#Construction adhesives

Explore tagged Tumblr posts

Text

Introduction to Synthetic Resin Adhesives

The building business was completely transformed by the introduction of Synthetic Resin Adhesives. These adhesives are effective in packing, long-lasting, and multipurpose. They consist of several chemicals. These days, resin-based products are a necessary part of modern manufacturing and may be found in everything from high-end to bulky packaging.

Types of Synthetic Resin Adhesives

Epoxy Resin Adhesives

Epoxy resin adhesives are renowned for having outstanding bond strength and resilience to abrasive environments. Applications needing strong adhesion and structural stability, such joined concrete, metal, and plastic, frequently employ it.

Polyurethane Adhesives

Because polyurethane adhesive is so strong and flexible, it’s perfect for packaging that comes in different widths. It is used in construction for joint coverings and wood fastening to various components.

Acrylic Adhesives

Acrylic adhesives are frequently used in construction to assemble furniture, affix decorative panels, and make windows. They are prized for their quick speed and strong adherence to a variety of materials, including metal, glass, and ceramics.

Cyanoacrylate Adhesives

Super glue, or cyanoacrylate adhesives, are thought to be advantageous due to its quick cure and great resilience. In construction, it is widely used to bind small pieces, repair cracks, and fuse soft materials together.

Properties of Synthetic Resin Adhesives

Resin-based adhesives exhibit several key characteristics that make them ideally suited for construction applications.

Strength

One of the number one blessings of artificial resin adhesives is their exquisite bonding strength, which allows them to create robust connections among numerous materials.

Durability

Synthetic resin adhesives are recognized for their sturdiness, resisting degradation from exposure to moisture, chemical compounds, and environmental elements over time.

Flexibility

Many synthetic resin adhesives offer flexibility, permitting them to resist the stresses of motion and vibration with out dropping their bond energy.

Resistance to Moisture and Chemicals

It is common for synthetic resin adhesives to be designed to withstand chemical exposure and moisture, which qualifies them for usage in outdoor and industrial settings.

Applications in the Construction Industry

Synthetic resin adhesives locate several packages in the construction industry, ranging from bonding materials to structural repairs.

Bonding Materials

Synthetic resin adhesives are used to bond a wide variety of substances, together with timber, metal, concrete, and plastic, permitting the construction of long lasting and resilient systems.

Structural Repairs

In cases in which traditional creation techniques are impractical or costly, artificial resin adhesives can be used to restore and toughen current systems quick and efficaciously.

Flooring Installation

Synthetic resin adhesives are typically used in floors set up, imparting a robust and dependable bond between the floors material and the substrate.

Wall Paneling

Synthetic resin adhesives are used to connect wall panels and decorative factors, supplying a steady and aesthetically pleasing end to indoors areas.

Advantages of Synthetic Resin Adhesives

In many production processes, synthetic resin adhesives are the favored choice due to their numerous advantages over traditional bonding methods.

Fast Curing Time

Synthetic resin adhesives usually have a fast curing time, bearing in mind rapid assembly and set up of production additives.

High Strength

Synthetic resin adhesives provide high bond electricity, making sure the structural integrity and sturdiness of constructed factors.

Versatility

Synthetic resin adhesives can bond a wide variety of materials together, imparting versatility and versatility in creation initiatives.

Resistance to Environmental Factors

Synthetic resin adhesives are resistant to moisture, chemicals, and other environmental factors, making them suitable for use in diverse climatic conditions.

Real-Life Applications

Several case studies highlight the effectiveness and flexibility of synthetic resin adhesives in production tasks international.

Challenges and Limitations

Despite their many advantages, artificial resin adhesives additionally face demanding situations and limitations, such as restricted temperature tolerance and capacity health risks in the course of software.

Future Trends and Innovations

The destiny of artificial resin adhesives in the construction enterprise looks promising, with ongoing research and improvement targeted on improving their overall performance, sustainability, and safety.

Conclusion

In conclusion, synthetic resin adhesives have revolutionized the development enterprise by way of supplying superior bonding energy, durability, and versatility. From bonding materials to structural maintenance, those adhesives play a crucial role in cutting-edge creation practices, paving the manner for innovative and sustainable constructing solutions.

Unique FAQs

Are synthetic resin adhesives suitable for outdoor applications?

How do synthetic resin adhesives compare to traditional adhesives?

What safety precautions should be taken when using synthetic resin adhesives?

Can synthetic resin adhesives be used underwater?

