#Conveyor Expo

Explore tagged Tumblr posts

Text

#conveyorbelt#lappingbelt#conveyorsystems#mining#aggregates#gypsum#forestry#recycling#trash#oilandgas#maritimeoperations#freight#coal#mines#rockquarry#hardwork#appreciation#bluecollar#conveyor#madeinchina#Baiqi#Conveyor Belt Buyers#Conveyor Belt Distributors#Conveyor Expo#Industry Conferences#conveyorbelts#belt#conveyorsplice#vulcanized#fabrication

1 note

·

View note

Text

did you know that amputation is literally never medically necessary? the only reason doctors do it is because im paying them to graft the limbs onto me. i have millions of arms. they ran out of room on my body so theyve started stitching the limbs to the ends of other limbs like expo markers. i look like a tumbleweed, just a huge horrifying ball of limbs collected from all over the world. i can't see things, i can't hear anymore either. too many shifting legs and arms on me. i just roll around like katamari, doctors chasing me down to attach more limbs to me because i pay them to. sometimes i graze something i recognize as food, and my many various hands and feet bring it into the center of me to ny mouth conveyor style. i dont even remember life before the limbs orb. i dont know where i got the money to pay the doctors, i think i live in hell

21 notes

·

View notes

Text

Industrial Bearings Wholesale Dealers In Bangalore | Expo Groups

When it comes to sourcing high-quality industrial bearings, businesses in Bangalore have a trusted partner in Expo Groups. As one of the leading industrial bearings wholesale dealers in Bangalore, Expo Groups offers an extensive range of products that cater to various industries, from manufacturing to automotive and heavy machinery. With a strong reputation built on years of service and commitment, Expo Groups stands out as a reliable supplier of top-tier bearings that ensure the smooth functioning of machinery and equipment.

Why Choose Expo Groups for Industrial Bearings?

Expo Groups has established itself as a key player in the bearings market in Bangalore, providing an array of products from trusted global brands. Whether you need ball bearings, roller bearings, tapered bearings, or custom solutions for unique applications, Expo Groups can meet your needs efficiently. Here’s why businesses trust Expo Groups as their preferred industrial bearings dealer:

Wide Range of Bearings Expo Groups offers an extensive selection of industrial bearings that are suitable for different applications. From standard bearings to specialized solutions for high-speed, high-load, or temperature-sensitive operations, Expo Groups has the right product for every industry. The company's catalogue includes products from leading manufacturers, ensuring long-lasting performance.

Competitive Pricing As a wholesale dealer, Expo Groups is able to offer its products at competitive prices. Bulk buying options allow businesses to save significantly, making Expo Groups the go-to choice for cost-effective solutions without compromising on quality.

Quality Assurance With an emphasis on delivering only the highest quality bearings, Expo Groups ensures that every product meets international standards. The bearings are thoroughly tested for performance, durability, and reliability, so you can rest assured that your machinery will function smoothly for longer periods.

Customized Solutions Different industries have different needs when it comes to bearings. Expo Groups understands this and provides customized bearing solutions to meet specific requirements. Whether you need precision-engineered bearings or solutions for unusual applications, Expo Groups offers expert guidance and a wide range of products that can be tailored to your needs.

Timely Delivery Expo Groups values the importance of minimizing downtime. As one of the trusted industrial bearing suppliers in Bangalore, the company ensures prompt and reliable delivery of bearings. Whether you are ordering in bulk or need urgent replacements, Expo Groups is committed to delivering on time.

Types of Bearings Available at Expo Groups

Expo Groups stocks a comprehensive range of bearings, including:

Ball Bearings: Ideal for low-friction applications and ensuring smooth rotation, ball bearings are a popular choice in machines and motors.

Roller Bearings: These bearings can handle heavy radial loads, making them suitable for applications such as conveyor belts, crushers, and large machinery.

Tapered Roller Bearings: Known for their ability to handle both radial and axial loads, these bearings are widely used in automotive and industrial machinery.

Needle Bearings: These bearings are perfect for applications with limited radial space, offering a compact solution for heavy-load machinery.

Thrust Bearings: Designed to handle axial loads, thrust bearings are essential for machines like pumps, compressors, and gearboxes.

Self-Aligning Bearings: Used in equipment where alignment errors are common, these bearings adjust to the shaft misalignment automatically, ensuring smooth operation.

Industries Served by Expo Groups

Expo Groups serves a wide variety of industries, including:

Automotive Industry: Bearings are crucial components in engines, gearboxes, and other machinery that power vehicles. Expo Groups ensures that the bearings provided can withstand the intense conditions in the automotive sector.

Manufacturing Sector: From assembly lines to packaging machines, Expo Groups supplies bearings that ensure continuous operation and improved productivity.

Heavy Machinery and Construction: Bearings are critical in construction machinery such as cranes, excavators, and bulldozers. Expo Groups offers durable and high-performance bearings to meet the demands of heavy-duty equipment.

Renewable Energy: Bearings play a crucial role in wind turbines and solar power systems. Expo Groups supplies bearings that contribute to the efficient functioning of renewable energy projects.

Agricultural Machinery: Bearings are key in ensuring that agricultural equipment such as tractors, harvesters, and plows operate without issues. Expo Groups provides bearings designed for these heavy-duty applications.

