#Chemical Cleaning Pipe & Equipment

Explore tagged Tumblr posts

Text

https://jgbqatar.com/product/misting-system-overhead-fans/

Discover top-quality district cooling products distributors in Qatar with JGB Qatar. Offering a comprehensive range of efficient cooling solutions for your projects. Contact us now for reliable distribution and superior customer service.

#District Cooling Products Distributors in Qatar#Chemical Cleaning Solutions in Qatar#Electromechanical Equipment Suppliers in Qatar#Pipe Support Solutions in Qatar#Earthing and Lighting Protection System Dealers in Qatar#Hvac Equipment Suppliers in Qatar#Rock Wool Insulation Products Suppliers in Qatar#Ups Suppliers in Qatar#Water Purifier Suppliers in Qatar#Skylights for Home in Qatar#Valve Suppliers in Qatar#Best Selling Humidifiers in Qatar

0 notes

Text

Chemical Cleaning Pipe & Equipment

Leading Non-welded piping company supply non-welded piping systems, components, mechanically attached fitting and installation services to worldwide Visit here for more details: https://tube-mac.com/en/services/chemical-cleaning-pipe-equipment

1 note

·

View note

Text

Hormone disrupters are chemicals 🧪 that interfere with your body’s endocrine system, which regulates hormones. They can be found in a lot of every day products like:

Plastic bottles and food containers

Pesticides in agriculture

Cleaning supplies

Chemicals used for clothing

Personal care products like lotions, shampoos & makeup

❌ These are hormone disrupters found in common every day products that you should stay away from ❌

- Bisphenol A (BPA) (plastics and can liners)

- Phthalates (personal care products, fragrances, flexible plastics)

- Parabens (makeup & personal care products)

- Triclosan (antibacterial soaps and cleaning products)

- Polychlorinated Biphenyls (older electrical equipment and industrial products)

- Flame Retardants (furniture, textiles, electronics)

- Pesticides (agriculture)

- Perfluorinated Chemicals (stain resistant treatments, non-stick cookware)

- Dioxins (industrial processes, combustion byproducts)

- Lead (older paints, pipes)

- Dye chemicals (textiles and clothing)

- Water repellents (outdoor clothing, upholstery)

- Stain repellents (carpets, fabrics)

- Formaldehyde (wrinkle free and anti-shrink treatments for fabric)

- Mercury (fish, some thermometers, dental amalgams)

- Cadmium (batteries, some fertilizers)

- Atrazine (herbicides)

- Glyphosate (weed killers)

- Perchlorate (rocket fuel, fireworks, fertilizers)

- Arsenic (contaminated water, pesticides)

- Styrene (plastics, rubber, insulation materials)

- Phosphates (detergents, fertilizers)

- Nonylphenol ethoxylates (industrial detergents, cleaners)

- Organotins (PVC plastics, marine antifouling paints)

- Benzophenone (sunscreens, plastics)

- Octinoxate (sunscreens, makeup)

- 4 Methylbenzylidene camphor (sunscreens, makeup)

‼️ Exposure to these can lead to health issues like reproductive problems, developmental issues and cancer.

🌿 Needless to say, that in order to protect our hormones 🫶 it’s important to recognize these risks and take measures to reduce our exposure them.

91 notes

·

View notes

Text

Uh-Oh

The human formerly known as Davce (The Human), currently running under the moniker of Phalanges Mittens, who was, for staffing purposes a two-meter-tall marsupial lizard of no particular gender paused and took a step back to look at the hardware that was causing issues.

Phalanges looked over at the equipment cart, repurposed to be the office of Cat Fantastic, a small, iguana-sized Atrix, and technically Phalanges spouse adjacent partner.

"Doing OK, Cat?" he asked and got a cheery "Graak" back.

Garfield, an actual Atrix looked amused and asked her little guy the same. "Doing Ok, Un-Named?" and got a "Grak?" from her natural pouch where her little guy was riding.

"Nobody asks me if I'm OK." said Dave The Human, an Adult female Tsin.

"Should have got yourself a Little Guy." Garfield told her good buddy cheerfully.

"Ugh. They're too big to fit in a pocket and besides my pet rat would get jealous." Dave stated, and checked, for the twentieth time, the schematics of the lump of scheming machinery.

"What about that dude who nearly ate number 43?" suggested Phalanges, shining a light behind the input pipes.

Dave tried to recall them "Oh yeah... nah, they're nice but a bit thirsty. I'm not planning on a family yet." she said. "I need someone who's less desperate to..." she looked around at the other four all of whom were legally Atrix, the least sexually oriented species known to breathe oxygen.

Even Phalanges, who's genetically human had never shown any interest in sex. "... less desperate." she said. "But I think I need someone who gets me on a more... Tsin level? No offence"

Everyone paused to consider this, apart from Un-Named Male who was asleep again.

Dave was a Big Female: The klunky translation of a concept for the Tsin gender of "The most female type of female", which culturally also carried the suggestion of being the sort of person who's in charge of everyone else: "She who shouts at everyone to clean their claws".

Tsin have at least four main genders. At least one gender is capable of swapping naturally. Dave's at the far end of the Tsin gender spectrum, biologically at least, and interpersonal relationships are complex when one's bestie girl-friend might spend too much time hanging out with you and accidentally swap to male. On the other hand (of which, Dave has four) Dave's picked a male name from a species that has two broad categories for biological genders and still managed to make things weird.

Everyone took a moment to consider this as they stared at the hardware giving them issues.

The Waste Organic Matter/Biologicals from Living Environments Recycling unit was supposed to scavenge through any organic matter that ordinary people left behind, and crack the compounds down into base blocks that could then be used to build up any other chemicals or compounds via one of the bio-reactors. Soap for example.

On a space station, this sort stuff is considered useful, since nobody wants to be hip deep in garbage and leftover food.

"We need this thing's full name." said Phalanges thoughtfully.

"Wot?" said Dave and Garf did the rippling colour display that was equivalent.

"It's human hardware. It runs on human rules, so if we knew it's full name I could call it out and it'd know it was in trouble."

Dave and Garfield, who both had degrees in Human Stuff gave each other some pretty hilarious side eye.

Phalanges pulled up the pitch shifter for the rarely used translator, and said "Squeap sqk qk sqwp, what do you think you're doing?"

Dave, startled by the use of her real, full name dropped her tablet and cringed, scales all folding flat, and her big hands coming up over her head as she pulled her small hands out of her front pocket and covered her muzzle.

Garf stared in amusement, cheeks and forehead rippling opalescently. Cat Fantastic peered from the little office that Dave and Phalanges had built him. "Graak?"

"No it's not sorcery." said Phalanges.

"Could have fooled me." muttered Dave. "Gods of the place, I see what you mean. Don't do it again, I'd have to murder you and not eat you." she muttered shaking her scales back out and patting the air down one handed to show it was meant lightly.

"Graaaaak?" asked Cat.

"Tsin eat people they like or admire, if they can, when they die. It's respectful." explained Phalanges distractedly.

"'S right." agreed Dave. "For example I wouldn't take a single bite of this squeap machine."

Meanwhile Un-Named Male who'd been disturbed form his nap, reached out unseen by anyone but Garf and pointed at the fuse panel: The fuses were fine but the wiring harness connector had been pulled half out.

Garf looked around and pushed it back with a surreptitious claw...

"I have an idea." she announced.

Garf picked up Dave's Tablet and looked at it. Then she planted herself in front of it, crossed her arms, and said:

"Waste Organic Matter/Biologicals from Living Environments unit model Zero Romeo Indigo November Zero Charlie Oscar, serial number... five dash two dash one nine seven three, what do you think you're doing? We were relying on you to do your job. You need to take responsibility for your role on this station! I'm not angry, I'm just very disappointed"

And then clicked the reset button.

She stood there with Un-named Male's nose hanging out of her pouch, Phalanges, Dave and Cat staring in surprise: Of course the recycler clicked and powered up.

"Good." declared Garfield, who passed Dave his tablet back and grabbed her tool bag. "I'm on break!" she called as she swaggered off.

