#Commercial Conveyor Ovens manufacturer

Explore tagged Tumblr posts

Text

#Commercial Conveyor Ovens#Conveyor Ovens#Commercial Conveyor Ovens supplier#Commercial Conveyor Ovens dealer#Commercial Conveyor Ovens distributor#Commercial Conveyor Ovens manufacturer#Commercial Conveyor Ovens for sale

0 notes

Text

Top bread making machine manufacturer & Suppliers | iframachine

IFRA Machine Technology is the go-to choice for businesses looking to enhance their bread production capabilities. bread making machine manufacturers in india, bread making machine manufacturers, bread making machine manufacturers in delhi, bread making machine manufacturer in Haryana,

#bread making machine manufacturers in india#bread making machine manufacturers#bread making machine manufacturers in delhi#bread making machine manufacturer in Haryana#bread machine manufacturer in Haryana#bakery machine manufacturers in india#bakery machine manufacturers in Sonepat#top manufacturers bakery machine in delhi#Automatic Bakery Machine Manufacturers In haryana#commercial bread making machine in delhi#bakery machine manufacturers in delhi#bread loaf run belt conveyor#Top bakery Equipment Suppliers in india#rusk toast making machine#depanner rusk manufacturer in delhi#Tunnel Oven Manufacturers & Suppliers in India#swing baking oven manufacturers in delhi#Stacker Conveyor Manufacturers & Suppliers#rusk feeding conveyor india#Cooling Tunnel Supplier and Exporter#Tray Type Bread Cooling Tunnel Manufacturer#high speed mixer supplier in delhi#high speed slicer machine#dough divider machine manufacturers in delhi#roto rack oven manufacturers in india#bread ms trolley manufacturers in delhi#stainless steel bakery trolley manufacturers in delhi#dough proofing chamber manufacturer & supplier#dough tunnel proving chamber manufacturer in delhi#bakery machines and bakery equipments manufacturers

1 note

·

View note

Text

Bakery Oven Manufacturers: Crafting Quality for Modern Bakeries

In the thriving food industry, bakeries stand out for their artistry in creating breads, cakes, pastries, and other delicacies. To ensure consistent quality and freshness, bakeries rely heavily on advanced bakery ovens, making the choice of oven a pivotal aspect of their success. Behind this essential equipment are bakery oven manufacturers, responsible for creating ovens that deliver on performance, durability, and efficiency.

In India, especially in food hubs like Bangalore, bakery oven manufacturers play a critical role in supporting both small bakeries and large-scale industrial bakeries. As the demand for bakery items increases, so does the need for reliable, energy-efficient ovens tailored to different baking needs. Let’s explore the various types of bakery ovens, what manufacturers prioritize, and why Bangalore is emerging as a significant hub for bakery oven production.

Key Types of Bakery Ovens

The versatility in baking is largely due to the diversity of ovens available, each suited to a specific style or scale of baking. Bakery oven manufacturers understand these requirements and focus on crafting ovens that cater to a variety of needs:

1. Deck Ovens: Known for their consistency, deck ovens feature multiple baking surfaces (or “decks”) that can each hold several trays. These ovens use radiant heat and often feature stone decks, perfect for bread baking. They allow bakers to control each deck’s temperature, making them suitable for a range of products. Manufacturers ensure that deck ovens meet high-temperature consistency requirements, a key factor in producing high-quality baked goods.

2. Convection Ovens: Using circulating hot air, convection ovens are popular for their fast, even baking, suitable for cookies, cakes, and pastries. These ovens allow efficient baking at relatively lower temperatures and shorter times, reducing energy costs. Manufacturers focus on robust fan designs, precise temperature controls, and insulation to make them energy-efficient and durable.

3. Rotary Rack Ovens: Designed for large-scale production, these ovens use rotating racks to ensure even baking across multiple trays. Bakery oven manufacturers use advanced technology to create models with optimal airflow, consistent temperature distribution, and high production capacities, making them ideal for commercial bakeries. They are also equipped with humidity controls to keep baked items from drying out.

4. Tunnel Ovens: Primarily used in industrial-scale baking, tunnel ovens are conveyor-belt systems that bake continuously. Products are placed on a conveyor belt that moves through different heating zones. Manufacturers often customize these ovens to meet specific baking requirements, like precise temperature zones and adjustable conveyor speeds, allowing for high output and uniform baking results.

5. Specialized Ovens: Manufacturers also create ovens tailored to specific needs, such as pizza ovens or pastry ovens. These ovens often have unique features such as stone baking surfaces, high-temperature capabilities, or steam injection systems to achieve the desired texture and appearance in the final product.

Innovations in Bakery Oven Manufacturing

Bakery oven manufacturers focus on technology and materials to enhance the baking process, maximize energy efficiency, and ensure safety. Here are some of the innovations driving modern bakery oven manufacturing:

Energy Efficiency: In response to the need for cost-effective operations, manufacturers are producing energy-efficient ovens that minimize heat loss through improved insulation, optimized airflow systems, and high-performance heating elements.

Advanced Control Systems: Digital control panels with programmable settings enable bakers to automate temperature, baking time, and humidity levels. These controls provide consistent results, reduce human error, and offer flexibility for different products.

Sustainable Materials: Many manufacturers now use eco-friendly materials and designs that reduce the environmental impact. For instance, stainless steel constructions are not only durable but also reduce the need for frequent replacements.

