#Cetane Rating

Text

Introduction to the Revolutionary CFR® F5 Cetane Rating Unit

In the ever-evolving landscape of diesel fuel testing, few innovations have left a mark as significant as the CFR® F5 Cetane Rating Unit. Since its debut in 1938, this ground-breaking tool has continually redefined how we evaluate and certify diesel fuels' ignition quality. The CFR F5 remains a pivotal element in maintaining the integrity of the fuel supply chain from refinery to pump.

Setting the Gold Standard in Fuel Testing

At the heart of this revolution lies the CFR F5 Cetane Rating Unit, meticulously engineered to not only meet but exceed globally recognized standards such as ASTM D613, IP 41, and EN ISO 5165. This unit ensures that diesel fuels consistently reach their highest potential in quality.

Seamless Integration for Testing Confidence

The comprehensive cetane fuel testing system provided by CFR Engines Inc. includes the F5 engine unit, XCP™ Technology, and a CFR® exhaust surge tank. These components work harmoniously to manage critical parameters, ensuring a seamless cetane test process. Users can trust this integrated system for heightened efficiency and reliability, whether they opt for a complete unit or upgrade/conversion kits.

Data Prowess with XCP Technology

The XCP Digital Control Panel is a transformative feature that automates data collection and presentation. By eliminating manual errors and integrating with Laboratory Information Management Systems (LIMS), it ensures precise data on handwheel positions, fuel flow rates, and environmental conditions are always available.

Reliability Woven into Design

Since 1929, CFR Engines Inc. products have built a legacy of reliability. The latest upgrades and enhancements to engine crankcases and cylinder heads ensure that these units withstand modern testing environments with minimal maintenance required.

Precision Unleashed Through Modern Instrument Control

Combining the CFR F5 with XCP Technology leverages digital instrumentation for recording and processing crucial system data. Features like on-board handwheel position recording, automatic cetane number calculation, and multi-pass data recording contribute significantly to achieving greater precision and accuracy in tests.

Cost-Efficiency Through One System Flexibility

Beyond precision improvements, the CFR F5 offers unmatched flexibility and cost savings. With push-button control and guided testing prompts, users benefit from more efficient resource utilization—leading to faster tests and reduced operator training requirements.

Additional Highlights: Elevating Safety and Convenience

Safety is paramount with integrated monitoring systems guarding against power loss, low oil pressure, overheating, and electrical overloads. A fuel flow safety shut-off solenoid prevents uncontrolled engine over-speed during power outages. User-friendly XCP Technology further simplifies operation via an easy-to-use touch-screen HMI panel featuring on-screen stability indicators for "Injection Advance" and "Ignition Delay." An electronic maintenance log records essential maintenance information for future reference.

Experience Tomorrow’s Diesel Fuel Testing Today

Embrace the future of diesel fuel testing with the CFR F5 Cetane Rating Unit—transforming your processes for superior results and peace of mind.

Frequently Asked Questions (FAQs) About the CFR® F5 Cetane Rating Unit

What is the CFR F5 Cetane Rating Unit?

The CFR F5 is essential equipment used to determine and certify diesel fuels' ignition quality—ensuring their suitability for use in automotive engines within petroleum industries.

How long has it been in use?

Introduced in 1938, the CFR F5 has proven its reliability over more than eight decades of service.

Which standards does it comply with?

The unit adheres to globally recognized standards including ASTM D613, IP 41, and EN ISO 5165—guaranteeing accurate cetane number measurements consistently.

What components are included in a complete system?

A complete system consists of an F5 engine unit paired with XCP™ Technology along with a CFR® exhaust surge tank—all working together seamlessly during cetane tests.

How does XCP Technology enhance data integrity?

XCP Technology automates capturing/presenting data while reducing manual errors; providing accurate details about handwheel positions/fuel flow/environmental conditions through LIMS integration.

Is it user-friendly? How easy is operator training?

Absolutely! Designed for ease-of-use—the intuitive interface makes operator proficiency achievable quickly—saving both time/resources during training sessions effectively!

How does it ensure reliability/longevity?

CFR Engines Inc.'s long-standing legacy dating back since 1929 assures enduring durability through well-planned upgrades/enhancements minimizing maintenance needs significantly!

Are there additional safety/monitoring features integrated within this unit?

Yes indeed! Various integrated safety measures protect against multiple factors ensuring operational equipment/operator safety throughout usage durations effectively!

Does it offer on-screen stability indicators too? Certainly! On-screen indicators eliminate manual averaging enhancing consistency among operators massively overall improving efficiency/productivity rates exponentially higher beyond expectations usually met beforehand traditionally speaking generally speaking categorically put forth clearly stated objectively noted herein specified concisely elaborated upon succinctly expressed precisely articulated definitively concluded.

0 notes

Text

CFR Engines is a global leader in manufacturing fuel testing equipment, offering highly reliable octane and cetane rating units. These units are essential for accurately assessing the ignition quality of fuels, aiding the automotive and petroleum industries in maintaining performance standards. With decades of experience, CFR’s products are trusted worldwide for delivering precision in fuel analysis, making them a key partner in fuel testing and quality control across various industries.

0 notes

Text

0 notes

Text

Revving Up Your Ride: Unleashing Peak Performance with Diesel Power Additives

Diesel engines are renowned for their workhorse capabilities, powering trucks, machinery, and even some high-performance vehicles. However, like any machine, diesel engines can experience a decline in performance over time. This can manifest as decreased power, reduced fuel efficiency, and increased emissions. Here at Bluchem, we understand the importance of keeping your diesel engine running smoothly. That's why we offer a range of high-quality diesel power additives in Australia, designed to optimize performance and keep your engine purring like new.

Beyond the Pump: Unveiling the Challenges Faced by Diesel Engines

Several factors can contribute to a decline in diesel engine performance:

Low Cetane Levels: Cetane rating indicates a diesel fuel's ability to ignite. Lower cetane levels lead to rough idling, increased engine noise, and incomplete combustion, resulting in wasted fuel and higher emissions.

