#Concrete Mixing Plant

Explore tagged Tumblr posts

Text

youtube

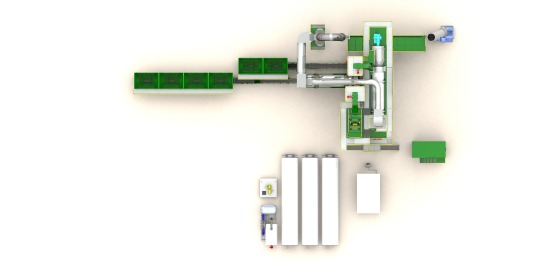

The mobile concrete batching plant with the horizontal cement silo shows significant advantages. The mobile batching plant is flexible and convenient, which can quickly transfer the construction site and adapt to the changing construction environment. The horizontal cement silo is designed without foundation, easy to install, saves space and cost, and has a low height, which is suitable for use in the plant. The combination of the two not only improves the construction efficiency, but also ensures a stable supply of materials. The large-capacity storage of the horizontal cement silo cooperates with the efficient production of the mixing plant to meet the needs of large-scale projects. The intelligent control system makes the operation simple and safe. In short, this combination has the advantages of high efficiency, flexibility, stability and intelligence, and has become an ideal choice for modern building construction.

0 notes

Text

The HZS50 concrete mixing station is a small and medium-sized equipment that is very easy to maintain and operate. In addition, the high-quality raw materials and components used in the equipment also have good wear resistance and corrosion resistance, which is conducive to extending the service life of the equipment, reducing the maintenance costs of the enterprise, and bringing greater economic benefits to the project construction. The HZS50 concrete mixing station adopts an advanced automatic control system, which can realize fully automatic operation and greatly improve production efficiency. In addition, the equipment also has functions such as automatic weighing, automatic batching and automatic mixing, which greatly reduces the time and labor cost of manual operation to a certain extent.

0 notes

Text

Concrete Batching Plants and the Vital Role They Play in Infrastructure Development

Infrastructure development is the backbone of any thriving economy. It encompasses a broad spectrum of projects such as roads, bridges, airports, buildings, and more, all of which rely heavily on the production of high-quality concrete. Concrete batching plants, often overlooked in the grand scheme of infrastructure development, play a crucial role in ensuring that the foundation of these projects is strong and durable. In this blog, we will explore the significance of concrete batching plant and how they contribute to the success of infrastructure development.

What is a Concrete Batching Plant?

A concrete batching plant, also known as a concrete mixing plant or a concrete batching system, is a specialized facility designed to produce concrete by combining various ingredients such as cement, water, sand, aggregates, and additives in a precise and controlled manner. These ingredients are mixed in predetermined proportions to ensure the consistency and quality of the concrete produced. The resulting mixture is then transported to construction sites in concrete trucks and used in various applications like pouring foundations, constructing bridges, and erecting buildings.

The Role of Concrete Batching Plants in Infrastructure Development

Consistent and High-Quality Concrete Production: Concrete batching plants are designed to produce a consistent and uniform mix of concrete. This consistency is vital for infrastructure projects where the strength and durability of the concrete are of utmost importance. A dependable supply of high-quality concrete ensures that the constructed structures meet safety and longevity standards.

Efficient Resource Utilization: Concrete batching plants optimize the use of resources by carefully measuring and mixing the components of concrete. This leads to minimal waste, reduced material costs, and efficient energy usage. In an era where sustainability and resource conservation are critical, these plants contribute to more responsible construction practices.

Large-Scale Production Capability: Infrastructure projects often require vast quantities of concrete. Concrete batching plants have the capacity to produce large volumes of concrete in a relatively short time. This scalability is crucial for meeting the demands of massive infrastructure projects that can involve thousands of cubic meters of concrete.

Precision and Customization: Concrete batching plants are equipped with advanced control systems that allow for precision in mixing and customization of concrete to meet specific project requirements. Whether the project calls for high-strength concrete for bridges or flowable, self-compacting concrete for foundations, batching plants can tailor their output accordingly.

On-Site and On-Time Delivery: Concrete batching plants can be strategically located near construction sites to ensure on-time and just-in-time deliveries. This minimizes the need for long-distance transportation, reducing the risk of delays and ensuring a constant supply of concrete when and where it is needed.

