#Conduit Pipes

Explore tagged Tumblr posts

Text

0 notes

Text

Understanding the Importance of Conduit Pipes in Electrical Installations

Ever wondered what keeps your electrical systems running smoothly behind the scenes? Introducing conduit pipes, the often overlooked backbone of electrical systems. These modest tubes serve a crucial function, shielding wires from moisture, corrosion, and physical harm. From safeguarding against external elements to optimising function, wire pathways, and conduit pipes are the unsung heroes that professionals rely on daily.

1 note

·

View note

Text

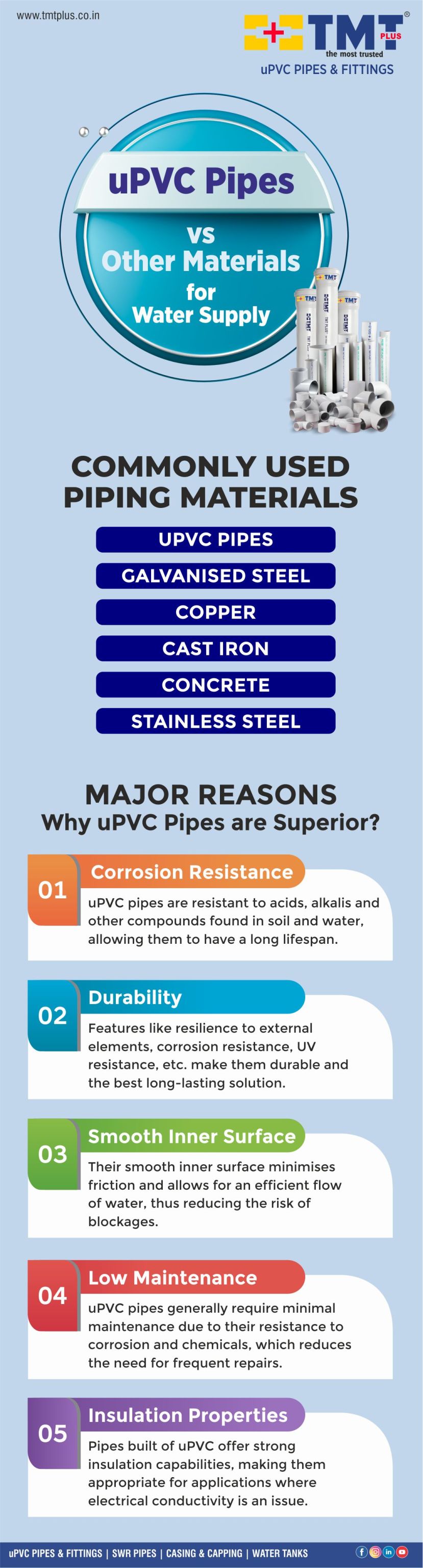

uPVC pipes are notch above other material pipes on the market as they are corrosion-resistant, low maintenance, have a smooth inner surface, etc. Install today!

#tmtplus#upvc pipes and fittings manufacturers in india#upvc pipes#conduit pipes#pipes#upvc pipes and fittings

0 notes

Text

Sitting in the dark hallows of the garage at night.. I see. Splayed across the shadows of water-heaters and air-conditioner vents.. the shadowy beast lurking.

#this. is actually a set of water pipes. and electrical conduits#the light provided by my phone shows the actual layout if you map the shadows.#also sus amongus baka content yuri yaoi boku no please help me#IT IS SHADOW OF A WATER PIPE OMFG

2 notes

·

View notes

Text

2 notes

·

View notes

Text

#pvc conduit pipes#pvc pipe manufacturers in bihar#pipes and fittings manufacturers#flexible pvc pipes#pvc pipe bend#pvc pipe fittings#electrical pvc pipe#flexible pipes

0 notes

Text

Choosing the Best PVC Pipe for Electrical Wiring

When it comes to electrical wiring, the safety and durability of the materials used are paramount. One of the most commonly used materials for electrical wiring is PVC (Polyvinyl Chloride), thanks to its cost-effectiveness, strength, and ease of installation. However, not all PVC pipes are created equal, and choosing the best PVC pipe for electrical wiring is essential for ensuring long-lasting, safe electrical systems.

