#Pipe Laser Cutting Machine Suppliers

Explore tagged Tumblr posts

Text

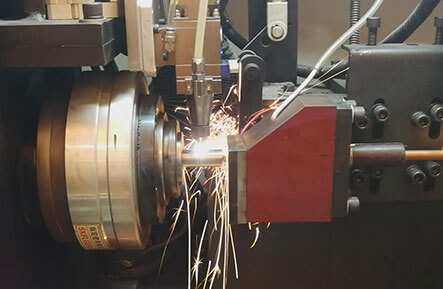

A pipe laser cutting machine is a specialized industrial tool designed to accurately cut and shape various types of metal pipes using a focused laser beam. These machines offer high accuracy and speed, allowing for complex cuts and intricate designs with very less material waste. We are widely used in industries such as automotive, aerospace, construction, and manufacturing due to our ability to craft a wide range of pipe sizes and materials with corrosion protection

#ces laser machine#Pipe Laser Cutting Machine#laser welding machine manufacturers#double laser cutting machine suppliers#automatic laser welding machine manufacturers#ces machine ahmedabad#pipe laser cutting machine suppliers

0 notes

Text

Tube Cutting Machine in India

A tube cutting machine is an essential tool used for cutting pipes or tubes with precision and efficiency. Widely used in industries like construction, automotive, and manufacturing, these machines are vital for ensuring clean and accurate cuts, which minimize material wastage and improve productivity. The demand for tube cutting machines in India has grown due to the rapid industrialization and the need for high-quality cutting solutions across various sectors.

Available in different types, these machines cater to diverse needs. Manual tube cutting machines are suitable for small-scale operations, while automatic and CNC machines are preferred for large-scale production due to their speed and accuracy. Laser tube cutting machines, on the other hand, are ideal for industries requiring intricate designs and superior precision. Materials such as steel, aluminum, copper, and plastic are commonly handled by these machines, making them versatile for multiple applications.

The primary benefits of using a tube cutting machine in India include enhanced productivity, cost-efficiency, and safety. Automated systems reduce labor costs and improve output, while advanced features like programmable controls ensure high accuracy in repetitive tasks. These machines are extensively used in sectors like construction for cutting plumbing pipes, automotive for exhaust systems, and manufacturing for structural components.

When selecting a tube cutting machine, businesses in India should consider factors such as material compatibility, cutting speed, and after-sales support. Reputed manufacturers and suppliers in India offer a wide range of options, from basic manual machines to advanced CNC and laser systems, ensuring solutions for every industrial need. Investing in the right tube cutting machine not only boosts operational efficiency but also ensures long-term reliability and reduced downtime.

0 notes

Text

Refuse Bin

Ningbo Simple Creative has two own factories named Ningbo Yuxin Metal Products and Ningbo Nuoerxin. As a famous Custom Refuse Bin Suppliers and OEM Refuse Bin Manufacturers, Now the company has the following processing equipment: laser cutting machine 15000w, 6000W, 2000W, laser pipe-cutting machine 2000W (pipe length 9000mm, diameter 208mm), CNC plate-cutting machine, bending machine, reaming machine, rolling machine, stainless steel, precision Key plate metal processing equipment.

0 notes

Text

China Fiber Laser Cutting Machine Manufacturer & Factory

15 years of experience in laser equipment production and manufacturing, serving 1000+ customers, specializing in the production of laser cutting machines, laser pipe cutting machines, laser cleaning machines, laser welding machines and other products. The professional design and R&D team can provide OEM and ODM services to provide you with the most affordable price.

1 note

·

View note

Text

Steel Fabrication Machinery Suppliers in the UAE: Powering the Nation’s Infrastructure

The steel fabrication industry plays a crucial role in the development and growth of infrastructure across the UAE. From the towering skyscrapers that define the skyline of Dubai to the vast industrial plants and oil refineries, steel fabrication is at the heart of construction and manufacturing in the region. The demand for high-quality, precise, and efficient steel fabrication machinery is paramount to meet the rigorous standards of the industry. This article delves into the world of steel fabrication machinery suppliers in UAE, highlighting the significance of their offerings and the impact they have on the country's infrastructure.

The Role of Steel Fabrication in the UAE

Steel fabrication is the process of cutting, bending, and assembling steel to create various structures and components. It is a critical component of construction, manufacturing, and industrial projects. The UAE, with its rapidly growing economy and ambitious construction projects, relies heavily on steel fabrication for everything from residential buildings to complex industrial facilities.

In the UAE, the construction sector alone is a significant contributor to the nation's GDP. The demand for steel products, such as beams, columns, trusses, and custom-fabricated components, is ever-growing. This demand is met by a network of steel fabrication companies that rely on advanced machinery to deliver precision-engineered products.

The Importance of High-Quality Machinery

Steel fabrication is a precise and intricate process that requires the use of advanced machinery. The quality of the machinery directly affects the quality of the final product. In the UAE, where construction standards are among the highest in the world, the need for top-notch machinery cannot be overstated.

The machinery used in steel fabrication includes cutting machines, bending machines, welding machines, and various other tools designed to manipulate steel into the desired shapes and sizes. Each piece of equipment must be capable of handling the specific demands of the project, whether it's creating intricate designs or ensuring the structural integrity of large steel components.