The Expo Groups Advantage: Customer-Centric Approach

Expo Groups believes in building long-term relationships with clients by providing exceptional service, reliable products, and expert guidance. The company’s team of knowledgeable professionals is always ready to offer support and technical assistance, helping businesses make informed decisions when it comes to bearings.

As a wholesale bearings supplier in Bangalore, Expo Groups stands out not only for its broad product range but also for its commitment to customer satisfaction. Whether you’re a small business or a large corporation, Expo Groups offers personalized service that meets your specific needs.

Conclusion

For businesses in Bangalore looking for high-quality industrial bearings at competitive prices, Expo Groups is the name to trust. As leading industrial bearings wholesale dealers, they offer an unmatched variety of products and solutions that ensure the smooth and efficient running of your machinery. Whether you’re in manufacturing, automotive, or construction, Expo Groups has the perfect bearings solution for your business.

Contact Expo Groups today to learn more about their range of industrial bearings and how they can support your operations with reliable and cost-effective bearing solutions.

0 notes

Text

Mespack's stand-up pouch filling machine at PackMach Asia Expo

Mespack India, a provider of advanced packaging solutions, showcased a compact, user-friendly machine targeting emerging markets at the PackMach Asia Expo 2024 in Mumbai. The RM260 SC can fill pre-made stand-up pouches that are automatically fed from a manually loaded in-feed conveyor and individually collected in order to enter the machine. This model is operable with zip pouches as well. The RM260 SC is operational with dosing powder, granules, and pieces products. The machine includes a rejection system for unopened pouches or unfilled pouches.

Anthony Dsouza, managing director of Mespack India, discussed with Packaging South Asia the machine's features and the company's approach to addressing the needs of smaller companies and customers.

Dsouza explained that the company’s new compact machine was designed specifically for two-tier and three-tier companies with limited product volumes. In contrast to large, costly equipment often available in the market, this machine provides an affordable, space-efficient option for small businesses aiming to enhance their packaging quality.

Mespack says its latest offering is a game-changer, featuring an easy and extremely quick changeover time between pack sizes, making it ideal for businesses with diverse product lines, Dsouza said. “For those packaging 15 or more product variants – such as tea in different weights – this machine saves significant time,” Dsouza noted. Launched in June 2024, the machine has already garnered attention at the expo. “Our message is clear: we listen to industry needs, and we deliver.”

The primary market for this compact packaging machine is emerging economies, including India, where demand is surging among smaller companies. While larger manufacturers have access to premium packaging machinery, Dsouza argued that Mespack wants to empower smaller players with cost-effective, high-quality solutions.

Dsouza also highlighted a shift in the Indian packaging industry, driven by rising consumer expectations for hygienically packaged goods, a trend accelerated by the COVID-19 pandemic. “Before the pandemic, packaging’s value was less understood,” he said. “The pandemic changed everything, making people aware of the benefits of sealed, safe packaging.” This increased demand for packaged goods extends beyond large companies to smaller businesses in rural areas, who are now keen to access quality packaging solutions to reach broader markets.

The Indian packaging market, Dsouza observed, is primed for exponential growth, especially in the food and beverage sectors. He predicted rapid development in the coming years as more small-scale manufacturers enter the formalized packaging market. “The industry will see enormous growth in the coming years – not just incremental but in leaps,” he said. “Packaging companies must adapt, innovate, and capture these opportunities to stay competitive.”

Talking about the PackMach Asia Expo, Dsouza remarked on the event’s vibrant atmosphere and increasing footfall, which he attributes to the industry’s booming growth. “Indian packaging is a flourishing sector,” he said. “The next three to four years will be crucial as stakeholders adapt to meet the rising demand.”

0 notes

Text

I worked as a food runner and expo/qa at chili’s before, through, and “after” covid (restaurants allowed to become open at full capacity even though there were still THOUSANDS of cases of covid going on locally 🫠).

Chili’s opened TWO ghost kitchens at our location within a year. For some perspective, our location was the BUSIEST in our entire northern half of our state. Our kitchen already could not keep up with the huge amount of dine in and to go orders on a regular basis. If you’ve worked in food service with a digital order system, you’ll know what I mean when I say that our order screens (both dine in and to go) consistently went past 15 pages on a regular basis (particularly on nights and weekends). People were constantly calling out or simply not showing up, as is normal in most restaurant jobs, but it got 10x worse when they shoved ghost kitchens onto us.

It’s Just Wings was the first ghost kitchen to show up. The cooks who worked in the appetizer/chicken/deep fryer section got royally screwed on this, as EVERYTHING for IJW was prepared in their section. These people ALREADY got overwhelmed by regular chili’s orders, as we always needed food from their section constantly, like fries. Throw in MORE chicken, MORE fries (+another kind), a new dessert (which they quickly got rid of lmao) and us contantly having to remind them we needed special flavored dipping sauces with the orders (because for some reason we couldn’t have the sauce on our side of the window), and it was a disaster. No raise in pay for cooks in that section, nor to go people.

On weekends, to go orders got so bad that we would all be stumbling over each other to get our dine in and to go orders put together. The window would get so full with to go boxes that there would be no space for the dine in orders. Boxes full of food would get knocked to the floor in the chaos.

But all the companies saw was how much money they were making, so Brinker (the parent company) decided to open ANOTHER ghost kitchen, this time from one of its other franchises, Maggiano’s. This one consisted of pasta dishes and breadsticks, and was placed into the salad/oven conveyor section of the kitchen. Once again, no raise in pay for anyone. This isn’t even mentioning the amount of prep work that got added on before opening every day by the ghost kitchens, plus the extra cleanup at closing.