Reduced Environmental Impact: Modern Best concrete batching plant are designed with environmental sustainability in mind. They incorporate dust collection systems, water recycling, and other eco-friendly features to minimize their impact on the environment, aligning with the global shift towards greener construction practices.

Conclusion

Concrete batching plant Manufacturer are the unsung heroes of infrastructure development. Their ability to produce consistent, high-quality concrete in large quantities, with customization options, and minimal waste, is indispensable for the success of construction projects. As we continue to invest in building resilient and sustainable infrastructure, the role of these plants becomes increasingly vital. By understanding and appreciating their significance, we can ensure that our infrastructure developments stand the test of time and contribute to the growth and prosperity of our communities.

#Tags:best Concrete batching plant#concrete batching plant#Concrete Batching Plant Manufacturer#concrete batching plants#concrete mixing plant#What is a Concrete Batching Plant#batching plant

0 notes

Text

What is Asphalt Recycling Plant?

The use of reclaimed asphalt, or recycling, has become a necessity. Governments increasingly want the reclaimed asphalt from old roads re-used in an effort to be more environmentally friendly. Recycled asphalt also can provide you with cost savings on several fronts.

To use this valuable secondary resource, ZOOMLINE offers the Asphalt Recycling Plants to help your recycling and cost-saving efforts. Regardless of the system you choose, modern ZOOMLINE plant technology will provide a quality recycling process and product.

Asphalt Recycling Plant | Hot & Cold RAP Recycling, RAPpro 100% Recycled Asphalt Hot Mix Plant, Recycled asphalt hot mix plant, RAPpro 100% Recycled Hot Mix Asphalt Production Plant.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#asphalt plant#concrete#heavy equipment#asphaltplant#construction#mobile asphalt drum mix plant#recycling asphalt plant#asphalt recycling plant#recycled asphalt plant#RAP Recycling#recycled asphalt hot mix plant#recycled hot mix asphalt production plant#asphalt production plant

3 notes

·

View notes

Text

crack resistant concrete dealer Lucknow | Awadh rmc

Need Crack Proof Cement?

Find top suppliers in Lucknow.

Get the best prices and compare quotes.

Ensure durable and long-lasting structures. Contact us today for expert assistance: +91 8400949595"

0 notes

Text

A Complete Guide to Mini Concrete Plant and Mini Portable Batching Plant

Complete guide to mini concrete plants and portable batching plants. Explore batch mix plant prices, concrete batch mix plant specs, and compact solutions for your construction needs.

0 notes

Text

Ready Mix Supplier: The Key to Efficient and Quality Construction

In the world of modern construction, efficiency, consistency, and quality are critical for success. Ready Mix Concrete (RMC) has emerged as a revolutionary solution, offering pre-mixed, high-quality concrete that saves time and ensures superior performance. Choosing the right ready mix supplier is crucial for achieving seamless construction results. At Kamdhenu Cement, we are proud to be a trusted supplier of Ready Mix Concrete, catering to diverse construction needs across India.

What Is Ready Mix Concrete?

Ready Mix Concrete is a pre-engineered mixture of cement, water, aggregates, and other additives, prepared in a controlled environment at a batching plant. Delivered to construction sites in specially designed transit mixers, RMC ready mix concrete ensures consistent quality and ready-to-use convenience.

Why a Trusted Ready Mix Supplier Matters

Consistent Quality A reputable supplier ensures uniformity in every batch, delivering RMC that meets strict quality standards.

Timely Delivery On-time delivery minimizes project delays, helping you adhere to construction schedules.

Customized Mixes Reliable suppliers offer tailored RMC solutions to meet specific construction requirements.

Technical Expertise The best suppliers provide expert advice on the appropriate mix design for your project.

Eco-Friendly Practices A good supplier emphasizes sustainable manufacturing processes, reducing environmental impact.

Why Kamdhenu Cement Is Your Ideal Ready Mix Supplier

1. Unmatched Quality Control

Kamdhenu Cement ensures every batch of Ready Mix Concrete undergoes stringent quality checks, providing strength, durability, and consistency.

2. Nationwide Reach

Our extensive logistics network ensures timely delivery to construction sites across India.