"How the hell did she...?" said Phalanges, and Dave shrugged.

"I guess it really does run on human rules." she said.

#Tsin#Atrix#Dave the Human#Phalanges Mitten#Cat Fantastic#Station Stories#Humans being weird little guys#humans are space orcs#when you see it...

82 notes

·

View notes

Text

Excerpt from this story from Inside Climate News:

Inside a cinder block office building perhaps best known for the Hindu temple and table tennis club next door, a startup company is testing what may be one of the hottest new developments in clean energy technology.

At the back of a small warehouse laboratory buzzing with fans and motors, an MIT spinoff company called Electrified Thermal Solutions is operating something its founders call the Joule Hive, a thermal battery the size of an elevator.

The Hive is a large, insulated metal box loaded with dozens of white-hot ceramic bricks that convert electricity to heat at temperatures up to 1800 degrees Celsius—well beyond the melting point of steel—and with enough thermal mass to hold the heat for days.

As the price of renewable energy continues to plummet, one of the biggest challenges for the clean energy transition is finding a way to convert electricity to high temperature heat so societies don’t have to continue burning coal or natural gas to power heavy industries. Another thorny issue is finding a way to store energy—in this case heat—for when the sun doesn’t shine and the wind doesn’t blow.

“If you are running an industrial plant where you’re making cement or steel or glass or ceramics or chemicals or even food or beverage products, you burn a lot of fossil fuels,” Daniel Stack, chief executive of Electrified Thermal Solutions, said. “Our mission is to decarbonize industry with electrified heat.”

The industrial sector accounts for nearly one-fourth of all direct greenhouse gas emissions in the U.S., which drive climate change, according to the EPA. Thermal batteries powered by renewable energy could reduce roughly half of industry’s emissions, according to a 2023 report by the Center for Climate and Energy Solutions, a nonprofit, and its affiliated Renewable Thermal Collaborative.

Additional emissions come from chemical reactions, such as carbon dioxide that is formed as an unwanted byproduct during cement production, and from methane that leaks or is intentionally vented from natural gas pipes and other equipment.

The challenge to replacing fossil fuel combustion as the go to source for heat, is that there aren’t a lot of good options available to produce high temperature heat from electricity, Stack said. Electric heaters, like the wires that turn red hot in a toaster, work well at low temperatures but quickly burn out at higher temperatures. Other, less common materials like molybdenum and silicon carbide heaters can withstand higher temperatures, but are prohibitively expensive.

As a grad student at MIT, Stack wondered if firebricks, the bricks commonly used in residential fireplaces and industrial kilns, could be a less expensive, more durable solution. Bricks do not typically conduct electricity, but by slightly altering the recipe of the metal oxides used to make them, he and ETS co-founder Joey Kabel were able to create bricks that could essentially take the place of wires to conduct electricity and generate heat.

“There’s no exotic metals in here, there’s nothing that’ll burn out,” Stack said standing next to shelves lined with small samples, or “coupons,” of brick that he and his team have tested to find the ones with the best heating properties.

5 notes

·

View notes

Text

GI Flanges Manufacture

Galvanized Iron (GI) flanges are essential components used in a variety of industrial applications, particularly in piping systems. They connect pipes, valves, pumps, and other equipment, ensuring a secure and efficient transfer of fluids or gases. Industries like water treatment, oil and gas, power plants, and chemical processing frequently rely on GI flanges due to their durability and resistance to corrosion.

What Are GI Flanges?

GI flanges are manufactured from galvanized iron, which is coated with zinc to prevent corrosion. This protective layer enhances their lifespan and makes them ideal for use in environments exposed to moisture, chemicals, and harsh conditions.

The main functions of GI flanges include:

Pipe Connection: They help form strong joints between pipes.

Maintenance Access: Flanges allow easy disassembly for cleaning, inspection, or repairs.

Valve Support: They secure valves in place within the piping system.

The GI Flange Manufacturing Process

Material Selection: High-quality iron or steel is selected for the manufacturing process.

Forging: The raw material is heated and shaped into a flange.

Galvanization: The flange is dipped in molten zinc to form a protective layer.

Machining: Final dimensions are achieved through precise machining processes.

Quality Inspection: A thorough inspection ensures that the flange meets the required standards.

Types of GI Flanges

Weld Neck Flanges: Designed for high-pressure systems, these flanges are welded to pipes, providing a strong connection.

Slip-On Flanges: These are slid over the pipe and then welded, commonly used in low-pressure applications.

Blind Flanges: Used to close the ends of pipes, they help isolate sections of a pipeline.

Socket Weld Flanges: Ideal for small-diameter pipes, they offer a smooth bore for better fluid flow.

Advantages of Using GI Flanges

Corrosion Resistance: The zinc coating protects the flange from rust, especially in environments with high moisture or chemical exposure.

Durability: GI flanges are known for their strength and long service life.

Cost-Effective: The extended lifespan of GI flanges reduces the need for replacements, saving costs in the long run.

Versatility: These flanges can be used in various industrial applications, from plumbing to firefighting systems.

Udhhyog: Leading GI Flanges Manufacturer

Udhhyog is a trusted manufacturer of high-quality flanges, including GI flanges, designed to meet the needs of different industries. The company ensures strict quality controls and precision manufacturing to deliver durable, efficient products for various piping systems.

For further information on Udhhyog’s GI flange products, visit their website or get in touch through their social media platforms.

#GIFlanges#FlangeManufacture#PipingSystems#GalvanizedIron#IndustrialFlanges#PipeConnection#CorrosionResistance#Udhhyog#IndustrialSolutions#ValveSupport#DurableFlanges#PipeFittings#EngineeringSolutions#IndustrialManufacturing

2 notes

·

View notes

Text

Flange AISI 304

When it comes to selecting high-quality flanges for your industrial needs, the flange AISI 304 stands out as a premium option. At Udhhyog, we offer top-grade AISI 304 stainless steel flanges that deliver unparalleled durability and performance. These flanges are crafted to meet the highest industry standards, ensuring reliability and efficiency in various applications.

What is Flange AISI 304?

The flange AISI 304 is made from 304-grade stainless steel, a material known for its excellent resistance to corrosion and high strength. Comprising 18% chromium and 8% nickel, this grade offers superb durability and a non-magnetic property that makes it ideal for a broad range of uses, from industrial piping systems to food processing equipment.

Key Features of Flange AISI 304

Material: 304 Stainless Steel

Pressure Rating: Available from 150 lbs to 2500 lbs

Size Range: From 1/2" to 48", with custom sizes upon request

Corrosion Resistance: Exceptional resistance to chemicals, chlorides, and acids

Temperature Tolerance: Reliable performance in both high and low temperatures

Types of Flanges AISI 304 Offered by Udhhyog

Udhhyog provides a diverse selection of flange AISI 304 types to meet various industrial requirements:

Slip-On Flange: Ideal for general-purpose applications with easy installation.

Weld Neck Flange: Designed for high-pressure environments, offering superior stress distribution.

Blind Flange: Used to seal the ends of pipes securely.

Threaded Flange: Convenient for systems that cannot be welded.

Lap Joint Flange: Suitable for applications requiring frequent disassembly and alignment.

For detailed information, explore our range of flange AISI 304 here.

Benefits of Using Flange AISI 304

Outstanding Corrosion Resistance: Ideal for harsh environments and chemical exposure.

Long-Lasting Durability: Minimizes maintenance and extends service life.

Temperature Versatility: Functions effectively under extreme temperature conditions.

Aesthetic Finish: Provides a smooth and polished appearance for exposed installations.

Applications of Flange AISI 304

The flange AISI 304 is suitable for various industries and applications:

Chemical Processing: Handles corrosive substances with ease.

Food and Beverage: Meets hygienic standards and is easy to clean.

Pharmaceuticals: Ensures sanitary conditions and precision.

Petrochemical: Effectively manages aggressive chemicals and gases.

Marine: Withstands saltwater exposure for marine applications.

Why Choose Udhhyog for Your Flange AISI 304?