Fuel Impurities: Contaminants like water and dirt in your fuel system can clog injectors, hinder proper combustion, and even lead to corrosion.

Carbon Buildup: Over time, carbon deposits can accumulate on injectors and valves, reducing fuel flow and efficiency.

Bluchem Diesel Power Additives: The Solution for Optimal Performance

Bluchem's range of diesel power additives addresses these challenges head-on, helping you restore and maintain peak engine performance:

Cetane Boosters: These additives elevate the cetane rating of your diesel fuel, promoting cleaner and more complete combustion. This translates to smoother starts, reduced engine noise, and improved fuel efficiency.

Fuel System Cleaners: Our additives act as detergents, removing harmful contaminants and preventing future buildup in your fuel system. This ensures optimal fuel flow and injector performance.

Lubricity Enhancers: Modern diesel fuels often lack the lubricating properties of traditional diesel. Bluchem's additives act as lubricity enhancers, protecting your engine components from wear and tear.

Water Dispersants: These additives help disperse water droplets present in your fuel tank, preventing corrosion and ensuring smooth engine operation.

Beyond Additives: The Bluchem Advantage

Choosing Bluchem for your diesel power additives in Australia goes beyond just the product itself. Here's what sets us apart:

High-Quality Formulations: We use only premium ingredients in our additives, ensuring their effectiveness and safety for your engine.

Performance Enhancement: Our additives are rigorously tested to deliver measurable improvements in engine performance, fuel efficiency, and emissions reduction.

Easy Application: Our diesel power additives are designed for user-friendly application, allowing you to easily maintain your engine's health.

Variety of Options: We offer a range of diesel power additives tailored to address specific engine needs and challenges.

Imagine a Restored and Optimized Engine

Investing in Bluchem's diesel power additives empowers you to breathe new life into your diesel engine. Imagine regaining lost power, maximizing fuel efficiency, and reducing harmful emissions. Our additives not only enhance performance but also contribute to a cleaner and more environmentally friendly operation.

Contact Bluchem Today!

Explore Bluchem's range of high-quality diesel power additives in Australia today! We have the perfect solution to keep your engine running smoothly and efficiently. Contact us and discover how our additives can help you achieve optimal diesel engine performance.

Contact-

Web - https://www.bluechemaustralia.com.au/diesel-power-additive/

Mail - [email protected]

Ph - 0498 880 115

Address - UNIT 4, 63 Brunel Rd, Seaford VIC 3198, AU

#diesel power additive#diesel cetane booster#diesel fuel booster#diesel booster additive#diesel additive#diesel additive Australia#diesel fuel additive#diesel fuel additives australia

0 notes

Text

Fueling Innovation: SINPAR's Precision in Energy

In the bustling metropolis of Shanghai, SINPAR stands as a beacon of innovation in the fuel testing industry. With a focus on precision and reliability, SINPAR's advanced octane and cetane rating units are transforming the way the world measures fuel quality.

A Legacy of Excellence

SINPAR's commitment to excellence is evident in their flagship product, the FTC-M2 Combination Octane Rating Unit. This instrument is not just a tool but a symbol of SINPAR's dedication to upholding the highest standards of testing, as defined by ASTM D2699 and D2700.

Global Impact

The reach of SINPAR's technology extends far beyond Shanghai, impacting industries across the globe. Their products ensure that whether it's a fuel testing lab in Europe or an oil refinery in the Middle East, the quality of motor fuels is assessed with unparalleled accuracy.

Looking Ahead

As SINPAR looks to the future, they remain steadfast in their mission to support the energy sector with innovative solutions. Their recent software enhancements for the Automatic Reference Fuel Blending System are set to redefine industry benchmarks once again.

To know more, visit the website of SINPAR.

For inquiries, reach out at [email protected] or call +86 21-60538164.

###

0 notes

Text

Octane and Cetane tester

Labotronics octane and cetane portable tester ,implies research and motor measuring methods (RON and MON).It measure octane rating of fuel's resistance to knocking(damaging engine components) under range 40 to 125ON,cetane which promotes quicker and more efficient to fuel combusts in a diesel engine under range 20 to 100 CN with international standards .Its features settings under temperature conditions for winter, summer, and arctic diesel measurements.The display presents the measured results.

Read more

0 notes

Text

Fuel Additives Market, Size, Trends, Future Forecast and Outlook

Fuel Additives Market

The market research report provides a comprehensive analysis of the industry, with a specific focus on the Fuel Additives Market. It examines the size, growth rate, and major trends within the Fuel Additives Market, offering valuable insights into its current state and future prospects. The report explores the significance of Fuel Additives in driving market dynamics and shaping business strategies. It investigates the market drivers, such as increasing consumer demand and emerging trends related to Fuel Additives, providing a deep understanding of the factors influencing market growth. Additionally, the report assesses the competitive landscape within the Fuel Additives Market, profiling key players and their market share, strategies, and product offerings. It also addresses market segmentation, identifying different segments within the Fuel Additives Market and their unique characteristics. Overall, the market research report equips businesses operating in the Fuel Additives Market with valuable information and actionable recommendations to capitalize on opportunities and navigate the challenges in the industry.

Request Free Sample Report @ https://www.vertexbusinessinsights.com/request-sample/181/fuel-additives-market

This research covers COVID-19 impacts on the upstream, midstream and downstream industries. Moreover, this research provides an in-depth market evaluation by highlighting information on various aspects covering market dynamics like drivers, barriers, opportunities, threats, and industry news & trends. In the end, this report also provides in-depth analysis and professional advices on how to face the post COIVD-19 period.