3. Tailored Solutions

We offer customized RMC mixes to suit a wide range of construction needs, from residential homes to large-scale infrastructure projects.

4. Technical Support

Our team of experts assists you in selecting the right RMC mix for your specific requirements, ensuring optimal results.

5. Sustainability Commitment

Kamdhenu Cement prioritizes eco-friendly production, utilizing sustainable practices to minimize environmental impact.

Applications of Ready Mix Concrete

Residential Construction

Foundations, walls, driveways, and floors.

Commercial Buildings

Office complexes, shopping malls, and high-rise structures.

Infrastructure Projects

Bridges, highways, dams, and airports.

Industrial Constructions

Factories, warehouses, and heavy-duty structures.

Benefits of Choosing Kamdhenu as Your Ready Mix Supplier

High-Performance Concrete Our RMC is designed to withstand heavy loads and extreme conditions, ensuring durable and long-lasting structures.

Reduced Construction Time Pre-mixed and ready to use, our RMC eliminates the need for on-site mixing, saving time and labor.

Cost-Effective Minimized material wastage and efficient use of resources reduce overall project costs.

Reliable Partner Kamdhenu Cement’s reputation for quality and trust makes us the preferred choice for builders and developers.

How to Choose the Best Ready Mix Supplier

Assess Quality Standards Ensure the supplier adheres to stringent quality control measures for consistent and reliable products.

Check Delivery Reliability Choose a supplier with a strong logistics network to guarantee timely delivery.

Look for Customization Options Opt for a supplier who can provide tailored RMC mixes based on your specific project needs.

Consider Sustainability Partner with a supplier that emphasizes environmentally responsible practices.

Evaluate Customer Support Ensure the supplier offers expert guidance and technical support throughout your project.

Why Builders Choose Kamdhenu Cement

Trusted Brand: Known for reliability, innovation, and excellence in the construction industry.

Comprehensive Solutions: Offering a wide range of cement products and Ready Mix Concrete.

Customer Satisfaction: Dedicated to exceeding customer expectations with premium products and services.

Conclusion

Choosing the right ready mix concrete plant is essential for ensuring the success of your construction project. With Kamdhenu Cement, you get more than just a product—you get a reliable partner committed to quality, innovation, and sustainability.

Trust Kamdhenu Cement to deliver superior Ready Mix Concrete tailored to your needs. Build with confidence, build with Kamdhenu Cement.

Frequently Asked Questions

Q: What makes Kamdhenu Cement a preferred Ready Mix Supplier? A: Kamdhenu Cement ensures premium quality, timely delivery, customized mixes, and eco-friendly practices, making it the trusted choice for builders and developers.

Q: Can Kamdhenu RMC be used for small-scale projects? A: Yes, our Ready Mix Concrete is suitable for projects of all sizes, from small homes to large-scale developments.

Q: How can I order Ready Mix Concrete from Kamdhenu Cement? A: Contact our team or visit our website to learn more about our RMC products and place your order.

#best cement#cement supplier#top cement#cement manufacturer#no 1 cement in india#best cement for house construction#ready mix concrete plant

0 notes

Text

Why batching plant support equipment is necessary for efficient production

Timeliness, accuracy and efficiency are critical in today’s construction industry. One sector that plays an important role in the availability of these products is concrete manufacturing, which relies heavily on pouring plants. These plants ensure the production of high quality concrete through the proper mixing of ingredients such as cement, aggregate and water. However, the success of this project is highly dependent on the Batching Plant Support Equipment. In this blog, we’ll explore why Batching Plant Support Equipment is important, how it increases productivity, and its role in ensuring production continuity.

Understanding Batching Plant Support Equipment

Batching plant support equipment includes auxiliary machinery and tools that make a concrete batching plant more efficient and effective. This includes cement storage, conveyor belts, loading containers, water level systems, and more. Together, these tools ensure efficiency, reduce working time and assure that the concrete produced meets the required standards

Why is batching plant support equipment necessary

1. Improve productivity

The use of batching plant support equipment such as conveyors and hoppers ensures efficient collection and transportation of raw materials such as cement, sand and aggregate. These tools automate a variety of processes, eliminating the need for manual intervention and speeding up production. With the proper concreting machinery, work can be done with ease, and large quantities of concrete can be produced in a short period of time.

