#Conveyor Automation

Explore tagged Tumblr posts

Text

Been playing stupid amounts of Plate Up lately, and the Tetris effect of this one is constantly having the urge to optimize/automate my kitchen in ways that are tragically impossible.

Listen if the dishes could just automatically move back to the cabinet once they completed drying—

#Once I get conveyors in my blueprint pool we'll be in business#In game I automated cakes the other night and I was so proud#We don't need to talk about how much sleep I got#Vee life

3 notes

·

View notes

Text

Conveyor Roller Systems: The Complete Guide: Effectiveness and Creativity in Material Processing

Conveyor roller systems have revolutionized the material handling industry, offering efficiency, reliability, and cost-effectiveness. Whether in warehouses, manufacturing plants, or distribution centers, these systems play a vital role in streamlining logistics. This guide explores conveyor roller systems in-depth, covering types, benefits, and key considerations when selecting the right system for your needs.

What Are Conveyor Roller Systems?

A conveyor roller system is a mechanical assembly designed to transport materials effortlessly across a defined path. It consists of rollers, frames, and a drive system that work together to move goods efficiently. These systems are commonly used in industries such as logistics, food processing, mining, and e-commerce fulfillment centers.

Types of Conveyor Roller Systems

Conveyor roller systems come in different variations, each designed for specific applications. Understanding their differences helps businesses choose the right solution for their operational needs.

1. Gravity Roller Conveyors

Operate without external power.

Relies on gravity to move items.

Ideal for lightweight packages and manual operations.

2. Powered Roller Conveyors

Uses motors or belt drives to transport materials.

Suitable for high-speed and automated operations.

Offers better control over material movement.

3. Chain-Driven Roller Conveyors

Uses chains to rotate rollers.

Best for heavy-duty applications such as automotive and industrial manufacturing.

Provides robust durability and load capacity.

4. Belt-Driven Roller Conveyors

Features a belt running beneath the rollers for movement.

Great for fragile or irregularly shaped items.

Used in applications requiring precise product handling.

5. Flexible Roller Conveyors

Can expand, contract, and curve as needed.

Excellent for temporary or space-limited workspaces.

Common in retail, e-commerce, and parcel distribution centers.

Key Benefits of Conveyor Roller Systems

Investing in a conveyor roller system provides a range of benefits that enhance operational efficiency.

1. Increased Productivity

Automating material handling reduces manual labor, ensuring faster throughput and increased efficiency in manufacturing and distribution processes.

2. Reduced Labor Costs

By minimizing manual handling, businesses can cut labor expenses while improving workplace safety.

3. Improved Accuracy and Consistency

Conveyor roller systems reduce errors and inconsistencies that often occur in manual handling, leading to better inventory management and order fulfillment.

4. Versatility in Applications

These systems can handle various materials, including boxes, pallets, and bulk materials, making them adaptable for diverse industries.

5. Enhanced Workplace Safety

By automating movement, conveyor systems reduce workplace injuries related to heavy lifting and repetitive strain.

Real-World Applications and Testimonials

Many businesses have successfully integrated conveyor roller systems into their operations, experiencing remarkable improvements in productivity and efficiency.

Case Study: E-commerce Distribution Center

A leading online retailer implemented a powered roller conveyor system to handle high order volumes. The result? A 40% increase in order processing speed and a significant reduction in manual labor costs.

Testimonial: Manufacturing Industry

“After installing a chain-driven roller conveyor, our production line became 30% faster with fewer material handling errors. It has been a game-changer for our efficiency.” – Operations Manager, Automotive Manufacturer

Future Trends in Conveyor Roller Systems

With advancements in automation and AI, conveyor roller systems are evolving to become smarter and more efficient. Here are some future trends to watch:

IoT-Enabled Monitoring – Smart conveyors with sensors provide real-time analytics on system performance and maintenance needs.

AI-Powered Sorting – Artificial intelligence helps improve sorting accuracy and operational efficiency.

Sustainability Improvements – Energy-efficient motors and recyclable materials are making conveyor systems more eco-friendly.

Conclusion

Conveyor roller systems are an indispensable asset in material handling, providing unparalleled efficiency and reliability. Whether for a small warehouse or a large manufacturing plant, choosing the right system can significantly improve operations. By understanding the different types, benefits, and industry applications, businesses can optimize their workflows and stay competitive in a fast-paced market.

0 notes

Text

Rugged Variable Frequency Drives (VFDs)

When the job gets hot, the Optidrive E3 steps up. Designed for extreme environments like hot manufacturing plants, dusty workshops, and washdown areas, this NEMA 4X outdoor rated VFD is rugged, dust-tight, and resistant to UV, oils, greases, and acids—all while delivering smooth, efficient motor control.