Steam Injection Technology: Steam injection is crucial for certain bakery items like crusty bread. Advanced steam injection technology enables bakers to add moisture at precise intervals, helping to create desired textures and appearances.

Safety and Hygiene: To meet safety standards, manufacturers ensure ovens are equipped with thermal insulation, robust handles, and safety features like automatic shut-off and emergency release systems. Hygiene is also a priority, with designs that allow for easy cleaning and maintenance, which is essential in food production.

Why Bangalore for Bakery Oven Manufacturing?

Bangalore has a thriving manufacturing sector, skilled workforce, and strong infrastructure, which have made it a prominent hub for industrial machinery, including bakery ovens. Bakery oven manufacturers in Bangalore benefit from proximity to raw material suppliers, access to technical expertise, and a market with a growing demand for quality bakery products. Additionally, Bangalore’s central location and logistics networks facilitate easy distribution across India and exports to international markets.

The city’s bakery oven manufacturers often collaborate with local bakery experts to understand market trends and baking preferences, allowing them to design ovens that cater specifically to the Indian market. As the demand for quality baked goods increases, particularly with the growth of commercial bakeries and café chains, Bangalore’s reputation as a key location for bakery oven manufacturing continues to rise.

Conclusion

The choice of oven is crucial in any bakery setup, influencing product quality, energy consumption, and production capacity. Bakery oven manufacturers are at the forefront of innovation, developing ovens that combine durability, efficiency, and precision. As the industry grows, particularly in food-centric cities like Bangalore, these manufacturers are poised to support bakeries in delivering quality products while meeting operational and environmental standards. For bakeries, investing in the right oven is a pathway to success, and reliable bakery oven manufacturers are key partners in this journey.

0 notes

Text

The Importance of Industrial Electrical Services

Industrial electric systems are the backbone of producing plants, warehouses, and big commercial centers across Chicago. These structures are some distance extra complex than popular residential or industrial electrical in Chicago, and they require specialised know-how and expertise. Ensuring the right installation, upkeep, and restore of business electrical structures is critical for operational efficiency and safety.

In a dynamic city like Chicago, wherein industries are the riding pressure in the back of the nearby financial system, the demand for professional industrial electricians has by no means been better. Whether your enterprise operates in production, distribution, or large-scale creation, dependable electric offerings are important to maintain the entirety strolling smoothly. Let’s discover why industrial electrical services in Chicago are so essential and what you should look for while choosing an electrical contractor in your business.

Specialized Expertise for Complex Systems

One of the maximum important distinctions among industrial electric work and different varieties of electric carrier is the complexity of the systems worried. Industrial electrical systems frequently strength heavy equipment, computerized methods, and excessive-voltage system. Any malfunction or miscalculation can cause extreme disruptions in production or, worse, create unsafe running conditions.

Chicago's industries call for electricians who're properly-versed in handling excessive-voltage systems, motor controls, and specialised equipment consisting of conveyor belts, business ovens, and large-scale cooling systems. An industrial electrician have to be able to troubleshooting problematic problems fast and efficiently to limit downtime and make sure safety requirements are met.

Electrical System Installation and Upgrades

If you're putting in a brand new facility or expanding an present one, you will want professional industrial electrical offerings in Chicago to install wiring, transformers, switchboards, and other crucial additives. These installations must be done with precision and in compliance with both nearby building codes and the unique necessities of your enterprise.

Industrial electricians additionally play a key function in upgrading outdated structures. As groups grow, electric call for frequently will increase, and older systems can warfare to preserve up. Upgrading your electrical infrastructure allows ensure that your facility can handle extended production, automation, and new era.

Preventative Maintenance to Avoid Downtime

In an business setting, downtime may be noticeably high priced. For example, in manufacturing, even a quick interruption in electrical carrier can halt manufacturing, cause ignored time limits, and decrease profitability. Preventative renovation from a certified industrial electrical contractor in Chicago is the best manner to keep away from those expensive disruptions.

Regular inspections, testing, and servicing of your electric structures assist become aware of ability issues before they change into giant issues. Whether it's analyzing wiring for put on, checking equipment for correct grounding, or making sure electrical panels are functioning successfully, preventative preservation is a clever funding that can keep your enterprise time and money ultimately.

Adherence to Safety Standards

Industrial electrical systems function below strict protection regulations, and compliance with these standards is non-negotiable. Safety is paramount, in particular while coping with excessive-voltage systems, dangerous materials, and commercial equipment.

Hiring a Chicago-based business electrician guarantees your structures are compliant with neighborhood and federal protection standards, inclusive of the Occupational Safety and Health Administration (OSHA) recommendations. A knowledgeable electrician can install protection functions like emergency shutdown systems, defensive relays, and other fail-safes that assist in saving you from accidents and injuries in the place of work.

Emergency Electrical Services

Electrical troubles don’t continually occur during normal enterprise hours. When a hassle arises, having a business electrician in Chicago who gives 24/7 emergency services can make all of the distinction. Quick response instances are important in emergency conditions to reduce the risk of prolonged downtime, device damage, or hazardous situations.

Whether it's a power outage, gadget malfunction, or wiring failure, having a dependable contractor on call guarantees that your enterprise can get back up and jogging as quickly as viable.

