#Close laser cutting machine exporter

Explore tagged Tumblr posts

Text

#fiber laser cutting machine manufacturer#double laser cutting machine suppliers#ces laser marking machine#ces machine ahmedabad#close laser cutting machine exporter

0 notes

Text

Welcome to Success Technologies

Success Technologies has over 15 years of experience in providing customized solutions for Laser Machines. Our Registered Office and Manufacturing Unit are located in Ahmedabad, Gujarat, India. Success Technologies Is a Manufacturer, Exporter, and Supplier of CNC Wood Router Machine, CNC Stone Router Machine, CNC Metal Engraving Machine, Co2 Laser Machine, Fiber Laser Metal Cutting Machine, CNC Lathe Machine, Welding Machine, Channel Letter Bending Machine, Fiber Laser Marking Machine, Printer. Success Technologies is a distinguished manufacturer and exporter, offering a comprehensive range of advanced industrial machines. We specialize in providing tailored solutions for all aspects of Laser Machines, helping us achieve leadership in the industry. Our experienced team works closely with clients to understand their unique requirements, ensuring we offer the most effective solutions to enhance productivity and efficiency. At Success Technologies, our mission is to transform the manufacturing industry by offering advanced, high-quality machinery designed to boost efficiency, precision, and productivity for our clients. We are dedicated to innovation, delivering top-tier products, and providing exceptional customer service, all while promoting sustainable practices. For more information about our product catalog, please feel free to reach out to us through the contact details below: Contact Number: +91 99989 61184 76000 08995 Email ID: [email protected] View Product: Click Here Read the full article

#Ahmedabad#AluminumChannel#ChannelLetterBendingMachine#CNCLatheMachine#CNCMetalEngravingMachine#CNCRouter#CNCStoneRouterMachine#CNCWoodRouterMachine#Co2LaserMachine#Exporter#FiberLaserMarkingMachine#FiberLaserMetalCuttingMachine#Gujarat#India#LaserMachines#LaserMarkingMachine#LetterBendingMachine#Manufacturer#SuccessTechnologies#Supplier#WelcometoSuccessTechnologies#WeldingMachine

1 note

·

View note

Text

Exploring China’s Leading Extruded Aluminium Enclosure Manufacturers: A Hub of Innovation and Qualit

Overview of Extruded Aluminium Enclosures

Extruded aluminium enclosures are protective casings, often used to house electronic devices, circuit boards, control systems, and other sensitive components. Aluminium's natural properties—lightweight, strong, and corrosion-resistant—make it an ideal material for these enclosures. The extrusion process allows for the creation of complex shapes with precision, ensuring that enclosures meet the specific design and functional needs of various industries.

Chinese manufacturers have perfected the art of aluminium extrusion, delivering enclosures that meet international quality standards while remaining cost-competitive.

Advantages of China as a Manufacturing Hub

Cost Efficiency One of the primary reasons companies across the globe look to China for extruded aluminium enclosures is the cost advantage. China Extruded Aluminium Enclosure Manufacturer Chinese manufacturers can produce high-quality products at lower costs due to economies of scale, streamlined supply chains, and efficient production processes. Moreover, the availability of raw materials and access to advanced extrusion technologies ensure that these companies can pass on savings to their customers without compromising on quality.

Advanced Manufacturing Techniques

China has invested heavily in state-of-the-art equipment and production technologies. From CNC machining, anodizing, powder coating to laser cutting, Chinese manufacturers offer a wide range of post-extrusion services that ensure the final product is tailored to meet client specifications. These advanced capabilities allow for the creation of intricate designs and precise dimensions in aluminium enclosures.

Customization and Flexibility

Chinese extruded aluminium enclosure manufacturers excel in offering customized solutions to meet unique client requirements. Whether it's specific dimensions, custom cut-outs, surface treatments, or particular mechanical properties, these manufacturers are adept at delivering tailored products. This flexibility ensures that clients from various industries, including aerospace, automotive, and electronics, can find solutions that perfectly fit their needs.

Focus on Sustainability

As the demand for eco-friendly products continues to rise, many Chinese manufacturers are prioritizing sustainability. Aluminium is a highly recyclable material, and many manufacturers are now using recycled aluminium in their extrusion processes. This not only reduces the carbon footprint of the manufacturing process but also appeals to environmentally-conscious clients looking to make greener choices in their supply chains.

Quality Control and International Standards

Quality control is a top priority for Chinese manufacturers. Many companies adhere to international standards such as ISO 9001, ensuring that every product undergoes rigorous testing before reaching the customer. From material inspection, precision measurement to performance testing, every aspect of production is closely monitored. Additionally, Chinese manufacturers are increasingly gaining certifications such as RoHS and CE, which enable them to export products that meet the stringent requirements of global markets.

Key Applications of Extruded Aluminium Enclosures

Electronics and Telecommunications

Aluminium enclosures are commonly used in the electronics industry to house delicate components such as power supplies, circuit boards, and communication devices. Their durability and heat dissipation properties make them ideal for protecting sensitive electronics.

Automotive and Aerospace

In the automotive and aerospace industries, lightweight and strong enclosures are essential. Extruded aluminium enclosures offer a perfect blend of durability and weight reduction, making them invaluable for housing control systems, battery modules, and other critical components.

Industrial and Consumer Products

From lighting systems to control panels, extruded aluminium enclosures are used in a wide range of industrial and consumer products. Aluminum Project Box Their versatility, coupled with aesthetic appeal due to surface treatments like anodizing, makes them a popular choice.

0 notes

Text

From Raw Material to Finished Product: The Manufacturing Process of Buttweld Fittings - Metal Forge India

From Raw Material to Finished Product: The Manufacturing Process of Buttweld Fittings

Buttweld fittings are crucial components used in various industries for piping systems. They ensure a secure and leak-free connection between pipes, enabling the smooth flow of liquids or gasses. Metal Forge India, is the leading buttweld fittings manufacturer, supplier, stockist, and exporter in India. With a comprehensive range of sizes, specifications, standards, materials, and grades available, we pride ourselves on delivering top-quality fittings that cater to diverse project requirements.

In this in-depth blog post, we will delve into the fascinating world of manufacturing buttweld fittings, exploring each stage from the selection of raw materials to the production of finished products. Join us as we unveil the intricacies of this process, showcasing the meticulous craftsmanship and attention to detail that goes into every fitting we produce.