Are there eco-friendly alternatives to synthetic resin adhesives?

#synthetic resin adhesives#construction adhesives#acrylic adhesive#industrial adhesives#flooring installation#adhesive properties#durability#polyurethane adhesive

2 notes

·

View notes

Text

Successful Applications of Ceramic Epoxy Adhesives in Various Industries

Ceramic epoxy adhesives are gaining prominence across multiple industries due to their exceptional strength, durability, and resistance to extreme conditions. These adhesives are engineered to bond ceramics and other materials, providing reliable solutions for demanding applications. Their unique properties make them ideal for high-performance environments, particularly in high-temperature applications.

In the aerospace sector, high temperature ceramic epoxy adhesives are used to assemble engine components and thermal protection systems. These adhesives withstand intense heat and mechanical stress, ensuring the structural integrity of critical components. As a result, they contribute significantly to the overall safety and efficiency of aerospace vehicles.

The automotive industry also benefits from the best ceramic epoxy adhesive for bonding parts that experience high stress and exposure to harsh conditions. Manufacturers utilize these adhesives to secure exhaust systems, engine components, and structural elements, enhancing vehicle performance and longevity. Their superior bonding capabilities help reduce the risk of failure, which is paramount in automotive applications.

Another significant application of ceramic epoxy adhesives is in the electronics industry. With the increasing demand for lightweight and durable materials, epoxy bonding adhesives are essential for assembling electronic components. These adhesives provide excellent insulation and thermal stability, making them suitable for circuit boards and other critical electronics, ensuring functionality even under extreme conditions.

In addition to these applications, the construction industry relies on high temperature ceramic adhesives for bonding tiles, stones, and other building materials. Their ability to withstand environmental factors, such as moisture and temperature fluctuations, makes them a preferred choice among builders and contractors.

As an adhesive manufacturer in India, Kohesi Bond offers a range of ceramic epoxy adhesives designed for diverse applications. Our products are formulated to meet the highest industry standards, ensuring reliability and performance. With our commitment to quality and innovation, we provide the right solutions for your adhesive needs, helping you achieve successful outcomes in your projects.

#Ceramic Epoxy Adhesive#High Temperature Adhesives#Industrial Adhesives#Epoxy Bonding#Adhesive Solutions#Aerospace Adhesives#Automotive Adhesives#Electronics Manufacturing#Construction Adhesives#Adhesive Manufacturer in India#High Performance Adhesives#Durable Bonding Solutions#Ceramic Adhesive Applications#Epoxy Adhesive Properties#Advanced Adhesives

1 note

·

View note

Text

Double-Sided Tape Market: Key Applications, Industry Players, and Future Outlook

The double-sided tape market plays a pivotal role across various industries due to its versatility, offering innovative adhesive solutions for a multitude of applications. From packaging to healthcare, this industry is poised for substantial growth, driven by technological advancements and a rising demand for efficient bonding solutions. The market is growing at a high rate due to the increased demand from various sectors. The global double-sided tape market size was USD 11.6 billion in 2022 and is projected to reach USD 17.2 billion by 2028, at a CAGR of 6.7% between 2023 and 2028.

Key Applications

Packaging: Double-sided tape is extensively used in the packaging sector due to its strength and reliability. Its use is especially prevalent in e-commerce, where it provides secure sealing solutions for boxes and packages. This ensures the integrity of goods during transport and storage, making it a critical component in maintaining product quality throughout the supply chain.

Building and Construction: In construction, double-sided tape is employed for mounting signs, panels, mirrors, and other materials. It allows for clean, quick installations, offering flexibility in design and application. The rapid urbanization and ongoing infrastructure development worldwide have further fueled its demand in this sector.

Automotive: The automotive industry leverages double-sided tape for attaching interior trims and exterior components. This adhesive technology supports lightweight design, helping manufacturers enhance both assembly efficiency and vehicle performance, which is crucial given the increasing focus on fuel efficiency.

Electrical and Electronics: Double-sided tape is also widely used in the electronics industry due to its affordability and ease of use. It helps secure components and facilitate connections, contributing to the overall functionality of electronic devices.

Healthcare: With the growing trend toward minimally invasive medical devices, the healthcare sector has embraced double-sided tape for the assembly of wearable sensors, infusion pumps, and other medical equipment. These tapes are designed to be hypoallergenic and breathable, ensuring patient comfort while providing secure bonding.

