#Compressed Air Treatment Equipment Market by growth

Explore tagged Tumblr posts

Link

0 notes

Text

The Oxygen Therapy Equipment market is projected to grow from USD 3.59 billion in 2023 to USD 5.19 billion by 2032, at a compound annual growth rate (CAGR) of 7.46%.The global Oxygen Therapy Equipment Market has seen significant growth in recent years, driven by the increasing prevalence of respiratory disorders, advancements in technology, and rising awareness about the benefits of oxygen therapy. Oxygen therapy is a critical component in the treatment of various respiratory diseases, including chronic obstructive pulmonary disease (COPD), asthma, pneumonia, and COVID-19. This article delves into the key factors influencing the market, the types of equipment available, and the future outlook.

Browse the full report at https://www.credenceresearch.com/report/oxygen-therapy-equipment-market

Market Drivers

1. Rising Prevalence of Respiratory Diseases: Respiratory diseases are a major public health concern worldwide. According to the World Health Organization (WHO), COPD is the third leading cause of death globally. The increasing incidence of these diseases has led to a surge in demand for oxygen therapy equipment. Additionally, the COVID-19 pandemic highlighted the importance of oxygen therapy in managing acute respiratory distress, further propelling market growth.

2. Technological Advancements: The oxygen therapy equipment market has benefited from significant technological advancements. Modern devices are now more efficient, portable, and user-friendly, making oxygen therapy more accessible to patients. Innovations such as oxygen concentrators, which can provide a continuous supply of oxygen without the need for refilling, have revolutionized the market. Moreover, the integration of smart technology, such as remote monitoring and mobile apps, has enhanced patient compliance and treatment outcomes.

3. Aging Population: The global aging population is another key driver of the oxygen therapy equipment market. Older adults are more susceptible to respiratory conditions, and as life expectancy increases, the demand for oxygen therapy is expected to rise. This demographic shift is particularly pronounced in developed countries, where the elderly population is growing rapidly.

4. Rising Awareness and Home Healthcare: There is a growing awareness of the benefits of oxygen therapy among both patients and healthcare providers. This, coupled with the trend towards home healthcare, has increased the demand for home-use oxygen therapy equipment. Patients prefer the convenience of receiving treatment in the comfort of their homes, which has driven the adoption of portable oxygen concentrators and other home-use devices.

Types of Oxygen Therapy Equipment

The oxygen therapy equipment market is broadly categorized into three main types: oxygen concentrators, compressed gas systems, and liquid oxygen systems.

1. Oxygen Concentrators: Oxygen concentrators are devices that filter and concentrate oxygen from ambient air, providing a continuous supply to the patient. They are available in stationary and portable models. Portable oxygen concentrators are particularly popular due to their convenience and mobility, allowing patients to maintain their lifestyle while receiving treatment.

2. Compressed Gas Systems: These systems consist of oxygen cylinders filled with compressed oxygen gas. They are commonly used in hospitals and healthcare facilities, but their portability and limited supply make them less suitable for home use.

3. Liquid Oxygen Systems: Liquid oxygen systems store oxygen in a liquid state, providing a higher oxygen concentration than gas systems. They are used for patients who require high-flow oxygen. However, they are less commonly used due to their complexity and the need for regular refilling.

Market Challenges

Despite the promising growth, the oxygen therapy equipment market faces several challenges. One of the primary challenges is the high cost of advanced oxygen therapy devices, which can be prohibitive for some patients, especially in developing regions. Additionally, the need for regular maintenance and the complexity of some devices can be a barrier to widespread adoption.

Another challenge is the lack of adequate healthcare infrastructure in certain regions, which limits access to oxygen therapy. In rural and remote areas, the availability of oxygen therapy equipment is often limited, impacting patient outcomes.

Future Outlook

The future of the oxygen therapy equipment market looks promising, with continued growth expected in the coming years. The ongoing development of new technologies and the increasing focus on home healthcare are likely to drive market expansion. Additionally, efforts to improve healthcare infrastructure and increase access to oxygen therapy in developing regions will further support market growth.

The market is also expected to benefit from the growing emphasis on personalized medicine, with devices being tailored to meet the specific needs of individual patients. Furthermore, the integration of artificial intelligence and machine learning in oxygen therapy devices could enhance patient monitoring and treatment efficacy.

Key player:

Philips Healthcare

Linde Healthcare

Chart Industries, Inc.

Invacare Corporation

Becton, Dickinson and Company

Smiths Medical

Essex Industries, Inc.

HERSILL, S.L.

Teleflex Incorporated

Fisher & Paykel Healthcare Corporation Limited

Taiyo Nippon Sanso Corporation, Inogen, Inc.

Heinen + Löwenstein GmbH & Co. KG

DeVilbiss Healthcare

Weinmann Emergency Medical Technology GmbH + Co. KG

Messer Medical Austria GmbH

TECNO-GAZ S.p.A, HUM – Gesellschaft für Homecare und Medizintechnik mbH

medicap homecare GmbH

GCE Holding AB

Drägerwerk AG & Co. KGaA

Segments:

By Product:

Oxygen Source Equipment

Oxygen Delivery Devices

By Portability:

Stationary

Portable

By Application:

COPD

Asthma

Cystic Fibrosis

Pneumonia

Others

By End User:

Hospitals

Home Care

Ambulatory Surgical Centers

Physician Offices

Others

By Region:

North America

US

Canada

Mexico

Europe

Germany

France

UK

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/oxygen-therapy-equipment-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

From the Sky to the Field: How Drones are Transforming Farming Practices

"Drone technology is revolutionizing agriculture by providing farmers with real-time data and imagery, enabling them to make informed decisions about crop management, irrigation, and pest control. This level of precision helps to optimize yields and reduce resource use, ultimately leading to more sustainable farming practices."

Henry Gordon-Smith, CEO of Agritecture, on the use of drones in agriculture:

Introduction

Drones have revolutionized various industries, and agriculture is no exception. Drone farming represents the cutting edge of agricultural technology, promising efficiency, precision, and sustainability. The agricultural drone market is expected to grow from $1.2 billion in 2019 to $4.8 billion by 2024.