Types of Steel Fabrication Machinery

Steel fabrication machinery encompasses a wide range of equipment, each designed for specific tasks within the fabrication process. Some of the most commonly used machines include:

Cutting Machines: These machines are used to cut steel plates, beams, and other components to the required dimensions. Types of cutting machines include plasma cutters, laser cutters, and oxy-fuel cutters. Precision and efficiency are key in this stage, as accurate cuts are essential for the integrity of the final product.

Bending Machines: Bending machines are used to shape steel into various forms, such as angles, curves, and tubes. These machines are vital for creating components like beams, pipes, and structural elements. CNC (Computer Numerical Control) bending machines are particularly popular due to their precision and ability to handle complex bending tasks.

Welding Machines: Welding is a critical process in steel fabrication, as it joins steel components together to form the final structure. Welding machines come in various types, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and arc welding machines. Each type of welding machine is suited for different applications, depending on the material thickness and the required strength of the weld.

Drilling and Punching Machines: These machines are used to create holes and notches in steel components, allowing for the assembly of structures. Precision drilling and punching are essential for ensuring that components fit together correctly and that the final structure is secure.

Shearing Machines: Shearing machines are used to cut large sheets of steel into smaller, more manageable sizes. These machines are particularly useful for preparing materials for further processing, such as bending or welding.

Roll Forming Machines: Roll forming machines are used to create long, continuous shapes, such as beams and channels, by passing steel through a series of rollers. This process is ideal for producing large quantities of uniform components quickly and efficiently.

The Significance of Local Suppliers

In the UAE, sourcing steel fabrication machinery from local suppliers offers several advantages. Local suppliers are more attuned to the specific needs of the region’s industries, and they can provide machinery that is tailored to the unique requirements of projects in the UAE. Additionally, local suppliers often offer better after-sales support, including maintenance services and the availability of spare parts, which is crucial for minimizing downtime and ensuring the longevity of the machinery.

Another advantage of local suppliers is their ability to offer training and support to operators. Operating complex steel fabrication machinery requires specialized skills, and local suppliers can provide training to ensure that operators are proficient in using the equipment. This not only improves the efficiency of the fabrication process but also enhances the safety of the workplace.

Challenges Faced by Steel Fabrication Machinery Suppliers

While the demand for steel fabrication machinery in the UAE is strong, suppliers face several challenges in meeting the needs of their customers. One of the primary challenges is keeping up with technological advancements. The steel fabrication industry is constantly evolving, with new technologies and techniques being developed to improve efficiency and precision. Suppliers must stay ahead of these trends to provide their customers with the latest and most advanced machinery.

Another challenge is the need to balance cost and quality. While customers in the UAE demand high-quality machinery, there is also pressure to keep costs down. Suppliers must carefully select the machinery they offer to ensure that it meets the required standards while remaining cost-effective.

Future Trends in Steel Fabrication Machinery

The steel fabrication industry in the UAE is poised for further growth, driven by ongoing infrastructure projects and the development of new industrial sectors. As the industry grows, so too will the demand for advanced steel fabrication machinery. Several trends are expected to shape the future of the industry:

Automation: The adoption of automation in steel fabrication is expected to increase, with more companies investing in CNC machines and robotic systems. Automation can significantly improve the efficiency and precision of the fabrication process, reducing the need for manual labor and minimizing errors.

Sustainability: As sustainability becomes a greater focus in the construction industry, there will be a growing demand for machinery that is energy-efficient and capable of working with sustainable materials. Suppliers will need to offer machinery that meets these requirements to stay competitive.

Customization: The ability to customize machinery to meet the specific needs of a project will become increasingly important. Suppliers who can offer flexible solutions and tailor their machinery to the unique requirements of their customers will have a competitive edge.

Integration with Digital Tools: The integration of digital tools, such as Building Information Modeling (BIM) and advanced software for design and planning, will become more prevalent. Suppliers will need to offer machinery that can seamlessly integrate with these tools to enhance the overall fabrication process.

Conclusion

Steel fabrication machinery suppliers in UAE play a vital role in supporting the nation's construction and industrial sectors. Their ability to provide high-quality, advanced machinery is essential for ensuring that projects are completed to the highest standards. As the industry continues to evolve, suppliers will need to stay ahead of trends and challenges to meet the growing demands of their customers. By focusing on innovation, quality, and customer support, steel fabrication machinery suppliers in the UAE will continue to power the nation’s infrastructure and contribute to its ongoing development.

0 notes

Text

Stainless Steel T Patti

INTRODUCTION:-

The above Decorative SS “T” Profile Sections are made by CNC Bending. Before Bending, these Sheets are cut to their required sizes by Laser Cutting Machines. Our SS T-Profiles Grooving is done on Metal Sheets before bending them. By following this Process, we can achieve 90 right angle on the bend area.

Our Profile Sections are also available in various colours as per your Requirement. Decorative SS “T” Profile Section are used in many Applications such as exterior cladding, interior decoration, Skirting, Wall Edge Protection, Floor Partitions, Wall Partitions and Many More.

BENEFITS:-

Durability: Stainless steel T Pattis are highly durable and resistant to corrosion, making them suitable for both indoor and outdoor use, even in harsh environments.

Strength: T Pattis made of stainless steel exhibit high strength-to-weight ratio, providing structural stability and support in various applications.

