#Cobalt Oxide Market

Explore tagged Tumblr posts

Text

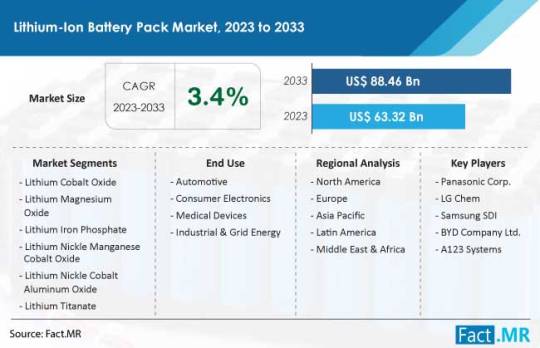

The lithium ion battery pack market size is currently valued at approximately US$ 63.32 billion as of 2023. Projections indicate that this market is expected to expand to US$ 88.46 billion by 2033, with a Compound Annual Growth Rate (CAGR) of 3.4% during the ten-year forecast period from 2023 to 2033.

#Lithium Ion Battery Pack Market#Lithium Cobalt Oxide battery back market#Lithium Ion Battery Pack Market drivers#Lithium Ion Battery Pack Market forecast

1 note

·

View note

Link

#adroit market research#lithium-ion battery market#lithium cobalt oxide battery#lithium iron phosphate battery#lithium manganese oxide batter

0 notes

Text

Swedish engineers have improved the process through which hydrogen fuel is produced from solar electricity by 800%.

Hydrogen fuel is considered one of the best renewable alternatives to fossil fuels in heavy machinery like planes and ships, but its creation requires electricity.

That electricity can be from renewable sources like solar or wind, but the efficiency is limited. Now, according to researchers at Linköping University, a combination of materials has greatly improved the ability to generate hydrogen with solar energy.

The research team has previously shown that a material called cubic silicon carbide (3C-SiC) has beneficial properties for facilitating the reaction where water is split into hydrogen and oxygen. The material can effectively capture the sunlight so that the energy therein can be used for hydrogen production through the photochemical water splitting reaction.

In their current study, the researchers have further developed a new combined material consisting of three layers: a layer of cubic silicon carbide, a layer of cobalt oxide and a catalyst material that helps to split water.

“Passenger cars can have a battery, but heavy trucks, ships or aircraft cannot use a battery to store the energy. For these means of transport, we need to find clean and renewable energy sources, and hydrogen is a good candidate,” says Jianwu Sun, associate professor at Linköping University, who has led the study published in the Journal of the American Chemical Society.

“It’s a very complicated structure, so our focus in this study has been to understand the function of each layer and how it helps improve the properties of the material. The new material has eight times better performance than pure cubic silicon carbide for splitting water into hydrogen,” says Sun.

When sunlight hits the material, electric charges are generated, which are then used to split water. A challenge in the development of materials for this application is to prevent the positive and negative charges from merging again and neutralizing each other.

In their study, the researchers show that by combining a layer of cubic silicon carbide with the other two layers, the material becomes more able to separate the charges, thereby making the splitting of water more effective.

Almost all hydrogen present on the market is “grey” hydrogen produced from a fossil fuel. The production of one ton of “grey” hydrogen gas causes emission of up to ten tons of carbon dioxide. “Green” hydrogen is produced using renewable electricity as a source of energy.

The long-term goal of the Linköping University researchers is to be able to use only energy from the sun to drive the photochemical reaction to produce “green” hydrogen.

HYDROGEN DEVELOPMENT: Hydrogen Gas Blend Will Reduce Power Plant’s Emissions by 75%–as it Helps Power 6 States

Most materials under development today have an efficiency of between 1% and 3%, but for commercialization of this green hydrogen technology the target is 10% efficiency. Being able to fully drive the reaction using solar energy would lower the cost of producing green hydrogen, compared to producing it using supplementary renewable electricity as is done with the technology used today.

Jianwu Sun speculates that it may take around five to ten years for the research team to develop materials that reach the coveted 10% limit, but they’re off to a flying start.

5 notes

·

View notes

Text

Described as a ‘Virtuoso of the potter’s wheel’ by Peter Timms, Art Critic for the Melbourne Age John Stroomer is a master potter who is internationally recognized for his work with Crystalline Glazes. His forms are classical, balanced, simple, full bodied and reflect his mastery of both the potter’s wheel and crystalline process.

“I have been making for almost 50 years, employing 23 potters during the 80s/90s supplying wheel thrown domestic stoneware to major retailers, direct selling companies and homeware stores Australia-wide.

The recession of 1981, a devastating factory fire in 1988 followed by the 1990 recession and subsequent fluctuating market forces eventually led to a change in personal philosophy/direction. They were all pivotal in leading me to where and who I am today.

The exacting nature, temperature control, balance and understanding of materials and glaze technologies demanded by the Crystaline process reflect John’s mastery of his craft over many years. Each pot is fired at over 1,300 Degrees Celsius for at least 18 hours. Once peak temperature has been reached, the kiln is rapidly cooled to pre-determined temperatures, at which point the crystals begin to be formed. As crystal formation requires slow cooling, the temperature is held and slowly reduced/managed with a crystal growth period of an additional six hours.

Crystals can take on a myriad of shapes and are three dimensional in nature. In direct sunlight or strong light, spectacular effects can be created by the refraction of light bouncing off the crystals, giving each pot a true three dimensional appearance.