From scouting to security, drones are becoming common on both large and small farms. In many areas, drone use is already essential for large-scale precision farming operations. Data collected by drones help farmers optimize planting and treatments, potentially increasing yields by up to 5%. This blog explores the benefits, applications, challenges, and future prospects of drone farming, highlighting its transformative impact on modern agriculture.

What is Drone Farming?

Definition: Drone farming, or UAV (Unmanned Aerial Vehicle) farming, involves the use of drones to perform agricultural tasks such as monitoring crops, spraying pesticides, and analyzing soil.

Historical Context: Initially used for military and recreational purposes, drones have found significant applications in agriculture over the past decade, driven by advancements in technology and the need for precision farming.

Benefits of Drone Farming

Increased Efficiency: Drones can cover large fields quickly, performing tasks like spraying and monitoring in a fraction of the time it takes using traditional methods.

Precision Agriculture: By using sensors and GPS technology, drones can apply fertilizers and pesticides with pinpoint accuracy, reducing waste and environmental impact .

Cost Reduction: Although the initial investment in drone technology can be high, the long-term savings from reduced labour and input costs can be substantial.

Environmental Impact: Drones help reduce the overuse of chemicals and water, contributing to more sustainable farming practices .

Applications of Drones in Agriculture

Crop Monitoring: Drones equipped with multispectral and thermal sensors can monitor crop health, detect disease, and assess plant growth .

Soil and Field Analysis: Before planting, drones can create detailed 3D maps to analyze soil health, moisture levels, and nutrient distribution, aiding in better planning and resource management .

Planting: Some drones can plant seeds by shooting them into the soil with compressed air, which is especially useful in difficult-to-reach or hazardous areas .

Spraying: Drones can spray pesticides and fertilizers more evenly and precisely than traditional methods, reducing the amount of chemicals needed and minimizing human exposure to harmful substances .

Irrigation Management: By identifying areas of the field that are too dry or too wet, drones help farmers optimize irrigation and conserve water .

Sensor Technologies in Agricultural Drones

Agricultural drones are equipped with advanced sensor technologies that revolutionize farming practices. These sensors provide detailed insights into crop health, soil conditions, and more. Here are some key sensor technologies used in agricultural drones:

RGB Cameras: Capture high-resolution images for detailed crop analysis.

Multispectral Cameras: Is used to detect Nutrient deficiencies and early signs of disease.

Thermal Cameras:

Detects heat to identify plant stress and pests.

LiDAR: Create 3D terrain maps for topographical analysis.

GPS: Enables autonomous flight, accurate mapping, and issue identification.

Real-World ExamplesCase Studies:

Case Study: Enhancing Agricultural Efficiency with Krishi

Background

Modern agriculture increasingly relies on technological advancements to improve productivity and sustainability. One such innovation is the use of drones for various farming tasks, including crop management and irrigation.In this case study we will explore the impact of Krishi, a high-efficiency agricultural drone, on a medium-sized farm.

Challenge

Farmers often face the challenge of managing large areas of crops with limited resources and time. Traditional methods of spraying and monitoring can be labour-intensive and time-consuming.

Solution

The introduction of Krishi, an advanced agricultural drone, aimed to address these challenges by offering high efficiency and outstanding capacity.

Implementation

Krishi was deployed on a 50-acre farm to assist with crop management and irrigation tasks. The drone's capabilities were tested over a growing season, focusing on its efficiency and capacity.

Krishi was designed for maximum efficiency, covering 2-3 acres in a single flight. This exceptional capability saved considerable time and improved the overall effectiveness of crop management and irrigation systems. For instance, tasks that would typically take several hours were completed in just a fraction of the time, allowing for more precise and timely interventions.

Krishi's substantial 10-litre capacity enabled extended operation without frequent refills. This feature allowed the drone to cover large areas before requiring additional inputs, significantly enhancing convenience for the farmers. During peak spraying season, the drone managed extensive fields with fewer interruptions, ensuring consistent application of fertilizers and pesticides.

Results

The deployment of Krishi resulted in notable improvements in farm operations:

Increased Efficiency: The time required for crop management tasks was reduced by 60%, allowing farmers to allocate more time to other critical activities.

Higher Yields: The precision and timeliness of interventions led to a 15% increase in crop yields.

Cost Savings: Reduced labour and operational costs due to the drone's efficiency and capacity contributed to overall savings.

Krishi's high efficiency and outstanding capacity demonstrated significant benefits in enhancing agricultural productivity. This case study highlights the potential of advanced agricultural drones to transform farming practices, making them more efficient, cost-effective, and sustainable.

InJapan, drones are used extensively for rice cultivation, where they spray pesticides and monitor crop health . In the United States, large agricultural firms use drones for precision agriculture to improve crop yields and reduce costs .

Innovative Companies:

Companies like DJI, drone ,PrecisionHawk, and AgEagle are at the forefront of developing drone technology for agriculture, offering solutions that range from crop monitoring to automated spraying systems.

Challenges and Limitations

Regulatory Issues: The use of drones in agriculture is subject to strict regulations regarding airspace, privacy, and safety, which can vary significantly between countries .

Technical Limitations: Drones have limited battery life and may face difficulties operating in adverse weather conditions. The complexity of managing and analyzing the vast amounts of data they collect is another challenge .

Cost and Accessibility: The high initial cost of purchasing drones and the need for specialized training to operate them can be barriers for small-scale farmers.

Future Prospects

Technological Advancements: Future advancements in drone technology, such as improved battery life, AI integration, and better sensors, will likely enhance their capabilities and reduce costs .

Global Adoption: As drone technology becomes more affordable and accessible, its adoption is expected to grow globally, potentially transforming agricultural practices and improving food security.

Conclusion

Drone farming offers numerous benefits, from increased efficiency and precision to cost savings and environmental sustainability.The adoption of drone technology in the agriculture sector has the potential to revolutionize the way farmers manage their crops and improve yields. While challenges such as concerns about job displacement and a lack of knowledge and training persist, there are ongoing initiatives to promote the use of this technology and provide support to farmers looking to implement it.Despite challenges, its future looks promising with ongoing technological advancements

Final Thoughts: Embracing drone technology can significantly enhance agricultural productivity and sustainability, making it a vital tool for the future of farming.