Aesthetic Appeal: Stainless steel T Pattis have a sleek and modern appearance, adding an aesthetic appeal to architectural designs and interior spaces.

Low Maintenance: These T Pattis require minimal maintenance, as they are easy to clean and do not require painting or coating to maintain their appearance.

Environmentally Friendly: Stainless steel is a recyclable material, making T Pattis an eco-friendly choice for sustainable construction projects.

PRODUCT OVERVIEW:-

Stainless steel T Patti, supplied by various suppliers in India, is a versatile construction material used in various architectural and structural applications. These suppliers offer a wide range of T Pattis in different sizes, grades, and finishes to meet the diverse needs of their customers. Stainless steel T Pattis are commonly used in construction, interior design, fabrication, and industrial settings.

ABOUT US:-

Shasan Piping Solution was founded by a group of many years of experienced specialists in product developing, designing, producing management, and quality control. Our Organisation is ISO 9001:2015. We supply only good quality, traceable inspection, and reliable delivery with excellent customer service.

We are professionals and specialize in manufacturing, stockist, importing, and export of Pipe Fittings, Flanges, Fasteners, Instrumentation Fittings, Hammer Union, Valves, Gaskets, Pipes and Tubes, Sheet, Plates, Coils, Bars & Structural Steel Products as per customer’s projects, drawings, standards, and specifications.

MORE DETAILS:- CONTACT US: +91 22-6651 8642 EMAIL ID: [email protected] WEBSITE: https://www.decorativecoatedprofiles.com/stainless-steel-t-patti-profile.html

#Stainless Steel T Patti in Mumbai#Stainless Steel T Patti Suppliers in Mumbai#Stainless Steel T Patti Stockists in Mumbai.

0 notes

Text

Jinan Dowell Photoelectricity equipment Co. ltd

13 years of experience in laser equipment production and manufacturing, serving 1000+ customers, specializing in the production of laser cutting machines, laser pipe cutting machines, laser cleaning machines, laser welding machines and other products. The professional design and R&D team can provide OEM and ODM services to provide you with the most affordable price.manufacturing, serving 1000+ customers, specializing in the production of laser cutting machines, laser pipe cutting machines, laser cleaning machines, laser welding machines and other products. The professional design and R&D team can provide OEM and ODM services to provide you with the most affordable price.

Room A1-803, Xinyuanxin Center, Dongfeng Street, Licheng District, Jinan, Shandong, China

1 note

·

View note

Text

Fiber Laser Pipe Cutting Machines: A Boon for Modern Metalworking

Fiber laser pipe cutting machines are revolutionizing the metalworking industry with their precision, speed, and versatility. These machines use a focused beam of light to cut through metal pipes of various thicknesses and shapes, producing clean, burr-free edges with minimal heat-affected zone.

Benefits of Fiber Laser Pipe Cutting Machines

High precision and accuracy: Fiber laser cutting machines can achieve cutting tolerances of up to +/- 0.005 mm, making them ideal for applications requiring tight tolerances.

Fast cutting speeds: These machines can cut through metal pipes at speeds several times faster than traditional plasma or oxy-fuel cutting methods.

Minimal heat-affected zone: The concentrated laser beam creates a narrow kerf, minimizing the heat-affected zone and reducing the risk of distortion or warping.

Versatility: Fiber laser pipe cutting machines can cut a wide variety of metals, including mild steel, stainless steel, aluminum, copper, and brass. They can also cut a variety of pipe shapes, including round, square, rectangular, and oval.

Low operating costs: Fiber laser cutting machines have low operating costs due to their high energy efficiency and minimal maintenance requirements.

Environmentally friendly: These machines produce minimal waste and emissions, making them a more environmentally friendly option than traditional cutting methods.

Applications of Fiber Laser Pipe Cutting Machines in Specific Industries

Automotive industry: Cutting components for cars, trucks, and motorcycles.

Aerospace industry: Cutting lightweight and high-strength materials for aircraft and spacecraft.

Medical device industry: Cutting precision components for medical devices.

Furniture industry: Cutting intricate designs and shapes for furniture parts.

Construction industry: Cutting beams, columns, and other structural components.

Oil and gas industry: Cutting pipes for pipelines and drilling equipment.

Advantages of Fiber Laser Pipe Cutting Machines for Businesses

Increased productivity: The high cutting speed and precision of fiber laser pipe cutting machines can significantly increase production throughput.

Improved product quality: The clean cuts and minimal heat-affected zone produced by these machines result in higher quality finished products.

Reduced material waste: The narrow kerf width of fiber laser cutting minimizes material waste, saving businesses money.

Lower operating costs: The low energy consumption and minimal maintenance requirements of these machines lead to lower operating costs.

Increased competitiveness: Businesses that invest in fiber laser pipe cutting machines can gain a competitive edge by offering faster turnaround times, higher quality products, and lower costs.

If you are a metalworking business looking to improve your productivity, quality, and competitiveness, then a fiber laser pipe cutting machine is a wise investment.

In addition to the benefits mentioned above, fiber laser pipe cutting machines are also:

Easy to operate: These machines are equipped with user-friendly CNC controls that make them easy to operate, even for those with limited experience.

Safe to use: Fiber laser cutting machines are inherently safe due to their enclosed design and laser safety features.

Reliable: These machines are built to last and require minimal maintenance.

