#Commodity Plastic Market Trends

Text

#Commodity Plastic Market Growth#Commodity Plastic Market Analysis#Commodity Plastic Market Insight#Commodity Plastic Market Forecast#Commodity Plastic Market Index#Commodity Plastic Market Trends

0 notes

Text

Commodity Plastics Market to Exhibit Fastest Growth in Future Scope 2022-2032 | ExxonMobil Corporation, LG Chem, Sumitomo Chemical Co. Ltd

Commodity Plastics Market to Exhibit Fastest Growth in Future Scope 2022-2032 | ExxonMobil Corporation, LG Chem, Sumitomo Chemical Co. Ltd

This report estimates the growth rate and the market value based on industry dynamics and growth driving factors. While preparing this Global Commodity Plastics market research report, a few of the attributes that have been adopted include updated domain performance. The report offers wide-ranging statistical analysis of the market’s continuous developments, capacity, production, production…

View On WordPress

#Commodity Plastics#Commodity Plastics manufacturing Vendors#Commodity Plastics market#Commodity Plastics market share#Commodity Plastics market size#Commodity Plastics market SWOT analysis#Future Trends of Commodity Plastics industry#Scope of Commodity Plastics industry

0 notes

Text

Propylene Prices | Pricing | Trend | News | Database | Chart | Forecast

Propylene is a key petrochemical feedstock that plays a crucial role in the production of a wide variety of industrial and consumer products, including plastics, packaging materials, and automotive components. The prices of propylene, like many other commodities, are subject to significant fluctuations, influenced by a complex interplay of supply and demand dynamics, market sentiment, geopolitical events, and raw material costs. Over the years, propylene prices have shown sensitivity to a range of factors, making them highly volatile and a focal point for industries relying heavily on its derivatives.

One of the primary factors that influence propylene prices is the global supply and demand balance. Propylene is primarily produced as a byproduct of the cracking process used in refining crude oil and natural gas. The output of propylene can vary depending on the type of feedstock used and the production process, which can create imbalances between supply and demand. For instance, when the refining industry slows down, whether due to lower crude oil prices or reduced demand for gasoline, there is typically a corresponding decrease in the supply of propylene, which can drive prices higher. Conversely, an oversupply situation can exert downward pressure on propylene prices, especially if it coincides with sluggish demand in the end-use markets.

Get Real Time Prices for Propylene : https://www.chemanalyst.com/Pricing-data/propylene-51Crude oil prices also play a significant role in determining propylene prices. Since crude oil is a major raw material for propylene production, fluctuations in oil prices directly impact production costs. When crude oil prices rise, it generally leads to an increase in propylene prices as producers pass on the higher costs to consumers. Conversely, when crude oil prices fall, the cost of producing propylene decreases, and this can result in lower prices, provided there is no significant disruption in demand. However, the relationship between crude oil prices and propylene is not always linear, as other factors such as refinery outages, seasonal maintenance, and technological advancements in production methods can also influence prices.

Another important driver of propylene prices is the regional supply situation. Different regions have different propylene production capacities and varying levels of demand, which can create regional price discrepancies. For example, in regions like North America, where shale gas production is abundant, propylene production has surged in recent years due to the availability of ethane, a cheaper feedstock derived from natural gas. This has led to lower propylene prices in the region compared to Europe and Asia, where naphtha, a more expensive feedstock derived from crude oil, is the primary source for propylene production. Regional demand patterns, trade policies, and logistical constraints also contribute to price differentials, creating opportunities for arbitrage and trade flows between regions.

Seasonal factors can further influence propylene prices. Certain periods of the year typically see higher demand for propylene derivatives, such as polypropylene, which is used extensively in packaging materials and consumer goods. For example, the summer months often see an increase in demand for packaging and automotive products, driving up the demand for propylene. Additionally, maintenance shutdowns at refineries and chemical plants, which are often scheduled during low-demand seasons, can create temporary supply shortages, putting upward pressure on prices.

Geopolitical events also play a pivotal role in shaping propylene prices. Political instability in major oil-producing regions can disrupt the supply of crude oil, thereby affecting the availability of propylene. For instance, tensions in the Middle East, which is a significant producer of both crude oil and naphtha, can lead to supply disruptions that ripple through the petrochemical markets, causing prices to spike. Trade policies, tariffs, and sanctions can further exacerbate these issues by limiting the flow of propylene and its derivatives across borders, affecting global supply chains and price stability.

Environmental regulations and sustainability initiatives are increasingly influencing propylene prices as well. The global shift toward greener technologies and more sustainable production methods has led to investments in alternative feedstocks and production techniques. For example, bio-based propylene and recycling technologies are being explored as environmentally friendly alternatives to traditional petrochemical processes. While these innovations hold the potential to reduce the environmental footprint of propylene production, they also come with higher production costs, which could drive up prices in the short term as industries adjust to these new technologies.

Market sentiment and speculation can further contribute to the volatility of propylene prices. Like other commodities, propylene is subject to futures trading, where investors and traders speculate on future price movements based on their outlook for supply and demand conditions. Sudden changes in market sentiment, driven by factors such as economic data releases, geopolitical developments, or technological advancements, can cause price swings even in the absence of actual supply or demand changes. For example, a positive economic forecast might lead traders to anticipate higher future demand for propylene, pushing up prices even before the actual demand materializes.

Looking forward, the outlook for propylene prices remains uncertain, as it is influenced by a multitude of factors that are difficult to predict. The transition to a lower-carbon economy, advancements in recycling technologies, and the potential for new regulatory frameworks could all play a role in shaping the future trajectory of propylene prices. At the same time, the traditional drivers of price fluctuations, such as crude oil prices, geopolitical events, and market sentiment, will continue to exert their influence. As industries and governments navigate these challenges, the ability to anticipate and adapt to changes in the propylene market will be critical for companies operating in sectors that rely heavily on this versatile and indispensable petrochemical.

Get Real Time Prices for Propylene : https://www.chemanalyst.com/Pricing-data/propylene-51

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Propylene#Propylene Price#Propylene Prices#Propylene Pricing#Propylene News#Propylene Price Monitor#Propylene Database#Propylene Price Chart

0 notes

Text

PC prices on downward trend

The Polycarbonate (PC) prices are on a downward trend at Delhi polymer market today as per sources of Indian Petrochem, the price of the commodity has dropped by 2/kg on September 16, 2024 from Rs 215/kg on September 14, 2024. Polycarbonate (PC) is an amorphous clear plastic suitable for industrial engineering. This versatile thermoplastic polymer is easy to process and has many applications within different branches. Indian PC Prices, PC Prices In India, Indian Prices PC, Imdianpetrochem.