Metallic oxides and combinations of various materials are used to produce a wide range of colours, ranging from dark browns, to cobalt blues and coral greens, amongst many others.

The end result are a range of pots that are exquisite.

29 notes

·

View notes

Text

Multi-Element Cathodes Market Share by Region, Type, and Application – Detailed Report

Unleashing the Future of Advanced Battery Technologies

The global multi-element cathodes market is entering a transformative growth phase, driven by rising demand for high-performance batteries across electric vehicles (EVs), renewable energy storage systems, and next-generation consumer electronics. From a valuation of $25.9 billion in 2023, the multi-element cathodes market is projected to soar to $52.6 billion by 2031, expanding at a CAGR of 15.2% over the forecast period.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40425-global-multi-element-cathodes-market

Multi-Element Cathodes Market Segmentation Analysis

Diverse Cathode Chemistries Powering Innovation

Nickel Manganese Cobalt (NMC) Cathodes

NMC cathodes lead the multi-element cathodes market due to their balanced energy density, thermal stability, and cost-efficiency, making them ideal for electric vehicles and portable consumer electronics. Their ability to support long-range performance and fast charging is vital for e-mobility growth.

Nickel Cobalt Aluminum (NCA) Cathodes

NCA cathodes are the cornerstone of high-energy applications, particularly in aerospace, advanced robotics, and premium EV segments. Their enhanced thermal tolerance and high voltage stability enable sustained operation under extreme conditions.

Lithium Iron Phosphate (LFP) Cathodes

Favored for their safety, longevity, and cost-effectiveness, LFP cathodes are widely used in grid-level energy storage systems and power tools. Their high cycle life makes them attractive for industrial and commercial stationary applications.

Emerging Cathode Materials

Beyond conventional chemistries, research is intensifying around multi-metal oxides and doped lithium compounds to optimize battery performance, sustainability, and cost. These innovations are expected to redefine cathode technologies in the coming decade.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40425-global-multi-element-cathodes-market

Battery Type Segmentation

Lithium-Ion Batteries (Li-ion)

Li-ion batteries maintain dominance, underpinned by mass adoption in EVs, smartphones, laptops, and smart appliances. Their maturity, efficiency, and scalable manufacturing infrastructure solidify their stronghold.

Solid-State Batteries

Solid-state batteries are redefining the future of battery safety and energy density. By eliminating flammable liquid electrolytes, these batteries offer superior thermal stability, compactness, and cycle life—a disruptive technology poised to revolutionize the automotive and aerospace sectors.

Composition Ratios: Tailoring Performance

High Nickel Content Cathodes

These cathodes deliver exceptional energy density and reduced cobalt usage, aligning with EV manufacturers' drive to lower cost per kWh while enhancing vehicle range. They are especially favored in high-performance and long-range EV models.

Medium Nickel Content Cathodes

Providing a balanced trade-off between safety, cost, and performance, these cathodes are used extensively in hybrid vehicles, personal electronics, and backup energy systems.

Low Nickel Content Cathodes

Low-nickel cathodes prioritize thermal stability and environmental safety, making them suitable for medical devices, wearables, and systems operating under high-temperature conditions.

Application-Specific Customization

Fast Charging

Advanced cathode materials are engineered to withstand rapid lithium-ion transfer, reducing downtime in electric vehicle charging infrastructure and mobile devices.

Extended Cycle Life

Multi-element cathodes are central to batteries that endure thousands of charge-discharge cycles, crucial for renewable energy systems, satellites, and industrial robotics.

High Temperature Stability

Industries such as defense, aviation, and manufacturing require cathodes that sustain performance in extreme heat, ensuring operational continuity and safety.

Reliability and Safety

In mission-critical applications, cathode stability is paramount to avoid thermal runaway, leakage, or degradation, thereby ensuring safe and dependable power delivery.

Production Methodologies: Engineering Excellence

Solid-State Synthesis

The most common industrial process, solid-state synthesis offers uniform material distribution and crystalline stability, critical for premium battery applications.

Sol-Gel Method

Preferred in R&D and specialty batteries, this method enables precise control over particle morphology, facilitating the design of tailored electrochemical properties.

Co-Precipitation

Used for high-volume manufacturing, this method ensures consistent particle size distribution and is cost-effective for automotive and utility-scale production lines.

Mechanical Milling

A flexible, scalable method suited for prototyping and custom formulation of cathode blends, especially in pilot lines and specialty chemistry development.

Multi-Element Cathodes Market Segmentation by Price Tier

Premium Segment

Targeted at aerospace, defense, and high-end EVs, this segment demands top-tier cathode materials characterized by maximum energy density, cycle life, and safety features.

Mid-Range Segment

Balancing affordability and performance, mid-range cathodes serve consumer electronics, residential energy systems, and light electric vehicles.

Economy Segment

Built for cost-sensitive markets, economy cathodes are optimized for entry-level electronics, utility tools, and short-lifecycle devices.

Distribution Channels

Direct Sales to OEMs

Large-scale manufacturers leverage OEM partnerships for customized solutions, just-in-time delivery, and technical integration into EV platforms or storage systems.

Indirect Sales via Distributors

Distributors and retailers enhance market penetration by offering broad accessibility, logistics support, and regional adaptability to emerging markets and diverse industries.

Regulatory Compliance and Certification

IEC Standards

Compliance with IEC safety and performance standards ensures global interoperability, quality assurance, and acceptance across regions.