Overall, fiber laser pipe cutting machines are a versatile and powerful tool that can benefit businesses of all sizes in a variety of industries.

I hope this blog post has been helpful. If you have any questions, please feel free to leave a comment below.

Call to action:

If you are interested in learning more about fiber laser pipe cutting machines, please contact Chirag International a reputable manufacturer or distributor. They can help you choose the right machine for your needs and budget.

www.chiraginternationals.com

Phone No - 9811958196

#laser#lasercutter#pipecutter#metal cutter#laser metal cutter#lasercutting#fiber laser cutting machine#lasermarking#laserengraved

0 notes

Text

https://ceslasermachine.com/double-pallet-fiber-laser-cutting-machine/

A double laser cutting machine exporter expert in the all over the globe distribution of advanced dual-laser systems designed for accurate and efficient cutting of different materials, including metals, plastics, and textiles. These machines benefit from dual-laser technology to get cutting speed, exactness, and versatility, providing to industries such as automotive, aerospace, and manufacturing.

#ces laser marking machine#ces machine ahmedabad#laser welding machine manufacturers#double laser cutting machine suppliers#close laser cutting machine exporter#Single pallet laser cutting machine Manufacturer#Pipe Laser Cutting Machine Suppliers

0 notes

Text

Alloy Steel Compression Fittings and Titanium Fittings: Revolutionizing Industrial Applications

In the realm of industrial applications, the use of robust and reliable materials is paramount. Among these, the significance of specialized metal fittings, particularly alloy steel compression fittings and titanium fittings, cannot be overstated. These components are crucial in various industries, from petrochemicals to aerospace, offering durability, efficiency, and safety.

Understanding Alloy Steel Compression Fittings

Alloy steel compression fittings are essential in various piping and tubing systems. These fittings are known for their high strength and resistance to impact and corrosion. Made from a blend of iron, carbon, and other elements, these fittings are engineered to withstand high pressures and extreme temperatures. This makes them ideal for applications in harsh environments where traditional materials might fail.

One of the key advantages of these fittings is their ease of installation. Unlike welded fittings, they do not require special tools or skills for installation, reducing downtime and maintenance costs. This feature also allows for quick disassembly and reassembly, crucial in maintenance-intensive industries.

The Role of Titanium Fittings in Modern Industries

Titanium fittings stand out due to their exceptional properties. Titanium is renowned for its strength-to-weight ratio, being as strong as steel but significantly lighter. This unique characteristic makes titanium fittings distributor ideal for applications where weight is critical, such as in the aerospace and automotive industries.

Another notable feature of titanium is its corrosion resistance. Titanium, unlike many other metals, does not rust easily, even in corrosive substances like seawater or chlorine. This quality extends the life of the fittings, ensuring long-term reliability and reducing the need for frequent replacements.

Applications Across Industries

Both alloy steel and titanium fittings find extensive use in various sectors. In the oil and gas industry, they are used in pipelines and control systems, where they endure high pressure and corrosive substances. In the aerospace sector, their lightweight and durable nature contributes to the efficiency and safety of aircraft. Similarly, in the automotive industry, they are used in high-performance vehicles for their strength and resistance to extreme conditions.

Advancements and Sustainability

The advancement in manufacturing technologies has further enhanced the qualities of these fittings. Modern techniques like precision machining and laser cutting have allowed for more complex and accurate designs. This precision ensures a perfect fit, minimizing leaks and increasing the system's overall efficiency.

Sustainability is another aspect where these fittings contribute positively. The durability and longevity of alloy steel and titanium fittings mean less frequent replacements, reducing waste and resource consumption. Additionally, many manufacturers are adopting eco-friendly practices in their production processes, minimizing environmental impact.

Choosing the Right Supplier

When sourcing these fittings, choosing a supplier that guarantees quality and reliability is crucial. Look for suppliers with a proven track record in the industry and offer a wide range of products to suit different applications.

Conclusion

In summary, alloy steel compression fittings and titanium fittings are transformative in various industrial applications. Their strength, durability, and versatility make them indispensable in today's technology-driven industries. For those looking to source these high-quality fittings, samvayglobal.com is a reliable option, offering a comprehensive range of products to meet diverse industrial needs. Industries can ensure efficiency, safety, and sustainability by choosing the right fittings.

0 notes

Text

We Offers a Variety of High-Tech Fitness Equipment to Satisfy the Needs of Residential Clients

We are internationally renowned for their outstanding biomechanics, robustness, and dependability, the company's products partner with the world-renowned fitness brand. We are a well-known gym machine supplier across the world with more a lot of years of experience in manufacturing, building fitness facilities, and opening sales offices. The company is also proud of its extensive distributor network, which and includes successful installations.

We have Excellent Manufacturing Facility

The main reason why so many customers choose us is the superior equipment we produce in our cutting-edge manufacturing facility. Our plant is near several of the biggest companies in the world and we use state-of-the-art techniques and technologies to manufacture our workout equipment. Much of the gym machine supplier production process in our factory is automated and driven by systems. Because it reduces errors and waste, this is a significant advantage. We provide a substantial breakthrough in the gym manufacturing field with our Cutting Machine and Plate Laser Cutting Machine. Our crew is made up of highly skilled and productive professionals. This, together with procedures and methods that are compared to the Production System, ensures that every piece of equipment manufactured is made to a constant standard of quality. Additionally, it is necessary to reach our goal of "Zero Product and Process Defects."

