#China PCB manufacturing

Explore tagged Tumblr posts

Text

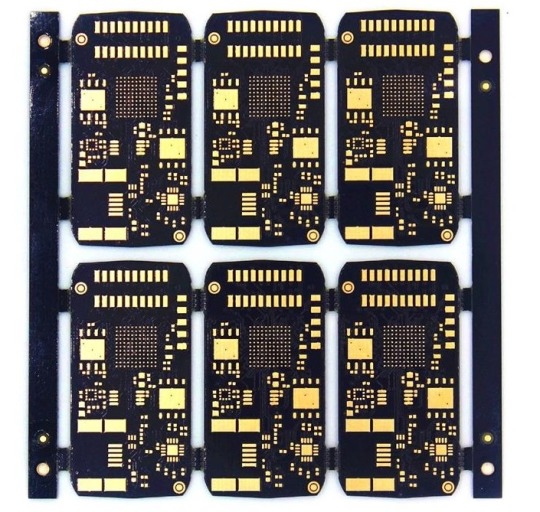

Test Development Process - Topscom Technology

Test development activities follow documented procedures. Processes have been refined from experiences to meet relevant standards such as ISO9001-2000, TL9000, EN46001 and FDA medical device standards. Development activity is focused on test requirement analysis and documentation in the form of a test specification. Design Verification activities included design reviews at key points during the design. Reviews include organized review by peers of the hardware, fixture, and software associated with this test development. The reviews and other key activities are called out in a project plan. As an ISO9001 China PCB manufacturing company, projects are not complete without a validation process. A Test Plan is written, approved, and implemented to fulfill the validation phase. https://is.gd/L0zV3L

PCB SMT assembly, China printed circuit board assembly, China PCB factory, China PCB fabrication, China PCB manufacturing, China PCB board, China PCB manufacturer, China PCB service, China PCB prototype, China PCB supplier, China PCB, PCB China, China PCB online, PCB board, China PCB assembly, PCBA China, China PCB design, PCB assembly, China PCB quote, PCBA, contract manufacturing China, China contract manufacturing, contract manufacturing, China electronic assembly, China electronic manufacturing, electronics manufacturing, electronic board manufacturers, China OEM manufacturing, OEM manufacturing, China cable wire harness assembly

0 notes

Text

Trusted China PCB Manufacturer for All Your Electronics Needs

Partner with a leading China PCB manufacturer for your printed circuit board solutions. We offer fast, precise manufacturing services at competitive prices. Our expert team handles everything from design to final assembly, ensuring top-quality products that meet your technical specifications. Fast turnaround and great customer service make us the go-to choice in the PCB industry.

0 notes

Text

Game Changers: How New Technologies Are Transforming PCB Manufacturing

Printed Circuit Boards (PCBs) are the unsung heroes behind every electronic device you use. From your smartphone to your gaming console, none of it would work without these intricate little boards that bring everything together. But as our gadgets get smarter and more advanced, the way PCB boards are made also has to evolve. New technologies are shaking up the world of PCB manufacturing, and these innovations are helping printed circuit board manufacturers stay ahead of the curve.

Let’s look into how these tech advancements are turning the game upside down!

AI and Machine Learning in PCB Manufacturing

Artificial Intelligence (AI) and Machine Learning (ML) aren’t just for science fiction movies anymore—they’re becoming crucial in making PCBs more efficient. By using AI, PCB manufacturers can quickly detect defects or potential issues in a board's design before they become costly mistakes.

Machine learning algorithms can analyze tons of data from past manufacturing processes. This helps manufacturers predict the most efficient way to produce boards and avoid problems down the line. This not only speeds up production but also improves the quality of the final product. So, if you’re dealing with a PCB board manufacturer in China, for example, you can be sure they are utilizing the latest AI technologies to produce the most reliable products.

The Role of 3D Printing

You’ve probably heard of 3D printing for creating toys or even medical devices, but it’s also making a big splash in the PCB world. With 3D printing, manufacturers can create complex PCB prototypes quickly and without the need for traditional tooling. This is a huge advantage, especially when companies need to test new designs quickly.

