#Ceramic based PCB

Text

Addressing Common Myths and Misconceptions about Ceramic-Based PCB

Ceramic-based circuit boards are changing electronics with their great ability to handle heat and last a long time. But there are some myths and misconceptions about these ceramic based PCBs. Let's talk about what's really true about these special circuit boards.

Myth #1: Ceramic PCBs are too expensive for everyday use.

Fact: Sometimes, ceramic PCBs might seem more expensive upfront compared to regular FR4 boards. But that's not always true. If you need electronics that handle a lot of power or need to be super reliable, ceramic PCBs are worth it in the long run. They work better, so your devices last longer and have fewer problems with parts breaking.

Myth #2: Ceramic PCBs are too complex to manufacture.

Fact: Making ceramic PCBs needs special methods, but things have gotten easier with new advancements. Lots of good companies can make custom ceramic PCBs now, so they're available for more kinds of projects.

Top of Form

Myth #3: Ceramic PCBs are too fragile for real-world applications.

Fact: Ceramic is really strong and stable. Unlike FR4, which can get weak in extreme temperatures, ceramic PCBs are super durable and can handle tough environments easily.

Myth #4: Ceramic PCBs are only for high-powered electronics.

Fact: Ceramic base PCBs are great for powerful uses, but they're useful for more than that. They can handle really hot or really cold temperatures, so they're perfect for things like planes, medical devices, and factories. Plus, they're really good for stuff like radar and communication systems that need strong signals.

Ceramic based PCBs are a strong choice compared to regular ones. They're great at handling heat, lasting a long time, and working really well, which makes them a good pick for tough jobs. And now, it's getting easier to make them, so we can expect even better electronics in the future.

Don't believe the myths! Think about using ceramic PCBs for your project and discover how amazing this new technology can be.For best ceramic PCBs solutions contact to BSTCeramicPCB.

0 notes

Text

LED PCB Assembly

What is the LED Circuit Board assembly?

Generally, LED PCB assembly is considered to be a circuit board that has the LED components soldered to it. The LED is soldered to the printed circuit board and features a chip that creates the light as electrically connected. A thermal heat sink and a ceramic base are used to bond the chip. Not all the PCB products can be used in Led industry, as an LED PCB is easy to create a high volume of heat, but making it hard to cool with traditional methods. For this reason, metal core PCB is widely used in LED application because of their enhanced ability to dissipate heat, especially aluminum pcb is often used to fabricate PCB for LED lights.

We’ve had great LED PCB assembly experiences with top LED chips to brand such as Cree, Luxeon, Osram, Nichia, Lumileds, MLS, EVERLIGHT, Samsung, LG, Seoul., etc. PCB LED lights can be incorporated into numerous lighting applications due to their combination of excellent energy efficiency, low cost and maximum design flexibility.

Application of LED PCB Assembly

Hitechpcba serves customers in different industries, providing highly reliable and innovative LED PCBs for various applications:

• Horticulture light LED PCB Assembly

• LED controller PCB Assembly

• Computer LED display and indicators

• LED lights PCB Assembly for medical use

• Automotive LED PCBs Assembly include PCBs for brake lights and headlights

• Street lighting LED PCB Assembly

• Flashlights and camping accessories

• Traffic light PCB Assembly

• Commercial lighting LED PCB Assembly

LED PCB Assembly specification

Number of layers for LED PCB

These layers are made up of aluminum and magnesium, but now have Copper base material and Ceramic base materials for LED PCB industry, we can meet it.

Aluminum LED PCBs stand out among other PCBs because it has a good insulation characteristic and has a better machinery performance, the cheap cost is one important factor too.

Types of layers for LED PCB Assembly

Normally, the base layer is made using aluminum alloy metal.

This aluminum alloy substrate used in making the base makes it ideal for through-hole technology which transfers and dissipates heat.

A thermal insulation layer is made using some ceramic polymer which has good viscoelasticity characteristics.