Retail: In the retail sector, double-sided tape is often used to mount promotional materials such as posters and signs. Its ease of use allows for quick updates to displays, making it ideal for seasonal promotions and product launches, helping retailers create dynamic and engaging shopping experiences.

Major Industry Players

The global double-sided tape market features key players who lead the industry through innovation, sustainability efforts, and a focus on high-performance products.

3M Company: A pioneer in adhesive technologies, 3M provides a wide range of double-sided tape solutions catering to industries such as electronics and automotive.

Avery Dennison Corporation: Known for its diverse adhesive product portfolio, Avery Dennison continues to expand its offerings to meet rising market demand.

Lohmann GmbH & Co. KG: A strong player in the market, Lohmann offers tailored adhesive solutions for various industries.

Lintec Corporation: Specializing in high-quality adhesive products, Lintec leverages technological advancements to continuously enhance its product lineup.

Tesa SE (Beiersdorf AG): Tesa is well-known for its innovative adhesive solutions and its commitment to sustainability, catering to the eco-conscious consumer base.

Future Outlook

The double-sided tape market is expected to witness significant growth from 2024 to 2032. Technological innovations, rising consumer demand, and increased government investments in urbanization and infrastructure development are key factors driving this growth. The market is evolving rapidly to meet the specific needs of diverse sectors.

Technological Advancements: Continuous improvements in manufacturing processes are enabling the development of high-performance double-sided tape solutions for specialized applications.

Sustainability: As regulatory requirements and consumer preferences shift towards eco-friendly products, manufacturers are focusing on developing sustainable and green adhesive solutions.

Customization: Tailored solutions designed to meet specific consumer requirements are gaining traction, providing manufacturers with new avenues to enhance customer satisfaction and loyalty.

Regional Insights on the Double-Sided Tape Market

North America: North America, especially the United States and Canada, holds a significant share of the global double-sided tape market. This can be attributed to the region’s strong manufacturing and construction sectors, which demand high-quality adhesive solutions for a variety of applications. Additionally, North America's advanced distribution networks, innovative tape technologies, and strict quality standards bolster its position as a key hub for both the production and consumption of double-sided tape. Despite facing challenges during the early stages of the COVID-19 pandemic, with manufacturing activities temporarily declining, the region has been recovering since 2021 as economic activities gradually resume.

Europe: Europe is another major player in the double-sided tape market, with notable contributions from countries like Germany, the United Kingdom, France, Italy, and Spain. The market in this region is characterized by a mature industrial base, high consumer demand, and diverse applications. European market players focus on developing advanced adhesive technologies to meet strict regulations and quality standards, driving innovation and growth across the region.

Asia-Pacific: Asia-Pacific is projected to see the fastest growth in the double-sided tape market, fueled by rapid urbanization and industrialization in countries like China and India. Government support and the availability of inexpensive raw materials contribute to this expansion. The region's booming automotive industry and increasing business investments further enhance its market potential, making it highly attractive for new entrants. Key contributors to this growth include Japan, South Korea, Australia, and emerging markets such as Indonesia and Thailand.

Latin America: Brazil and Mexico are the primary markets driving growth in the double-sided tape sector in Latin America. While the region is smaller compared to North America and Asia-Pacific, rising industrial activities and increasing consumer demand for adhesive products are contributing to its development.

Middle East and Africa: The Middle East and Africa are gradually gaining momentum in the double-sided tape market, though their market share remains relatively small. Factors such as ongoing infrastructural development and industrialization are expected to drive demand in this region in the coming years.

Download PDF Brochure :

The double-sided tape market is thriving, driven by rising demand for efficient bonding solutions across sectors such as packaging, construction, automotive, electronics, healthcare, and retail. Its versatility and efficiency have made it indispensable in modern industries, particularly as e-commerce and urbanization trends continue to rise. With innovations in adhesive technology, a shift towards sustainable products, and increasing regional demand, the double-sided tape market is well-positioned for significant growth in the coming years.

#North America adhesive market#Europe adhesive technologies#Asia-Pacific market growth#industrial adhesives#construction adhesives#rapid urbanization#COVID-19 recovery trends

0 notes

Text

Construction Adhesives Market Will Reach USD 14,541.9 Million By 2030

The size of the construction adhesives market was USD 9,101.5 million in 2021, and the figure is set to rise at a CAGR of 5.3% in the duration of 2021–2030, and to reach USD 14,541.9 million by the end of this decade, as per P&S Intelligence.