Top-Quality Products: We provide flanges that adhere to the highest industry standards.

Competitive Pricing: Offers excellent value for money.

Extensive Range: A wide variety of flange types to meet your specific needs.

Reliable Delivery: Timely delivery to keep your projects on track.

Discover more about our flange AISI 304 and other industrial solutions by visiting Udhhyog’s website. For inquiries or orders, contact us at [email protected] or +91 9311120784. Udhhyog is dedicated to delivering the best products and services for all your industrial needs.

#FlangeAISI304#StainlessSteelFlanges#Udhhyog#PipeFlanges#FlangeManufacturers#FlangesAndFittings#FlangeFitting#FlangePipeFitting#QualityFlanges#IndustrialFlanges

4 notes

·

View notes

Text

Exporters of Stainless Steel 304 Pipes & Tubes: Global Supply

@manilaxmiindustrial : Manilaxmi Industrial

Explore the features, applications of Stainless Steel 304 Pipes & Tubes. This guide highlights their importance in various industries, emphasizing durability and corrosion resistance. Stainless Steel 304 Pipes, Stainless Steel 304 Tubes, SS 304 Pipes, SS 304 Tubes, Stainless Steel, Pipes, Tubes, Industrial Materials

Stainless Steel 304 is one of the most widely used and versatile types of stainless steel in the industry. Known for its exceptional corrosion resistance, durability, and aesthetic appeal, Stainless Steel 304 Pipes and Tubes are vital components in a variety of applications, spanning across multiple industries.

What is Stainless Steel 304?

Stainless Steel 304 belongs to the austenitic family of stainless steel, which is composed of 18-20% chromium and 8-10.5% nickel, along with other elements such as carbon, manganese, and silicon.

The high chromium content provides excellent corrosion resistance, while the nickel enhances its strength and toughness.

This combination makes Stainless Steel 304 a popular choice for pipes and tubes, particularly in environments where corrosion resistance is a critical factor.

Applications of Stainless Steel 304 Pipes & Tubes

Stainless Steel 304 Pipes and Tubes are used in a wide array of industries due to their adaptability. Some of the most common applications include:

Food and Beverage Industry: The hygienic properties of Stainless Steel 304 make it ideal for food processing, storage, and transportation. It is resistant to corrosion from food products, cleaning agents, and the wide range of temperatures involved in food production.

Chemical and Petrochemical Industries: Stainless Steel 304 can withstand harsh chemicals, making it a preferred material for chemical processing equipment and pipelines. Its resistance to acidic and alkaline solutions ensures longevity in these demanding environments.

Construction Industry: Stainless Steel 304 Pipes and Tubes are frequently used in architectural structures, particularly in areas where aesthetics and durability are important. Its resistance to weathering and corrosion makes it a suitable material for both interior and exterior applications.

Automotive Industry: The durability and strength of Stainless Steel 304 make it an excellent choice for automotive exhaust systems, fuel lines, and other components that require resistance to high temperatures and corrosion.

Pharmaceutical Industry: In environments where cleanliness is paramount, Stainless Steel 304 shines. Its non-reactive properties and ease of cleaning make it ideal for the pharmaceutical industry, especially in the manufacturing of medicines and medical equipment.

#Manilaxmi Industrial#manufacturers#exporters#suppliers#industrial#innovation#pipeaccessories#manilaxmiindustrial

3 notes

·

View notes

Text

it's my monthly respawn time and what better to do than show off a tf2 merc oc i have and some shit about them 🗿👍

There were a couple sketches I did not too long ago bc why sleep (it's almost 4am where I live btw), but I have more sketches of them of course. They were actually my first TF2 merc oc, and they're a support class mercenary who specializes in chemistry, hence being called The Chemist. They even have a chemical lab in the base that they've had to beg to get secured, as Scout keeps killing himself going in there. I'll rehash some of the basic notes too in case it's unclear on the image.

(Basic Notes)

The Chemist's legal name is Shannon Ridley.

They 35 years old in the game, and 39 years old in the comic; they were born circa 1933.

They are trans and nonbinary, and they use they/them pronouns.

They are 6'2" (189cm) and 200lbs (91kg).

They are Irish and Polish, and due to being raised in Ireland, they have an Irish accent. (When angry enough it bleeds into a near Scottish sounding accent.)

For the most part, they'd be the only merc to ever be consistently referred to by name, as most of the other mercs refer to them as Ridley (sometimes with a prefix of Mx. or Dr.), and their first name is rarely ever said.

Their lab coat is tight on them, aside from the bottom half of it. The upper half is tight though and it clings to their torso.

They are androsexual, which essentially just means they're attracted to masculinity.

Like how the other mercenaries have unique teeth shapes, Ridley has a vampire-like tooth structure, with their canines being pointy like fangs.

Their hair is a darker reddish-brown color, though for a while it was dyed to be a slightly brighter tone.

They carry a special carrier with them that stores their chemicals in a secure manner.

While they may be a strong merc they aren't the fastest. Their speed sits at about 93%, matching with Demo; so while it isn't terrible, it could be faster.

Their health matches with Medic (when he has Vita-Saw equipped), with their health being 140/210.

They seem to be close friends with Demoman. On the opposite spectrum, they're seen chasing Scout around a lot of times.

(Not so Basic Notes)

Ridley has attachment issues, and seems to want to cling to loved ones out of fear they'll leave them.

They have a romantic (and more) interest in Medic, though they get skittish about talking to him about it.

The "scars" they have above their chest are just tattoos.

They have a PhD in biochemistry, a master's degree in chemistry, and a bachelor's degree in biology.

Their bedroom is rather messy in comparison to their workspace, however like with their workspace, they don't like having open food containers in the area.

They overheat rather fast, and require white noise to sleep. Their solution? Two fans going constantly.

They were originally born in Poland, however due to the time period and certain circumstances, their parents made it so they could flee and at least try to live a good life. However, their aunt took this as an opportunity to raise the daughter she never had, at the expense of Ridley's own happiness.

Ridley is intersex.

They'd likely be one of the only mercs to not have a driver's license as they don't feel comfortable with driving like... at all.

They do research with Medic a lot, and they like to teach him stuff about chemistry, much as how he likes to teach them about medical practices.

They're a martial artist, and has a black belt in taekwondo. (They also do training sessions with Heavy, and Soldier has been mistaken a few times in thinking they're calling Heavy a hussy because of them saying "huss" when they do something.)

They do not use the bases tap water and instead has a water jug they use. They also claim they're trying to petition Teufort to install new water pipes and deep clean the water intake system, to no avail.

They crochet in their free time, and one of their melee attacks involves them trying to stick a crochet hook through someone's eye.

I'll likely post something later on that goes more in depth about them, but in the meantime, here they are! (And watch me disappear for like a few more months lmao)

#tf2#team fortress 2#tf2 oc#tf2 oc art#tf2 chemist#tf2 ridley#the chemist#shannon ridley#they/them#transgender#nonbinary#intersex

15 notes

·

View notes

Text

Mastering the Art of Plumbing: Essential Tips and Tricks for Every Homeowner

Introduction: Plumbing is the circulatory system of your home, quietly working behind the scenes to keep everything flowing smoothly. From the moment you turn on the faucet to the flush of the toilet, plumbing plays a crucial role in our daily lives. However, when plumbing issues arise, they can quickly turn into a homeowner's worst nightmare. But fear not! With the right knowledge and a few handy tips, you can become a plumbing pro in no time.

Understanding Your Plumbing System: Before diving into fixing leaks or unclogging drains, it's essential to have a basic understanding of your home's plumbing system. Typically, plumbing consists of two subsystems: the water supply system and the drainage system. The water supply system brings fresh water into your home, while the drainage system removes wastewater.

Common Plumbing Issues and Solutions:

Leaky Faucets: A dripping faucet may seem like a minor annoyance, but it can waste a significant amount of water over time. Usually, a leaky faucet can be fixed by replacing a worn-out washer or O-ring. Remember to turn off the water supply before attempting any repairs.