In this blog, we will discuss which PVC electrical PVC pipes are best for wiring and the factors to consider when choosing the best PVC electrical conduit pipe in India.

Which PVC Pipe Is Best for Electrical Wiring?

When selecting the best electrical PVC pipe for wiring, it is important to look for specific features that ensure safety and performance. PVC electrical conduit pipes are typically used for protecting electrical wires, shielding them from mechanical damage and environmental elements. The best PVC electrical conduit pipe will be strong, durable, and resistant to external damage.

The most commonly used PVC for electrical wiring is rigid PVC, also known as Schedule 40 PVC. This type of pipe is ideal for electrical systems because it is sturdy and resistant to impact. It also offers excellent insulation properties, ensuring that the electrical wires inside are well-protected. For outdoor applications, the best PVC electrical conduit pipe should be UV resistant to ensure that it doesn’t degrade under exposure to sunlight. UV-resistant pipes are essential for preventing the breakdown of the material over time, especially in areas where the conduit is exposed to harsh weather conditions.

How to Select the Best PVC Pipe for Electrical Wiring?

Choosing the right PVC pipe for your electrical wiring project involves considering several factors:

Material Durability: The electric pipe should be strong and durable, offering protection against physical damage, especially in high-traffic areas.

UV Resistance: For outdoor electrical wiring, ensure that the PVC pipe is UV-resistant. This feature is crucial for protecting the conduit from sun exposure, which can cause the pipe to become brittle over time.

Size: Choose a PVC electrical conduit pipe with the correct diameter to fit the number of wires you plan to run. It is important to select a pipe that will allow for the safe passage of all the wires without overcrowding.

Compliance with Standards: Ensure that the PVC electrical conduit pipe complies with local safety standards and certifications, such as ISI (Indian Standards Institute) certification in India. This guarantees that the pipe has been tested for quality and safety.

Choosing the best PVC pipe for electrical wiring is critical to ensuring both the safety and durability of your electrical system. PVC electrical conduit pipes provide excellent protection for wiring, and by selecting the right type of pipe, you can ensure that your electrical installation remains safe and reliable for years to come. Whether you’re working indoors or outdoors, selecting the appropriate PVC electrical conduit pipe based on its strength, UV resistance, and compliance with safety standards is crucial. By considering these factors, you can make an informed decision and ensure your electrical wiring is properly protected.

#best pvc electrical conduit pipe in india#pvc electrical conduit pipe#electric pipe#electrical pvc pipe

0 notes

Text

Reliable Tubing Solutions by AST PIPES

AST PIPES specializes in premium piping solutions, including furniture pipes, boom tubes, and ERW precision tubes, tailored to meet diverse industrial needs. Their offerings feature high-quality steel conduit pipes, corten steel tubes, and CRCA pipes, ensuring durability and precision. With competitive GP pipe prices, they also provide reliable APH tubes, corten tubes, and boom pipes for advanced applications. Trust AST PIPES for innovative, high-performance tubing solutions that set industry benchmarks.

#furniture pipes#boom tube#erw precision tubes#gp pipe price#steel conduit pipes#corten steel tubes#boom pipe#corten tube#aph tubes#crca pipe

0 notes

Text

Jamnagar: India’s Hub for High-Quality Brass Components

India is renowned for its robust manufacturing sector, and the brass components industry is no exception. Among the top hubs for brass fittings and brass components manufacturing in India, Jamnagar stands out as a key player. Known as the "Brass City of India," Jamnagar is home to numerous manufacturers producing a range of products, from brass fittings to brass precision turned components.

Why Jamnagar Leads in Brass Manufacturing

Jamnagar’s success in the brass components industry is driven by several key factors:

Strategic Location: Located near the coast of Gujarat, Jamnagar benefits from easy access to raw materials and major shipping routes, making it an ideal location for both manufacturing and brass pipe fittings manufacturing.

Skilled Workforce: Jamnagar has developed a highly skilled labor force, specializing in brass turned components and brass fittings. The workforce’s expertise ensures the production of high-quality, precision products.

Raw Material Availability: The proximity to raw materials plays a critical role in Jamnagar’s dominance in the industry, ensuring a steady supply for brass components manufacturers.