This can be credited to the rising construction sector, and snowballing demand for low-VOC adhesives, including water-based adhesives and pressure-sensitive adhesives.

In 2021, the acrylic category held the largest revenue share of approximately USD 3,862.3, and this number will surge at a CAGR of 5.7% by the end of this decade. This can be ascribed to the fast development of the construction sector in the MEA and APAC regions. Acrylic adhesives are favorite in the construction industry mainly because of their solid bonding with substrates, outstanding water resistance, and better impact strength.

To receive free sample pages of this report@ https://www.psmarketresearch.com/market-analysis/construction-adhesives-market/report-sample

For example, China presently has a large number of airport building projects in the stage of expansion, including, Chengdu Shuangliu International Airport, Guangzhou Baiyun International Airport, and Beijing Capital International Airport. Furthermore, the Chinese government has publicized key strategies for the relocation of 250 million public to new megacities in the coming ten years.

In 2021, the residential category held the largest revenue share, of approximately 60%, credited to the high-volume utilization of construction adhesives in residential constructions.

This can be ascribed to the increasing expenditure in residential construction actions than for commercial and industrial construction. According to an Indian government organization, the ‘Housing for All” scheme is purpose to fetch investments of USD 1.3 trillion in the residential industry by 2025.

#Construction adhesives#Building materials#Structural bonding#Adhesive technology#Infrastructure development#Sustainable construction#High-performance adhesives#Versatile bonding solutions#Waterproofing adhesives#Green building practices#Market trends#Industrial applications#Adhesive innovation#Interior and exterior bonding#Rapid curing adhesives#Adhesive compatibility#Bonding durability#Market growth#Construction industry#Future of adhesive technologies in construction.

0 notes

Text

Construction Adhesives Market: Key Trends and Growth Opportunities

The size of the construction adhesives market was USD 9,101.5 million in 2021, which will reach USD 14,541.9 million by 2030, at a rate of 5.3% in the years to come, as said by a market research company, P&S Intelligence. The acrylic category had approximately a revenue of USD 3,862.3 million in 2021, and this will propel at a rate of 5.7% in the projection period. This will be because of the…

View On WordPress

0 notes

Text

Fuck superglue. The devil’s precum. All my homies love High Strength Construction Adhesive

SHE HAS THE RANGE!!!

Wip: Clay sculpted koi pen holder with wooden base. construction adhesive was used to glue it down AND create wave effects. (Yes actual sculpture medium would be better but its 11pm im not running to the store again)

8 notes

·

View notes

Text

How Synthetic Resin Adhesives Are Revolutionizing the Construction Industry

Introduction to Synthetic Resin Adhesives

The building business was completely transformed by the introduction of Synthetic Resin Adhesives. These adhesives are effective in packing, long-lasting, and multipurpose. They consist of several chemicals. These days, resin-based products are a necessary part of modern manufacturing and may be found in everything from high-end to bulky packaging.

Types of Synthetic Resin Adhesives

Epoxy Resin Adhesives

Epoxy resin adhesives are renowned for having outstanding bond strength and resilience to abrasive environments. Applications needing strong adhesion and structural stability, such joined concrete, metal, and plastic, frequently employ it.

Polyurethane Adhesives

Because polyurethane adhesive is so strong and flexible, it’s perfect for packaging that comes in different widths. It is used in construction for joint coverings and wood fastening to various components.

Acrylic Adhesives

Acrylic adhesives are frequently used in construction to assemble furniture, affix decorative panels, and make windows. They are prized for their quick speed and strong adherence to a variety of materials, including metal, glass, and ceramics.

Cyanoacrylate Adhesives

Super glue, or cyanoacrylate adhesives, are thought to be advantageous due to its quick cure and great resilience. In construction, it is widely used to bind small pieces, repair cracks, and fuse soft materials together.

Properties of Synthetic Resin Adhesives

Resin-based adhesives exhibit several key characteristics that make them ideally suited for construction applications.

Strength

One of the number one blessings of artificial resin adhesives is their exquisite bonding strength, which allows them to create robust connections among numerous materials.

Durability

Synthetic resin adhesives are recognized for their sturdiness, resisting degradation from exposure to moisture, chemical compounds, and environmental elements over time.

Flexibility

Many synthetic resin adhesives offer flexibility, permitting them to resist the stresses of motion and vibration with out dropping their bond energy.

Resistance to Moisture and Chemicals

It is common for synthetic resin adhesives to be designed to withstand chemical exposure and moisture, which qualifies them for usage in outdoor and industrial settings.

