also having external wash for optimum washing of Ampoule. We are having two different models in this machine. AVRW-120 Automatic Ampoule Washing Machine provided output up to 100 ampoules per minute whereas AVRW-240 High Speed Ampoule Washing Machine provided output up to 200 ampoules per minute. Both the ampoule washers (automatic ampoule washer and high speed ampoule washer) can wash 1ml to 20ml ampoules. We provide extended support for ampoule washer change parts and ampoule washer validation.

0 notes

Text

What is an automatic rotary ampoule and vial washing machine?

Automated high-speed rotary ampoules and vial washing machines wash ampoules and vials with minimal contact between machine parts. These machines are suitable for washing or cleaning various sizes of ampoules and vials with the help of interchangeable parts. Automatic rotary ampoules and vial washing machines are generally used in the pharmaceutical, veterinary, and biotech industries.

#ampoule washing machine#rotary ampoule washing machine#automatic ampoule washing machine#ampoule washing#automatic rotary ampoule washing machine#vial washing machine#rotary ampoule washing machine manufacturer#automatic ampoule washing machine exporter#rotary ampoule washing machine exporters#ampoule washing machine gujarat

1 note

·

View note

Text

Multijet Ampoule Washing Machine - Lodha Machine

Lodha Machine is a renowned manufacturer and exporter of the Multijet Ampoule Washing Machine in India. Our multijet ampoule washing machines are designed to provide efficient and thorough cleaning for ampoules, ensuring the highest standards of hygiene and quality. These machines uses multiple jets to ensure comprehensive cleaning, making them ideal for the pharmaceutical industry. With advanced technology and durable construction, our multijet ampoule washing machines deliver reliable and consistent performance. Lodha Machine's commitment to quality, innovation, and customer satisfaction has made us a trusted name in the industry. Visit our site - https://www.lodhamachines.com/multijet-ampoule-washing-machine

#ampoule washing machine#multijet ampoule washing machine#multijet ampoule washing machine manufacturer#ampoule washing machine exporter#multi jet ampoule washing machine manufacturer#multijet ampoule washing machine price#ampoule washing machine manufacturer in gujarat#automatic multiJet vial washing machine in india#ampoule washing machine manufacturer in india#multijet ampoule washing machine manufacturer in india#manufacturer of multijet ampoule and vial washing machine

0 notes

Text

Automatic Ampoule Sticker Labeling Machine in Egypt

Laxmi Pharma Equipment is Manufacturer, Supplier, and Exporter of Automatic Rotary Gipper Type Washing Machine in Egypt . Our Registered office and manufacturer unit is in Ahmedabad, Gujarat, India. An automatic ampoule sticker labeling machine applies labels accurately and efficiently to ampoules, small glass containers commonly used in the pharmaceutical and healthcare industries. These machines are essential for ensuring product traceability, safety, and compliance with regulatory standards. Process of Automatic Ampoule Sticker Labeling Machines: Ampoule Feeding: The machine automatically feeds the ampoules into the labeling area. Label Dispensing: The labeling machine dispenses the appropriate label from a roll. Label Application: The machine accurately applies the label to the ampoule, ensuring proper alignment and adhesion. Inspection: The machine may include an inspection system to verify that the labels are applied correctly. Product Output: The labeled ampoules are conveyed to the next stage of the production process. Features: High Speed: Capable of labeling a large number of ampoules per minute. Accuracy: Ensures precise label placement and alignment. Flexibility: Can handle various ampoule sizes and shapes. Ease of Use: User-friendly interface with touch screen controls. Durability: Built to withstand continuous operation in demanding environments. Customization: You can customize it to meet specific labeling requirements, such as different label sizes, materials, or adhesives. Laxmi Pharma Equipment is an Automatic Ampoule Sticker Labeling Machine in Egypt Including Cario, Alexandria, Giza, Shubra el-Khema, Port Said, Suez, EL mahalla el Kubra, El Mansoura, Tanta, Asyut, Fayoum, Zagazig, Ismailia, Khusus, Aswan, Damanhur, El- Minya, Damietta, Luxor, Qena, Beni Suef, Sohag, Shibin el-Kom, Hurghada, Banha, Mallawi. For more information, please feel free to contact us. View Product: Click Here Read the full article