Choosing the Right Industrial Electrical Contractor in Chicago

When deciding on a commercial electrician, it’s important to pick out a contractor who revels in dealing with big-scale, complicated systems. Look for electricians who're certified, insured, and licensed to carry out commercial work. They should have a stable recognition for supplying outstanding services and adhering to stringent protection protocols.

Additionally, choose a company that offers a complete variety of offerings, which include installation, maintenance, maintenance, and emergency response. Working with a single contractor who knows your facility’s specific needs can cause quicker service and higher universal consequences.

In a metropolis as bustling and industrious as Chicago, corporations need the assistance of reliable and experienced commercial electrical offerings to hold safety, efficiency, and productivity. Whether it’s putting in new structures, upgrading previous infrastructure, or offering preventative maintenance, choosing the right commercial electrical in Chicago is critical in your enterprise’s fulfillment. With an expert group at your facet, you may ensure your facility runs smoothly, minimizing disruptions and maximizing overall performance.

#commercial charging station chicago#electrical business chicago#industrial electrician chicago#electrical companies chicago

0 notes

Text

Privacy Management Software Market Size, Share, Growth, Trends [2032]

Privacy Management Software Market provides in-depth analysis of the market state of Privacy Management Software manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Privacy Management Software in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Privacy Management Software Market Report:

The report offers a comprehensive and broad perspective on the global Privacy Management Software Market.

The market statistics represented in different Privacy Management Software segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Privacy Management Software are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Privacy Management Software.

Major stakeholders, key companies Privacy Management Software, investment feasibility and new market entrants study is offered.

Development scope of Privacy Management Software in each market segment is covered in this report. The macro and micro-economic factors affecting the Privacy Management Software Market

Advancement is elaborated in this report. The upstream and downstream components of Privacy Management Software and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/privacy-management-software-market-100578

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Global Party Supplies MarketMarket Size

Pizza Conveyor Oven MarketMarket Growth

Minimally Invasive Surgical (Mis) Device MarketMarket Analysis

Microwave Ovens MarketMarket Size

Global Human Capital Management MarketMarket Share

Global Reflective Insulation Material MarketMarket Growth

Custom Clothing (Made to Measure) MarketMarket

Feed Phytogenics MarketMarket Share

Next-Generation Sequencing Services MarketMarket Growth Rate

RF MEMS MarketMarket Forecast

Global Digital Twin MarketMarket Size

Cloud Electronic Design Automation (Eda) MarketMarket Growth

Off Road Electric Vehicles MarketMarket Analysis

Online Fundraising Tools MarketMarket Size

Global High Purity Synthetic Quartz Glass MarketMarket Share

Global Partial Discharge Monitoring Systems MarketMarket Growth

Battery Energy Storage Systems (BESS) MarketMarket

Solar Photovoltaic Glass MarketMarket Share

Drone Services MarketMarket Growth Rate

Healthcare Chatbots MarketMarket Forecast

Global Connected Enterprise MarketMarket Size

Annual Wellness Visits (AWV) Software MarketMarket Growth

ITSM Consulting, Implementation and Managed Services MarketMarket Analysis

Electric Vehicle (EV) Charging Infrastructure MarketMarket Size

Global Anionic Dispersants MarketMarket Share

Global Thyristor MarketMarket Growth

Electric Vehicle Range Extender MarketMarket

Organic and Natural Tampons MarketMarket Share

Sterilization Equipment and Disinfectants MarketMarket Growth Rate

Commercial Heavy-Duty Laundry Machinery MarketMarket Forecast

Global Games and Puzzles MarketMarket Size

Microchannel Plate Detector MarketMarket Growth

Honeycomb Sandwich Material MarketMarket Analysis

Soft Covering Flooring MarketMarket Size

Global Preimplantation Genetic Testing MarketMarket Share

Global Sinter Hip Furnace MarketMarket Growth

DKDP-Q-Switcher MarketMarket

Laser Picosecond Pen Market Market Share

Single-use Face shield Screens Market Market Growth Rate

Silicon on Insulator (SOI) Market Market Forecast

0 notes

Text

Commercial Pizza Ovens: The Heart of the Pizzeria

A commercial pizza oven is the cornerstone of any pizzeria. The type of oven you choose can significantly impact the taste, texture, and overall quality of your pizza.

Types of Commercial Pizza Ovens

Deck Ovens: These ovens feature multiple decks or shelves for baking pizzas. They often use brick or stone floors, which absorb and retain heat, resulting in a crispy crust. Deck ovens are ideal for restaurants with consistent pizza volume and a preference for traditional pizza styles.

Conveyor Ovens: Using a conveyor belt to move pizzas through the oven, these offer consistent cooking times and high output. Perfect for fast-paced environments and pizza chains, conveyor ovens prioritize speed and efficiency.

Wood-fired Ovens: Renowned for imparting a smoky flavor, wood-fired ovens require skilled operators. While more challenging to maintain, they offer a distinctive taste that many pizza lovers crave.

Gas and Electric Ovens: Balancing speed, efficiency, and control, gas and electric ovens are reliable and easy to operate. While they may not replicate the flavor of wood-fired ovens, they provide consistent results.

Factors to Consider When Choosing a Pizza Oven

Pizza Style: Your pizza style will influence oven choice. For example, Neapolitan pizzas often require high heat and a stone floor.

Kitchen Layout: Consider the oven's size and placement within your kitchen.

Pizza Volume: Determine the oven's capacity based on your expected pizza output.

Budget: Factor in the cost of the oven and installation.