Applications in the Construction Industry

Synthetic resin adhesives locate several packages in the construction industry, ranging from bonding materials to structural repairs.

Bonding Materials

Synthetic resin adhesives are used to bond a wide variety of substances, together with timber, metal, concrete, and plastic, permitting the construction of long lasting and resilient systems.

Structural Repairs

In cases in which traditional creation techniques are impractical or costly, artificial resin adhesives can be used to restore and toughen current systems quick and efficaciously.

Flooring Installation

Synthetic resin adhesives are typically used in floors set up, imparting a robust and dependable bond between the floors material and the substrate.

Wall Paneling

Synthetic resin adhesives are used to connect wall panels and decorative factors, supplying a steady and aesthetically pleasing end to indoors areas.

Advantages of Synthetic Resin Adhesives

In many production processes, synthetic resin adhesives are the favored choice due to their numerous advantages over traditional bonding methods.

Fast Curing Time

Synthetic resin adhesives usually have a fast curing time, bearing in mind rapid assembly and set up of production additives.

High Strength

Synthetic resin adhesives provide high bond electricity, making sure the structural integrity and sturdiness of constructed factors.

Versatility

Synthetic resin adhesives can bond a wide variety of materials together, imparting versatility and versatility in creation initiatives.

Resistance to Environmental Factors

Synthetic resin adhesives are resistant to moisture, chemicals, and other environmental factors, making them suitable for use in diverse climatic conditions.

Real-Life Applications

Several case studies highlight the effectiveness and flexibility of synthetic resin adhesives in production tasks international.

Challenges and Limitations

Despite their many advantages, artificial resin adhesives additionally face demanding situations and limitations, such as restricted temperature tolerance and capacity health risks in the course of software.

Future Trends and Innovations

The destiny of artificial resin adhesives in the construction enterprise looks promising, with ongoing research and improvement targeted on improving their overall performance, sustainability, and safety.

Conclusion

In conclusion, synthetic resin adhesives have revolutionized the development enterprise by way of supplying superior bonding energy, durability, and versatility. From bonding materials to structural maintenance, those adhesives play a crucial role in cutting-edge creation practices, paving the manner for innovative and sustainable constructing solutions.

4 notes

·

View notes

Text

Hm. I bought a 24 metre roll of wire for my artificial feathers before actually measuring them to know how much wire I actually need

Now that I've measured them and properly realised I'll need to add length for adjustment allowance, bending in a hook (to hang them while the feather fabric dries), and leverage to twist a loop to put a screw through to attach them to the frame arm......

Hm. I wonder if I'll need more than the 24 metres....

Gonna need to figure out how to straighten all the wires but I also hope it won't bend under the feather fabric.... Needing to balance wire strength that's thin enough I can cut and bend it by hand but thick enough to hold itself....... Let's hope it works out lads 😓

#ramblings of a bystander#a bystander makes cosplay#looks like the adhesive for feather construction will arrive on monday#darn. i was hoping for friday.

2 notes

·

View notes

Photo

Kerakoll can provide several different systems when it comes to pools these systems, include silica free and efflorescence free products. For more information please contact us at Kerakoll Australia. Lachlan Holloway, Sales Manager 0451 306 646 Ian Cummaudo, Technical Manager 0499 995 352 #Kerakoll #keepingtheenvironmentgreen #livinggreen #buildgreen #Construction #Melbourne #sydney🇦🇺 #perth #Brisbane #waterproofers #waterproofing #waterproofingsystems #builders #architects #tilers #tiling #adhesive #Levelling #screed #balcony #bathroom #melbournebuilders #concretor #Sustainability #greenbuilding #landscaping#poolbuilding #silicafree (at Melbourne, Victoria, Australia) https://www.instagram.com/p/CpPZZtIvYg7/?igshid=NGJjMDIxMWI=

#kerakoll#keepingtheenvironmentgreen#livinggreen#buildgreen#construction#melbourne#sydney🇦🇺#perth#brisbane#waterproofers#waterproofing#waterproofingsystems#builders#architects#tilers#tiling#adhesive#levelling#screed#balcony#bathroom#melbournebuilders#concretor#sustainability#greenbuilding#landscaping#poolbuilding#silicafree

4 notes

·

View notes

Text

Name your FAVORITE adhesive.

