#Coated Abrasives Market

Explore tagged Tumblr posts

Text

#Abrasion-Resistant Coatings Market Revenue#Abrasion-Resistant Coatings Market Report#Abrasion-Resistant Coatings Market Demand#Abrasion-Resistant Coatings Market Value#Abrasion-Resistant Coatings Market Estimation#Abrasion-Resistant Coatings Market Segmentation#Abrasion-Resistant Coatings Market Growth

0 notes

Text

Seamless Protection: Exploring the Polyurea Coatings Market

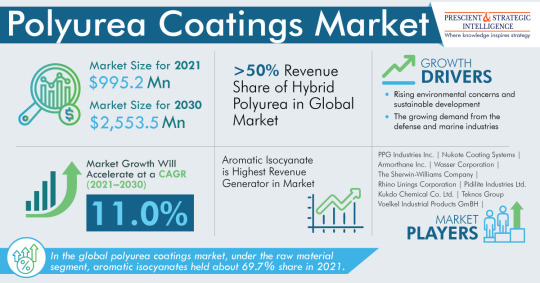

The size of the polyurea coatings market was USD 995.2 million in the recent past, and it will power at a rate of 11% and reach a value of USD 2,553.5 million by 2030, according to P&S Intelligence.

The automotive and transportation sector had the second-largest share, of about 26%. Polyurea coatings are used on the exteriors of vehicles, such as two-wheelers and trucks. They are usually seen on the chassis, driveshafts, gearboxes, and engines, as they provide good resistance to the exterior thermal and physical pressure.

To receive free sample pages of this report@ https://www.psmarketresearch.com/market-analysis/polyurea-coatings-market/report-sample

Consequently, polyurea coatings are becoming popular among automakers. China, Germany and Japan are the top three passenger vehicle producers. Consequently, polyurea coatings’ applications have advanced greatly in these countries. Volkswagen, Mercedes, Audi, Porsche, Opel, and BMW are all part of Germany's extremely competitive automobile industry. This industry generates about USD 468.5 billion, which accounts to about 20% of the total revenue of the German industry. Aromatic isocyanates are formulated with the use of benzene and toluene as raw materials. Methylenediphenyl disocyanate and Toulenedisocyanate are two of the most-common aromatic isocyanates used in the construction industry. The weather of Europe and North America is favorable for the use of aromatic polyurea coatings, which are less expensive than aliphatic substitutions. Aromatic isocyanates are used as a basecoat, meaning they are the first layer applied to any surface. Consequently, they are widely used in vehicles, that is the reason aromatic polyurea coatings market size will grow rapidly. The requirement for polyurea coating will surge in the APAC with a rate of 11.9% in the years to come. The high-pace monetary growth and substantial investment by private and government companies in numerous sectors, such as maritime, manufacturing, automotive, and construction, are driving the regional demand for industrial coatings. It is because of the increasing ecological concerns and requirement for sustainable expansion, polyurea coatings had a major place in the coatings sector, garnering high investment in R&D.

#Polyurea coatings#Protective coatings#Industrial applications#Corrosion resistance#Waterproofing solutions#Abrasion resistance#Coating technology#Surface protection#Infrastructure maintenance#Automotive coatings#Flooring solutions#Market trends#Seamless coatings#Chemical resistance#Environmental durability#Spray-on coatings#Application versatility#Market growth#Coating innovation#Future of polyurea coatings.

0 notes

Text

Now for thoughts on arranged marriage AU with Silvio.

Arranged marriage with Silvio is... difficult. He agrees to marrying you, but only just. In fact, it takes a lot of convincing between nobles of both his court and yours for him to finally agree, and even then, it's glaringly obvious how much he hates the idea. Even in your own kingdom, your people hear rumors about his womanizing ways, sleeping with the prettiest women that approach him and the way he all but kicks them out after, leaving you unsure and doubtful about the success of this relationship.

As is expected, your impression of him doesn't change much after the first meeting, or after attending a nobles party to become acquainted with him and his court, or even after the wedding. He's arrogant, snobby, abrasive, and downright cruel, in all honesty. It's clear what his priorities are, expanding his wealth and the prosperity of his kingdom's economy, without a care for anything else. And you are just the tool to help him branch out and utilize your old kingdom's resources and connections to get what he wants.

There's plenty of arguments in the beginning, and comments from one often incite a smartass response from the other. You have no problem with attending him in his work, meeting the merchants and checking out new wares, getting an idea of what new products will be entering the market. But it quickly wears on you how shallow he seems, his focus on glam and money and status, and the way he tries to treat you like an object as well. It's almost endless the way he tries to throw expensive jewels and silks and rare items at you, dressing you like a living doll sometimes, but they're all empty gestures.

Every attempt to get closer to him as a person seems to be met with a brick wall, answering questions about his work but never anything personal. He avoids your touch like the plague, something like fear or vulnerability visible in his eyes that only serves to confuse you, and snaps at you when you try to approach. It eventually results in the first full fight, plenty of yelling and curse words exchanged before it ends with doors being slammed. Silvio's attendant, Carlo, seems to fear him but still makes an effort to apologize secretly on his behalf, helping to calm you down a little.

This explosion of feelings only pushes you to work harder, determined to change his opinion and accept you as his partner. For a while, it feels like nothing is changing, and that your efforts are for nothing. But the truth is, even before the first big fight, Silvio had fallen for you early, and he fell hard. He just couldn't bring himself to make himself vulnerable like that. Anybody could be bought with money, he had been convinced of that time and time again, and although it was unlikely anyone had riches to match his, he couldn't take that chance with someone he was legally tied to.

But somewhere in the arguments, the sass, and your persistence in breaking down his walls, you'd achieved your goal unknowingly in exposing the true man inside. It takes longer than both of you would like for him to accept these feelings, and even longer for him to come clean about how he got here. But once he accepts that he is yours, it's like a change overcomes him.

True to the dalmatian on his coat of arms, he changes from his prior abrasive attitude to one of protection and loyalty. Silvio is no stranger to the way people use money to buy others, and he works to protect you from being used as he had been in the past. The sassy remarks continue, but you both do it lovingly now, a strongly knit bond connecting you as you work together for the prosperity of the kingdom. Silvio never would have imagined forging a union not bought by his massive wealth in the past, but now that he has you, he realizes you were truly the answer all along.