CE Certification

Essential for European market access, CE compliance signals adherence to stringent product testing, safety protocols, and performance criteria.

End-Use Applications Driving Demand

Electric Vehicles (EVs)

The dominant consumer of multi-element cathodes, EVs require high-energy, fast-charging, and long-lasting batteries. Cathode innovation directly correlates with vehicle range, cost-efficiency, and environmental impact.

Energy Storage Systems (ESS)

With the rise of solar and wind energy, ESS applications demand durable, high-capacity batteries capable of managing grid fluctuations and off-grid storage.

Consumer Electronics

From smartphones to smartwatches, the need for compact, reliable power sources places cathodes at the heart of innovation in portable device manufacturing.

Regional Insights

North America: Spearheaded by the U.S., the region leads in EV innovation, battery R&D, and government-backed energy initiatives.

Asia-Pacific: China, Japan, and South Korea dominate manufacturing and exports, home to key market players and integrated battery supply chains.

Europe: A hub for regulatory-driven green transition, with significant investments in battery gigafactories and circular economy practices.

Middle East & Africa: Emerging interest in grid-scale storage and e-mobility pilot projects.

South America: Growth tied to raw material extraction (lithium, cobalt) and rising consumer electronics demand.

Leading Players in the Multi-Element Cathodes Market

Panasonic Corporation

LG Chem

Samsung SDI

SK Innovation

Umicore

Sumitomo Metal Mining Co., Ltd.

BASF SE

Mitsubishi Chemical Corporation

Johnson Matthey

Ganfeng Lithium Co., Ltd.

These companies lead through vertical integration, R&D investment, and strategic alliances across the energy and automotive value chains.

Strategic Outlook and Opportunities

As the world transitions to electrified transport, smart cities, and sustainable energy, multi-element cathodes are poised to become critical enablers of decarbonization and digital transformation. Key strategic imperatives include:

Scaling domestic supply chains for cathode materials.

Investing in circular economy for material recovery and recycling.

Accelerating research into post-lithium technologies, such as sodium-ion and lithium-sulfur cathodes.

Establishing robust regulatory frameworks to ensure safety and interoperability globally.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40425-global-multi-element-cathodes-market

Conclusion

The global multi-element cathodes market is not just growing—it is accelerating into the future. Stakeholders who align with technological innovation, sustainability, and regulatory readiness will shape the next era of advanced energy storage solutions.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

1 note

·

View note

Text

Making up more items for my Christmas market on the 1st December in Exeter to support the RSPCA.

This is a tree wire wrap in silver filled wire on a beautiful sparkling blue goldstone cabachon.

(Blue goldstone is a pretty man-made gemstone created with a mixture of silica, cobalt and other metal oxides).

#Tree of life#Wire wrapped jewellery#Wire tree#gemstone jewelry#Jewellery artist#Small business#Blue goldstone

2 notes

·

View notes

Text

0 notes

Text

Samarium Cobalt Permanent Magnet Market to 2031

As industries demand higher reliability in harsh environments, Samarium Cobalt (SmCo) permanent magnets are emerging as the material of choice. These rare-earth magnets are known for their superior thermal stability, high magnetic strength, and excellent resistance to corrosion and demagnetization. According to the Samarium Cobalt Permanent Magnet Market Report, the market is on a growth trajectory through 2031, supported by increased applications in aerospace, defense, medical, and automotive sectors.

SmCo magnets maintain magnetic strength at temperatures above 300°C, making them suitable for high-stress environments such as jet engines, satellites, military systems, and high-speed motors. Unlike neodymium magnets, SmCo variants exhibit better resistance to oxidation and require little to no protective coating.

In aerospace and defense, SmCo magnets power actuators, missile guidance systems, and radar components—applications where failure is not an option. Their predictable behavior under thermal and magnetic stress ensures mission reliability.

The renewable energy sector is also turning to SmCo magnets for use in wind turbine generators and advanced electric motors. As the world transitions toward sustainable power, the demand for robust and efficient magnet systems is intensifying.

Medical technology is another growth area. SmCo magnets are used in MRI machines, surgical tools, and implants where biocompatibility and temperature resilience are critical.

Advances in powder metallurgy and sintering techniques have improved magnet consistency and reduced manufacturing costs. Customized compositions allow manufacturers to tailor magnetic properties to specific performance needs.

Geopolitical dynamics have prompted nations to diversify rare-earth supply chains. This is encouraging investments in SmCo recycling, rare-earth mining, and local magnet manufacturing—enhancing global resilience.

SmCo magnets are also gaining traction in electric mobility. While heavy-duty EVs and aerospace applications may favor SmCo for its temperature performance, innovations in magnet miniaturization are opening doors to consumer electronics and compact robotics.

In the coming years, collaboration among raw material suppliers, magnet manufacturers, and OEMs will be vital to scale production and meet industry-specific demands.

With their proven reliability in extreme conditions, Samarium Cobalt magnets are not just a niche material—they are a foundation for performance in advanced technological systems worldwide.

0 notes

Text

Cathode MaterialsMarket Size, Share, Trends, Key Drivers, Demand, Opportunities and Competitive Analysis

Executive Summary Cathode Materials Market

Data Bridge Market Research analyses that the cathode materials market will witness a CAGR of 66.6% for the forecast period of 2022-2029.

