#Chemical Plant Contractors

Explore tagged Tumblr posts

Text

Are you searching for best Steel Tubes in UAE? Look no further! TradersFind offers a comprehensive list of companies providing top-quality steel tubes. Explore now and get the best value for your needs.

#Chemical Plant#Chemical Plant Companies#Chemical Plant Companies in UAE#Chemical Plant in UAE#Chemical Plant Consultants#Chemical Plant Contractors#Chemical Industry Plant#chemical plant operator#Industrial Chemical Plant#List of Chemical Plants

0 notes

Text

Batman: The Animated Series - Paper Cut-Out Portraits and Profiles

Jack Napier

A ruthless and thoroughly cold-blooded criminal, Jack Napier joined Sal Valestra’s criminal organization and quite quickly became the gangster’s premier assassin. Even these hardened mobsters were given pause by Napier’s sadism and sociopathic blood-lust. Nonetheless, he was a highly effective enforcer who Valestra turned to with his most important jobs.

One of Napier’s last assignments for Valestra saw him traveling to Europe where he tracked down and murdered Carl Beaumont, a businessman who had fled the States after embezzling funds. After this Napier began working as an independent contractor.

Some years later, Napier led a job to loot the Axis Chemical plant. This was shortly after Batman had become active in Gotham City. The Dark Knight broke up the robbery and, in the ensuing fracas, Napier fell into a vat of strange chemicals.

He was believed to have perished but managed to survive. Yet exposure to these chemicals turned his skin chalk white and his hair green. It also unhinged his already tenuous grip on sanity, releasing unto the world one of the most dangers villains of them all. Jack Napier had died, but in his place The Joker had been born.

Napier did not have any lines of dialogue in his appearance in the animated feature ‘Batman: The Mask of The Phantasm.’ Mark Hamill voiced the villain in his subsequent appearances as The Joker.

#batman the animated series#Batman The Mask of The Phantasm#Batman#Joker#cut-out#paper art#Mark Hamill#DCAU

33 notes

·

View notes

Text

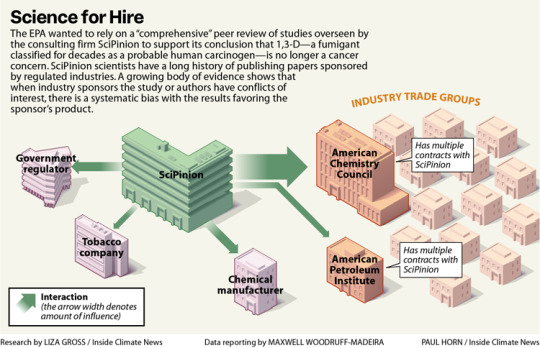

Note that the studies that were released by companies affiliated with polluters happened in 2019, during the trump administration.

Excerpt from this story from Inside Climate News:

On a Southern California spring morning in 1973, a tanker truck driver jackknifed his rig and dumped the agricultural fumigant he was transporting onto a city street. A Los Angeles Fire Department emergency response team spent four hours cleaning up the chemical, 1,3-dichloropropene, or 1,3-D, a fumigant sold as Telone that farmers use to kill nematodes and other soil-dwelling organisms before planting.

Seven years after the spill, two emergency responders developed the same rare, aggressive blood cancer—histiocytic lymphoma—and died within two months of each other. In 1975, a farmer who’d accidentally exposed himself to 1,3-D repeatedly through a broken hose was diagnosed with another blood cancer, leukemia, and died the next year.

Within a decade of the men’s deaths, described as case studies in JAMA Internal Medicine, the National Toxicology Program, or NTP, reported “clear evidence” that 1,3-D causes cancer in both rats and mice. The finding led the U.S. Environmental Protection Agency to classify the chemical as “likely to be carcinogenic to humans” the same year, 1985. So it wasn’t a surprise when researchers at the University of California, Los Angeles reported in 2003 that Californians who’d lived at least two decades in areas with the highest applications of 1,3-D faced a heightened risk of dying from pancreatic cancer.

Yet EPA’s Office of Pesticide Programs’ Cancer Assessment Review Committee, or CARC, concluded in 2019 that 1,3-D—originally embraced by tobacco companies for its unparalleled ability to kill anything in soil that might harm their plants—isn’t likely to cause cancer after all.

In doing so, EPA, whose mission is to protect human health and the environment, rejected the human evidence, calling the UCLA study “low quality.” It also dismissed the authoritative NTP study and studies in lab animals that documented 1,3-D’s ability to damage DNA, a quintessential hallmark of cancer.

Instead, EPA’s CARC relied on studies provided by Dow AgroSciences (now called Corteva), the primary manufacturer of 1,3-D, and proposed a review of evidence linking the fumigant to cancer by SciPinion, a consulting firm hired by Dow, as an external peer review of its work. The decision to entrust external review to a Dow contractor has drawn repeated criticism, including from the agency’s watchdog, the Office of Inspector General, or OIG.

���During EPA’s search of the open literature, a comprehensive third-party peer review of the cancer weight-of-evidence assessment that considered toxicokinetics, genotoxicity and carcinogenicity data for 1,3-D was conducted and published in 2020 by SciPinion,” said agency spokesperson Timothy Carroll. EPA argued that the SciPinion review satisfied the criteria for an external review, Carroll said, and that another panel would have arrived at the same conclusion, given the specialized expertise required.

The OIG had recommended EPA conduct an external peer review of its 1,3-D cancer risk assessment in a 2022 report that outlined several problems with the agency’s process. An external review, the OIG said, requires “independence from the regulated business,” again noting the deficiency in a new report released in early August.