#ikemen prince#silvio ricci x reader#ikepri silvio#ikemen prince silvio#ikepri au#the minx can write ✍️

109 notes

·

View notes

Text

this started out as a short rant about non-stick cookware but i've got an infodump about cookware in general and suggestions for what's the most useful vs the least useful in the kitchen. the thing about cooking is you can do a lot with a little equipment, despite appearances to the contrary. however the vessels you cook in are the most used tools in the kitchen, aside from a chef's knife

ok, first my little rant about non-stick cookware:

it doesn't last, and that's the main flaw of non-stick cookware. whether it has a non-stick coating or it's a special material that is inherently non-stick (at first), eventually they wear down and the non-stick benefits you bought the pan for pretty much disappear.

that isn't to say non-stick cookware is not useful. I have one non-stick frying pan in my kitchen and I use it to cook eggs and other things that are notorious for sticking. i also use it to reheat leftovers just because it's easier to clean. that's all i use it for

so, if you're in the market for cookware because you're moving out or just finally getting a kitchen of your own, do not go buying all non-stick pots and pans. sauce pans, skillets, stock pots (the big pots you use for soup), sauté pans, etc, those actually need your food to stick in some cases, especially for soups and sauces. why's that?

it's about the fond. example: when you're making a soup you usually start by sautéing solid ingredients in the pan first. those get browned and they leave a bit of slightly-burned foodstuff on the bottom of the pot. that's called fond. it's super concentrated savory flavor. right before you add the stock to the soup, you "deglaze" the pan by adding a little bit of liquid to the bottom of the pot and gently scraping it off and integrating it into the soup. fond is also like the basis of all sauces and stews and gravies pretty much anything else you're cooking

where should you buy cookware? obviously you can always buy new, I suggest buying direct from the manufacturer if you really want new. you can also find good cookware at garage sales.

if you have access to them, restaurant supply stores have cheap cookware but it's also made to be beat to death in a commercial kitchen. it works just as well as the stuff aimed at the consumer because, well, metal pans are metal pans. it's not rocket science. but there is cheap bad cookware in the restaurant supply store so shop carefully

so what kind of cookware should you buy? here are options i recommend, but not in any particular order:

stainless steel

stainless steel pans are versatile and they last forever. they work on the stovetop and they go in the oven too. so not only can you use them to fry up some veggies, you can also use them to roast a beast in the oven. they're easy to keep clean, though they eventually get a patina especially on the bottom. use dish soap. the easiest way to get tough spots off them are gentle abrasives like Barkeeper's Friend. these range from cheap to expensive, and some of the expensive ones are worth it (but not too expensive. like $100-200 range for really nice ones. remember, they last forever, so it's like a one-time fee)

good stainless steel pans should be heavy. if you're out shopping for them, pick them up and compare how they feel. if you spot a really cheap one and it feels light like a non-stick pan, avoid it.

carbon steel

these got popular lately, and frankly i don't have too much experience with them since the one i had ended up being left behind in a move. however they're totally fine to work with and are easier to maintain than a cast iron pan. however they sometimes come with wooden handles (a lot of them are wok-shaped because, well, a lot of woks are carbon steel), so remember you can't put wooden-handle pans in the oven. also since they're thinner they're probably not as good for the oven as other materials in terms of both performance and longevity

taking care of them is a little harder than stainless steel, because after you wash and dry them, you have to coat them in a thin layer of oil to prevent rusting

cast iron

okay first i want to get the cleaning bit out the way: YOU CAN WASH YOUR CAST IRON PANS WITH DISH SOAP. that bullshit about only using salt and water and never getting soap on it is from an era when soaps were made of lye. MODERN DETERGENTS ARE NOT MADE OF LYE, THEY'RE NOT EVEN SOAP. HOWEVER: DO NOT SCRUB YOUR CAST IRON WITH METAL SCRUB SPONGES

now about cast iron itself: it's cheap and it's a long-term investment. your cast iron gradually becomes a non-stick pan over time if you maintain its seasoning. a cast iron pan becomes seasoned naturally over time as long as you wash it soon after it cools down from cooking (don't ever leave food or water in it, it will rust), and after it's clean, you cover it with an extremely thin layer of cooking oil.

you can re-season cast iron that has lost its seasoning too. i don't want to turn this post into a cast-iron infodump post so i'll leave it to you to google "how to season cast iron pans" and "how to maintain cast iron pans". just remember the "don't wash it with soap" line is bullshit unless you actually have dish soap that contains lye, like where'd you get that?

these are also great for cooking in the oven as well as the stovetop. their high-density and dark color make for good heat distribution. a lot of people swear by cast iron as the best material to sear meat with, however i never really noticed the difference between cast iron and stainless steel.

enameled cast iron

le creuset can sit on it and spin. don't buy their shit it's overpriced. enameled cast iron is much more affordable from companies like lodge who already make cheap, good, regular cast iron pans. it's a cast iron pan coated with ceramic. enameled cast iron is really good for even heat distribution, however you do have to be careful not to chip it. it may also, despite your best efforts, just wear down over time because ceramic isn't as wear-resistant as metal.

enameled pans can go in the oven as well.

non-stick pans

only buy one (1) non-stick pan. make it a frying pan or sauté pan. and do not spend a lot of money on it. like $40-50 tops. i've seen $100+ non-stick pans and i think someone made those as a joke. it's a grift. you will be replacing it on a semi-regular basis depending on how often you use it.

if your non-stick pan uses a coating, if it starts flaking it's time to get rid of it. those ceramic non-stick pans you just gotta toss it when they lose their smoothness

that's it. post over. go cook. if you have any questions send an ask

127 notes

·

View notes

Text

Just a little Nicky V self indulgent imagination that has been with me for years:

We're sitting atop some building in Diamond City. It's nearing midnight, hardly anyone is still out and about save for the ocasional city guard or nightowl, and the colorful lights about the Diamond City market are beautiful. The only sounds are the howl of the wind and the ocasional bleep from Takahashi below. Nick and I lean against each other, a lit cigarette in his hand, a fifth of brown liquor in mine. We're passing both between the two of us. The yellow halos of his eyes pierce me.

We talk, we laugh. Nick drapes his coat over my shoulders to shield me from a brisk breeze. He tastes like tobacco and whiskey. His intact hand is abrasive, but pleasant, as he frames my cheek.

7 notes

·

View notes

Text

A Guide To Choose The Right Concrete Sealers For Home

Maintaining the efficiency of the commercial property is extremely important especially the concrete that makes the floor pitch perfect. In fact, not just maintaining but preventing the damage to concrete is equally essential. Concrete is one of the crucial construction elements owing to its strength and longevity. However, because concrete is porous, it can absorb soluble salts and water, which can be harmful. Furthermore, the absorption of salts by the concrete, especially chlorides, can eventually lead to corrosion problems when steel reinforcement is inserted in the concrete to strengthen it.