Clogged Drains: Whether it's in the kitchen sink, bathroom shower, or toilet, clogged drains are a common plumbing problem. For minor clogs, a plunger or plumbing snake can often do the trick. Avoid using chemical drain cleaners as they can damage your pipes over time.

Running Toilet: A toilet that continues to run after flushing can waste gallons of water and inflate your water bill. In most cases, a running toilet is caused by a faulty flapper or fill valve. Replacing these components is relatively simple and can save you money in the long run.

Low Water Pressure: If your faucets are trickling instead of flowing, low water pressure may be the culprit. Potential causes include mineral buildup in the pipes, a faulty pressure regulator, or a partially closed shut-off valve. Checking these components and cleaning or replacing them as needed can help restore proper water pressure.

Frozen Pipes: During the winter months, exposed pipes are susceptible to freezing, which can lead to burst pipes and costly water damage. Insulating your pipes and keeping your home adequately heated can prevent this issue. If you suspect a frozen pipe, never use an open flame to thaw it—instead, use a hairdryer or heating pad.

DIY Plumbing Tips:

Invest in Quality Tools: A well-equipped toolbox is essential for any DIY plumber. Basic tools like wrenches, pliers, and pipe cutters will come in handy for most plumbing projects.

Know Your Shut-Off Valves: Familiarize yourself with the location of your home's main water shut-off valve, as well as individual shut-off valves for sinks, toilets, and appliances. Knowing how to turn off the water in an emergency can prevent water damage to your home.

Practice Preventative Maintenance: Regularly inspecting your plumbing system for leaks, corrosion, or other signs of damage can help catch potential issues before they escalate into major problems. Additionally, scheduling annual professional inspections can identify hidden issues early on.

Conclusion: While some plumbing tasks may require the expertise of a licensed plumber, many common issues can be resolved with a little DIY know-how. By understanding how your plumbing system works and learning some basic maintenance techniques, you can save time, money, and stress in the long run. So don't let plumbing problems dampen your spirits—empower yourself with knowledge and tackle them head-on!

2 notes

·

View notes

Text

Unveiling the Latest Innovations: What is New in Rig Wash Additive Technology

In the dynamic and ever-evolving oil and gas industry, maintaining clean and efficient drilling operations is paramount. One of the critical aspects of this process is the use of specialized additives to ensure the integrity and cleanliness of drilling equipment. As a leading pipe free agent additive manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. is at the forefront of developing innovative solutions that enhance the performance and reliability of drilling operations. This blog explores the latest advancements in rig wash additive technology and their impact on the industry.

The Importance of Rig Wash Additives

Rig wash additives play a crucial role in the maintenance of drilling rigs and associated equipment. These chemicals are designed to remove contaminants such as oil, grease, and drilling mud from surfaces, ensuring that the equipment operates efficiently and safely. By preventing the build-up of residues, rig wash additives help to extend the lifespan of equipment, reduce maintenance costs, and minimize downtime.

Key Benefits of Rig Wash Additives:

Enhanced Equipment Performance: Clean equipment operates more efficiently, leading to improved overall performance.

Reduced Maintenance Costs: Regular cleaning with effective additives reduces the need for frequent repairs and maintenance.

Safety: Clean rigs and equipment help prevent accidents and ensure a safer working environment.

Environmental Compliance: High-quality rig wash additives help in adhering to environmental regulations by ensuring proper disposal of contaminants.

Innovations in Rig Wash Additive Technology

The oilfield chemicals industry is constantly advancing, with new technologies and formulations emerging to address the specific needs of modern drilling operations. As a leading rig wash additive manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. is committed to staying at the cutting edge of these innovations. Here are some of the latest developments in rig wash additive technology:

Environmentally Friendly Formulations

With increasing environmental regulations and the industry's shift towards sustainable practices, there is a growing demand for environmentally friendly rig wash additives. Manufacturers are now focusing on developing biodegradable and non-toxic formulations that effectively clean equipment without harming the environment.

Features of Eco-Friendly Rig Wash Additives:

Biodegradable Ingredients: Break down naturally without leaving harmful residues.

Non-Toxic: Safe for use around personnel and wildlife.

Low VOCs: Reduced volatile organic compounds to minimize air pollution.

Enhanced Cleaning Efficiency

The efficiency of rig wash additives is critical to their performance. Recent advancements have led to the development of high-performance additives that offer superior cleaning capabilities. These formulations are designed to penetrate and remove even the most stubborn contaminants, ensuring that equipment remains in optimal condition.

Key Characteristics:

High Penetration: Ability to reach and clean hard-to-access areas.

Superior Solvency: Effectively dissolves oil, grease, and other residues.

Quick Action: Reduces cleaning time, enhancing operational efficiency.

Multi-Purpose Additives

To simplify the maintenance process and reduce costs, there is a trend towards multi-purpose rig wash additives. These versatile formulations can be used for various cleaning applications, from washing rigs to cleaning pipelines and casings.

Advantages of Multi-Purpose Additives:

Cost-Effective: Reduces the need for multiple products.

Simplified Logistics: Easier inventory management and storage.

Consistent Performance: Ensures uniform cleaning results across different applications.

Specialized Additives for Specific Applications

Recognizing that different components of drilling operations may require unique cleaning solutions, manufacturers are developing specialized additives tailored to specific applications. For example, a casing wash additive manufacturer in India might produce formulations specifically designed to clean and protect casing pipes, ensuring their longevity and performance.

Examples of Specialized Additives:

Casing Wash Additives: Formulated to clean and protect casing pipes from corrosion and build-up.

Pipe Free Agent Additives: Designed to prevent the formation of hydrates and other blockages in pipelines.

Rig Wash Additives: Targeted formulations for cleaning drilling rigs and related equipment.

Imperial Oilfield Chemicals Pvt. Ltd.: Leading the Way

As a premier pipe free agent additive manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. is dedicated to innovation and excellence. Our range of rig wash additives is formulated to meet the highest standards of performance and safety, ensuring that our clients can maintain efficient and reliable operations.

Our Product Range:

Rig Wash Additives

Our rig wash additives are designed to remove a wide range of contaminants, from oil and grease to drilling mud. They are formulated to provide thorough cleaning while being safe for both equipment and the environment.

Casing Wash Additives

Our casing wash additives are specifically designed to clean casing pipes, preventing corrosion and build-up that can compromise the integrity of the pipes. These additives are essential for maintaining the safety and efficiency of drilling operations.

Pipe Free Agent Additives

Our pipe free agent additives prevent the formation of hydrates and other blockages in pipelines, ensuring smooth and uninterrupted flow. These additives are critical for maintaining the efficiency and reliability of pipeline operations.

Case Study: Successful Implementation of Rig Wash Additives

To illustrate the impact of our innovative rig wash additives, let's consider a case study involving a major drilling operation in India. The client faced significant challenges with equipment contamination, leading to frequent maintenance and downtime.

The Challenge:

Frequent Downtime: Equipment contamination caused frequent shutdowns for cleaning and maintenance.

High Maintenance Costs: Regular repairs and part replacements due to build-up and corrosion.

Environmental Concerns: Need for environmentally friendly cleaning solutions.

The Solution:

Imperial Oilfield Chemicals Pvt. Ltd. provided a comprehensive solution with our range of rig wash and casing wash additives. The implementation involved:

Regular Cleaning Schedule: Establishing a routine cleaning schedule using our high-performance additives.

Training and Support: Providing training to the client's staff on the proper use of the additives and best cleaning practices.

Environmental Compliance: Ensuring that the products used were environmentally friendly and compliant with local regulations.

The Results:

Reduced Downtime: The client experienced a significant reduction in equipment downtime, leading to uninterrupted operations.

Lower Maintenance Costs: The effective cleaning reduced the need for frequent repairs and part replacements, resulting in cost savings.

Enhanced Safety and Compliance: The use of eco-friendly additives ensured a safer working environment and compliance with environmental regulations.