The scientists who run SciPinion have long consulted for manufacturers of harmful products, often publishing studies that deploy computer models to question the need for more protective health standards.

4 notes

·

View notes

Text

MS Blind Flange at Lowest Price in India

In industrial systems, MS Blind Flanges play a crucial role in closing off pipe ends, ensuring safety and system efficiency. Udhhyog offers high-quality MS Blind Flanges at the lowest prices in India. Whether you're a contractor or an industry professional, we make purchasing flanges more affordable and efficient.

Benefits of MS Blind Flange

An MS Blind Flange (Mild Steel) is renowned for its versatility and affordability, making it suitable for various industrial applications. Here’s why it’s a popular choice:

Durable & Cost-Effective: MS Blind Flanges are sturdy, offering durability at competitive pricing.

Corrosion Resistance: With the right coating, these flanges perform well in demanding environments.

Easy to Install: Mild steel flanges are lightweight, making installation and maintenance easier.

Lowest Price Guarantee on MS Blind Flange

Udhhyog is committed to providing MS Blind Flanges at the lowest price without compromising on quality. As a leading supplier and manufacturer in India, we ensure that our customers get the best value. Browse our offerings and Buy MS Blind Flange at the Lowest Price with ease.

Applications of MS Blind Flanges

MS Blind Flanges are widely used in industries that require efficient flow control and safety:

Water Treatment Plants

Oil and Gas Refineries

Chemical Processing

Shipbuilding

The adaptability of these flanges across different environments makes them an essential component in many industrial systems.

Why Choose Udhhyog for MS Blind Flanges?

Competitive Prices: We offer the best rates on MS Blind Flanges, ideal for bulk orders.

Fast Delivery: Timely delivery across India ensures your projects run smoothly.

Quality Assurance: All our products meet high standards, ensuring reliability and performance.

Ready to make a purchase? Buy MS Blind Flange at the Lowest Price from Udhhyog and experience unmatched service and quality.

#MSBlindFlange#LowestPrice#BuyNow#IndustrialSupplies#Udhhyog#FlangeSupplier#DelhiSuppliers#BulkOrders#MildSteelFlange

2 notes

·

View notes

Text

EPOXY FLOOR GRINDING WORKS

Manycon Saudi is one of the best Epoxy Floor Grinding Contractors in Saudi Arabia & all GCC & India

In Saudi Arabia, Manycon Contracting Company offers professional epoxy floor coating application services in addition to a variety of other concrete flooring services for clients throughout Qatar, Saudi Arabia and India. Our flooring services epoxy floor paint application, concrete polishing, shot blasting and concrete grinding, concrete stain application, flooring and adhesive removal.. Our epoxy floor coating and concrete flooring services are ideal for commercial buildings and industrial plants.

The following are some of the main types of buildings, which would benefit from our epoxy coating and floor finishing services.

Aircraft Hangars

Chemical Plants

Manufacturing Plants

Warehouses & Distribution Facilities

Laboratories

Hospitals

Commercial and Residential Garages

Showrooms

Commercial Kitchens

Office Buildings

Retail Spaces & Mall

Athletic Facilities

2 notes

·

View notes

Note

Please tell me about your superhero au IMMEDIATELY 🙏

I went to sleep right after I posted that so this was great to wake up to but YES OKAY!!

So powers are split up into two groups: psychic and physical, the vast majority of powers being classified as physical. Psychic powers are anything mental based ie conjuring items out of nothing, telepathy, ect whereas physical is anything that affects only the physical world so enhanced strength, flight, or any type of matter manipulation. The psychic to physical ratio is about 1<5, again the vast majority of ability users being physical.

There are hero agencies and then teams within those agencies. To operate as a hero you need a team, and for a team you need to work under an agency. There are some loopholes and permits but the easiest and most accepted way to to get hired by an agency and then join a team within it. Most heros essentially work as contractors, usually hired by the city but can be hired by individuals. Civilian hires mostly function as glorified PI work and tend not to pay as well so most successful heros avoid that unless they're desperate.

Dream has a team of 3 people, Dream, Sapnap, George, with only one of them (Sapnap) having physical powers. That fact alone makes them a very unique team considering most agencies only have a few psychics in total let alone several on one team. Dream works under Bad's agency Badlands, which is the largest agency in the city. Dream Team is the most successful team under that agency, and Quackity and Karl will tag along as essentially per diem heros. Sam also works with this agency but usually behind the scenes tech work. He built almost everyone's gear.

Things really start to take off story wise when they get hired to investigate a robbery of a chemical plant. They locate a warehouse where the suspects are hiding and jump in to kick some ass, where they run into another hero team, headed up by Punz.

Punz, who before this has only worked alone, is a old friend of Dream's and co who just kinda drifted away from everyone and turned more into doing solo work. He's definitely more into the hero work for the pay than helping people, but he didn't like the idea of signing onto an agency. He worked alone for years until he ran into a dry spell and needed more consistent work. This is where he ended up teaming up with independent hero duo Tina and Foolish to form a temporary team to seem more credible and get some more jobs flowing in. They did one of those afformentioned loopholes and got a temporary permit, so they aren't signed onto any agency. Foolish and Tina have worked together for about 6 years and Punz has been with them for around 2 months. They, unknowingly, get hired for the same job as the Dream team and have an MCU style meetup where they fight each other until a Dream and co recognize Punz and Spiderman point at each other.

This kick-starts the whole story, and they end up working together to solve the case and hopefully not die! Foolish and Tina have wanted to sign with an agency for awhile and this just might be there chance, Punz is looking for this big payday and hopefully get his name on the map, and for Dream, Sapnap, and George this is just another day on the job but who knows if it'll stay this way!