With NEMA 4X sealed enclosure, it's ideal for splash zones and harsh industrial areas. Setup is simple with application macros for fans, pumps, and general machinery, plus a built-in and lockable power disconnect, potentiometer, and 3 position switch for fast and easy local control. Contact us today if you need a rugged, high performance VFD built for harsh environments.

The VFD Exchange

#invertek#vfd#electrical#industrial#automation#torque#speed#frequency#voltage#current#engineering#hvac#pumps#fan#mixer#compressor#conveyor#nema4x

0 notes

Text

How to Choose the Right Conveyor System for Your Industry

Conveyor systems play a huge role in the spread of productivity, safety issues minimization, and material handling optimization in most industries. Whether it is manufacturing, packaging, food processing, or logistics, the appropriate conveyor system is of prime importance while maximizing business processes. Having such a long list to pick from, the crucial thing to determine is which among these fields will influence your choice. Below are the rules for selecting the best conveyor system for your line of business.

1. Understand Your Industry’s Needs

Start by defining the specific requirements of your business. Different businesses have diverse types of conveyors and material handling, and your conveyor must be able to accommodate these requirements for peak performance.

Conveyors used in manufacturing must be heavy-duty to handle bulky, heavy materials.

Conveyors used in food processing must be sanitary.

E-commerce shipping conveyors must be automated and speedy to handle volumes of packages.

Consider factors like:

Weight and size of the items

Production throughout (how much material needs moving per hour)

Operating environment (hygienic, temperature-controlled, or heavy-duty)

Space available for system integration

2. Evaluate Different Types of Conveyor Systems

Once you know your requirements, it’s time to explore the different types of conveyor systems. Some common options include:

Belt Conveyors: Best suited for light-weight to medium-weight materials. Used most in food processing, electronics assembly, and packaging.

Roller Conveyors: Perfectly suited for bulkier loads such as pallets, usually deployed in warehouses.

Chain Conveyors: Suitable for hard-core items such as metal shavings or car parts. Most robust and most resilient.

Decline and Incline Conveyors: Utilized to transfer goods from one plane to another throughout a factory floor or warehouse complex and remove manpower.

Automated Guided Vehicles (AGVs): Sophisticated, automated machines that are inexpensive and multi-functional.

3. Automation and Advanced Features

When it comes to efficiency, automated conveyors will be your lifesavers. Smart conveyors track real-time movement, decrease downtime, and optimize product flow with Programmable Logic Controllers (PLCs) and IoT sensors. For example, for conveyors and material handling in warehouses, smart conveyors with sensors streamline sorting and routing. Completely automated material handling systems even use robotic arms for pick-and-place operation to ensure improved speed and accuracy of packing.

4. Industry-Specific Conveyor Solutions

Every industry has unique needs. Some industrial conveyor solutions are designed specifically to meet these requirements. For example:

Manufacturing: Heavy-duty conveyors like chain-driven live rollers (CDLR) or high-speed pallet conveyors transport heavy and bulky loads and so they are the best conveyor system for manufacturing.

Packaging: Wondering how to choose a conveyor for packaging? Accumulation conveyors or drag chain conveyors offer excellent good movement with machinery.

Food and Drink: Sanitary conveyors easy to clean and corrosion-resistant are required for food processing to ensure hygiene and keep away contaminants.

5. Consider Maintenance and Durability

Reliability is the top priority. Select a conveyor system which requires less maintenance and is easy to repair. Modularity is best, since they can be re-configured easily to accommodate evolving needs. This provides long-term value and minimum possible disruption to your business.

6. Initial Cost and Return on Investment (ROI)

Consider the initial expense and long-term cost savings. An effectively designed conveyor system saves labor, saves time, and eliminates mistakes. Ultimately, the correct conveyor system will earn its money back in the form of enhanced efficiency and reduced operational expenses.

0 notes

Text

#PneumaticConveying#IndustrialFabrication#ConveyingSystems#FabricationExperts#HighQualityManufacturing#EngineeringSolutions#MaterialHandling#PneumaticSolutions#Automation#IndustrialInnovation#pneumatic conveyor systems#lump breaker#bulk materials handling#macawberindia#bulkmaterialhandling#dense phase pneumatic conveying system#macawber engineering

0 notes

Text

Streamlining Industrial Success With Reliable Spare Parts Supply

The industrial sector relies on the effectiveness of its processes and machinery; hence, spare parts suppliers are the backbone of this success. These suppliers provide key parts that keep production lines rolling without any form of delay. Their main priority is to deliver high-quality parts that meet industrial standards while focusing on timeliness. This way, industries can continue without being interrupted, minimize downtime, and maintain operational integrity. With a well-established network, a Spare Parts Supplier for the Industrial Sector helps to streamline procurement and logistics for industries worldwide.