Established Ecosystem: The city has created a strong ecosystem for brass plumbing fittings and brass tube fittings, with supporting industries in plating, polishing, and machining, which are essential for producing top-tier brass components.

Brass Precision Turned Components: A Key to Industrial Success

Brass precision turned components are at the heart of industries requiring high durability and accuracy. From automotive to telecommunications, sectors across the globe rely on these components for smooth operations. Manufacturers in Jamnagar, including industry leaders like Atlas Metal Industries, are known for producing components that meet international standards of precision, making them essential in high-precision applications.

Atlas Metal Industries: Your Trusted Brass Components Manufacturer

As a leading brass fitting manufacturer in India, Atlas Metal Industries plays a pivotal role in the industry. With decades of experience, Atlas Metal Industries is recognized for providing superior brass components and brass precision turned components that meet the needs of diverse industries. The key benefits of sourcing products from Atlas Metal Industries include:

Competitive Pricing: Thanks to its strategic location and access to raw materials, Atlas Metal Industries offers cost-effective solutions for brass pipe fittings without compromising on quality.

Quality Assurance: Rigorous quality control processes ensure that every brass component produced meets the highest standards, making it ideal for critical applications.

On-Time Delivery: With a well-established supply chain, Atlas Metal Industries guarantees timely delivery of brass components to clients globally.

The Future of Brass Manufacturing in India

The brass components manufacturing industry in India is on an upward trajectory, with several emerging trends shaping the future:

Technological Innovations: The integration of CNC machining and automation is enhancing the efficiency and accuracy of brass components manufacturing.

Sustainability: Manufacturers are increasingly adopting eco-friendly practices and focusing on the recycling of materials to reduce their environmental impact.

Global Expansion: As demand for high-quality brass components increases, Jamnagar is poised to expand its presence in the global market.

Companies like Atlas Metal Industries are embracing these trends, integrating new technologies to meet evolving market demands.

Conclusion: Why Choose Brass Components from Jamnagar

Jamnagar’s prominence in the brass fittings manufacturing sector is a result of its strategic location, skilled workforce, and robust manufacturing infrastructure. For businesses looking for top-quality brass components and precision turned components, Jamnagar offers the perfect solution. Atlas Metal Industries stands out as a reliable partner for businesses seeking high-performance brass components.

To learn more about the high-quality brass components we offer, visit Atlas Metal Industries or contact us at [email protected] or +91-288 2730 944.

#brass components#brass components manufacturer#brass precision turned components manufacturers#brass turned components#brass manufacturers in india#brass pipe manufacturers in jamnagar#brass precision turned components factory#best brass products in india#brass components manufacturer in jamnagar#brass conduit fittings in india#copper lugs manufacturers in india#cable lugs manufacturers in india#lugs manufacturers in india#brass fitting manufacturers in india#brass fittings manufacturers in jamnagar

1 note

·

View note

Text

Conduit Pipe Manufacturers in India

Tycon Cables is one of India's leading Conduit Pipe Manufacturers, offering high-quality PVC conduit pipes designed for durability and safety. Known for their precision engineering and robust performance, Tycon Cables ensures every conduit pipe meets industry standards. With a wide range of options to suit various applications, they are a trusted name among Conduit Pipe Manufacturers. Choose Tycon Cables for reliable solutions that provide excellent protection for electrical wiring systems.

0 notes

Text

Understanding Modern Plastic Pipes in Plumbing: A Comprehensive Guide

Plastic pipes have revolutionised how we transport water and waste throughout our buildings. From humble beginnings as an alternative to traditional metal pipes, plastic plumbing solutions now dominate the market, offering superior durability, cost-effectiveness, and ease of installation. The development of various plastic pipe materials, including HDPE pipes, has transformed both residential and commercial plumbing practices, making it essential for homeowners and contractors alike to understand their options.

The Evolution of Plastic Plumbing

The journey of plastic pipes in plumbing began in the mid-20th century, marking a significant departure from traditional metal piping systems. Initially met with scepticism, plastic pipes have proven their worth through decades of reliable service. Today, modern plumbing systems utilise a variety of plastic materials, each engineered for specific applications and environments. The innovation in plastic pipe manufacturing has led to the development of specialised products like conduit pipes for electrical and communication systems, demonstrating the versatility of plastic materials in construction.