It is highly heat resistant and protects the PCB against heat and mechanical stress.

The circuit layer, which is covered by a copper foil which can range from one to ten ounces.

LED Board type- single or in panel

Some boards are shapeless. For this reason, LED PCB panels are used. This reduces time, labor production and testing time.

Some LED PCB Assembly is done on a single board while others are done on panel boards.

LED PCB Assembly Process

Roughly, the PCBA process can be divided into theses phases: soldering paste printing > SMT (surface mounted technology) > reflow soldering > AOI (automated optical inspection)> THT (through-hole technology) > wave soldering > touch-up and cleaning > IC-programming > FCT (functional tests) > aging testing.

Below we show you the process.

Step1. Summarizing Project Information

Before contacting your supplier, make sure you have all the project information. Suppliers will need info following for quoting LED PCB assembly:

Gerber

BOM

LED PCB specification

Quotation quantity

Once you have gathered these information, you can contact us and request for a quote.

Of course, you can also provide the schematic, LED PCB Assembly pictures and even samples to us. The more details they have, the more accurate the supplier’s quotation will be.

Step2. Discussion and details about custom LED PCB Assembly

Different projects will have different requirements. Remember the special requirements mentioned in step 1? That’s going to be the focus of this session. Equipment and engineering capacity will not be identical between suppliers. Make sure your supplier has the equipment to produce and assemble major components and the corresponding testing capabilities.

For example, some vendors don’t have X-ray testing equipment, which means they can’t check the mount quality of BGA chips. Outsourcing this step will increase risk and cost. That’s what you don’t want.

Also, pay attention to time taken by the supplier to quote. Motherboards often contain hundreds or even thousands of components, and they are supplied by different manufacturers. To ensure the quality of the components, the supplier sourcing team will make multi-inquiries from these manufacturers or authorized suppliers to match customer’s requirement, which usually takes 2-3 business days, and even longer for some scarce chips. Therefore, if your project is complex and the supplier quotes you within few hours, double check with them.

Step3. Sample and feedback

After confirming the PI, the supplier will usually provide pre-production samples for your approval. At the same time, the supplier will also confirm with you the logistics plan of the bulk goods. Make sure they understand your shipping requirements, including details on packaging, customs clearance, taxes, etc.

For us to have a successful LED PCB Assembly process, its functions must be defined. Compliance requirement is defined to reduce the effect when components are selected.

The Bill of Materials is then generated from the information installed on the LED PCB.

All this information is used to assemble components which are identified from MOB to the LED PCB.

After that, the routing of traces is determined to each component, based on the size, shape of the circuit board and location of connectors.

Hitech Circuits is trusted by thousands of electronic engineers on their LED PCB assembly projects, from consumer, led bulb to precisely medical LED light, we can help you from the beginning of design stage; From commercial flood LED to industrial high power LED, from automotive LED to military LED, Venture is the perfect place for your LED PCB assembly requirement.

Hitech Circuits has been participated in hundreds and thousands of LED lighting projects, by providing LED PCB and also LED PCB assembly service.

Our LED PCB assembly had covered both ends of the Lighting Class LED size spectrum, assembling some of the largest (2 meter long boards) and some of the smallest LED Lighting applications which used in Medical Endoscopes.

LED PCB Assembly is very crucial in the current industrial development. Many electrical devises are being innovated and the old once being improved.

LED PCBs are useful due to the fact that they are made using materials that can transfer and dissipate heat. This characteristic increases device durability.

The world is changing with new technology, especially PCB technology that plays an essential role in the application of LED circuits. And the LED industry is taking advantage of this technology and growing faster.

As a full feature PCB solutions provider with more than a decade of experience, we're capable to provide LED PCB fabrication, components procurement and LED PCB assembly all under one roof. We can work with you to develop metal core PCB, aluminum circuit boards customized to your specific applications. We feature competitively priced PCBs made with standard FR-4 material that includes a thermal aluminum clad layer that will efficiently dissipate heat, keep all LED PCB components cool and significantly enhance the performance of your products.