The key highlights of this Cathode Materials Market report are key market dynamics, current market scenario and future prospects of the sector. By understanding and keeping into focus customer requirement, one method or combination of many steps have been applied to build the most excellent market research report. Whereas market definition covered in this Cathode Materials Market report explores the market drivers which indicate the factors causing rise in the market growth and market restraints which indicate the factors causing fall in the market growth. It helps customers or other market participants to be aware of the problems they may face while operating in this market over a longer period of time.

A team of skilled analysts, statisticians, research experts, enthusiastic forecasters, and economists work painstakingly to structure such a great market research report for the businesses seeking a potential growth. This team is focused on understanding client’s businesses and its needs so that the finest market research report is delivered to the client. This market research report encompasses a comprehensive study of the product specifications, revenue, cost, price, gross capacity and production. With the use of up to date and proven tools and techniques, complex market insights are organized in simpler version in this Cathode Materials Market report for the better understanding of end user.

Discover the latest trends, growth opportunities, and strategic insights in our comprehensive Cathode Materials Market report. Download Full Report: https://www.databridgemarketresearch.com/reports/global-cathode-materials-market

Cathode Materials Market Overview

**Segments**

- By Material Type - Lithium Cobalt Oxide (LCO) - Lithium Iron Phosphate (LFP) - Lithium Manganese Oxide (LMO) - Lithium Nickel Cobalt Aluminum Oxide (NCA) - Lithium Nickel Manganese Cobalt Oxide (NMC) - Others

- By Battery Type - Lithium-Ion Batteries - Lead-Acid Batteries - Others

- By End-Use Industry - Automotive - Consumer Electronics - Industrial - Energy Storage Systems - Others

- By Region - North America - Europe - Asia-Pacific - South America - Middle East & Africa

**Market Players**

- Umicore - Sumitomo Corporation - POSCO - Johnson Matthey - Mitsubishi Chemical Corporation - Hitachi Chemical Co., Ltd. - 3M - BASF SE - Targray - Arkema - Showa Denko Materials Co., Ltd.

The global cathode materials market is witnessing significant growth due to the increasing demand for electric vehicles, portable consumer electronics, and energy storage systems. The market is segmented based on material type, battery type, end-use industry, and region. The material type segment includes lithium cobalt oxide (LCO), lithium iron phosphate (LFP), lithium manganese oxide (LMO), lithium nickel cobalt aluminum oxide (NCA), lithium nickel manganese cobalt oxide (NMC), and others. Lithium-ion batteries dominate the battery type segment, followed by lead-acid batteries and others. The end-use industry segment covers automotive, consumer electronics, industrial, energy storage systems, and others. Geographically, North America, Europe, Asia-Pacific, South America, and the Middle East & Africa are the key regions driving the market growth.

The market players in the global cathode materials industry include Umicore, Sumitomo Corporation, POSCO, Johnson Matthey, Mitsubishi Chemical Corporation, Hitachi Chemical Co., Ltd., 3M, BASF SE, Targray, Arkema, and Showa Denko Materials Co., Ltd. These companies are focusing on research and development activities to enhance the performance and efficiency of cathode materials for various applications. Strategic partnerships, mergers, and acquisitions are common trends observed in the market to expand product portfolios and geographical presence. The increasing investments in sustainable energy solutions and the growing adoption of electric vehicles are driving the demand for high-performance cathode materials in the global market.

The global cathode materials market is poised for substantial growth in the coming years, fueled by the rising adoption of electric vehicles, increasing usage of portable consumer electronics, and the growing demand for energy storage systems worldwide. One key trend that is expected to impact the market is the shift towards sustainable energy solutions and the push towards decarbonization. As governments and industries focus on reducing carbon emissions and transitioning towards cleaner energy sources, the demand for high-performance cathode materials will continue to surge.

In terms of material type, while lithium-ion batteries currently dominate the market, there is a growing interest in alternative materials such as lithium iron phosphate (LFP) and lithium nickel manganese cobalt oxide (NMC) due to their improved safety and performance characteristics. These advancements in material technology are expected to drive innovation and product development within the cathode materials market, leading to enhanced efficiency and longer battery life.

The end-use industry segment, particularly the automotive sector, is anticipated to be a key driver of growth in the cathode materials market. With the accelerating transition towards electric vehicles globally, the demand for high-energy-density batteries with superior performance attributes is on the rise. Additionally, the consumer electronics and energy storage system sectors are also expected to contribute significantly to the market growth, driven by the proliferation of smart devices and the need for reliable energy storage solutions.

Geographically, Asia-Pacific is projected to remain a dominant force in the cathode materials market, driven by the presence of key manufacturing hubs, technological advancements, and the rapid expansion of the automotive and electronics industries in countries like China, Japan, and South Korea. North America and Europe are also expected to witness substantial growth, supported by favorable regulatory frameworks, increasing investments in sustainable energy solutions, and the growing focus on reducing carbon footprints.

In conclusion, the global cathode materials market is poised for robust growth driven by factors such as the increasing demand for electric vehicles, advancements in material technology, and the push towards sustainable energy solutions. Market players need to focus on innovation, research, and strategic partnerships to capitalize on these opportunities and stay competitive in the dynamic landscape of the cathode materials industry.The global cathode materials market is currently experiencing a significant transformation driven by the increasing demand for electric vehicles, consumer electronics, and energy storage systems. The market segmentation based on material type highlights the diverse options available, with lithium cobalt oxide (LCO), lithium iron phosphate (LFP), and lithium nickel manganese cobalt oxide (NMC) gaining traction due to their enhanced safety and performance attributes. As the industry shifts towards sustainable energy solutions, there is a growing focus on developing innovative cathode materials that can meet the evolving needs of various applications.