(This post is really long so I'll probably make another where I talk about other hero teams, everyone's powers, and character's backstory. But yeah, while I want the interpersonal conflict I also want it to be toned down enough that everyone can be friends and so no one is the villain. Self indulgent but I think we all deserve that now and then ! Main villain is going to be the crimson [the egg] so it doesn't feel like I'm just picking a dsmp character I hate and making them evil. Very very excited for this!!)

#dsmp au#dreblr#c!dream#c!foolish#c!punz#dsmp#ask#Charlie my beloved 🫶🫶🫶 ty for indulging me#root talks#superhero au

22 notes

·

View notes

Text

The Labor Department said Friday that investigators found Packers Sanitation Services Inc. had employed more than 100 minors at 13 meat processing facilities across eight states, and that the children were cleaning dangerous industrial equipment using hazardous chemicals.

Officials said they found at least three children had been injured while working for the company, known as PSSI. The equipment they were cleaning included “back saws, brisket saws and head splitters,” according to the Labor Department.

Packers Sanitation agreed to pay $1.5 million in civil penalties as a result of the investigation, the agency said.

The probe began last year following complaints made involving plants in Minnesota and Nebraska owned by meatpacking giant JBS and the poultry processor Turkey Valley Farms. PSSI serves as a contractor for meat processors.

Jessica Looman, head of the Labor Department’s wage and hour division, called the child labor findings part of a “corporate-wide failure” at the company.

“These children should never have been employed in meatpacking plants,” Looman said.

This is a developing story. Please check back for updates.

10 notes

·

View notes

Text

:O an actual post from me! I wanted to give my (fully unwarranted and outsider) opinion on the response to the Ohio derailment. Of course, this is all from the experience and perspective of a hazmat technician who hasn't dealt with large scale environmental disasters like this.

Yes, it's scary. Yes, it's dangerous. Norfolk railroad didn't have the *best* response they could've, but in a real life situation nothing ever goes to plan. The one thing they did right is immediate notification of the EPA.

Now, on to current events. Vinyl chloride is an incredibly dangerous chemical, with the only good form of long distance transportation being by train. I cannot state anything about the status of the safety mechanisms on the rail car, however in a derailment it usually doesn't matter as the car gets punctured anyway. Safety wise, the TLV (Threshold Limit Value) is the acceptable value for continual exposure to a worker over an eight hour period is 1 ppm (part per million). A part per million can be equated to a single drop in 10 gallons of water, this is a very low TLV. OSHA also lists their own values, called PEL (permissible exposure limit), which is 1 ppm for vinyl chloride. Of course, these values are weighted for a chemical worker who is exposed 5 days a week for 8 hours a day. During an environmental disaster the short term exposure levels may be set higher based on recovery needs and other factors (such as being outside in an open area). Most of the other chemicals are toxic only with skin contact, however they are miscible in water.

I know there's a lot of worry about the water supply. The inlets and outlets of all water treatment plants, water inflows, etc are constantly monitored (on average a reading is taken every 2 seconds, 24/7/365, with automated systems to shutdown inflows if certain chemical concentrations are exceeded). These chemicals will most likely flow downstream and join the multitude of other chemicals dissolved in the water from leaking ship tanks, shipyards, military sites, etc. I don't forsee any long-term effects to the water supply after the initial bloom passes downstream.

The soil does need to be removed and remediated, and I believe the EPA is investigating why Norfolk's cleanup contractor didn't do that. The EPA is on your side frens, their number one priority is to keep you safe. They are one of the few alphabet soup agencies that has no ulterior motives.

In short, yes this is scary. I understand those who don't want to return, I would be cautious as well. But this isn't the end of the world, the town isn't going to be destroyed. Within a few months the area should be completely back to normal. Modern chemical monitoring equipment is fantastic and allows for blanket networks of monitoring equipment that can detect chemicals down to parts per billion (1 drop of water in 10,000 gallons of water, the average swimming pool) and smaller.

Drink bottled water, reduce time outside, and monitor your physical health. You can worry yourself sick, literally, the brain is an incredible organ, and the placebo effect works incredibly well. The mayor himself lives two blocks away from the accident, this is going to get solved properly.

If you have any questions feel free to send an ask, I love talking about chemical safety and protecting the environment.

5 notes

·

View notes

Text

The place I left 2 jobs so was a chemical plant that literally blew up 4 months later. The most recent one was a NASA contractor that's just begging to fold. But it's only been a month. So we're still waiting...

38K notes

·

View notes

Text

Top Benefits of Professional Industrial Line Marking Services

Industrial line marking is one thing that keeps workplaces clean, efficient, and safe, especially industrial plants, warehouses, parking lots, and production facilities. From defining pathways to marking hazardous zones and organizing storage areas, precise and resilient line markings are compulsory for smooth-running operations. Truthfully, not all companies would do the line marking in-house; professional industrial line marking services have many advantages for businesses beyond just painting. Let's find out the top benefits of hiring experts in fulfilling your industrial line marking needs.

Enhanced Workplace Safety In the industrial environment, safety is always the first priority. Professional line marking ensures each of the pathways, working zones, and hazardous areas are marked clearly and accurately, thus avoiding any unwanted accidents. High-visibility markings, provided through Industrial Line Marking, will keep staff, visitors, and contractors safe within the facility by circumventing restricted or hazardous areas. For instance, pedestrian walkway markings and vehicle lane markings in the warehouse minimize the likelihood of collision. Vibrant-colored zones are observed around heavy machinery to mark zones that are off-limits to workers for safety reasons.