LED pcb board, LED pcb assembly

LED with its advantages of high brightness, high efficiency, low heat, long life, is considered the most development potential in the 21st century lighting. In the market and policy driven by the rapid development of the domestic LED industry blowout has formed a relatively complete industrial chain, including the production of epitaxial wafers, chip preparation, packaging, integration, LED application. In 2010, China's LED industry scale, up from $ 827 billion in 2019 to 220 billion yuan, an annual growth rate of over 70%, higher than the 50% level of growth of the global LED lighting industry output value. Among them, the middle and lower reaches of the most complete industrial chain, accounting for 90% of the overall percentage of the GDP.Chinahas become the world's leading LED manufacturing base and important application market.

To further promote the technological innovation of the LED industry, construction and wide application of independent industry chain, China Electronic Appliance Corporation and industry associations to organize the theme of "Focus on the core energy LED Exhibition will be held November 9-11, 2010 in Shanghai International Expo Center and the 78th China Electronics Fair over the same period will be held will create from raw materials, epitaxial wafers, chip, LED bracket, LED accessories, LED packaging and supporting materials, the LED backlight upstream firm to the upstream and downstream enterprises of the display, lighting, landscaping, decorative lighting, traffic lights, automotive lighting, special lighting, to the equipment, instrumentation, software, finance, consulting and other service enterprises and technological exchanges and market trading platform, help the domestic industry sustained and healthy development, and promote the steady expansion of the LED application market.

In the LED industry chain upstream of the epitaxial wafers and LED chips accounted for 70% of the profits of the whole industry, and technology-intensive, capital-intensive, where the core technology of the LED. Well-known epitaxial wafer and chip production enterprises will be exhibited a number of energy-efficient, low heat, cost-effective LED products, many of whom have excellent products of international advanced level.

LED electronic pcb assembly manufacturing 100% Original LED Chip with one-stop in-house pcba services

3 notes

·

View notes

Text

Understanding Special PCB: The Backbone of Customized Electronics

In today’s rapidly evolving technology landscape, Special PCBs (Printed Circuit Boards) have become a cornerstone in customized electronics, playing a pivotal role in industries like aerospace, healthcare, telecommunications, and automotive. These specialized boards are tailored to meet unique design requirements and performance standards that exceed conventional PCB capabilities.

What are Special PCBs?

Special PCBs are distinct from standard circuit boards due to their specific materials, layout designs, and intended applications. These boards are used for devices that operate in harsh environments, require higher performance, or need to be compact and efficient. Whether it’s rigid-flex PCBs, aluminum-based PCBs for LED lighting, or multilayer boards, special PCBs are designed to cater to niche market needs.

The Role of PCB Manufacturing in Special PCBs

Creating special PCBs demands cutting-edge PCB manufacturing processes and advanced technology. The production of these PCBs involves multiple stages, including:

Design and Prototyping: Advanced software is used to design the layout, followed by the creation of prototypes for testing.

Material Selection: Special materials, such as ceramic, polyimide, or copper-clad laminates, are chosen based on the application’s specific needs.

Precision Assembly: The manufacturing of special PCBs requires high-precision assembly techniques like surface mount technology (SMT) and through-hole assembly to ensure reliability and performance.

PCB Board Makers: Experts in Customization

Leading PCB board makers like Shenzhen Shuoqiang Electronics (SQPCB) specialize in delivering high-quality special PCBs tailored to individual specifications. With state-of-the-art manufacturing facilities, SQPCB can handle small-scale prototype projects or large-scale production orders, ensuring precision, durability, and performance.