The research methodology used to estimate and forecast this market begins by capturing the revenues of the key players and their shares in the market. Various secondary sources such as press releases, annual reports, non-profit organizations, industry associations, governmental agencies and customs data, have been used to identify and collect information useful for this extensive commercial study of the market. Calculations based on this led to the overall market size. After arriving at the overall market size, the total market has been split into several segments and sub segments, which have then been verified through primary research by conducting extensive interviews with industry experts such as CEOs, VPs, directors, and executives. The data triangulation and market breakdown procedures have been employed to complete the overall market engineering process and arrive at the exact statistics for all segments and sub segments.

Fuel Additives Market Segment Analysis

Fuel Additives Market by Type

Deposit Control

Cetane Improvers

Lubricity Improvers

Cold Flow Improvers

Stability Improvers

Octane Improvers

Corrosion Improvers

Fuel Additives Market by Application

Gasoline

Diesel

Aviation Fuel

Fuel Additives Market by Region

North America

Europe

Asia Pacific

South America

Middle East & Africa

Ask Queries @ https://www.vertexbusinessinsights.com/enquiry/181/fuel-additives-market

Table of Content

1 Executive Summary

2 Market Introduction

2.1 Definition

2.2 Architecture

2.3 Scope of the Study

2.4 Related Stakeholders

3 Research Methodology

3.1 Introduction

3.2 Primary Research

3.2.1 Key Insights

3.2.2 Breakdown of Primary Interviews

3.3 Secondary Research

3.3.1 Important Sources

3.4 Market Size Estimation Approaches

3.4.1 Top-Down Approach

3.4.2 Bottom-Up Approach

3.4.3 Data Triangulation

3.5 List of Assumptions

4 Market Dynamics

4.1 Introduction

4.2 Drivers

4.3 Restraints

4.4 Opportunities

4.5 Porter's Five Forces Model Analysis

4.6 Value Chain Analysis

4.7 Impact of COVID-19 on Global Fuel Additives Market

5 Global Fuel Additives Market, By Type

5.1 Introduction

5.2 Deposit Control

5.3 Cetane Improvers

5.4 Lubricity Improvers

5.5 Cold Flow Improvers

5.6 Stability Improvers

5.7 Octane Improvers

5.8 Corrosion Improvers

6 Global Fuel Additives Market, By Application

6.1 Introduction

6.2 Gasoline

6.3 Diesel

6.4 Aviation Fuel

7 Global Fuel Additives Market, By Region

7.1 Introduction

7.2 North America

7.2.1 US

7.2.2 Canada

7.2.3 Mexico

7.3 Europe

7.3.1 Germany

7.3.2 UK

7.3.3 France

7.3.4 Italy

7.3.5 Spain

7.3.6 Rest of Europe

7.4 Asia-Pacific

7.4.1 China

7.4.2 India

7.4.3 Japan

7.4.4 South Korea

7.4.5 Rest of Asia-Pacific

7.5 Middle East and Africa

7.6 South America

8 Competitive Landscape

8.1 Introduction

8.2 Vendor Evaluation Criteria

8.3 Vendor Share Analysis, 2021

8.4 Recent Developments, 2019-2021

8.4.1 New End User Launches

8.4.2 Partnerships

8.4.3 Mergers or Acquisitions

8.4.4 Business Expansions

9 Company Profiles

(This section covers the Business Overview, Financial Overview, End User and End User Offerings, Recent Developments, SWOT Analysis, and Key Strategies of the top market vendors. The given sequence does not represent their rankings in the market.

9.1 Afton Chemical Corporation

9.2 BASF SE

9.3 Chevron Corporation

9.4 The Lubrizol Corporation

9.5 Innospec Inc.

9.6 Evonik Industries AG

9.7 Clariant AG

9.8 Infineum International Ltd.

9.9 TotalEnergies Additives and Special Fuels

9.10 Croda International Plc

9.11 Dorf Ketal

9.12 Ecolab Inc.

9.13 Cerion LLC

9.14 Cummins Filtration

9.15 Chemtura Corporation

9.16 Fuel Performance Solutions, Inc.

9.17 Baker Hughes (a GE company)

9.18 Eastman Chemical Company

9.19 Shell Chemicals

9.20 Buckman Laboratories International, Inc.

9.21 ENI SPA

9.22 Chemours Company

9.23 Dorf Ketal Chemicals India Private Limited

9.24 Wynn's (Prestone Products Corporation)

9.25 Amtecol LLC

9.26 Others

10 Appendix

10.1 Discussion Guide

10.2 Customization Options

10.3 Related Reports

Continue…

ABOUT US:

Vertex Business Insights is one of the largest collections of market research reports from numerous publishers. We have a team of industry specialists providing unbiased insights on reports to best meet the requirements of our clients. We offer a comprehensive collection of competitive market research reports from a number of global leaders across industry segments.

CONTACT US

Phone:

+ (210) 775-2636 (USA)

+ (91) 853 060 7487

0 notes

Text

Gangour Group: Udaipur's Premier Biofuel Manufacturer

Are you tired of the rising fuel prices and the detrimental impact of fossil fuels on the environment? Look no further because Gangour Group, the premier biofuel manufacturer in Udaipur, is here to revolutionize your energy choices. In this article, we'll delve deep into the world of biofuels, discover what makes Gangour Group stand out, and explore the benefits of choosing biofuels for your energy needs.

What is Biofuel?

Let's start with the basics. Biofuels are eco-friendly alternatives to traditional fossil fuels like gasoline and diesel. They are derived from renewable biological sources, such as plants and animal waste. Biofuels are the future of sustainable energy, and Gangour Group is at the forefront of this green revolution.

Types of Biofuels

There are different types of biofuels, including biodiesel, bioethanol, and biogas. Each has its unique characteristics and applications. Gangour Group specializes in producing biodiesel, which is made from vegetable oils or animal fats through a process called transesterification.

Gangour Group: A Brief Introduction

Gangour Group is not just another biofuel manufacturer in Udaipur; it's a name synonymous with quality, innovation, and sustainability. Founded with a vision to reduce carbon emissions and promote a cleaner planet, Gangour Group has been relentlessly pursuing excellence in the biofuel industry.