As a result, opting for the right type of concrete sealers is of utmost necessity. It ensures protection by shielding surfaces from a wide range of water-related issues caused by the cycles of thawing and freezing, stains from dirt, oil, and other impurities. In addition, it also prevents an individual from investing unnecessarily.

Understanding The Role Of Concrete Sealers

The sealers for concrete are intended to provide protection for the concrete's surface against degradation, rust, and discolouration over time. Most concrete surface degradation is usually caused by surface moisture penetration. It's essential to safeguard and preserve the concrete surfaces while doing regular maintenance to increase their lifespan. Concrete sealers function by covering your concrete's surface or by penetrating into its pores and attaching to its inherent attributes. There are several types of sealers and choosing the right one can be the game changer.

How To Choose The Right Concrete Sealers?

In order to choose the right kind of sealers for a concrete surface, one must be aware of the different types of concrete sealers in the market and their benefits.

Waterproof Concrete Sealers

A sealer should be a product that has the ability to penetrate deep into the surface as well as the substrate in order to seal and act as a protective covering. A waterproof sealer protects the concrete surface from penetrating water deep into the seal on which it turns into a solid form enclosing all alkali and lime in its impenetrable layer.

As a result, the concrete surface coated with waterproof sealers becomes water resistant along with other dirt, grease and acid which extends the overall life of the surface.

Epoxy Concrete Sealers

Epoxy concrete sealers are a great option for heavily utilized interior floors. This specific sealer not only offers a durable finish but also deters excessive abrasion. The most popular applications for epoxy coatings are concrete flooring and countertops. As a matter of fact, this type of sealer offers a glossy finish with a thick composition.

Depending on the requirement of an individual, pigments can be added to the sealers for better colours and one can choose either some mid-level sheen or highly glossy one.

Acrylic Concrete Sealers

If an individual is looking for a cost-effective option, acrylic sealers are the best. Not only is it easy to apply but is also best suited for the interiors and exteriors for sealing the concrete. In addition, this type of sealer is well resistant to UV and therefore doesn’t fade away with time.

If one is looking for sealers for the garage or wants to seal the pool decks and walkways, individuals can opt for acrylic sealers as they offer protection against chlorine water. The paint dries really fast and enhances colours while protecting against damage.

Final Thoughts

Choosing the right concrete sealers perth and applying them correctly is extremely crucial. To find the ideal balance of protection, durability, and affordability, consider the specific needs, surface, and location.

Spraypave Pro is a concrete sealer expert in Perth and can help with the process of concrete sealing.

2 notes

·

View notes

Text

⸻ PHIL DUNSTER. HE/HIM / have you ever heard of A MAKER OF MY TIME by the paper kites, well, it describes OWEN MARR to a tee! the thirty year old, and PERSONAL TRAINER/FITNESS GURU was spotted browsing through the stalls at portobello road market last sunday, do you know them? would you say HE is more cocky or more CARING instead? anyway, they remind me of trainers even with a suit, an abrasive attitude covering up a heart of gold, crumpled sheets, late night runs and a constant need to be the best, maybe you’ll bump into them soon!

time in notting hill ; all his life.

tw: eating disorder mention

ABOUT.

Name: Owen Marr Age: Thirty Date of Birth: 17th August 1993 Birthplace: London, UK Occupation: Personal Trainer/Fitness GuruRomantic/sexual orientation: Heteroromantic/heterosexual

The oldest of the Marr children, Owen always felt a slight disassociation from his siblings. He's the one who was a trial in a way for his parents, he had the boring name and he had three years where it was just him, growing and learning, toddling around in a house the family couldn't really afford.

That became more and more apparent as the family grew over the coming years and when he finally hit a point where he wanted to do more than just hang around at home and keep his younger siblings company, he realised he couldn't really do that. So it didn't take long for him to take in the usual Marr shenanigans. if he wanted on the football team he'd have to steal the kit he needed —- and he did, repeatedly, from other students, from the lost and found, from the local sports shop where he'd sneak it under his coat.

As he grew older, he'd spend day after day in the local coffee shop uploading videos he'd filmed out on the football field and in the park. Fitness was really the only thing he was interested in and he started gaining a following through that. It wasn't hard for that to become his only focus.

He was the first to leave the family home, getting his own place out on the Isle of Dogs and starting a whole other life for himself.

His career blossomed and it wasn't long before he was starting a family all of his own... even if it wasn't intentional and it certainly wouldn't last. His daughter, Daisy, means the absolute world to him, though. Always has and always will.

It wasn't until recently that he made the move back to Notting Hill to be closer to the rest of the Marrs. No matter how often he might try and pretend he's a different person now, there's no getting away from that. He's always been a little rough around the edges, swears a tiny bit too much ( when he's not on camera anyway ), drinks more than he should, and then proceeds to try and run the calories off in a pretty unhealthy way the same night.

WANTED CONNECTIONS.

siblings. ( 3/3. ) ( sparrow, jagger & wilde marr. )

best friend. ( kash bronson. )

mother of his daughter.

ex-girlfriends.

good friends.

clients.

3 notes

·

View notes

Text

The Ultimate Guide to Choosing the Perfect Teeth-Whitening Product

Introduction

Achieving a brighter, whiter smile is a goal for many people, but with so many teeth-whitening products on the market, it can be overwhelming to figure out which one is the best for you. In this blog post, we will go over the different types of teeth-whitening products available and provide tips on how to choose the perfect one for your needs.

Types of Teeth-Whitening Products

There are a number types of teeth-whitening products available in the market today. Let’s dive in and look through some common types:

1. Whitening Toothpaste - This product, typically contains mild abrasives and special chemicals that help to remove surface stains on teeth. While they can be effective for maintaining already white teeth, they may not be strong enough to remove deep stained teeth.

2. Whitening Strips - These are are thin, flexible strips coated with a bleaching agent that is applied directly to the teeth. They are generally easy to use and can produce noticeable results in as little as a week. However, they may not be suitable for people with sensitive teeth, and it can be challenging to apply them evenly.

3. Whitening Trays - They are custom-fitted trays that are filled with a bleaching gel and worn over the teeth for a certain amount of time each day. They are more effective than toothpaste or strips, but they can be uncomfortable to wear and may cause sensitivity.

4. In-Office Whitening - In-office whitening is a professional treatment done by a dentist that involves applying a high-concentration bleaching gel to the teeth. It is the most effective and fastest method of teeth whitening, but it is also the most pricy.