In terms of battery type segmentation, lithium-ion batteries continue to dominate the market, propelled by their high energy density and performance capabilities. However, lead-acid batteries and emerging technologies are also playing a crucial role in shaping the market landscape, especially in applications where safety and cost-effectiveness are paramount. The end-use industry segmentation underscores the significant role of automotive, consumer electronics, and energy storage systems in driving market growth. With the increasing adoption of electric vehicles and the proliferation of smart devices, the demand for high-performance cathode materials is only expected to rise in the coming years.

Regionally, Asia-Pacific holds a strong position in the cathode materials market, fueled by the rapid industrialization, technological advancements, and government support for sustainable initiatives. This region, particularly countries like China, Japan, and South Korea, serves as a key manufacturing hub for the global supply chain, further boosting market growth. North America and Europe are also witnessing robust growth, driven by regulatory incentives, investments in clean energy solutions, and the growing awareness of environmental conservation.

In conclusion, the global cathode materials market is undergoing a period of dynamic change, with opportunities arising from the increasing demand for electric vehicles, advancements in material technology, and the global shift towards sustainable energy solutions. Market players need to focus on innovation, strategic collaborations, and continuous research to stay competitive and meet the evolving needs of the industry. As technological advancements continue to shape the market landscape, agility and adaptability will be key factors for success in the increasingly competitive cathode materials sector.

The Cathode Materials Market is highly fragmented, featuring intense competition among both global and regional players striving for market share. To explore how global trends are shaping the future of the top 10 companies in the keyword market.

Learn More Now: https://www.databridgemarketresearch.com/reports/global-cathode-materials-market/companies

DBMR Nucleus: Powering Insights, Strategy & Growth

DBMR Nucleus is a dynamic, AI-powered business intelligence platform designed to revolutionize the way organizations access and interpret market data. Developed by Data Bridge Market Research, Nucleus integrates cutting-edge analytics with intuitive dashboards to deliver real-time insights across industries. From tracking market trends and competitive landscapes to uncovering growth opportunities, the platform enables strategic decision-making backed by data-driven evidence. Whether you're a startup or an enterprise, DBMR Nucleus equips you with the tools to stay ahead of the curve and fuel long-term success.

Key Benefits of the Report:

This study presents the analytical depiction of the global Cathode Materials Market Industry along with the current trends and future estimations to determine the imminent investment pockets.

The report presents information related to key drivers, restraints, and opportunities along with detailed analysis of the global Cathode Materials Market

The current market is quantitatively analyzed to highlight the Cathode Materials Market growth scenario.

Porter's five forces analysis illustrates the potency of buyers & suppliers in the market.

The report provides a detailed global Cathode Materials Market analysis based on competitive intensity and how the competition will take shape in coming years.

Browse More Reports:

Brazil Contrast Injector Market Global Implantable Infusion Pumps Market North America Automotive Battery Thermal Management System Market Global Closed Molding Composites Market Global Dysphagia Market Global Pressure Sensitive Adhesives Market Europe Smoked Cheese Market Global Small Cell 5G Network Market Global Self-Storage and Moving Services Market North America Cenospheres Market Global Image Recognition in Consumer Packaged Goods (CPG) Market Global Onshore Legal Processing Market Global Gynecomastia Procedures Market Global Bio Based Leather Market Europe Extreme Lateral Interbody Fusion (XLIF) Surgery Market Global Food Essence Market Global Antifuse Field Programmable Gate Array Market Global Blowing Agents Market Global Seaweed Snacks Market Global Organic Poultry Feed Market Global Wavefront Aberrometer Market Global Freight Management System Market Global Rodenticides Market Global RTD Canned Cocktails Market Global Sitosterolemia Market Global Sweet Potato Powder Market North America Microbial Air sampler Market Global Tow Bar Market Europe Cenospheres Market Global Automotive Relay Market Global Contrast Injector Market Global Legal Analytics Market Global Preparative and Process Chromatography Market Global Aluminium Nitride Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us: Data Bridge Market Research US: +1 614 591 3140 UK: +44 845 154 9652 APAC : +653 1251 975 Email:- [email protected]"

Cathode Materials Market, Cathode Materials Market Trends, Cathode Materials Market Growth, Cathode Materials Market Demand, Cathode Materials Market Size, Cathode Materials Market Scope, Cathode Materials Market Insights, Cathode Materials Market Analysis

0 notes

Text

0 notes

Text

Lithium-Ion Battery Pack Market Outlook Development Factors, Latest Opportunities and Forecast by 2033

The Lithium-Ion Battery Pack market in United State is poised to achieve a valuation of US$ 17 billion by the year 2033. This projected growth is primarily attributed to the implementation of policies aimed at encouraging the adoption of electric vehicles and government incentives targeting carbon footprint reduction. The surge in sales of smart electronic devices plays a pivotal role in propelling market expansion, while the electrification of pickup trucks and delivery vehicles is expected to further bolster the demand for these batteries.

The lithium ion battery pack market size is currently valued at approximately US$ 63.32 billion as of 2023. Projections indicate that this market is expected to expand to US$ 88.46 billion by 2033, with a Compound Annual Growth Rate (CAGR) of 3.4% during the ten-year forecast period from 2023 to 2033.