At our manufacturing facility, we have a pipe bending equipment. With the help of this machine, we can precisely bend tubes, ensuring accurate arcs and angles. We employ highly sophisticated Fixtures to guarantee precision and consistency in all of our products. All products will have the same quality and biomechanics, no matter how many there are. In addition to them, our production plant uses state-of-the-art tools and processes, such as shot blasting machines fully automated Power Coating Plant that has a burner.

The commercial workout equipment industry has seen a substantial transition as a result of contemporary technologies. We have transformed as a result of technological advancements in the commercial gym equipment industry. Our production plant is a green factory that uses environmentally friendly manufacturing techniques to reduce our carbon footprint. We use solar power plant and a rainwater collection system during the manufacturing process. Not to add that we always uphold the tightest safety and shop floor hygiene standards, guaranteeing the security and safety of our employees. We make sure that comprehensive quality testing is done before packaging and shipping, and our product assembly process is incredibly well-organized. To ensure that our clients receive the best possible product, we follow meticulous quality inspection and pre-dispatch inspection protocols. Since we have total control over the products, we can guarantee that our clients will get the greatest possible products at the finest possible costs.

0 notes

Text

YX-T650-3 medium stainless steel trash can niche

Ningbo Simple Creative has two own factories named Ningbo Yuxin Metal Products and Ningbo Nuoerxin. As a famous Custom YX-T650-3 medium stainless steel trash can niche Suppliers and OEM YX-T650-3 medium stainless steel trash can niche Manufacturers, Now the company has the following processing equipment: laser cutting machine 15000w, 6000W, 2000W, laser pipe-cutting machine 2000W (pipe length 9000mm, diameter 208mm), CNC plate-cutting machine, bending machine, reaming machine, rolling machine, stainless steel, precision Key plate metal processing equipment.

0 notes

Text

Advancing Precision and Efficiency with Laser Tube Cutting Equipment

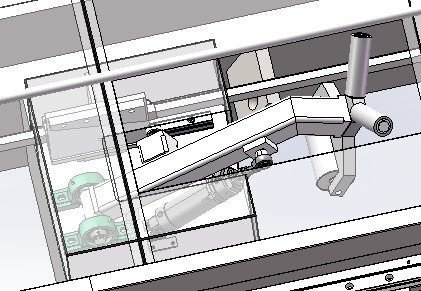

In the rapidly evolving landscape of industrial machinery, laser tube cutting equipment has emerged as a game-changer. These cutting-edge machines, often referred to as tube cutting laser machines, have revolutionized the way metal pipes are processed and shaped. In this article, we will delve into the world of laser tube cutting equipment and explore how they are transforming the manufacturing industry.

A Technological Marvel

It represents a significant advancement in the field of metalworking and fabrication. These machines employ cutting-edge laser technology to precisely and efficiently cut metal pipes of various shapes and sizes. The result is a level of accuracy and speed that was previously unattainable through traditional cutting methods.

Versatility and Precision

One of the key advantages of laser tube cutting equipment is its remarkable versatility. These machines can effortlessly cut a wide range of materials, including steel, aluminum, and even exotic alloys, with unparalleled precision. Whether you require intricate designs, sharp angles, or complex contours, a tube cutting laser machine can handle it all with ease.

Efficiency and Cost-effectiveness

In today's competitive manufacturing landscape, efficiency and cost-effectiveness are paramount. They excel in both these aspects. The speed and precision with which these machines operate significantly reduce material waste and labor costs. Moreover, the automation features integrated into these systems ensure consistent quality and minimal downtime.

Customization and Specialization

The world of metalworking is diverse, and different industries have unique requirements. This is where they truly shine. Companies like lxcuttingmachine.com offer a wide array of laser pipe cutting machines to cater to various needs. Whether you are in automotive, aerospace, or construction, there's a specialized machine to meet your demands.

Non-Standard Customization

For those seeking a tailored solution, non-standard customization services are available. These services allow you to configure a laser tube cutting machine to your precise specifications, ensuring that it perfectly aligns with your production requirements. This level of flexibility is invaluable in today's fast-paced manufacturing environment.

A Comprehensive Solution

Providers like lxcuttingmachine.com understand the importance of offering a comprehensive solution. Their commitment to being the world's leading supplier of pipe cutting equipment is evident in their business philosophy: "width of one centimeter for range, depth of one kilometer for profession." They strive to provide customers with not just cutting machines but a full range of metal pipe processing solutions.

Conclusion

laser tube cutting equipment, often referred to as tube cutting laser machines, is a testament to the advancements in modern manufacturing technology. These machines offer unparalleled versatility, precision, efficiency, and cost-effectiveness. Whether you require standard models or custom solutions, companies like lxcuttingmachine.com are determined to meet your needs and become the world's leading supplier of pipe cutting equipment.

For more information on laser tube cutting equipment and their wide range of offerings, visit lxcuttingmachine.com. Experience the efficient and convenient "one-stop purchase" service they provide, and witness how their machines are shaping the future of metalworking.

Our website has all the information you need to know and more.