2. Precision in mixing

Accurate quantification of concrete production is important. Batching machines ensure that the correct amount of material is used in each batch, resulting in a superior mix. Cement silos, water level systems and water mixing systems all help maintain accurate proportions, reduce errors and improve the overall strength and durability of concrete.

3. Regular Time and Maintenance Reduction

Having reliable batching plant support equipment allows the plant to experience minimal downtime. Equipment such as dust collectors, dust suppressors and water recycling keep the plant running smoothly, while reducing the need for frequent maintenance Not only does This save time but also reduces maintenance costs.

Key Types of Batching Plant Support Equipment

To better understand the importance of batching plant support equipment, it is important to look at the various types of equipment involved in the concrete batching process: ‘

Cement silos: These are used to store large quantities of cement, ensuring a constant supply during batching.

Conveyors: These are required for transporting aggregate, sand and cement between different parts of the plant.

Water level settings: These settings control the amount of water added to the mix, ensuring that the concrete is not too dry or too wet.

Aggregate bins: These store aggregates of different sizes before they are used in the batching process.

Dust collectors: These help control the dust generated during the concreting process, creating a cleaner and safer working environment.

The Role of Support Equipment in Dry Mix Batching Plants

Dry mix batching plants are very popular in the construction industry because of their efficiency and flexibility. These plants mix dry materials such as cement, aggregate and sand before being transported where water is added to the mix.

1. Efficient use of resources

Equipment such as conveyors and cement silos are essential for efficient material handling in dry mix batching plants. Without the proper sorting equipment, delivery would not be efficient, leading to delays and reduced productivity.

2. Equal mixing

Although water is added later at the construction site, the exact mixing of dry materials is important. Batching plant support equipment ensures consistency of each batch of dry mix, creating uniformity in the final concrete product.

Why batching of plant support equipment is important in cement mix plants

Batching machines play a key role in ensuring uniform and efficient mixing of cement and other raw materials at cement mixing plants Equipment such as cement silos and dosing systems enable plants to operate consistently, reducing risk in rare materials, in each batch If the correct is used the ratio is ensured

1. Storage and quantification

Cement silos provide a reliable cement storage solution, increasing purchasing power and reducing the need for frequent refills. At the same time, the chemical feed ensures that the correct amount of cement is added to each batch, improving the quality of the final product.

2. Environmental reduction

Utilizing dust collectors and other environmentally friendly technologies, the batching plant’s assistive technology helps reduce carbon emissions and dust pollution, producing cement production is constant

Benefits of Batching Plant Support Equipment

Increased efficiency: Machinery such as conveyors and dosing systems allow plants to work faster, increasing the amount of concrete produced in a day

Cost efficiencies: Reduced waste, improved accuracy, and reduced downtime all contribute to significant cost savings over the long term.

Advanced Quality Control: Batching plant support equipment of accurate sizes and regular inventory controls ensure that each batch processed meets industry standards.

Sustainability: Tools such as dust collection and water recycling reduce the environmental impact of concrete production by linking it to construction practices that it is on the green hole

conclusion

Batching plant support equipment plays an important role in optimizing the performance of concrete batching plant. By ensuring quality control, accurate size and minimal downtime, these machines increase the overall concrete production and quality especially dry mix batching plants and cement mixing plants stand more supportive equipment to make it more efficient and sustainable.

As the construction industry moves towards greener and more efficient practices, investing in reliable batching plant support equipment is the key to maintaining a competitive market lead At ReadyMix Construction Machinery Pvt. Ltd., we provide state-of-the-art solutions that help you optimize your batching plant while maintaining the highest standards.

Frequently Asked Questions (FAQ)

What is batching plant support equipment?

Batching Plant Support Equipment refers to machinery and auxiliary equipment that assist in concrete batching operations, including cement silos, conveyors, dosing systems and dust collectors.

How do batching machines improve productivity?

The batching machines deliver, store and quantify products effectively, ensuring consistent quality and reducing production time.

Why is Animal Machinery Important for Dry Mix Batching Plants?

Auxiliary machinery in dry mix batching plants ensures proper handling and mixing of dry materials, improves uniformity and reduces waste.