Understanding Buttweld Fittings!

Buttweld fittings are pipe fittings that are designed to be welded onto the ends of pipes or other fittings, creating a strong and leak-proof joint. The name "buttweld" comes from the welding technique used, which involves two pieces of pipe or fittings being aligned and welded together at the ends.

Manufacturing Process of Buttweld Fittings

Raw Material Selection:

The manufacturing process of buttweld fittings begins with the careful selection of raw materials. At Metal Forge India, we prioritize utilizing premium-grade materials to ensure the highest quality and performance of our fittings. We offer an extensive range of materials, including Stainless Steel 304, 316, 304L, 316L, 317, Alloy 20, SMO 254, UNS N06600, Hastelloy C276 Buttweld Fittings, Stainless Steel 904L Buttweld Fittings, and Inconel 600 Buttweld Fitting. These materials are chosen for their exceptional durability, corrosion resistance, and mechanical properties, guaranteeing fittings that meet or exceed industry standards. Our experts meticulously evaluate and source the finest raw materials, working closely with trusted suppliers to maintain consistent quality throughout the manufacturing process.

Cutting and Shaping:

Once the raw materials are selected, they undergo a precise cutting and shaping process. Advanced machinery and cutting-edge techniques are employed to achieve accurate dimensions and uniformity. The raw materials are cut into appropriate sizes and shapes required for the specific type of buttweld fitting being manufactured. Computer Numerical Control (CNC) machines, saws, shears, and laser cutting tools are utilized to ensure optimal precision. Skilled technicians with expertise in metalworking techniques handle the machinery, carefully monitoring the process to maintain tight tolerances and achieve the desired shapes with utmost accuracy.

Heating and Forming:

After the cutting process, the raw materials move on to the heating and forming stage. Heating the materials to a specific temperature ensures they become malleable, facilitating the shaping process. Furnaces or induction heaters are used to achieve the necessary heat levels. The heated materials are then skillfully formed into the desired shapes, including butt weld elbows like 45-degree elbows, 90-degree elbows, 180-degree elbows, crosses, caps, tees, concentric reducers, eccentrics, and stub ends. Experienced technicians employ various forming techniques, such as hot forming, cold forming, or forging, depending on the material and specific requirements. The goal is to create fittings with smooth contours, excellent dimensional accuracy, and structural integrity.

Welding and Joining:

Welding and joining are pivotal steps in the manufacturing process of buttweld fittings. These processes ensure secure and leak-proof connections, enhancing the reliability and longevity of the fittings. Different welding techniques are utilized, depending on the material being used. Common methods include TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and electric resistance welding. Welders with expertise in these techniques carefully join the various components of the fittings, paying close attention to maintaining uniformity, strength, and precision. Stringent quality control measures, such as non-destructive testing and visual inspections, are implemented throughout the welding and joining process to detect any potential defects or imperfections.

Finishing and Quality Control:

Once the welding and joining processes are complete, the buttweld fittings undergo comprehensive finishing and quality control procedures. These steps are crucial for ensuring the fittings meet the highest industry standards. Finishing techniques, including polishing, grinding, deburring, and surface treatment, are employed to achieve a smooth and aesthetically pleasing finish. These processes also help eliminate any sharp edges or surface irregularities, ensuring the fittings are safe and easy to handle.

Quality control is an integral part of our buttweld fittings manufacturing process. We have a dedicated team of quality control professionals who perform rigorous inspections at every stage to ensure dimensional accuracy, strength, and adherence to industry standards. Specialized tools and instruments, such as coordinate measuring machines and ultrasonic testing equipment, are utilized to verify the precise measurements and integrity of the fittings. We also provide Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, along with Test Certificates certifying NACE MR0103 and NACE MR0175. These certifications offer our customers complete traceability and assurance of the fittings' quality and compliance.

Packaging and Delivery:

At Metal Forge India, we understand the significance of safe transportation and timely delivery. To ensure our buttweld fittings reach their destination in pristine condition, we employ careful packaging techniques. Each fitting is meticulously packaged using suitable materials that provide optimal protection against damage during transit. Additionally, we have a robust logistics network in place, enabling us to deliver our products efficiently and promptly to customers across the globe. Our export operations extend to various countries, including the United Arab Emirates, the USA, Germany, South Korea, Russia, Singapore, France, Thailand, Turkey, Vietnam, and Indonesia. We take pride in our ability to serve customers internationally and meet their diverse project requirements.

Standards & Specifications of Buttweld Pipe Fittings

Size

1/8” NB – 48” NB

Standards

ASME/ANSI and DIN

Schedules

5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS with NACE Certifications

Types

45 Degree elbow, 90 Degree elbow & 180 Degree elbow, Cross, Caps, Tee, Concentric Reducers, Eccentric and Stub End

Materials

Stainless Steel & Alloy 20 Steel, Monel, Inconel, Hastelloy, Duplex Steel, Super Duplex Steel, and 254 SMO

Forms

Seamless, Welded & Fabricated

Grades

Stainless Steel 304, 316, 304L, 316L, 317, Alloy 20 Buttweld Fittings, SMO 254 Buttweld Fittings, UNS N06600 Buttweld Fittings, Hastelloy C276 Buttweld Fittings, Stainless Steel 904L Buttweld Fittings, and Inconel 600 Buttweld Fittings

Advantages of Buttweld Fittings:

Strength and Durability:

Buttweld fittings offer excellent strength and durability due to the welded joint. The welded connection ensures a secure bond, making it resistant to leakage, vibration, and mechanical stresses. This reliability makes buttweld fittings suitable for high-pressure and high-temperature applications.

Smooth Flow Characteristics:

The seamless construction of buttweld fittings ensures smooth flow characteristics within the piping system. The absence of any internal irregularities or turbulence-causing features minimizes pressure drops and enhances the overall efficiency of fluid transportation.

Versatility and Compatibility:

Buttweld fittings are available in a wide range of materials, grades, sizes, and specifications, making them versatile and compatible with various piping systems. Whether you require fittings for stainless steel, alloys, or special materials, there is a suitable buttweld fitting to meet your specific requirements.

Clean Aesthetics:

Buttweld fittings provide a visually appealing and clean finish to the piping system. The welded joints are seamless and blend seamlessly with the pipes, offering an aesthetically pleasing appearance.