Tube Laser Cutter

Bar Chamfering Machine

0 notes

Text

Remcor technology is a global supplier for the turnkey fiber laser cutting lines, which have around 18 years experiences, 5000 sets installations globally. No matter what type what size and how thickness your sheet material is, we can provide you the suitable equipment. Pipe Fiber laser cutting machine mainly been applied in metal pipes and tubes fabrications, with the character of fast speed, high precision or accuracy, environmental friendly, low power consumption, low table cost, and low maintenance cost. which is widely applied in fast cutting metal pipes of steel, stainless steel, carbon steel, aluminum, copper, galvanized steel, titanium alloy, gold, silver and other material. OEM ODM services are available.

Heavy Duty bed, apply the fully plate welding bed, with higher rigidity and durable use.

Compared with two chuck clamping or traditional metal pipes cutter. Three chucks equipment can realize the real zero tailing .processing details as the following descriptio.

More flexible for pipe cutting processing especially for extra heavy duty pipes or tubes, less swing or shake.Perfect accuracy and precision.

Heavy duty type load longer tailing material avaliable.

Apollo AK Two-chuck Tube Laser Cutting Machine 1000w-6000w Parameter Details

APOLLO BK SERIES-3 Chucks

Type

6020-BK

7025-BK

9025-BK

9034-BK

Power Range

1500-6000W

Chuck Structure

3 chucks

Tube Size

Round Type: 15-200mm Square

Round Type:15- 245mm

Round Type:15- 245mm Square

Round Type:15- 330mm Square

Type:15- 140mm

Square Type:15- 175mm

Type:15- 175mm

Type:15- 230mm

Positioning accuracy of X& Y

土0.05mm/m

Max Positioning speed X&Y

100m/min

80m/min

Max cutting length

6000mm

7000mm

9000mm

9000mm

Tail length

2 0mm

Max weight single tube

135KG

260KG

260KG

500KG

Max loading length

6000mm

7000mm

9000mm

9000mm

Fully Annealed Table

The bed body adapts the segmented rectangular tube welding bed with fully annealed treatment at over 600⁰. After tempering, the strength, rigidity and stability are guaranteed, the precision would be tested and debugged which can make sure the precision can be maintained for a long time. The table is equipped with automatic lubrication device, which ensure the moving parts operate in good condition and improve the service life of guide rails, gears and rack.

Follower Support

The follower support device will be optional. The follower support is mainly to assist in controlling the excessive deformation of cutting longer pipes (pipes with smaller diameter), and the servo motor drives the up and down movement of the pallet assembly. When the chuck moves to the corresponding position, the auxiliary support automatically drops for avoidance.

Smart Auto Focus Laser Head

Standard auto focus function, no need focus adjustment while changing sheet; Automatic tracking and accurately adjusting the focus according to the material thickness to ensure the best cutting effect of the whole board. Shorter perforation time, better perforation quality, high-speed cutting, saving time.

Intelligent CNC Operating System

It simplifies complex CNC machine operation and integrates CAD, Nest and CAM modules in one. From drawing, nesting to workpiece cutting all can be finished by a few clicks on big IPAD Screen. Realize the intelligent diagnosis, multi-threading operation, three-level perforation, laser energy control, adaptive edge-finding, automatic corner acceleration and deceleration, flight cutting, switching worktables, mechanical accuracy compensation etc.

Pneumatic Clamp Chucks

Pneumatic clamp design on both sides. The dual-chucks help reduce tube vibration to a minimum, guaranteeing high accuracy in even complex tube configurations at high cutting speed. Suitable for cutting a range of tube diameters from Ø20 mm to Ø220 mm and various wall thicknesses.

Front chuck

tube laser cutting machine front chuck

Back chuck

tube laser cutting machine back chuck

Fractional Automatic Support Technology

Applies the intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

Equipped with two sets of variable-diameter support structures, which are automatically lifted by the cylinder to avoid the rear chuck in processing. When processing profiles with different diameters, manually turn the variable-diameter wheels to achieve fit and support for different-sized profiles. The variable-diameter wheels It can be supported every two degrees of rotation to reduce the diameter of the circumscribed circular tube by 2mm

0 notes

Text

From Raw Material to Finished Product: The Manufacturing Process of Buttweld Fittings - Metal Forge India

From Raw Material to Finished Product: The Manufacturing Process of Buttweld Fittings

Buttweld fittings are crucial components used in various industries for piping systems. They ensure a secure and leak-free connection between pipes, enabling the smooth flow of liquids or gasses. Metal Forge India, is the leading buttweld fittings manufacturer, supplier, stockist, and exporter in India. With a comprehensive range of sizes, specifications, standards, materials, and grades available, we pride ourselves on delivering top-quality fittings that cater to diverse project requirements.

In this in-depth blog post, we will delve into the fascinating world of manufacturing buttweld fittings, exploring each stage from the selection of raw materials to the production of finished products. Join us as we unveil the intricacies of this process, showcasing the meticulous craftsmanship and attention to detail that goes into every fitting we produce.

Understanding Buttweld Fittings!

Buttweld fittings are pipe fittings that are designed to be welded onto the ends of pipes or other fittings, creating a strong and leak-proof joint. The name "buttweld" comes from the welding technique used, which involves two pieces of pipe or fittings being aligned and welded together at the ends.