Download a Sample Copy of This Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=3120

In a world increasingly focused on environmental sustainability and reducing our carbon footprint, the automotive industry is undergoing a significant transformation. As electric vehicles (EVs) gain popularity, one crucial component at the heart of this green revolution is the lithium-ion battery pack. The lithium-ion battery pack market is experiencing an unprecedented surge, driven by the growing demand for electric vehicles.

The Driving Force: Lithium-Ion Batteries

At the heart of every electric vehicle lies a lithium-ion battery pack. These powerful and energy-dense batteries have become the preferred choice for EV manufacturers due to their high energy density, long cycle life, and relatively low maintenance requirements. This popularity has fueled the growth of the lithium-ion battery pack market.

The Impact on the Lithium-Ion Battery Market

The surge in electric vehicle adoption has had a profound impact on the lithium-ion battery pack market. Manufacturers in this space have witnessed a substantial increase in demand, prompting them to expand production capacities and invest in research and development to enhance battery performance.

One of the most notable effects of this surge is the reduction in the cost of lithium-ion batteries. Over the past decade, the cost of lithium-ion batteries has plummeted, making electric vehicles more affordable for consumers. As a result, EV sales have experienced exponential growth, further driving the demand for lithium-ion battery packs.

Environmental Concerns Drive the Transition

Environmental concerns are a significant driver behind the shift to electric vehicles. With the automotive industry being a major contributor to greenhouse gas emissions, EVs offer a cleaner alternative. They produce zero tailpipe emissions and reduce the overall carbon footprint of transportation.

In response to these environmental concerns, governments around the world are offering incentives, subsidies, and tax breaks to promote the adoption of electric vehicles. This has created a more favorable market environment for both EV manufacturers and lithium-ion battery pack suppliers.

Competitive Landscape

Prominent players in the market are placing a strong emphasis on introducing advanced battery packs featuring high-quality conducting materials. Their strategic focus includes innovation, forging key partnerships, pursuing acquisitions, stringent quality control, efficient supply chain management, and expanding production capacities.

Leading manufacturers of lithium-ion battery packs are dedicated to enhancing battery efficiency while simultaneously aiming for lightweight and durable designs. They are actively promoting innovative battery recycling technologies to address the looming challenge of recycling a significant volume of used lithium-ion batteries, particularly those from older electric vehicles.

For example:

In March 2021, GS Yuasa International Limited received the Toyota Technology and Development award in recognition of its lithium-ion batteries for hybrid vehicles.

In November 2018, Johnson Controls and Toshiba Corporation collaborated to provide low-voltage lithium-ion solutions, aiming to improve efficiency.

In December 2019, LG Chem Ltd., a prominent player in lithium-ion battery packs, entered into a partnership with General Motors (GM) for the production of lithium-ion batteries used in GM's electric vehicles.

Key Segments of Lithium-Ion Battery Pack Industry Research

By Product Type :

Nickel Cobalt Aluminum Oxide

Cobalt Oxide

Iron Phosphate

Nickel Manganese Cobalt Oxide

Titanate

Magnesium Oxide

By Cell Type :

Cylindrical

Prismatic

Pouches

By Nominal Voltage :

Less than 12V

12V

24V

More than 24V

By Battery Capacity :

>20 kWh

30 to 60 kWh

60 to 80 kWh

More than 80 kWh

By End Use :

Automotive

BEVs

PHEVs

HEVs

Consumer Electronics

Laptops

Digital Cameras

AIDC

Others

Medical Devices

Industrial & Grid Energy

By Region :

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

Get Customization on this Report: https://www.factmr.com/connectus/sample?flag=RC&rep_id=3120

The surge in the lithium-ion battery pack market is closely intertwined with the rise of electric vehicles and the global shift toward sustainable transportation. As technology continues to advance and environmental concerns intensify, we can expect the lithium-ion battery pack market to play an even more significant role in shaping the future of transportation and clean energy solutions.

Check Out More Related Reports:

Load Break Switches Market Mechanical Control Cables Market Power Monitoring Market

Contact: US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

#Lithium Ion Battery Pack Market#Lithium Cobalt Oxide battery back market#Lithium Ion Battery Pack Market drivers#Lithium Ion Battery Pack Market forecast

1 note

·

View note

Link

The demand for lithium-ion batteries (LIBs) is expected to increase in economies with developed renewable energy sector. Asia Pacific dominated the global...

#adroit market research#lithium-ion battery market#lithium cobalt oxide battery#lithium iron phosphate battery#lithium manganese oxide batter

0 notes

Text

2025 U.S. Lithium-Ion Battery Recycling Market Trends: A Deep Dive into Industry Drivers and Emerging Opportunities

A new qualitative research report from Fortune Business Insights (2025-2030) offers a comprehensive analysis of the U.S. Lithium-Ion Battery Recycling Market trend. This report is designed to provide industry leaders, investors, and decision-makers with data-driven insights for strategic planning and informed decision-making.

The U.S. lithium-ion battery recycling market size was valued at USD 69.52 million in 2022 and is projected to grow at a CAGR of 19.11% during the forecast period.

Key Highlights of the U.S. Lithium-Ion Battery Recycling Market Report:

Market Overview: The report provides a deep dive into key market trends, drivers, and challenges, along with a detailed analysis of market size, revenue, production, and Compound Annual Growth Rate (CAGR) using validated methodologies for accuracy.

Growth Projections: The U.S. Lithium-Ion Battery Recycling Market is projected to experience substantial growth from 2025 to 2032, with major players increasingly adopting strategic initiatives to drive expansion.