Compliance with Regulations Industrial facilities fall within the umbrella of a myriad of health and safety regulations, such as OSHA in the United States or an equivalent governing body in your country, which requires lines to be marked indicating emergency exit and fire safety zones but also marking hazardous conditions. Professional line marking companies are well aware of such regulations and maintain your building according to all the regulations necessary. This not only prevents penalties and lawsuits but also provides a safer, more orderly place for workers and visitors.

Improved Productivity and Conditionality On-and-around indications are clear and professional line markings in an industrial facility; thereby marking specific areas for storage, machinery, vehicles, and pedestrians help in reducing bottlenecks during operations and interruptions in the industry.

Long Lasting Results Industrial settings are rough due to heavy machines, high walking patterns, and exposure to chemicals. Quick wear outs for DIY line marking or low-quality materials can lead to repainting frequencies and maintenance costs. The best material for professional industrial line markings is usually either thermoplastic or epoxy-based paint, both used in heavy industrial environments. It withstands every extreme condition meant to ruin it and maintains its visibility with little or no touch-ups and can be very bright for many years.

Custom Solutions for Unique Needs Each industrial facility has its own needs and operations. Professional line marking services can thus be tailored to meet your needs and requirements. Whether you want to mark up storage zones in a warehouse or design an intricate plan in a manufacturing unit, there are experts who can tailor their techniques and materials to suit your needs. What's more, professionals can add directional arrows, color-coded zones, or even company branding in the line markings to amplify not only functionality but also aesthetics. Such personalization may guarantee that your facility will be not only efficient but also visually coherent.

Time and Cost Efficiency Handling line marking in-house can be time consuming, disrupt operations, and yield suboptimal results that might have to be redone right away. Professional services are equipped with special equipment and experienced teams that ensure the job is done quicker and better. Working professionals on the job reduces downtime and ensures the tasks result in long-lasting, high-quality results. This, therefore, proves to be cost-effective in the long run. Businesses save on labor, materials, and future maintenance as the company does not need to think about their permanent line marking operations.

Expertise and Precision Professional line marking teams have years of experience and professional knowledge on the task. They understand the subtleties of an industrial space-from the proper materials to use with specific surfaces to the guarantee of accurate measurement and alignment. A marking service with such expertise would ensure that the markings are accurate, uniform, and according to what the facility may need and what regulatory authorities impose. Be it a rather complex layout or an uncomplicated parking lot, professionals have got the right skills and equipment to do the job flawlessly.

Aesthetic and Professional Look An industrial setting is no exception to the concept that first impressions do indeed matter. A dimly painted and unevenly marked line in the facility can give the impression of an organization that is not well-coordinated or serious about professionalism. Professional services ensure clean, sharp, high-quality work that improves the overall look of the space. For highly visible areas, this is particularly important when dealing with clients, contractors, or visitors. A well-marked facility shows that you are serious about professionalism and actually do care about safety and quality.

Conclusion Involving line marking services in your industry would invest you in numerous benefits, right from enhancing the workplace safety as well as regulatory compliance to the efficiency and aesthetic benefits. The professionals ensure that your line markings are functional, long-lasting, and visually appealing due to having durable materials, expert execution, and custom solutions. Hiring professional experience is a smart, cost-effective decision for businesses that demand high-quality and reliable industrial line marking. You may end up with a safer, more organized environment, hence creating an efficient setting when you place this at the very top of your priority list, which includes both precision and safety.

0 notes

Text

Are you searching for Chemical Plant in UAE? Look no further! TradersFind offers a comprehensive list of Chemical Plant Companies providing top-notch chemical plant operator. Explore now and get the best value for your needs.

#Stainless Steel Tube#stainless steel tube in uae#stainless steel tube manufacturers#stainless steel tube manufacturers in uae#stainless steel tube suppliers#stainless steel tube suppliers in uae#seamless stainless steel tubes#stainless steel square tube#stainless steel tube distributors#u shape stainless steel tube#Chemical Plant#Chemical Plant Companies#Chemical Plant Companies in UAE#Chemical Plant in UAE#Chemical Plant Consultants#Chemical Plant Contractors#Chemical Industry Plant#chemical plant operator#Industrial Chemical Plant#List of Chemical Plants

0 notes

Text

Enhancing Your Property: Choosing the Right Concrete Company Near Southampton for New Driveways

A well-constructed driveway not only enhances the aesthetic appeal of your property but also adds significant value. For residents in Southampton, selecting a reputable concrete company near Southampton is crucial to ensure quality workmanship and durability. This comprehensive guide explores the importance of professional driveway installation, the benefits of concrete driveways, and provides insights into selecting the best service providers in the Southampton area.

1. Introduction to Driveway Installation

A driveway serves as the primary access point to your property, making its design and construction pivotal. Beyond functionality, a well-designed driveway contributes to the overall curb appeal and can significantly impact property value. In Southampton, where architectural styles vary, choosing a driveway that complements your home is essential.

2. Benefits of Concrete Driveways

Concrete driveways offer numerous advantages:

Durability: Concrete is known for its longevity and can withstand heavy loads without deteriorating.

Low Maintenance: Requires minimal upkeep compared to other materials.

Versatility: Available in various finishes and colors to match aesthetic preferences.

Cost-Effective: While the initial investment may be higher, the long-term benefits and minimal maintenance make it economical.

3. Selecting a Concrete Company Near Southampton

Choosing the right contractor is crucial for a successful driveway installation. Consider the following factors:

Experience: Opt for companies with a proven track record in driveway installations.

Reputation: Check customer reviews and testimonials.

Certifications: Ensure the company holds necessary licenses and certifications.

Portfolio: Review previous projects to assess quality and style.