PVC: The Versatile Standard

Polyvinyl chloride (PVC) remains the most widely recognised plastic piping material in plumbing applications. Its popularity stems from an impressive combination of strength, chemical resistance, and cost-effectiveness. Schedule 40 PVC, the most common variety, excels in both residential and commercial applications, particularly for drainage pipes and fittings in waste systems.

PVC pipes showcase remarkable versatility across different pressure ratings and sizes. Their smooth interior surfaces facilitate optimal flow rates while minimising the risk of blockages. Installation requires minimal specialised tools, though proper technique remains crucial, particularly when applying solvent cement to create watertight joints.

Cold water applications represent PVC's primary domain, as the material can become less stable at higher temperatures. However, manufacturers have developed variants specifically designed to handle warmer water, expanding PVC's utility in modern plumbing systems.

CPVC: Meeting Hot Water Challenges

Chlorinated polyvinyl chloride (CPVC) addresses the temperature limitations of standard PVC, making it ideal for hot water distribution systems. This enhanced material maintains structural integrity at temperatures up to 180°F (82°C), surpassing PVC's capabilities while retaining many of its beneficial properties.

CPVC pipes feature in both residential and commercial hot water systems, offering excellent resistance to corrosion and scale buildup. The material's natural insulating properties help maintain water temperature throughout the distribution system, potentially reducing energy costs. While installation procedures mirror those of PVC, CPVC requires specific solvent cement formulations designed for its unique chemical composition.

PEX: The Modern Marvel

Cross-linked polyethylene (PEX) represents one of the most significant innovations in residential plumbing over the past few decades. This flexible piping system has revolutionised installation practices, particularly in new construction and remodelling projects. PEX's flexibility allows it to navigate tight spaces and corners without requiring additional fittings, significantly reducing potential leak points.

The material's resistance to freezing represents a major advantage in colder climates. Unlike rigid pipes that can burst when water freezes, PEX can expand and contract with temperature changes, reducing the risk of catastrophic failures. The color-coding system (red for hot water, blue for cold) simplifies installation and maintenance, while its smooth interior surfaces resist mineral buildup and scale formation.

HDPE: Durability Meets Versatility

High-density polyethylene (HDPE) pipes have earned a reputation for exceptional durability and versatility in both underground and above-ground applications. Their superior impact resistance and flexibility make them ideal for challenging installation environments, while their resistance to chemical degradation ensures longevity in aggressive soil conditions.

HDPE's versatility extends beyond traditional plumbing applications. The material excels in gas distribution, industrial processes, and agricultural systems. Its ability to withstand ground movement and seasonal temperature variations makes it particularly valuable for underground installations. The fusion joining process creates connections stronger than the pipe itself, virtually eliminating the risk of leaks at joints.

ABS: The Black Alternative

Acrylonitrile Butadiene Styrene (ABS) pipes, recognisable by their black colour, offer another option for drainage and waste systems. Popular in residential construction, ABS provides excellent impact resistance and performs well in cold temperatures. The material's lightweight nature facilitates easy handling and installation, while its resistance to acids and chemicals makes it suitable for various drainage applications.

While similar to PVC in many respects, ABS offers some distinct advantages, including better performance in extreme cold and superior sound dampening properties. However, its use may be restricted by local building codes in some areas, particularly for above-ground applications.

Installation Considerations and Best Practices

Successful plastic pipe installation depends heavily on proper technique and attention to detail. Joint preparation remains crucial regardless of the material chosen. Clean cuts, proper deburring, and appropriate joint preparation ensure system integrity. When using solvent cement, technicians must follow manufacturer recommendations for application and curing times, considering environmental factors like temperature and humidity.

Professional installers understand the importance of proper support and anchoring systems for plastic piping. While lighter than metal alternatives, plastic pipes require appropriate hanging and bracing to prevent sagging and maintain proper slope in drainage systems. Temperature changes can affect pipe length, necessitating proper allowance for expansion and contraction in system design.