What role do batching machines play in cement mixing facilities?

Batching equipment in cement mix plants ensures accuracy, material control and continuity, improves efficiency and reduces downtime.

#Dry Mix Batching Plant#Batching Plant Support Equipment#Concrete Batching Plant#Dry Mix Plant#Batching Equipment#Cement Mixing Plant#Construction Batching Solutions

0 notes

Text

youtube

As a new type of silo that adapts to the modern environmental protection situation, the horizontal cement silo has significant advantages, especially after the installation of tires, which increases its flexibility and convenience. First of all, the vertical height of the horizontal cement silo is low, and the cylinder body has more legs, which makes it unnecessary to install complex foundation engineering, which greatly saves time and cost. At the same time, its low height also makes the horizontal cement silo particularly suitable for use in environments with limited space such as in the plant. Secondly, after the installation of tires, the mobility of the horizontal cement silo has been significantly improved. This allows users to easily move the cement silo to different construction sites or locations according to construction needs, which greatly improves the construction efficiency. In addition, the horizontal cement silo also has the advantages of large storage capacity, good sealing, convenient operation and high safety. Its sealing design can effectively prevent material leakage and external dust ingress, and ensure the quality of bulk materials such as cement. At the same time, the equipped material level system, safety valve, dust removal device, etc. also make the operation simpler and safer.

0 notes

Text

Wet Concrete Mixing Plant

Wet concrete mixing plant is a kind of equipment specialized in producing wet mortar and concrete, which is widely used in the fields of construction, bridge, tunnel and water conservancy project. Its unique mixing form, efficient equipment composition, diversified model selection and significant advantages make it an indispensable and important equipment in modern building construction.

Wet concrete mixing plant adopts advanced mixing technology to ensure that the concrete remains wet during the mixing process, thus improving the working performance and construction quality of concrete. By precisely controlling the proportion and mixing time of water, cement, sand, stone and additives, the wet mixing form can make the concrete reach the best working condition to meet various construction requirements. Wet mix concrete plant mainly consists of mixing machine, material weighing system, material conveying system, water supply system, electric control system and auxiliary equipment. The mixing machine is the core equipment, usually adopting double horizontal shaft forced concrete mixer, which has the advantages of strong mixing capacity, low energy consumption and long service life. The material weighing system ensures the accurate measurement of various raw materials, and the material conveying system is responsible for accurately and efficiently conveying the raw materials to the mixing machine. The water supply system provides the water resources needed for production, and the electrical control system is responsible for the automatic control of the whole concrete mixing plant.

Wet concrete mixing plant has various outputs and models to meet the needs of different scale projects. Common models include HZS25, HZS35, HZS50, HZS60, HZS75, HZS90, HZS120, etc. Different models of wet mix concrete batching plants have different production capacities, ranging from tens of cubic meters to hundreds of cubic meters per hour. For example, the annual production capacity of HZS120 concete mixing plant is about 250,000 cubic meters, which is suitable for large-scale engineering projects.

Wet concrete mixing plant has significant advantages: - Stable quality: it adopts full computer control, accurate measurement and advanced production process to ensure stable and reliable quality of concrete. - High production efficiency: the mixing host has superior performance, short mixing time and high production efficiency, which can greatly shorten the construction period. - Environmental protection and energy saving: reasonable equipment design, low noise, low dust, in line with environmental requirements; at the same time, low energy consumption, low operating costs. - Strong adaptability: the concrete proportion can be adjusted according to the needs of the project to meet different construction requirements; at the same time, the equipment is easy to maintain and convenient maintenance.

Wet concrete mixing plant has a wide range of applications in the fields of construction, bridges, tunnels and water conservancy projects. In the field of construction, it is mainly used to produce various types of concrete, such as ordinary concrete, cement mortar, etc. In the construction of bridges and tunnels, wet concrete mixing plant can ensure the quality of concrete and improve the safety and service life of bridges and tunnels; in water conservancy projects, such as reservoirs, embankments and other constructions, wet-mix concrete batching plant also plays an important role.

In summary, wet concrete mixing plant has become an indispensable equipment in modern building construction with its unique mixing form, efficient equipment composition, diversified model selection and significant advantages. With the continuous development of the construction industry, the application prospect of wet mix concrete plant will be more broad.