Fuel Type: Evaluate the advantages and disadvantages of gas, electric, or wood-fired options.

Maintaining Your Pizza Oven

Regular cleaning and maintenance are crucial for your pizza oven's longevity. Remove food residue, inspect heating elements, burners, and conveyor belts for wear and tear. Following the manufacturer's guidelines will help ensure your oven operates efficiently.

By carefully selecting and maintaining your pizza oven, you can create delicious pizzas that keep customers coming back.

0 notes

Text

Star MFG Manufacturing Company- Star Grill & Griddle/Fryers/Tosters/Ovens- PartsFe

youtube

Star Manufacturing has been a leading supplier of restaurant supplies since 1921, offering powerful commercial cooking equipment that can prepare a variety of meals and snacks in any setting. Customers have shown genuine loyalty to the brand due to the high quality and reliability of Star Manufacturing's products. They provide a wide range of commercial kitchen and restaurant equipment parts, ensuring that all their customers' support needs are met. Star Manufacturing has become a familiar sight in restaurants, stadiums, and convenience stores, providing countertop fryers, conveyor toasters, and other essential equipment to ensure that customers are always satisfied. For those in need of original Star mfg parts, PartsFe offers a wide selection to ensure that customers always have access to the components their machines require.

0 notes

Text

Reflow Ovens: Essential Equipment for Surface Mount Technology (SMT)

Reflow Ovens: Essential Equipment for Surface Mount Technology (SMT) A reflow oven is a crucial component in the field of Surface Mount Technology (SMT). Its primary purpose is to solder surface mount electronic components onto printed circuit boards (PCBs). Let’s delve into the details of reflow ovens and their significance.Get more news about Reflow Oven,you can vist our website!

How Reflow Ovens Work: Temperature Profile: A reflow oven operates similarly to a convection oven found in households. It follows a specific temperature profile during the soldering process, which consists of four stages: Preheat: The PCBs are gradually heated to a specific temperature. Soak: The temperature is maintained to allow the solder paste to melt and wet the components. Reflow: The solder paste reflows, creating strong solder joints. Cooling: The PCBs cool down to stabilize the soldered components. High-Volume Use: In commercial manufacturing, reflow ovens are often long tunnels with conveyor belts, allowing PCBs to travel through the various temperature zones. For prototyping or hobbyist use, smaller ovens with doors can suffice. Key Parameters of Reflow Ovens: Temperature Zones: Reflow ovens have multiple temperature zones, each with precise temperature settings. Reflow Time: The duration of the reflow process. Applications and Advantages: Efficiency: Reflow ovens enable efficient and consistent soldering of SMT components. Quality: They produce reliable solder joints without damaging the components. Automation: High-volume production lines benefit from automated reflow processes. In summary, reflow ovens play a vital role in modern electronics manufacturing, ensuring reliable soldering and efficient production. If you have any further questions or need additional information, feel free to ask!

0 notes

Text

Hotel kitchen Equipment Manufacturers in Delhi: Swastik Professionals Leading the Way

When it comes to hotel kitchen equipment manufacturers in Delhi, Swastik Professionals stands out as a leader in the industry. Providing a wide range of commercial kitchen equipment, Swastik Professionals ensures that every piece meets the highest standards of quality and efficiency. Let’s dive into what makes Swastik Professionals the go-to choice for hotel kitchen equipment in Delhi.

Overview of Swastik Professionals

Swastik Professionals is renowned for its extensive experience in manufacturing top-notch kitchen equipment for hotels and other commercial establishments. They specialize in creating equipment that is both durable and efficient, ensuring that the needs of their clients are met with precision and care.

Types of Kitchen Equipment Provided by Swastik Professionals

Cooking Equipment Swastik Professionals offers a comprehensive range of cooking equipment, from ovens and stoves to grills and fryers. Each piece is designed to handle the high demands of a commercial kitchen, ensuring consistent performance and durability.

Refrigeration Units Proper storage is crucial in any commercial kitchen. Swastik Professionals provides state-of-the-art refrigeration units, including walk-in coolers, freezers, and under-counter refrigerators, all designed to maintain optimal food safety standards.

Food Preparation Equipment To streamline the food preparation process, Swastik Professionals offers a variety of equipment such as mixers, slicers, and food processors. These tools help in maintaining efficiency and consistency in food preparation, crucial for any hotel kitchen.

Dishwashing Equipment Maintaining hygiene in the kitchen is paramount, and Swastik Professionals ensures this with their robust dishwashing equipment. From under-counter dishwashers to large conveyor systems, they have solutions for kitchens of all sizes.

Quality and Standards

Swastik Professionals prides itself on adhering to the highest quality standards. Each piece of equipment undergoes rigorous testing to ensure it meets industry standards, providing peace of mind to hotel operators who rely on their durability and efficiency.

Customization Options

Understanding that every kitchen has unique requirements, Swastik Professionals offers customization options. Whether it’s modifying the size of a piece of equipment or integrating specific features, they work closely with clients to deliver tailored solutions.

After-Sales Service and Support

The relationship with Swastik Professionals doesn’t end after the purchase. They offer comprehensive after-sales service and support, ensuring that any issues are promptly addressed and that the equipment continues to function optimally.

Why Choose Swastik Professionals?

Experienced and Knowledgeable Team Swastik Professionals boasts a team of experienced professionals who understand the intricacies of commercial kitchen requirements. Their expertise ensures that clients receive the best advice and solutions for their needs.