Their solutions cater to diverse operational challenges, from filtration systems to specialized machinery components. Suppliers are a vital part of operational success, combining experience, efficiency, and technological knowledge. Businesses rely on their expertise to quickly access the right spare parts when needed, empowering industries to thrive even in unforeseen disruptions. Through trusted supply chains and industry partnerships, they provide strategic solutions that sustain industries’ global demand.

#Control and automation systems Offenburg#VBN Hydraulic equipment#Conveyor equipment Offenburg#spare parts Supplier for industrial sector#industrial automation service providers#flexible export solutions offenburg#industrial spare parts

0 notes

Text

Hanging System Painting Line

The Hanging System Painting Line is an automated production line for spraying the surface of central air-conditioning shells and tubes. The hanging system ensures that the workpiece can move smoothly during the spraying process, ensuring the uniformity and quality of the spraying. The automated hanging spraying line can operate continuously, greatly improving production efficiency. It is widely used in central air-conditioning manufacturers, refrigeration equipment manufacturers and other fields. #factory #oem #odm #fyp #coatingline #paintingline #sprayingline #homeappliance coating line

#factory#oem#odm#fyp#coatingline#paintingline#sprayingline#homeappliance coating line#Metal Spraying Line#metal painting line#automated painting line#automatic spraying equipment#overhead conveyor system#Home appliance coating line

0 notes

Text

How Inventory Shelving Systems and Warehouse Fitting Drive Operational Streamlining

One of the most important objectives for companies that want to keep their competitive edge and satisfy the ever-changing requirements of the market is to streamline their operations and improve the efficiency with which they manage their inventory and warehouses' operations. When it comes to establishing operational excellence, one of the most important factors is the integration of advanced systems for inventory management and warehouse fittings, such as inventory shelving systems. This paper investigates the significance of implementing integrated systems that not only maximize the efficiency of storage solutions but also guarantee that warehouse operations are carried out without any gaps.

A Brief Introduction to Integrated Systems for the Management of Inventory and Warehouse Conditions

The idea of integration is the fundamental component of a strategy for managing inventory and warehouses that is effective and well-organized. The goal of integrated systems is to create a unified platform that consolidates a variety of operational operations, such as managing order fulfillment and shipping, tracking inventory levels, and so on. Through the utilization of technology, these systems guarantee that every component of the warehouse, including inventory storage systems and warehouse fittings, functions in harmony to facilitate the streamlining of operations and the enhancement of production efficiency.

Role of Inventory Shelving Systems

Inventory shelving solutions are critical for maximizing the storage and accessibility of items in a warehouse. These systems are intended to maximize space usage, improve inventory visibility, and provide quick access for picking and stocking processes. Businesses that use adjustable and modular shelf solutions may alter their storage spaces to fit a wide range of product sizes and quantities, saving waste and enhancing overall warehouse management.

The integration of inventory shelving systems with warehouse management software enables real-time inventory level and location tracking. This harmonization ensures that inventory data is constantly current, decreasing errors in order fulfillment and the danger of stockouts or overstocking. Furthermore, by designing shelf systems to be compatible with automated picking solutions, organizations can drastically reduce the time and manpower necessary for inventory management, hence increasing operational efficiency.

Warehouse Fitting for Improved Operations

Warehouse fitting is the strategic design and layout of warehouse areas to improve the flow of goods from reception to shipment. This includes the design of shelving systems, the location of picking and packing stations, and the integration of conveyor belts and other automated systems. The purpose of warehouse fitting is to establish an atmosphere that allows for effective operation processes, shortens handling times, and lowers warehouse personnel migration.

The implementation of integrated systems in warehouse fittings can have a considerable impact on order fulfillment speed and accuracy. For example, a well-designed warehouse plan that incorporates smart shelving solutions and automated conveyor systems can speed up the transportation of items through the warehouse, from storage to the packing room, and finally to the shipping dock. This not only speeds up the order fulfillment process, but also decreases the possibility of errors and damage to items.

The advantages of integration

The integration of inventory storage systems and warehouse fittings into a single management system provides various advantages. These include increased inventory accuracy, more efficient space utilization, lower operational expenses, and more customer satisfaction. By offering real-time visibility into inventory levels and improving the flow of items throughout the warehouse, firms can better satisfy customer requests and adjust to market changes.