Manufacturing Process of Buttweld Fittings

Raw Material Selection:

The manufacturing process of buttweld fittings begins with the careful selection of raw materials. At Metal Forge India, we prioritize utilizing premium-grade materials to ensure the highest quality and performance of our fittings. We offer an extensive range of materials, including Stainless Steel 304, 316, 304L, 316L, 317, Alloy 20, SMO 254, UNS N06600, Hastelloy C276 Buttweld Fittings, Stainless Steel 904L Buttweld Fittings, and Inconel 600 Buttweld Fitting. These materials are chosen for their exceptional durability, corrosion resistance, and mechanical properties, guaranteeing fittings that meet or exceed industry standards. Our experts meticulously evaluate and source the finest raw materials, working closely with trusted suppliers to maintain consistent quality throughout the manufacturing process.

Cutting and Shaping:

Once the raw materials are selected, they undergo a precise cutting and shaping process. Advanced machinery and cutting-edge techniques are employed to achieve accurate dimensions and uniformity. The raw materials are cut into appropriate sizes and shapes required for the specific type of buttweld fitting being manufactured. Computer Numerical Control (CNC) machines, saws, shears, and laser cutting tools are utilized to ensure optimal precision. Skilled technicians with expertise in metalworking techniques handle the machinery, carefully monitoring the process to maintain tight tolerances and achieve the desired shapes with utmost accuracy.

Heating and Forming:

After the cutting process, the raw materials move on to the heating and forming stage. Heating the materials to a specific temperature ensures they become malleable, facilitating the shaping process. Furnaces or induction heaters are used to achieve the necessary heat levels. The heated materials are then skillfully formed into the desired shapes, including butt weld elbows like 45-degree elbows, 90-degree elbows, 180-degree elbows, crosses, caps, tees, concentric reducers, eccentrics, and stub ends. Experienced technicians employ various forming techniques, such as hot forming, cold forming, or forging, depending on the material and specific requirements. The goal is to create fittings with smooth contours, excellent dimensional accuracy, and structural integrity.

Welding and Joining:

Welding and joining are pivotal steps in the manufacturing process of buttweld fittings. These processes ensure secure and leak-proof connections, enhancing the reliability and longevity of the fittings. Different welding techniques are utilized, depending on the material being used. Common methods include TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and electric resistance welding. Welders with expertise in these techniques carefully join the various components of the fittings, paying close attention to maintaining uniformity, strength, and precision. Stringent quality control measures, such as non-destructive testing and visual inspections, are implemented throughout the welding and joining process to detect any potential defects or imperfections.

Finishing and Quality Control:

Once the welding and joining processes are complete, the buttweld fittings undergo comprehensive finishing and quality control procedures. These steps are crucial for ensuring the fittings meet the highest industry standards. Finishing techniques, including polishing, grinding, deburring, and surface treatment, are employed to achieve a smooth and aesthetically pleasing finish. These processes also help eliminate any sharp edges or surface irregularities, ensuring the fittings are safe and easy to handle.

Quality control is an integral part of our buttweld fittings manufacturing process. We have a dedicated team of quality control professionals who perform rigorous inspections at every stage to ensure dimensional accuracy, strength, and adherence to industry standards. Specialized tools and instruments, such as coordinate measuring machines and ultrasonic testing equipment, are utilized to verify the precise measurements and integrity of the fittings. We also provide Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, along with Test Certificates certifying NACE MR0103 and NACE MR0175. These certifications offer our customers complete traceability and assurance of the fittings' quality and compliance.

Packaging and Delivery:

At Metal Forge India, we understand the significance of safe transportation and timely delivery. To ensure our buttweld fittings reach their destination in pristine condition, we employ careful packaging techniques. Each fitting is meticulously packaged using suitable materials that provide optimal protection against damage during transit. Additionally, we have a robust logistics network in place, enabling us to deliver our products efficiently and promptly to customers across the globe. Our export operations extend to various countries, including the United Arab Emirates, the USA, Germany, South Korea, Russia, Singapore, France, Thailand, Turkey, Vietnam, and Indonesia. We take pride in our ability to serve customers internationally and meet their diverse project requirements.

Standards & Specifications of Buttweld Pipe Fittings

Size

1/8” NB – 48” NB

Standards

ASME/ANSI and DIN

Schedules

5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS with NACE Certifications

Types

45 Degree elbow, 90 Degree elbow & 180 Degree elbow, Cross, Caps, Tee, Concentric Reducers, Eccentric and Stub End

Materials

Stainless Steel & Alloy 20 Steel, Monel, Inconel, Hastelloy, Duplex Steel, Super Duplex Steel, and 254 SMO

Forms

Seamless, Welded & Fabricated

Grades

Stainless Steel 304, 316, 304L, 316L, 317, Alloy 20 Buttweld Fittings, SMO 254 Buttweld Fittings, UNS N06600 Buttweld Fittings, Hastelloy C276 Buttweld Fittings, Stainless Steel 904L Buttweld Fittings, and Inconel 600 Buttweld Fittings

Advantages of Buttweld Fittings:

Strength and Durability:

Buttweld fittings offer excellent strength and durability due to the welded joint. The welded connection ensures a secure bond, making it resistant to leakage, vibration, and mechanical stresses. This reliability makes buttweld fittings suitable for high-pressure and high-temperature applications.