Applications of Buttweld Fittings

Buttweld pipe fittings are widely used in various industries for connecting and joining pipes. Here are some common applications of buttweld pipe fittings:

Plumbing Systems

Oil and Gas Industry

Chemical Processing

Power Generation

Food and beverage Industry

Pharmaceutical Industry

Water Treatment Plants

HVAC Systems

Shipbuilding and Marine Applications

Construction, Infrastructure, and so on

Final Thoughts!..

From the selection of premium raw materials to the meticulous manufacturing process and stringent quality checks, Metal Forge India ensures the production of superior buttweld fittings. Our commitment to excellence, extensive product range, and adherence to international standards have positioned us as a trusted buttweld fitting supplier in the industry. Whether you're looking for elbow manufacturer, Alloy 20 Buttweld Fittings to SMO 254 Buttweld Fittings, UNS N06600 Buttweld Fittings to Hastelloy C276 Buttweld Fittings, and Stainless Steel 904L Buttweld Fittings to Inconel 600 Buttweld Fittings, we are dedicated to offering solutions that perfectly suit your project requirements.

To explore the extensive range of buttweld fittings and place an order, visit their website or get in touch with their knowledgeable sales team.

1 note

·

View note

Text

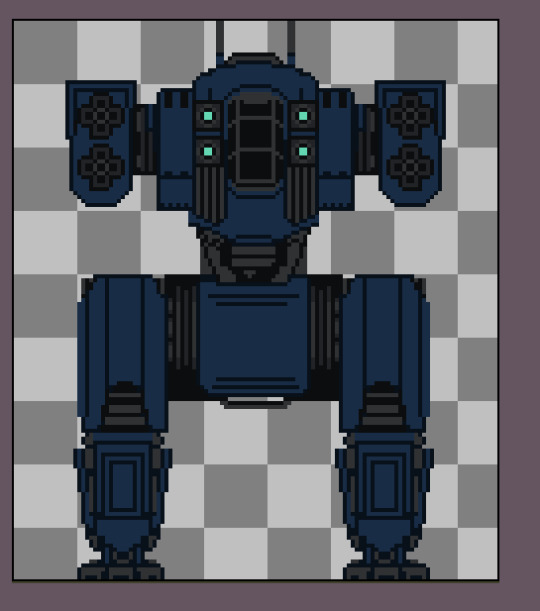

lil mechs, me and a few friends of mine were talking about trying to salvage whats left of my original mech game because I killed the original narrative and so started working on translating this design in to pixels the idea for this one was kinda like a cross between a mad dog and a catapult from battletech. the second version however has much less influence in its ideas and is a more medium version of the first.

Think I might have lost some of the original technical info from the setting, but its supposed to function as a fire support/command mech, featuring a pair of heavy caliber autocannons for long range, and rapid fire smaller caliber for lighter targets/closer engagements.

The Farlar like to make robust equipment with robust but cutting edge tech. Like extra viewing cameras or built in laser range finders to better hit targets from longer range, or linking pilots to their machines for better reaction etc.

But they wont go as far as to design very complicated mechs that are more people like in their design, like with fully functioning arms and such, the current Federated Republics of Farlar are more than happy to keep up this standard of mech design.

The medium version sheds a lot of the heavier guns, machine guns, and missiles for lasers and twin 40 mm gun mounts. They are meant to close the distance and overwhelm their opponents with overwhelming firepower and often run very hot due to the sheer amount of weapons on their frame.

I might try and dig up some of the Skattari Collective mech designs because those are a bit more fun and interesting, but other Factions Like The Imperial Vestige just use old Farlar mechs that they made off with, and anything they can capture or salvage

Whereas Ostilyia will just make whatever designs they can buy or whatever they make for export and have fewer domestic models because a significant part of their economy revolves around making weapons for other people.

These are some of the main factions in the current game I am working on, their importance in the mech game was mostly filtered down to what kind of mechs they made, but it is obs much more important in the current one as you are in the FRF specifically.

I dont want to say toooooooooooooooo much to give too much away, but the FRF is just trying to keep everything together after taking power back from the Imperials (now the Vestige who are trying to retake power and sabotage the new democratic government).

also these are def not finished and still need a bunch of work, but not bad translating some older drawings into pixel art in like 2 hours ^^

2 notes

·

View notes

Video

youtube

Shenzhen DNE Laser Science and Technology Co., Ltd focused on the R&D, production, and sales of fiber laser cutting machines.��After years of development, it has a huge market influence, market share, and unique service charm in the area of China fiber laser cutting machine. In 2016 the company established the Joint Venture with Swiss Bystronic Group. In 2020 DNE Laser was wholly-owned by Bystronic Group. DNE Laser has always been committed to the innovation of laser cutting technology. The company has a production base of more than 80,000㎡, professional laser technicians and expert teams. Integrating with international frontier laser technology and close collaboration with world-renowned device manufacturers such as Germany, America, England, etc., it develops and produces a series of laser cutting machine with high electro-optical conversion rate, unique beam optical quality, stable performance. The product is exported to nearly 100 countries around the world, which provides the full range of metal sheet processing and automatic solutions for users. #Bystronic #dnelaser #lasercutter #laser #lasercutting #lasermarking #fiberlaser #fiberlasercuttingmachine