4. Top Concrete Companies in Southampton

Here are some reputable concrete companies near Southampton:

2 Brothers Concrete & Pumping: Offers efficient concrete and pumping services in the south of England, based in Southampton.

Concrete247.com: Provides speedy ready-mix concrete delivery in Southampton and surrounding areas.

Mixamate: Specializes in mix-on-site concrete and screed services in Southampton.

South Coast Concrete: A leading supplier of ready-mix concrete throughout Portsmouth, Southampton, and Chichest

CEMEX Southampton Concrete Plant: Offers ready-mix concrete to businesses in the Southampton and wider Hampshire region.

5. Understanding the Driveway Installation Process

The installation of a concrete driveway involves several key steps:

Planning and Design: Assessing the area, determining dimensions, and selecting design elements.

Site Preparation: Excavating the area, ensuring proper drainage, and laying a stable sub-base.

Formwork Installation: Setting up wooden or metal forms to define the driveway's shape.

Pouring Concrete: Mixing and pouring concrete into the prepared forms.

Finishing: Smoothing the surface, adding textures or patterns, and allowing it to cure properly.

6. Maintenance Tips for Concrete Driveways

To prolong the lifespan of your concrete driveway:

Regular Cleaning: Remove debris and stains promptly.

Sealant Application: Apply a sealant every few years to protect against weathering.

Avoid De-icing Chemicals: Use sand instead of chemicals to prevent surface damage.

Address Cracks Promptly: Repair minor cracks to prevent them from expanding.

7. Cost Considerations for New Driveways in Southampton

Several factors influence the cost of installing a new driveway:

Size and Complexity: Larger or more intricate designs increase costs.

Material Quality: Higher-grade materials may have a higher upfront cost but offer better durability.

Labor Charges: Experienced contractors may charge more but ensure quality workmanship.

Additional Features: Incorporating elements like heating systems or decorative finishes will add to the overall expense.

8. Environmental Impact of Concrete Driveways

Concrete production has environmental implications due to CO₂ emissions. However, sustainable practices such as using recycled materials and implementing permeable concrete can mitigate some environmental concerns.

9. Alternative Materials for Driveways

While concrete is popular, other materials include:

Asphalt: Offers a smooth finish but may require more maintenance.

Gravel: Cost-effective but less durable.

Pavers: Provide aesthetic appeal with various design options.

Resin-Bound Surfaces: Combine durability with permeability and a range of color choices.

10. Legal and Planning Considerations (continued)

Consider Drainage Requirements: Ensure the driveway is compliant with regulations, such as Sustainable Urban Drainage Systems (SuDS), to prevent water runoff.

Consult Local Authorities: In some cases, altering access points to the highway may need council approval.

Shared Boundaries: If your driveway borders a neighbour’s property, consult them to avoid disputes.

12. Common Mistakes to Avoid When Installing a Driveway

Ignoring Proper Drainage: Poor drainage can lead to water pooling and structural damage.

Skipping Maintenance: Even durable materials like concrete require periodic care to remain in top condition.

Choosing the Cheapest Quote: Low costs may compromise quality; ensure a balance between affordability and workmanship.

Overlooking Local Climate Conditions: Materials should be selected based on Southampton’s mild, damp climate to ensure longevity.

13. Future Trends in Driveway Materials and Design

Eco-Friendly Materials: Permeable concrete and recycled aggregates are gaining popularity.

Smart Driveways: Features such as built-in heating systems to prevent ice formation.

Custom Designs: Increased demand for stamped concrete patterns and bespoke colour schemes.

Integration with Landscaping: Driveways are becoming part of cohesive outdoor designs, blending seamlessly with gardens and pathways.

14. FAQs

1. How do I choose the best concrete company near Southampton? Look for experience, verified reviews, and a strong portfolio of completed projects. Ensure the company offers clear communication and transparency in pricing.

2. How much does it cost to install new driveways in Southampton? The cost varies based on size, material, and design complexity. On average, concrete driveways in Southampton range from £50-£100 per square metre.

3. How long does it take to install a concrete driveway? Most installations take 1-2 weeks, including preparation, pouring, and curing time.

4. Are concrete driveways better than asphalt? Concrete driveways are more durable and require less maintenance than asphalt, although they have a higher initial cost.

5. Can I customise the design of my concrete driveway? Yes, concrete driveways can be tailored with stamped patterns, coloured finishes, and decorative borders to match your preferences.

15. Conclusion

Selecting a reputable concrete company near Southampton for your project ensures the longevity and aesthetic appeal of your driveway. With advancements in materials and techniques, homeowners can enjoy a durable, low-maintenance, and visually stunning addition to their property. Whether you’re considering new driveways in Southampton for a fresh look or increased functionality, investing in professional services will pay off in the long run.

0 notes

Text

Introduction: The Growing Importance of Sustainability in Cable Management

In today’s world, sustainability is more than just a buzzword—it's a crucial consideration across industries, from construction to telecommunications. As we strive for more environmentally friendly solutions, even the way we manage cables has evolved. Enter wire mesh cable trays, an innovative and eco-conscious alternative to traditional cable management systems. These trays are not only practical but also offer a variety of environmental benefits that make them a greener option for businesses, contractors, and building managers.

In this post, we’ll explore the environmental advantages of wire mesh cable trays and why they’re quickly becoming the preferred choice for those looking to reduce their carbon footprint and promote sustainability.

Wire Mesh Cable Tray

1. Made from Recyclable Materials

One of the most significant environmental benefits of wire mesh cable trays is that they are often made from recyclable materials, such as galvanized steel, aluminum, or stainless steel. These materials can be recycled at the end of their life cycle, minimizing waste and reducing the need for new raw materials.