So, How Do I Choose the Perfect Teeth-Whitening Product?

Now that you know the different types of teeth-whitening products available, here are some tips on how to choose the perfect one for you:

1. Consider Your Budget - One of the essential factors to consider when choosing a teeth-whitening product is your budget. Whitening toothpaste and strips are generally the most affordable options, while trays and in-office whitening treatments can be more expensive.

Whitening toothpaste can cost anywhere between $5 to $20 per tube, while whitening strips can range from $20 to $60 for a pack. Whitening trays can cost anywhere from $100 to $300, depending on the brand and whether they are custom-fitted or not. In-office whitening treatments can range from $300 to $1,000 or more.

It's important to keep in mind that while in-office whitening treatments may be more expensive, they are also the most effective and produce results much faster than other methods.

2. Look for a Recommended Product -When choosing a teeth-whitening product, it's important to choose one that is recommended by dentists or has positive reviews from customers. It is wise to look for products that have the American Dental Association (ADA) Seal of Acceptance, as this means that the product has been tested and proven to be safe and effective.

Remember to always do an online research and read reviews from other customers to get a better idea of how well a particular product works. However, keep in mind that everyone's teeth are different, so what works for one person may not work for another.

3. Determine the Severity of Your Stains - The severity of your stains will also play a role in determining which teeth-whitening product is best for you. If you have mild surface stains caused by things like coffee or tea, smoking, or aging, then whitening toothpaste or strips may be sufficient.

However, if you have deeper stains or discoloration caused by things like medication, trauma, or genetics, then whitening trays or in-office whitening treatments may be more effective.

4. Consider Sensitivity - If you have sensitive teeth or gums, it's essential to choose a teeth-whitening product that is gentle and won't cause discomfort. Whitening toothpaste and strips are generally safe for people with sensitivity, as they contain lower concentrations of bleaching agents.

However, if you have more severe sensitivity, then trays or in-office whitening treatments may not be the best option. It's important to talk to your dentist if you have concerns about sensitivity before choosing a teeth-whitening product.

5. Check for Ingredients - Before choosing a teeth-whitening product, it's important to check the ingredients to ensure they are safe and effective. The most common bleaching agents used in teeth-whitening products are hydrogen peroxide and carbamide peroxide.

Hydrogen peroxide is a stronger bleaching agent and is typically used in in-office whitening treatments. Carbamide peroxide is a milder bleaching agent and is found in most over-the-counter teeth-whitening products.

It's important to note that while these ingredients are generally safe for use, they can cause sensitivity and irritation if used too frequently or in high concentrations.

6. Consult with a Dentist - If you're unsure which teeth-whitening product is best for you, it's always a good idea to consult with a dentist. They can evaluate your teeth and recommend a product that is safe and effective for your particular needs.

They can also help you determine the cause of your stains and recommend lifestyle changes or treatments to prevent further staining.

Conclusion

Choosing the perfect teeth-whitening product requires careful consideration of your budget, the severity of your stains, sensitivity, ingredients, and consulting with a dentist if needed.

By keeping these factors in mind and choosing a recommended product, you can achieve a brighter, more confident smile.

2 notes

·

View notes

Text

Mastering Epoxy Floor Waterproofing: Essential Tips and Tricks

Epoxy flooring is a popular flooring option for both residential and industrial areas. It is durable, easy to clean, and offers a sleek, modern look. However, one of the biggest concerns is its susceptibility to water damage. This is where floor waterproofing singapore comes into play. In this article, we'll discuss essential tips and tricks for mastering floor waterproofing.

Understand the Importance

Before we dive into tips and tricks, it's important to understand why floor waterproofing is so essential. floors are not naturally waterproof and can suffer from damage due to water exposure. Water damage can lead to bubbling, peeling, and even cracking of the flooring. This can result in costly repairs and replacements. You can protect them from water damage, extend their lifespan, and save money in the long run.

Choose the Right Waterproofing Product

Choosing the right waterproofing product is crucial for effective floor waterproofing. There are many options available in the market, but not all products are created equal. It's important to choose a high-quality product that is specifically designed for floors. Look for a product that is easy to apply, dries quickly, and offers long-lasting protection against water damage.

Prepare the Surface

Proper surface preparation is key to successful floor waterproofing. Before applying any waterproofing product, make sure the surface is clean and free of any dirt, oil, or debris. Use a degreaser to remove any oil or grease stains, and then thoroughly clean the surface with a pressure washer or a scrub brush. Once the surface is clean, allow it to dry completely before applying any waterproofing product.

Apply the Waterproofing Product

When applying the waterproofing specialist product, make sure to follow the manufacturer's instructions carefully. Use a roller or a brush to apply the product evenly over the entire surface. Be sure to apply a sufficient amount of the product to ensure complete coverage. Once the product has been applied, allow it to dry completely before walking on the surface or applying any additional coats.

Maintain Your Epoxy Floors

Proper maintenance is key to preserving the waterproofing of your floors. Regularly clean your floors using a mild detergent and a soft-bristled brush or mop. Avoid using abrasive cleaners or tools that could damage the waterproofing layer. If you notice any damage or wear on your floors, address it immediately to prevent further water damage.

Consider Adding a Sealant

In addition to using a waterproofing product, you may also want to consider adding a sealant to your floors. A sealant can provide an extra layer of protection against water damage and can help to enhance the durability and lifespan of your floors.

Use a Moisture Meter

Before applying any waterproofing product, it's important to check the moisture levels of your concrete or substrate. Use a moisture meter to ensure that the surface is dry and free of any moisture. Applying a waterproofing product to a surface that is not completely dry can result in ineffective waterproofing and may even cause more damage.

Conclusion

epoxy floor waterproofing services is a crucial step in protecting your floors from water damage and extending their lifespan. By choosing the right waterproofing product, properly preparing the surface, and maintaining your floors, you can master floor waterproofing and enjoy the benefits of a long-lasting, waterproof flooring option.