Environmental Impact and Sustainability

The environmental implications of plastic piping systems merit consideration in today's sustainability-conscious construction industry. While plastic pipes require petroleum products in their manufacture, their longevity and recyclability offer environmental benefits. Modern plastic pipes typically last 50 years or more, reducing replacement frequency and associated resource consumption.

Additionally, the smooth interior surfaces of plastic pipes improve flow efficiency, potentially reducing energy requirements for pumped systems. Some manufacturers now incorporate recycled materials in their products, particularly for non-pressure applications like drainage pipes and fittings, further reducing environmental impact.

Looking to the Future

Innovation in plastic pipe technology continues, with manufacturers developing new materials and improving existing formulations. Smart pipe systems incorporating sensors for leak detection and flow monitoring represent an emerging trend, while advances in manufacturing processes promise even more durable and sustainable products.

The future of plumbing lies in these evolving plastic technologies, offering solutions that balance performance, cost-effectiveness, and environmental responsibility. As building practices evolve and environmental concerns grow more pressing, the role of plastic pipes in modern plumbing systems will likely expand further, driven by ongoing improvements in materials science and manufacturing techniques.

Understanding the various types of plastic pipes available for plumbing applications helps property owners and contractors make informed decisions about their plumbing systems. Each material offers distinct advantages for specific applications, and proper selection ensures optimal system performance and longevity. As technology advances and environmental considerations become increasingly important, the plastic pipe industry continues to innovate, providing ever more efficient and sustainable solutions for modern plumbing needs.

0 notes

Text

The Basics of Conduit Pipe Fittings: Types and Applications

Conduit pipe fittings play a vital role in safeguarding electrical wiring by providing protection and structure, especially in environments where durability is critical. Whether it's for residential, commercial, or industrial purposes, understanding the types and applications of these fittings can help ensure safe, efficient, and long-lasting electrical systems. In this blog, we’ll break down the fundamentals of conduit pipe fittings, focusing on their types, uses, and benefits.

What Are Conduit Pipe Fittings?

Conduit pipe fittings are essential components that guide and protect electrical wiring. They’re designed to ensure that wires stay secure, organized, and insulated from external damage. An electrical product company like Asio Electricals offers a range of high-quality conduit fittings that meet varied needs in different settings.

1. Importance of Conduit Pipe Fittings in Electrical Installations

Protection: Conduit fittings protect electrical wires from physical damage, such as cuts, abrasions, and environmental elements like moisture and dust.

Safety: These fittings reduce fire risks by shielding wires from accidental exposure, which helps in preventing electrical sparks.

Organization: Conduit fittings provide a structured way to run wiring across spaces, improving organization, aesthetics, and accessibility.

Durability: Using conduit fittings extends the life of wiring systems, making them more reliable and efficient over time.

2. Types of Conduit Pipe Fittings

Conduit pipe fittings come in a variety of types, each suited for different environments and applications. Here’s a look at the main types:

A. Rigid Metal Conduit (RMC) Fittings

Material: Made from steel or aluminum.

Application: Best for industrial setups, where strong protection against external damage is essential.

Features: Resistant to corrosion and provides high-strength support for electrical wires.

B. Electrical Metallic Tubing (EMT) Fittings

Material: Usually made from galvanized steel.

Application: Commonly used in commercial buildings.

Features: Lighter than RMC, EMT fittings are ideal for indoor installations, where they’re protected from harsh environmental factors.

C. Flexible Metal Conduit (FMC) Fittings

Material: Constructed with a flexible metal coil.

Application: Often used in areas with vibration, such as near motors or machinery.

Features: Flexibility allows it to bend around obstacles, making it perfect for tight spaces and areas requiring frequent adjustments.

D. Liquid-Tight Flexible Non-Metallic Conduit (LFNC) Fittings

Material: Typically made from plastic materials.

Application: Suitable for wet or outdoor environments.

Features: Watertight and resistant to UV radiation, these fittings are great for outdoor applications.

E. PVC Conduit Fittings

Material: Made from polyvinyl chloride (PVC).

Application: Used both indoors and outdoors, especially in residential and commercial buildings.

Features: Lightweight, corrosion-resistant, and affordable, PVC fittings are easy to install and suitable for damp environments.