0 notes

Text

Commodity Plastics Market is expected to display a steady growth by 2028

According to a new report published by UnivDatos Markets Insights, the Commodity Plastics Market is expected to grow at a CAGR of around 6% from 2022-2028. The analysis has been segmented Type (Polyethylene (PE), Polypropylene (PP), Polyvinyl Chloride (PVC), Polystyrene (PS), Acrylonitrile Butadiene Styrene (ABS), Polyethylene Terephthalate (PET), Poly (Methyl Methacrylate) (PMMA)); End-User (Packaging, Automotive, Electronics, Consumer Goods, Construction, Textiles, Medical & Pharmaceutical, Others); Region/Country.

The Commodity Plastics market report has been aggregated by collecting informative data on various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the Commodity Plastics market. The Commodity Plastics market report offers a detailed analysis of the latest industry developments and trending factors in the market that are influencing the market growth. Furthermore, this statistical market research repository examines and estimates the Commodity Plastics market at the global and regional levels.

Market Overview

Commodity plastics are entire families of products made of a particular polymer. Commodity plastics are inexpensive and do not possess any exceptional mechanical properties. Such plastics are produced in large volumes for a wide spectrum of applications such as food packaging and storage, household products, and carry bags. In addition, they exhibit relatively weak mechanical properties. The most common examples of commodity plastics include polyethylene, polypropylene, polystyrene, polyvinyl chloride, and poly (methyl methacrylate).

Factors such as the growing demand use of plastics in the packaging industry as well as other end-use industries with multiple applications, such as packaging, photographic, electronics, and pharmaceuticals, and the increase in demand for consumer goods are positively influencing the market demand for commodity plastics. In addition, the rising need for specialized commodity plastics in the healthcare sector for manufacturing medical masks, gowns, and other safety kits is expected to boost the market growth in the coming years. However, rising consumer awareness regarding the harmful effects caused by improper disposable plastics is anticipated to hamper the market.

Some of the major players operating in the market include Exxon Mobil Corporation, The Dow Chemical Company, BASF SE, Reliance Industries, Sinopec, Mitsubishi Chemical, Nova Chemicals, Sumitomo Chemical, LyondellBasell, Chevron Phillips Chemical.

COVID-19 Impact

The advent of global pandemic resulted in creating a global crisis in the FMCG industry. Impacting over 195 countries across the globe, the pandemic has already created an economic backdrop the globe. social distancing has made a drastic negative impact on the FMCG industry. Logistic issues, lack of adequate labor force, and operations limiting the production of only essential items are some of the few examples most FMCG companies are facing across the globe. Moreover, the usage of plastic decreased in most sectors as demand and output dropped, especially in large-scale plastics-using sectors including motor vehicles, trade, and construction which significantly impacted the market growth of commodity plastics.

The global Commodity Plastics market report is studied thoroughly with several aspects that would help stakeholders in making their decisions more curated.

· Based on type, the commodity plastics market is segmented into polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), acrylonitrile butadiene styrene (ABS), polyethylene terephthalate (PET), poly (methyl methacrylate) (PMMA). Polypropylene (PP) caters substantial share of the market. As It is one of the cheapest thermoplastics and caters to a considerable share of global plastics materials consumption. Also, owing to its low price, ease of processing, chemically inertness, and many other attractive properties, it has replaced metals, glass, wood, cellophane, and paper in countless applications.

· Based on end-user, the commodity plastics market is classified into oil & gas, manufacturing, healthcare/ pharmaceutical, food & beverages, energy & utility, consumer goods, metal & mining, transportation, and others. Among these, the packaging segment to hold a significant share in the market in 2020. Increasing demand for packaged food and beverages and growing demand for flexible packaging are some major factors driving revenue growth of this segment. Furthermore, the development in packaging materials technology and the increasing use of renewable plastics for packaging are anticipated to propel the segment growth in the coming years.

Commodity Plastics Market Geographical Segmentation Includes:

North America (United States, Canada, and Rest of North America)

Europe (Germany, United Kingdom, Spain, Italy, France, and the Rest of Europe)

Asia-Pacific (China, Japan, India, Australia, and the Rest of Asia-Pacific)

Rest of the World

Asia Pacific is anticipated to grow at a substantial CAGR during the forecast period. This is mainly attributed to the rapid growth in the e-commerce sector coupled with the increasing population and growing demand for packaged foods contributing to the growth of the market.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=25603

Competitive Landscape

The degree of competition among prominent global companies has been elaborated by analyzing several leading key players operating worldwide. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the Commodity Plastics market. The major players have been analyzed by using research methodologies for getting insight views on global competition.

Key questions resolved through this analytical market research report include:

• What are the latest trends, new patterns, and technological advancements in the Commodity Plastics market?

• Which factors are influencing the Commodity Plastics market over the forecast period?

• What are the global challenges, threats, and risks in the Commodity Plastics market?

• Which factors are propelling and restraining the Commodity Plastics market?

• What are the demanding global regions of the Commodity Plastics market?

• What will be the global market size in the upcoming years?

• What are the crucial market acquisition strategies and policies applied by global companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature and geography. Please let us know If you have any custom needs.

Browse Related Newsletter from UnivDatos Market Insights

Manganese Alloys Market: SWOT Analysis [2023-2028]

Green Methanol Market: SWOT Analysis [2023-2028]

About Us:

UnivDatos Market Insights: Your Partner in Data-Driven Market Strategies. Unlock growth opportunities and make smart decisions with our expert research and insights.

Contact us:

UnivDatos Market Insights (UMI)

Email: [email protected]

Web: https://univdatos.com

LinkedIn: www.linkedin.com/company/univ-datos-market-insight/

Ph: +91 7838604911

0 notes

Text

Driving Business Growth with Polyvinyl Chloride (PVC) Procurement Intelligence 2024 - 2030

Procurement of PVC benefits buyers from several end-use sectors, such as construction, packaging, automotive, electronics, and healthcare, due to its versatility and abundant applications in these sectors. The global market size was estimated at USD 54.6 billion in 2023. In 2023, APAC dominated the industry, comprising 38% of the global market share in 2023. Countries such as India, China, and Japan are the key contributors to APAC’s growth, prompting supply chain managers to foster their strategies. Key driving factors for other regions, such as North America and Europe, include the substantial presence of key players and technological advancements in manufacturing. Moreover, this is an important material in shock-absorbing automotive components, and sales of automobiles in the aforesaid regions are forecasted to rise exponentially during the next few years.