Future Trends in Rig Wash Additive Technology

The future of rig wash additive technology looks promising, with ongoing research and development aimed at addressing the evolving needs of the oil and gas industry. Here are some trends to watch:

Smart Additives

The integration of smart technologies into rig wash additives is an exciting development. These additives can be designed to change their properties in response to specific conditions, enhancing their effectiveness and efficiency.

Nano-Technology

Nano-technology is set to revolutionize rig wash additives by enabling the development of formulations with enhanced penetration and cleaning capabilities. Nano-particles can reach and clean areas that traditional additives cannot, ensuring thorough cleaning.

Sustainability Focus

As environmental concerns continue to grow, there will be an increased focus on developing sustainable rig wash additives. This includes not only biodegradable and non-toxic formulations but also products that require less water and energy for their application.

Conclusion

The advancements in rig wash additive technology are transforming the oil and gas industry, making drilling operations more efficient, safe, and environmentally friendly. As a leading rig wash additive manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. is proud to be at the forefront of these innovations. Our commitment to quality, performance, and sustainability ensures that our clients receive the best possible solutions for their cleaning needs.

Whether you are looking for a pipe free agent additive manufacturer in India or a casing wash additive manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. has the expertise and products to meet your requirements. Stay ahead of the curve with our innovative rig wash additives and experience the difference they can make in your operations.

#Pipe free agent additive manufacturer in India#Rig wash additive manufacturer in India#Casing wash additive manufacturer in India#petrochemical products#petrochemical companies#petrochemical industries#petrochemical solutions#oil and gas industry#oil and gas companies#chemical product#chemical industry#chemical companies#oil & gas supply chain#India#Upstream activities#exploration and production#upstream oil and gas segment#upstream oil and gas industry

4 notes

·

View notes

Text

What Is an Industrial Water Treatment System and How Does It Work?

Water is the lifeblood of countless industrial processes. But unlike the kind that comes out of your tap, industrial water often needs a little extra TLC before it's ready for action. That's where industrial water treatment systems come in. At PureBact, we understand the importance of clean, reliable water for your facility's operations.

Here's a breakdown of what industrial water treatment systems are and how they work:

What is an Industrial Water Treatment System?

An industrial water treatment system is a customized set of processes designed to remove impurities and adjust the properties of water to make it suitable for a specific industrial application. This could involve anything from making boiler feed water ultra-pure to treating wastewater before it's released back into the environment.

Why is Industrial Water Treatment Important?

Untreated water can wreak havoc on your industrial processes. Minerals can cause scaling and corrosion in pipes and equipment, while contaminants can affect product quality. Proper water treatment helps to:

Protect equipment: By removing impurities that can cause corrosion and scaling, you can extend the lifespan of your valuable machinery.

Ensure product quality: Consistent water quality is essential for producing consistent, high-quality products.

Minimize environmental impact: Industrial wastewater treatment helps to remove pollutants before they are released back into the environment.

Reduce operating costs: By preventing equipment damage and ensuring efficient operation, proper water treatment can save you money in the long run.

How Does Industrial Water Treatment Work?

The specific treatment processes used will vary depending on the source water and the desired end product. However, some common methods include:

Pre-treatment: This stage removes large particles such as sand, debris, and organic matter through filtration or sedimentation.

Clarification: Coagulation and flocculation techniques help suspended solids clump together and settle out of the water.

Filtration: Various filtration technologies, like sand filters or membrane filters, remove finer particles and contaminants.

Ion exchange: This process removes unwanted ions by exchanging them for harmless ones.

Deionization: A specialized form of ion exchange that removes both positively and negatively charged ions to create high-purity water.

Disinfection: Chemicals like chlorine or ultraviolet light can be used to kill bacteria and other microorganisms.

PureBact: Your Partner in Industrial Water Treatment

At PureBact, we offer a comprehensive range of industrial water treatment solutions. Our team of experts will work with you to assess your specific needs and design a custom system that ensures optimal water quality for your operations.

Contact PureBact today to learn more about how we can help your business thrive with clean, reliable industrial water.

2 notes

·

View notes

Text

【The ultimate guide to choosing the perfect Dry Ice Cleaning Machineand dry ice machine for your needs】

UNDERSTANDING YOUR REQUIREMENTS

1. Determine your application area:

Before diving into machine specifications, determine your primary application. Whether it’s industrial cleaning, food preservation, or special effects in the entertainment industry, understanding your specific use case will allow you to more accurately select the machine that’s best for you.Or you can tell us your needs and we will recommend the best solution for you.

2. Dry ice quantity issue:

Consider the amount of dry ice you need. Industrial applications may require high-capacity machines, while smaller equipment can meet smaller-scale needs. Understanding your production requirements is critical.You can refer to 【Dry Ice Production Demystified: Go Behind the Scenes and Uncover the Magic of Pelletizers】and 【How to set up your own dry ice manufacturing factory?】Learn more about dry ice in two articles.

TYPES OF DRY ICE CLEANERS AND DRY ICE PELLETIZERS

1. Dry ice cleaning machine(Dry ice blasting machine):

Compressed air is used to accelerate dry ice pellets to supersonic speeds and spray them onto the surface being cleaned. The high-speed ice particles hit the dirt, and through the freezing and mechanical action of the ice, the dirt is peeled off the surface.It is widely used for cleaning machinery and equipment, production lines, building surfaces, etc. It is especially suitable for the food and pharmaceutical industries because the cleaning process does not require water or chemicals.(Want to learn more about Dry Ice Cleaning?)

· P7X Dry ice cleaning machine: Very suitable for cleaning carbon deposits and oil stains in car engines. It can effectively complete cleaning without damaging engine parts etc..(Suitable for use in car repair service centers, auto repair shops, home cleaning and maintenance, etc.)Go to view product details

· A625i Dry ice cleaning machine: Suitable for cleaning oily molds, motor windings, paint rust cleaning, and printing machine ink residues etc.. (Suitable for rubber factories, shoe factories, factory machine maintenance, etc.)Go to view product details

· P60 Dry ice cleaning machine: Used for car interior renovation and cleaning, car seat cushions, surface glue residue, and oil stain cleaning etc..(Suitable for use in car repair service centers, auto repair shops, home cleaning and maintenance, etc.)Go to view product details

· T6 Dry ice cleaning machine: Used for PCB circuit board renovation and cleaning, soldering residue, surface glue residue, oil stains, PPS material deburring, etc. (Suitable for component factories, component maintenance, factory machine maintenance, etc.)Go to view product details

· B3+ Dry ice cleaning machine: Used for cleaning motor winding dust, printing machine ink, oil sludge, rust stains, heavy oily metal, etc.(Used to clean and maintain a variety of industrial equipment, including engines, pumps, valves, pipes, etc.)Go to view product details

Generally speaking, the dry ice cleaning machine is an efficient, environmentally friendly, and multi-purpose cleaning equipment. Its working principle is based on high-speed spraying of dry ice particles to clean the surface through freezing and mechanical impact. The advantages of this cleaning method include being water-free, leaving no chemical residue, being non-abrasive, suitable for a variety of surfaces and materials, and having a wide range of applications in a variety of industries.

For potential users, when choosing a dry ice cleaning machine suitable for specific needs, factors such as cleaning objectives, working environment, cleaning effect requirements, production capacity and budget need to be considered. Whether in industrial, food, medical or other industries, dry ice cleaning machines have demonstrated their excellent performance in improving cleaning efficiency and protecting equipment surfaces.You can also tell us your needs and our engineers will recommend the most suitable solution for you. Contact an engineer now >>

2. Dry ice pellet machine(Dry Ice Granulator Machine):

Dry ice pelletizer is a piece of equipment specially used to turn liquid carbon dioxide (CO2) into solid carbon dioxide (dry ice) pellets.

Dry ice pelletizers usually deliver liquid CO2 into the machine through a liquid carbon dioxide supply system. Liquid carbon dioxide undergoes a series of cooling and pressurization processes, causing its temperature and pressure to rise. The pressurized liquid carbon dioxide passes through the nozzle or spray head and enters a relatively low-pressure environment. In this environment, liquid CO2 rapidly relaxes and expands, lowering its temperature and turning into a solid state. Because the temperature drops sharply, liquid CO2 turns into a gaseous state and forms tiny CO2 particles, known as dry ice particles.