ResourcesLinks:

PrecisionHawk: Drone Solutions for Agriculture

DJI Agriculture: Drones for Farming

Key Sessions at AgriNext Awards Conference & Expo

The AgriNext Awards Conference & Expo is not just a platform for showcasing innovations but also a hub for insightful sessions on cutting-edge agricultural technologies. One such noteworthy session is:

Standalone Session 2: 'Drones and Robotics in Precision Agriculture'

Date: 14 November 2024

Time: 12:15 PM - 12:45 PM

Venue: Crowne Plaza Dubai - Festival City

This session will delve into the latest advancements in drone and robotics technology, demonstrating their applications in precision agriculture. It’s a must-attend for anyone interested in understanding the future of farming technology.

0 notes

Text

Polypropylene Film for Capacitors, The Top 18 Largest Companies in World Ranked by Revenue in 2023 (2023)

Polypropylene Film for Capacitors Market Summary

Polypropylene film is the core material of the capacitor, which is made of polypropylene resin by casting, blow molding or biaxial stretching. Polypropylene film has good physical stability, mechanical strength, air tightness, high transparency and gloss, and is tough and wear-resistant. It is currently the most widely used capacitor film.

Polypropylene Film Production Process:

Thick film production: resin is melted and extruded at 170-210 ° C, and flows out from the circular rotating head through the filter to the inner cooling jacket, and is cooled to obtain a thick tube film.

Vertical and horizontal stretching: the tube film is preheated to the stretching temperature by infrared rays, and under the action of compressed air and clamping wheels with different speeds before and after, the tube film is stretched in both vertical and horizontal directions at the same time.

Trimming and winding: After cooling, the cylinder is divided into two layers of membranes, and then rewound after heat treatment.

According to the new market research report "Global Polypropylene Film for Capacitors Market Report 2024-2030", published by QYResearch, the global Polypropylene Film for Capacitors market size is projected to grow from USD 2026 million in 2023 to USD 3478 million by 2030, at a CAGR of 8.6% during the forecast period.

Figure. Global Polypropylene Film for Capacitors Market Size (US$ Million), 2019-2030

Figure. Global Polypropylene Film for Capacitors Top 18 Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

According to QYResearch Top Players Research Center, the global key manufacturers of Polypropylene Film for Capacitors include Toray Industries, Hebei Haiwei Group, Jindal Films, Zhejiang Great Southeast, Quanzhou Jiadeli Electronic, Anhui Tongfeng Electronics, Hubei Longchen Technical, Oji F-Tex, Aerospace CH UAV, Foshan Plastics Group, etc. In 2023, the global top 10 players had a share approximately 79.0% in terms of revenue.

Figure. Polypropylene Film for Capacitors, Global Market Size, Split by Product Segment

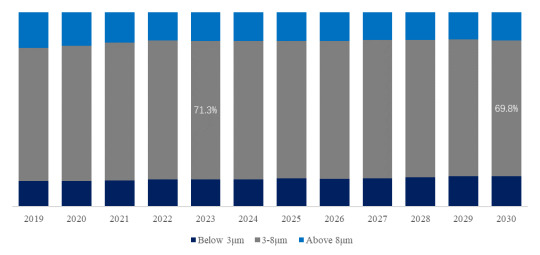

In terms of product type, 3-8μm Film is the largest segment, hold a share of 71%. Films in this range are mainly used in PV & Wind Power, home appliances, medical equipment, industrial equipment, LED lights and other consumer electronics. ≤5μm is also available for NEV.

Figure. Polypropylene Film for Capacitors, Global Market Size, Split by Application Segment

In terms of product application, Automotive is the largest application, hold a share of 38% in 2023. The main applications of film capacitors in the field of new energy vehicles are: new energy vehicle electric drives, OBCs and charging piles. The drive inverter is one of the most important components in the electric vehicle power system. Power modules, sensors, and film capacitors are the most critical equipment. The growth of new energy vehicles will drive up the demand for film capacitors/raw material films.

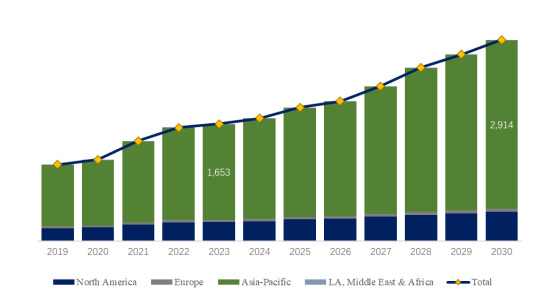

Figure. Polypropylene Film for Capacitors, Global Market Size, Split by Region

Market Drivers:

1. Support from national policies: For example, in China, Benefit from China’s emphasis on new energy, the market has grown rapidly. And considering the long-term impact of "peak carbon dioxide emissions" and "carbon neutrality" policies, the business cycle of the capacitor film industry will be extended, and it is expected to show a slow upward trend in the future.

2. Downstream market demand: The development and growth of the capacitor film market is driven by many driving factors, especially in the fields of new energy vehicles, electronics, energy storage systems and 5G.

Restraint:

1. Market competition intensifies:

The polyester film industry is highly competitive, with continued growth in market capacity and an increasing number of large-scale production companies. As the production scale of polyester film companies continues to expand, market competition in the global polyester film industry has further intensified. In this competitive environment, the gross profit margin of some companies' products may decline.

2. High technical barriers in high-end industries:

Among the companies capable of producing BOPP ultra-thin capacitor films, due to factors such as high technical thresholds, large R&D investment, and multiple product functions, there are relatively few companies that can produce ultra-thin films. But on the contrary, it has a strong competitive advantage in market segments.

Trend:

1. Improved product performance: mainly reflected in film thickness (ultra-thin), corrosion resistance, high temperature resistance, and high-pressure resistance. And it can meet the mechanical and electrical performance requirements of different application scenarios.

Ultra-thin Film: In the field of new energy vehicles, ultra-thin capacitor films can accommodate more energy storage materials, increase the energy density of batteries or capacitors, increase vehicle cruising range, and meet users' needs for long-distance driving. And ultra-thin films can also reduce capacitor weight and control costs.

High temperature resistance: New energy vehicle batteries will generate heat during operation. The high temperature resistant film can cycle stably in this environment, avoiding performance degradation in high temperature environments and maintaining long-term use. High-temperature resistant film capacitors are the key to ensuring the stable, safe and long-term operation of NEV batteries under complex working conditions and promoting the reliability and popularity of electric vehicles.