Furthermore, integrated systems make data collecting and analysis easier, allowing firms to see patterns, estimate demand, and make informed decisions about inventory purchases and warehouse operations. This data-driven approach to inventory and warehouse management not only boosts operational efficiency, but it also aids strategic planning and corporate expansion.

Challenges and Considerations

Even while it is obvious that integrating inventory systems and warehouse fitting will result in a number of benefits, the implementation of such systems is not without its difficulties. The initial cost of investment, the difficulty of integrating new technologies with current systems, and the requirement to train workers in order to successfully use and maintain the integrated system are some examples of these potential challenges. To guarantee a seamless transition and achieve the highest possible return on investment, businesses need to give serious consideration to the aforementioned aspects and plan their implementation strategy.

The Finalization

When it comes to inventory and warehouse management, it is crucial for firms that want to achieve excellence in inventory and warehouse management to integrate inventory systems and warehouse fittings into a unified management approach. Not only can integrated systems improve operational efficiency, but they also contribute to improved customer satisfaction and corporate growth. This is because integrated systems optimize storage solutions and enhance the efficiency of warehouse operations while simultaneously improving operational efficiency. It is without a doubt that the implementation of integrated systems will become increasingly important for organizations that are striving to preserve their competitiveness in the ever-changing market landscape as technology continues to advance.

#inventory shelving systems#automated shelving systems#custom fitting solutions#shop fitting equipment#merchandising solutions#display shelving systems#shelving systems#warehouse fittings solutions#warehouse fitting manufacturer#retail display manufacturers#warehouse fitting equipment manufacturer#warehouse fitting#shopfitting warehouse shelves#workspace planners#warehouse planners#warehouse management#integrated systems#inventory systems#inventory storage systems#automated conveyor systems

0 notes

Text

Waste Management And Recycling

Looking for effective waste management and recycling solutions? The Mark Costello Co offers comprehensive waste management and recycling services tailored to your needs. Our experienced team ensures efficient waste collection, recycling, and disposal. With a commitment to sustainability and environmental responsibility, we are your trusted partner in waste management. Contact The Mark Costello Co today for innovative and eco-friendly waste solutions that make a difference.

#Waste Management And Recycling#garbage compactor#conveyor system#pull out drawer#automated conveyor systems#industrial trash compactor

0 notes

Text

Experience the future of logistics and automation with Winroller's gearless motor roller series! Our sorting wheels are ideal for high-speed sorting and precise item redirection. With a lightning-fast response time of 0.1 seconds and impressive sorting efficiency of up to 4,000 items per hour, our gearless technology ensures smooth, reliable performance, even with loads of up to 120kg.

Available in 50mm and 67mm diameters, the sorting wheels can be rubber-coated to increase friction, perfect for industrial automation and express logistics applications. Powered by a 48V supply, these rollers offer optimized performance and efficiency, making them a top choice for companies looking to boost operational productivity.

Ready to transform your sorting process?

Learn more at www.drum-roller.com.

We Move, You Win — Tailored to Your Needs, Focused on Your Success!

0 notes

Text

🚛 Looking for Reliable Conveyor Belt Solutions?

At Lakhotia India, we specialize in high-quality conveyor belts designed for efficiency and durability across industries. From manufacturing to logistics, we provide the perfect solution for seamless material handling.

⚙️ Our Expertise Includes: 🔸 Custom conveyor belts 🔸 Heavy-duty & industrial-grade solutions 🔸 Fast delivery and reliable support

Streamline your operations with Lakhotia India—the trusted name in conveyor technology.

📞 Contact us today for a free consultation!

📞 Call us at +91 9025194360 🌐 https://lakhotiaindia.in/

[ conveyor belt suppliers, rubber conveyor belt suppliers, bucket conveyor belt ]

#conveyor belt suppliers#rubber conveyor belt suppliers#bucket conveyor belt ]#lakhotiaindia#conveyorbelt#materialhandling#industrialsupply#manufacturing#logistics#automation#customsolutions#heavyindustry#beltsolutions#conveyortechnology#industrialbelts#efficiency#reliableproducts#qualitymanufacturing#transportation#supplychain#equipment#businesssolutions#madeinindia

0 notes

Text

The Evolution of Pallet Dispensers: Enhancing Efficiency in Warehousing

Understanding the Role of a Pallet Dispenser

In modern warehousing and logistics, efficiency is key. A pallet dispenser is an automated or semi-automated system designed to streamline pallet handling, reducing manual labor and improving workflow. These machines automatically dispense pallets one at a time, eliminating the need for manual stacking and unstacking, which can be time-consuming and hazardous.

For businesses operating in high-volume industries, integrating a pallet dispenser into their supply chain ensures seamless operations while reducing workplace injuries associated with manual pallet handling.