What Sets Gangour Group Apart?

State-of-the-Art Facilities Our manufacturing facilities are equipped with cutting-edge technology, ensuring the highest quality biofuels. We take pride in our commitment to environmental responsibility, and our facilities are a testament to that.

Local Sourcing We believe in supporting local farmers and businesses. Gangour Group procures raw materials from local sources, contributing to the economic growth of the community.

Rigorous Quality Control Our biofuels undergo stringent quality control measures to meet international standards. We ensure that every drop of biofuel you use is of the highest quality and eco-friendly.

Innovation and Research Innovation is at the core of our operations. Our dedicated research and development team continually seeks ways to improve biofuel production and reduce our carbon footprint.

Benefits of Choosing Biofuels

Now that you know what makes Gangour Group exceptional, let's explore the numerous advantages of using biofuels.

Environmental Friendliness

Biofuels are a cleaner and greener energy option. They produce significantly fewer greenhouse gas emissions compared to fossil fuels, helping combat climate change.

Renewable Resource

Unlike fossil fuels, which are finite and depleting, biofuels are made from renewable resources. As long as we have crops and animal waste, we can continue producing biofuels.

Energy Security

Biofuels reduce a nation's dependence on imported oil. By supporting local biofuel production, you contribute to your country's energy security.

Economic Benefits

The biofuel industry creates jobs and stimulates economic growth in local communities. Choosing biofuels helps build a stronger and more sustainable economy.

Engine Performance

Biofuels can enhance engine performance and longevity. They have a higher cetane rating, which means cleaner combustion and less wear and tear on your vehicle's engine.

Reduced Pollution

Biofuels produce fewer pollutants, such as sulfur and particulate matter, which can be harmful to both the environment and human health.

Gangour Group's Commitment to Sustainability

At Gangour Group, we don't just stop at producing biofuels. We are committed to a sustainable future in every aspect of our business.

Waste-to-Energy

We are actively exploring innovative ways to convert organic waste into biogas, further reducing waste and carbon emissions.

Community Engagement

Our company engages with local communities to create awareness about the benefits of biofuels and provides training and employment opportunities.

Green Initiatives

We invest in green initiatives and eco-friendly technologies to minimize our environmental footprint.

How You Can Make a Difference

As a conscious consumer, you have the power to make a difference. By choosing Gangour Group's biofuels, you not only reduce your carbon footprint but also support a sustainable future for generations to come.

Spread the Word

Tell your friends and family about the benefits of biofuels and Gangour Group's commitment to sustainability.

Support Local

By choosing biofuels produced by Gangour Group, you support local farmers and businesses, contributing to your community's growth.

Drive Green

Switch to biofuels for your vehicles and equipment, and experience the benefits of cleaner energy firsthand.

Conclusion

In a world where environmental concerns are paramount, Gangour Group emerges as a shining beacon of hope. As Udaipur's premier biofuel manufacturer, we are committed to providing you with high-quality, eco-friendly biofuels that not only meet your energy needs but also contribute to a cleaner and greener planet. Join us in this journey towards a sustainable future, one biofuel at a time. Make the switch today, and together, we can drive positive change for our environment and our communities.

0 notes

Text

Maximizing Efficiency and Longevity: The Importance of Diesel Fuel Service

Diesel engines have been the backbone of industries ranging from transportation to manufacturing due to their unparalleled power and efficiency. However, maintaining and optimizing the performance of diesel engines requires diligent care, with one critical aspect being diesel fuel service. This process is essential for ensuring both the efficiency of the engine and its long-term operational lifespan.

Understanding Diesel Fuel Service

Diesel fuel service encompasses a range of activities designed to ensure that the diesel fuel used in engines is of high quality and properly treated to provide optimal combustion and performance. This process involves a combination of fuel filtration, additives, and regular maintenance to prevent any contaminants from entering the engine, while also enhancing the fuel's properties for efficient combustion.

Importance of Diesel Fuel Service

Enhanced Engine Performance: Diesel fuel that is laden with impurities, water, or contaminants can significantly hamper engine performance. These particles can clog fuel injectors, reduce combustion efficiency, and lead to incomplete fuel burn, all of which result in reduced power output and increased fuel consumption. Regular diesel fuel service helps maintain the fuel's cleanliness, ensuring smooth operation and maximum power.

Fuel Efficiency: A well-maintained diesel fuel system translates to better fuel efficiency. By ensuring the proper mix of air and fuel, diesel engines can achieve higher energy output per unit of fuel consumed. Inefficient combustion, caused by poor quality fuel, results in wasted energy and higher fuel consumption.

Emission Control: Diesel engines are known for their higher emissions of particulate matter and nitrogen oxides. However, proper diesel fuel service can minimize these emissions by promoting efficient combustion. When fuel burns completely, fewer harmful pollutants are released into the atmosphere.

Longevity of Components: Contaminants in diesel fuel can accelerate wear and tear on engine components. Fuel injectors, pumps, and other vital parts can suffer damage when exposed to impurities. Regular fuel service prevents such damage, thereby extending the lifespan of these components and reducing the need for costly repairs or replacements.

Preventing Water Accumulation: Diesel fuel can absorb moisture over time, leading to the formation of water droplets. These water droplets can cause corrosion within the fuel system and promote microbial growth. Diesel fuel service involves removing water from the fuel through filtration and additives, preventing these issues from arising.

Key Components of Diesel Fuel Service

Fuel Filtration: Filtration systems are used to remove solid particles and contaminants from the diesel fuel before it enters the engine. These filters prevent particles from reaching sensitive components and causing damage.

Fuel Additives: Additives are mixed with diesel fuel to enhance its properties. They can improve cetane ratings (which affects combustion efficiency), stabilize fuel, and prevent the formation of harmful deposits.