#Alexandria#Aswan#Asyut#AutomaticAmpouleStickerLabelingMachineinEgypt#AutomaticAmpouleStickerLabellingMachine#Banha#BeniSuef#Cario#Damanhur#Damietta#Egypt#ELmahallaelKubra#ElMansoura#El-Minya#Exporter#ExporterofAutomaticAmpouleStickerLabelingMachine#ExporterofAutomaticAmpouleStickerLabelingMachineinEgypt#Fayoum#Giza#Hurghada#Ismailia#Khusus#LaxmiPharmaEquipment#Luxor#Mallawi#Manufacturer#ManufacturerofAutomaticAmpouleStickerLabelingMachine#ManufacturerofAutomaticAmpouleStickerLabelingMachineinEgypt#PortSaid#Qena

0 notes

Text

We are a leading provider of top-of-the-line Ampoule Filling & Sealing solutions and take great pride in delivering high-quality machinery that meets the needs of pharmaceutical companies and guarantees the integrity of their products. Our Ampoule Filling & Sealing Machine Line features a variety of highly efficient and versatile equipment, including Automatic Rotary Ampoule Washing Machines, Automatic Ampoule Filling & Sealing Machines, and Automatic Ampoule Sticker Labeling Machines. For detailed information visit;

https://www.parthec.com/product/category/ampoule-filling-sealing-machine

0 notes

Text

External Air Jet Bottle Cleaning and Washing Machine Manufacturer

Brothers is a leading manufacturer of Air Jet Cleaning and Washing Machines in India. We deliver all types of Ampoule Washing machine, linear vial washing, with all industrial safety and quality features. External Vial Washing Machine & Rotary Bottle Washing Multi Head Air Jet Cleaning Machine External Vial Washing Machine Automatic air jet cleaning machine Air Jet Cleaning Machine manufacturer Air Jet bottle washing machine air jet washing machine Bottle Washing and Air Jet Cleaning Machine Air jet bottle cleaning machine Air jet cleaning machine High Speed Automatic Rotary Ampoule linear tunnel bottle washing machine Air jet vacuum cleaning machine Rotary vial washing machine Rotary Bottle Washing Machine Multi head air jet cleaning machine Washing and air jet cleaning machine

For More Details Click here : https://www.brothers.in

0 notes

Text

#SterileWashingMachines are used to wash vials, ampoules, or syringes, with advanced features like automatic loading and unloading, multi-stage washing, and customizable cycles, our washing machines offer superior performance and efficiency. Ensuring that your product meets the highest standards of hygiene and safety.

Visit - https://www.lodhapharma.com/sterile-washing-machines.php

0 notes

Link

We have wide range of Products Including Multijet Ampoule Vial Washing Machine, High Speed Rotary Ampoule Washing Machine, Automatic Linear Vial Washing Machine, Automatic Linear Bottle Washing Machine, Automatic Airjet Vacuum Cleaning Machine, Automatic External Vial Washing Machine, Automatic Rotary Vial Washing Machine, Rotary Bottle Washing Machine Model.

#Multijet Ampoule Vial Washing Machine#High Speed Rotary Ampoule Washing Machine#Automatic Linear Vial Washing Machine#Automatic Linear Bottle Washing Machine#Automatic Airjet Vacuum Cleaning Machine

0 notes

Photo

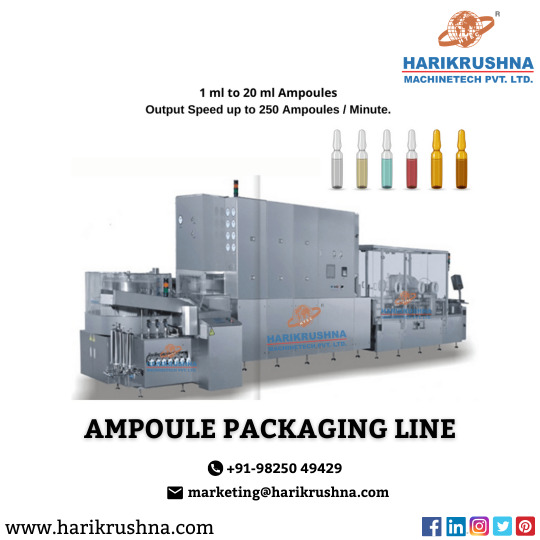

The Ampoule Packing line consists of Rotary Ampoule Washing Machine, Sterilizing Tunnel, Ampoule Filling & Sealing Machine and Ampoule Sticker Labelling Machine, etc. with the speed up to 300 Ampoules/Minute. Contact us:- [email protected] For more info visit our site:- http://harikrushna.com/ #Packagingmachinery #Machinery #PharmaMachinery #harikrushnamachinetech #FillingLine #BottleCappingMachine #packagingmachinery #ampoulefillingmachine #ampoulesealingmachine Vial Washing Machine, Linear Vial Washing Machine, Rotary Vial Washing Machine, Vial Capping Machine, Vials Sealing Machine, Dry Powder Injection Filling Machine, Injectable Liquid Filling Machine, Injection Vial Filling Machine, Pharmaceutical Vial Filling Machine, Vial Cap Sealing Machine, Vials Filling and Capping Machine, Filling and Sealing Machine For Vial, Automatic Vial Filling Equipment, Vial Filling Line For Pharma, Vial Filling Machine, Filling Machine For Vials