Assembly of Special PCBs

PCB manufacturing assembly is a critical phase where components are mounted onto the PCB substrate. For special PCBs, the assembly process requires meticulous attention to detail due to their complexity. Whether it’s high-density interconnect (HDI) boards or PCBs with intricate multilayer designs, the right assembly process ensures the optimal functionality of the circuit.

The PCB assembly process typically involves:

Soldering Components: High-quality soldering methods, like reflow soldering, are used to attach components to the board accurately.

Testing and Quality Control: After assembly, PCBs undergo rigorous testing to ensure they meet quality standards and perform as intended in their specific applications.

Why Choose SQPCB for Special PCB Manufacturing?

SQPCB stands out as a trusted PCB board maker for several reasons:

Customization: Their team of experts works closely with clients to deliver customized special PCBs tailored to specific requirements.

Advanced Technology: They use the latest tools and technologies to ensure the highest standards of manufacturing and assembly.

Quality Assurance: With a robust quality control process, every PCB manufactured by SQPCB is rigorously tested to ensure reliability and performance.

Competitive Pricing: SQPCB offers cost-effective solutions without compromising on quality, making them a preferred partner for businesses of all sizes.

Conclusion

Special PCBs are critical in driving innovation in various sectors, offering unmatched performance and adaptability for custom electronic devices. By partnering with experienced PCB board makers like SQPCB for PCB manufacturing and assembly, businesses can ensure the production of high-quality, reliable, and efficient special PCBs for their unique applications.

#Special PCB#pcb manufacturing#customize pcb#flex pcb#pcb manufacturers#multilayer pcb#advertising#rigid flex pcb#business

0 notes

Text

Smart Electronics Demand Fuels Printed Circuit Board Market Growth

As per Inkwood Research, the Global Printed Circuit Board Market is anticipated to grow at a CAGR of 4.98% in terms of revenue over the forecasting period of 2024-2032.

VIEW TABLE OF CONTENTS

A printed circuit board (PCB) is a flat board used to connect electronic components through conductive pathways, traces, or tracks etched from copper sheets laminated onto a non-conductive substrate. It serves as the backbone of most electronic devices, enabling the assembly and integration of complex circuits in a compact and organized manner.

REQUEST FREE SAMPLE

Elevating Smart Electronics Demand to Aid Printed Circuit Board Market Growth

The growing demand for smart electronics is driving significant growth in the printed circuit board market. As consumers increasingly adopt devices like smartphones, wearables, and home automation systems, the need for advanced PCBs that support miniaturization and enhanced functionality has surged. This trend is further fueled by advancements in IoT technology, which requires high-density, reliable, and efficient PCBs for seamless connectivity. Additionally, the rise of electric vehicles and renewable energy solutions is contributing to the printed circuit board market’s expansion, as these sectors demand sophisticated boards capable of handling complex, high-power applications.

Epoxy Resin is Estimated to be an Eminent Raw Material over the Forecast Period

Epoxy resin plays a vital role in the production of printed circuit boards (PCBs), acting as the substrate material that offers insulation and mechanical support to conductive traces. PCBs made with epoxy resin are recognized for their superior thermal and electrical properties, making them ideal for various applications, including consumer electronics, automotive, and aerospace industries. The demand for epoxy resin in PCBs is rising, driven by the increasing need for lightweight, compact electronic devices that deliver enhanced performance and reliability.

Asia-Pacific was the Major Region in the Printed Circuit Board Market

The Asia-Pacific dominates the PCB market and is projected to experience the fastest growth, driven by its role as a key electronics manufacturing hub with cost efficiencies and skilled labor. The rising demand for smart devices, advancements in the automotive industry, and the booming consumer electronics market are key growth factors.

In the global printed circuit board market, industry rivalry is intense, driven by the need for innovation, cost competitiveness, and rapid technological advancements. Companies strive to differentiate themselves through quality, speed of delivery, and the ability to meet diverse customer demands across various sectors. Some of the leading companies operating in the market include Ascent Circuit Private Limited, AT&S (Austria Technologie & Systemtechnik Aktiengesellschaft), Compeq Ltd, Daeduck Electronics, Epitome Components Ltd, etc.