1 note

·

View note

Text

How to contour cut signmaster pro

(Spooler with Vulcan SC-350 continues until out of sheets) Updated Spooler to v0.20 adding Vulcan SC-350 sheetcutter support.Added QR-folder support for spooler with Vulcan.Added Graphtec CE7000-series and CE Lite-50.Added weeding line collision on Regmarks and short weeding lines.Updated Spooler to support multiple machines connected by USB.Updated SignCut to support multiple machines connected by USB.Updated Vulcan plugin to support multiple machines connected by USB.Added Wait Until Finished function for contourcut and calibration.Fixed layer-parsing in postscript parser, adding support for tool-presets.Added support for custom tool-presets for different cutter models.Fixed crash when changing colour order up or down.Fixed postscript-parser missing eps-solid color fill.Added Graphtec FC9000 series contourcut.Fixed attributes-dialog to set current cutout dialog parameters if not assigned.Fixed crash when importing combined paths from Signcut Draw.Added document size to be sent from plugins for Vulcan SC-350 sheetcutter.Added repeat-until-no-more-sheets for normal and contour cutting with Vulcan SC-350.Added QR-code support for vulcan drivers.Added startup-guide in the plotter-dialog.Added new plugin-installer with option to choose the installation path.Added contour / inset feature to the Illustrator and CorelDraw plugins.Added option to sort by changing the starting-point.(Corner mark aligns knife for better quality) Added option to turn off the initial corner-mark.Added Vulcan SC-350 Sheetcutter support.Updated EPS-parser, fixed colors for newer Abode Illustrator versions.Updated SVG-parser, refactored the code for CSS/CDAT parsing.Updated SVG-parser, fixed double-decimal issues and ARC-issues.Fixed crash when selecting Tool 2 in Windows 7 for Skycut drivers.Fixed dealercode registration to tell if a code was already used.Added support to create layers in CorelDraw, with your SignCut Tool-Preset names to automatically assign the preset to the layer.Added support to create layers in Adobe Illustrator, with your SignCut Tool-Preset names to automatically assign the preset to the layer.Added support to create layers in CorelDraw, called Tool 1, Tool 2 or Pen 1 and Pen 2 to automatically assign multiple tools.(For this to work, the function: Paste Remembers Layers must be enabled in Adobe Illustrator) Added support to create layers in Adobe Illustrator, called Tool 1, Tool 2 or Pen 1 and Pen 2 to automatically assign multiple tools.Added more options to the sorting algorithm.Added ARC and ARCN to the postscript parser.Fixed Saga-driver to not go back to home after each object.Fixed crash when closing attributes-dialog in the cut-out dialog.Improved the postscript-parser increasing speed and stability.Refactored Adobe Illustrator-plugins and added over 22 different types of registration marks.Refactored CorelDraw-plugins and added over 22 different types of registration marks.Added baudrate timer for serial communication.Updated GCC-contourcut, added support for GCC's own regmarks with the starting-cornermark.Added drivers for E-CUT and VEVOR including contourcut feature.Important to set correct blade offset value. Updated flat-designed tool set icons in SignCut Pro 2.Added Graphic Tracer for Windows to revive low-quality vector graphics together with its font-tracking ability.Added new SignCut BoxMaker feature as a ready-to-cut box template library.Updated SignCut Draw v1.63 with SignCut BoxMaker and 75,000 free cliparts.> Ai, Eps, Pdf and Svg import/export (inc. > Contour cutting wizard plus print and cut from two or more devices > Image editing tools and special image effects > Vectorizer for super accurate tracing of images Exporting your artwork to an Ai, Dxf, Eps, Pdf or Svg SignMaster Professional includes the following tools and features plus much more: a laser/ARMS cutters, engraver or routerĥ. Cutting your artwork from a vinyl cutter inc. Easily laying out your artwork/designs/logos professionallyĤ. Providing you with a suite of sign design tools and featuresģ. Designing super high quality vector artworkĢ. SignMaster Professional is dedicated software for:ġ. Product packaging may vary from images shown. Please Note: Pictures are for illustrative purposes only. SignMaster PRO allows you to produce a wide range of vinyl lettering, logos, signage, pinstriping and comes with a suite of powerful text, curve and object tools. SignMaster Professional (PRO) is dedicated sign software designed specifically for making the most amazing vinyl lettering. SignMaster Demo / Features / Extras / Showcase

0 notes

Text

does anybody have a high level of ease with a program like draftsight or autocad (or even illustrator: I can use illustrator but I have never done what I’m trying to learn right now on a short time frame and I know that it is an EXTREMELY easy task that is just way beyond me.)

original plan was to cut a roughly 3x3 plastic frame using scrap thermoplastics or acrylic but lucas did this four to six times over the past week and each time turned up with a prototype that was not remotely the measurements discussed. I don’t have access to the cutting tools to do it myself, and I’m afraid of them anyway. in the final iteration he bought me a set of files to file down a version that he made to the wrong dimensions such that it would be the right dimensions, and while I’m happy to have my own multi-function files now, that process has not been helpful, has driven me insane, and I am this close to filing my own head off my body. which I think would take less time than filing down this plastic.

SO I’m just taking this to the laser cutter, but I’m super super super new to these formats and feeling overwhelmed given all of the above. the laser place accepts AI and SVG files only. they do have programs in the space where the laser cutter is, but what I have at home is just the free version of draftsight and possible access to illustrator. lucas claims familiarity with vectorworks but I don’t believe vectorworks exports to these formats.

here is what I am trying to make:

the cutter has 1/4 inch acrylic on hand, and I’m just going to use that, so the height of these is... 1/4 inch. I believe that’s the max thickness the machine can handle anyway.

I need to fabricate

(1) a square frame with inner (opening) dimensions of 8 cm by 8 cm, and outer dimensions 8.5x8.5 cm. (I feel like this is a little bit slim for a lot of applications, and on later versions of this project I will widen it--I have half of this thing done already and this is what will fit, so, that’s what I want. the most important thing are the inner dimensions, because it is being designed to fit a thing inside of it.

(2) a second square with the same dimensions as the above, except in the center of one of the sides, there is a 1 cm notch removed, such that the square isn’t fully completed.

I’ve watched some videos and tried to figure this out and I feel like over a longer period of time I could, but what I’m asking now is:

a) if you could sometime teach me how to do this extremely basic 2d work on draftsight or illustrator

b) if you are somebody who KNOWS you could make these files in less than ten minutes, could you early birthday gift them to me

#stem problems#this was supposed to be easy!#gluing four pieces of plastic together should have been easy

1 note

·

View note

Text

Low Cost Fiber Laser Cutting Machine Manufacturers

What Is fiber laser cutting machine ?

fiber laser cutting machine is a kind of CNC laser metal cutting system with high quality, high speed, high precision and high efficiency. It is suitable for all kinds of metal cutting which will be your good metal working partner. It is equipped with different powers (from 1000W to 15000W) for cutting metal sheets/plates and metal tubes/pipes of stainless steel, carbon steel, electrical steel, galvanized steel, aluminum zinc plate, aluminum, aluminum alloy, titanium alloy, copper, brass, iron and other metal materials with different thicknesses. Fiber laser cutter is also known as fiber laser metal cutting machine, fiber laser cutting machine, fiber laser cutting system, laser cutting machine equipment.