So now TWO sections of the kitchen were constantly screwed, in turn screwing the to go people and the runners and expos/QAs (I ended up being able to work all three positions because we just didn’t have enough people). Ultimately this hurt the customers as well because we took so long to make the food everyone was constantly upset at the wait and/or pick up times. But the money was all the company cared about.

I ended up leaving shortly after the second ghost kitchen, but I wanted SO badly to leave so long before, when covid first started. But because the government didn’t care about “essential workers” — why were restaurants considered essential??? I will never understand — we had to push through without any extra compensation + dealing with entitled assholes who absolutely needed their chili’s fix on a daily basis or else they’d lose their minds. Fear of covid (I was most concerned about passing it to someone vulnerable) wasn’t considered a good enough reason to quit and still receive unemployment to survive, so I had no choice but to stay. I had already been screwed over by the company prior to the outbreak when they cut food runner tips by more than half, even though arguably we had the most responsibilities over time as we slowly lost expos/QAs, we constantly had to help the cooks, the dishwasher, the servers, to go people, basically everyone. It definitely became a job that I did not sign up for in terms of stress, and they only piled more and more on everybody as time went on. New people hired for the position never stayed because it was simply too much to handle.

This turned into a bit of a venting session for me, I still have lots of issues with the way chili’s treated us which sucks because I really did used to like working for them. In the end they got too greedy and I refuse to work in another restaurant because of the experience.

So TL;DR, I worked at chili’s with two ghost kitchens and it absolutely f*cked the employees. The end.

Ghost kitchens suck. I ordered from a supposedly vegan restaurant because I was in the mood for some orange tofu and they sent me orange chicken. Like it’s fine for me because I’m not vegan but if you advertise yourself as a vegan restaurant and send someone chicken because you can’t keep your two dozen different fake restaraunts straight I think that may be an issue.

26K notes

·

View notes

Text

Welcome to Visit Our Booth:

E096/4.1H

Exhibition Invitation : Booth: E096/4.1H

Shanghai Industrial Expo

This year's Shanghai Industrial Expo will take place at the National Exhibition and Convention Center (Shanghai) from September 24 to 28, 2024. The event will cover over 300,000 square meters and feature more than 2,800 exhibitors from 30 countries and regions. This highlights the important role of the Shanghai Industrial Expo in the global industrial community and shows how much attention is being paid to low-carbon and digital trends.

At the expo, visitors can see the latest advancements in industrial development up close. They will find displays on robotics, automation equipment, smart manufacturing, and the industrial internet, showcasing the newest trends and technologies in these fields. This event offers a great opportunity to learn and explore various advanced technologies and products.

Welcome to Our Booth No.: E096/4.1H

Shenyang Toshine Aluminum Co., Ltd.

We are an industrial manfuacturer of Conveyors, pallet conveyors, belt conveyors, chain conveyors, roller conveyors, industrial stairs and platforms, industrial aluminum workbenches, industrial enclosures and machine guards.

0 notes

Text

Duratuf #1 Silicone Rubber Gasket Supplier - Quality & Reliability

Find Duratuf top-rated Silicone Rubber Gasket in India. Premium quality rubber sheets, insulating mats, conveyor belts and cow mats are available at the most competitive rates. Visit our website to explore the product categories.

0 notes

Text

Common Challenges in Bulk Handling and How to Overcome Them

Bulk handling systems are essential for industries that manage large quantities of materials, such as agriculture, mining, and manufacturing. These systems streamline operations, improve efficiency, and ensure safety. However, they come with their own set of challenges. In this blog, we will explore some common issues faced in bulk handling and provide practical solutions to overcome them.

1. Material Spillage

Challenge: Material spillage is a frequent problem in bulk handling systems. It occurs when materials overflow or escape from conveyors, hoppers, or bulk bag loaders. Spillage not only results in material loss but also creates safety hazards and requires additional cleanup efforts.

Solution: To mitigate material spillage, ensure that all equipment is properly sealed and maintained. Installing skirting and sealing systems around conveyors can help contain materials. Regularly inspecting and maintaining equipment, such as conveyors and hoppers, will also reduce the likelihood of spillage.

2. Equipment Blockages

Challenge: Blockages in bulk handling systems can occur due to various reasons, such as material clumping, oversized particles, or foreign objects. These blockages disrupt the flow of materials and can cause downtime, leading to decreased productivity.

Solution: Implementing a bag opener is an effective way to prevent blockages caused by clumped materials. A bag opener ensures that materials are properly loosened and dispersed before entering the system. Additionally, regular monitoring and cleaning of equipment, along with the use of screens or filters, can prevent foreign objects from causing blockages.

3. Dust Generation

Challenge: Dust generation is a significant issue in bulk handling operations, especially when dealing with fine or powdery materials. Excessive dust can lead to health hazards for workers, environmental pollution, and equipment wear and tear.

Solution: To control dust, use enclosed conveyors and transfer points wherever possible. Installing dust collection systems, such as baghouses or filters, can capture and contain dust particles. Regularly maintaining and inspecting these systems ensures they function effectively. Additionally, using a bulk bag loader with dust-tight connections can help minimize dust during the loading process.