2. Market size and downstream demand growth: The rapid development of downstream new energy vehicles, photovoltaics, UHV and other fields will further drive demand in the electronic components/electronic component materials industry. For example, the "New Energy Vehicle Industry Development Plan (2021-2035)" issued by the Chinese government proposes that by 2025, China's new energy vehicle sales will account for more than 20% of new automobile sales, and by 2035, new energy vehicle sales will account for more than 20% of new automobile sales. New car sales are mainstream. In the future, the market capacity of PP films for new energy vehicle capacitors is expected to exceed 10 times, and the film thickness is mainly concentrated at 2.0-2.9 microns.

About The Authors

Jiashi Dong

Lead Author

Email: [email protected]

QYResearch Nanning Branch Analyst, as a member of the QYResearch Semiconductor Equipment and Materials Department, his main research areas include automotive electronics, semiconductor equipment, materials and thermally conductive powders. Some subdivided research topics include automotive diodes, automotive inductors, automotive lidar, radio frequency power supplies, plastic sealing machines, high-purity non-ferrous metals, battery materials, precursors, electroplating equipment, thermal conductive ball aluminum, semiconductor chemical plating solutions, semiconductor coating devices, etc. At the same time, he is also engaged in the development of market segment reports and participates in the writing of customized projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

0 notes

Text

Analyzing the consumer demand and functional material opportunities of functional insoles in the sports and outdoor market nowadays

In recent years, with the economic development and increasing public health awareness, the sports industry has been booming, stimulating the public's high demand for sports equipment. Against this background, functional insoles, as an important accessory in sports shoes, have also ushered in the opportunity for upgrading and innovation. In the face of the expectations of a new generation of consumers, major insoles brand manufacturers are busy developing more advanced products that better meet the needs of consumers.

When shopping for functional insoles, consumers are increasingly inclined to choose insoles that are more comfortable, lighter and more durable. With the rise of the sports boom, many consumers are keen on outdoor extreme activities, and pay particular attention to the cushioning function of insoles and shoes.

Functional insoles can basically be divided into four structures:

Fabric layer, filling layer, support layer and bottom layer.

Each structure has different material requirements

What do the new generation of consumers expect from each part of the insole?

What are the expectations?

Let's unlock them together!

Breathable and anti-bacterial for more comfortable sports

The first is the fabric layer, which is in direct contact with the foot. The fabric layer is usually made of moisture-wicking, breathable and soft materials such as mesh, cotton and polyester to ensure comfort and hygiene for the feet. Some high-end or functional insoles may also use fabrics with special treatments such as antimicrobial and anti-odor.

New generation consumers' demand for fabric layers

Moderate softness √ Non-slip and abrasion resistant √

Good breathability √ Excellent antimicrobial properties √

ACF shock-absorbing and energy-absorbing functional insoles are made of Big BK/Small BK mesh fabric, which can effectively expel sweat and moisture from the feet, keeping them dry and comfortable. At the same time, the large BK fabric layer also has good breathability, which ensures air circulation, reduces bacterial growth and prevents foot infections.

In addition to its breathability and moisture wicking properties, the Big BK fabric layer has some other important functional properties. It usually has good abrasion resistance and stretch resistance, and can withstand prolonged use and frequent washing.

Cushioning and compression for easier movement

The padding layer, located under the fabric layer, is usually made of foam (e.g. EVA, sponge, etc.) or memory foam, and carries the dual mission of reducing impact and enhancing comfort. The main function of this layer is to provide cushioning, reduce the impact on the foot and increase the comfort of the insole.

What the new generation of consumers wants in a midlayer

Good impact resistance √

Lightweight design √

Balance between good support and comfort √

ACF artificial cartilage material SH series can give functional insoles, provide excellent cushioning performance, lightweight and comfortable, applied to the middle layer can absorb more than 90% of the impact energy transmitted from the foot to the ground, reduce sports fatigue and reduce sports injuries.

ACF Artificial Cartilage Insole (Professional Sports) - Structure Breakdown Diagram

The middle layer of SH material also incorporates intelligent temperature sensing particles, when you wear your feet for 5-10 minutes, the heat from the sole of your feet is transferred to the middle layer of the insole, it will become soft and comfortable so as to fit the shape of your feet, and provide you with a customized wearing experience for your feet.

Support and Stabilization for Safer Exercise

The support layer is a key part of the insole's construction and is usually made of harder materials such as rigid EVA, Ossolite, and other composites. The purpose of the support layer is to provide stabilization, ensure the foot's natural position, and prevent excessive twisting or deformation during movement. Some insoles also integrate specific designs, such as arch support, into the support layer to better accommodate different foot shapes and athletic demands.

What the new generation of consumers wants in a support layer

Good support √ Excellent durability √

Stable arch √ Antimicrobial and breathable √

ACF's functional insoles are made of high end Ossolite as the main component of the support layer, which has excellent support and durability to meet the needs of prolonged exercise and frequent friction. At the same time, ACF has also paid attention to the importance of arch stability and antimicrobial breathability, which are realized through unique design and technology.

ACF's solutions meet the needs of a new generation of consumers who are looking for support layers that focus on support, durability, arch stabilization, and antimicrobial breathability.

Durable and non-slip for long-lasting sports

The bottom layer is the part of the insole that comes into contact with the sole, and is usually made of wear-resistant and non-slip materials, such as rubber and PU materials. The main function of the bottom layer is to ensure a tight fit between the insole and the sole, preventing slipping and providing extra durability and stability.

What the new generation of consumers want in a bottom layer

Anti-slip and anti-shift √ Excellent durability √

ACF continues to use its high-performance ACF Artificial Cartilage material SH series and has specifically applied it to the design of the bottom layer. This material provides excellent cushioning to minimize foot impact when landing, as well as excellent durability and resistance to compression deformation, retaining its original shape and performance even under prolonged use and frequent wear and tear.

SH material also has the property of not sliding and shifting easily, which can improve the durability of sports.

ACF High Performance Cushioning Solutions

SH material, developed in ACF labs and tested by authoritative organizations, has been proven to have excellent shock absorption and cushioning performance, absorbing up to 97.1% of impact energy. This unique material is not only suitable for insoles, but also can be widely used in the midsole of sports shoes, especially for sports enthusiasts who require high safety in sports, and the application of SH material in the midsole of sports shoes will provide a safer and more comfortable wearing experience for sportsmen.