📷

Machine Application:

Fiber laser cutting machine application materials:

Fiber Laser Cutting Equipment is suitable for metal cutting like Stainless Steel Sheet, Mild Steel Plate,

Carbon Steel Sheet, Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, If you equipped with the rotary axis, Metal Plate, Tubes and Pipes, all ok.

Fiber laser cutting machine application Industries:

igoldencnc CNC Fiber Laser Cutting Machines are widely used in manufacture Billboard, Signs, Advertising, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Machine Features of fiber laser cutting machine:

1. High-performance laser device associated with stable operation system enables optimal cutting effects.

2. Perfect cooling, lubrication and dedusting systems ensure stable, efficient and durable performance of the whole machine.

3. Single countertop make plates loading and unloading available during cutting, which improves the processing eficiency.

4. Large-size closed enclosure improves dedusting effects and avoids optical pollution.

5. Automatic height-adjustment performance keeps constant focal length and stable cutting quality.

6. Gantry structure and inblock aluminum cast cross beam make the device highly rigid, stable and antiknock.

7. It could ut mental in various materials and realize excellent and stable cutting effects.

About us:

We are a company integrating manufacturing and sales of CNC routers, laser engraving machines, laser cutting machines, plasma cutting machines, cutting plotters, etc. The main configuration all adopt top parts imported from Italy, Japan, Germany, etc.We adopt international advanced producing technologies to improve our products. Our products are widely used in advertising, woodworking, artworks, model, electric, CAD/CAM industry models, clothing, package printing, marking, laser sealing and so on.

Our company adheres to the

Market-Oriented

business principles, and implements the business philosophy of "Quality First and Customer First". We have set up more than 20 sale and service departments around China which can offer our customers the services of design, fixing, training, maintenance and so on. Besides sale in China, our products exports around the world including the Middle East, Africa, Europe and the USA.

Monolithic cast aluminum beam,light weight, high strength, no deformation. Molded and framed by integral steel mold and die-casting technology, light crossbeam make equipment a high operation speed, improving processing efficiency and processing quality.

High speed

The light crossbeam can ensure the machine have high moving speed and improve the processing efficiency.

More efficient

The aluminum profile beam of the aerospace industry makes the equipment have efficient dynamic performance, greatly improving processing efficiency while ensuring processing quality.

Machine Parameters

Model

iGR-FT 3015

Working area/ Tube length

3000*1500mm/ 6000mm

X axis stroke

1500mm

Y axis stroke

3000mm

Z axis stroke

300mm

Tube diameter

20-220mm

Accuracy

X, Y axis positioning accuracy

0.05mm

X, Y axis repositioning accuracy

0.03mm

Speed

W axis rotate angle

n*360

W axis max. ratate speed

80rpm

X, Y axis max. running speed

150m/min

U axis max. positioning speed

800mm/s

X, Y axis max. accelerated speed

1.5G

Power supply

Phase

3

Nominal voltage

380V

Frequency

50/60Hz

Protection grade

IP65

Machine body

Max. working loading

1000kg

Body weight

2600kg

Size(L*W*H)

8060*3000*1965mm

Laser power

500w/ 750w/ 1000w/ 1500w/ 2000w/ 3000w/ 4000w/ 5000w/ 6000w/ 8000w/ 10000w/ 12000w

Worktable optional

4000*1500mm/ 4000*2000mm/ 6000*2000mm/ 6000*2500mm

Tube length optional

3000mm/ 9000mm

0 notes

Text

Laser Cutting Machine Supplier

Fiber laser cutting machine is an affordable, easy-to-use, and versatile tool that is used for high-speed cutting of metal plates and pipes. It can help you begin a new startup venture or increase the profits of your well-established company.CNC Fiber Laser Cutting Machine for Metal Sheet1200W fiber laser cutting sheet metal maximum thickness of 14mm carbon steel, 6mm stainless steel, 4mm aluminum, 4mm galvanized steel, 4mm brass, 3mm copper.📷Closed Type Fiber Laser Cutting Machine Pallet changer fiber laser cutting system. Germany IPG fiber laser resonator. Cutting maximum 12mm mild steel, 6mm stainless steel, 4mm aluminum, 3mm brass, 3mm copper. Adopting double gear rack closed-loop system and PMAC Controller (America Delta Tau Systems Inc), enable high processing accuracy and high working efficiency during high speed cutting.📷1KW Fiber Laser Pipe Cutting Machine Pipe laser cutting machine with 1KW fiber laser source. Maximum cutting wall thickness 12mm carbon steel, 6mm stainless steel, 4mm aluminum, 3mm brass, 3mm copper. Cutting round, square, rectangular, oval, waist round metal pipe & tube, etc. Standard Φ=20mm~200mm, L=6m. Pipes length longer than 6m and diameter more than 200mm, machine can be customized.📷Tube Laser Cutting Machine IGOLDEN LASER - tube laser cutting machine is specially for metal tube of round, square, rectangular, triangle, oval, waist tube and other shaped. The tube outer diameter can be 10mm~300mm, length 6m, 8m, 12m. tube length can be customized.📷Take the oil industry for example, the main route of oil transport is the pipeline, and because of the characteristics of the oil itself, leading to the high quality requirements of the pipeline. While fiber laser cutting machine can achieve the pipes multi-angle precision processing to fulfil the oil transportation requirement.Professional tube fiber laser cutting machine—LF60M is used for cutting square tube, rectangular tube, oval tube, waist type tube, hexagonal tube; square tube □ 20 * 20- □150 *150mm, round tube Φ20-Φ 210mm wall thickness of 0.5-10mm carbon steel tube, 0.5-10mm stainless steel tube.Fiber Laser Cutting Machine for Metal Plate A variety of functions and better performance on the fiber laser cutting machine! The Highest Stability Laser Power 1KW 2KW 3KW 4KW,Enclosure design conforms to CE standard for reliable and safe processing. Pallet changer is convenient for material uploading and unloading and further improving working efficiency.📷1500W Fiber Laser Cutting Machine for Metal Large format cutting area 2m × 4m, 2m × 6m Fiber laser 1500W cutting maximum thickness 14mm mild steel, 6mm stainless steel, 5mm aluminum, 5mm brass, 4mm copper, 5mm galvanized steel。📷6000W 8000W Fiber Laser Cutting Machine It is a hi-tech system integrating laser cutting, precision machinery and CNC technology. Mainly used for cutting and forming carbon steel sheets, stainless steel sheets, aluminum alloys, composite materials, etc. With the features of high speed, high precision, high efficiency and high cost performance, it is specially for cutting larger format metal sheets, with the cutting area 1500mm×3000mm and 2500mm×8000mm. The 6000W fiber laser cutting machine can cut a maximum thickness of 25mm carbon steel and 12mm stainless steel.Laser Cutting Machine Supplier iGOLDENCNC, as a professional laser machine application solution supplier, covers flatbed fiber laser cutting machine, metal sheet and tube fiber laser cutter, metal tube fiber laser cutter, protective fiber laser cutting machine, CO2 laser engraving cutting machine, fiber laser marking machine, CO2 laser marking machine, UV laser marking machine, handheld laser welding machine, handheld laser cleaning machine and so on. As the top laser cutting machine manufacturer, the equipment from iGOLDENCNC is exported to more than 180 countries and regions around the world. Every day we accept and organize the opinions and feedback from customers from different countries and regions. We believe that this will help us further improve and optimize our products.Our fiber laser cutting