In 2024, the PVC industry has been significantly impacted by challenges such as raw material price volatility, prohibited usage in green buildings, intense competition from steel and concrete pipes, and health hazards. For instance, the prices of key raw materials used in the production of this commodity, including ethylene and chlorine, are witnessing market fluctuations due to geopolitical tensions, supply chain disruptions, and changes in energy prices. Moreover, green building certifications such as LEED (Leadership in Energy and Environmental Design) and other sustainable building standards are increasingly restricting the use of this commodity due to environmental and health concerns.

Key technology trends that are driving the growth include Oriented Polyvinyl Chloride (PVC-O) technology, nanotechnology integration, IoT-integrated pipes, use of hybrid materials, compounding, 3D printing, and climate-resilient designs. Nanotechnology integration is revolutionizing this industry by enhancing material properties through nanocomposites. Innovations like ‘NanoVinyl’ integrate nanomaterials to improve strength and durability while preserving flexibility. Compounding involves enhancing basic resin by adding plasticizers, stabilizers, fillers, pigments, and lubricants. These components influence properties, including flexibility, color, thermal stability, and resistance to UV light and chemicals.

Order your copy of the Polyvinyl Chloride (PVC) Procurement Intelligence Report, 2024 - 2030, published by Grand View Research, to get more details regarding day one, quick wins, portfolio analysis, key negotiation strategies of key suppliers, and low-cost/best-cost sourcing analysis

Key suppliers compete based on pricing, customization, lead time reduction, improving customer service, and enhancing brand reputation. Moreover, they emphasize product quality, use of sustainable materials, innovations, durability and R&D as buyers consider these parameters while sourcing PVC.

The prices of products in this industry fluctuate based on several parameters, including raw material price fluctuations, supply chain disruptions, labor cost variations, fluxes in energy costs, quality, and demand. For instance, various grades of PVC resin serve specific applications and come with different price tags. Premium, impact-resistant PVC commonly used in pipes tends to be more expensive than general-purpose grades. Moreover, resin pricing is significantly impacted by crude oil costs (due to crude oil being a key component used in manufacturing). When crude oil prices rise, resin prices tend to follow a similar trend.

Amid the COVID-19 pandemic, disruptions in supply chains caused global prices to surge temporarily. In response, many governments reduced import duties to stabilize prices. Consequently, PVC imports increased during the pandemic. By 2023, the supply-demand situation somewhat stabilized, although global demand remained slightly below pre-pandemic levels due to a slower-than-anticipated economic resurgence.

PVC Sourcing Intelligence Highlights

• This market consists of a fragmented landscape, with the players engaged in intense competition.

• Owing to the availability of substitutes, buyers have substantial bargaining power and the flexibility to switch to alternative suppliers.

• China, India, and Vietnam are preferred as low-cost or best-cost countries for sourcing due to their low costs of raw materials, cheap labor costs, inexpensive equipment cost, and high domestic production volume.

• The key components of the cost structure include raw materials (such as ethylene and chlorine), labor, equipment, energy, packaging, transportation, and other costs. Other costs include R&D, rent and utilities, compliance, general and administrative, sales and marketing, and taxes.

Browse through Grand View Research’s collection of procurement intelligence studies:

• Polyethylene Terephthalate (PET) Procurement Intelligence Report, 2024 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

• Methanol Procurement Intelligence Report, 2023 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

PVC - Key Suppliers

• Arkema S.A.

• Formosa Plastics Corporation

• INEOS AG

• KEM ONE SAS

• LG Chem, Ltd.

• Mitsubishi Chemical Group Corporation

• Occidental Petroleum Corporation

• Shin-Etsu Chemical Co., Ltd.

• Sinochem Holdings Corporation Ltd.

• Solvay S.A.

• Westlake Corporation

• Xinjiang Zhongtai Chemical Co., Ltd.

PVC Procurement Intelligence Report Scope

• Growth Rate: CAGR of 3.9% from 2024 to 2030

• Pricing Growth Outlook: 5% - 10% increase (Annually)

• Pricing Models: Cost-plus pricing, volume-based pricing, demand-based pricing, competition-based pricing

• Supplier Selection Scope: Cost and pricing, past engagements, productivity, geographical presence

• Supplier Selection Criteria: Geographical service provision, industries served, years in service, employee strength, revenue generated, key clientele, regulatory certifications, product type (unplasticized / chlorinated / molecularly-oriented / modified), product source (chemical-based / bio-based), delivery mode (offline / online), customer service, lead time, and others

• Report Coverage: Revenue forecast, supplier ranking, supplier matrix, emerging technology, pricing models, cost structure, competitive landscape, growth factors, trends, engagement, and operating model

Brief about Pipeline by Grand View Research:

A smart and effective supply chain is essential for growth in any organization. Pipeline division at Grand View Research provides detailed insights on every aspect of supply chain, which helps in efficient procurement decisions.

Our services include (not limited to):

• Market Intelligence involving – market size and forecast, growth factors, and driving trends

• Price and Cost Intelligence – pricing models adopted for the category, total cost of ownerships

• Supplier Intelligence – rich insight on supplier landscape, and identifies suppliers who are dominating, emerging, lounging, and specializing

• Sourcing / Procurement Intelligence – best practices followed in the industry, identifying standard KPIs and SLAs, peer analysis, negotiation strategies to be utilized with the suppliers, and best suited countries for sourcing to minimize supply chain disruptions

#Polyvinyl Chloride (PVC) Procurement Intelligence#Polyvinyl Chloride (PVC) Procurement#Procurement Intelligence#Polyvinyl Chloride Market#Polyvinyl Chloride Industry

0 notes

Text

The Lost Art of Recycling: How Our Ancestors Navigated Sustainable Living Before It Was Trendy

In the modern world, when eco-consciousness and sustainability are buzzwords frequently linked to hip lifestyle choices, it's easy to forget that many of the behaviours we now take for granted were once typical customs handed down through the years. One such activity is recycling, which refers to the age-old custom of repurposing, reusing, and making the most of every resource available rather than the contemporary practice of sorting plastics and paper into designated receptacles. Come along on a historical adventure with us as we study the forgotten skill of recycling and learn how our predecessors managed sustainable living before it was trendy in this blog.

A Way of Life, Not a Trend

For our predecessors, recycling was more than simply a fleeting trend; it was a way of life based on need and resourcefulness. Every scrap of material had worth in small towns like Beaver, West Virginia, where waste was not an option and access to commodities was restricted. Our ancestors were resourceful and valued all they had, from furniture fashioned from reclaimed wood to patchwork quilts made from discarded clothing.

The Circle of Life

Everything in the days before mass manufacture and throwaway consumer products had a use and a lifespan that extended much beyond its initial usage. Consider the custom of feeding kitchen leftovers to cattle, which converts food waste into beneficial nutrients for the land and the animals that would subsequently provide for the family. Nothing was wasted even after death: hides were tanned to make leather, bones were reduced to soup, and feathers were used as insulation or bedding.