Steel is the most commonly used material for wire mesh trays, and it's one of the most recycled metals globally. Choosing cable trays made from steel helps support a circular economy, where materials are reused and repurposed rather than discarded.

Aluminum is lightweight and highly recyclable, with a lower carbon footprint than many other metals, making it an excellent choice for environmentally-conscious cable management.

By selecting wire mesh trays made from these materials, companies can reduce their reliance on virgin resources and contribute to waste reduction efforts.

2. Energy Efficiency Through Better Airflow

Wire mesh cable trays feature an open design that allows for improved airflow around cables. This not only helps with cable cooling but also reduces the need for additional energy-consuming systems like fans or air conditioning to regulate temperature in cable-intensive environments such as data centers, factories, and industrial plants.

Natural cooling: The open, mesh design promotes natural airflow, helping prevent heat buildup around cables. This is especially important in areas where cables handle high power loads or heat-sensitive equipment, such as server rooms.

Reduced reliance on cooling systems: By maintaining optimal temperature conditions for cables, wire mesh trays can reduce the need for energy-intensive cooling solutions, resulting in lower energy consumption and a reduced carbon footprint.

3. Long-Lasting Durability Reduces Waste

Wire mesh cable trays are designed for durability. With proper installation and maintenance, they can last for many years, even in harsh environments. The robust materials used, like galvanized or stainless steel, are resistant to corrosion, wear, and physical damage, which translates to less frequent replacement and maintenance.

Reduced frequency of replacements: Because wire mesh trays last longer, businesses don’t need to replace them as often, leading to less material waste over time.

Resilient against environmental factors: Whether in outdoor settings or industrial environments with high humidity or chemicals, wire mesh trays can withstand conditions that might degrade other types of cable management systems.

This durability ensures that less waste is generated, making wire mesh trays a sustainable long-term investment.

Wire Basket Cable Tray

4. Lightweight Design Means Lower Transportation Impact

Wire mesh cable trays are generally much lighter than traditional solid cable trays made from concrete or heavy-duty steel. The lighter weight offers significant transportation benefits, including lower fuel consumption during shipping and handling.

Lower emissions during transport: Lighter trays reduce the overall weight of shipments, which translates to lower fuel consumption and fewer emissions associated with transport.

Fewer resources required: The manufacturing process for wire mesh trays uses fewer raw materials compared to solid trays, further reducing the environmental impact during production.

Choosing a lighter product like wire mesh cable trays contributes to an overall reduction in transportation-related carbon emissions.

Wire Cable Tray

5. Flexible and Easy to Install, Leading to Less Waste

Wire mesh cable trays are designed for flexibility, meaning they can be easily adjusted or reconfigured as needed. This ability to adapt to changing needs or layouts helps reduce waste associated with unnecessary installation of additional components or replacements.

Minimal cutting and fitting: The modular nature of wire mesh trays means that sections can be added or rearranged without needing to discard extra material. This reduces the likelihood of waste during installation or modifications.

Easy to modify: If an installation requires a change, it’s much easier to modify wire mesh trays compared to more rigid systems, preventing unnecessary material use.

This adaptability can save both time and resources, reducing the overall environmental footprint of a project.

6. Minimal Chemical Coatings and Paints

Many wire mesh cable trays are treated with galvanization (a zinc coating) or other simple finishes that protect against corrosion without the need for harmful chemical coatings or paints. Unlike other cable tray options, which may require toxic chemical treatments, wire mesh trays are designed to be environmentally friendly in both their production and end-of-life phases.

Fewer harmful chemicals: Since galvanized wire mesh trays are resistant to rust and corrosion naturally, there's no need for additional paints, coatings, or preservatives that may contain volatile organic compounds (VOCs) or other harmful substances.

Non-toxic finishes: The coatings used in wire mesh cable trays are typically non-toxic, posing fewer environmental hazards during production, use, and disposal.

This makes them a safer and more eco-conscious choice for projects in sensitive environments, such as hospitals, laboratories, or food production facilities.

7. Reduced Carbon Footprint Over Time

When you combine the energy savings, long-lasting durability, recyclability, and reduced waste of wire mesh cable trays, the result is a significant reduction in a project’s overall carbon footprint. By opting for these sustainable cable management systems, businesses can achieve greener, more energy-efficient solutions while supporting a circular economy.

SS Wire Mesh Cable Tray

Conclusion: Wire Mesh Cable Trays as a Greener Future for Cable Management

Wire mesh cable trays offer more than just functional cable management—they provide a sustainable alternative to traditional solutions, helping businesses reduce their environmental impact. From being made of recyclable materials to promoting energy efficiency and reducing waste, these trays are a greener, more efficient choice for managing cables in industrial, commercial, and residential projects.

As sustainability becomes an increasing priority for industries worldwide, the adoption of wire mesh cable trays can play a crucial role in creating more environmentally friendly systems. Whether you’re designing a new building, upgrading an existing installation, or managing an industrial plant, wire mesh cable trays offer the versatility, durability, and eco-conscious benefits that align with today’s green building standards.

0 notes

Text

Broad Application Range: Ebara Submersible Pumps

Ebara submersible pumps are renowned for their versatility across a broad range of applications, from residential water management to heavy-duty industrial and municipal projects. Their durable construction, energy-efficient design, and wide selection of models make them suitable for numerous water handling tasks. Whether it’s for clean water supply, wastewater treatment, irrigation, or flood control, Ebara pumps deliver reliable performance in diverse settings. This adaptability is a key benefit, enabling businesses, municipalities, and homeowners to find the right solution for virtually any water management need.