machine is suitable for cutting carbon steel, stainless steel, alloy steel, spring steel, aluminum, copper, brass, galvanized iron, etc., and has been widely used in the processing of metal sheet fabrication, steel furniture, fire pipes, automotive, fitness equipment, agricultural and forestry machinery, food machinery, advertising, electrical cabinets, elevators and other industries.

0 notes

Text

Video Tours 360 Software Review

BIG Brands are already making use of 360-degree videos to wow customers and close sales

Samsung posted a snowboarding video that puts viewers right in the middle of the action taking viewers on a snowboarding adventure

Oreo lets viewers explore the world that inspired Filled Cupcake Flavored Oreo Cookies

If you’ve ever dreamed of being a passenger in a race car, BMW’s 360 video takes you one step closer to making that a reality. These videos capture the thrill of riding at a speed that would normally cost you a hefty ticket.

Expedia entices viewers to explore Australia

Warner Bros takes audiences inside a haunted house

Who Is It For?

Works for the following industries:

Real estate and realtors

Ecommerce

Airbnb Listings

Car Sales

Travel and recreation

Video games

Film and music

Virtual shopping and retail

Education

And ANYONE who wants to make good money online selling a high in-demand service...

Features Of VideoTours360

Live Video Calls To Engage & Close Your Prospects: Combine the power of virtual tours with ZOOM like LIVE Video Calls to engage & close prospects during the virtual tour

Gamification To Boost Engagement & Incentivize Action: Have users unlock coupons, discounts, freebies, etc... from right inside your video when they complete pre-defined actions. E.g get a 10% discount after opening 7 hotspots or 'Spend 5 mins inside the tour Download FREE ebook'

Sell Your Products With The Inbuilt Ecommerce Engine: Sell Merchandise with eCommerce. Run an online 360° store tour and sell products directly

Power Up Your Lead Generation Game: Collect your visitor's leads (email, phone, and messenger) for effective follow-up (Add Any Major Autoresponder)

Other Features Include;

The Fastest & Easiest Drag n Drop Video Tour BuilderSeamless Integration With All The Popular Marketing Apps

Drag & Drop Unlimited Hotspots With Ease

Go Viral

Tour Experience Optimization Powered By Artificial Intelligence (A.I) & Machine Learning

Embed Everywhere For Maximum Exposure

Export & Host Yourself

What’s New in VideoTours 360 Ultimate?

Assign video chat time to tours and client accounts.

Full tour download (Host on your server).

Robust Analytics Dashboard.

Multi-Language System - 108 languages

Duplicate and save Hotspots as a template.

Etcetera

With the Ultimate Edition, you also get a;

Fail-Proof And Result-Driven Virtual Tour Selling Accelerator Programme: This Virtual Tour Selling Accelerator Programme is a step-by-step training program that’ll walk you through everything you need to start and scale a widely successful VR Agency and start closing clients from day one.

The Ultimate Lead Finder: Effortlessly Finds You Laser-Targeted Buyer Leads In ANY Niche In Just 45 Seconds FLAT.

A Step By Step Video Training On How To Create & Capture Beautiful & Professional 360-Degree Images Using Just Your Smartphone: This is a robust video training that'll guide you subscribers step by step on "How To Capture Beautiful & Professional 360 Degree Images" that they can use to create virtual tours. This means they don't NEED a 360 camera to get started - all they need is a smartphone and with this training, they’ll be spilling out beautiful and professional-looking 360 Degree Images.

What’s The Price?

VideoTours360 is going for a very TINY one-time fee of $47. . . Can you beat that?

That’s is a very tiny bitty fraction of its true value, market cost, not to mention the income potential!

Fair warning though, this low one-time fee is valid only during the launch special period, DON’T MISS IT!

What Are The Upsells?

Upsell 1: VideoTours360 Pro Unlimited - $37/month - $197 yearly

Users get access to create unlimited tours with unlimited scenes, Top up to 10,000 minutes of video chat time, unlimited eCom products.

Newly Added:

PRO Feature #1: Drawing feature

PRO Feature #2: Before & After using two 360 images

PRO Feature #3: Custom Domain

Upsell 2: VideoTour360 Agency & Consultant ToolKit - $47

You get all the assets you need to start and run a 6-Figure Virtual Tour Agency.

Newly Added:

Improved VR Agency & Consultant Toolkit

Agency Feature #1: Assign video chat time to tours & client accounts

Agency Feature #2: Share to Google Street View Virtual Tours

Agency Feature #3: Integration/share to with Trulia, Realtor.com

Agency Feature #4: Unbranded Client Area

And many more!

Upsell 3: Ultimate Software & Digital Agency Package - One Mega Deal

With this, YOU can start and scale a profitable digital marketing agency that sells services to local businesses. You get a Software App Bundle, including;

A Social Media Marketing & Traffic App

Ads & Influencer Marketing App

Content Marketing App

Messenger Bot Marketing App

A Robust Design App Suite

A Video Marketing App

And many more

With these apps, you can deliver stellar digital marketing services with little or no experience and in record time!

Plus, you get a ready-made agency website, prospecting kit, brochures, proposals, etc... for 10 local niches.

Get 10 New State-of-The-Art Agency Kits in One Awesome Package!

Done-For-You Websites, Proposals, Graphics, Contracts & More Designed To Skyrocket Your Results!