How a Pallet Dispenser Works

A pallet dispenser functions by holding a stack of pallets and releasing them one at a time as needed. These systems are often integrated with conveyor system manufacturers who design complete automated solutions for warehouses and production lines.

Typically, the process works as follows:

A stack of pallets is loaded into the dispenser.

The dispenser lifts the entire stack while allowing one pallet to slide out from the bottom.

The released pallet is then used for loading products, either manually or through an automated system.

The remaining stack lowers, preparing for the next dispensing cycle.

This automation reduces downtime and ensures a steady supply of pallets, improving productivity in distribution centers and manufacturing facilities.

Key Benefits of Using a Pallet Dispenser

1. Improved Workplace Safety

Handling pallets manually can lead to injuries such as back strain, pinched fingers, and other musculoskeletal disorders. Automating pallet dispensing reduces these risks and ensures compliance with workplace safety standards.

2. Increased Efficiency

A pallet dispenser significantly reduces time spent retrieving and organizing pallets. Workers can focus on more value-added tasks, leading to increased output and efficiency in operations.

3. Space Optimization

Warehouses with limited space can benefit from a pallet dispenser as it helps in keeping pallets neatly stacked and accessible, reducing clutter and optimizing storage areas.

4. Cost Savings

By minimizing manual labor and potential injuries, businesses can save on operational costs, including worker compensation and downtime. A well-integrated system from a trusted conveyor system manufacturer ensures that automation leads to long-term cost savings.

Industries Benefiting from Pallet Dispensers

E-commerce and Retail

With the rise of online shopping, warehouses need efficient ways to move goods. Pallet dispensers help in quickly deploying pallets for packing and shipping operations, keeping up with high-demand fulfillment requirements.

Manufacturing

Manufacturing plants rely on a consistent supply of pallets for transporting raw materials and finished goods. A pallet dispenser ensures a steady workflow without bottlenecks in production lines.

Food and Beverage Industry

Hygiene and efficiency are crucial in food handling. Automated pallet dispensers reduce human contact with pallets, minimizing contamination risks while keeping the supply chain smooth.

Pharmaceutical Sector

Pharmaceutical warehouses require precision and automation for handling goods. Pallet dispensers ensure that pallets are readily available for moving medical supplies without manual intervention.

Integrating a Pallet Dispenser with a Conveyor System

To maximize automation, many businesses integrate pallet dispensers with conveyor systems. A conveyor system manufacturer can design a setup that seamlessly moves pallets from dispensers to different workstations, ensuring a continuous flow in operations.

Some common integrations include:

Automated Guided Vehicles (AGVs): These transport pallets to specific locations within a facility.

Roller and Belt Conveyors: These systems work alongside pallet dispensers to move pallets efficiently across warehouse zones.

Robotic Arms: In some setups, robotic arms pick pallets from dispensers and place them onto conveyors for further processing.

Testimonials: Real-World Success Stories

“Game-Changer for Our Warehouse” – Mark T., Warehouse Operations Manager

“Implementing a pallet dispenser in our facility has dramatically reduced our reliance on manual labor. Productivity has increased, and we’ve seen a significant drop in workplace injuries related to pallet handling.”

“Seamless Integration with Our Conveyor System” – Sarah L., Logistics Director

“Our conveyor system manufacturer recommended a pallet dispenser to improve efficiency, and it has exceeded our expectations. Now, we have a continuous flow of pallets without interruptions, making our warehouse operations smoother.”

Choosing the Right Pallet Dispenser

When selecting a pallet dispenser, consider the following factors:

Capacity: Determine how many pallets the dispenser needs to hold at a time.

Type of Pallets: Ensure compatibility with different pallet sizes and materials (wood, plastic, metal).

Automation Level: Decide whether a fully automated or semi-automated system suits your operation.

Integration Needs: Check if the dispenser can work with existing conveyor systems and other warehouse automation tools.

Durability and Maintenance: Opt for a robust system with low maintenance requirements to ensure long-term reliability.

Conclusion

A pallet dispenser is a critical component in modern warehousing and manufacturing, providing efficiency, safety, and cost savings. When integrated with conveyor systems, these dispensers contribute to a seamless supply chain, reducing bottlenecks and enhancing productivity.

0 notes

Text

Unleash Power & Performance with the Optidrive P2 series

Take your operations to the next level with the Optidrive P2, a high performance variable frequency drive engineered for industrial durability. Designed to handle the toughest applications, it delivers 150% overload for 60 seconds and 200% overload for 4 seconds, ensuring reliable torque from zero speed. With sensorless vector control, built-in EMC filter, and integrated brake transistor, the Optidrive P2 simplifies installation while providing efficient motor control.