Comparison of Impact Test and Energy Absorption of ACF Material vs. Other Materials

400-6543-699

www.acf.com

0 notes

Text

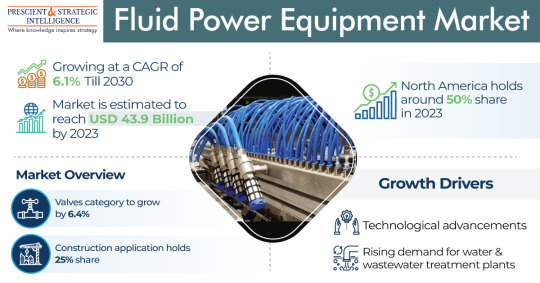

Fluid Power Equipment Market Will Touch USD 66.0 Billion in 2030

The fluid power equipment market was USD 43.9 billion in 2023, which will rise to USD 66.0 billion, advancing at a 6.1% compound annual growth rate, by 2030.

The growth of this industry is mainly because of the increasing need for water and wastewater treatment plants, and the continuous technological developments.

In 2023, hydraulic led the type category, with a revenue of USD 26.3 billion. This can be ascribed to the cost-effectiveness and high efficiency of this type, and its extensive adoption in oil & gas and construction applications.

The pneumatic category, on the other hand, will propel at a healthy rate during this decade. This is because these systems rely on compressed air pressure to send power and are extensively employed in numerous industrial applications.

Furthermore, pneumatic valves are available in different designs, sizes, and configurations, and thus, allow free flow in a single direction and avoid flow in the opposite direction.

In 2023, the construction category, based on end user, was the largest contributor to the fluid power equipment market, with a 25% share. This can be because of the high usefulness of these components in various applications like material demolition or handling in the construction sector.

The automotive category, on the other hand, is advancing at a tremendous rate, because of the increasing customer's disposable salary, along with the increasing standards of living, worldwide.

Motors is leading the component category. This can be because motor components provide great torque & power, and are extensively employed across various sectors, including agriculture, construction, and automotive.

Moreover, the developments in motor technologies enhance their performance and efficiency, and thus, are cost-effective solutions for businesses to utilize for different applications.

On the other hand, the valves category will advance at the highest rate during this decade. This is ascribed to the growing requirement for valves to track high pressure, which will boost the demand for valve components.

North America led the industry in 2023, with a 50% share. This can be attributed to the existence of greater infrastructure, coupled with the rising progression in R&D and manufacturing activities.

Moreover, the increasing count of initiatives implemented to guarantee the worker's safety in oil & gas and chemicals sectors further boost the regional industry growth.

APAC will propel at the highest rate, of 6.5%, in the coming years. This will be because of the surging urbanized populace along with the increasing requirement for energy, and the progression of the construction and automobile sectors in Japan, China, and India.

With the rise in the requirement for water & wastewater treatment plants, the fluid power equipment industry will continuously progress in the coming years.

Source: P&S Intelligence

#Fluid Power Equipment Market Share#Fluid Power Equipment Market Size#Fluid Power Equipment Market Growth#Fluid Power Equipment Market Applications#Fluid Power Equipment Market Trends

1 note

·

View note

Link

#market research future#compressed air treatment#air treatment equipment#air treatment equipment market#air treatment technology

0 notes

Text

Transmission Sales Strategies: Unveiling Opportunities in a Changing Market"

The process of pressurizing and accumulating gas within pipelines involves efficient gas processing to ensure control, safety, and proper pressure levels. Additionally, the recovery and recompression of processed gas are vital steps in this process. A critical aspect of transmission sales equipment is its role in preventing contamination of the processed gas, particularly when dealing with biogas derived from water and residential waste. The market offers two types of compressors, utilizing dynamic mechanisms and positive displacement, which are essential for meeting compressed air requirements across various industries such as power generation, oil and gas, wastewater and water management, chemicals and petrochemicals, automotive, food and beverage, mining and metals, and construction.

Request The Sample PDF Of This Report: https://www.alliedmarketresearch.com/request-toc-and-sample/12456

COVID-19 Impact Analysis

The oil industry witnessed a significant decline in prices in 2020 due to the global impact of the COVID-19 outbreak. The pandemic led to shutdowns within the oil and gas sector, resulting in reduced demand for offshore drilling rigs and subsequently affecting the transmission sales market. Disruptions in the global supply chain further contributed to decreased demand in numerous countries. The transmission and distribution of products also experienced setbacks due to the pandemic's influence, resulting in repercussions for the transmission sales market.

Get a Customized Research Report @ https://www.alliedmarketresearch.com/request-for-customization/12456

Key Influential Factors

The power sector is witnessing an increasing demand for transmission sales, driven by the growth of wastewater treatment initiatives supported by national governments. Government-initiated wastewater treatment programs are fostering demand for transmission sales in the power sector. Additionally, the rise of shale gas activities, characterized by low operation costs, is boosting the transmission sales market. However, the market's growth may be hindered by high maintenance costs. The control and safety systems crucial to oilfields rely on transmission sales equipment, and concerns about oil spills are propelling global demand. Oil and gas inverters are expected to contribute to the expansion of the transmission sales market. The utilization of compressors in various oil and gas industry applications, including wellhead gas reinjection and hydrocarbon vapor recovery, presents opportunities for growth. However, the environmental pollution associated with the oil and gas industry poses a potential obstacle.

Market Trends

Europe is witnessing an upsurge in the oil and gas sectors, alongside increased power generation, which is set to boost the transmission sales market in the region. The growth of industrial activities and heightened competition in Eastern and Central Europe, coupled with increased oil and gas production and exploration, are driving the transmission market's expansion in Europe. Industry players are embracing strategies such as contracts, agreements, new product launches, acquisitions, and mergers to capture a larger share of the transmission sales market. An example of this is Siemens receiving a contract to provide residue compression trains (compressors) for cryogenic gas plants in the Delaware Basin.

Enquiry Before Buying: https://www.alliedmarketresearch.com/purchase-enquiry/12456

Key Report Benefits

This study offers a comprehensive analytical overview of the transmission sales industry, highlighting current trends and future investment opportunities.