Innovation Born of Necessity

Our forefathers had to use their imaginations to find inventive solutions to daily difficulties because they were not afforded the current comforts. They discovered creative ways to recycle items and prolong their usefulness much beyond their original lifespan, from utilising old newspapers as insulation to making brooms out of straw and twigs. By doing this, they improved their inventiveness and artistry in addition to conserving resources.

Lessons for the Present

We can't help but wonder what lessons the sustainable living methods and the lost art of recycling from previous generations can teach us for our own lives in the present. Even though our predecessors may not have faced the same difficulties, we may still benefit from their resourcefulness, reverence for the environment, and dedication to living in balance with the natural world. There are many things we can do to commemorate their legacy and use less energy on the environment, such as cutting back on our consumption, reusing old objects, or coming up with original solutions to common problems.

Conclusion

Though sustainability has gained popularity as a marketing buzzword, it's crucial to keep in mind that recycling and sustainable living are age-old concepts that predate humans. Restoring the ancient skill of recycling and taking a cue from our predecessors' resourcefulness can help us not only lessen our influence on the environment but also reestablish a connection with their timeless wisdom. Let us not overlook the importance of drawing inspiration and direction from history as we work to create a more sustainable future.

Embark on a nostalgic journey through the pages of "Moonshine Memories & Staggering Cows: Tales from Raleigh County" by Pearl Todd Miller and Anna Miller-Tiedeman. Explore the rich tapestry of life in rural Appalachia, where sustainable living wasn't a trend but a way of life. Delve into the captivating stories of ordinary people who lived off the land, recycled with ingenuity, and cherished the simple joys of nature. Discover how our ancestors navigated sustainability long before it became fashionable. Buy your copy today from here: https://amz.run/8eyG, and reconnect with the timeless wisdom of the past. Let these tales inspire you to embrace a more sustainable future.

0 notes

Text

Plastic Pallets in the UK: The best solution within your budget

The United Kingdom is one of the countries that has experienced a significant shift in the logistics and transportation industry in the recent past with an emphasis on sustainability. One of the most notable changes that can be seen is the increasing tendency in the use of plastic pallets which possess certain advantages over timber pallets.

Plastic Pallets for Sale near Me are more durable, hygienically acceptable, and reusable hence capable of serving various sectors of the economy. This article is going to talk about the advantages of using plastic pallets and in which field they are most useful; here also provides information about the shops to buy plastic pallets in the United Kingdom.

Benefits of Plastic Pallets

Durability and Longevity: Known as Plastic Pallet UK, this product is famous for its durability as well as the ability to withstand rigorous services. They do not break, crack, or swell as most pallets are made from wood and are usually used in moving goods. This makes them perfect for use over several years and hence they do not require frequent replacement saving a lot of money in the long run.

Hygiene and Cleanliness:

Chemical, bacterial, and pest resistant, plastic pallets are ideal for use in industries or companies that maintain high levels of hygiene like the pharmaceutical and food industries. It can be easily cleaned and can be made sterile to conform to the health and safety of the organization.

Environmental Impact:

Plastic pallets are recyclable and reusable because the types of raw materials used in making pallets are recyclable and the pallets themselves can be recycled. The same can be said about their durability; it is evidenced that a lesser amount of pallets end up in landfills compared to wooden ones.

Lightweight and Safe: Plastic Pallets for Sale near Me are normally lighter than wooden pallets and this has a way of decreasing the cost of transport and the rate of accidents. Their equal dimensional volume also helps prevent products from getting crushed while in transit since they have no edge.

Applications of Plastic Pallets

However, we know that Plastic pallets are versatile and used across various sectors. Considered below the sector that you might know:

• Food and Beverage: Preserving cleanliness and safety as well as the products when transporting perishable commodities.

• Pharmaceuticals: We also went to the extent of washing our hands before and after performing any activity, wearing a face mask and goggles.

• Manufacturing: Bearings are used to support several different masses of heavy machinery and components with stability and high durability.

• Retail and Wholesale: Facilitating easy and safe means of conveyance of the commodities.

Conclusion

The application of plastic pallets continues to change the face of the logistics and transportation industry in the United Kingdom due to the environmentally friendly, durable, and easy-cleaning aspects compared to wooden pallets. Today there are many suppliers in the market supplying all kinds of products and therefore it is easy for a business to get plastic pallets that will meet their needs. This trend is expected to rise as industries seek to establish sustainable and efficient methods of production, which leads to the use of plastic pallets as a solution to attaining a sustainable future.

0 notes

Text

Exploring Commodity Chemicals: Industry Insights

Commodity Chemicals Market is thriving on Surge in Industrialization

The commodity chemicals market comprise of basic chemicals that serve as raw materials and intermediates for various end-use industries such as construction, automotive, healthcare, packaging, and others. Commodity chemicals find widespread applications in manufacturing plastics, synthetic rubbers, fibers, solvents, adhesives, agricultural chemicals, and numerous other products.

The commodity chemicals are basic building blocks for a wide range of industrial and consumer goods. Ethanolamines, ethylene, propylene, butadiene, benzene, toluene, xylene,Methanol and formaldehyde are some of the major commodity chemicals. They are widely used as intermediates in various manufacturing processes and end products. The commodity chemicals market is driven by the fast-paced industrialization and infrastructure development activities worldwide. Rapid urbanization and rising disposable income are fueling the sales of end-use commodities like furniture, electronics, textiles, and packaging, thereby augmenting the market growth.

The Global Commodity Chemicals Market is estimated to be valued at US$ 67.72 Bn in 2024 and is expected to exhibit a CAGR of 6.6% over the forecast period 2023 to 2030.

Key Takeaways

Key players operating in the commodity chemicals market are BASF SE, Dow Inc., SABIC, and LyondellBasell Industries. BASF SE is one of the leading producers of commodity chemicals globally. Dow Inc. offers a wide range of basic and intermediate chemicals.

The growing demand from various end-use industries such as construction, automotive, packaging is propelling the commodity chemicals market. Rapid industrialization and infrastructure developmental activities across emerging nations are boosting the consumption of commodity chemicals.

The commodity chemicals market players are focusing on global expansion by tapping opportunities in fast-growing markets in the Asia Pacific, Latin America, and Middle East regions. Acquisitions and partnerships are helping companies to enhance their geographic presence and manufacturing capabilities.

Market key trends

One of the key trends witnessed in the commodity chemicals market is the shift towards sustainable and eco-friendly chemicals. Stringent environmental regulations regarding emission control and waste management are prompting manufacturers to develop bio-based and greener chemical alternatives. Advancements in green chemistry technologies are assisting players to reduce hazardous waste generation and carbon footprint. Development of renewable feedstock-based commodity chemicals will be a defining trend shaping the future course of this industry.