4. Inconsistent Material Flow

Challenge: Inconsistent material flow can lead to operational inefficiencies and affect the overall productivity of bulk handling systems. This issue is often caused by variations in material properties, such as moisture content, particle size, or density.

Solution: To achieve consistent material flow, it is essential to understand the properties of the materials being handled. Adjusting the speed and angle of conveyors, as well as using flow aids like vibrators or air cannons, can help maintain a steady flow. Regularly calibrating and adjusting equipment settings based on material characteristics is also crucial.

5. Equipment Wear and Tear

Challenge: Bulk handling equipment is subject to constant wear and tear due to the abrasive nature of many bulk materials. Over time, this can lead to equipment failure, increased maintenance costs, and unexpected downtime.

Solution: Using high-quality, durable materials for equipment components that come into direct contact with bulk materials can extend the lifespan of the machinery. Implementing a proactive maintenance schedule, including regular inspections and part replacements, will help identify and address wear and tear before it leads to equipment failure.

6. Handling Hazardous Materials

Challenge: Handling hazardous materials, such as chemicals or toxic substances, presents unique challenges in terms of safety and regulatory compliance. Ensuring the safe transfer and storage of these materials is paramount.

Solution: Equip bulk handling systems with safety features, such as containment and ventilation systems, to prevent exposure to hazardous materials. Providing specialized training for employees on how to handle and respond to spills or accidents involving hazardous materials is essential. Using a bulk bag loader designed for hazardous materials can also improve safety by minimizing manual handling and exposure.

Conclusion

While bulk handling systems are vital for efficient material management, they come with their own set of challenges. By addressing issues such as material spillage, equipment blockages, dust generation, inconsistent material flow, wear and tear, and hazardous material handling, businesses can improve the efficiency and safety of their operations. Utilizing tools like a bag opener and a bulk bag loader can play a significant role in overcoming these challenges. Regular maintenance, proper equipment selection, and employee training are key components in ensuring the smooth operation of bulk handling systems.

0 notes

Text

WAE’s Glass Botting Plants aim to eradicate the use of Plastics

WAE, an expert in water and its reuse is a complete hygienic drinking water solution-providing company, committed to this indispensable resource called “water” of the planet, Earth. An Original Equipment Manufacturer (OEM) with a firm foundation in scientific research and innovative technology, its focus and collegial approach enables it to develop sustainable products and solutions that sync with the principles of circular economy and help to become an active participant in the resource revolution.

The company is well-known in the industry for providing efficient and sustainable drinking water solutions as well as other vending machines and has recently come up with its latest launch, the Glass Bottling Plant inaugurated at the India International Hospitality Expo (IHE), 2023, all set to completely transform the hospitality sector by introducing sustainable and reusable glass bottles, eradicating plastics for good. In fact, the above is also the main motto of the company for launching this scientifically designed glass bottle filling plant which will certainly help in minimizing plastic waste forever. As a renowned innovator in offering complete hydration solutions, WAE is making waves in the hospitality industry with its latest endeavour: the Glass Bottle Filling Plant (GBFP), which is now serving the Hilton International Airport Hotel, Mumbai.

The Unique Concept behind Glass Bottle-filling Machines

WAE’s Glass Bottling Station has certainly revolutionized the hospitality sector by its innovative, hi-tech, state-of-the art technology machine to mechanically rinse, clean, fill and cap the recyclable glass bottles with pure drinking water, ready to use. Only the bottles have to be manually placed on the machine in an inverted position for cleaning and rinsing purposes with hot water or detergents, and this process is also customizable. Then these cleaned inverted bottles pass through a conveyor belt to get dried up by air. It is after the execution of all these processes that the refillable glass bottles pass through the LED chamber for further cleaning and sterilization.

Then these stylish, sleekly designed, small glass bottles pass through the filling stage where they are filled with clean and hygienic water for drinking purposes. The bottles are then screened or inspected manually in the next stage. Then these glass bottles are finally capped and screwed properly to avoid any spillages or leakages. The last stage is labelling or putting stickers on the bottles. Therefore, this technologically advanced Glass Bottle Filling Plant (GBFP) is undoubtedly the best choice for the hospitality sector and can be ideally used in all luxury hotels, restaurants and resorts.

WAE prefers Glass instead of Plastics or Other Materials

Since glass is a natural compound, there is no fear or concern about its leaching or other such chemical reactions. Moreover, glass is often regarded as a more sustainable alternative to plasticbecause it has a higher environmental footprint than plastics and other bottled container materials, including drinking bottle cartons and aluminium cans. This is also because WAE, which has a vast expertise and experience in drinking water solutions and products, has recently developed several modern technologies for bottling and packaging solutions. With this extensive knowledge, expertise and experience in water and packaging solutions, WAE has a good exposure to the modern packaging automation, thus offering the long-tested turnkey solutionsto the Food & Beverages industry.

Versatile & Sustainable Solutions to the Bottling Sector

To sum up, WAE through its latest Glass Bottle Filling Plants (GBFPs) offers complete sustainable water dispensing solutions for cafes, restaurants and hotels, beginning from water purification to bottle rinsing and cleaning as well as filling and capping, including manual inspections for complete control and satisfaction. Further, these bottling plants are fully customizable offering a variety of shapes and sizes of bottles and caps as per the clients’ requirements.

#sustainable drinking water solutions#wae#automatic bottle filling plant#glass bottling plant for hotels#glass bottle filling station#no plastic

0 notes

Text

Conveyor System Market is poised to grow at a CAGR of 5.4% and reach a worth of US$ 10.9 Billion by forecast 2033 | Data By Future Market Insights, Inc.