Key Applications for Ebara Submersible Pumps

Residential and Commercial Water Supply

Consistent Water Pressure and Flow: Ebara pumps support reliable water pressure and steady flow for residential complexes, high-rise buildings, and commercial properties.

Compact and Efficient Design: Ebara submersible pumps, such as the OPTIMA and 3 Series, are ideal for tight spaces, offering a compact and efficient solution for clean water supply and pressure boosting.

Wastewater and Sewage Management

Effective Waste Removal: Ebara’s submersible pumps are well-suited for sewage handling, offering clog-resistant impellers and the ability to handle solids, ideal for wastewater treatment facilities.

Municipal and Industrial Use: The DML and RIGHT series are specifically designed for heavy-duty wastewater applications, providing high flow rates and durable construction for municipal and industrial waste management.

Flood Control and Stormwater Management

Rapid Water Removal: For flood-prone areas, Ebara’s submersible pumps offer quick, effective water removal to protect properties and infrastructure.

Versatile Installation Options: Pumps like the DW series are ideal for both permanent installations and temporary, mobile setups, helping manage stormwater and prevent basement and garage flooding.

Agricultural Irrigation and Drainage

Reliable Water Supply for Crops: In agriculture, Ebara pumps provide essential water distribution for crop irrigation, ensuring efficient use of resources.

Drainage and Flood Control in Farmland: For areas susceptible to waterlogging, Ebara pumps help drain excess water, protecting soil health and crop yields.

Industrial Processing and Cooling Systems

Efficient Cooling Water Circulation: Industrial plants often use Ebara submersible pumps for circulating cooling water, vital for managing heat in manufacturing processes.

Chemical and Abrasion Resistance: With robust materials, these pumps handle abrasive fluids and harsh environments found in various industries, including mining and chemical processing.

Construction Dewatering

Site Preparation and Safety: In construction, Ebara’s submersible dewatering pumps remove accumulated groundwater and rainwater, ensuring safe and dry conditions for ongoing work.

Portability for Dynamic Environments: Models like the DW series offer easy transport and set-up, allowing contractors to move them between job sites as needed.

Aquaculture and Fish Farming

Maintaining Optimal Water Quality: Ebara pumps help circulate and aerate water in fish farming tanks and ponds, providing a healthy environment for aquatic life.

Efficient Waste Removal: These pumps also aid in removing waste and debris from tanks, supporting water quality and operational efficiency in aquaculture facilities.

Recreational Water Features and Fountains

Aesthetic and Functional Applications: Ebara pumps are commonly used in decorative fountains, ponds, and water features for both residential and commercial landscaping.

Quiet and Reliable Operation: With noise-reducing design and energy-efficient motors, these pumps operate smoothly, adding ambiance to outdoor areas without disruptions.

Benefits of Ebara Pumps for a Broad Range of Applications

High-Performance Efficiency Across Settings

Ebara submersible pumps are engineered for optimal energy efficiency, which translates to reduced operational costs across applications, from residential water supply to industrial processing.

Wide Variety of Models for Customized Solutions

With a diverse range of series—such as the DW, DML, RIGHT, and OPTIMA models—Ebara offers solutions tailored to the specific needs of each application, ensuring effective performance across a wide range of environments.

Durable, Long-Lasting Construction

Built with high-quality materials, Ebara pumps provide longevity and reliability, especially in demanding applications like construction, industrial processing, and wastewater treatment.

Low Maintenance Requirements

Ebara pumps are designed to require minimal maintenance, providing hassle-free operation and reducing downtime, which is crucial in applications where consistent performance is key.

Easy Installation and Versatile Setups

With flexible installation options, Ebara submersible pumps are easy to set up for both permanent and temporary applications, making them adaptable to changing project or environmental needs.

Environmentally Friendly and Energy-Conscious

Ebara’s focus on energy-efficient motors and designs helps users minimize environmental impact, supporting sustainable practices across a variety of sectors.

The broad application range of Ebara submersible pumps makes them a reliable choice for water management across multiple sectors. Their adaptability and durable design enable them to meet the needs of residential, commercial, agricultural, and industrial applications alike. Ebara’s commitment to performance and sustainability has resulted in a line of pumps that not only delivers reliable, efficient service but also supports users in optimizing water management, controlling costs, and reducing environmental impact across diverse industries. For more info contact Ebara Pump Suppliers in UAE or call us at +971 4 2522966.

0 notes

Text

Industrial Epoxy Flooring Contractors in Chennai - Sree Saravana

Industrial Epoxy Flooring Contractors in Chennai: The Ideal Solution for Heavy-Duty Environments

In industrial environments, the flooring system plays a critical role in ensuring smooth operations, safety, and durability. When it comes to choosing the right flooring for factories, warehouses, manufacturing units, or any other industrial setting, epoxy flooring has emerged as one of the most preferred options. In Chennai, a city known for its booming industrial sector, specialized industrial epoxy flooring contractors offer tailored solutions that provide long-lasting and high-performance floors to meet the unique demands of such spaces.

What is Industrial Epoxy Flooring?

Industrial epoxy flooring refers to a highly durable and resilient coating made from epoxy resins that are applied over concrete floors. This coating forms a hard, glossy surface that can withstand heavy traffic, chemical spills, extreme temperatures, and mechanical wear. Epoxy flooring systems in industrial settings are designed to handle the toughest conditions, providing an effective barrier that helps protect the underlying concrete while offering an easy-to-clean, seamless finish.

Why Choose Epoxy Flooring for Industrial Spaces?

Superior DurabilityIndustrial spaces often experience heavy foot traffic, machinery movement, and the constant wear and tear from operational activities. Epoxy flooring is renowned for its exceptional durability and strength. It can withstand the weight of heavy machinery, forklifts, and constant movement without cracking or showing signs of deterioration. This makes it an ideal choice for factories, warehouses, and assembly lines where the floor needs to endure constant stress.