#concrete crack repair epoxy injection#injection grouting chemical#water leakage repair#water pipe leakage repair#ceiling water damage repair

2 notes

·

View notes

Text

The Beauty of Black Shower Enclosures

Are you looking to add a touch of elegance and class to your bathroom? Look no further than black shower enclosures. Black shower enclosures have become increasingly popular in recent years due to their sleek and stylish look. With such an array of designs and styles available, there is something for everyone. Not only do black shower enclosures add an aesthetically pleasing look to your bathroom, but they are also incredibly durable and can last for many years with proper maintenance. In this article, we will discuss the benefits of black shower enclosures and why they are becoming a popular choice for many homeowners. Table of Contents: I. Introduction II. Benefits of Black Shower Enclosures III. Types of Black Shower Enclosures IV. Maintenance Tips V. Conclusion

II. Benefits of Black Shower Enclosures Black shower enclosures bring a unique and modern look to any bathroom. They provide a chic and stylish look that stands out and can make any bathroom look more elegant. Not only are they aesthetically pleasing, but they are also incredibly durable and long-lasting. The materials used to make black shower enclosures are usually made of high-quality materials that can withstand the wear and tear of everyday use. They are also easy to clean and maintain, so you don’t have to worry about any extra upkeep.

In addition to being aesthetically pleasing and durable, black shower enclosures are also energy-efficient. The materials used to make them are usually thick and insulating, which means that they can help keep your bathroom warm and comfortable. This can also help reduce your energy bills since you won’t have to use as much energy to heat your bathroom.

Black shower enclosures are also a great way to add some extra privacy to your bathroom. They provide a barrier between you and the rest of the bathroom, which can be especially helpful if you share a bathroom with other people.

III. Types of Black Shower Enclosures There are a variety of black shower enclosures available on the market, so you are sure to find one that fits your needs. You can choose from traditional framed enclosures, frameless enclosures, and sliding door enclosures. Each type has its own benefits and drawbacks, so it’s important to consider your needs before making a decision.

Framed enclosures are the most common type of black shower enclosures. They are made of metal frames that are usually finished with a black powder coating. These enclosures are usually the most affordable option and can be easily installed in any bathroom.

Frameless enclosures are a bit more modern and offer a sleek and contemporary look. They are usually made of tempered glass and can be more expensive than framed enclosures. However, they can add a lot of style to your bathroom and are very easy to maintain.

Sliding door enclosures are a great option for small bathrooms since they don’t require a lot of space. These enclosures have doors that slide open and closed and are usually made of tempered glass. They can be a bit more expensive than other types of enclosures, but they are also very easy to maintain.

IV. Maintenance Tips Black shower enclosures require regular maintenance in order to keep them looking their best. It’s important to inspect your enclosure regularly for any signs of damage or wear and tear. If you notice any, it’s important to take care of them as soon as possible in order to prevent further damage.

It’s also important to clean your black shower enclosures regularly. This will help keep them looking like new and prevent any build-up of dirt and grime. You can use a mild cleaner and soft cloth to gently clean the enclosure. It’s important to avoid using any harsh chemicals or abrasive cleaners as these can damage the enclosure.

Finally, it’s important to consider the weather when it comes to black shower enclosures. If you live in an area with a lot of moisture and humidity, it’s important to make sure your enclosure is properly sealed to prevent any water damage. You should also consider using a sealant or weatherproofing product in order to protect your enclosure from the elements.

V. Conclusion Black shower enclosures are a great way to add a modern and stylish look to your bathroom. They are incredibly durable and can last for many years with proper maintenance. Not only do they provide a sleek and stylish look, but they are also energy-efficient and can help keep your bathroom warm and comfortable. There are a variety of types available, so you are sure to find one that fits your needs. With the right maintenance, your black shower enclosure can look like new for years to come.

Tags:Black Shower Enclosures

#Black shower enclosures#bathroom#homedecor#interiordesign#bathroomdesign#design#bathroomdecor#home & lifestyle#home#interior#bathroomremodel

2 notes

·

View notes

Text

How Much Does Dry Cleaning Cost? A Comprehensive Guide

Dry cleaning is a vital service that prolongs the life of your clothes and ensures they look their best. It’s an ideal solution for those who lack the time, inclination, or ability to wash, iron, and press their garments. Surprisingly, it can often be more budget-friendly than expected!

Many people wonder: how much does dry cleaning cost? Prices vary among providers, so it’s wise to compare options to find the best local deal.

In this blog post, we’ll explore the factors that influence dry cleaning prices and provide insights to help you estimate the costs associated with this essential service.

The Growth of the Dry Cleaning Industry According to Grand View Research, the U.S. laundry facilities and dry-cleaning services market was valued at $10.82 billion in 2021 and is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2022 to 2030.

What is Dry Cleaning? Dry cleaning is a specialized method of cleaning clothes using solvents instead of water. This process is ideal for delicate fabrics like silk and wool, which could be damaged by traditional laundering. Dry cleaning helps maintain a garment’s shape and texture, as it doesn’t cause fibers to swell.

Understanding dry cleaning costs is crucial, especially for materials that are sensitive to water, prone to shrinking, or have tough stains. Formal wear, business attire, and special-care garments typically require this service.

Benefits of Dry Cleaning Dry cleaning offers several advantages, making it a sought-after service for garment care. Here are some key benefits:

Gentle on Delicate Fabrics – Ideal for materials like silk, wool, and rayon that can be damaged by water and conventional washing.

Superior Stain and Odor Removal – Effectively removes tough stains and persistent odors that traditional washing may not tackle.

Less Abrasive Process – Reduces the risk of wear and tear on clothing, extending the lifespan of garments.

Convenience – Professionals handle cleaning, pressing, and sometimes even pickup and delivery.

Professional Finishing – Clothes are pressed, wrinkle-free, and ready to wear.

Preservation – Ensures special garments like wedding dresses or formal wear are maintained in pristine condition.

These benefits make dry cleaning an essential service for many, justifying its cost.

Factors Influencing Dry Cleaning Costs The cost of dry cleaning varies due to several factors:

1. Type of Garment The cost of dry cleaning depends significantly on the type of garment. Simple cotton shirts are less expensive to clean than a two-piece suit or a formal dress. More complex garments require extra care and time, resulting in higher costs.

2. Fabric Type Fabrics play a major role in determining dry cleaning costs. Delicate materials such as silk, wool, velvet, and synthetics require special solvents and handling, increasing the price.

3. Stain Removal Tough stains, such as those from oil, wine, or ink, require special treatments, adding to the overall cost.

Average Prices for Dry Cleaning Services When estimating dry cleaning costs, it’s helpful to consider the average price range for different garments:

Shirts: $2 - $5

Pants: $5 - $8

Skirts: $5 - $7

Suits: $10 - $15 (two-piece)

Sweaters: $5 - $10

Dresses: $10 - $20 (higher for formal gowns)

Coats: $10 - $25+

Comforters: $20 - $50

Wedding Dresses: Starting from $75 and can go much higher based on complexity

These prices vary depending on location, fabric type, and additional services required.