The report delves into key drivers, restraints, and opportunities, accompanied by a detailed analysis of transmission sales market share

Quantitative analysis illuminates growth scenarios in the transmission sales market. Porter's five forces analysis elucidates buyer and supplier dynamics.

The report provides an in-depth transmission sales market analysis, considering competitive intensity and the anticipated trajectory of competition in the coming years.

Transmission Sales Market Report Highlights

Key Aspects

Type

Reciprocating

Rotary

Centrifugal

Axial Flow

Application

Artificial Lift

Gas Processing Station

LNG and FPS

Storage

Others

End-Use Industry

Oil and Gas

Power Generation

Water and Wastewater Management

Others

Regional Landscape

North America (U.S., Canada, Mexico)

Europe (France, Germany, Italy, Spain, UK, Rest of Europe)

Asia-Pacific (China, Japan, India, South Korea, Australia, Rest of Asia-Pacific)

LAMEA (Brazil, South Africa, Saudi Arabia, UAE, Rest of LAMEA)

0 notes

Text

0 notes

Text

Shale Gas Processing Equipment set for Significant Growth

The global shale gas processing equipment market size was valued at $4.5 billion in 2018, and is projected to reach $13.5 billion by 2026, growing at a CAGR of 14.8% from 2019 to 2026.

The major key players operating in the global shale gas processing equipment industry include Schlumberger Ltd, Sivalls, Inc, Van Air Systems, Croft Production Systems, Inc., Koch Industries, Inc., Pall Corporation, PEMCO, Burckhardt Compression AG, Gas Processing Equipment, and ATB Riva Calzoni S.p.A.

Get a PDF brochure for Industrial Insights and Business Intelligence:

Shale gas equipment are used to eliminate components such as N2, H2S, heavy hydrocarbons, CO2, and water from the raw shale gas and oil before it is sent for transportation. This method includes various processes such as distillation, filtration, cracking, reheating, pyrolysis, and chemical treatment.

As per the U.S. energy information administration, the global shale gas industry surpassed more than $200 billion revenue in 2018 and as per their estimates it is anticipated to generate more than $390 billion revenue by 2025. Shale gas and oil infrastructure and markets for their related products, more specifically, processing equipment, altogether are heading toward their growth expansion phase as whole.

Due to abundant shale gas reserves, its infrastructure expected to grow significantly over the next decade. Hence, processing equipment is expected to have a promising future over the years to come

The U.S. reported shale gas production of over 37 billion cubic feet following Mexico and China at over 5 and 2.1 billion cubic feet respectively in 2015. As per the estimates of U.S. Energy Information Administration, the U.S. anticipated to produce over 80 billion cubic feet of shale gas by offering a scope to huge technological investment along with processing equipment manufacturing.

Equipment used in the shale gas processing are known as shale gas processing equipment. Popularly known equipment used in the shale gas processing include compressors & pumps, electrical machinery, heat exchangers, internal combustion engines, measuring & controlling devices, and others. Apart from these, the others segment includes separators & filters, hydrator/glycol dehydrator, injection systems, and storage tanks. These equipment are used in the midstream phase of the oil & gas industry, wherein, gas/shale gas is processed, refined, and treated before it is transported for commercial usage.

Abundance shale gas reserves in some of the geographies across the globe and its commercial exploitation is the major factor and it has an immense impact on the global market growth. In response to the increasing natural gas prices, oil & gas industry seeks an alternative

to natural gas resources at economic terms. Shale gas is nothing but a natural gas trapped within a shale formation whose reserves are spread almost all across the globe.

Enquiry Before Buying: https://www.alliedmarketresearch.com/purchase-enquiry/1007

Heat exchanger is important equipment used in the overall gas processing plants. Technological evolution of heat exchangers is further contributing in the global shale gas processing equipment market growth. On the other hand, environmental hazards associated with hydraulic fracturing is the major restraining factor hampering the growth of the global shale gas processing equipment market. Nevertheless, growing initiatives from government from various geographies is anticipated to offer new growth opportunities over the forecast period.

The global shale gas processing equipment market is segmented on the basis of component and country. On the basis of component, the global market is studied across compressors & pumps, electrical machinery, heat exchangers, internal combustion engines, measuring & controlling devices, and others. Others segment includes separators & filters, hydrator/glycol dehydrator, injection systems, and storage tanks. Compressor and pumps is the largest segment among all and its growing demand is significantly expanding the global shale gas processing equipment market size.

Based on country, the global shale gas processing equipment market is studied across the U.S., Canada, China, Algeria, Mexico, Argentina, and others. The U.S. is the largest country level market among others due to abundant shale gas reserves and technically sound nature of the country, and investment in the shale gas exploration. Increased penetration of small-scale and mid-scale processing equipment manufacturers over large scale equipment manufacturers in the U.S. is one of the recent shale gas processing equipment market trend observed in recent years.

Browse complete industry report : https://www.alliedmarketresearch.com/shale-gas-processing-equipment-market

The U.S. is the largest country level market among others. The U.S. is the first country that has undertaken successful commercial scale production of shale gas and is offering scope to gas processing equipment. Therefore, the U.S. has the dominant share in the global shale gas market and is expected to be the largest one during the forecast period.

Based on component, Compressors and pumps segment accounted for the largest market share in 2018 and is expected to be the largest segment by the end of the forecast period. Demand for compressors is mainly seen in the U.S. as it is the largest market for shale gas processing equipment. Gas processing capacity have expanded in most of plants located in the U.S. as a result of increasing shale gas production. Hence, demand for compressors is rising in the U.S.

About Us

Allied Market Research (AMR) is a full-service market research and business-consulting wing of Allied Analytics LLP based in Portland, Oregon. Allied Market Research provides global enterprises as well as medium and small businesses with unmatched quality of "Market Research Reports" and "Business Intelligence Solutions." AMR has a targeted view to provide business insights and consulting to assist its clients to make strategic business decisions and achieve sustainable growth in their respective market domain. Pawan Kumar, the CEO of Allied Market Research, is leading the organization toward providing high-quality data and insights. We are in professional corporate relations with various companies and this helps us in digging out market data that helps us generate accurate research data tables and confirms utmost accuracy in our market forecasting. Each and every data presented in the reports published by us is extracted through primary interviews with top officials from leading companies of domain concerned. Our secondary data procurement methodology includes deep online and offline research and discussion with knowledgeable professionals and analysts in the industry.