The conveyor system market will be worth US$ 6.4 billion globally in 2023. According to reports from Future Market Insights, the market is predicted to grow at a CAGR of 5.45% from 2023 to 2033 and will be worth US$ 10.9 billion by 2033.

The growth in vehicle production is expected to accelerate the market growth. In addition, an increase in mining activities around the globe, with an increase in passenger handling capacities of airports & freight, rising e-commerce trends will boost the demand for conveyor systems. A rise in demand for processed will increase demand for the same in the food & beverage industry.

Upliftment of advanced technologies in conveyor systems, with growth in digitization in the material handling industry, and increase in advanced conveyor systems will further create new opportunities for the conveyor system market in the forecasted time period. Rise in initial investments, with rising concerns over the environmental impact of mining activities and an increase in the usage of automated guided vehicles & robotics are the major factors among others restraining the market growth.

Download your sample report to get highlights on market drivers and challenges affecting businesses https://www.futuremarketinsights.com/reports/sample/rep-gb-48

Key Takeaways:

Sales of global conveyor systems market expanded at a CAGR of 4.2% from 2018 to 2022:

The North American market for global conveyor systems market is likely to have a market share of 26.9%.

The Unites States market for global conveyor systems market is likely to expand at a share of 16.9%.

Belt type conveyors are expected to generate maximum demand for the global conveyor systems market.

Global conveyor system market in 2022 was US$ 5.6 billion.

European market is said to grow at a CAGR of 3.4%.

Germany is said to lead the market with the valuation of 8.76%.

China is said to grow at a CAGR of 4.66% in the conveyor systems market.

Agriculture and related activities in China account for more than 7% of its total GDP according to World Bank in 2020.

Market value for conveyor system market in India is said to hold a market share of 3.65%.

Belt type conveyors are said to hold a market share of 18.2% in the conveyor industry.

Automatic Conveyors are said to Gain in the Market of Conveyors.

Automatic conveyors are said to grow at a CAGR of 4.9% in the conveyor systems market.

Automotive and Transportation Industry is Most Commonly Used in Conveyor systems Market.

Automotive and transportation industry will exhibit a dominant growth rate with a market share of 3.52%.

“Impact of circular economy on conveyor system market is one of the major driver of the global conveyor systems market,”- says an analyst at Future Market Insights (FMI).

Competitive Landscape:

Some of the prominent players in this market are-

Daifuku Co., Ltd.

Fives

Interroll Group

Kardex

Kuka AG

Mahindra Tsubaki Conveyor Systems Pvt. Ltd.

Murata Machinery, Ltd.

Siemens

Taikisha Ltd.

Caterpillar

Some of the important developments of the key players in the market are:

In March 2023, Caterpillar announced the development of the Cat® C13D, a new 13-liter diesel engine platform, which is designed to achieve best-in-class power density, torque, and fuel efficiency for optimizing the performance of heavy-duty off-highway applications.

In November 2022, Caterpillar announced the launch of two new hydraulic excavators on Monday, one of just a few major equipment launches ahead of the 2023 CON-EXPO show. New Cat 340 Hydraulic Excavator features a more powerful engine, wider track, and 7.5-ton counterweight to increase productivity by 10% over the 2020 model year Cat 336, according to Caterpillar. New Cat 352 Hydraulic Excavator combines more power and a heavier counterweight to work with larger tools, Caterpillar said in a press release.

Key Segmentation:

By Product Type:

Belt Conveyor

Roller Conveyor

Pallet Conveyor

Overhead Conveyor

Tri-Planar Conveyor

Crescent Conveyor

Skid Conveyor

Trailer Conveyor

Others

By Operation Type:

Manual

Semi-Automatic

Automatic

By Capacity Type:

Unit Handling

Bulk Handling

By Application Type:

Packaging & Warehouse Distribution

Textile & Paper

Construction & Mining

Automotive & Transportation

Consumer Electronics

Food & Beverage

Chemical & Pharmaceutical

By Region:

North America

Latin America

Europe

Asia Pacific

Middle East and Africa

0 notes

Text

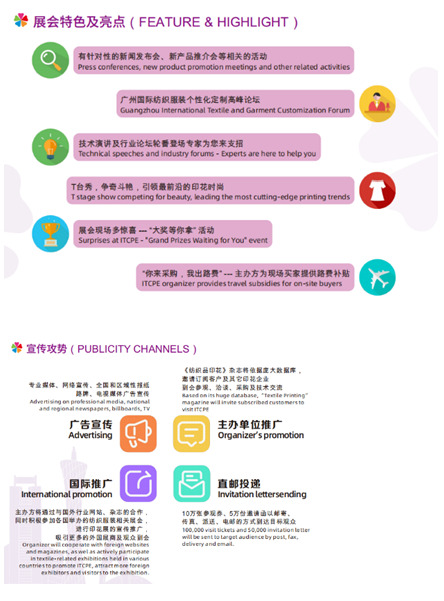

The Registration Channel for the 2024 (19th) Guangzhou International Textile, Clothing and Printing Industry Expo(ITCPE) is officially open!