High-Quality Products The commitment to quality is evident in every piece of equipment manufactured by Swastik Professionals. They use only the best materials and the latest technology to ensure their products stand the test of time.

Customer-Centric Approach At Swastik Professionals, the customer always comes first. Their approach is centered on understanding the unique needs of each client and providing solutions that enhance the efficiency and productivity of their kitchens.

Conclusion

For those seeking top-quality hotel kitchen equipment manufacturers in Delhi, Swastik Professionals is a name you can trust. Their extensive range of products, commitment to quality, and customer-centric approach make them the ideal choice for any commercial kitchen setup.

#commercial kitchen equipment dealers in delhi#commercial kitchen equipment suppliers in delhi#Best Commercial Kitchen Equipment Manufacturers in Delhi NCR#Commercial Kitchen Equipment Manufacturers in Delhi NCR

0 notes

Text

Top Infrared Heating Equipment Manufacturer & Supplier

Discover premier infrared heating solutions crafted by Kerone Engineering Solutions Ltd. As a leading manufacturer and supplier of infrared heating equipment, we specialize in innovative technology for industrial and commercial applications. Explore our innovative range of infrared heating solutions for enhanced efficiency and performance. If you want to buy Industrial heating, drying and coating equipment's online from India, you are right place….. Contact us today for all your industrial needs. For more detail visit at our website: https://www.kerone.in/ P.H: +91-22-48255071 / 72 Enquiry: https://www.kerone.in/contact/ Email-Id : [email protected],[email protected]

1 note

·

View note

Text

The Heart of the Kitchen: Choosing the Right Commercial Oven for Your Restaurant

In any restaurant, the commercial oven serves as the beating heart of the kitchen. It's a crucial piece of equipment that can make or break a dish, and choosing the right commercial oven is paramount to the success of your establishment. Whether you're starting a new restaurant or looking to upgrade your kitchen equipment, understanding the various types of commercial ovens, their features, and their suitability for different culinary needs is essential.

Types of Commercial Oven

Convection Ovens: These ovens use fans to circulate hot air, resulting in even heat distribution and faster cooking times. Convection ovens are ideal for baking pastries, roasting meats, and achieving consistent results across large batches of food.

Deck Ovens: Commonly used in pizzerias and bakeries, deck ovens feature stone or ceramic decks that provide radiant heat, producing crisp crusts on bread and pizzas. They are available in gas or electric models and can have multiple decks for increased capacity.

Conveyor Ovens: Widely used in fast-food establishments and casual dining settings, conveyor ovens feature a continuous belt that moves food through a heated chamber, ensuring consistent cooking times and high volume production.

Rotisserie Ovens: These specialty ovens are designed specifically for roasting meats on a rotating spit. They are popular in rotisserie chicken restaurants and can create succulent, evenly cooked meats with a delicious caramelized exterior.

Choosing the Right Commercial Oven

When selecting a commercial oven for your restaurant, consider the following factors:

Menu Items: Assess the types of dishes you'll be preparing and determine the specific cooking methods and temperatures required. For example, if your menu includes a variety of baked goods, a convection oven with precise temperature control would be essential.

Capacity: Evaluate the volume of food you'll be producing during peak service hours. A high-capacity deck oven may be necessary for a busy bakery, while a smaller convection oven may suffice for a fine dining restaurant with a focus on plated entrees.

Energy Efficiency: Look for commercial ovens with energy-efficient features to help reduce utility costs over time. Modern ovens often incorporate advanced insulation and programmable settings to optimize energy usage.

Maintenance and Durability: Prioritize ovens with easy-to-clean surfaces, removable components, and durable construction. Regular maintenance and cleaning are essential for extending the lifespan of your commercial oven and ensuring food safety.

Installation and Support: Factor in the installation process and ongoing support from the manufacturer or supplier. Some commercial ovens may require professional installation or specialized electrical and gas connections.

In conclusion, the commercial oven is indeed the heart of the kitchen in any restaurant. Whether you opt for a convection oven, deck oven, conveyor oven, or rotisserie oven, understanding the unique features and benefits of each type will guide you in making an informed decision. By choosing the right commercial oven for your restaurant, you'll set the stage for culinary excellence and seamless kitchen operations, ensuring that your customers receive exceptional, consistently prepared dishes every time they dine with you.

0 notes

Photo

Bread Baking Oven Belt

Bread Baking Oven Belt is also named bread conveyor belt. It is a metal type of wire mesh conveyor belt for bread oven. As food grade conveyor belt, it is famous in the food field.

1: Introduction

Overview (1) Crafted for precision baking. (2) Elevates baking efficiency. (3) Unparalleled in the baking industry. (4) Unveiling the Bread Baking Oven Belt.

Features (5) Heat-resistant technology at its core. (6) Seamless design for optimal consistency. (7) Enhanced durability for prolonged use. (8) Precision engineering ensures uniform results. (9) This wire belt is easy to clean and maintain.

Benefits (10) Boosts bakery productivity. (11) Delivers consistent and golden-brown perfection. (12) Versatile, accommodating various bread types. (13) Accelerates baking time without compromising quality. (14) Cost-effective solution for commercial kitchens. (15) Elevates the overall baking experience.

Applications (16) Ideal for artisanal bakeries. (17) Perfect for high-volume production. (18) Ensures even baking for delicate pastries. (19) Enhances efficiency in pizza oven setups. (20) Essential for meeting industry standards.