Smooth Flow Characteristics:

The seamless construction of buttweld fittings ensures smooth flow characteristics within the piping system. The absence of any internal irregularities or turbulence-causing features minimizes pressure drops and enhances the overall efficiency of fluid transportation.

Versatility and Compatibility:

Buttweld fittings are available in a wide range of materials, grades, sizes, and specifications, making them versatile and compatible with various piping systems. Whether you require fittings for stainless steel, alloys, or special materials, there is a suitable buttweld fitting to meet your specific requirements.

Clean Aesthetics:

Buttweld fittings provide a visually appealing and clean finish to the piping system. The welded joints are seamless and blend seamlessly with the pipes, offering an aesthetically pleasing appearance.

Applications of Buttweld Fittings

Buttweld pipe fittings are widely used in various industries for connecting and joining pipes. Here are some common applications of buttweld pipe fittings:

Plumbing Systems

Oil and Gas Industry

Chemical Processing

Power Generation

Food and beverage Industry

Pharmaceutical Industry

Water Treatment Plants

HVAC Systems

Shipbuilding and Marine Applications

Construction, Infrastructure, and so on

Final Thoughts!..

From the selection of premium raw materials to the meticulous manufacturing process and stringent quality checks, Metal Forge India ensures the production of superior buttweld fittings. Our commitment to excellence, extensive product range, and adherence to international standards have positioned us as a trusted buttweld fitting supplier in the industry. Whether you're looking for elbow manufacturer, Alloy 20 Buttweld Fittings to SMO 254 Buttweld Fittings, UNS N06600 Buttweld Fittings to Hastelloy C276 Buttweld Fittings, and Stainless Steel 904L Buttweld Fittings to Inconel 600 Buttweld Fittings, we are dedicated to offering solutions that perfectly suit your project requirements.

To explore the extensive range of buttweld fittings and place an order, visit their website or get in touch with their knowledgeable sales team.

1 note

·

View note

Text

Top CNC Plasma cutting machine manufacturer in India - Pusaanindia

A CNC flame cutting machine, also known as a CNC oxy-fuel cutting machine, is a type of industrial cutting tool used for cutting through thick metal plates or sheets. It utilizes a combination of fuel gases and oxygen to create a controlled flame that melts and removes the metal in the cutting path.

This machine is used for facilitating the process of plasma cutting, which uses an accelerated jet of hot plasma to cut through electrically conducting materials. Furthermore, it is a well-liked option for applications in both large-scale enterprises and tiny hobbyist shops due to its fast speed and accuracy cut.

Additionally, it is put through a variety of quality tests with expert supervision. Additionally, a variety of metals are cut using a CNC plasma cutting machine of the gantry type. Computers run plasma CNC machines, which use programmed instructions to make materials that adhere to exact requirements. The cutting torch is the standard tool used in plasma cutting machines to cut metal plates, sheets, bolts, pipes, etc.CNC plasma cutter machines have a system that can move the path of plasma torch by computer. Pusaan Automation PVT LTD is the best gantry type CNC Plasma cutting machine manufacturer in India. In the industrial world, our plasma cutting machine is highly regarded. Compared to a fibre laser cutting machine, a plasma cutter can easily cut materials that are the same thickness or thicker. When compared to other dealers and manufacturers, the price of the Gantry type CNC plasma cutting machine is reasonable. For more information about the Bench type machine and Portable CNC plasma cutting machine.

Here's an overview of how a CNC flame cutting machine typically operates:

Material Preparation: The metal sheet or plate to be cut is placed on a cutting table or platform. It is securely clamped or held in place to ensure stability during the cutting process.

Gas Supply: The machine has gas supply systems to provide the necessary fuel gases, typically acetylene or propane, and oxygen. These gases are mixed in precise ratios to create a combustible flame.

Ignition and Preheating: The CNC flame cutting machine has torches or burners that ignite the fuel gas and oxygen mixture. The torches are positioned above the material, and the preheating process begins. The preheating flame raises the temperature of the metal along the cutting path.

CNC Control: The machine is equipped with a computer numerical control (CNC) system that controls the movement of the cutting torch. The operator programs the desired cutting path into the CNC system or imports a pre-designed cutting pattern.

CNC flame cutting machines are commonly used for cutting thick metal plates, typically over 1 inch (25 mm) in thickness. They are suitable for materials like carbon steel, stainless steel, and aluminum. However, the heat-affected zone produced by flame cutting is larger compared to other cutting methods, which may require additional post-cutting operations for surface finishing.

It's important to note that as of my knowledge cutoff in September 2021, CNC flame cutting machines were widely used. However, there may be more advanced cutting technologies available at present.

CNC plasma cutting machines are widely used in India for their versatility and ability to cut through various types of metals. These machines utilize a plasma torch that generates a high-temperature plasma arc to melt and sever the metal.

When considering purchasing a CNC plasma cutting machine in India, it's essential to assess the specific requirements of your application, such as the material type, thickness, and cutting speed needed. Additionally, consider factors like after-sales support, warranty, training, and service availability from the manufacturer or supplier.

To make an informed decision, it's recommended to reach out to multiple suppliers, compare their offerings, and request quotations based on your specific requirements. This will help you determine the most suitable CNC plasma cutting machine that meets your needs and budget in India.

#CNC plasma cutting machine in India#CNC plasma cutting machine#CNC Plasma cutting machine manufacturer

1 note

·

View note