Imagine being able to print a whole circuit board layer by layer in just a few hours instead of waiting days or even weeks. That’s exactly what 3D printing offers. Plus, 3D printing allows for more complex designs that wouldn’t be possible with traditional methods. This gives designers the freedom to innovate without being held back by manufacturing limitations.

Advanced Materials for PCBs

When you think of PCBs, you probably imagine green boards with lots of little lines and tiny components. But there’s more to the story. New materials are being used to make these boards faster, more durable, and even more flexible.

For instance, flexible PCBs are made from materials that allow them to bend and fold. This is perfect for wearables like smartwatches or fitness trackers, where space is tight and the board needs to flex. High-frequency PCBs, made from advanced materials like ceramic-filled polymers, are also becoming more common. These materials allow boards to work efficiently at much higher speeds, which is essential for 5G technology and beyond.

Automation and Smart Manufacturing

It’s no secret that automation has taken over many industries, and PCB manufacturing is no exception. Robots, automated assembly lines, and smart manufacturing processes are becoming the norm. Printed circuit board manufacturers are investing in automation to reduce human error, lower costs, and increase production speeds.

In a PCB board manufacturer China facility, you might find robots assembling tiny components with incredible precision. These machines can work around the clock without breaks, producing a massive number of PCBs in less time. With the rise of the Internet of Things (IoT), these smart manufacturing systems can even communicate with each other, sharing data to make the entire process more efficient.

Laser Technology for Precision

When it comes to manufacturing PCBs, precision is everything. Even a tiny mistake can lead to a faulty board, which could cause an entire electronic device to fail. That’s why laser technology is becoming such an important tool for PCB manufacturers.

Lasers are being used to cut and etch PCBs with incredible accuracy. This allows manufacturers to create boards with more complex designs and tighter tolerances. Laser drilling, for example, makes it easier to create microvias (tiny holes that connect different layers of the PCB) with extreme precision. This is especially important for high-density boards where every millimeter counts.

Sustainability and Green Tech

Sustainability is a growing concern in every industry, and PCB manufacturing is no different. Thankfully, new technologies are helping manufacturers reduce waste and energy use. For example, some companies are using environmentally friendly materials that are easier to recycle.

Additionally, advancements in manufacturing techniques mean that less material is wasted during production. This is especially important as the demand for electronics continues to rise. By making the process greener, PCB manufacturers can help reduce their environmental footprint while still meeting the needs of modern tech.

The Last NOTE!

New technologies are revolutionizing the way PCBs are made. From AI and machine learning to advanced materials and 3D printing, these innovations are allowing printed circuit board manufacturers to create faster, more efficient, and more reliable products than ever before.

Whether you're looking at a PCB board manufacturer in China or anywhere else in the world, these advancements mean better devices for everyone. And with the pace of technology continuing to accelerate, who knows what the future holds for PCB manufacturing? One thing’s for sure—it’s an exciting time to be in the world of electronics!

0 notes

Text

Best 5 Main Reasons to Companion With a PCB Manufacturer in China

Think of a world where your electronic devices business flourishes on minimized creation prices, cutting-edge innovation, and lightning-fast turnaround opportunities. You are actually not simply dreaming- this is the truth awaiting you in China, where partnering along with a PCB manufacturer may be a game-changer. Along with work and product prices considerably lower than in Western side nations, you'll be actually in a far better placement to contend in the international market. However that's only the beginning. As you check out the benefits of partnering with a Mandarin PCB supplier, you'll find much more perks that can easily thrust your business to the next amount- and we'll take a deeper consider all of them next off.

Lessened Creation Costs

When you companion with a PCB supplier in China, you may considerably minimize your manufacturing expenses. This is actually due to the fact that pcb board manufacturing in China delivers reduced work and material expenses reviewed to various other countries. Consequently, you can anticipate notable discounts on your total production expenses. By partnering with a pcb board vendor in China, you can likewise take benefit of economies of scale, which can additionally reduce your prices. A pcb board supplier in China can easily offer you with high-quality printed circuit board at a lower cost than a maker in various other countries. This is actually due to the fact that China possesses a well-established pcb board production field with a lot of vendors and producers. This competition drives down prices, creating it feasible for you to acquire top notch pcb boards at a reduced expense.