Regular Maintenance: Consistent maintenance, including filter replacement and system inspections, is crucial for keeping the fuel system in top condition. Regular maintenance helps catch potential issues before they escalate.

Conclusion

Diesel fuel service is an essential practice for maintaining the performance, efficiency, and longevity of diesel engines. By ensuring that the fuel entering the engine is clean, properly treated, and of high quality, industries can reap the benefits of lower fuel consumption, reduced emissions, and prolonged engine life. In a world that increasingly values sustainability and operational efficiency, diesel fuel service emerges as a vital component in achieving these goals for both businesses and the environment.

For More Info :-

anytime fuel ppros in san antonio

anytime fuel pros

anytime fuel pros san antonio

0 notes

Text

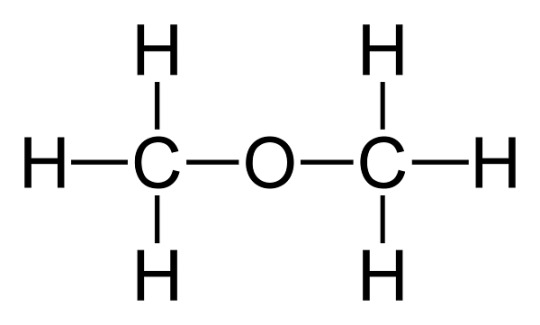

Driving the Transition: Di Methyl Ether Market as a Key Renewable Energy Resource

Di Methyl Ether (DME) is a colorless gas with a faint sweet odor. It is commonly used as an aerosol propellant, fuel, and intermediate chemical in various industries. DME is a versatile alternative to traditional fossil fuels and has gained significant attention due to its favorable environmental characteristics. This article provides a comprehensive overview of the Di Methyl Ether market, including its production, applications, key players, and market trends.

Market Size and Forecast:

The Di Methyl Ether market has witnessed substantial growth in recent years. According to industry reports, the global Di Methyl Ether market was valued at approximately USD 5.3 billion in 2020. The market is projected to grow at a compound annual growth rate (CAGR) of around 8% from 2021 to 2028, reaching a value of over USD 9 billion by the end of the forecast period.

Key Drivers and Challenges:

Several factors are driving the growth of the Di Methyl Ether market:

Increasing Demand for Clean-Burning Fuels: DME is considered an environmentally friendly fuel as it emits lower levels of pollutants compared to conventional fossil fuels, contributing to reduced greenhouse gas emissions and improved air quality.

Government Regulations and Incentives: Stringent government regulations aimed at reducing emissions and promoting sustainable energy sources are encouraging the adoption of DME as a transportation fuel and industrial feedstock. Incentives and subsidies provided by various governments further support market growth.

Growing Industrial Applications: DME is extensively used as a raw material in the production of chemicals, aerosol propellants, and solvents. The expanding chemical industry, particularly in emerging economies, is expected to drive demand for DME.

Despite the positive market outlook, a few challenges may hinder the growth of the Di Methyl Ether market:

High Production Costs: The production of DME involves complex processes, including syngas generation and methanol synthesis. The capital-intensive nature of DME production and the requirement for advanced technologies contribute to higher production costs, which may limit market expansion.

Infrastructure Limitations: The adoption of DME as a transportation fuel requires appropriate infrastructure, including refueling stations and storage facilities. The lack of a well-established infrastructure network poses a challenge to the widespread adoption of DME as a fuel.

Competition from Alternative Fuels: DME faces competition from other alternative fuels, such as liquefied petroleum gas (LPG), compressed natural gas (CNG), and electric vehicles (EVs). The availability and increasing popularity of these alternatives may affect the demand for DME.

Applications:

The Di Methyl Ether market finds applications in various sectors:

Transportation: DME is gaining traction as a fuel for diesel engines due to its high cetane number and low emissions. It can be used as a standalone fuel or blended with diesel, providing a cleaner-burning alternative for heavy-duty trucks, buses, and off-road equipment.

Chemical Industry: DME serves as a versatile chemical intermediate for the production of solvents, dimethyl sulfate, dimethyl ether-based aerosol propellants, and other specialty chemicals. It offers advantages such as low toxicity and excellent solubility.

LPG Blending: DME can be blended with liquefied petroleum gas (LPG) to enhance its combustion properties, improve fuel efficiency, and reduce emissions.

Refrigeration and Aerosols: DME is used as a propellant in aerosol products such as paints, cosmetics, and household sprays due to its low toxicity and non-flammability.

Key Players:

The Di Methyl Ether market comprises several prominent companies operating globally. Some of the key players include:

Akzo Nobel N.V.

China Energy Ltd.

Ferrostal GmbH

Grillo-Werke AG

Korea Gas Corporation

Mitsubishi Corporation

Oberon Fuels Inc.

Royal Dutch Shell plc

Toyo Engineering Corporation

Zagros Petrochemical Company

These companies focus on research and development activities, strategic collaborations, and capacity expansions to strengthen their market position and meet the growing demand for Di Methyl Ether.

Conclusion:

The Di Methyl Ether market is witnessing significant growth due to its eco-friendly properties, increasing adoption as a transportation fuel, and diverse industrial applications. Government support, technological advancements, and rising environmental concerns are expected to drive market expansion in the coming years. However, challenges related to production costs and infrastructure need to be addressed to unlock the full potential of the Di Methyl Ether market.

0 notes

Text

Fuel Additives Market May See a Big Move by 2028

The report on the Fuel Additives Market published by Stratview Research covers in depth details associated with the Fuel Additives Market.

To get a free sample report, Click here:

The Fuel Additives Market is likely to witness a CAGR of 8.8% during the forecast period. The prime factors that are driving the Fuel Additives Market is its superior thermal conductivity property leading to its wide usage in a wide array of industries.

Key Players

The following are the key players in the Fuel Additives Market:

Afton Chemical Corporation

Innospec Inc.