2: Innovation

Design Excellence (1) Revolutionary belt design for precision. (2) Incorporating cutting-edge materials. (3) Engineered for seamless operation. (4) A testament to innovation in baking technology.

Materials Used (5) High-grade, heat-resistant polymers. (6) Advanced composite construction. (7) Resilient against wear and tear. (8) Ensures longevity and consistent performance. (9) Crafted for the demands of professional kitchens.

Technology Integration (10) Smart technology for temperature control. (11) Responsive to diverse baking requirements. (12) Adapts to different oven configurations. (13) Elevates baking precision to new heights. (14) Guarantees a hassle-free baking experience. (15) The bakery wire belt is ideal for modern, tech-driven bakeries.

Environmental Considerations (16) Eco-friendly materials reduce environmental impact. (17) Contributes to sustainable baking practices. (18) Aligns with green kitchen initiatives. (19) Meets regulatory standards for environmental responsibility. (20) A step forward in eco-conscious baking solutions.

3: Industry Standards

Compliance (1) Meets and exceeds industry benchmarks. (2) Compliant with global food safety regulations. (3) Ensures quality in line with international standards. (4) A trusted choice for bakeries worldwide.

Certifications (5) ISO-certified for quality assurance. (6) Endorsed by baking industry associations. (7) Upholds hygiene and safety protocols. (8) Recognized for reliability and performance. (9) Adherence to stringent manufacturing standards.

Customer Satisfaction (10) Positive reviews from leading bakeries. (11) Endorsed by renowned pastry chefs. (12) Enhances customer satisfaction with superior products. (13) Meets the evolving demands of discerning chefs. (14) A testament to customer loyalty and trust. (15) Setting the benchmark for baking excellence.

Global Presence (16) Trusted in bakeries across continents. (17) Exported to diverse culinary markets. (18) Celebrated for consistency on the global stage. (19) A preferred choice in international kitchens. (20) Contributing to the globalization of baking standards.

4: Choosing Bread Baking Oven Belt for Your Bakery

Economic Advantage (1) Cost-effective solution for commercial kitchens. (2) Maximizes return on investment. (3) Reduces operational costs with efficient baking. (4) A strategic choice for budget-conscious businesses.

Ease of Integration (5) Seamless integration with existing ovens. (6) Compatible with various baking setups. (7) Quick and hassle-free installation process. (8) Adaptable to different kitchen layouts. (9) Ensures minimal downtime during implementation.

Training and Support (10) Comprehensive training for kitchen staff. (11) Ongoing support for troubleshooting and maintenance. (12) Accessible customer service for timely assistance. (13) Empowers staff with product knowledge. (14) Ensures optimal performance through continuous support. (15) Choosing ease and reliability in baking solutions.

Innovation for Future Growth (16) Aligns with the trajectory of baking industry advancements. (17) Future-proof technology for evolving bakery needs. (18) A catalyst for innovation in your kitchen. (19) Positions your bakery for sustained growth. (20) Invest in the future of baking with Bread Baking Oven Belt.

The product Bread Baking Oven Belt appeared first on Alex Wire Mesh.

#Bread Baking Belt#Bread Baking Conveyor Belt#Bread Baking Mesh Belt#Bread Baking Oven Belt#Bread Baking Steel Belt#Bread Baking Wire Belt#Bread Conveyor Belt#Bread Oven Belt#Conveyor Belt#Food Grade Conveyor Belt#Mesh Conveyor Belt#Metal Conveyor Belt#Wire Conveyor Belt#Wire Mesh Conveyor Belt

0 notes

Text

Chapatti making machine

There wasn’t a widely available or commercially successful fully automated roti-making machine on the market. However, technology and product availability can change rapidly, so it’s a good idea to check the latest developments.

Making roti involves a combination of tasks such as mixing the dough, flattening it into circles, and cooking on a hot surface. Some automated machines may be able to handle portions of this process, but the complete automation of roti making, including the quality aspects that are important in many cultural cuisines, can be challenging.

If you’re interested in a roti-making machine, consider checking online retailers, appliance stores, or technology expos for the latest products. Additionally, keep an eye on developments in smart kitchen appliances, as advancements in technology may lead to more automated solutions for traditional cooking tasks.

It’s important to read reviews, consider user feedback, and evaluate the features of any product before making a purchase. Additionally, the availability of such products can vary by region.

Commercial roti making machine:

There were commercial roti-making machines available in the market. These machines are designed to automate the process of making roti’s, and they are commonly used in commercial kitchens, restaurants, and other food establishments where large quantities of roti’s are required.

Commercial roti-making machines typically consist of a series of conveyor belts, rollers, and heating elements to automate the entire process, from dough preparation to cooking. These machines can produce roti’s in bulk, saving time and labor in commercial settings.

To find a commercial roti-making machine, you may want to explore specialized kitchen equipment suppliers, restaurant supply stores, or online platforms that cater to commercial kitchen needs. It’s essential to consider factors such as the production capacity, size, and maintenance requirements when choosing a commercial roti-making machine.

Keep in mind that product availability and advancements in technology can change, so it’s a good idea to check the latest offerings from manufacturers and suppliers in your region. Additionally, customer reviews and testimonials can provide insights into the performance and reliability of specific machines.