Porter’s Analysis

Threat of new entrants: Explaining in two line - Chemical manufacturing requires large capital investments which acts as a significant barrier for new players. Strict regulations related to environmental impact and safety compliance also pose entry barriers.

Bargaining power of buyers: Explaining in two line - Commodity chemicals have many substitute options available, giving buyers high bargaining power to negotiate on price with suppliers. Commodity chemicals buyers can easily shift to other suppliers.

Bargaining power of suppliers: Explaining in two line - Commodity chemicals have numerous global suppliers due to their homogeneous nature. This gives buyers option to change suppliers easily without quality compromise giving suppliers low bargaining power.

Threat of new substitutes: Explaining in two line - New alternative materials are continuously emerging as substitutes to commodity chemicals but require huge R&D investments, limiting threats from new substitutes in short term.

Competitive rivalry: Explaining very shortly in one line - Intense due to numerous global players and mature industry.

Geographical regions

The North American region currently holds the major share of the global commodity chemicals market in terms of value due to high demand from end-use industries like packaging, automotive, construction, and healthcare in countries like US and Canada.

Asia Pacific region is expected to be the fastest growing market for commodity chemicals during the forecast period due to rapid industrialization and rising manufacturing activities in emerging economies like China, India, Indonesia and Thailand leading to growing consumption.

0 notes

Text

Commodity Plastics Market Sales Revenue Strategies Insights 2022-2032 | ExxonMobil Corporation, LG Chem, Sumitomo Chemical Co. Ltd

Commodity Plastics Market Sales Revenue Strategies Insights 2022-2032 | ExxonMobil Corporation, LG Chem, Sumitomo Chemical Co. Ltd

This Global Commodity Plastics Market assessment by insightSLICE evaluates past and present economic prospects and trends for the years 2022 to 2032 to provide significant insight into key market drivers. To provide a deep analysis of the global Commodity Plastics market’s progress and make judgments about the industry’s development potential, a dependable research methodology was utilized. This…

View On WordPress

0 notes

Text

Commodity Chemicals Market Innovation: Driving Technological Advancements and Product Development

Commodity Chemicals Market is thriving on Surge in Industrialization

The commodity chemicals market comprise of basic chemicals that serve as raw materials and intermediates for various end-use industries such as construction, automotive, healthcare, packaging, and others. Commodity chemicals find widespread applications in manufacturing plastics, synthetic rubbers, fibers, solvents, adhesives, agricultural chemicals, and numerous other products.

The commodity chemicals are basic building blocks for a wide range of industrial and consumer goods. Ethanolamines, ethylene, propylene, butadiene, benzene, toluene, xylene,Methanol and formaldehyde are some of the major commodity chemicals. They are widely used as intermediates in various manufacturing processes and end products. The commodity chemicals market is driven by the fast-paced industrialization and infrastructure development activities worldwide. Rapid urbanization and rising disposable income are fueling the sales of end-use commodities like furniture, electronics, textiles, and packaging, thereby augmenting the market growth.

The Global Commodity Chemicals Market is estimated to be valued at US$ 67.72 Bn in 2024 and is expected to exhibit a CAGR of 6.6% over the forecast period 2023 to 2030.

Key Takeaways

Key players operating in the commodity chemicals market are BASF SE, Dow Inc., SABIC, and LyondellBasell Industries. BASF SE is one of the leading producers of commodity chemicals globally. Dow Inc. offers a wide range of basic and intermediate chemicals.

The growing demand from various end-use industries such as construction, automotive, packaging is propelling the commodity chemicals market. Rapid industrialization and infrastructure developmental activities across emerging nations are boosting the consumption of commodity chemicals.

The commodity chemicals market players are focusing on global expansion by tapping opportunities in fast-growing markets in the Asia Pacific, Latin America, and Middle East regions. Acquisitions and partnerships are helping companies to enhance their geographic presence and manufacturing capabilities.

Market key trends

One of the key trends witnessed in the commodity chemicals market is the shift towards sustainable and eco-friendly chemicals. Stringent environmental regulations regarding emission control and waste management are prompting manufacturers to develop bio-based and greener chemical alternatives. Advancements in green chemistry technologies are assisting players to reduce hazardous waste generation and carbon footprint. Development of renewable feedstock-based commodity chemicals will be a defining trend shaping the future course of this industry.

Porter’s Analysis

Threat of new entrants: Explaining in two line - Chemical manufacturing requires large capital investments which acts as a significant barrier for new players. Strict regulations related to environmental impact and safety compliance also pose entry barriers.

Bargaining power of buyers: Explaining in two line - Commodity chemicals have many substitute options available, giving buyers high bargaining power to negotiate on price with suppliers. Commodity chemicals buyers can easily shift to other suppliers.

Bargaining power of suppliers: Explaining in two line - Commodity chemicals have numerous global suppliers due to their homogeneous nature. This gives buyers option to change suppliers easily without quality compromise giving suppliers low bargaining power.

Threat of new substitutes: Explaining in two line - New alternative materials are continuously emerging as substitutes to commodity chemicals but require huge R&D investments, limiting threats from new substitutes in short term.

Competitive rivalry: Explaining very shortly in one line - Intense due to numerous global players and mature industry.

Geographical regions

The North American region currently holds the major share of the global commodity chemicals market in terms of value due to high demand from end-use industries like packaging, automotive, construction, and healthcare in countries like US and Canada.

Asia Pacific region is expected to be the fastest growing market for commodity chemicals during the forecast period due to rapid industrialization and rising manufacturing activities in emerging economies like China, India, Indonesia and Thailand leading to growing consumption.

0 notes

Text

Polyethylene Terephthalate (PET) Prices | Pricing | Trend | News | Database | Chart | Forecast

Polyethylene Terephthalate, commonly known as PET, is a highly versatile and widely used polymer in industries such as packaging, textiles, and consumer goods. Its applications in the packaging sector, especially for food and beverages, have driven significant global demand. PET’s lightweight, strong, and recyclable nature makes it the preferred material for manufacturing bottles, containers, and synthetic fibers. However, the price of PET is subject to fluctuations due to several interconnected factors that affect the overall supply and demand dynamics in the market.

One of the primary factors influencing PET prices is the cost of raw materials, particularly crude oil and its derivatives, such as paraxylene (PX) and monoethylene glycol (MEG), which are essential components in the production of PET. The prices of these feedstocks are closely tied to global oil prices, which can be volatile due to geopolitical tensions, natural disasters, and fluctuations in supply from major oil-producing regions. When crude oil prices rise, the cost of producing PET typically increases, pushing prices higher. Conversely, when oil prices fall, PET production costs decline, often leading to lower prices in the market. This strong correlation with oil prices makes PET a commodity that is sensitive to global economic conditions and energy market dynamics.