For nearly two decades, the HK Allallinfo Group has proudly hosted the Guangzhou International Textile, Clothing and Printing Industry Expo(ITCPE). Throughout this journey, we have shouldered the responsibilities of numerous exhibitors and spectators, exceeding expectations with each successful exhibition. Leveraging our extensive event organization experience and the professionalism of our team, we have consistently exceeded goals, facilitating access to industry leaders, cutting-edge technologies, and valuable business opportunities. Join us at the 19th edition of this highly anticipated event, and witness the power of professional expertise driving the future of textiles, clothing, and printing!

To meet the evolving needs of textiles, dressmaking, printing, and dyeing, and to respond to the needs of exhibitors and spectators, the organizing committee of ITCPE has opened the registration and investment channels for the 2024 Guangzhou (19th) International Textile Clothing and Printing Industry Expo in advance.

Larger Scale

Among participating exhibitors, there are more than 1,000 quality enterprises with the reputations of High and New-tech Enterprises and specialized, high-end and innovation-driven SMEs.

More Spectators

Invitations have expanded to include over 60,000 professional visitors online and offline. One-on-one invitations boost purchasing power and conversion rates.

Overview

Four Sub-exhibitions

Textile Printing Industry Technology Exhibition.

Intelligent Sewing and Embroidery Industry Technology Exhibition.

International Printing, Dyeing, and Finishing Technology Exhibition.

Clothing Fabrics and Accessories Exhibition

2. Exhibition Scope

Textile Printing Machines - Inkjet digital printing system, Fully automatic/semi-automatic/manual printing machines, heat transfer equipment, steaming machines, stretching machines and other finishing equipment, Flatbed and rotary printing machines, laser engraving and cutting equipment, printing plates conveyor system, etc

Textile Dyeing Machines and Accessories - Pre- and post-treatment equipment for printing and dyeing, Dewatering and drying equipment, Sizing systems, Printing and dyeing waste gas and water treatment systems, etc.

Embroidery Machines - Single-needle embroidery machines, multi-needle/super multi-needle embroidery machines, garment computer embroidery machines, Embroidery-making system and embroidery software, CNC system and components, etc.

Intelligent Sewing Machines - Sewing machines, CNC and drive systems, fabric cutting/stretching/ironing/finishing equipment, hanger systems, packaging equipment, laser equipment, automated garment production line solutions, etc.

Apparel Fabrics and Accessories - Various types of clothing fabrics, functional/sportswear fabrics, pattern designs, transfer films, rhinestones/appliques/sequins, glitter, etc.

Materials for Textile Printing - Printing dyes, coatings, adhesives, water-based inks, heat-set inks, inks, pastes, thickeners, and other printing auxiliaries

Related Software - CAD systems, 3D body measurement software, 3D virtual fitting software, 3D smart design systems, etc.

Chemical and Auxiliaries Used for Dyeing - Various dyes, pre- and post-printing and dyeing treatment agents, etc.

Customization - Fabrics and accessories, blank T-shirts, patterns and designs, e-commerce platforms, equipment suppliers, etc.

Others - Plate-making equipment, silk screen, photosensitive adhesives, equipment and material concerning heat/transfer, various patents, technologies and software related to textile printing, professional newspapers, magazines and media, etc.

3. Date and Address

Date: May 20, 2024-May 22, 2024

Address: China, Guangzhou, Poly World Trade Center

4. Multi-channel Publicity

5. Our Cooperative Partners

https://textilesouthasia.com/wp-content/uploads/2023/12/9.png

A Retrospect of ITCPE 2023

Now, the recruitment channel for the 2024 ITCPE has been opened, and you are just one registration away from a great business opportunity! Click for more details: https://www.allallinfo.com/itcpe/ad.html or mail us at: [email protected].

1 note

·

View note

Text

Chapatti making machine

There wasn’t a widely available or commercially successful fully automated roti-making machine on the market. However, technology and product availability can change rapidly, so it’s a good idea to check the latest developments.

Making roti involves a combination of tasks such as mixing the dough, flattening it into circles, and cooking on a hot surface. Some automated machines may be able to handle portions of this process, but the complete automation of roti making, including the quality aspects that are important in many cultural cuisines, can be challenging.

If you’re interested in a roti-making machine, consider checking online retailers, appliance stores, or technology expos for the latest products. Additionally, keep an eye on developments in smart kitchen appliances, as advancements in technology may lead to more automated solutions for traditional cooking tasks.

It’s important to read reviews, consider user feedback, and evaluate the features of any product before making a purchase. Additionally, the availability of such products can vary by region.

Commercial roti making machine:

There were commercial roti-making machines available in the market. These machines are designed to automate the process of making roti’s, and they are commonly used in commercial kitchens, restaurants, and other food establishments where large quantities of roti’s are required.

Commercial roti-making machines typically consist of a series of conveyor belts, rollers, and heating elements to automate the entire process, from dough preparation to cooking. These machines can produce roti’s in bulk, saving time and labor in commercial settings.

To find a commercial roti-making machine, you may want to explore specialized kitchen equipment suppliers, restaurant supply stores, or online platforms that cater to commercial kitchen needs. It’s essential to consider factors such as the production capacity, size, and maintenance requirements when choosing a commercial roti-making machine.

Keep in mind that product availability and advancements in technology can change, so it’s a good idea to check the latest offerings from manufacturers and suppliers in your region. Additionally, customer reviews and testimonials can provide insights into the performance and reliability of specific machines.