The Lubrizol Corporation

BASF SE

Infinieum Limited

Evonik Industries AG

Chevron Oronite Company LLC

Lanxess

Dorf Ketal Chemicals

Cummins Inc.

Cerion LLC.

Growth drivers and Market Value:

This report, from Stratview Research, studies the Fuel Additives Market value and growth drivers over the trend period of 2022-27. According to the report -

Fuel Additives Market is likely to witness a modest CAGR of 3.4% during the forecast period. Mounting sales of automobiles worldwide, launch of improved products, increasing demand for performance products, growing awareness towards benefits of fuel additives, imposition of emission norms by governments are some of the key factors driving the market growth of the industry.

Segment Analysis:

Based on Additive Type:

Based on the additive type, the market is segmented as deposit control, dyes & markers, cetane improvers, lubricity improvers, cold flow improvers, octane improvers, corrosion inhibitors, stability improvers, anti-icing, and others. The deposit control segment held the largest share of the market in 2021, and is expected to register a moderate CAGR during the forecast period. The extensive use of deposit control additives in various applications is driving the growth of this segment.

Based on Region:

In terms of regions, North America is estimated to be the largest as well as fastest-growing fuel additives market during the forecast period, with the US being the largest fuel additive consumer in the region. The country is one of the matured markets for fuel additives. The high regulation of the Environmental Protection Agency (EPA) plays a major role in the commercialization of fuel additive products in the region.

Critical Questions Answered in the Report

What are the key trends in the Fuel Additives Market?

How the market (and its various sub-segments) has grown in the last five years and what would be the growth rate in the next five years?

What is the impact of COVID-19 on Fuel Additives Market?

What are the key strategies adopted by the major vendors to lead in the Fuel Additives Market?

What is the market share of the top vendors?

Order a Copy of Fuel Additives Market report here

About Us

Stratview Research is a global market research and consulting service provider, offering syndicated and custom research reports along with growth consulting services. Our business intelligence and industry research reports offer clients with insightful and actionable market data to aid strategic decision making. These exclusive reports are the result of exclusive research methodology and are available for key industries such as chemicals, composites, advanced materials, technology, renewable energy, and more. Stratview Research helps its user’s tract the ever-evolving market scenarios through its top-notch market reports.

Get in touch with us at – [email protected] connect with our experts at +1-313-307-4176

0 notes

Text

Revolutionizing Diesel Fuel Quality Assessment with the CFR® F5 Cetane Rating Unit

In 1938, CFR® introduced the CFR F5 Cetane Rating Unit, a groundbreaking invention that transformed diesel fuel quality assessment globally. Today, the CFR F5 remains a reliable and precise tool influencing the automotive and petroleum industries, ensuring fuel supply chain integrity from refinery to pump.

Setting the Bar for Diesel Fuel Assessment

The CFR F5 Cetane Rating Unit takes centre stage as the designated equipment for evaluating fuels according to pivotal standards such as ASTM D613, IP 41, and EN ISO 5165. Committed to excellence, it guarantees that diesel fuels adhere to the highest quality standards, instilling confidence across the industry.

Seamless Integration for Comprehensive Fuel Testing

A complete CFR Engines Inc. cetane fuel testing system comprises three essential components: the F5 engine unit, XCP™ Technology, and a CFR® exhaust surge tank. These elements work together seamlessly to control critical parameters for a successful cetane test. Whether you choose the complete unit, an upgrade/conversion kit, or authentic CFR service parts, rest assured that each product undergoes meticulous design, manufacturing, and rigorous testing, ensuring smooth operation, allowing users to focus on other vital tasks.

Elevating Data Integrity with XCP Technology

The XCP Digital Control Panel revolutionizes the game by automating data collection and presenting it in an easily accessible Excel-based report. It eliminates the hassles of manual data recording and calculation errors, providing invaluable information, including handwheel positions, fuel flow rate micrometeor settings, environmental data (temperatures and pressures), and ignition advance and delay values. Additionally, the XCP seamlessly integrates into a Laboratory Information Management System (LIMS), enhancing data accuracy and accountability.

Dependability Rooted in Proven Design

With a legacy dating back to 1929, CFR Engines Inc. products have earned the trust of countless users. This trust is built on a series of system upgrades and product enhancements that consistently ensure reliability. Components like the robust engine crankcase and cylinder/head are constructed to endure the demanding conditions of modern fuel testing environments with minimal maintenance.

Precision through Cutting-Edge Instrument Control

The CFR F5 Cetane Rating, when coupled with XCP Technology, leverages the power of digital instrumentation to record and process critical system data. On-board handwheel position recording, automatic cetane number calculation, and multi-pass data recording are just a few of the advantages offered by CFR's digital instrument control system, leading to higher precision and accuracy.

Efficiency and Savings Through System Flexibility

The CFR F5 Cetane Rating Unit offers unparalleled flexibility and cost savings through its standard product offerings. Users benefit from push-button control and guided testing prompts, streamlining the ASTM Method D613 testing procedure. These innovations result in more efficient resource utilization, quicker tests, and reduced operator training.

Additional Highlights

XCP integrated safety monitoring systems ensure protection against power loss, low oil pressure, overheating, and electrical overload. A fuel flow safety shut-off solenoid prevents uncontrolled engine over-speed in case of electrical power loss. A straightforward design of the thermal siphon cooling condenser maintains consistent cylinder jacket water temperature for stable operation. XCP Technology is user-friendly, reducing the training required for operators to achieve proficiency. Environmentally friendly resistance temperature detectors (RTDs) manage critical temperature variables. An electronic maintenance log records vital maintenance information for future reference. The synchronous/reluctance motor powers starting and absorbs engine output to maintain constant speed. An easy-to-use touch-screen HMI panel simplifies unit/test operation. Integrated digital cetane meter and temperature control reduce maintenance and servicing of specialized instrumentation. On-screen indicators inform when "Injection Advance" and "Ignition Delay" stability are achieved, enhancing operator consistency. A built-in diagnostic feature simplifies troubleshooting when maintenance is needed. On-screen operations and maintenance manuals are readily accessible for user convenience.