This resource is from http://www.batchingplantng.com/haomei-news/wet-concrete-mixing-plant.html Should you be interested in, please contact us at: Haomei Machinery Equipment Co.,ltd Whatsapp/Wechat: 0086 181 3788 9531 Email: [email protected]

0 notes

Text

Deck Barge-mounted 1000T

1000T deck barge (Deck Barge-mounted 1000T) usually refers to a flat-bottomed barge with a rated load capacity of 1000 tons, which is widely used in marine transportation, marine engineering, heavy object handling and other fields. Its design features mainly include the following aspects:

1. Load capacity

The maximum load capacity of 1000T deck barge is 1000 tons, which is suitable for the transportation of bulk cargo, construction materials, equipment, etc. It can be effectively transported in shallow waters and offshore environments.

2. Flat bottom design

The barge adopts a flat bottom design, which is suitable for navigation in shallow waters, is not easy to run aground, and is suitable for operation in ports, rivers and other shallow waters. The flat bottom structure also enhances the stability and load capacity of the barge.

3. Strong structure

Deck barges are usually made of steel or other corrosion-resistant materials, have high durability, and can withstand large load pressure. The hull structure is generally strong to adapt to the working environment under complex sea conditions.

We FOCUS MECHINERY stand for new product ideas and courageous vision of the future, we stand for our never-stopping dedication and devotion to your construction equipment solutions, we focus on your project needs.If you're looking for a particular supplier or specific configurations, I can provide more details or recommendations!

Whatsapp:+86 13676986531

#1000T deck barge#1500T deck barge#concrete contractors#concrete mixer plant#concrete plant customization#https://www.concrete-mixing-plant.com/#concrete bag breaker

0 notes

Text

Unveiling the Concrete Mixing Plant Prices in India: A Comprehensive Guide

Are you planning to invest in a concrete mixing plant in India? Understanding the prices and factors that influence them is essential for making an informed decision. In this comprehensive guide, we will delve into the various aspects of concrete mixing plant prices in India, providing you with valuable insights to aid your investment journey. As a renowned manufacturer, Nilkanth Engineering Works offers top-quality concrete mixing plants, ensuring optimal performance and value for your money.

Plant Capacity: The capacity of a concrete mixing plant plays a significant role in determining its price. Plants with higher production capacities generally have higher costs. Consider your project requirements and the expected concrete output to choose the appropriate capacity that aligns with your needs and budget.

Plant Type: Concrete mixing plants come in various types, including stationary, mobile, compact, and reversible drum mixer plants. Each type has its unique features and advantages. The type of plant you select will impact the pricing. Assess your project specifications and site conditions to determine the most suitable plant type for your requirements.

Plant Configuration: The configuration and components of a concrete mixing plant can affect its price. Factors such as the number and size of aggregate bins, cement storage silos, water storage and heating systems, and control systems can influence the overall cost. Customizing the plant configuration to meet your specific needs may incur additional expenses.

Quality and Technology: The quality and technology employed in the construction of a concrete mixing plant have an impact on its price. Higher-quality materials, advanced equipment, and innovative features may contribute to a slightly higher cost upfront. However, investing in a plant that offers durability, reliability, and advanced automation can yield long-term benefits and cost savings.

After-Sales Support: Consider the after-sales support provided by the manufacturer. Nilkanth Engineering Works offers comprehensive after-sales services, including maintenance, spare parts availability, and technical assistance. Such support ensures smooth plant operation and minimizes downtime, enhancing the value of your investment.

Installation and Transportation: The cost of installing and transporting the concrete mixing plant should be factored into your budget. Depending on the size and complexity of the plant, installation and transportation expenses may vary. Discuss these aspects with Nilkanth Engineering Works to get a clear understanding of the associated costs.

Regulatory Compliance: Complying with environmental and safety regulations is crucial. Ensure that the concrete mixing plant meets the necessary standards and requirements set by regulatory bodies. Adhering to these regulations may involve additional costs, but it is essential for sustainable and responsible operation.