Automatic chapatti making machine:

Automatic chapatti-making machines are designed to simplify and expedite the process of making chapatti’s (also known as roti’s or flatbreads). These machines are commonly used in commercial kitchens, canteens, and other food establishments where there is a high demand for chapatti. Here are some key features and aspects to consider when looking for an automatic chapatti-making machine:

Capacity: These machines come in various capacities, ranging from a few hundred to several thousand chapatti per hour. Choose a machine that meets the production needs of your establishment.

Automation Levels: Different machines offer varying degrees of automation. Some machines can handle the entire process, from dough preparation to cooking, while others may require manual input at certain stages.

Dough Feeding System: Automatic chapatti-making machines usually have a dough feeding system that automates the process of feeding the dough into the machine. Some machines may have hoppers or conveyors for this purpose.

Pressing and Cooking Mechanism: The machines typically have a mechanism for pressing the dough into flatbreads and a cooking element for baking them. The cooking process may involve heated plates, ovens, or other methods.

Adjustability: Look for machines that allow you to adjust the thickness and size of the chapatti’s to meet specific preferences.

Material and Build Quality: Consider the material and build quality of the machine to ensure durability and ease of maintenance. Stainless steel is a common material for components that come into contact with food.

Energy Efficiency: Check the energy efficiency of the machine, especially if sustainability and operating costs are important considerations for your business.

Ease of Cleaning and Maintenance: Opt for a machine that is easy to clean and maintain. Look for features such as removable components and user-friendly controls.

Safety Features: Ensure that the machine has adequate safety features to protect operators during use.

When searching for automatic chapatti-making machines, you can explore online platforms, commercial kitchen equipment suppliers, or industry trade shows to find suitable options. It’s crucial to read reviews, compare specifications, and possibly seek recommendations from others in the food service industry to make an informed decision based on your specific needs and preferences. Keep in mind that product offerings and technology may have evolved since my last update in January 2022, so checking the latest developments is advisable.

Automatic chapatti maker:

Automatic chapatti makers were available in the market. These machines are designed to automate the process of making chapatti’s (also known as roti’s or flatbreads). Automatic chapatti makers are particularly useful in commercial settings where there’s a high demand for chapatti’s, such as restaurants, hotels, and large-scale catering services.

Here are some general features you might find in an automatic chapatti maker:

Dough Feeding System: Automatic chapatti makers typically have a system for feeding the dough into the machine. This can involve hoppers or conveyor belts that streamline the process.

Pressing Mechanism: The machine usually includes a mechanism for pressing the dough into flatbreads. This can involve rollers or other pressing elements.

Cooking Element: There is a cooking element that bakes or cooks the chapati. This could be through heated plates, ovens, or other methods.

Adjustable Settings: Many machines allow you to adjust settings such as the thickness and size of the chapatti’s to meet your preferences.

Capacity: These machines come in different capacities, with the ability to produce a certain number of chapatti per hour. Choose a machine that meets your production requirements.

Material and Build Quality: Consider the material and build quality of the machine, especially components that come into contact with food. Stainless steel is commonly used for hygiene and durability.

Ease of Cleaning: Look for a machine that is easy to clean, with features like removable components.

Safety Features: Check for safety features to ensure the machine can be operated safely.

To find an automatic chapatti maker, you can explore commercial kitchen equipment suppliers, online retailers, or industry-specific trade shows. Read product reviews, compare specifications, and possibly consult with other businesses in the food industry for recommendations.

Keep in mind that the availability of products and technological advancements may have changed since my last update, so it’s a good idea to check for the latest models and reviews from reliable sources.

#automatic chapatti machine#fully automatic roti maker#domestic automatic roti making machine#fully automatic roti making machine

0 notes

Text

Best Fenner Dealers In Bangalore| Expo Groups

When it comes to high-quality mechanical and industrial solutions, Fenner products have earned a reputation for excellence worldwide. In Bangalore, finding a reliable dealer who can provide these trusted products is crucial for maintaining the efficiency and longevity of your equipment. That's where Expo Groups comes in. As the best Fenner dealers in Bangalore, we are proud to offer a comprehensive range of Fenner belts, Fenner pulleys, motors, and other essential power transmission products.

Why Choose Fenner Products?

Fenner is synonymous with high-quality engineering and performance. The brand is well-known for its advanced technology and robust products that cater to various industries, including manufacturing, construction, and material handling. Fenner V-belts, Fenner pulleys, and Fenner motors are trusted for their durability, efficiency, and ability to handle tough operational conditions.

At Expo Groups, we recognize the importance of these products in ensuring the smooth functioning of your machinery and systems. Whether you're looking to replace existing components or upgrade your equipment, Fenner products are the ideal choice for maintaining optimal performance.

What Makes Expo Groups the Best Fenner Dealers in Bangalore?

As the leading Fenner dealers in Bangalore, Expo Groups stands out for several reasons:

1. Wide Range of Fenner Products

We offer a vast selection of Fenner belts, Fenner pulleys, motors, and other mechanical components. This means that no matter what your requirements are, we have the right product to meet your needs. Whether you're in need of Fenner V-belts for power transmission or Fenner pulleys for efficient movement, we have it all.

2. Superior Quality and Durability

Fenner products are designed to last, and at Expo Groups, we ensure that you get the best. We only stock authentic Fenner products known for their high performance and longevity, providing your machinery with the reliability it needs to operate smoothly for years.