Additional Services and Their Costs Some dry cleaners offer extra services that can impact the overall cost:

1. Alterations and Repairs Many dry cleaners provide tailoring services, from simple hemming to resizing garments. Prices vary based on complexity:

Simple alterations: $10 - $30

Complex alterations: $30 - $100+

Basic repairs: Starting around $5

2. Bulk Cleaning Services Some dry cleaners offer discounts for bulk orders, such as:

Bulk shirt cleaning: $2.50 per shirt for orders of 10 or more

Comforters: 10-20% discount on multiple items

Flat-rate bulk orders: Discounted prices for mixed garments

Tips for Reducing Dry Cleaning Costs If you frequently use dry cleaning services, these tips can help manage costs:

1. Selective Dry Cleaning Not all "dry clean only" items need professional cleaning after every use. Suits, for example, can often be worn multiple times before needing a clean unless visibly stained or odorous.

2. Proper Garment Care Taking care of garments at home can extend the time between dry cleaning visits:

Spot cleaning – Treat small stains at home to delay full cleaning.

Airing out clothes – Eliminates odors and refreshes fabric.

Using garment steamers – Helps remove wrinkles and freshen clothes.

Gentle hand washing – Some “dry clean only” items can be carefully hand-washed.

By being selective and maintaining proper garment care, you can significantly reduce your dry cleaning frequency and costs.

How Amenify Can Help At Amenify, we understand the personal and sentimental value of clothing. With over 50,000 five-star reviews and a service network covering more than 2 million homes across 900+ cities, we offer reliable Dry Cleaning & Laundry Delivery Services. Our services ensure that garments receive exceptional care and convenience.

Final Thoughts Understanding how much dry cleaning costs helps customers make informed decisions. By considering factors such as garment type, fabric, and stain treatment, individuals can better anticipate costs and explore ways to save. Whether you need a quick refresh or deep cleaning, professional dry cleaning services provide valuable care and preservation for your clothing.

Source - https://www.amenify.com/blog/how-much-does-dry-cleaning-cost

0 notes

Text

Global 1,6-diisocyanate (HDI) Market:Asia-Pacific Is the Largest Market, With a Share About 48%

Global Info Research announces the release of the report “Global 1,6-diisocyanate (HDI) Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2031” . This report provides a detailed overview of the market scenario, including a thorough analysis of the market size, sales quantity, average price, revenue, gross margin and market share.The report provides an in-depth analysis of the competitive landscape, manufacturer’s profiles,regional and national market dynamics, and the opportunities and challenge that the market may be exposed to in the near future. Global 1,6-diisocyanate (HDI) market research report is a comprehensive analysis of the current market trends, future prospects, and other pivotal factors that drive the market.

According to our (Global Info Research) latest study, the global 1,6-diisocyanate (HDI) market size was valued at US$ 1540 million in 2024 and is forecast to a readjusted size of USD 1562 million by 2031 with a CAGR of 0.2% during review period.

1,6-diisocyanate (HDI) or hexamethylene diisocyanate (HDI) is an organic compound in the class known as isocyanates. More specifically, it is an aliphatic diisocyanate. Aliphatic diisocyanates are used in special applications, such as enamel coatings which are resistant to abrasion and degradation from ultraviolet light. These properties are particularly desirable in, for instance, the exterior paint applied to aircraft and vessels. Global core 1,6-diisocyanate (HDI) manufacturers include Covestro, Vencorex, Wanhua Chemical etc.The top 1 company hold a share about 43%.Asia-Pacific is the largest market, with a share about 48%, followed by Europe with the share about 38%.

This report is a detailed and comprehensive analysis for global 1,6-diisocyanate (HDI) market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Type and by Application. As the market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of selected competitors, along with market share estimates of some of the selected leaders for the year 2025, are provided.

Market Segmentation 1,6-diisocyanate (HDI) market is split by Type and by Application. For the period 2020-2031, the growth among segments provides accurate calculations and forecasts for consumption value by Type, and by Application in terms of volume and value.

Market segment by Type: 0.995、Others

Market segment by Application:Polyurethane Coatings、Adhesive、Inks、Others

Major players covered: Covestro、Vencorex、Tosoh、Wanhua Chemical、BASF

The content of the study subjects, includes a total of 15 chapters: Chapter 1, to describe 1,6-diisocyanate (HDI) product scope, market overview, market estimation caveats and base year. Chapter 2, to profile the top manufacturers of 1,6-diisocyanate (HDI), with price, sales, revenue and global market share of 1,6-diisocyanate (HDI) from 2020 to 2025. Chapter 3, the 1,6-diisocyanate (HDI) competitive situation, sales quantity, revenue and global market share of top manufacturers are analyzed emphatically by landscape contrast. Chapter 4, the 1,6-diisocyanate (HDI) breakdown data are shown at the regional level, to show the sales quantity, consumption value and growth by regions, from 2020 to 2031. Chapter 5 and 6, to segment the sales by Type and application, with sales market share and growth rate by type, application, from 2020 to 2031. Chapter 7, 8, 9, 10 and 11, to break the sales data at the country level, with sales quantity, consumption value and market share for key countries in the world, from 2020 to 2025.and 1,6-diisocyanate (HDI) market forecast, by regions, type and application, with sales and revenue, from 2025 to 2031. Chapter 12, market dynamics, drivers, restraints, trends and Porters Five Forces analysis. Chapter 13, the key raw materials and key suppliers, and industry chain of 1,6-diisocyanate (HDI). Chapter 14 and 15, to describe 1,6-diisocyanate (HDI) sales channel, distributors, customers, research findings and conclusion.

Our Market Research Advantages: Global Perspective: Our research team has a strong understanding of the company in the global 1,6-diisocyanate (HDI) market.Which offers pragmatic data to the company. Aim And Strategy: Accelerate your business integration, provide professional market strategic plans, and promote the rapid development of enterprises. Innovative Analytics: We have the most comprehensive database of resources , provide the largest market segments and business information.

About Us: Global Info Research is a company that digs deep into global industry information to support enterprises with market strategies and in-depth market development analysis reports. We provide market information consulting services in the global region to support enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

Text

PPF Vs. Ceramic Coating – Which Provides Better Protection?

Paint Protection Film (PPF) and Ceramic Coating are the two most widely used products on the market for maintaining the immaculate appearance of any car. Although they are both protective solutions, their roles and characteristics differ. By understanding their features, benefits, and drawbacks, this guide will help you select the best option for your car.

What is Paint Protection Film (PPF)?