Get Real Time Prices for Polyethylene Terephthalate (PET): https://www.chemanalyst.com/Pricing-data/polyethylene-terephthalate-72

Another important factor in determining PET prices is the balance between supply and demand in the global market. As the global economy grows, so does the demand for consumer goods, packaging, and textiles, all of which rely heavily on PET. Countries with rapidly growing populations and rising middle classes, such as China and India, have experienced significant increases in demand for PET-based products. This surge in demand can lead to tight supply conditions, driving up PET prices, particularly in regions where production capacity is limited. On the other hand, when there is an oversupply of PET, either due to increased production capacity or reduced demand, prices tend to fall.

Regional differences in supply chains and production capacities also play a significant role in shaping PET prices. Asia, particularly China, is a major producer and consumer of PET. Chinese producers have a dominant presence in the global PET market, which means that any disruptions in China’s production capabilities, whether due to environmental regulations, energy shortages, or other factors, can have a ripple effect on global prices. Meanwhile, regions like Europe and North America often rely on imports of PET, making them more vulnerable to price fluctuations driven by changes in international trade policies, tariffs, and shipping costs.

Seasonal demand trends can further contribute to variations in PET prices. For instance, the beverage industry, which is a significant consumer of PET, tends to see higher demand during the summer months, when consumption of bottled drinks peaks. This seasonal surge in demand can lead to temporary price increases as manufacturers scramble to secure enough PET to meet their production needs. Similarly, holiday seasons and special events can drive up demand for PET packaging, contributing to short-term price fluctuations.

In recent years, sustainability concerns have also influenced PET prices. Governments and environmental organizations worldwide are pushing for increased recycling rates and reduced reliance on virgin plastics. As a result, there is growing demand for recycled PET (rPET), which is produced by processing post-consumer PET products. The price of rPET can fluctuate based on the availability of recyclable materials, the efficiency of recycling processes, and regulatory incentives for using recycled content. In some cases, rPET prices may be higher than those of virgin PET due to the complexities of the recycling process and the need for high-quality feedstocks. However, as the global push for sustainability intensifies, the demand for rPET is expected to rise, potentially affecting overall PET market prices.

Technological advancements in PET production processes can also have an impact on prices. Innovations that improve production efficiency, reduce energy consumption, or enable the use of alternative feedstocks could lead to lower production costs, ultimately driving down PET prices. However, the adoption of new technologies can take time, and their impact on prices may not be immediate. Moreover, the costs associated with transitioning to more sustainable production methods or meeting stricter environmental standards can put upward pressure on prices in the short term.

Global economic conditions and trade policies also play a pivotal role in shaping PET prices. For instance, during periods of economic growth, consumer spending tends to increase, driving up demand for PET-based products. Conversely, during economic downturns, demand for these products may decline, leading to lower PET prices. Trade policies, including tariffs, quotas, and import/export restrictions, can also affect PET prices by influencing the flow of goods between countries. Trade disputes between major PET-producing and consuming nations can create uncertainty in the market, leading to price volatility.

Shipping and logistics costs are additional factors that influence PET prices. PET, like many other commodities, is often transported long distances from production facilities to end-users. Increases in shipping costs due to rising fuel prices, labor shortages, or disruptions in global supply chains can add to the overall cost of PET. Similarly, delays at ports or other transportation bottlenecks can lead to supply shortages, which in turn may drive up prices.

The COVID-19 pandemic had a significant impact on PET prices, as it disrupted supply chains, slowed down production, and altered consumer behavior. During the initial phases of the pandemic, there was a sharp decline in demand for PET due to lockdowns and reduced consumer spending. However, as economies reopened and demand for personal protective equipment, packaged food, and bottled beverages surged, PET prices began to recover. The pandemic highlighted the vulnerability of global supply chains and the need for greater resilience in the face of unexpected disruptions.

In conclusion, PET prices are influenced by a complex web of factors, including the cost of raw materials, supply and demand dynamics, regional production capacities, seasonal trends, sustainability efforts, technological advancements, economic conditions, trade policies, and shipping costs. Understanding these factors is crucial for businesses and consumers alike, as they navigate the ever-changing landscape of the global PET market.

Get Real Time Prices for Polyethylene Terephthalate (PET): https://www.chemanalyst.com/Pricing-data/polyethylene-terephthalate-72

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Polyethylene Terephthalate#Polyethylene Terephthalate Price#Polyethylene Terephthalate Prices#Polyethylene Terephthalate Price Monitor

0 notes

Text

"Diving Deep into the Specialty Polymers Market: Trends, Innovations, and Strategic Insights

Specialty Polymers: Harnessing the Power of Specialty Macromolecules for Next-Generation Technologies

Specialty Polymers Overview

Specialty macromolecules, also known as engineering macromolecules, are a class of macromolecules that are specially engineered to have targeted physical and chemical properties that make them suitable for advanced applications. Though they only represent a small fraction of the total macromolecules market, specialty macromolecules command a significant revenue share due to their higher value and more niche end uses.

Types of Specialty Macromolecules

There are several main types of specialty macromolecules classified based on their monomer makeup and resultant properties. Some of the major types include:

Polyamides (Nylons)

Polyamides, best known by the brand name Nylon, are a class of thermoplastic macromolecules containing amide linkages along their polymer chains. They are known for their high strength, toughness, and relative durability compared to other plastics. Engineering polyamides such as Nylon 46 and Nylon 610 can withstand higher temperatures than commodity nylons.

Fluoromacromolecules

Fluoromacromolecules contain strong carbon-fluorine covalent bonds which give them unique oil, chemical, heat and weather resistance properties. Popular fluoromacromolecules include polytetrafluoroethylene (PTFE or Teflon), fluorinated ethylene propylene (FEP), and polyvinylidene fluoride (PVDF). They are used in applications requiring non-stick, low friction surfaces.

Polyesters

Engineering polyesters such as liquid crystal macromolecules (LCP), polybutylene terephthalate (PBT), and polyethyleneterephthalate (PET) can be formulated with enhanced heat resistance, strength and rigidity over traditional polyesters. They are employed in automotive, electrical/electronic and consumer goods.

Liquid Silicone Rubbers

Liquid silicone rubbers (LSRs) are two-part addition-cure silicone elastomers that vulcanize at room temperature. Their biocompatibility, stability and flexibility make them well-suited for medical, food and microfluidic device applications. Low compression set LSRs retain shape over time.