3. Competitive Pricing

We understand the importance of keeping your project costs within budget, which is why we offer competitive pricing on all Fenner products. At Expo Groups, you can get the best deals on Fenner V-belts, motors, pulleys, and more, without compromising on quality.

4. Excellent Customer Support

At Expo Groups, we believe in building long-lasting relationships with our clients. Our expert team is always available to guide you in choosing the right Fenner products for your specific requirements. From technical assistance to after-sales service, we ensure that you're fully supported throughout your purchasing journey.

5. Timely Delivery

We understand the urgency of keeping your business running smoothly. With our reliable distribution network, Expo Groups ensures that your Fenner products are delivered on time, minimizing any delays in your operations.

Applications of Fenner Products

Fenner products have applications across a wide range of industries. Whether it's for power transmission, machinery parts, or mechanical systems, Fenner belts and pulleys are designed to handle the toughest conditions. Here are some common uses:

Manufacturing: For conveyor systems, production lines, and assembly operations.

Construction: Powering heavy machinery and equipment.

Material Handling: Ensuring smooth and efficient transportation of materials.

Agriculture: Driving machinery in farming operations.

Conclusion

When searching for the best Fenner dealers in Bangalore, look no further than Expo Groups. With our extensive range of Fenner products, competitive pricing, and dedicated customer service, we are committed to meeting your industrial needs. Whether you require Fenner V-belts, motors, pulleys, or other power transmission solutions, Expo Groups is your trusted partner for all things Fenner in Bangalore.

Contact us today to learn more about our products and services, and let us help you optimize your operations with the best Fenner solutions available!

0 notes

Text

BHS talks of automation in corrugated industry

At the recently concluded IndiCorr Expo 2024 in Mumbai, BHS talked about how its automation solutions can help reduce input costs and improve margins for players in the corrugated industry. Ajay Bhardwaj, sales manager for India at BHS, highlighted the company's focus on minimizing reliance on manpower.

"We are going to help customers by reducing the dependency on manpower, adding more and more automation—not just on the corrugated line, but beyond it,” he said.

BHS has been working on introducing automated systems to streamline production, such as automated conveyor systems that enhance efficiency from the exit conveyor to the work-in-progress and final goods areas. Bhardwaj pointed out that this development aligns with the growing demand from customers for automation, particularly after Covid-19.

Asked about the Indian corrugation industry’s adoption of automation, Bhardwaj noted a significant shift post-Covid. He explained, "Before 2020, the industry was very low-tech, with basic jobs and simple machines. However, we have seen a major shift since Covid, with customers moving from semi-automatic to fully automatic machines."

This trend, he said, has led to the industry's embrace of technology that not only automates production but reduces costs by cutting electricity and glue consumption, as well as minimizing wastage. This is especially important as 80-85% of product cost in the corrugated industry is paper.

Bhardwaj highlighted the advanced technology BHS offers for reducing wastage, specifically in managing paper splices during job changes. "Our splice technology allows customers to manage all five paper joints within a 3-5 meter length, significantly reducing paper wastage," he explained.

Looking to the future, Bhardwaj expressed optimism about BHS’ growth in the Indian market. He said since starting operations in 2011, BHS initially sold only one machine by 2015, but the company has since gained momentum. "From 2016 to now, we have increased the number of corrugators from 4-5 to over 20," Bhardwaj said. He attributed this growth to the introduction of more suitable products for the Indian and African markets, such as the 2.2-meter and 1.8-meter working width corrugators, which have been well-received in India.

Bhardwaj said BHS’s journey in India has been spurred by key partnerships with major customers in the corrugation industry, which have placed repeat orders.

In addition to its success in India, BHS has expanded its footprint to neighboring countries such as Nepal, Bhutan, Bangladesh, and Sri Lanka, selling multiple machines in these regions.

Bhardwaj concluded by expressing confidence in the company's trajectory, saying, "With our continuous innovation and strong customer relationships, the growth we have seen since 2019 is set to continue."

0 notes

Text

CPHI was successfully concluded in Xiamen

From November 13 to 15, 2023, the 2023 (Autumn) China International Pharmaceutical Machinery Expo was successfully concluded in Xiamen. Nearly 60,000 spectators gathered here. Suzhou Halo attended the exhibition with much equipment, including: capsule/tablet checkweigher, desktop capsule/tablet weight sampling machine, dynamic weight checker, brushless capsule polishing machine, deblister machine, decapsulator, capsule feeding machine. Capsule checkweigher relies on high precision measurement, set the upper and lower limits of the scale which closer to the allowable upper and lower limits of the product. In this way, the proportion of qualified products will be increased, which is conducive to improving production efficiency and reducing raw material costs. SMC desktop capsule/tablet weight sampling machine, it is used for sampling weighing of capsule and tablets, which can help users to effectively monitor the change situation of drug weight in the production process. Desktop capsule/tablet weight sampling machine adopts desktop design, compact and easy to use, simple operation, easy to clean.

Conveyor Checkweigher can be connected with various production equipment or packaging equipment to achieve online weight detection of all forms of packaged drugs such as PVC blister board hose, bottle, box, bag, can, etc., online sorting of drugs according to the pre-set qualification range, and eliminate unqualified products. Brushless capsule polishing machine, adopts brushless mode, completely solve the problems of traditional brush polishing machine, such as unclean polishing, sticky powder polishing dirtier, and brushes are difficult to cleaning.

Read the full article

0 notes