3. Applications of Conduit Pipe Fittings

The applications of conduit pipe fittings vary widely depending on the setting and specific needs of the project:

Industrial Settings: In industrial environments, fittings such as RMC and LFNC are commonly used to ensure high levels of protection and resistance against physical damage.

Commercial Buildings: EMT fittings are preferred in commercial buildings due to their lightweight nature, which makes installation easier in office and retail spaces.

Residential Areas: PVC conduit fittings are widely used in residential areas for their durability, ease of installation, and affordability.

Outdoor Installations: LFNC and PVC fittings are typically chosen for outdoor installations due to their resistance to moisture and environmental damage.

4. Benefits of Using Conduit Pipe Fittings

Enhanced Safety: Conduit fittings reduce fire hazards by protecting wires from exposure to external elements and keeping them insulated.

Longevity: Quality fittings improve the longevity of wiring systems, reducing the need for frequent maintenance and replacements.

Aesthetic Appeal: Well-organized conduit fittings help create a tidy and professional look in commercial and residential spaces.

Efficiency: Properly chosen and installed fittings enhance the overall efficiency of electrical systems by minimizing energy loss and maintaining stable currents.

5. How to Choose the Right Conduit Pipe Fittings

Selecting the right fittings involves evaluating a few factors, such as:

Environment: Identify if the installation is for indoor or outdoor use, as some materials are more resistant to moisture and UV light.

Flexibility Needs: Determine if you need flexible or rigid fittings based on whether the installation is static or may need frequent adjustments.

Budget: Consider the project budget, as PVC fittings are generally more affordable, while metal conduits are more durable but costly.

Safety Standards: Ensure the fittings meet the relevant safety and compliance standards as set by the government or industry regulations.

Compatibility: Check that the fittings are compatible with the specific wiring requirements, such as size, voltage, and type of wiring.

6. Why Choose Asio Electricals for Conduit Pipe Fittings?

As a trusted electrical product company, Asio Electricals provides high-quality conduit pipe fittings designed to meet both residential and industrial needs. Here are a few reasons why Asio Electricals stands out:

Extensive Range: We offer a wide range of fittings suitable for diverse applications, from rigid to flexible options.

Quality Assurance: Every product undergoes strict quality checks to ensure durability and compliance with safety standards.

Competitive Pricing: Asio Electricals offers cost-effective solutions without compromising on quality, making it accessible for all project budgets.

Expert Guidance: Our team provides expert guidance on selecting the right fittings based on your specific needs and environment.

Conclusion

Understanding the types and applications of conduit pipe fittings is essential for creating secure, efficient, and organized electrical systems. Whether you’re managing a commercial building, installing wiring in a residential area, or working in an industrial setup, selecting the right conduit pipe fittings will make a significant difference in the system’s longevity and safety. Asio Electricals, a leading electrical product company, is here to offer high-quality, durable conduit fittings designed to meet diverse requirements.

By choosing Asio Electricals, you’re ensuring the safety and efficiency of your electrical system with products that stand the test of time.

Also Read:

The Importance of Quality Control in Wire and Cable Manufacturing

The Impact of Electrical Switches on Modern Electrical Systems

Originally published at https://asioworld.blogspot.com

0 notes

Text

Threaded Casing Pipes Manufacturers in Chhattisgarh

Introduction

Are you searching for the best Threaded Casing Pipes Manufacturers in Chhattisgarh? Your search ends here!

Welcome to Polycarb Industries, a leading name among Threaded casing pipe manufacturers in Chhattisgarh. Based in Raipur, Chhattisgarh, India, since 2006, we have developed expertise in producing high-quality threaded casing pipes that meet the diverse needs of our clients. Our pipes are made from top-grade materials under rigorous standards, making them durable and reliable for applications such as oil and gas extraction and industrial uses. We understand that every project is unique. That’s why we offer a range of sizes and specifications to suit our clients' requirements. Our competitive pricing makes it easy for you to get the best quality at an affordable cost. Choose Polycarb Industries for your threaded casing pipe needs and experience the quality and service that have made us a trusted choice among threaded casing pipe manufacturers in Chhattisgarh.