Built to withstand harsh environments, the NEMA 4X rated enclosure is dust-tight, washdown ready, and resistant to UV, oils, and acids, making it ideal for demanding applications. Its sealed enclosure and corrosion-resistant heatsink ensure long-term reliability in food and beverage, processing, and outdoor installations. Get the power, protection, and performance you need!

The VFD Exchange

#vfd#motors#drives#torque#speed#frequency#current#voltage#phase#variablefrequencydrives#machines#industrial#mixer#crusher#conveyor#crane#hoist#pump#automation#electrical

0 notes

Text

How Alligator Automations Helps in Reducing Manual Labour Through Technology

Automation has become a core driver of productivity, shifting from a futuristic idea to an essential part of modern industry. Tasks once handled manually, especially repetitive ones, are now managed by intelligent machines, revolutionizing manufacturing, packing, and distribution processes. Alligator Automations is a leader in this shift, delivering cutting-edge solutions that streamline industrial workflows. Imagine a busy factory floor: products moving on conveyors, robots assembling intricate devices, and a synchronized packaging system—all showcasing automation’s potential. This vision of seamless collaboration between humans and machines has now become a reality due to companies like Alligator Automations.

From Humble Beginnings to Industry Leaders

Founded in 2008, Alligator Automations started with competition-based robotics and has evolved into a major player in end-of-line packaging automation. Committed to driving innovation, we provide automated solutions to diverse sectors like automotive, food and beverage, FMCG, agriculture and many more, positioning ourselves as a leader in industrial transformation.

How Alligator Automations Reduces Manual Labour in Key Areas

Advanced Palletizing Systems: Handling heavy palletizing loads manually is labour-intensive and risky. Alligator Automations’ robotic palletizers streamline this process, reducing worker strain and injuries while adapting to varied product shapes and weights. With robotic precision, companies can achieve high palletizing efficiency with minimal labour.

Automated Sorting & Product Handling: Our advanced systems use vision recognition to automate sorting, a valuable feature for industries like food and beverage, chemical, retail and many more, which demand high precision and hygiene. Automation enhances sorting accuracy, reduces manual input, and improves operational speed.

Bulk Material Bagging Solutions: For sectors like agriculture and construction, Alligator’s automated bagging systems manage bulk materials quickly and efficiently, reducing contamination, spillage, and wastage. This enhances productivity and safety on bagging lines, thus reducing manual labour through technology.

Improved Safety & Cost Savings: Automation reduces repetitive tasks and heavy lifting, lowering workplace injuries and labour costs. Alligator’s robotics improve safety and meet industry standards, making the work environment secure and efficient.

Data-Driven Production Insights: Alligator Automations’ IoT-enabled systems track real-time productivity, helping businesses optimize operations and asset maintenance. This AI-driven monitoring minimizes human oversight, ensuring seamless and efficient process control.

Applications Across Industries

Alligator Automations’ solutions cater to diverse industries, from FMCG and food production to warehousing, agriculture to automotive and many more. These automation solutions address unique pain points and labour-intensive tasks in each sector, allowing companies to scale their operations efficiently. For example:

Food & Beverages: Automation solutions like automatic bagging, secondary packaging, and intralogistic conveyor systems ensure compliance with food safety and quality standards.

Cement: Transitioning to automated packaging increases precision and operational speed.

Chemicals & Fertilizers: Safe handling systems reduce risks associated with hazardous materials.

Tyre Industries: Specialized systems streamline tyre manufacturing and handling.

Petrochemical, FMCG, Agro Commodities, Appliances, Automobile, E-commerce, Oil & Paints, Papers & Battery, and Seed industries benefit from enhanced packaging, palletizing, and intralogistics solutions tailored for high efficiency, safety, and reliability in each application.

Embrace Future-Ready Production with Alligator Automations

As labour shortages and operational costs rise, adopting automation becomes not just beneficial but essential. Alligator Automations empowers industries to enhance productivity, safety, and precision. By transitioning to automated systems, companies can significantly cut down on manual labour, streamline processes, and gain a competitive edge in today’s technology-driven market.

For an in-depth assessment and solution tailored to your production line, reach out to Alligator Automations today and explore the future of intelligent, labour-free automation.