Accessibility to Advanced Innovation

Partnering with a PCB producer in China can easily save you money on production costs, yet that's just one benefit. You'll additionally gain accessibility to advanced technology that may be also expensive to execute in-house. China has invested heavily in cultivating its own electronics creating capacities, and this has triggered the creation of sophisticated PCB manufacturing centers. By partnering with a Chinese PCB maker, you can use this proficiency and create premium PCBs that meet your certain requirements. You'll have accessibility to sophisticated modern technologies such as high-frequency PCB manufacturing, and the potential to make complicated PCBs with precision. For instance, if you require a hitech ceramic PCB for a high-frequency application, a Mandarin ceramic pcb manufacturer can easily deliver the necessary skills and tools.

Swift Turn-around Moments Ensured

Many thanks to China's strong electronics manufacturing structure, you can expect prompt turnaround opportunities from a PCB supplier in China. This enables you to quickly relocate your products from the concept period to assembly-line production, giving you an one-upmanship in the market. A dual sided pcb producer in China can usually create a hitech dual sided pcb board in a matter of times, certainly not weeks. China's very dependable logistics and transportation systems also play a pivotal duty in making sure swift turnaround times. As a double sided pcb distributor, a Chinese maker can promptly ship your order to any component of the world. This reduces lead times and permits you to fulfill limited deadlines. Through partnering with a double sided pcb provider in China, you may improve your development procedure and obtain your items to market a lot faster.

Top Quality PCBs at Scale

Rapid turn-around opportunities are actually simply one aspect of a productive PCB production process. When partnering with a PCB maker in China, you additionally would like to promise that the boards are actually of premium quality, whether you're ordering a small set or even a large-scale manufacturing run. A trustworthy ceramic pcb supplier or aluminum pcb supplier in China may offer you along with hitech ceramic pcb panels that fulfill your certain requirements. For complicated designs, a hitech double side pcb may be needed, and a Mandarin PCB supplier can easily supply this capability. They are going to make use of innovative devices and manufacturing techniques to produce high-grade panels along with specific coating placement and enrollment. Tip right into the future of electronics with Hitech double sided pcb board; look into the benefits of utilization innovative innovation to accomplish premium efficiency and reliability in each your electronic tasks.

Streamlined International Logistics

When it pertains to manufacturing and shipping PCBs internationally, going across intricate coordinations can easily be a major hurdle. You require a PCB manufacturer that can simplify worldwide coordinations, guaranteeing your items, like hi-tech light weight aluminum PCBs, light weight aluminum PCBs, LED PCBs, dual side PCBs, and ceramic PCB panels, reach your clients efficiently. A Chinese PCB manufacturer can easily enhance your coordinations through leveraging its own substantial system of delivering partners and warehouses. This allows you to use reputable connections and take advantage of discounted prices, lessening your freight costs. Furthermore, a neighborhood supplier can easily browse the difficulties of Mandarin customs and laws, ensuring that your products crystal clear custom-mades rapidly and uncreative.

Closure

By partnering along with a PCB producer in China, you'll access to the door to a planet of benefits that may drive your business ahead. Imagine your production prices plunging like a rock in water, maximizing sources to sustain technology and growth. Along with China's competence within your reaches, you'll be actually positioned to utilize on the newest innovations and put out the market with high-quality PCBs - the property blocks of a prosperous electronic devices business.

3F, Bldg B5, Zhimeihuizhi Industrial Park

FuYong, Bao'an Dist. Shenzhen, GuangDong, China

+86-755-29630063

0 notes

Text

Flexible rigid PCB board

Rigid Flex PCB boards are a combination of both rigid and flex circuits serving the purpose of each. High precision, substantial reduction of interconnects, and the freedom of packaging geometry make these boards a right match for the medical, military, and aerospace industries. These boards provide better quality control and higher component density and are designed to fit in hard-to-reach places.

The demand for portable electronic circuits is increasing every day. To blend both rigid and flex circuits into a single package, designers require cost-effective solutions that fill in the gap for using both rigid and flex circuits separately.

0 notes

Video

youtube

Flexible rigid PCB board

Rigid Flex PCB boards are a combination of both rigid and flex circuits serving the purpose of each. High precision, substantial reduction of interconnects, and the freedom of packaging geometry make these boards a right match for the medical, military, and aerospace industries. These boards provide better quality control and higher component density and are designed to fit in hard-to-reach places.