Contact:

David Correa

5933 NE Win Sivers Drive

205, Portland, OR 97220

United States

USA/Canada (Toll Free):

+1-800-792-5285, +1-503-894-6022

UK: +44-845-528-1300

Hong Kong 852 - 301 - 84916

India (Pune): +91-20-66346060

Fax: +1(855)550-5975

Web: www.alliedmarketresearch.com

Allied Market Research Blog:

Follow Us on Facebook | LinkedIn | YouTube

0 notes

Text

GCC Industrial Gases Market To Explore Industry Trends: 2023, Segmentation, Development Growth, and Industry Challenges till 2030

Industrial gases are gases that are produced and used for industrial purposes, such as in manufacturing, healthcare, food processing, welding, and electronics. Some of the most common industrial gases include oxygen, nitrogen, argon, hydrogen, carbon dioxide, helium, and acetylene. These gases are produced in large quantities and are often sold to customers in compressed gas cylinders or liquid containers. They are used in various industrial processes, such as welding and cutting, heat treatment, chemical processing, and cooling and refrigeration.

Industrial gases play a critical role in many industries, including healthcare, where they are used for medical treatments and diagnostic purposes. They are also used in the food and beverage industry, where they help to preserve and package food products.

Key companies covered as a part of this study include Air Liquide, Air Products and Chemicals Inc., The Linde Group, Praxair Inc., Abdullah Hashim Industrial & Equipment Co. Ltd, Bristol Gases, Buzwair Industrial Gases factory, Dubai Industrial Gases, Gulf Cryo, Mohsin Haider Darwish LLC, National Industrial Gas Plants, and Yateem Oxygen

The demand for industrial gases is driven by several factors, including the growth of industries that use these gases, advancements in technology, and the increasing need for more efficient and sustainable processes.

The largest industrial gas consumers are the manufacturing and chemical industries, which use these gases for a wide range of applications, including welding and cutting, chemical synthesis, and packaging. The healthcare industry is also a significant consumer of industrial gases, where they are used for medical treatments, diagnosis, and anesthesia.

The demand for industrial gases is also driven by the increasing need for sustainable production processes. Many industries are looking to reduce their carbon footprint and improve their environmental performance, and industrial gases can help achieve these goals. For example, carbon dioxide is used in many industrial processes, including carbon capture and storage, as well as in the production of renewable fuels and chemicals.

The industrial gases market has been experiencing steady growth over the years and is expected to continue this trend in the future. Industrial gases such as nitrogen, oxygen, argon, and hydrogen are used in a wide range of industries such as healthcare, food and beverage, automotive, chemicals, and electronics, among others.

One of the key drivers of the industrial gases market growth is the increasing demand from the healthcare industry. Industrial gases are used in various medical applications such as anesthesia, respiratory therapy, and cryotherapy. Additionally, the growing adoption of industrial gases in the food and beverage industry for packaging and preservation purposes is also contributing to the growth of the market.

The increasing demand for energy and the rising focus on reducing carbon emissions have led to the growing adoption of industrial gases in the energy sector. For instance, industrial gases such as hydrogen are used in fuel cells to generate electricity, while carbon dioxide is used in enhanced oil recovery and as a feedstock for the production of chemicals.

Moreover, the expansion of various end-user industries in emerging economies is also contributing to the growth of the industrial gases market. The increasing investments in infrastructure development and the growth of the manufacturing sector are driving the demand for industrial gases in these regions.

Overall, the industrial gases market is expected to continue growing in the coming years, driven by the increasing demand from various end-user industries and the growing focus on sustainable development.

0 notes

Text

Marine Pneumatic Watertight Doors Market : Advanced Technologies & Growth Opportunities Worldwide By 2030

The marine pneumatic watertight doors market refers to the industry that produces and sells watertight doors for use on marine vessels. These doors are designed to prevent water from entering into different compartments on ships, such as engine rooms, cargo holds, and living quarters. They are typically made from materials like steel, aluminum, or composite materials, and are operated by a pneumatic system that uses compressed air to open and close the door.

For Sample Report Click Here:-https://www.globmarketreports.com/request-sample/258653

The market for marine pneumatic watertight doors is driven by the demand for safer and more efficient ships. The use of watertight doors helps to improve the safety of ships by minimizing the risk of flooding and other water-related accidents. They also help to improve the efficiency of ships by allowing them to carry more cargo and travel at higher speeds.

Marine pneumatic watertight doors are specially designed doors that are used on ships and other marine vessels to prevent water from entering different compartments of the ship during emergency situations such as flooding or collision. These doors are constructed using high-quality materials such as steel or aluminum and are equipped with an airtight seal to prevent water from passing through.

The doors are operated by a pneumatic system that uses compressed air to open and close the door. This system is designed to ensure that the doors can be easily operated in the event of an emergency, even if the ship’s power supply has been compromised.

Marine pneumatic watertight doors are an essential safety feature on ships, and they are required to meet strict regulations and standards to ensure their reliability and effectiveness. They are typically classified based on their watertightness rating, which indicates the maximum water pressure that the door can withstand without leaking.

In addition to their use in ships and other marine vessels, pneumatic watertight doors can also be used in other applications that require a high level of protection against water, such as flood barriers and water treatment plants.

0 notes

Text

Hydrogen Energy Storage System Market to Eyewitness Massive Growth by 2027

Advance Market Analytics released a new market study on Global Hydrogen Energy Storage System Market Research report which presents a complete assessment of the Market and contains a future trend, current growth factors, attentive opinions, facts, and industry validated market data. The research study provides estimates for Global Hydrogen Energy Storage System Forecast till 2027*.

Hydrogen energy storage (HES) is a procedure that involves using surplus energy supplied by renewables to power electrolysis during periods of low energy demand. It helps to improve supply reliability while also lowering carbon emissions and the total use of conventional petroleum fuels. It provides material handling equipment (MHE), such as forklifts and airport tugs, with supplementary grid services and fuel. In comparison to pumped storage hydropower (PSH) and compressed air energy storage, it also has a large storage capacity (CAES). As a result, hydrogen is stored as compressed gas, cryogenic liquid, and loosely bound hydride compounds in the HES.