#alligator automations#bagging machine#agatha harkness#packaging machine manufacturer#automatic conveyor systems

0 notes

Text

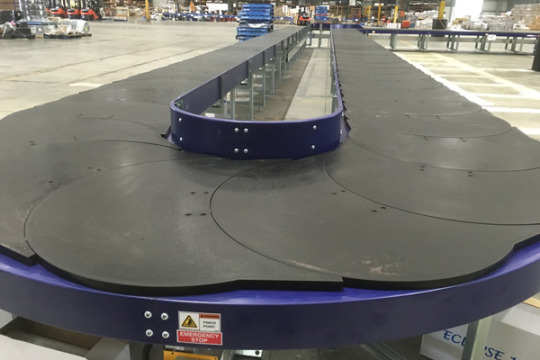

The Importance of Rotary Conveyor Systems in Modern Manufacturing

In the fast-paced world of modern manufacturing, the need for efficiency and automation is greater than ever. Conveyor systems play a pivotal role in streamlining production processes, and among the various types of conveyors available, the Rotary Conveyor System has emerged as a powerful and flexible solution. This system is increasingly being adopted across industries to ensure seamless product flow, reduce labor costs, and improve overall operational efficiency.

In this blog, we will explore why Rotary Conveyor Systems are vital in modern manufacturing. We’ll discuss their functionality, the specific benefits they offer to manufacturers, and how they contribute to optimizing production processes. We will also look at how these systems compare with other types of conveyors and how they can be customized to meet the specific needs of different manufacturing environments.

What Makes Rotary Conveyor Systems Essential in Manufacturing?

Manufacturing is all about efficiency, precision, and scalability. A Rotary Conveyor System provides all these qualities by offering a solution that can transport materials or products smoothly across different points in the production process while utilizing minimal space. Unlike straight-line conveyor systems that move products in a linear direction, rotary conveyors move in a circular or semi-circular path, allowing for greater flexibility in how items are transported.

This circular movement is highly advantageous in manufacturing processes that require high throughput, the ability to redirect products, or the need to move items back through multiple stages of the production line. The design of a rotary conveyor can be customized to fit into tight spaces, making it ideal for manufacturing facilities where floor space is at a premium.

Key Features of a Rotary Conveyor System in Manufacturing

The Rotary Conveyor System is not just about moving products from one point to another; it is a highly efficient and versatile solution designed to enhance the entire production process. Some key features include:

Rotating Platforms: The system operates on rotating platforms or belts that can move items in multiple directions, ensuring a continuous flow of products. This feature is particularly useful when different production stages need to interact with each other.

Flexible Configuration: Rotary conveyors can be configured to handle products of varying shapes, sizes, and weights. Whether the products are fragile, bulky, or require specific handling techniques, these systems can be tailored to meet diverse manufacturing requirements.

Customizable Speed: The speed of the conveyor can be adjusted based on the specific needs of the production line. High-speed rotary conveyors are ideal for environments that require fast movement of goods, while slower speeds are suitable for tasks that require more precision, such as inspection or packaging.

Space Efficiency: One of the major advantages of a rotary system is its ability to function in confined spaces. Instead of requiring extensive straight-line floor space, rotary conveyors utilize circular or semi-circular paths, which can save significant amounts of space in crowded manufacturing facilities.

How Rotary Conveyor Systems Improve Manufacturing Efficiency

Manufacturing processes involve multiple stages, and the efficient handling of materials between these stages is critical for maximizing output. Here’s how Rotary Conveyor Systems contribute to improving efficiency in manufacturing environments:

Seamless Integration into Production Lines One of the primary reasons why Rotary Conveyor Systems are becoming a staple in manufacturing is their ability to seamlessly integrate with other machinery and automation systems. Whether the conveyor is moving products between assembly stations, packaging areas, or inspection zones, its flexible configuration allows it to easily adapt to the specific layout of a production line.This integration minimizes downtime and ensures that products flow smoothly through each stage of the process, ultimately speeding up production cycles.

Reduction of Manual Labor Automating material handling with a rotary conveyor system significantly reduces the need for manual labor, which can lower operational costs and reduce the risk of human error. In traditional conveyor systems, workers often need to intervene in processes such as sorting, loading, or redirecting products. However, a rotary conveyor can handle these tasks automatically, making the entire process more efficient.The automated nature of these systems also enhances safety in the workplace by reducing the risk of accidents related to manual handling.

High Throughput Manufacturers dealing with large volumes of products or materials require conveyor systems that can handle high throughput efficiently. The circular motion of a rotary conveyor allows for continuous movement of products, eliminating bottlenecks that can slow down production. By handling large quantities of goods without interruption, rotary conveyors contribute to higher productivity.

Precise Control and Versatility Rotary conveyors can be programmed to pause, rotate in different directions, and transport products at varying speeds, making them a versatile solution for manufacturers that need precise control over their production processes. Whether the task involves inspection, labeling, or assembly, the ability to customize the system's behavior ensures that it can meet the specific demands of each production stage.