Automatic chapatti making machine:

Automatic chapatti-making machines are designed to simplify and expedite the process of making chapatti’s (also known as roti’s or flatbreads). These machines are commonly used in commercial kitchens, canteens, and other food establishments where there is a high demand for chapatti. Here are some key features and aspects to consider when looking for an automatic chapatti-making machine:

Capacity: These machines come in various capacities, ranging from a few hundred to several thousand chapatti per hour. Choose a machine that meets the production needs of your establishment.

Automation Levels: Different machines offer varying degrees of automation. Some machines can handle the entire process, from dough preparation to cooking, while others may require manual input at certain stages.

Dough Feeding System: Automatic chapatti-making machines usually have a dough feeding system that automates the process of feeding the dough into the machine. Some machines may have hoppers or conveyors for this purpose.

Pressing and Cooking Mechanism: The machines typically have a mechanism for pressing the dough into flatbreads and a cooking element for baking them. The cooking process may involve heated plates, ovens, or other methods.

Adjustability: Look for machines that allow you to adjust the thickness and size of the chapatti’s to meet specific preferences.

Material and Build Quality: Consider the material and build quality of the machine to ensure durability and ease of maintenance. Stainless steel is a common material for components that come into contact with food.

Energy Efficiency: Check the energy efficiency of the machine, especially if sustainability and operating costs are important considerations for your business.

Ease of Cleaning and Maintenance: Opt for a machine that is easy to clean and maintain. Look for features such as removable components and user-friendly controls.

Safety Features: Ensure that the machine has adequate safety features to protect operators during use.

When searching for automatic chapatti-making machines, you can explore online platforms, commercial kitchen equipment suppliers, or industry trade shows to find suitable options. It’s crucial to read reviews, compare specifications, and possibly seek recommendations from others in the food service industry to make an informed decision based on your specific needs and preferences. Keep in mind that product offerings and technology may have evolved since my last update in January 2022, so checking the latest developments is advisable.

Automatic chapatti maker:

Automatic chapatti makers were available in the market. These machines are designed to automate the process of making chapatti’s (also known as roti’s or flatbreads). Automatic chapatti makers are particularly useful in commercial settings where there’s a high demand for chapatti’s, such as restaurants, hotels, and large-scale catering services.

Here are some general features you might find in an automatic chapatti maker:

Dough Feeding System: Automatic chapatti makers typically have a system for feeding the dough into the machine. This can involve hoppers or conveyor belts that streamline the process.

Pressing Mechanism: The machine usually includes a mechanism for pressing the dough into flatbreads. This can involve rollers or other pressing elements.

Cooking Element: There is a cooking element that bakes or cooks the chapati. This could be through heated plates, ovens, or other methods.

Adjustable Settings: Many machines allow you to adjust settings such as the thickness and size of the chapatti’s to meet your preferences.

Capacity: These machines come in different capacities, with the ability to produce a certain number of chapatti per hour. Choose a machine that meets your production requirements.

Material and Build Quality: Consider the material and build quality of the machine, especially components that come into contact with food. Stainless steel is commonly used for hygiene and durability.

Ease of Cleaning: Look for a machine that is easy to clean, with features like removable components.

Safety Features: Check for safety features to ensure the machine can be operated safely.

To find an automatic chapatti maker, you can explore commercial kitchen equipment suppliers, online retailers, or industry-specific trade shows. Read product reviews, compare specifications, and possibly consult with other businesses in the food industry for recommendations.

Keep in mind that the availability of products and technological advancements may have changed since my last update, so it’s a good idea to check for the latest models and reviews from reliable sources.

#automatic chapatti machine#fully automatic roti maker#domestic automatic roti making machine#fully automatic roti making machine

0 notes

Text

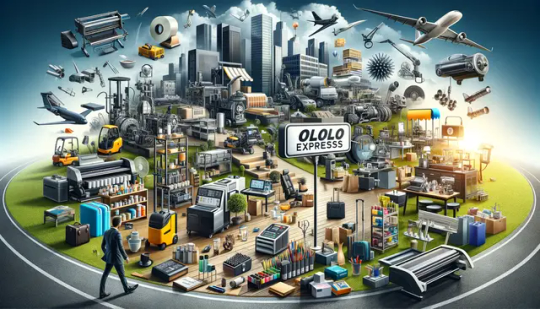

Revolutionizing Your Business with Commercial Equipment & Tools on Ololo Express

In the dynamic world of commerce, having the right tools and equipment is the cornerstone of efficiency and success. Ololo Express, a leading online marketplace in Ghana, offers a diverse range of commercial equipment and tools, catering to various industries. From Industrial Ovens to Stage Lighting & Effects, the platform is a one-stop-shop for sellers and buyers alike. This comprehensive guide highlights the key categories available on Ololo Express, and how they can transform businesses and attract a wide range of customers.

I. Industrial Ovens:

The Heat of Efficiency Industrial ovens are pivotal in various manufacturing processes. Whether it's for curing, drying, or baking, these ovens offer precision and reliability. Sellers on Ololo Express can reach businesses in food production, material processing, and more, showcasing the versatility and advanced technology of their products. Buyers, on the other hand, can find ovens that guarantee energy efficiency and high productivity.

II. Manufacturing Equipment:

The Backbone of Production The manufacturing sector demands robust and high-performing equipment. From textile machines to heavy-duty conveyors, Ololo Express offers equipment that embodies innovation and durability. Sellers have the opportunity to present their state-of-the-art machinery to a wide audience, while buyers can access a variety of tools to streamline their production processes.