FAQs About the CFR® F5 Cetane Rating Unit

What is the CFR F5 Cetane Rating Unit, and why is it important?

The CFR F5 Cetane Rating Unit is a standard testing equipment used to determine and certify the ignition quality of diesel fuels. It's essential because it ensures that diesel fuels meet quality standards and are suitable for use in engines. This equipment is crucial for the automotive and petroleum industries.

How long has the CFR F5 Cetane Rating Unit been in use?

The CFR F5 Cetane Rating Unit was first introduced in 1938, making it a reliable and proven testing platform with a history of over eight decades.

Which standards does the CFR F5 Cetane Rating Unit comply with?

The CFR F5 Cetane Rating Unit is designed to comply with industry standards, including ASTM D613, IP 41, and EN ISO 5165. These standards are recognized globally and ensure the accuracy and consistency of cetane number measurements.

What components are included in a complete CFR Engines Inc. cetane fuel testing system?

A complete system includes three key components: the F5 engine unit, XCP™ Technology, and a CFR® exhaust surge tank. These elements work together to control critical parameters for a successful cetane test.

How does XCP Technology improve data integrity in cetane testing? XCP Technology automates the capture and presentation of critical data, reducing manual data recording and calculation errors. It provides information on handwheel positions, fuel flow rates, environmental conditions, and ignition advance and delay values, ensuring data accuracy.

Is the CFR F5 Cetane Rating Unit user-friendly, and how easy is it to train operators? Yes, the CFR F5 Cetane Rating Unit is designed to be user-friendly. The technology and user interface make it easier for operators to become proficient with minimal training, saving time and resources.

How does the CFR system ensure reliability and longevity in testing equipment?

CFR Engines Inc. products have a history dating back to 1929, and they consistently maintain reliability through well-designed system upgrades and enhancements. Components like the robust engine crankcase and cylinder/head are built to withstand the demands of modern fuel testing environments with minimal maintenance.

Are there additional safety and monitoring features integrated into the CFR F5 Cetane Rating Unit?

Yes, the CFR F5 Cetane Rating Unit includes XCP integrated safety monitoring systems to protect against various factors, such as power loss, low oil pressure, overheating, and electrical overload, ensuring the safety of both the equipment and operators.

Does the CFR F5 Cetane Rating Unit offer on-screen indicators for monitoring stability?

Yes, the system includes on-screen green lights to indicate when "Injection Advance" and "Ignition Delay" stability is achieved. This eliminates manual averaging and improves operator consistency.

Can the CFR F5 Cetane Rating Unit be easily maintained?

The CFR F5 Cetane Rating Unit is designed for ease of maintenance, and it comes with an electronic maintenance log to document vital maintenance information for future reference.

Conclusion: Shaping the Future of Diesel Fuel Testing

In this exploration of the world of diesel fuel testing, we've delved into the remarkable CFR F5 Cetane Rating Unit and its invaluable contributions to the automotive and petroleum industries. Dating back to its inception in 1938, this exceptional equipment has consistently set the gold standard for assessing the ignition quality of diesel fuels.

The CFR F5 Cetane Rating Unit, with its state-of-the-art XCP Technology, offers a seamless and dependable solution that not only guarantees precision and reliability but also simplifies the testing process. Its ability to automate data collection and reduce manual errors ensures data integrity, making it an indispensable tool for operators seeking efficiency and peace of mind.

The versatility and flexibility of the CFR F5 Cetane Rating Unit, along with its integrated safety features, user-friendly interface, and commitment to sustainability, make it a standout choice for modern fuel testing environments. Its legacy of reliability, rooted in a history dating back to 1929, reassures users that they are investing in equipment that withstands the test of time.

As we conclude this exploration, we invite you to experience the future of diesel fuel testing with the CFR F5 Cetane Rating Unit. Revolutionize your testing process, improve results, and enjoy the confidence that comes with this exceptional piece of equipment. Join the ranks of satisfied users who have found a trusted partner in CFR Engines Inc. and witness the difference that precision, reliability, and cutting-edge technology can make in your operations. Your journey towards better results and peace of mind starts here.

0 notes

Text

1 note

·

View note

Text

The fuel additives market size was valued at USD 6.0 billion in 2021 and is expected to grow at a compound annual growth rate (CAGR) of 3.4% from 2021 to 2026. The market is mainly driven by the rising demand for fuel additives in applications such as diesel, gasoline, aviation fuels, and others. Factors such as stringent governmental regulations will drive the fuel additives market. APAC is the key market for fuel additives, globally, in terms of volume. It is also the fastest-growing region in the fuel additives market. Whereas North America is the largest market for fuel additives, globally, in terms of value, followed by APAC and Europe.

0 notes

Text

Everything You Should Know About HVO Fuel

Now that people have become more and more conscious of their carbon footprint, different sustainable alternatives of everyday commodities have gained popularity – and one example of this is HVO fuel. HVO stands for hydrotreated vegetable oils and is another type of biofuel. For businesses, switching to HVO will not only make operation entirely eco-friendly, but it also brings so much more benefits to the table. If you want to know more about HVO, below are commonly asked questions, plus the corresponding answers.

What is HVO fuel?

Also known as Hydroprocessed Esters and Fatty Acids (HEFA) or sustainable Diesel, HVO biofuels (Hydrotreated Vegetable Oils) are much better for the climate and motors than mineral diesel. During the production process, hydrogen is used instead of methanol, which leads to hydrotreatment. When hydrotreating vegetable oils, oxygen is eliminated, reducing the factors that cause the fuel to oxidise. HVO is an excellent alternative for a range of applications that have an environmental impact.

How does the production of HVO works?