Request for Customization

Related Reports:

FLEXIBLE ELECTRONICS MARKET

AUTOMOTIVE SEMICONDUCTOR MARKET

MULTI-LAYER CERAMIC CAPACITOR MARKET

About Inkwood Research

Inkwood Research specializes in syndicated & customized research reports and consulting services. Market intelligence studies with relevant fact-based research are customized across industry verticals such as technology, automotive, chemicals, materials, healthcare, and energy, with an objective comprehension that acknowledges the business environments. Our geographical analysis comprises North & South America, CEE, CIS, the Middle East, Europe, Asia, and Africa.

Contact Us

1-(857)293-0150

0 notes

Text

Enhance Your Electronics with Aluminum PCB Boards

Hitech Circuits Co., Ltd. is a top PCB manufacturer in China, dedicated to providing high-quality products. We offer a variety of metal-based printed circuit boards, including Aluminum PCBs, Copper PCBs, Ceramic PCBs, and Metal Core PCBs, all at great prices. Trust us for your PCB needs. Visit our website today!

0 notes

Text

DMD laser engraver/exposure machine is widely used in fine details screen printing industry like PCB, packaging, ceramic/automotive decal, graphic, silkscreen label, decoration, heat transfer etc.

It is based on laser direct image equipment of Digital Micro-Mirror Device (DMD); In the course of patterning, it transforms the patterns to the mechanical data through computer, and transmits to the Digital Micro-Mirror Device.

It directly projects the patterns to the photosensitive material so as to compete the exposure. It adopts the high-power 405nm laser light source with a long service life, low energy consumption, and high image resolution; With the cooperation of high-precision linear motor, it performs the high-precision exposure at the silk-screen surface so as to provide the high-resolution, high-efficiency and low-cost products for the customers with the resolution reaches 2540dpi.

The stable cooling system ensures the inside of equipment to keep a temperature constant state of 22℃, which guarantees the stability of equipment; The newly designed pneumatic clamping can tightly fasten the screen frame to facilitate the replacement for screen frame of various specifications. Feel free to DM us and we are pleased to offer our best prices and printed samples for your checking. #CTS#LTS#DTS#Laserengraver#laserengravingmachine#computertoscreen#lasertoscreen#directtoscreen

0 notes

Text

https://www.verifiedmarketreports.com/product/ceramic-based-pcb-market/

0 notes

Text

What is a ceramic PCB and what are the benefits of ceramic PCBs?

Ceramic Printed Circuit Boards (PCBs) are advanced circuit boards that offer superior performance and reliability, especially in demanding high-performance electronic applications. Unlike conventional circuit boards made from organic materials such as fiberglass or epoxy, ceramic PCBs are manufactured using ceramic materials, which gives them unique properties and features. These boards are designed to excel where high thermal conductivity, excellent electrical performance at high frequencies, and robustness in harsh environments are critical.

Comprehensive Introduction to Ceramic PCBs

The foundation of a ceramic circuit board lies in its ceramic substrate, which has many advantages that distinguish it from conventional circuit boards. One of its outstanding features is its excellent thermal conductivity, which enables it to efficiently dissipate the heat generated by components. This makes ceramic PCBs the first choice for applications that generate large amounts of heat and require efficient thermal management.

The excellent electrical properties of ceramic materials, especially at high frequencies, make ceramic PCBs particularly suitable for radio frequency (RF) and microwave applications. These boards maintain signal integrity and minimize signal loss, making them indispensable in industries such as telecommunications, aerospace and satellite communications.

In addition, ceramic PCBs have impressive mechanical strength and durability, allowing them to withstand challenging mechanical stresses and vibrations. Their chemical resistance and ability to withstand harsh environments make them ideal for applications that require exposure to corrosive substances.