The demand for portable electronic circuits is increasing every day. To blend both rigid and flex circuits into a single package, designers require cost-effective solutions that fill in the gap for using both rigid and flex circuits separately.

0 notes

Text

PCB China

China is a major hub for PCB (Printed Circuit Board) manufacturing and assembly due to its vast electronics industry and competitive production capabilities. Many companies in China offer PCB fabrication and assembly services, providing a wide range of options for both domestic and international customers. It's important to research and select a reputable PCB manufacturer in China to ensure quality and reliability.

Visit Now: https://sqpcb.com/

0 notes

Text

Explore Viasion's blog to find the top 15 PCB manufacturers in China. Discover reliable partners for quality electronic solutions with our comprehensive guide. In this article, we will talk about the top 15 PCB manufacturers in China and share with you their websites, brief introduction, the latest sales revenue, years in business, capabilities, advantages, etc.

0 notes

Text

Carbide corn endmill router

#pcb #fiberglass #carbonfibre #epoxy #circuitboard #sd #tooldistributor #cnc #facemill #groove #holemill #madeinchina #quality #enginering #wholesale #buy #manufacturer #factory

#carbide#metalwork#tool#engineer#china#distributor#2023#merry xmas#thanksgiving#pcb#pcb manufacturer#carbon fiber#fiberglass

0 notes

Text

Seeking High-Quality, Cost-Effective High Density PCBs from a Reliable Chinese Supplier?

Look no further than XPCB Limited, your trusted partner for cutting-edge HDI PCB solutions. We offer a comprehensive range of HDI PCB manufacturing services, from prototyping to mass production, catering to diverse industries, including consumer electronics, automotive, medical devices, and telecommunications. Our state-of-the-art facilities, coupled with our team of experienced engineers, ensure the delivery of PCBs that meet the highest international standards. Our commitment to quality, efficiency, and customer satisfaction has earned us a reputation as a leading HDI PCB manufacturer in China.

0 notes

Text

Excellence Unleashed: Unrivaled PCB Manufacturer in China

Top-quality PCB manufacturing services from China's leading manufacturer. Get precision-engineered circuit boards for your electronic projects. Fast turnaround, competitive prices, and reliable delivery. Contact PCB Manufacturer in China today for all your PCB needs! Visit our site: https://www.readapcb.com/

#PCB Manufacturer in China#PCB manufacturing in China#pcb quick prototype#LED PCB manufacturer#PCB assembly in China#Aluminum pcb manufacturer#PCB design in China#HDI PCB manufacturer#Multilayer PCB manufacturing#PCBA manufacturing in China

0 notes

Text

Plastic injection Molding & Professional China PCB Manufacturing Supplier - Topscom

Topscom's plastic molding capabilities allow for the manufacturing of complex forms, components and enclosures. Our engineers are always available to advise on design and performance considerations to ensure quality, compliance and manufacturability. One of China's leading plastic molding companies, customers around the world trust Topscom for our contract manufacturing and plastic injection molding services. Our entire operation is designed to deliver strict compliance and unmatched quality, with on-going training on the latest technologies and equipment for efficiency, accuracy and value. Customers often rely on Topscom's expert engineering services, which provide design assistance as well as quality oversight. From molding structure, plastic material selection to detailed processes, the Topscom team works to ensure our plastic molded parts provide reliable performance in the final application. https://is.gd/ItuaBp

PCB SMT assembly, China printed circuit board assembly, China PCB factory, China PCB fabrication, China PCB manufacturing, China PCB board, China PCB manufacturer, China PCB service, China PCB prototype, China PCB supplier, China PCB, PCB China, China PCB online, PCB board, China PCB assembly, PCBA China, China PCB design, PCB assembly, China PCB quote, PCBA, contract manufacturing China, China contract manufacturing, contract manufacturing, China electronic assembly, China electronic manufacturing, electronics manufacturing, electronic board manufacturers, China OEM manufacturing, OEM manufacturing, China cable wire harness assembly

0 notes

Text

Unveiling Excellence: The Journey of a China PCB Manufacturer

Join us for an insightful look into the life of a China PCB manufacturer. This activity highlights the competitive edge and global influence of Chinese manufacturers in the PCB industry. Learn about their advanced techniques, sustainable practices, and commitment to innovation that set them apart on the world stage.