Key Players included in the Research Coverage of Hydrogen Energy Storage System Market are

Cummins Inc. (Canada)

ITM Power (United Kingdom)

Hexagon Composites (Norway)

Worthington Industries (United States)

Linde (United Kingdom)

Nel ASA. (Norway)

Plug Power (United States)

Chart Industries (United States)

Air Liquide (France)

Air Products and Chemicals (United States) What's Trending in Market: Growing demand for hydrogen in industries such as metal treatment, food processing, and petroleum refining

The number of policies that directly encourage investment in hydrogen technology is growing

Challenges: Refueling times are too long

Opportunities: Growth in demand for hydrogen energy storage, utilizing excess electric energy

Growing demand for the hydrogen fuel cell

Market Growth Drivers: Increasing need for energy conservation

Reducing consumption of conventional petroleum fuels

The Global Hydrogen Energy Storage System Market segments and Market Data Break Down by Storage Technology (Compression, Liquefaction, Material Based), State (Liquid, Gas, Solid), End-use (Industrial, Commercial, Utilities) To comprehend Global Hydrogen Energy Storage System market dynamics in the world mainly, the worldwide Hydrogen Energy Storage System market is analyzed across major global regions. AMA also provides customized specific regional and country-level reports for the following areas. • North America: United States, Canada, and Mexico. • South & Central America: Argentina, Chile, Colombia and Brazil. • Middle East & Africa: Saudi Arabia, United Arab Emirates, Israel, Turkey, Egypt and South Africa. • Europe: United Kingdom, France, Italy, Germany, Spain, Belgium, Netherlands and Russia. • Asia-Pacific: India, China, Japan, South Korea, Indonesia, Malaysia, Singapore, and Australia. Presented By

AMA Research & Media LLP

0 notes

Text

Compressed Air Treatment Equipment Market Predicted to Witness Steady Growth by 2030

The global compressed air treatment equipment market is anticipated to register commendable growth, owing to increased efficiency of air compressors through improvements to the equipment lifecycle.

Energy cost is a crucial factor when upgrading an air compressor. These costs account for more than 75% of the compressor's overall life-cycle cost (LCC). Air audits for measuring the total input power are thus essential for the evaluation of the benefits of a new compressor.

Get sample copy of this research report @ https://www.gminsights.com/request-sample/detail/124

Furthermore, air compressors can be upgraded through the integration of IoT capabilities, and enhancements in controller features. These enhancements result in improved uptime, inputs for maximized operational settings apart from 24x7 remote monitoring, and insights for enhancement in energy efficiency, stimulating market demand.

The compressed air treatment equipment market is bifurcated in terms of product, application, end-user, and region.

Concerning the product, the others segment is expected to depict a CAGR of over 4% over the forecast period. This growth can be accredited to the growing adoption of drain traps, purifiers, and condensate treatment equipment.

In terms of application, the plant air/shop air segment will be worth more than USD 2 billion by 2030. The plant air/shop air is an essential component of the compressed air treatment equipment as it replaces the necessity for purchasing a separate compressor and reduces the overall capital and operating expenses.

Based on end-user, the food & beverage segment is expected to record a CAGR of over 6% through 2030. Air compressors are used in the foods & beverages sector for transporting products across the supply line, handling products, and fluid pumps. These systems filter compressed air for producing nitrogen, thereby meeting all safety regulations for its adoption in the process of food packaging.

The steel segment is anticipated to exhibit a CAGR of more than 6% through 2030. Dry compressed air is crucial in steel manufacturing factories for various purposes such as conveying, molding, welding, coolant supply, feeding metal sheets, ash handling, and controlling carbon content, which may accelerate segmental progress.

Request for customization @ https://www.gminsights.com/roc/124

The compressed air treatment equipment market from the electronics segment is expected to depict over 7% CAGR through 2030. This growth can be credited to the increased usage of compressed air in the electronics sector. Air compressor is used by power pneumatic machines for polishing & removing chemical deposits, component conveying, direct production, cleaning PC boards, and for assembling memory chips, circuit boards, LCD panels, and wafers.

Regionally, the Middle East & Africa segment is anticipated to be worth USD 400 million by 2030. The region has witnessed the development of large-scale petrochemical & chemical plants, which have contributed significantly to industry growth. Furthermore, surging development in the healthcare sector will stimulate regional industry growth over the forecasted timeframe.

Table of Contents (ToC) of the report:

Chapter 1 Methodology and Scope

1.1 Methodology

1.2 Base estimation & working

1.2.1 North America

1.2.2 Europe

1.2.3 Asia Pacific

1.2.4 Latin America

1.2.5 Middle East & Africa

1.3 Forecast calculation

1.3.1 COVID-19 impact calculations on industry forecast

1.4 Data sources

1.4.1 Primary

1.4.2 Secondary

1.4.2.1 Paid sources

1.4.2.2 Public sources

Chapter 2 Executive Summary

2.1 Compressed Air Treatment Equipment market 360? synopsis, 2018 – 2030

2.1.1 Business trends

2.1.2 Product trends

2.1.3 Application trends

2.1.4 End-user trends

2.1.5 Regional trends

Browse complete Table of Contents (ToC) of this research report @ https://www.gminsights.com/toc/detail/compressed-air-treatment-equipment-market

HVAC & Construction Research Reports

Air Compressor Market

Window and Door Frame Market

Remodeling Market

About Global Market Insights:

Global Market Insights, Inc., headquartered in Delaware, U.S., is a global market research and consulting service provider; offering syndicated and custom research reports along with growth consulting services. Our business intelligence and industry research reports offer clients with penetrative insights and actionable market data specially designed and presented to aid strategic decision making. These exhaustive reports are designed via a proprietary research methodology and are available for key industries such as chemicals, advanced materials, technology, renewable energy and biotechnology.

Contact Us:

Aashit Tiwari

Corporate Sales, USA

Global Market Insights Inc.

Toll Free: 1-888-689-0688

USA: +1-302-846-7766

Europe: +44-742-759-8484

APAC: +65-3129-7718

Email: [email protected]

#Compressed Air Treatment Equipment Market Analysis#Compressed Air Treatment Equipment Market by Type#Compressed Air Treatment Equipment Market Share#Compressed Air Treatment Equipment Market Development

0 notes