Paint Protection Film (PPF), often known as a clear bra, is a transparent, flexible, and long-lasting urethane film that is immediately sprayed to the surface of a car. Its main purpose is to shield the paint from physical harm like small abrasions, scratches, and rock chips. The self-healing ability of contemporary PPF, which makes small scratches vanish when heated, is one of its best qualities. Because of this, PPF is a great option for drivers who regularly travel on roads or in environments where their cars are subject to physical dangers like debris. The film acts as a sacrificial layer by absorbing impacts and shielding the paint underneath from damage.

What is Ceramic Coating?

Ceramic coating is a liquid polymer that forms a semi-permanent protective layer by chemically bonding with the car’s paint. Ceramic coating offers remarkable resistance to environmental pollutants but no physical protection against scratches or chips. Cleaning is greatly facilitated by the hydrophobic coating it creates on the car’s surface, which repels water, dirt, and grime. Ceramic coating also improves the sheen and depth of the paint, giving the vehicle a showroom-quality finish that, with the right care, will last for many years.

Comparing PPF and ceramic coating

When it comes to protecting vehicles, Paint Protection Film (PPF) and Ceramic Coating have different advantages. While ceramic coating offers little protection against physical damage but is resistant to swirl marks, PPF excels at protecting against physical damage by absorbing impacts from debris, scratches, and chips. It also has the ability to self-heal tiny scratches. Both provide UV protection, but ceramic coating has better stain, chemical, and UV resistance. PPF has a mild hydrophobic effect, while ceramic coating has a far superior one and much more efficiently adds gloss and depth. Depending on quality, PPF can last anywhere from five to ten years, whereas ceramic coating, with the right maintenance, can last anywhere from two to five years.

Advantages and limitations of PPF

Advantages: Paint Protection Film (PPF) is a popular option for vehicle protection since it provides a number of benefits. It offers complete defence against physical harm, especially in high-impact locations. Furthermore, PPF is self-healing, which means that when heated, it may repair small abrasions. Another advantage of premium PPF is its durability; the film can last up to ten years. An additional noteworthy benefit is its invisible shield, which provides protection without sacrificing style by preserving the vehicle’s original look with a transparent application.

Limitations: PPF is not without its limits. The cost is a significant disadvantage because premium protection is more expensive than ceramic coating. Additionally, improper installation may result in noticeable bubbles or borders. Poorer PPF can eventually become yellow, especially on white automobiles, which can make the car look less appealing. Last but not least, although PPF offers protection, it lacks the cosmetic advantages of ceramic coatings, which include improving paint gloss or depth.

Advantages and limitations of Ceramic Coating

Advantages: For car owners looking for a better look and easier maintenance, ceramic coating has a number of benefits. It gives the car a lustrous, showroom-like shine that can make it appear like new. Because the hydrophobic surface repels dirt, washing isn’t necessary as frequently. Furthermore, ceramic coating protects the vehicle from impurities like tree sap, bug spatter, and bird droppings, prolonging its clean appearance. Its affordability, which provides long-term paint protection at a lower initial expenditure than PPF, is a major advantage.

Limitations: There are certain restrictions associated with ceramic coating. It cannot guard against chips or scratches brought on by debris since it lacks impact resistance. Even though cleaning is easier, the coating still needs to be cleaned and maintained on a regular basis to remain effective. Additionally, the coating needs to be reapplied every a few years due to its limited duration. For best results, expert installation is required because the coating is susceptible to improper application, which might render it ineffective.

Which should you choose?

The decision between Paint Protection Film (PPF) and ceramic coating ultimately depends on your lifestyle, driving habits, and other requirements.

For people who regularly travel on highways or gravl roads, where rock chips are a typical problem, PPF is suitable. For owners of expensive cars or high-end vehicles that need to be protected from physical harm, it’s also a fantastic choice. PPF is the best option if longevity and all-around protection are important to you.

For people who want to improve the look of their car and make maintenance easier, ceramic coating is a fantastic option. It is especially helpful if protecting the environment—such as protecting your car from water stains, bird droppings, and UV rays—is your top priority. If you’re on a tighter budget but still want long-lasting paint protection, ceramic coating is an excellent choice as it’s less expensive than PPF.

For those who want the best of both worlds, combining PPF and ceramic coating is becoming a more and more popular choice. This approach entails coating the entire car with ceramic coating to improve shine and provide a hydrophobic barrier, after applying PPF to high-impact areas to prevent physical damage. This combination guarantees that the car will continue to look beautiful over time in addition to providing complete protection..

Both ceramic coating and PPF have special benefits and are designed to meet certain protection requirements. PPF is the obvious choice if physical protection is your top concern. On the other hand, ceramic coating is a great option if you want to improve the shine of your car and make maintenance easier. Whichever option you decide on, getting the highest possible return on your investment requires expert installation and regular upkeep. For instance, you can turn to Autopad for professional services. No matter what your choice, Autopad has both the options to offer. Autopad is the “ceramic coating near me” you could be searching for to give your car a glossy surface and long-lasting defence against environmental damage and pollutants. However, if you want to guarantee better protection against rock chips, scratches, and physical damage, Autopad “Paint Protection Film near me” is what you could be searching for, making it ideal for high-impact areas of your car. Choose wisely and ensure that your car stays pristine for years.

Resource: Read more

#AutopadDetailing#CarCareJayanagar#PaintProtectionFilm#CeramicCoatingBangalore#GrapheneCoating#SunFilmsForCars#AutomobileDetailing#WindshieldProtection#CarPaintingJayanagar#PremiumCarMats#AutoProtectionBangalore#LuxuryCarCare#CarDetailingExperts#ProtectYourCar#AutopadJayanagar#BangaloreCarServices#AutomobileCoatingSolutions#DriveInStyle#CarDetailingBangalore#Autopad

0 notes

Text

Anti-Corrosion Coating Market — Forecast(2025–2031)

🌍 𝐃𝐫𝐢𝐯𝐢𝐧𝐠 𝐭𝐡𝐞 𝐅𝐮𝐭𝐮𝐫𝐞 𝐨𝐟 𝐃𝐮𝐫𝐚𝐛𝐢𝐥𝐢𝐭𝐲: 𝐀𝐧𝐭𝐢-𝐂𝐨𝐫𝐫𝐨𝐬𝐢𝐨𝐧 𝐂𝐨𝐚𝐭𝐢𝐧𝐠 𝐌𝐚𝐫𝐤𝐞𝐭 𝐓𝐫𝐞𝐧𝐝𝐬 | IndustryARC™

The global anti-corrosion coating market was valued at $32.6 billion in 2023, and is projected to reach $54.4 billion by 2033, growing at a CAGR of 5.4% from 2024 to 2033.