The Dry ice machine can efficiently convert liquid CO2 into a large number of evenly distributed dry ice pellets. The advanced control system can achieve precise control of parameters such as temperature, pressure and particle size to ensure the production of dry ice that meets requirements. Some Dry Ice Granulator have adjustable mechanisms that allow the user to select different sizes of dry ice pellets. There is no need to add any chemicals during the manufacturing process, and the waste material is CO2 gas, so the dry ice pelletizer is considered a relatively environmentally friendly production method. Most Dry Ice Pelletizer Making Machine are equipped with automated operation functions, including automatic adjustment and monitoring systems to improve production efficiency.

3. Dry Ice Block Machine(Dry ice briquetting machine):

A dry ice block press is a piece of equipment specifically designed to compress dry ice pellets or pieces into block form.

Dry ice block presses typically use previously produced dry ice pellets or chips as raw material. These pellets or chips are usually prepared through an overhead dry ice pelletizer or other means. Dry ice raw material is transported to the compression zone and heated to a certain level. The purpose of heating is to cause the dry ice pellets or blocks to begin to soften and melt. After heating, the softened dry ice is placed in a compression zone, where compression machinery or a hydraulic system exerts tremendous pressure to compress the dry ice into blocks. The compressed dry ice blocks pass through the cooling system, where they are quickly cooled and re-solidified to form solid dry ice blocks. The formed dry ice blocks enter the collector through the collection system, and then enter the packaging area through the conveyor system for final packaging.

Go to view product details >>

Main feature:

Efficient production: The dry ice block press can efficiently convert dry ice pellets or fragments into large, solid dry ice.

Uniformity of dry ice blocks: Compression machinery and control systems ensure uniform shape and size of dry ice blocks, suitable for different applications.

Save space: Dry ice in block form is easier to store and transport than in crushed or pellet form, thus saving space.

Energy savings: Previously produced dry ice pellets or crumbs are used as raw material, reducing the need for additional refrigeration and helping to save energy.

Automated operation: Most modern dry ice block presses are equipped with automated operation functions, including automatic adjustment and monitoring systems to improve production efficiency.

Application areas:

Food and pharmaceutical transportation: Dry ice blocks are widely used in cold chain transportation to keep food and pharmaceuticals at low temperatures.

Laboratory and scientific research: In laboratories and scientific research fields, dry ice blocks are used to prepare low-temperature environments, such as refrigeration reagents.

Special effects production: Dry ice cubes are often used in film productions and stage performances to create special smoke and cold fog effects.

Environmentally Friendly Cleaning: Dry ice cubes are also used in the cleaning industry for cleaning and removing dirt, especially for electrical equipment cleaning.

Overall, the dry ice block press provides a reliable production method for producing large blocks of dry ice, suitable for the different needs of multiple industries.

RODUCTION CAPACITY

Evaluate the machine's productivity in pounds per hour. Make sure it fits your needs without sacrificing quality. To meet high-volume demand, faster production may be required.

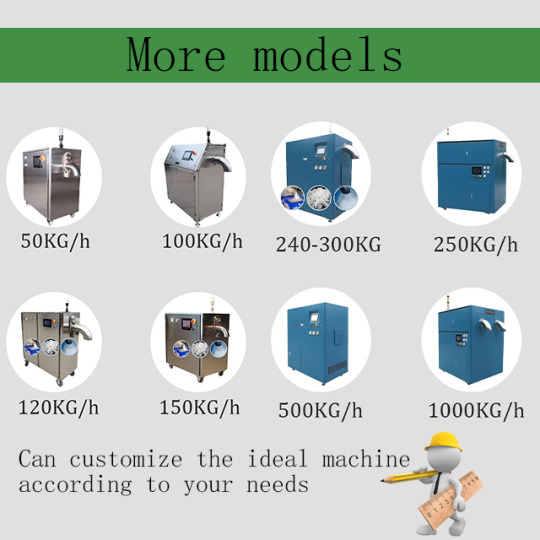

OLLITAL aims to provide customers with more choices in production capacity. Independently developed: 50KG/H (110 lbs/H), 100KG/H (220 lbs/H), 150KG/H (330 lbs/H), 250KG/H (551 lbs/H), 500KG/H (1102 lbs/H), and 1000KG/H (2204 lbs/H) dry ice pellet machine. Or you can tell us your needs and our engineers will customize the most suitable solution for you according to your needs. Contact an engineer immediately for customization >>

TECHNICAL SPECIFICATIONS

1. Size and portability:

Consider the physical size of the machine. A compact, portable unit may be better for versatility and ease of use, especially if you work from different locations or have limited space. If you need to move your cleaning equipment between job sites, choosing a dry ice blaster that is compact and portable may be key. This is important for tasks that require frequent movement or operation in limited spaces.

* Machine size: View the actual dimensions of your dry ice blaster, including length, width, and height. Make sure the machine is sized to fit your workplace and can be easily stored or carried.

* Weight: In addition to size, consider the weight of your dry ice blaster. The lightweight design can improve portability, reduce the burden of transportation, and make the device easier to carry and operate.

* Easy to carry design: Choose a machine with a user-friendly carrying design, such as handles, wheels, or other structures for easy movement. These designs make it easier for operators to move equipment from one location to another.

* Versatility: Some portable dry ice blasters are designed for versatility and can be used in a variety of applications. This flexibility increases the equipment's usefulness and makes it suitable for different types of cleaning tasks.

* Easy to store: Consider the storage needs of the machine when not in use. Some machines may have folding or removable parts to make it easier to store in limited spaces.

* Power and energy requirements: Consider the power and energy requirements of your dry ice blaster. Portable devices are often easier to connect to different types of power sources, such as batteries, generators, or standard electrical outlets.

When selecting a dry ice blaster, considering size and portability can ensure the equipment is better suited to your job requirements, increasing operational flexibility and efficiency.

2. Automation and control:

Automation and control are crucial considerations when selecting a dry ice pelletizer and cleaning machine. Look for user-friendly controls and automation features. An intuitive interface and automation streamline operation, making the machine easier for operators of all skill levels to use.

* Intuitive interface: Choose a dry ice granulator/cleaner with an intuitive interface. An intuitive control panel or touch screen makes it easier for operators to understand and operate the equipment, reducing training time.

* User-friendly controls: Consider choosing a machine with user-friendly controls. Simple buttons, knobs or digital controls allow operators to easily adjust and monitor cleaning parameters.

* Default program: Look for machines with preset cleaning programs. Preset programs improve operational consistency and efficiency, reducing manual setup and adjustments by the operator.

* Automation features: Understand whether the machine has automated functions, such as automatic nozzle adjustment, cleaning trajectory planning, etc. These features simplify the cleaning process and reduce operator intervention.

* Remote control and monitoring: If possible, choose machines that support remote control and monitoring. In this way, operators can monitor and adjust the cleaning process remotely, increasing the operational flexibility of the equipment.

* Fault diagnosis and alarm system: Look for machines with fault diagnosis and alarm systems. These systems can detect and report potential problems in a timely manner, helping to quickly resolve faults and improve equipment reliability.

* Data logging and reporting: Some advanced dry ice cleaning machines have data logging and reporting capabilities that can record key parameters during the cleaning process. This is very useful for quality control and traceability.

* Programmability: If you need to personalize it for a specific application, consider choosing a machine with some programmability to accommodate different cleaning needs.

By choosing a dry ice pelletizer/cleaner with an intuitive interface, automated features, and user-friendly controls, you can increase the ease of use of your equipment, reduce training costs, and ensure consistent cleaning results among operators of different skill levels .

Choosing the perfect dry ice machine requires a thorough understanding of your specific needs, technical specifications, and cost considerations. By carefully evaluating these factors, you will be able to make an informed decision that meets your application requirements and provides long-term value.

Whether you're venturing into a new business or upgrading an existing setup, investing the time in selecting the right dry ice machine is a critical step toward efficiency and success.