What are the advantages of ceramic PCBs?

Ceramic Printed Circuit Boards (PCBs) offer a variety of advantages that make them well suited for a wide range of applications, especially those requiring high performance, reliability and efficiency. Here are some of the key benefits of ceramic PCBs:

-High Thermal Conductivity: Ceramic materials such as Aluminum Oxide (Al2O3), Aluminum Nitride (AlN), and Silicon Carbide (SiC) have excellent thermal conductivity. This means that ceramic PCBs can effectively dissipate heat generated by components, preventing overheating and ensuring reliable operation of high-power electronic devices.

-Excellent electrical properties: Ceramic materials have low dielectric loss and excellent electrical properties, especially at high frequencies. This makes ceramic PCBs ideal for applications in radio frequency (RF), microwave and high-speed digital circuits where signal integrity and low signal loss are critical.

-Mechanical strength and durability: Ceramic PCBs have higher mechanical strength and rigidity than organic PCBs. This robustness allows them to withstand mechanical stress, vibration and shock, making them suitable for applications in challenging environments.

-Chemical Resistance: Ceramics are highly resistant to chemicals, solvents, acids and bases. This resistance makes ceramic PCBs ideal for applications in industries such as automotive, aerospace, and industrial where harsh chemicals are frequently encountered.

-High Temperature Resistance: Ceramic PCBs can withstand higher temperatures than traditional organic PCBs. This ability is critical for industries such as automotive and aerospace, where electronics must operate reliably at high temperatures.

Miniaturization: Ceramic PCBs can accommodate fine alignments, smaller components, and high-density interconnects, allowing for the design of compact electronic devices. This feature is critical for applications that require miniaturization without sacrificing performance.

-Signal Integrity: Ceramic PCBs provide excellent signal integrity due to their low loss angle tangent and high dielectric constant, especially at high frequencies. This makes them suitable for high-speed data transmission and communication systems.

-Harsh Environment Compatibility: Because of their thermal, mechanical, and chemical resistance, ceramic PCBs are well suited for applications in harsh environments such as oil and gas exploration, aerospace, and military applications.

Reliability and longevity: The combination of high thermal performance, ruggedness and chemical resistance contributes to the long-term reliability of ceramic PCBs, reducing the risk of failure and extending the life of electronic devices.

-Customization: Ceramic PCBs can be customized to meet specific design requirements, including substrate materials, layer configurations, alignment layouts and component placement. This flexibility allows engineers to optimize board performance for a given application.

-EMI/EMC Performance: Ceramic materials inherently provide better electromagnetic interference (EMI) and electromagnetic compatibility (EMC) performance due to their electrical properties and shielding capabilities.

0 notes

Text

Different kinds of Aluminum PCBs

Flexible Aluminum PCBs

One of the newest developments in IMS materials is flexible dielectrics. These materials feature a polyimide resin system with ceramic fillers which provides excellent electrical insulation, flexibility and of course thermal conductivity. When applied to a flexible aluminum material like 5754 or similar, the product can be formed to achieve a variety of shapes and angles which can eliminate costly fixtures, cables and connectors. Although these materials are flexible, they are intended to be bent into place and remain in place. They are not suited for applications that are intended to be flexed regularly.

Hybrid Aluminum PCBs

In a ‘Hybrid’ IMS construction a “Sub-assembly” of a non-thermal material is processed independently and then bonded to the aluminum base with thermal materials. The most common construction is a 2-Layer or 4-Layer Sub-assembly made from conventional FR-4. Bonding this layer to an aluminum base with thermal dielectrics can help dissipate heat, improve rigidity and act as a shield. Other benefits include:

Less costly than a construction of all thermally conductive materials

Provides superior thermal performance over a standard FR-4 product

Can eliminate costly heat sinks and associated assembly steps

Can be used in RF applications where a surface layer of PTFE is desired for its’ loss characteristics.