Nilkanth Engineering Works understands the diverse needs of customers and offers competitive pricing based on individual project requirements. By collaborating with Nilkanth Engineering Works, you can obtain accurate and up-to-date information on concrete mixing plant prices, customized solutions, and expert guidance to make an informed investment decision.

Investing in a high-quality concrete mixing plant is a crucial step toward achieving efficient and cost-effective concrete production. It ensures consistent supply, improved project timelines, and enhanced overall productivity. With the right knowledge and information, you can select the ideal concrete mixing plant from Nilkanth Engineering Works that perfectly matches your project requirements and budget.

In conclusion, understanding the concrete mixing plant prices in India involves evaluating plant capacity, type, configuration, quality, after-sales support, installation and transportation costs, and regulatory compliance. By considering these factors and partnering with Nilkanth Engineering Works, you can make a well-informed investment and embark on successful concrete production ventures in India.

#concrete mixing plant price in india#Best concrete mixing plant price in india#\concrete mixing plant price#concrete mixing plant#concrete mixing plant india#concrete mixing plant in india#Nilkanth Engineering Works

0 notes

Text

What's the Functions of Asphalt Plant Dryer Drum?

The asphalt plant dryer drum is to preheat the cold aggregate, dry and heat it up to ensure that discharge temperature meets the requirements.

Drying drum is one of the core components of asphalt mixing plant. The performance of drying drum directly determine the production of a complete set of asphalt mixing plant.

The Advantages of Drying Drum: Long service life Energy saving Low emission Low fuel cost

ZOOMLINE provide stationary and mobile type drying drums for choice.

#dryer drum#drying drum#asphalt plant dryer#asphalt dryer drum#asphalt drum mix plant#asphalt mixing plant#road construction#asphalt plant#construction#asphaltplant#mobile asphalt drum mix plant#heavy equipment#concrete#bitumen#dryer#dryer drum mix

2 notes

·

View notes

Text

rmc bagcrete lucknow | Awadh rmc

Looking for RMC Bagcrete in Lucknow?

Find top manufacturers and suppliers.

Get the best prices and compare quotes.

Ensure high-quality Bagcrete for your project. Contact us today for expert assistance: +91 8400949595"

0 notes

Text

Advantages of On-Site Concrete Ready Mix Productions

Consider a construction site where every aspect operates with precision and efficiency. This is made possible with an on-site concrete ready mix plant, which revolutionizes how concrete contractors and projects are managed. By setting up a concrete ready mix plant directly at the job site, teams can produce large volumes of concrete exactly when needed. This approach ensures top-quality results and simplifies the scheduling of pours, leading to better management of tight deadlines and resources. The outcome is a reliable, smooth process for large-scale projects.

Optimized Workflow:

Integrating a concrete ready mix plant directly on-site significantly enhances the management of construction projects. With the concrete produced as needed, contractors can avoid the delays typically caused by transportation and supply issues, as the readymix company ensures a steady supply of high-quality concrete. This method helps to reduce waste and keeps the project on track.

Additionally, having a concrete ready mix plant on-site provides valuable flexibility. It allows for quick adjustments to concrete mix designs and quantities, which is crucial when project needs change or unforeseen requirements come up.

Cost and Time Savings

Having a concrete ready mix plant on-site can also lead to considerable cost reductions. By removing the need for transportation and cutting down on delays, overall project costs are lowered. Producing concrete as needed helps avoid the expenses linked with excess material and waste disposal.

This approach speeds up project completion. Immediate access to concrete and the ability to adjust mix designs quickly lead to shorter construction timelines. This not only speeds up the delivery of projects but also ensures better use of resources and workforce, making project management more streamlined.

Improved Project Control

Having a concrete ready mix plant on-site improves project management by allowing the project manager to closely monitor production, ensuring it meets precise specifications and reducing errors. This level of control ensures that outcomes align with project needs. Immediate access to concrete and the ability to make on-the-spot adjustments improve communication and resolve issues quickly, leading to better results in concrete contracting and a more efficient construction process.

The Ultimate Benefit

Opting for on-site concrete ready-mix production brings many advantages. It’s a cost-friendly choice that also saves valuable time, ensuring your project runs smoothly and avoids unnecessary delays.

For trusted on-site concrete services, Martin Concrete is a preferred choice.