👉𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐒𝐚𝐦𝐩𝐥𝐞 𝐏𝐃𝐅 :

🔹Increase in demand for infrastructure development and rise in focus on #sustainable_coatings are key drivers of growth in the anti-corrosion coating market. Infrastructure projects such as bridges, highways, pipelines, and buildings require robust protective solutions to withstand environmental challenges and extend asset lifespans, leading to higher demand for anti-corrosion coatings.

🔹Anti-corrosion coatings are protective layers applied to metal surfaces to prevent or slow down the process of #corrosion caused by environmental factors such as moisture, chemicals, and temperature fluctuations. These coatings act as a barrier, shielding the underlying material from exposure to corrosive elements, thereby extending the lifespan and maintaining the structural integrity of the object or surface.

🔹According to the opinions of various CXOs of leading companies, the anti-corrosion coating market is expected to witness growth during the forecast period owing to increase in demand for infrastructure development and surge in focus on sustainable coatings.

📊 𝐆𝐞𝐭 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 :

𝐊𝐞𝐲 𝐌𝐚𝐫𝐤𝐞𝐭 𝐃𝐫𝐢𝐯𝐞𝐫𝐬:

✨ Rising Infrastructure Projects: Global investments in bridges, pipelines, and offshore platforms are boosting demand.

♻️ Sustainability Focus: Eco-friendly, low-VOC coatings are becoming industry standards.

🚀 Technological Innovations: Nanotechnology and smart coatings are revolutionizing corrosion resistance.

Get this Report on discount of $1000 on purchase of Credit Card

✅ 𝗞𝗲𝘆 𝗖𝗼𝗺𝗽𝗮𝗻𝗶𝗲𝘀 𝗣𝗿𝗼𝗳𝗶𝗹𝗲𝘀 𝗚𝗶𝘃𝗲𝗻 𝗶𝗻 𝘁𝗵𝗶𝘀 𝗠𝗮𝗿𝗸𝗲𝘁 𝗥𝗲𝗽𝗼𝗿𝘁: Evonik Coating Additives | Evonik | Wasco | Graco Protective Coatings Equipment | OIL TECH OIL & GAS SERVICES LLC | HILONG GROUP OF COMPANIES | Man Industries Ltd | Vitracoat, Inc. | Guangzhou Lushan New Materials Co.,Ltd | Lushan Advanced Materials (Malaysia) Sdn. Bhd. | Shandong Kaitai Metal Abrasive Co.,Ltd | Kansai Paint Co.,Ltd | PPG | PPG Asian Paints | Nippon Paint Holdings Co., Ltd. | AkzoNobel | 3M | Sika | Hempel A/S | Axalta | Sherwin-Williams |

#AntiCorrosionCoating#CorrosionProtection#IndustrialCoatings#ProtectiveCoatings#SurfaceTreatment#RustPrevention#MarineCoatings#OilAndGasCoatings#PipelineProtection#CoatingTechnology#AdvancedCoatings#MetalProtection#CorrosionControl#EpoxyCoatings#NanoCoatings#WaterproofCoatings#PolyurethaneCoatings#SurfaceEngineering#CoatingInnovation#SustainableCoatings

0 notes

Text

Potassium Feldspar: Properties, Uses, and Importance in Industry

Introduction

Potassium feldspar is a crucial mineral widely used in various industries, from ceramics and glassmaking to construction and electronics. It is a significant component of igneous rocks and plays a vital role in rock formation. In this article, we will explore the properties, types, uses, and economic importance of potassium feldspar.

What is Potassium Feldspar?

Potassium feldspar (K-feldspar) is a group of aluminosilicate minerals containing potassium (K), aluminum (Al), and silica (SiO₂). It is one of the most abundant minerals in the Earth's crust and is commonly found in granite, syenite, and pegmatites. The chemical formula of potassium feldspar is KAlSi₃O₈.

Types of Potassium Feldspar

There are three major types of potassium feldspar:

Orthoclase (KAlSi₃O₈) – Commonly found in granite and pegmatite, it has a monoclinic crystal structure.

Microcline (KAlSi₃O₈) – Identical in composition to orthoclase but with a triclinic crystal structure. It often exhibits a greenish or bluish tint.

Sanidine (KAlSi₃O₈) – A high-temperature variety of feldspar found in volcanic rocks with a monoclinic structure.

Physical and Chemical Properties of Potassium Feldspar

Color: Ranges from white, pink, and reddish to green or bluish hues.

Hardness: 6 on the Mohs scale, making it a durable mineral.

Luster: Vitreous to pearly.

Cleavage: Two directions of perfect cleavage at nearly 90°.

Specific Gravity: 2.5 – 2.6.

Chemical Stability: Resistant to weathering, but prolonged exposure to acidic environments can alter it into clay minerals.

Uses of Potassium Feldspar

1. Ceramic and Glass Industry

Potassium feldspar is a fundamental raw material in the production of ceramics and glass. It enhances the durability and strength of ceramics while improving glass transparency and resistance to thermal shock.

2. Construction Industry

Used as an aggregate in concrete and asphalt.

Acts as a filler in paints and coatings.

3. Agriculture and Soil Conditioning

Used as a source of potassium in fertilizers, promoting plant growth.

Helps in soil improvement by balancing nutrient content.

4. Electronics and Industrial Applications

Involved in the production of insulating materials.

Used in the manufacturing of abrasives and cleaning agents.

Economic Importance of Potassium Feldspar

Potassium feldspar is mined globally, with major producers including the United States, China, India, and Turkey. The demand for feldspar is continuously growing due to its wide range of industrial applications. The global feldspar market is expected to expand, driven by increasing demand in the glass and ceramics industries.

Conclusion

Potassium feldspar is an essential mineral with diverse applications in various industries. Its unique physical and chemical properties make it an indispensable raw material in ceramics, glassmaking, construction, and even agriculture. As demand for potassium feldspar continues to rise, sustainable mining practices will play a crucial role in ensuring its availability for future generations.

By understanding the significance of potassium feldspar, industries can maximize its benefits while adopting responsible sourcing and usage practices.

1 note

·

View note

Text

The process of colorless, transparent printing ink formulation without pigments is called as varnishing. The overprint varnish is a technique applied as coating after printing on the printed piece. The overprint varnish protects surfaces from moisture, abrasion and other sources of damage.

0 notes