0 notes

Video

youtube

flex pcb fabrication 2023 3

#youtube#flex.pcb.fabrication.2023.3.mp4 single layer and double layer flexible flex PCB manufacturer fast flex prototype shenzhen China antennaIC ca

0 notes

Text

Choosing a Vendor for Outsourcing PCB Prototype Assembly

You may either construct the printed circuit board (PCB) prototype yourself or contract out its production to a company that specializes in PCB prototype assembly if you are creating a product and require a rogers PCB prototype. However, creating a PCB prototype in-house would need a PCB manufacturing and assembly facility, which would not be cost-effective if used primarily for extremely limited production runs like PCB prototypes. Subcontracting with a supplier who specializes in producing prototype PCBs makes more commercial sense. The following are the main recommendations for choosing a vendor to contract out prototype PCB fabrication work:

Reduce Your Costs

Making a large batch of PCBs is typically less expensive than making a small batch. Prototype PCBs are nonetheless often made in modest numbers since the circuit architecture is still being improved. To keep the overall cost of producing short runs of PCBs very low, a vendor that specializes in PCB assembly can reduce the expenses of assembly setup and distribute the cost of production by sharing the production task among numerous clients.

Lead Periods

Make sure you are aware of the elements that affect the lead time when picking a vendor to outsource your PCB assembly. There will be fewer clients that have the same criteria as your PCB design, thus it will take longer for the vendor to arrange your production run if your rogers PCB China design includes uncommon materials or measurements (such as thicknesses). Depending on the desired lead time, an online quotation system will adjust the quote's price.

Services for Design and File Formats When choosing a rogers PCB manufacturer, the file types you utilize for your electronic circuit designs matter. If you use different file formats, be sure the vendor can deal with them. The majority of vendors utilize the Gerber format. Due to its technical skills and internal experience, a PCB assembly firm that also provides design services in addition to contract manufacturing services is the best option for handling any issues that may arise during pre-assembly.

Follow our Facebook and Twitter for more information about our product.

0 notes

Text

latest Freddie DeBoer seems odd. It's very focused on a sort of consumer-facing understanding of technology for a lot of its runtime. He's not wrong that the changes are smaller than they were in the 1800's but like. That's the low hanging fruit, we all know this, the jump from "not having trains" to "having trains" beats almost any improvement in "trains"

A major change technology has brought to the modern world imo is heavily streamlined manufacturing all across the industrial stack.

If you read like, Bunie Huang's Made in China blog series, in the early 2000's getting a piece of technology made required enormous in-person investment of time and effort working with your manufacturing teams across a pretty broad number of suppliers and industries, you had to get PCB's made, components sourced, moulds designed and set up for injection.

I know people manufacturing small to medium run commercial and industrial electronics, and I did that at my last job. You order machine populated PCB's from your favourite Chinese PCB solutions provider over a web form. If you need ten thousand buttons, you can get that delivered with three emails. Hell, if you want a custom genome to use for some experimental bioreactor, there's multiple competing suppliers who will mail you plasmids that you can customise from online templates and you don't even have to talk to anyone.

And that's just mass manufacturing. If you're making a few thousand of some high end medical equipment, or still in the development phase of design, you can order a titanium laser print to be delivered by the end of the week, or run off a dozen prototypes on your company's fleet of printers using body safe plastics.

Consumer needs don't change much because people are people, we have limited capacity to need things and do things. I've long said that no human can digest more than 50Mbps of media in real time, really. One home cook can only economise their movements so much. A food processor and a pressure cooker can save you some time but the solution to"I want to spend less time cooking at home" will eventually become "don't cook at home, lean on industrial manufacturing of food" and that's fine. There's only so much tech can improve your individual experience before you become the bottleneck.

Faster computers sure, means you can edit video on your phone a little quicker (also hey people ARE editing video on their phone, despite what this blog post says) but it also means Netflix can serve their 4 Petabytes of video library at 400+Gbps from a single server occupying less than 50 liters of space.

It seems disingenuous to act like consumer products feeling stagnant means technology is stagnant.

21 notes

·

View notes