If you want to know more about Dry Ice Pellet Manufacturing Machinery or you want to build a dry ice production line, please refer to [Dry Ice Production Demystified: Go Behind the Scenes and Uncover the Magic of Pelletizers].

In this era of cleaning revolution, choose a dry ice cleaning machine to make cleaning easier, more efficient and more environmentally friendly! Thank you for reading our blog, if you have any questions or cooperation intentions, please feel free to contact us. Let us help the cleaning industry together and create a better future!

2 notes

·

View notes

Note

i would say yes! there are pollution issues caused from the city of dis above

Well that certainly limits the romantic bubble baths… I bet homie drinks bottled water and wine, wears perfume, and uses a lot of talcum powder as dry shampoo in his hair. Maybe even bathes with oil and scrapers as the Romans did. Maybe I need to elope with Kayn and enjoy his hot springs instead.

But… while Dorian probably already does some or all of this water cleaning I’m thinking about how to automate it or do it on a bigger more efficient scale.

Imagine if Aeron made beautiful marble sculptures of trees that were hollow in the middle, and the branches funnelled rainwater down the centre through layers of gravel, sand and charcoal. Like the ancient sand filtration columns, cleaning and storing large volumes of water passively.

Or Dorian’s cathedral could have gargoyles on the back that spout the roof runoff through filters into water tanks for treatment. The falling of the water would aerate it too, against anaerobic bacteria. The tank also allows sediments to fall to the bottom, the water to be flocculated with iron or alum, and all the resulting coagulated junk to sink to the bottom.

Actually none of it should be marble though. Filtering water through ash can make it extremely alkaline (doing that with wood ash makes lye) and if it was acid rain from the smog… either would quickly erode the soft marble. I wonder how the cathedral and gravestones resist damage.

Better alternatives would be metal, resistant asphalt concrete, or a more resistant stone. There is also the Roman concrete that ‘self heals’ by recrystallising to resist erosion. But that requires the inclusion of quicklime which may leach excessive minerals like calcium into the water and raise the pH.

However if the water is acidic (low pH) that may help buffer and impurities can be addressed later?

Dorian totally knows about aqueducts, which slow the movement of water to let crud settle out, aerate it, keep it moving to avoid stagnation.

However the lead levels in Roman aqueducts were so incredibly high compared with non-aqueduct water. Maybe it doesn’t matter if you’re a demon or dead but it’s not good. Perhaps this explains Dorian’s emotionality and mood swings if this is what he’s doing and can be somewhat affected.

However this contamination was due to lining them with sheets of lead, and as lead was known to be dangerous clay pipes were preferred.

All this stuff is mostly for physical impurities and maybe charcoal removes some of the other chemicals but not all.

Distillation is very energy intensive, time consuming and would be bulky in equipment but Dorian does at least have eternal fire available and space for tanks.

It removes salinity, minerals and heavy metals but not things with lower boiling points than water ie oil, alcohol or petroleum. Boiling and recollecting the condensation was done to seawater by the ancient Greeks. However heating some of the contaminants can create dangerous compounds.

Reverse osmosis is possible with very old tech (pigs bladder in the 1700s) but hard to do on a large scale with a low tech setting and flesh won’t stay usable for long. Frequent replacement, inadequate size or strength, biohazard.

Disinfection is possible with iodine or chlorine (sunlight too but there’s little in Heresy and no electricity for ultraviolet lights unless a generator is made). pH can be fixed by buffer chemicals.

All of this is in the wrong order and has glaring issues but I am trying to apply ancient water purification methods and environmental engineering to Hell!

i saw this at work and blew up so sorry for the late answer.

Imagine if Aeron made beautiful marble sculptures of trees that were hollow in the middle, and the branches funnelled rainwater down the centre through layers of gravel, sand and charcoal. Like the ancient sand filtration columns, cleaning and storing large volumes of water passively.

he probably did. by accident.

Dorian totally knows about aqueducts, which slow the movement of water to let crud settle out, aerate it, keep it moving to avoid stagnation. However the lead levels in Roman aqueducts were so incredibly high compared with non-aqueduct water. Maybe it doesn’t matter if you’re a demon or dead but it’s not good. Perhaps this explains Dorian’s emotionality and mood swings if this is what he’s doing and can be somewhat affected. However this contamination was due to lining them with sheets of lead, and as lead was known to be dangerous clay pipes were preferred.

you know this guy is lead poisoned. maybe that's why his hair is falling out and isn't as poofy as it was once before. and why he can't ejaculate? that's a joke.

maybe what the church is made out of does not matter. maybe it resists damage. is made of something that looks like marble but is not. he doesn't remember how it got there. but he remembers...making it?

i know he makes noise complaints to the city of dis, because despite it being usually quiet, he does hear it sometimes, very late in the "night."

but hell has no day, has no night, it has eternity.

2 notes

·

View notes

Text

Plumbing Plano Texas TX

At Plumbing Plano Texas, we can offer you with a professional and affordable plumbing company service right where you are anywhere in the Plano, TX area and surrounding areas every single day and night. Our plumbers are extremely well trained and qualified in their field with the ability to assist you with any of your plumbing fixtures for your residential and commercial plumbing issues and concerns in no time at all at a price you can afford.

We have all the right tools

We have all the right tools and equipment to assist you properly with anything you may be in need of from clogs in your bathroom or kitchen sink to toilet, shower drain, garbage disposal, water leak repair to much more in the safest way. Our prices which we provide you with are fair and cheap enough to fit with every ones budget and we will give that to you on the phone with us any time any day as a quote as well as answer any further concerns or questions you may have on your mind before we have an expert sent out to help you. Our drain cleaning cleaners are very much experienced

with many different situations and problems from some of the biggest and most serious to some of the easiest simplest ones and know very well the right way to rid your drains from any clogs or blockages and get them back to work in no time.

There are many ways you can un clog a drain on your own at home at a cheaper cost than calling a professional from chemical liquids to plungers. However, these are all only temporary solutions and are more damaging in the long run as they are very harmful to your pipe walls and material which will cause you to experience more issues and waste more money in the long run. service:- Plumbing, Sewer Line, Toilet Repair, Water Heater, Garbage Disposal.

Plumbing Plano Texas 700 Alma Dr, Plano, TX 75075 972-729-9147 www.plumbingplanotexas.com [email protected] Mon-Fri: 8 am to 7:30 pm Sat-Sun: 10 am to 5:30 pm

youtube

2 notes

·

View notes

Text

Stowaway Chapter 1:

Word count: 2025

Warnings: canon related violence, death.

A/N: HIII GUYS. So, to be completely honest, I've just binged Rough Day and it was the most amazing fanfic ever. Something about Din just gets my stomach in a twist, and so I was super inspired to get all my daydreaming and lusting down on paper. It's probably not going to be as smutty, but it will be full of feels, laughs, and fluff, cos I'm fluffy :> Honestly just want to explore what getting to know Din would be like, in my own way. Lots of adventure to follow, but not to worry my lusty friends! There will, be smut XD. Just not yet.

~•~•~•~•~•~•~•~•~•~•~•~•~•~•~•~•~•~•~•~•~•~

Cold. The first thing you notice when you open your eyes is just how cold it's gotten. The second thing you notice is that you feel lightheaded and your vision is blurry.

"Concussion... Great." You say out loud to the haze in front of your eyes.

Slowly you start to get your bearings as you try to blink away the greyness. Except you soon realise it's not your eyes, this dense smoke is coming from blown pipes and burning chemicals. You grab the top of the table and pull yourself up, groaning as your head pounds from the movement.

An attack. You remember that your prisoner transport was attacked. Likely another faction looking to save one of their own. You feel yourself get angry at them, the lives they stole today, without remorse.

You look around your lab and sigh deeply. Everything has been destroyed by blaster fire. All your equipment, all your research. You take a quick look around to see if there are any medical supplies left to patch yourself up with. You find an intact syringe of bacta and thank your little stars.