#Packagingmachinery#Machinery#PharmaMachinery#harikrushnamachinetech#FillingLine#BottleCappingMachine#ampoulefillingmachine#ampoulesealingmachine#Vial Washing Machine

1 note

·

View note

Photo

Devikrupa industries would like to inform following few lines for your ready information in respect of our range Pharmaceuticals & Packaging Machinery and more particularly our Wet Glue and specialty Sticker Labeling Machines.

We are the foremost Manufacturer and Exporter of Packaging Machinery, which are being used by Pharmaceutical, Agro-Chemical, Cosmetic, Food, Beverage and Pesticide Industries throughout India and export to Turkey, Morocco, Germany, Thailand, Haiti, Iraq, Saudi Arabia, Ukraine, Malawi, Nigeria, Bulgaria, Srilanka, Canada, Dubai, Ghana, Camroon, Moscow. etc.

Devi Krupa Industries - Leading manufacturer and exporter of Automatic Sticker Labeling Machine, Coding Machine, Code Printer Machine, Batch Printing Machine, Rotary Bottle Washing Machine, Tube, Liquid & Sealing Machine suppliers based in India.

Rotary Bottle Washing Machine, Label Stamping Machine, Liquid Bottle Packing Line, Linear Bottle Washing Machine, Tube Filling Sealing Machine, Semi Automatic Liquid Filling Machine, Visual Bottle Inspection Table, Automatic Sticker Labeling Machine, Ampoule Labeling Machine, Vial Sticker Labeling Machine, Automatic Ampoule Sticker Labeling Machine, Packing Belt Conveyor

1 note

·

View note

Text

Rotary Ampoule Washing Machine

Rotary Ampoule Washing Machine or rotary ampoule washer is specially designed washing machine to wash ampoules with minimum contact of machine parts with the ampoules complying cGMP standards. Machine with specially designed Gripper system holds the Ampoule from Neck and invert the Ampoule till the washing operation completed and again after washing release the ampoule on outfeed feedworm system in vertical position ensures positive wash of ampoules. Machine is suitable to wash 1ml to 20 ml ampoules with the help of change parts,

Absolute cleanliness and hygiene is paramount in pharmaceutical filling and packaging processes and this becomes of even more importance when you consider injectables filled into glass ampoules. Each ampoule must be absolutely sterile before it goes into the sterile filling area. Adinath, the leader in high technology pharmaceutical machinery offers a high precision ampoule washing machine that meets today’s high standards of sterility and hygiene.

Ampoule feeds through feedworm to infeed Star Wheel and specially designed Gripper hold the Ampoule from neck and invert the Ampoule and move it further on rotary moving system for washing process. Ampoules traveling in neck down position above washing needles and moves along with the Needle bar ensures maximum time for washing once the needle enter in the Ampoule neck. Machine with Standard Six Different Washing Stations each of 6 Needle for optimum Washing and the sequence can be change as per customer’s requirement. Machine also having external wash for optimum washing of Ampoule. We are having two different models in this machine. AVRW-120 Automatic Ampoule Washing Machine provided output up to 100 ampoules per minute whereas AVRW-240 High Speed Ampoule Washing Machine provided output up to 200 ampoules per minute. Both the ampoule washers (automatic ampoule washer and high-speed ampoule washer) can wash 1ml to 20ml ampoules. We provide extended support for ampoule washing machine change parts and ampoule washing machine validation.

#rotary ampoule washer#Ampoule Washing Machine#High Speed Ampoule Washing Machine#Automatic Ampoule Washing Machine

0 notes

Text

Harikrushna Machines Pvt. Ltd. offers a wide range of air jet cleaning machines, including a semi-automatic air-jet vacuum cleaning machine for pharmaceuticals, an automatic rotary ampoule vial washing machine, an automatic liner vial washing machine, a combi air-jet water washing machine, and an automatic bottle cleaning machine. The main components of an air-jet vacuum cleaning machine include the following:

(1) Semi-automatic ionizers

(2) Air nozzles and vacuum suction blowers

#air jet bottle cleaning machine#semi automatic air jet vacuum cleaning machine#semi automatic air jet vacuum cleaning machine manufacturer#semi automatic air jet vacuum cleaning machine exporter#semi automatic air jet vacuum cleaning machine in India#semi automatic cleaning machine#semi automatic air jet vacuum cleaning machine for pharmaceuticals#semi automatic air jet vacuum cleaning machine for dairy#semi automatic air jet vacuum cleaning machine for food#semi automatic air jet vacuum cleaning machine for beverages#semi automatic air jet vacuum cleaning machine for distilleries#semi automatic air jet vacuum cleaning machine for edible oil#semi automatic air jet vacuum cleaning machine for lubricants#semi automatic air jet vacuum cleaning machine for mineral water#semi automatic air jet vacuum cleaning machine for pesticides#semi automatic air jet vacuum cleaning machine for liquid based business

1 note

·

View note

Text

Semi-Automatic Bottle Washing Machine in Saudi Arabia

Company Overview: Laxmi Pharma Equipment is a prominent Manufacturer, Supplier, and Exporter of Semi-Automatic Bottle Washing Machine in Saudi Arabia. Recognized as one of the leading manufacturers in the pharmaceutical machinery sector. Laxmi Pharma Equipment offers a comprehensive range of pharmaceutical machinery, including vial filling machines, bottle filling machines, liquid filling machines, powder filling machines, vial sealing machines, ampoule filling machines, ROPP capping machines, screw capping machines, aluminum cap sealing machines, sticker labeling machines, and more. Operation Overview: Manual Loading: Bottles are manually loaded on a rotating platform. Cleaning Process: Bottles undergo a series of cleaning operations. Bottle Holder Design: Specially designed nylon cups accommodate bottles of various neck and diameter sizes. External Cleaning: Water spraying showers facilitate external cleaning. Solenoid Valves: Regulate timing and sequence of washing media. Manual Collection: Cleaned bottles are manually collected for subsequent operations. Features: Versatile Bottle Accommodation: Cups on the platform can accommodate bottles ranging from 30 ml to 1000 ml. Loading and Unloading Convenience: Two rows for efficient bottle handling. Control Mechanism: Individual solenoid valves control each washing sequence, ensuring precision. Maintenance Ease: We mount pumps and tanks on a portable stand for convenient maintenance. Compliance: GMP model adhering to standard pharmaceutical manufacturing practices. Washing Sequences Customization: Configurable washing sequences and positioning of washing stations for specific requirements. Nozzle Design: Stationary nozzles prevent contamination of water cycles. Applications: Industries: Suitable for Pharmaceuticals, Food, Cosmetics, Pesticides, and more. Laxmi Pharma Equipment is Semi-Automatic Bottle Washing Machine in Saudi Arabia Including Eastern Region, Riyadh, Makkah, Madinah, Najran, Tabuk, Northern Borders, Hail, Jouf, Asir, Qassim, Jazan, Baha, Riyadh, Jeddah, Mecca, Medina, Dammam, Al-Mubarraz, Taif, Tabuk, Buraydah, Jubail. For any questions or further information, please contact us. Read the full article

#Al-Mubarraz#Asir#Baha#Buraydah#Dammam#ExporterofSemi-AutomaticBottleWashingMachine#Hail#Jazan#Jeddah#Jouf#Jubail#Madinah#Makkah#Mecca#Medina#Najran#NorthernBorders#Qassim#Riyadh#SaudiArabia#SaudiArabiaIncludingEasternRegion#Semi-AutomaticBottleWashingMachine#Semi-AutomaticBottleWashingMachineinSaudiArabia#SupplierofSemi-AutomaticBottleWashingMachine#SupplierofSemi-AutomaticBottleWashingMachineinSaudiArabia#Tabuk#Taif

0 notes

Text

Pharma Machinery: Importance and Benefits

Being an owner of a pharma company, you require a set of quality-driven machines and equipment that enable a smooth end-to-end packaging process.

In this blog, we are going to highlight various pharma machinery produced by leading pharma machinery manufacturers in Ahmedabad, India, and their significance and benefits for the pharma industry.

Understanding the pharma machinery

What do you mean by pharma machinery? In simple language pharma machinery broadly means a wide range of machines, equipment, and tools that aid in the end-to-end manufacturing and packaging process of pharma products.