Benefits of Rotary Conveyor Systems in Manufacturing

Improved Space Utilization In modern manufacturing facilities where space is often limited, the ability to maximize available floor space is crucial. The Rotary Conveyor System is designed to make the most of small or irregularly shaped areas. By moving products in circular paths, these conveyors minimize the need for long stretches of linear space, which is especially valuable in factories that require compact and efficient layouts.

Enhanced Production Flexibility Rotary conveyors are highly adaptable and can be configured to handle various types of products. Whether a manufacturer is producing small parts or large assemblies, the system can be customized to meet the specific requirements of the operation. This flexibility allows manufacturers to adjust their production lines easily when switching between different products or processes.

Increased Productivity The continuous flow of products and the reduction of manual interventions provided by rotary conveyors directly contribute to increased productivity. By minimizing delays between production stages and improving overall throughput, rotary conveyor systems allow manufacturers to meet higher production targets in less time.

Cost-Effectiveness Although the initial investment in a Rotary Conveyor System may be higher than in simpler conveyor solutions, the long-term benefits far outweigh the costs. Reduced labor expenses, increased productivity, and improved efficiency all contribute to a better return on investment. Additionally, the ability to scale and modify the system as needed ensures that it remains a cost-effective solution as production demands change.

Common Applications of Rotary Conveyor Systems in Manufacturing

Rotary Conveyor Systems are versatile and can be used in various industries and applications. Some common uses include:

Assembly Lines In industries such as electronics, automotive, and consumer goods, rotary conveyors are used to move components and parts between different stages of the assembly process. Their ability to handle high-speed production and accommodate various product sizes makes them ideal for complex assembly lines.

Inspection and Quality Control Rotary conveyors provide an efficient way to move products through inspection or quality control stations. The system can be programmed to stop at specific intervals, allowing for manual or automated inspection of items before they continue to the next stage.

Sorting and Packaging In industries such as food and beverage, pharmaceuticals, and cosmetics, rotary conveyors are used to sort products and prepare them for packaging. Their ability to handle different product types and move them in multiple directions makes them ideal for sorting and packaging applications.

Material Handling in Warehouses Warehouses and distribution centers use rotary conveyor systems to move products from storage areas to shipping stations. Their ability to navigate tight spaces and manage high throughput makes them an efficient solution for warehouses dealing with large inventories.

FAQs About Rotary Conveyor Systems in Manufacturing

How does a rotary conveyor system differ from other conveyor types? A rotary conveyor system moves products in a circular or semi-circular path, whereas traditional conveyor systems usually move products in a straight line. This circular motion allows for greater flexibility in confined spaces and is ideal for applications where products need to be redirected or moved back to earlier stages of production.

What types of materials can a rotary conveyor system handle? Rotary conveyor systems can handle a wide range of materials, including small parts, fragile items, heavy components, and even irregularly shaped products. Their versatility makes them suitable for various manufacturing applications.

Are rotary conveyor systems customizable? Yes, rotary conveyor systems can be customized to meet the specific needs of a manufacturing facility. This includes adjustments to the platform size, speed, rotation angle, and load capacity to suit the requirements of different products and processes.

What industries benefit most from rotary conveyor systems? Industries such as automotive, electronics, pharmaceuticals, food and beverage, and consumer goods manufacturing benefit the most from rotary conveyor systems due to their flexibility, high throughput, and ability to handle diverse product types.

How does a rotary conveyor system improve production efficiency? Rotary conveyor systems improve production efficiency by reducing manual labor, ensuring continuous product movement, and allowing for precise control over the speed and direction of products. This results in faster production cycles and fewer delays between stages.

Conclusion

The Rotary Conveyor System is an essential component of modern manufacturing, providing flexibility, efficiency, and cost-effectiveness to various industries. By streamlining material handling processes, reducing labor costs, and improving production speed, rotary conveyors play a crucial role in enhancing the overall productivity of manufacturing operations. Whether you’re managing an assembly line, handling complex inspection tasks, or optimizing packaging operations, a rotary conveyor system offers a versatile and efficient solution.

0 notes

Text

Industrial Spare Parts Suppliers In Germany

VBN Vertriebs GmbH is one of the leading industrial spare parts suppliers in Germany, offering an extensive range of components to meet the needs of various industries. Our parts are sourced from reputable manufacturers, ensuring you receive high-quality and durable products. With quick delivery and exceptional customer service, we help keep your operations running smoothly. Visit our website today to explore our inventory and place your order.

#industrial spare parts suppliers#spare parts supplying company#Electric motors Offenburg#VBN Conveyor equipment#SEW Geared motor Offenburg#automation solutions Offenburg#tailor-made sensors solutions Offenburg

0 notes