Exclusive Rights To Use OUR Testimonial & Case Studies to Impress YOUR Clients

Our 'Tested-and-Trusted' List Of Service Providers For Drop services

PLUS as a launch special bonus… Get 10 ‘Done for you’ animated agency sales videos for each of the 10 niches. Each video comes with;

Professional video slides

Proven to convert sales video script

Real human voice-over.

Play these explainer videos for any local business owner… ask for $2,500 and they’ll bite your hands off. FACT!

Upsell 4: VideoTours360 Reseller Bundle Package $197, $297, $497

RESELL VideoTours360 Ultimate Edition as your own and KEEP 100% of the profit. Easy way to make money selling software products.

Plus Get A Reseller Bonus Bundle:

Get Reseller Rights to FIVE High-Quality Software Apps with Professionally Designed Sales Pages and Start Making Sales IMMEDIATELY!

App #1: Socicake All-In-One Social Media Marketing Suite

App #2: Design Bundle 10-In-One Design Suite

App #3: LeadGrow Done For You Lead Generation Funnel

App #4: Uduala eCom Domination Platform

App #5: AgencyBlitz - 4 Done For You Local Agency Marketing Package

This is a MASSIVE deal - we’ve NEVER done this before!

PROS & CONS

The pros are obviously endless, but I’ll just mention a few;

Higher conversions guaranteed

Cutting-edge technology

Maximum global reach

Super-easy to use

Easy to set up

Works seamlessly on any device

Cons:

The funnel is pretty deep; 4 whole upgrade options: this isn’t much of a con as the software still works perfectly without any of the upgrades.

You will need a good internet connection.

FINAL WORDS

If you want to leverage the ‘Zero touch’ trend in the new post covid economy where customers don’t want to leave their homes. With VirtualTours 360, you can create beautiful and highly engaging 360 videos in just a couple of minutes - WITHOUT any sort of special skills or knowledge.

Hence, on this note, I’ll say; VideoTours360 Ultimate is a timely solution and I highly recommend it.

Without any doubt, I can give it a five-star review, anything other than that will be “BIAS!”

You can go ahead and secure your access, your investment is SAFE & WISE, cheers!

>>> Click HERE to pick up your discounted launch special access.

0 notes

Photo

In 2020 Bystronic DNE was wholly-owned by Bystronic

Shenzhen DNE Laser Science and Technology Co., Ltd focused on the R&D, production and sales of fiber laser cutting machine. After years of development, it has a huge market influence, market share and unique service charm in the area of China fiber laser cutting machine. In 2016 the company established the Joint Venture with Swiss Bystronic Group.

DNE Laser has always been committed to the innovation of laser cutting technology. The company has a production base of more than 80,000㎡, professional laser technicians and expert teams. Integrating with international frontier laser technology and closely collaboration with world renowned device manufacturers such as Germany, America, England, etc., it develops and produces a series of laser cutting machine with high electro-optical conversion rate, unique beam optical quality, stable performance.

The product is exported to nearly 100 countries around the world, which provides the full range of metal sheet processing and automatic solutions for users.

More: http://en.dne-china.com/

#Bystronic #dnelaser #lasercutter #laser #lasercutting #lasermarking #fiberlaser #fiberlasercuttingmachine

1 note

·

View note

Text

Yuyao Qiangsheng Tools Co., Ltd.

New Post : https://www.clsfyd.com/ad/yuyao-qiangsheng-tools-co-ltd/

Yuyao Qiangsheng Tools Co., Ltd.

Yuyao Qiangsheng Tools Co., Ltd. is located in Yuyao City, Ningbo, close to Ningbo Port. It is a professional manufacturing, industrial tool cabinet, tool cart, toolbox and other metal equipment enterprises. The company has a factory area of 10,000 square meters and 50 employees, including Gaoxin. The company has 10 technical talents. The company has advanced CNC machine tools, large-scale laser cutting machines, bending machines, and automatic assembly line spraying equipment.

The company’s products are sold at home and abroad, and are currently exported to the United States, Europe and other regions. The company is looking forward to your visit and visit.

https://www.china-rollercabinet.com

by: mebalboolboxsb www.clsfyd.com #clsfyd #freeads #freeclassifieds

0 notes

Text

https://ceslasermachine.com/double-pallet-fiber-laser-cutting-machine/

A double laser cutting machine exporter expert in the all over the globe distribution of advanced dual-laser systems designed for accurate and efficient cutting of different materials, including metals, plastics, and textiles. These machines benefit from dual-laser technology to get cutting speed, exactness, and versatility, providing to industries such as automotive, aerospace, and manufacturing.

#ces laser marking machine#ces machine ahmedabad#laser welding machine manufacturers#double laser cutting machine suppliers#close laser cutting machine exporter#Single pallet laser cutting machine Manufacturer#Pipe Laser Cutting Machine Suppliers

0 notes

Photo

Friday 13th December

This is the laser cutting workshop that I had taken part in for the module 3D design principles. This workshop was something that I was interested in. The reason why I was interested in this workshop was that it would help me understand the software that you would need to use.

1) The first thing that we were taught was the software and what file you should save the outline as or what to export the file into. The software could have been Adobe Illustrator. The file that you should save the file as is either a pdf or a makes the file the original.

2) We then learned that the way to connect the software up to the laser cutting machine. The way that you do this is by logging onto the computer on the second floor and checking with a member of staff if the vector will work with the laser cutting.

3) After, checking that the vector will work you then move on to placing the material into the machine. Depending on which material you use you must place the material the correct way up. If the material is wood then the treated side of the wood should be placed upward.

4) You then close the lid off the machine and let it do the work.

This workshop was useful because it not only showed me how to use the machine it also helped me to understand the software and the materials to use.

0 notes

Text

Understand metal fabrication Before You Regret.

The enhancement of this brand-new CNC transforming facility with Multi-Tasking capacity combines advanced modern technology, productivity and also worth to provide exceptional performance. As an (MY) configuration, the maker showcases milling capacity and Y-axis performance together with a standard through-hole chuck package, and integral transforming pin electric motor to process a variety of components in a solitary arrangement. The enhancement of this new CNC lathe will certainly assist in allowing Prototek to manufacture parts rapidly as well as effectively! Whether in your balcony, stairway situation verandahs or balcony, you could quickly set up one such balustrade. No issue exactly what the layout and also colour code of your home is, a stainless steel balustrade would match every solitary style! RINOX Engineering - Asia's greatest factory creating Stainless Steel Handrail and also Glass Hardware. RINOX products are offered in even more than 65 countries throughout the world. This remark has been gotten rid of by the writer. This comment has been gotten rid of by the writer. Subscribe to our newsletter to obtain the most recent updates to your inbox. Your e-mail address is secure with us! July (10) How to Buy Authentic Sprinter Parts? Servicing your lorry is not needed legally, but there are multiple reasons to do so often.