Chemical and Stain ResistanceIn industrial environments, exposure to chemicals, oils, acids, and other harsh substances is a common concern. Epoxy floors are resistant to many chemicals, making them perfect for environments such as manufacturing plants, laboratories, and chemical storage areas. The non-porous surface prevents liquids and contaminants from seeping into the floor, ensuring that spills can be quickly cleaned up without damaging the surface.

Safety and Slip ResistanceSafety is a priority in industrial settings, and epoxy flooring offers enhanced safety features. Industrial epoxy flooring contractors in Chennai often apply slip-resistant additives to create a textured surface that reduces the risk of accidents, even in wet or oily conditions. This is crucial in high-traffic areas where slips and falls could lead to serious injuries.

Cost-Effective in the Long RunWhile the initial cost of epoxy flooring installation may be higher than traditional floor coverings, its long-term benefits far outweigh the initial investment. Epoxy floors require minimal maintenance, are highly resistant to damage, and have a long lifespan. The savings on repairs and replacements make epoxy flooring a cost-effective choice for industries.

Aesthetic Appeal and CustomizationWhile industrial flooring needs to be durable and practical, it doesn’t mean you have to compromise on appearance. Epoxy flooring offers a variety of colors, textures, and finishes that can be customized to suit the aesthetic requirements of your facility. Contractors in Chennai can create unique designs using decorative flakes or metallic pigments, giving your industrial space a clean, professional, and modern look.

Finding the Right Industrial Epoxy Flooring Contractor in Chennai

Choosing the right industrial epoxy flooring contractor is essential to ensure a successful installation and long-lasting results. Here are some important factors to consider:

Expertise and Experience: Look for contractors who specialize in industrial epoxy flooring systems and have experience working in similar environments. Experienced contractors will know the specific requirements of your industry, whether it's manufacturing, food processing, or warehousing.

Quality Materials: The quality of epoxy resin used plays a significant role in the performance and durability of the flooring. Reputable contractors in Chennai will use high-quality, industrial-grade epoxy that can withstand the rigors of your specific application.

Timeliness: Industrial facilities can’t afford prolonged downtimes during the flooring installation process. Choose a contractor who can complete the job on schedule with minimal disruption to your operations.

Maintenance and Aftercare: A good industrial epoxy flooring contractor should also offer ongoing maintenance services to ensure the floors continue to perform optimally over the years.

Conclusion

For industrial spaces in Chennai, epoxy flooring offers a durable, safe, and cost-effective flooring solution that meets the unique demands of high-traffic, heavy-duty environments. Whether you run a manufacturing unit, warehouse, or laboratory, industrial epoxy flooring provides unmatched resilience, resistance to chemicals, and an aesthetically pleasing finish that enhances the overall functionality of your space.

By working with experienced industrial epoxy flooring contractors in Chennai, you can ensure that your facility gets the best flooring system tailored to its needs, helping you maintain smooth operations while keeping maintenance costs low. If you’re looking to upgrade or install epoxy flooring in your industrial facility, reach out to a trusted contractor in Chennai today!

0 notes

Text

Exactly How Security Gloves Can Stop Injuries in the Workplace

Introduction

When you think about office safety and security, what comes to mind? Construction hats, safety and security goggles, or golf gloves possibly reflective vests? While all these things are essential, one item of safety equipment often takes a rear seat: safety gloves You leather work gloves might be stunned to learn just how vital these relatively basic tools can be in protecting against injuries throughout different job environments.

In this post, we'll dive deep right into the world of safety gloves We'll discover their value, kinds readily available on the market, and exactly how they can assist you stay clear of injuries while working. By the end of this read, you'll have a newfound admiration for these unhonored heroes of workplace safety.

Understanding the Importance of Safety And Security Gloves What Are Safety and security Gloves?

Safety handwear covers are protective handgear developed to minimize the danger of injury in various work settings. They are available in many products and designs gardening gloves customized to certain tasks-- be it building, food handling, or chemical direct exposure.

Why Are Safety and security Gloves Essential?

The human hands are unbelievably functional yet likewise rather prone. Whether you're lifting hefty objects or dealing with hazardous products, an absence of correct security can bring about serious injuries. This is where safety gloves action in as your initial line of defense.

Common Workplace Injuries Without Safety Gear

Without safety and security gloves, employees may face a number of dangers, consisting of:

Cuts and Lacerations: Sharp things can quickly create significant injuries. Chemical Burns: Exposure to hazardous substances without protection can bring about skin damage. Punctures: Tools and machinery parts can puncture skin otherwise appropriately shielded. Heat-Related Injuries: Hot surface areas or products can lead to burns.

Knowing these threats emphasizes why putting on safety handwear covers is non-negotiable!

How Safety and security Handwear covers Can Avoid Injuries in the Workplace The Function of Safety and security Handwear Covers in Injury Prevention

When it comes down to it, using safety gloves significantly lowers the possibilities of sustaining injuries at the workplace. They function as a barrier welding gloves between your skin and potential dangers-- consider them as your hand's individual bodyguard!

Different Sorts of Safety and security Gloves and Their Uses Cut-Resistant Gloves Ideal for industries entailing sharp devices or glass. Chemical-Resistant Gloves Perfect for labs or chemical plants where exposures are common. Heat-Resistant Gloves Designed for work that include high temperatures like welding. Electrical Protecting Gloves Essential for electrical contractors dealing with online wires. General Function Gloves Suitable for daily tasks that do not call for customized protection howe

0 notes