Types of machines used in the pharma industry

Machinery manufacturers in India are engineering a wide range of machinery that has found usage in the pharma industry. These include:

Oral Liquid/ Syrup/ Suspension Manufacturing Plant

Ointment/ Cream/ Lotion/ Shampoo/ Toothpaste Manufacturing Plant

Semi-Automatic Air Jet Vacuum Cleaning Machine

Automatic High-Speed Rotary Ampoule & Vial Washing Machine

Automatic Linear Vial Washing Machine

Automatic Linear Tunnel Type Bottle Washing Machine

Automatic Rotary Bottle Washing Machine – Glass and PP Bottles

Automatic Combi Air Jet Vacuum Cleaning & Water Washing Machine

Automatic Air Jet Vacuum Cleaning and Washing Machine

S.S. Air Jet Cleaning Machine

Automatic Bottle Air Jet Cleaning Machine

Automatic Linear Rotary Bottle Washing Machine

Semi Automatic Rotary Bottle Washing Machine

Semi Automatic Filling Machine

Semi Automatic Digital Filling Machine

Semi Automatic Piston Filling Machine – Table Top

Semi Automatic Volumetric Liquid Filling Machine – Table Top

Furthermore, there are tons of other pharma machinery that are aiding in various processes in pharma setup. Depending on your manufacturing unit’s requirement, you can choose the machine. Every product has its own application. What suits X, may not suit Y. As a result, it makes sense to use the product that suits your manufacturing requirement. In this regard, you can connect with a few pharma machinery manufacturers in Ahmedabad, India.

Applications of pharma machinery

The quality-driven range of pharma machinery has found usage for a wide range of applications. These include:

Manufacturing

Filling

Washing

Sealing

Labeling

Mixer

Dryer

Pharma machinery manufacturers in India are drawing benefits from the latest technology. Changing market dynamics throws new challenges every day for machinery manufacturers in India. Backed by modern technology, they are manufacturing industry-ready machines.

Salient features of pharma machinery

Let’s now shift our focus to salient features of the machinery. Quality-focused machines are recognized with numerous salient features; these include:

Less noise

Easy to clean

Low maintenance cost

Seamless functioning

Durable

Additionally, the quality-driven range of machines for pharmaceuticals is easy to operate. Your workforce doesn’t require any kind of specific training to operate and manage the pharma machinery.

Custom-designed pharma machinery

Quality matters a lot in a production setup. Never compromise with the quality and specifications of the machinery you require for your production process. A few prominent pharma machinery manufacturers in India hold the expertise to deliver custom-designed solutions.

In case, you are looking for machines with specific dimensions, get in touch with a professionally competent manufacturer. Enter into a dialogue with their engineers, technician, and designers. Based on the dialogue, the team will design a layout of the machine. Once it is approved, the design is sent for the production process.

1 note

·

View note

Photo

Pharmaceutical & Packaging Machineries

Lodha International LLP is considered as one of the largest and experienced pharmaceutical packaging machine and process equipment manufacturer and exporter in India. Founded in 2008, the company has grown significantly by laying more emphasis on quality, reliability, and innovation. The presence of our technical division in the packaging site provides the technical guidance and tooling production to provide these machines the capability to produce high output rates. We produce machines that possess cutting-edge technology at an attractive price range.

There has been a steady rise in Pharmaceutical, Biotech, Veterinary, Food, Cosmetic & Beverage market, and the companies strive hard to keep up with this demand. Lodha International LLP caters to the demand of these industries by offering high-speed packaging machines that are highly efficient and flexible in their operations. Our machine segment consists of Sterile Washing Machine, Volumatric Liquid Filling Machine, Injectable liquid filling and rubber stoppering machine, Powder Filling Machine, Cap Sealing Machine, Sticker Labeling Machine, Packaging Machine, Capsule Section, Tablet Section, Process Equipment, Sterilization Equipment, Chemical Machinery, Packing Conveyor, Turn Table, and Inspection Machine.

For Ampoule Filling & Sealing Machine visit us at - https://www.lodhapharma.com/automatic-ampoule-filling-and-sealing-machine.php

For Ampoule Sticker Labelling Machine visit us at - https://www.lodhapharma.com/automatic-ampoule-sticker-labeling-machine.php

For Capsule Filling Machine Visit us at - https://www.lodhapharma.com/automatic-capsule-filling-machine.php

For Auto Bottle Labelling Machine visit us at - https://www.lodhapharma.com/automatic-single-side-flat-bottle-sticker-labeling-machine.php

Follow us on

Facebook - https://www.facebook.com/lodhainternational/

Twitter - https://twitter.com/lodhaint

Linkedin - https://www.linkedin.com/company/lodhainternational

Instagram - https://www.instagram.com/lodhainternationalllp/

Youtube - https://www.youtube.com/channel/UChgKc5kXBrPTHASVNRWJPaw

Tumblr - https://lodhainternationalllp.tumblr.com/

1 note

·

View note

Link

0 notes