After patching yourself up, you start to move around the abandoned ship. You step over broken bodies, the lights flashing erratically and the pipes hissing out oxygen. You shiver, the life support must be down. You wonder if there is anyone left alive. You got knocked out from some sort of explosive and missed all of the action. But you feel glad you did. You don't think you'd still be walking around if you hadn't.

You reach the control room and your heart plummets. It's a mess. And not the kind you know how to clean up. Everything is flashing red, and the monitors tell you the engines and life support are down. You have a huge hull breach you're assuming the attackers used to get out, and your fuel has leaked into space. This ship... Is stranded. That means you're stranded.

You're about to sink to the floor in despair when you hear clomp clomp clomp behind you, the sound of heavy footsteps approaching. You quickly duck into the nearest hiding space (a tiny service hatch) and hold your breath, terrified that its one of the murderers looking for witnesses.

You peek through the tiny gap you left, scared of being caught, but needing to know who it is anyways. If you can get a description, maybe you can take it to the New Republic and they can catch these assholes. If.. you can get there.

The footsteps grow louder, and you stay very very still. You see a flash of bright silver, and the source stops in front of the controls. You hear a few beeps and the sounds of buttons being pressed, and one of the monitors comes to life with camera footage. You watch, having a better angle to see the monitor than the person, and you're horrified. They massacred everyone.

You hear a sigh, and the sound of a deep modulated voice fills the room

"Well kid, don't think there's anyone left alive. Let's get some supplies and get going."

Kid? You adjust as much as you can without making a noise, but all you can see is a round device floating alongside a large suit of armour. Is that beskar? You try to look upwards to see the face of the stranger, but all you see is a helmet. A very familiar looking helmet.

A Mandalorian? Traveling with a kid. You'd heard rumours out here in the Outer Rim, officers coming in and talking about the chaos a Mandalorian leaves in his wake. He was always traveling with a kid. Could this be him?

You can't be sure, but what you do know is that he isn't an intruder. He's not here to kill you. And, he's your ticket off this dead ship. You watch him turn around and leave the room, and you only crawl out of the hatch when you can no longer hear his footsteps. He has to have a ship.

You run over to the console and see if it can show you anything about a ship being docked. The display is cracked and flickery, but you just manage to make out where his ship is. Now you have a direction.

As quietly and quickly as you can, you make your way to where his ship has docked with this one. You keep an eye and ear out for any sounds of him and his companion as you jump over bodies and sidestep wiring, trying to make it there before they do. Please please please get there before they do.

You can't get stuck here.

You make it to where he docked his ship, and look up. The hatch is still open. You hope this means they haven't gotten back yet, and not that they've just climbed in. Giving your surroundings a quick glance, you jump onto the ladder and scramble up into his ship.

Peeking your head inside, you take it all in. It's not spacious, but it isn't small either. It's narrow, but long. To your right, you assume is the back of the ship, and the ramp for loading and offloading large objects. It's spacious enough to fit 3 Blurrgs comfortably, but it's mostly empty, apart from a few containers. In front of you, you see a mobile Carbonite freezing system, and your heart skips a few beats. You don't want to end up in there...

To your left is what you assume goes towards the front of the ship. You see a... urinal fresher type device (so old and outdated you hope it's not what you think it is), a storage compartment and a ladder leading upwards. No signs of the Mandalorian though. You continue to climb up until you're completely inside the ship.

Looking around, you don't see anywhere you can easily hide, so the stairs are your next best option. You head over and climb them, coming up into a small room with doors on either side. You look left again, and opening the door you see the cockpit. No. Definitely not there. You try right this time, and upon opening the door you have to bite back a gasp.

Three blocks of Carbonite stand in front of you, the faces of its captives frozen in time. You shudder, wondering what these poor souls did to deserve this. It also reminds you of another piece of information on this Mandalorian.... He's a bounty hunter. Dangerous and unbeatable. You shudder, wondering why it had to be his ship.

You ease your way past the blocks and open the next door. You're suddenly blasted with heat and squint your eyes, surprised. A reactor. You stand there for a moment, contemplating your knowledge of the ship and what you think would be the best place to hide. You look around the room, and your eyes light up when you see another panel. You open it up and there is a tiny little compartment, just big enough for you to squeeze into.

You climb in and settle in next to a camtono and a decapitated, bug-eyed droid.

"Hey, how's it going. Mind if I share with you for a little while?" You ask the droid, knowing you won't get an answer, but amusing yourself anyways.

You've just closed the door to the compartment when you hear footsteps climbing up the ladder outside, and your breathing starts to pick up along with your heart rate, hoping against hope he hasn't noticed or heard anything. You hold your breath as you hear the doors to the cockpit open, and don't release it until you feel the ship disengage from your transport and pull off into space.

You smile to yourself. Maybe you'll make it to civilization without any hiccups. Maybe you won't have to deal with the scary Mandalorian and have to explain to him exactly why you're on his ship. You rest your head against the cool metal wall, and close your eyes. Your head feels light and heavy, exhaustion is creeping in, taking the place of adrenaline. But you know sleep is last thing you should do when you have a concussion. You might not wake up.

So you just sit there, listening to the humming of the engines and the nothingness of hyperspace, wondering when the ship will reach its destination, and how long you'll be able to hide away like this.

You don't even make it half a day.

You start awake when you hear the doors being opened to the backlog room, and curse yourself for falling asleep. You listen, your heart beating erratically, as the footsteps outside draw near. You hear a grunt and a heavy click, and assume that another block of Carbonite has been added to the collection. You sit very still, waiting to hear footsteps receding.

You're still listening intently when the door in front of you is suddenly ripped open. You blink into the sudden brightness and don't have a chance to react before the Mandalorian grabs your arm and rips you out of the compartment, pushing you up against the wall with his arm under your throat, and blaster pointed straight at you.

"How did you get in here?" He asks, voice deadly.

"How did you find me?" You ask him, still dazed from the speed and catching up with the events.

"Heat. Now answer me." He bites back.

You look up at him, at the beskar helmet glinting into the light, reflecting everything around it, including your own disheveled, terrified expression. You assume that means the helmet has heat sensor technology. Dank farrik. You can't see anything behind the helmet, and you only have his voice to go off of. It's warning you, that you are in so much danger. The alarm bells in your head are going crazy, and a part of you regrets ever climbing on this ship. You may have just put yourself in more danger.

"I-I saw you in the control room and uh, went to find your ship. You weren't there and the uh the hatch was open and I climbed in and and hid away." You whisper, hoping it's enough.

"Why?" He grunts. You look at him, and notice his grip hasn't faltered once, he hasn't moved a millimetre. You try to gulp, but the pressure on your throat makes it difficult.

"The transport was.. was dead in the water. I needed a way off. I would have died there." You mutter, looking down when you feel your eyes burn.

He just stands there looking at you, keeping you in the same position. You squirm uncomfortably, wondering if he's going to kill you, or throw you in carbonite.

"Please, please just let me stay until we reach the next planet. I promise I mean no harm. I'm just trying to survive, and to get back home. Just don't put me in carbonite, please. Please, I can be useful. I'm a doctor." You babble, trying to save your own hide. He loosens his grip when you mention that you're a doctor, and he steps away slightly, but still makes sure you stay pinned.

"Come." He says brusquely, and without another word he grabs your upper arm and leads you out the door and across into the cockpit. He forces you into a chair, and then binds your wrists in front of you. You frown, but you suppose it's better than Carbonite. You look up to his captain's chair, and see two big black eyes staring at you, with big green floppy ears on either side of an old, but adorable face. This must be the kid.

"Stay put." He commands you, without giving you another glance and moving towards his seat. You lean to the side to try and get a glimpse of the planet he's put into the co-ordinates. Nevarro. You groan internally. You're at least three days away from Nevarro. Slumping into your chair you try to be grateful that you're still alive, while also thinking to yourself that it's going to be a loooong three days.

#mandalorian#din djarin#fanfic#mando x reader#it's mando hours#star wars#scifi#maybesomesmutlater#stowaway#breakingdownmandoswalls#maybeimobssesedwithdin#inspired by rough day

2 notes

·

View notes