Polyketones

Polyketones are a family of thermoplastics with high strength, heat resistance and chemical resistance derived from their ketone groups in the polymer backbone. They include comacromolecules like polyetheretherketone (PEEK) used in demanding mechanical and electrical end uses.

Markets and Applications

Specialty macromolecules are developing across diverse markets driven by the need for advanced material performance. Some of the major application areas include:

Automotive

In automotive, specialty macromolecules enable lightweighting through replacement of traditional metals. Nylons, PBT, polycarbonate and liquid silicone aid composites in vehicles. Use in engine components require heat resistance of PEEK and liquid crystal macromolecules.

Electronics

Electronics rely on specialty macromolecules for miniaturization and reliability. PTFE, FEP, PET and PVDF bring dielectric, insulating properties. PBT molding aids housings. Semiconductor uses benefit from high heat resistance of PEKK and LCP.

Medical

Biocompatible and non-leaching properties of silicones, nylons and PEEK suits medical industry. Implants, catheters, sensors and drug delivery use these. PEKK aids orthopedic devices. Silicones serve prosthetics, wound care and contact lenses.

Infrastructure

Resistance to chemical, heat and environmental stress qualifies many macromolecules for infrastructure. PVDF and silicones protect coatings and paints. Dams, tunnels utilize durability of PTFE and polyketones lining.

Other Developments

New technologies foster demand for high performance plastics. Renewable energy harvest requires specialty macromolecules in wind turbines, solar cells. Aerospace gravitates toward sturdy yet lightweight materials like PEKK, PEEK. Microfabrication leverages specialty silicones and fluoromacromolecules. As applications diversify, advanced macromolecules enable novel solutions.

Future Prospects

The specialty macromolecules market is forecast to sustain strong growth over the medium term supported by their rising penetration across major end-use industries. Polyketones, liquid silicone rubbers and high-temperature polyamides will be key winning product types. The Asia Pacific region is expected to lead future demand growth driven by its large manufacturing industries. Robust R&D focus on bio-based and high-tech specialty macromolecules will further fuel new product innovations and market opportunities going forward.

In Summary, specialty polymers represent a fascinating realm of materials science, offering tailored properties and applications beyond traditional macromolecules. These advanced materials are engineered to meet specific performance requirements, such as enhanced durability, conductivity, or biocompatibility. From aerospace components to medical devices, specialty macromolecules play a crucial role in a wide range of industries, driving innovation and pushing the boundaries of what's possible.

0 notes

Text

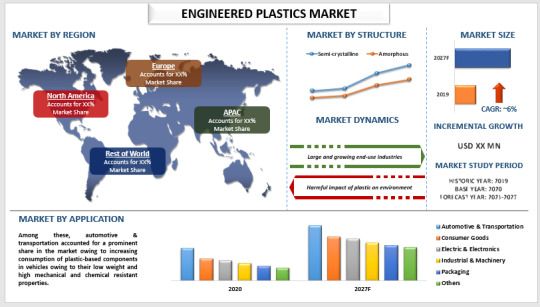

Analyzing the Engineered Plastics Market: Trends and Growth Potential

Engineered plastics, also known as engineering plastics market, are a group of plastic materials that have enhanced mechanical and thermal properties, making them suitable for more demanding applications than standard plastics. These materials are used in a wide range of industries, including automotive, aerospace, electronics, and healthcare. This article explores the current trends, driving forces, challenges, and future prospects of the engineered plastics market.

Understanding Engineered Plastics

Engineered plastics are polymers that exhibit superior strength, heat resistance, and durability compared to commodity plastics. Common types of engineered plastics include polycarbonate (PC), acrylonitrile butadiene styrene (ABS), polyamide (PA or nylon), polyoxymethylene (POM or acetal), and polyphenylene oxide (PPO). These materials are used in applications that require high performance and reliability.

Key Market Drivers

Growth in End-Use Industries: The expansion of industries such as automotive, aerospace, electronics, and healthcare is a major driver for the engineered plastics market. These industries demand materials that can withstand harsh environments, offer high precision, and contribute to lightweighting and energy efficiency.

Technological Advancements: Innovations in polymer science and manufacturing processes are enhancing the properties of engineered plastics. Advances such as reinforced composites, biodegradable polymers, and 3D printing materials are broadening the application scope of engineered plastics.

Environmental Regulations and Sustainability: Stringent environmental regulations and the growing emphasis on sustainability are driving the demand for engineered plastics. These materials are often recyclable, contribute to energy savings through lightweighting, and can replace metal parts, reducing the overall environmental impact.

Market Segmentation

The engineered plastics market can be segmented based on type, application, and region.

By Type:

Polycarbonate (PC): Known for its high impact resistance and transparency, used in automotive parts, electronics, and medical devices.

Acrylonitrile Butadiene Styrene (ABS): Offers good toughness and rigidity, used in automotive components, consumer electronics, and toys.

Polyamide (PA or Nylon): Known for its strength and wear resistance, used in automotive parts, textiles, and industrial applications.

Polyoxymethylene (POM or Acetal): Provides high stiffness and dimensional stability, used in precision parts like gears and bearings.

Polyphenylene Oxide (PPO): Offers high thermal stability and electrical insulation, used in electrical and electronic components.

By Application:

Automotive: Engineered plastics are used for components like fuel systems, interior and exterior parts, and under-the-hood applications.

Aerospace: These materials are used in lightweight structural components, interior parts, and insulation.

Electronics: Used in housings, connectors, and circuit boards.

Healthcare: Employed in medical devices, surgical instruments, and diagnostic equipment.

Industrial: Used in machinery parts, gears, bearings, and conveyor systems.

By Region:

North America: Driven by advancements in technology and the presence of key end-use industries.

Europe: Emphasis on sustainability and high-performance materials.

Asia-Pacific: Rapid industrialization and growth in automotive and electronics industries.

Latin America and Middle East & Africa: Emerging markets with increasing demand for high-performance materials.

Challenges in the Market

Despite the positive growth outlook, the engineered plastics market faces several challenges:

High Costs: The production and raw material costs for engineered plastics are higher than for commodity plastics, which can limit their adoption in cost-sensitive applications.

Regulatory Compliance: Meeting stringent environmental and safety regulations requires continuous innovation and investment in research and development.

Market Competition: The market is highly competitive, with numerous players offering a wide range of products. Differentiating based on quality, performance, and sustainability is crucial for gaining a competitive edge.

Request for a sample of the report browse through- https://univdatos.com/get-a-free-sample-form-php/?product_id=23691

Future Prospects

The future of the engineered plastics market is promising, with several growth opportunities on the horizon:

Advancements in Composite Materials: The development of reinforced composites and hybrid materials will enhance the performance characteristics of engineered plastics, expanding their application range.