Competitive Landscape:

Detailed profiling of top companies, including financials (gross profit, sales volume, revenue, manufacturing costs), product benchmarking, and SWOT (Strengths, Weaknesses, Opportunities, Threats) analysis.

Competitive analysis covers global players' revenue and sales volume rankings, average price by company, manufacturing base distribution, headquarters, product offerings, and strategic developments such as mergers, acquisitions, and expansions.

The report identifies key industry players, their innovations, and business strategies, highlighting the most promising long-term growth opportunities and advancements in processes and product development.

Get a Free Sample PDF: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/108899

Market Segmentation: Comprehensive segmentation by product type, application, end-user, region, and key competitors to identify market opportunities.

By Battery Chemistry:

Lithium Cobalt Oxide (LCO)

Lithium Iron Phosphate (LFP)

By Application:

Automotive

Industrial

By Region:

U.S.

Geographical Analysis: Expert analysis of the U.S. Lithium-Ion Battery Recycling Market across key regions:

North America (U.S., Canada, Mexico)

Europe (Germany, U.K., France, Russia, Italy, Spain)

Asia-Pacific (China, India, Japan, Australia, Singapore, NZ)

South America (Argentina, Brazil)

Middle East & Africa (Saudi Arabia, Turkey, UAE, Africa)

Drivers and Trends: Discusses factors driving and restraining market growth, their impact on demand, emerging trends, challenges, limitations, and growth opportunities. It provides a forward-looking perspective on factors expected to boost overall market growth.

Research Methodology: Employs a robust methodology involving primary research (interviews with market influencers) and secondary research to provide accurate market predictions and insights into supply-demand dynamics.

Key Opportunities and Benefits: Identifies key opportunities, analyzes factors driving industry growth, and considers past development patterns and future trends. Benefits include quantitative analysis of market segments, Porter's Five Forces analysis for strategic decision-making, revenue mapping, and benchmarking of market players.

Actionable Insights: Delivers actionable insights derived from secondary research, direct stakeholder interviews, and expert validation leveraging Fortune Business Insights' extensive regional database.

This report serves as a crucial resource for businesses seeking to make informed, strategic moves by understanding technological innovations, pricing trends, consumer behavior, and investment potential within the U.S. Lithium-Ion Battery Recycling Market.

Get More Info: https://www.fortunebusinessinsights.com/u-s-lithium-ion-battery-recycling-market-108899

About Us:

Fortune Business InsightsTM offers expert corporate analysis and accurate data, helping organizations of all sizes make timely decisions. We tailor innovative solutions for our clients, assisting them to address challenges distinct to their businesses. Our goal is to empower our clients with holistic market intelligence, giving a granular overview of the market they are operating in.

0 notes

Text

0 notes

Text

India sends geologists to Zambia to discover copper and cobalt deposits, sources say

India sends geologists to Zambia to discover copper and cobalt deposits, sources say Jul 01, 2025 12:31 PM IST UK-INDIA-MINERALS-ZAMBIA:India sends geologists to Zambia to discover copper and cobalt deposits, sources say By Neha Arora India sends geologists to Zambia to discover copper and cobalt deposits, sources say NEW DELHI -India has dispatched a group of geologists to Zambia to discover copper and cobalt deposits, two Indian authorities sources mentioned, as New Delhi steps up efforts to safe essential mineral provides important to its vitality transition. The Zambian authorities this 12 months agreed to allocate 9,000 sq. km to India for the exploration of cobalt - a key part in batteries for electrical automobiles and cell phones - in addition to for scouting copper, which is extensively utilized in energy technology, electronics, and building. The exploration mission will final for 3 years and a lot of the evaluation shall be performed in laboratories in India, one of many sources mentioned. The group is predicted to make a number of visits over the course of the whole mission, mentioned the sources, who declined to be recognized as a result of the data is just not public. After assessing the mining potential, the Indian authorities will search a mining lease from the Zambian authorities and can also invite private-sector corporations to take part within the mission, the sources mentioned. India's Ministry of Mines didn't reply to a request for remark. New Delhi has been in talks with a number of African international locations to amass essential mineral blocks on a government-to-government foundation, whereas additionally exploring alternatives in Australia and Latin America. India can also be in discussions with the Democratic Republic of Congo to signal an preliminary settlement to safe provides of cobalt and copper, Reuters reported in March. An Indian delegation attended a mining convention in Congo final month and toured native mines, the ministry mentioned in a put up on X. India has held inside discussions over its rising vulnerability to a tightening international copper market and plans to discover methods to safe provide from resource-rich international locations throughout ongoing commerce negotiations, Reuters reported final week. India's copper imports have risen sharply for the reason that 2018 closure of Vedanta's Sterlite Copper smelter. The nation imported 1.2 million metric tons of copper within the fiscal 12 months ending March 2025, up 4% from the earlier 12 months. India is sort of totally depending on cobalt imports and shipments of cobalt oxide rose 20% in 2024/25 to 693 metric tons, authorities information confirmed. This article was generated from an automatic information company feed with out modifications to textual content. Read More: https://news.unicaus.in/world/united-states-of-america/india-sends-geologists-to-zambia-to-discover-copper-and-cobalt-deposits-sources-say/

0 notes

Text

The Growing Lithium-Ion Battery Market: Trends, Drivers, and Future Outlook

The Global Lithium-ion Battery Market Size is expected to reach USD 273.8 Billion by 2030, at a CAGR of 19.3% during the forecast period 2021 to 2030.