III. Manufacturing Materials:

Quality at the Core The quality of manufacturing materials directly impacts the end product. Ololo Express connects sellers of high-grade materials like metals, plastics, and composites with businesses seeking to elevate their product quality. This category is a goldmine for industries aiming to optimize their manufacturing standards.

IV. Medical Supplies & Equipment:

Empowering Healthcare The healthcare sector requires precise and reliable medical supplies and equipment. Sellers on Ololo Express can offer everything from diagnostic tools to essential medical supplies, contributing to the advancement of healthcare services. Buyers benefit from a range of choices, ensuring they find the right tools for their medical needs.

V. Printing Equipment:

Unlocking Creative Potential The printing industry is evolving, and Ololo Express is at its forefront, offering the latest in printing technology. Sellers can showcase advanced printers, inks, and printing materials, targeting businesses in advertising, publishing, and more. Buyers can explore equipment that offers high-quality printing solutions, enhancing their creative output.

VI. Restaurant & Catering Equipment:

Culinary Excellence For the thriving culinary industry, the right equipment is key to success. From commercial stoves to refrigeration systems, Ololo Express provides a platform for sellers to reach restaurants, cafes, and catering services. Buyers can find everything they need to create a top-notch culinary experience.

VII. Safetywear & Equipment:

Ensuring Workplace Safety Safety is paramount in any industrial setting. Ololo Express offers a range of safetywear and equipment, from helmets to protective clothing. Sellers can provide essential safety solutions to businesses, ensuring a safe working environment. Buyers, meanwhile, can access a variety of safety equipment that meets international standards.

VIII. Salon Equipment:

Styling Success The beauty industry constantly seeks the latest in salon equipment. Ololo Express serves as a hub for sellers of styling chairs, hair dryers, and more, reaching a broad clientele in the beauty sector. Buyers can find premium equipment that enhances the client experience and efficiency of services.

IX. Stage Lighting & Effects:

Illuminating Performances Stage lighting and effects are crucial for any performance or event. Sellers on Ololo Express can offer innovative lighting solutions, impacting theaters, concert halls, and event companies. Buyers have access to a range of lighting equipment that can transform any space into a captivating scene.

X. Stationery:

Powering Offices and Schools Stationery is an essential category that spans across various sectors. From office supplies to educational materials, Ololo Express connects sellers with a diverse audience, including corporate offices and educational institutions. Buyers can find a comprehensive range of stationery products, catering to their specific needs.

XI. Store Equipment:

Retail Readiness For retailers, the right store equipment can enhance the shopping experience. Ololo Express offers everything from shelving systems to checkout counters. Sellers have the opportunity to provide solutions that optimize retail spaces, while buyers can access equipment that makes their stores more efficient and customer-friendly. Conclusion: Ololo Express is revolutionizing the way commercial equipment and tools are bought and sold in Ghana. With categories covering a wide range of Business Machinery and Instruments, the platform offers unparalleled opportunities for sellers to showcase their products and for buyers to equip their businesses with the best tools in the market. Join Ololo Express today and experience a marketplace where efficiency, quality, and innovation are at your fingertips. Call to Action: Whether you're a seller looking to expand your market reach or a buyer in search of the best commercial equipment and tools, Ololo Express is your destination. Explore our vast selection and take the first step towards elevating your business today. Buy Local, Sell Global – only on Ololo Express. Read the full article

0 notes

Text

Use of Food Manufacturing Cleaning Services

A Food Manufacturing Cleaning Services facility has a lot of equipment that requires a clean and sanitized environment to keep it in tip-top shape. This can include ovens, conveyors, meat grinders and slicers that are used to produce different types of foods. Keeping these surfaces clean and sanitized helps prevent the spread of disease.

Using commercial cleaning products that are safe for the production of your food is essential. These products are designed to be non-toxic, biodegradable and able to meet SQF and HACCP standards.

Properly disposing waste is also vital for the cleanliness of your food manufacturing facility. Professional commercial cleaning technicians ensure that waste is properly labeled and disposed of according to your company's policies.

Soil Removal

Food soils include a mixture of soluble and insoluble substances that have built up on food-contact surfaces over time. These compounds include residues from the food, water residues and cleaning compounds, as well as microbiological biofilms.

Getting all soils off of your equipment is a critical part of maintaining a clean and sanitary environment. Generally, a chemical-based cleaner that is alkaline with peptizing or dissolving properties will be effective at removing most soils.

Protein Soils

Some proteins, such as casein (a major milk protein) can be particularly difficult to remove due to their heat-denatured state. To avoid this, it's important to use a detergent that contains hypochlorite in addition to wetting agents.

Maintaining a sanitary and healthy environment is essential for the safety of both employees and customers. A reputable commercial cleaning service will ensure that your food manufacturing plant meets all required health and safety regulations, including OSHA standards.

0 notes

Text

Industrial Baking Equipment

Advantech is one of the best baking and processing equipment manufacturers that provides high-quality commercial bakery ovens, industrial cooling tunnels, and other equipment at affordable prices. https://advantechbake.com/products/ovens/

#tunnel oven manufacturers#commercial cookie ovens#bakery machinery#industrial cookie ovens#commercial bakery ovens#cooling tunnel conveyor#shopping cart sanitizing machine

0 notes