Visit https://www.martinconcrete.com/

Original Source: https://bit.ly/3AgY4xQ

0 notes

Text

Ready Mix Supplier: Why Kamdhenu Cement Is the Best Choice

When it comes to modern construction, Ready Mix Concrete (RMC) has become an essential material for ensuring efficiency, quality, and cost-effectiveness. Whether you’re working on a residential project, a commercial building, or infrastructure development, selecting the right ready mix supplier can significantly impact the success of your construction.

Kamdhenu Cement, a leading name in the cement industry, is renowned for its premium-grade products and dependable RMC solutions. Here’s why Kamdhenu Cement is the trusted choice for builders and contractors across India.

What to Look for in a Ready Mix Supplier

Choosing the right cement supplier is crucial to meet project deadlines and maintain construction quality. Key factors to consider include:

1. Quality Assurance

A reliable supplier ensures consistent quality in the concrete mix. Kamdhenu Cement’s RMC is lab-tested and adheres to stringent quality control standards, ensuring exceptional performance.

2. Timely Delivery

Timely delivery is critical in construction to avoid project delays. Kamdhenu Cement’s efficient logistics network ensures that RMC reaches your site on schedule.

3. Customization Options

Every project has unique requirements. Kamdhenu Cement offers customized RMC solutions tailored to meet the specific needs of your construction, whether it’s for strength, setting time, or workability.

4. Wide Coverage

A supplier with a broad service network can cater to projects across different locations. Kamdhenu Cement operates nationwide, ensuring seamless supply to your construction site.

5. Reputation and Experience

A trusted supplier with a proven track record is a safer choice. Kamdhenu Cement’s legacy of trust, durability, and innovation makes it a preferred name in the industry.

Why Kamdhenu Cement Is the Ideal Ready Mix Supplier

1. Superior Product Quality

Kamdhenu Cement’s RMC is made using high-grade cement, aggregates, and additives to deliver excellent compressive strength and durability. Every batch is tested for consistency and performance.

2. Eco-Friendly Manufacturing

Sustainability is at the core of Kamdhenu Cement’s operations. By adopting environmentally friendly manufacturing practices, we ensure minimal ecological impact while maintaining product excellence.

3. Versatile Applications

Our RMC is suitable for a wide range of construction projects, including:

Residential buildings: Foundations, walls, and roofs.

Commercial complexes: High-rise structures and office spaces.

Infrastructure: Roads, bridges, airports, and dams.

Industrial projects: Warehouses and factories.

4. Expert Support

Kamdhenu Cement provides expert technical support to help you select the right RMC mix and ensure proper usage for your project.

5. Competitive Pricing

Kamdhenu Cement offers premium-quality RMC Concrete at competitive rates, ensuring cost-effectiveness without compromising on quality.

Advantages of Using Kamdhenu Cement’s Ready Mix Concrete

Time-Saving: Pre-mixed and ready to use, reducing on-site mixing time.

Reduced Wastage: Precise quantities minimize material wastage.

Enhanced Workability: Superior flow properties make it easy to work with.

Consistent Quality: Manufactured in controlled environments for uniformity.

How Kamdhenu Cement Stands Out Among Ready Mix Suppliers

1. Nationwide Network

With a robust distribution network, Kamdhenu Cement ensures seamless delivery to construction sites across India.

2. Tailored Solutions

From standard RMC mixes to custom blends for specific applications, Kamdhenu Cement caters to all your project needs.

3. Proven Expertise

Backed by years of industry experience and a commitment to innovation, Kamdhenu Cement is a reliable partner for all construction requirements.

Conclusion

When searching for a dependable ready mix supplier, Kamdhenu Cement offers the perfect blend of quality, reliability, and innovation. With premium-grade RMC, timely delivery, and expert support, we ensure your construction projects are completed efficiently and effectively.

Build with confidence and trust Kamdhenu Cement—India’s leading name in cement and Ready Mix Concrete. Contact us today to learn more about our RMC solutions and how we can support your next project.

#best cement#cement supplier#top cement#cement manufacturer#cement dump#no 1 cement in india#ready mix concrete plant#best cement for house construction#ppc cement#cement#Ready Mix Concrete#ready mix supplier#RMC

0 notes