oh, you're into bondage? name every adhesive

6K notes

·

View notes

Text

ProudiGravel Premium Gravel Binder for Durable Outdoor Surfaces

Are you looking for a reliable and long-lasting solution for your gravel surfaces? Look no further than ProudiGravel, the top choice for creating stunning, durable, and safe outdoor areas. Made with a high-quality binder formula, this product offers the perfect mix for all your gravel needs, whether you���re working on driveways, walkways, or decorative pathways. What is…

View On WordPress

#binder for gravel#construction materials UAE#durable gravel#gravel adhesive#gravel binder#gravel chips#gravel coating#gravel driveway#gravel finish#gravel mix#gravel path#gravel surface coating#gravel surface solution#outdoor paving solutions#outdoor surfaces#ProudiGravel#ProudiGravel UAE#two-component binder#UAE construction materials#UAE gravel binder#UAE outdoor products#walkway binder

0 notes

Text

Exploring Innovations in Chemical Manufacturing

In the dynamic world of chemical manufacturing, particularly in the fields of industrial materials and silica products, companies like Minmetals East are leading the charge in creating high-quality solutions. One of the standout products in their lineup is the checker plate aluminium, which is known for its durability and versatility in various applications.

Checker plate aluminium is an excellent choice for construction materials due to its lightweight properties and resistance to corrosion. This makes it ideal for use in environments where strength and longevity are crucial. Minmetals East ensures that their aluminium products meet the highest standards, providing customers with reliable materials that can withstand the test of time.

Furthermore, in the realm of adhesives, Minmetals East offers innovative solutions that enhance the bonding process in construction and manufacturing. Their adhesives are designed to work seamlessly with various substrates, ensuring strong and lasting connections.

In addition, water treatment processes benefit significantly from the advancements in chemical manufacturing. Minmetals East is committed to providing eco-friendly solutions that contribute to cleaner water systems, promoting sustainability in industrial practices.

Overall, the commitment of Minmetals East to excellence in chemical manufacturing, along with their focus on innovative products like checker plate aluminium, positions them as a leader in the industry. Their dedication to quality and sustainability is paving the way for a brighter future in industrial materials.

#innovation#eco-friendly solutions#checker plate aluminium#water treatment#industrial practices#durability#construction materials#adhesives

0 notes

Text

Exploring Ceramic Fiber Modules in the Chemical Manufacturing Industry

In the heart of the Chemical Manufacturing and Industrial Materials sectors, Minmetals East stands out for its commitment to quality and innovation. Their ceramic fiber modules are a game-changer in enhancing the efficiency of various applications, particularly in the fields of adhesives, construction materials, and water treatment.

These modules provide excellent thermal insulation, making them an ideal choice for industries that require high-temperature resistance and energy efficiency. With Minmetals East's focus on sustainable practices, clients can trust that they are not only improving their operational performance but also contributing positively to environmental stewardship.

By integrating advanced technology and high-quality materials, Minmetals East continues to lead the way in providing solutions that meet the evolving needs of the marketplace. Embrace the future of industrial materials with Minmetals East and experience the benefits that come with their exceptional ceramic fiber modules!

#construction materials#adhesives#energy efficiency#thermal insulation#high-temperature resistance#industrial materials#sustainable practices#environmental stewardship

0 notes

Text

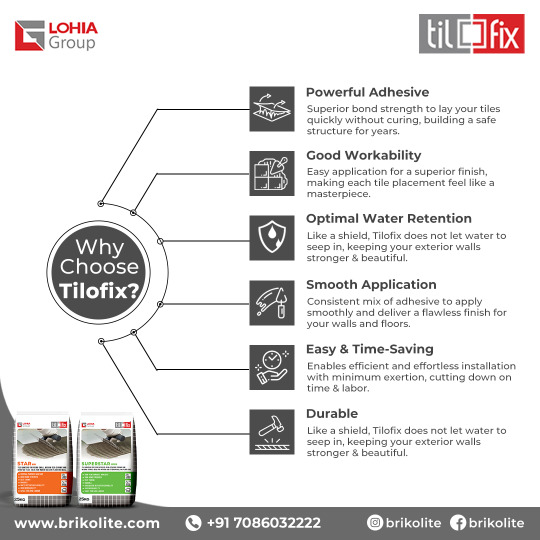

Tilofix is a revolutionary pre-mix mortar designed to elevate your tile fixing experience. Engineered for efficiency and performance, Tilofix ensures superior results in both residential and commercial applications

0 notes

Text

AKFIX 705 Universal Fast Adhesive

1 note

·

View note