Growth in Emerging Markets: Emerging economies in Asia-Pacific, Latin America, and Africa present significant growth opportunities. Increasing industrialization and infrastructure development in these regions will drive the demand for engineered plastics.

Sustainability Initiatives: The push for sustainability will continue to drive innovations in biodegradable and recyclable engineered plastics. These materials will play a crucial role in reducing the environmental impact of various industries.

Conclusion

The engineered plastics market is set for robust growth, driven by the expansion of end-use industries, technological advancements, and sustainability trends. While challenges such as high costs and regulatory compliance persist, innovations in composite materials and the growth of emerging markets offer substantial opportunities. As industries evolve, engineered plastics will continue to play a vital role in delivering high-performance, durable, and sustainable solutions.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

Sipping Trends: An Overview of the Global Soft Drinks Market

In a world where thirst knows no borders, the Global Soft Drinks Market stands as a refreshing oasis of innovation, taste, and consumer choice. From classic colas to exotic fruit blends, this dynamic industry caters to diverse palates around the globe. Let's delve into the effervescent world of soft drinks, exploring its key trends, challenges, and future prospects.

The Flavorful Landscape:

The Global Soft Drinks Market is a vast playground of flavours, encompassing carbonated sodas, fruit juices, sports drinks, energy drinks, and more. Traditional favourites like Coca-Cola and Pepsi continue to dominate, but consumer preferences are evolving. Health-conscious consumers are driving demand for low-sugar, natural, and functional beverages, prompting the rise of brands like LaCroix and Vitaminwater. Furthermore, the explosion of craft sodas and artisanal blends caters to discerning tastes, offering unique flavour profiles and premium experiences.

Market Dynamics:

The Global Soft Drinks Market is fueled by several factors, including changing lifestyles, urbanisation, rising disposable incomes, and increasing awareness of health and wellness. Emerging markets in Asia-Pacific, Latin America, and Africa are witnessing robust growth, driven by expanding middle-class populations and changing consumption patterns. On the other hand, saturated markets in North America and Europe are experiencing moderate growth, characterised by a shift towards healthier alternatives and a decline in sugary soda consumption.

Challenges and Opportunities:

Despite its resilience, the Global Soft Drinks Market faces challenges on multiple fronts. Growing concerns over sugar content, obesity, and environmental sustainability are prompting regulatory scrutiny and consumer activism. Beverage companies are under pressure to reformulate their products, reduce plastic packaging, and embrace eco-friendly practices to stay relevant in a changing landscape. Moreover, intensifying competition, volatile commodity prices, and supply chain disruptions pose additional challenges.

However, amidst these challenges lie abundant opportunities for innovation and growth. The shift towards healthier beverages opens doors for companies to develop innovative formulations, such as natural sweeteners, functional ingredients, and fortified drinks targeting specific health needs. Furthermore, technological advancements in flavour profiling, packaging, and distribution offer avenues for enhancing product quality, efficiency, and customer engagement. Additionally, strategic partnerships, acquisitions, and expansion into untapped markets enable companies to diversify their portfolios and capture new revenue streams.

Future Outlook:

The future of the Global Soft Drinks Market is poised for evolution, driven by shifting consumer preferences, regulatory changes, and technological advancements. Health and wellness will continue to be key drivers, with demand for low-sugar, natural, and functional beverages expected to grow. Moreover, sustainability will become increasingly important, influencing product design, packaging materials, and corporate practices. As the industry embraces innovation and adapts to changing dynamics, it will continue to thrive as a quintessential part of global beverage consumption.

In conclusion, the Global Soft Drinks Market is a vibrant tapestry of flavours, trends, and opportunities. From traditional favourites to avant-garde concoctions, it caters to the diverse tastes and preferences of consumers worldwide. As the industry navigates through challenges and embraces innovation, it remains a refreshing beacon of choice, convenience, and enjoyment for thirsty souls around the globe. Cheers to the enduring spirit of the Global Soft Drinks Market!

0 notes

Text

Overcoming Supply Chain Issues in Wire and Cable by cable suppliers in kuwait

Like several other sectors, the electrical wire along with the cable industry has encountered new challenges in the last two years. And, as you all know, the international supply chain has never been more sophisticated or dynamic. Increased manufacturing demand, as well as labour and product shortages, are just a few of the challenges you confront. Let's look at market trends affecting the hdmi cable kuwait and how smart planning and educated decision-making may help you respond.

Condition of the Industry

Labour Shortages

Tariffs increased the number of industrial manufacturing companies outsourcing and bringing facilities located overseas, hence raising manufacturing demand. Labour shortages have served as an industrial concern for some time, but the Covid-19 pandemic has aggravated the matter. One of the most difficult difficulties fr producers is finding enough labour to create cable while keeping lead times short.

Rising Costs and Inflation

In addition to labour constraints, rising commodity prices and inflation have forced many firms to allocate substance. So supply may remain tight. According to the survey, aluminium will reach a 13-year high in 2021. Furthermore, copper prices rose in 2021 compared to the previous year, with sustained increases in demand across all sectors.

Transportation cost

According to Accenture, the pandemic disrupted the supply chains of all Fortune, leading to increased transportation costs. Transportation expenses continue to climb through March 2022. Truck freight prices have risen sharply, while the Product Price Index continues to rise. Airfreight prices continue to rise on year until December 2023. Because freight prices are connected to how distance products ship, collaborating with worldwide facilities can assist cut transportation expenses.

Increased Manufacturing Lead Times

You may observe delays in near-term order shipments due to manufacturing issues, as well as an increase in long-term orders. The blend of the two is increasing product delivery times to new heights. New urgent requests may be shunted to the back of the queue when manufacturing from cable suppliers in kuwait capacity is occupied by speculative projection planning. This cycle can reoccur, resulting in longer lead times. Construction planning in this industry is being conducted more in advance to acquire raw materials, resulting in longer timeframes and increased costs. In the manufacturing businesses, many companies place orders regarding products weeks in advance.

Global Market

While businesses may source domestically and work with domestic producers, global events continue to have an impact on the supply chain. Plastics are made from oils, while wires, cables, and enclosures are made from metal. These commodities compete on a global scale. Disruptions in global supply might have an impact on local cost and availability. Long-term planning and use of inventory solutions can help you reduce supply volatility while smoothing out cost fluctuation.

The global marketplace is under pressure. Having an accomplice who understands how to handle disruptions and use global talents is more critical than ever. Customers through predictions, product reservations, and source substitutes, understand how to shift and employ alternatives whenever faced with shortages. Industry-leading knowledge and value-added services to help build a more resilient supply chain and drive efficiencies is your bottom line.

0 notes