Hydrotreating vegetable oils is a modern way to produce high-quality diesel fuels from completely renewable materials, regrowing when needed stock. The use of the crops and materials such as vegetable oils and food waste does not damage the environment, contribute to deforestation, nor affect the ecosystem in any way.

What’s in HVO?

Both HEFA and HVO contain high cetane numbers and can be portrayed as chain paraffinic hydrocarbons. These chemicals don’t contain any aromatic, sulphur, fossil, and oxygen. They have some tremendous benefits over Fatty Acid Methyl Esters (FAME), making them suitable for transportation, agriculture, aviation, marine, and other applications

What are the benefits of using HVO biodiesel?

Wondering what these benefits are? Using HVO biodiesel in your canopy generators can slash harmful NOx emissions by up to 25% - without any impact on the performance of your generators. Furthermore, HVO biofuel can also eliminate by 42% the amount of particulate matter, which is adequate to make it more eco-friendly and sustainable, especially for businesses. Even with a higher HVO price, all of its benefits make it more cost-efficient.

How can I know if I can fill my vehicle with HVO?

HVO fuel meets the fuel specification EN15940, which guarantees that it can be used in all applications that require fuel to that standard. However, it is advised for consumers to consult their OEM first for approval.

How efficient is HVO?

HVO price offers vast savings on the greenhouse gas potential of your operation with no changes needed to your engine or infrastructure. Furthermore, the differences in the number of greenhouse gases emitted by regular diesel and HVO are also significant. For mineral diesel, 1,000 litres burned can produce 3.6 tonnes of GHG CO2, while 1,000litres of HVO burned only constitute 195kg or 0.195 tonnes of GHG CO2.

Lastly, HVO received a high cetane rating of more than 70, while mineral diesel-only got 51. This means that HVO is a highly efficient fuel, about how fast it can combust. So a higher cetane number means that the fuel will ignite more quickly, resulting in improved engine performance and reduced greenhouse gas emissions.

How is the cetane rating of HVO compared to regular diesel?

As mentioned, diesel has a cetane number of 51, and FAME biodiesel has a cetane number between 50 and 65. In contrast, HVO has a rating of between 70 to 90, which means it has better performance, has cleaner combustion, and is less likely to degrade in cold climates.

Will I have to change my boiler for HVO?

HVO biofuels are drop-in substitutes to mineral diesel, which means most devices that utilise this fuel can also accommodate HVO. However, it can also depend on the type of boiler you have. The more modern your boiler is, the more likely it will be compatible with HVO with a couple of simple modifications. Some newer boilers can consume HVO without requiring any alterations at all.

The bottom line is switching to HVO fuel from regular mineral diesel will not only help the environment, but your business can also gain positive financial and marketing benefits. Now that consumers seem to lean to ethically and sustainably made products, it’s time for you to keep up and completely stop using harmful diesel. Furthermore, with HVO having better quality and performance, your fuel consumption will also be more cost-efficient, saving you tons of money.

1 note

·

View note

Text

Legal Systems of the Core Worlds

The modern Westernized legal system is by no means the only way that things have been mediated throughout human history. It should be no surprise that parahuman legal systems vary widely as well.

Pallene: The Houses prefer to handle things internally whenever possible. The House Primus is responsible for settling disputes between members of their House and is even empowered to impose penalties for misdemeanor crimes against other members. When disputes arise between people in different Houses their Primii will try to sort something out first. But crimes against another House, or torts that get out of hand, the parties involved hire an Arbitrator from the Civil Guard, paying equally. Arbitrators are also called in for every instance of a felony, and especially in the case of murder. Premeditated murder carries an unambiguous death penalty, voluntary manslaughter ("spontaneous murder") may be reduced to a hefty fine and probation for up to a century under drone surveillance or house arrest. Conspiracy to commit murder merits exile to an Outworld. Lesser penalties tend towards fines and probationary periods that might be reduced if the convict goes to therapy. Punitive incarceration is unheard of.

Gepatrono-klientoj contracts establish somewhat similar legal relationships between patron and client to that between a Primus and their House, but with a key difference. Nobody can be compelled to testify against another member of their House save in the case of capital offenses, but a patron can be made to testify against their client while the inverse is not true. However, patrons are also required to pay their clients' legal fees and unofficially expected to use their connections in the oligarchy behind the scenes. Simply having a client who's been convicted of a crime is a stain on the patron's reputation, if the patron were to break contract when their client got arrested it would be even worse. In fact many Pallene oligarchs have become known for recruiting clients from members of less-wealthy Houses who've been accused of a crime.

Cetan: Old system: A caste-based system, when both parties were of the same caste they were judged by a local elder of their caste. For Labor-majority villages this was typically the village headsman. However if the dispute involved members of different castes a judge of the warrior-noble caste was called in. The warriors themselves benefited from a privilege similar to the kiri-sute gomen of Japan's medieval samurai, allowing them to pass judgement and sentence on commoners who offended them. It was uncommon but not unknown for a commoner who bumped into a warrior on the streets to be cut down on the spot.

Federated: After contact with Alpha Centauri and the formation of a central government the warrior-nobles' relative power has steadily eroded. Judges are now certified by a central testing system, with others prohibited from passing judgement regardless of caste. More recently it became possible for judges of any caste to arbitrate inter-caste disputes, so long as the judge doesn't share a caste with either party.

Eridani: The Eridani Directorate (Inc) relies heavily on their surveillance system to detect crimes and dispatch security officers rapidly. Officers will then subdue (if necessary) and issue fines on the spot. The accused can attempt to appeal, but usually they'll be lucky if they're allowed to pay gradually. Very little private property in EDI areas is not owned by the company, with residents only leasing it, and the company tends to rate crimes based on damage to its' property first and the livelihood of residents and employees second.

I recommend looking into David Friedman's Legal Systems Very Different From Ours for more information.

4 notes

·

View notes