This study gives a detailed analysis of drivers, restrains, opportunities and challenges limiting the market expansion of Lithium-Ion Battery Market market. The survey included a diverse set of players, including a balance of leading and growing manufacturers for business profiling, such as;

Honda Automobile Co., Ltd., Hyundai Motor, Samsung SDI Co., Ltd., Hitachi Astemo, Ltd., NXP Semiconductors N.V., Proterial, Ltd., Contemporary Amperex Technology Co., Limited., Mikuni Corp., Dana Incorporated, Eaton Corporation, Faurecia SE, Gentherm Inc., Tesla, Visteon Corporation, BYD Company Ltd., Norsk Hydro ASA, Bharat Electronics Limited (BEL), Duracell, Inc., Sensata Technologies, Inc., TE Connectivity Ltd., ZF Friedrichshafen AG, LG Chem, Panasonic Holding Corporation, General Electric, Renault Group, Johnson Controls, A123 System, Okaya Power Group, TDS Lithium-Ion Battery Gujarat Private Limited, Telemax India Industries Pvt. Ltd.

Our expert team is consistently working on updated data and information on the key player's related business processes that value the market for future strategies and predictions

Get Access to a Free Copy of Our Latest Sample Report - https://www.sphericalinsights.com/request-sample/1693

Market Segmentation:

Lithium-Ion Battery Market, Type Analysis

Lithium Iron Phosphate (LFP)

Lithium Cobalt Oxide (LCO)

Lithium Nickel Manganese Cobalt Oxide (LI-NMC)

Lithium Nickel Cobalt Aluminum Oxide (LI-NCA)

Lithium Titanate (LTO)

Lithium-Ion Battery Market, Capacity Analysis

0 to 3,000 mAh

3,000 to 10,000 mAh

10,000 to 60,000 mAh

60,000 mAh and Above

Covered in this Report:

1. Go-to-market Strategy. 2. Neutral perspective on the market performance. 3. Development trends, competitive landscape analysis, supply side analysis, demand side analysis, year-on-year growth, competitive benchmarking, vendor identification, QMI quadrant, and other significant analysis, as well as development status. 4. Customized regional/country reports as per request and country level analysis. 5. Potential & niche segments and regions exhibiting promising growth covered. 6.Analysis of Market Size (historical and forecast), Total Addressable Market (TAM), Serviceable Available Market (SAM), Serviceable Obtainable Market (SOM), Market Growth, Technological Trends, Market Share, Market Dynamics, Competitive Landscape and Major Players (Innovators, Start-ups, Laggard, and Pioneer).

Buy this report now:- https://www.sphericalinsights.com/checkout/1693

Challenges & Opportunities

Challenges:

Raw material shortages (lithium, cobalt, nickel)

Safety concerns (thermal runaway risks)

Recycling infrastructure gaps

Opportunities:

Solid-state batteries (next-gen Li-ion tech with higher safety & energy density)

Second-life applications (repurposing used EV batteries for energy storage)

Expansion in emerging markets (India, Southeast Asia, Africa)

Future Outlook

The lithium-ion battery market is set to grow at a CAGR of over 15% in the next decade. Innovations in battery chemistry, increased production capacity, and sustainability initiatives will shape the industry’s future.

Industry Developments:

Regional Analysis for Lithium-Ion Battery Market Market:

✫ North America: (U.S., Canada, Mexico) ✫ Europe: (U.K., Italy, Germany, Russia, France, Spain, The Netherlands and Rest of Europe) ✫ Asia-Pacific: (India, Japan, China, South Korea, Australia, Indonesia Rest of Asia Pacific) ✫ South America: (Colombia, Brazil, Argentina, Rest of South America) ✫ Middle East & Africa: (Saudi Arabia, U.A.E., South Africa, Rest of Middle East & Africa)

Benefits of the Report:

⏩ A descriptive analysis of demand-supply gap, market size estimation, SWOT analysis, PESTEL Analysis and forecast in the global market. ⏩ Top-down and bottom-up approach for regional analysis ⏩ Porter’s five forces model gives an in-depth analysis of buyers and suppliers, threats of new entrants & substitutes and competition amongst the key market players. ⏩ By understanding the value chain analysis, the stakeholders can get a clear and detailed picture of this Market

Insightful inquiry before buying:- https://www.sphericalinsights.com/inquiry-before-buying/1693

Frequently asked questions:

➥ What is the market size of the Lithium-Ion Battery Market market? ➥ What is the market growth rate of the Lithium-Ion Battery Market market? ➥ What are the Lithium-Ion Battery Market market opportunities and threats faced by the vendors in the global Lithium-Ion Battery Market Industry? ➥ Which application/end-user or product type may seek incremental growth prospects? What is the market share of each type and application? ➥ What focused approach and constraints are holding the Lithium-Ion Battery Market market? ➥ What are the different sales, marketing, and distribution channels in the global industry?

Unlock the full report now! @ https://www.sphericalinsights.com/reports/lithium-ion-battery-market

Related URL

About the Spherical Insights

Spherical Insights is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

Contact Us:

Company Name: Spherical Insights

Email: [email protected]

Phone: +1 303 800 4326 (US)

Follow Us: LinkedIn | Facebook | Twitter

#Size#Share#Trend#Analysis#Insights#Forecast#Outlook#Scope#Statistics#Research report#Demand#Price#Market#Growth

0 notes