Unmatched Value in Casing Pipes from Top Threaded Casing Pipes Manufacturers in Chhattisgarh

At Polycarb Industries, we are proud to offer great value with our threaded casing pipes, making us a trusted choice among threaded casing pipe manufacturers in Chhattisgarh. We know that quality and affordability are both important, so we ensure our products meet industry standards and are priced competitively. Our threaded casing pipes are built to handle various industrial needs, making them perfect for any project. We use high-quality materials and modern manufacturing techniques to make sure our pipes are durable and reliable. This dedication to quality allows us to provide a range of options to fit your needs without exceeding your budget. When you choose Polycarb Industries, you’re getting more than just pipes; you’re making a smart choice for quality and performance. Find the best value in casing pipes with your reliable threaded casing pipe manufacturers in Chhattisgarh.

Why Our Threaded Casing Pipes Stand Out – Features from Threaded Casing Pipes Manufacturers in Chhattisgarh

At Polycarb Industries, we take pride in being among the leading threaded casing pipes manufacturers in Chhattisgarh. Our threaded casing pipes are designed with features that ensure durability, reliability, and efficiency for various applications. Here’s why our products stand out:

Lightweight and easy to handle

Resistant to corrosion and rust

Smooth inner surface for better flow

Easy to install with simple tools

Non-toxic and safe for drinking water

Good insulation properties against heat

#MS GI Pipes and Conduit Pipes Manufacturers in Chhattisgarh#PVC Casing Pipes Manufacturers in Chhattisgarh#PVC SWR Pipe fitting Manufacturers in Chhattisgarh#Rigid PVC Pipes Manufacturers in Chhattisgarh#Threaded Casing Pipes Manufacturers in Chhattisgarh

0 notes

Text

DIY electrical conduit installation can be rewarding, allowing you to customize your home and save money. This guide will walk you through the process.

#Electrical Conduit#Conduit Installation#Electrical Conduit Installation#pvc conduit#Types of Electrical Conduit#pvc pipe#nec code#electrical pipe

0 notes

Text

Discovering the Best PVC Conduit Pipes for Your Needs

When it comes to reliable and durable construction materials, PVC Pipes & Fittings are a top choice for many applications. Known for their versatility and resilience, PVC conduit pipes are especially popular in electrical installations due to their excellent insulation properties and resistance to corrosion. These pipes provide a secure and long-lasting solution for protecting electrical wires and cables, ensuring both safety and functionality in various environments.

Best PVC Conduit Pipes Manufacturers are crucial in providing high-quality products that meet rigorous standards. AKG Group manufacturers invest in advanced technologies and stringent quality control processes to ensure that their pipes and fittings offer superior performance. From residential to industrial uses, high-grade PVC conduit pipes are essential for efficient electrical systems and reliable performance. The market is full of options, but selecting the right manufacturer can make all the difference in ensuring that you receive a product that meets your specific needs.

When searching for the best options, it's important to consider manufacturers that adhere to industry standards and provide a range of solutions tailored to various applications. We are top manufacturers not only offer durable products but also excellent customer support and after-sales service, making them a preferred choice for many.

For those looking for top-tier quality and reliability, consulting the Top ASTM Pipes & Fittings Manufacturers in India is highly recommended. AKG Group manufacturers are known for their adherence to the stringent ASTM standards, ensuring that their PVC pipes and fittings deliver exceptional durability and performance. By choosing products from us reputable sources, you can be confident in the quality and longevity of your PVC conduit pipes and fittings, ensuring that your electrical systems are both safe and efficient.

0 notes

Text

Electrical Conduit Pipes Manufacturers & Suppliers in India | Tecmak India

Tecmak India specializes in high-quality Conduit Pipe Manufacturers in India that cater to various industrial and residential needs. A conduit used for electrical wiring in buildings and other structures is called an electrical conduit. Metal, polymer, fiber, or burned clay can all be used to make electrical conduit. Flexible conduit is utilized in certain applications, but most conduit is stiff. Every product is guaranteed to satisfy strict quality requirements by Tecmak India, which is dedicated to excellence. In the industry, they are well-known for their creative solutions and customer-focused methodology.

0 notes