Straight Bits: These tools reduced on both the end of the tool and on the sides. There are many variants of the geometry of these bits. A lot of the product listed below is committed to clarifying the differences and also their usage. Ball-End Bits: These bits have a round account at the tip. This enables them to reduce 3D surfaces. Chamfer and also Engraver Bits: These cutters involve a point at the idea. The most effective part is that they use sheet steel manufacture and laser cutting service, all under one roof. So, those who require these two services will definitely discover such firm handy. The company should meet all your sheet steel fabrication as well as laser cutting needs with utmost effectiveness and perfection. They have actually experienced and also effective specialists to provide service. They provide excellent engineered option to all the laser cutting as well as sheet metal manufacture issues. Prints have a border around the entire print that include letters as well as numbers as revealed in the above print between the red lines. These numbers as well as letters are used like a map in order to help situate as well as determine specific locations of a print. The letters remain in alphabetical order from the base up. The numbers are in mathematical order from right to left. Consequently, you are to read the zones from right to left. As with any type of market, the longer a business has stayed in business, the more probable it is that they do great and also supply outstanding consumer solution. More recent firms are not always a poorer option, but a steel stamping business that isn't really offering good solution and top quality items won't last long. When you're looking for the best die manufacturer or metal stamper for your needs, search for companies that have stayed in business for a minimum of five to ten years. This will develop even more jobs for U.S. With these new markets opening up, U.S. China might slow in the future as they fight with their own inner facilities as well as national debt scenarios. China's short-term issues are foreseeable and also as the worldwide economic climate relocates far from underwriting development, these problems will certainly come to be extra obvious. This will develop more work for U.S. U.S. for replacement manufacturing. Additionally, relying on just how they begin to check out the influences their manufacturers are bring upon on the environment from their low-cost, careless approach to production, contracting out to China can be extra pricey if they choose to enforce more stringent environmental laws. Requirements could consist of load-bearing capability, sorts of forms, alloys and sizes. Steel light beams, bars as well as plates have actually to be assembled in particular methods to produce some distinct structural components such as girders and trusses. The commercial applications of creating metal parts and structures are far and also wide. They cover both small building as well as massive building tasks. Several of the structures and parts that have to be fabricated are extremely specialized that they should comply with specs that are special to a specific project. Log in or Create Account to upload a comment. Author: Carla Bruni Metal making devices are used as a vital dimension of the manufacturing market. It is used in the structural steel sector as well as it helps in various other steel fabricating markets. Customers of the manufacturer of steel producing equipment array from average and also tiny sized enterprises to iron and fabricating shops and huge building business. Author: Robert Henson Metal producers collaborate with a selection of metal kinds, consisting of steel. One of the most intriguing aspects of the steel manufacture business is that there are lots of areas that an individual can focus on.

Toolmaking for metal stamping

4/4, 5/4, 6/4, 8/4, 12/4, 16/4

Robotic Welding

Version A Formed Part For Most Parts

Personalized steel cornice trim

Closing down when Finished

Publisher: Robertcorin Roof substitute is just one of the vital maintenance jobs of residence. Over the period, the top quality of roofing obtains shabby as well as it requires substitute. Author: Will Peartin When home owners choose roofing products, they take into consideration toughness as one of the most vital elements. You could additionally look at region, cost, and also your personal choice in determining what to obtain. Author: Francis Murphy When you desire to replace the roof of your residence then the most difficult decision is to make a decision the sort of roofing you are mosting likely to have. her comment is here Recently Astro Engineering was gotten in touch with for a large order of laser and developed components that had to be delivered in a limited period. The consumer provided the prints for the work which was composed of virtually 8000 parts constructed from 16 gauge mild steel. There were 8 different components needed, with amounts ranging from 40 to 2000 parts of each. For this huge laser job, the auto load/unload system on the laser was well made use of. Several press brakes were used to complete all the developing. Whatever is split independently for a simpler time designating toolpaths in the toolpath arrangement software program - Mastercam. Each part is exported to a different data if you like. Data concerning the table is stored in the Rhino data as notes. Right here you could see limit dimensions, board feet needed, as well as the dimension of the needed block of timber for each and every item. The model table was made from a single item of 16/4 Yellow Poplar. The board was 4" thick, 10" vast as well as 16' long. Components are welded with each other, and afterwards after cooling down the machine or structure is usually sand blasted and painted. This end product is thoroughly checked prior to it is delivered off to the client. Several metal fabricators focus on particular procedures based upon their clients' demands and also their very own expertise. These might be punching, welding, forging, spreading, brazing, shearing, drawing and spinning. Also greater degrees of specialization consist of electrical as well as hydraulics solutions. Do not miss the current information! Receive industry as well as products information from the market classifications that matter to you most. Keeping up to date on market information as well as trends, product statements and also the most recent advancements. Characteristic Metals is honored to announce we passed our yearly NADCAP Welding security audit. We are really happy of our team on this achievement and anticipate offering our fabrication and welding services to give a winning service to our existing or a new prospective consumer. Hallmark Metals would love to want you all an extremely Happy and also Safe Holiday Season! Trademark Metals wish to say thanks to all the service guys as well as women who fight for our liberty. Please permit us the possibility to quote on your Sheet Metal and also Machining requirements. We waiting to teaming with you as well as getting your components going for our center in the new future. Hallmark Metals is delighted to introduce we have upgraded our CNC Turret Press to a much extra power as well as expense effective machine that is currently up and running. Our consumers will certainly experience better cost via this while our environmental influence is lowered too. And also you'll require to collaborate with architects, specialists and also other building employees to bring styles to life. You'll desire to check about and also see what kind of openings there are if you're interested in the sheet metal area. The good news is, that procedure is easier than ever with making use of on the internet task sites, where there are any kind of variety of ads for different tasks. Have a look at just what these websites need to use as well as you're virtually guaranteed to discover something that suits your demands.

1 note

·

View note