Use of component windows in the aluminum to accommodate through-hole components. This allows connectors and cables to pass connections through the substrate while the solder fillet creates a seal without the need for special gaskets or other costly adapters.

Multilayer Aluminum PCBs

Common in the high performance power supply market, multilayer IMS PCBs are made from multiple layers of thermally conductive dielectrics. These constructions have one or more layers of circuitry buried in the dielectric with blind vias acting as either thermal vias or signal vias. While more expensive and less efficient at transferring heat as a single layer designs, they provide a simple and effective solution for heat dissipation in more complex designs.

Through-Hole Aluminum PCBs

In the most complex constructions a layer of aluminum can form a ‘Core’ of a multilayer thermal construction. The aluminum is pre-drilled and back-filled with dielectric prior to lamination. Thermal materials or sub-assemblies can be laminated to both sides of the aluminum using thermal bonding materials. Once laminated, the completed assembly is thru-drilled similar to a conventional multilayer PCB. The plated through holes pass through the clearances in the aluminum to maintain electrical insulation. Alternatively a Copper core can allow both direct electrical connections as well as with insulated through holes.

If you want to know ceramic PCBs, please feel freely to contact Cynthia at [email protected]

0 notes

Text

Global Top 5 Companies Accounted for 83% of total PCB Software market (QYResearch, 2021)

PCB design software aids electronic engineers in designing layouts for printed circuit boards. Engineers leverage the software to collaborate on the design process, pull previously used circuit board component designs from PCB libraries, and verify circuit schematic designs. PCB design software is most often used by engineering firms and teams that may be involved with product development. PCB design software is often implemented as a part of other design software systems such as product and machine design software and general-purpose CAD software.

The PCB Software industry can be broken down into several segments, On Premises, Cloud Based.

Across the world, the major players cover Siemens, Altium, etc.

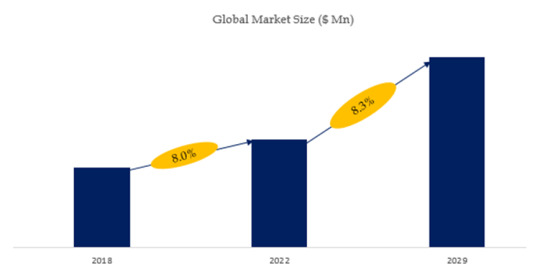

According to the new market research report “Global PCB Software Market Report 2023-2029”, published by QYResearch, the global PCB Software market size is projected to reach USD 1.82 billion by 2029, at a CAGR of 8.3% during the forecast period.

Figure. Global PCB Software Market Size (US$ Million), 2018-2029

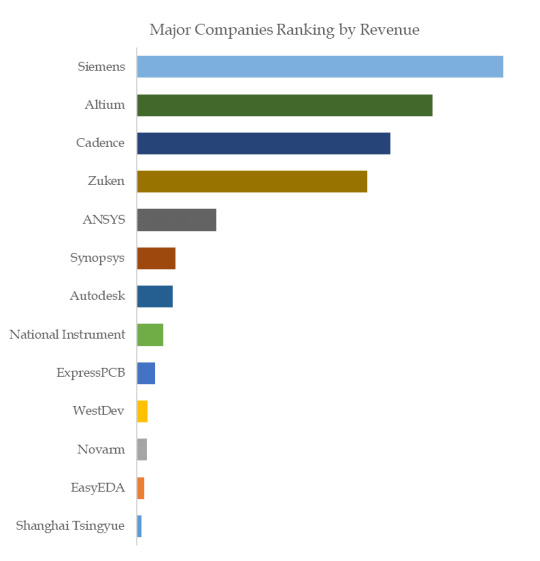

Figure. Global PCB Software Top 13 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of PCB Software include Siemens, Altium, Cadence, Zuken, ANSYS, Synopsys, Autodesk, National Instrument, ExpressPCB, WestDev, etc. In 2021, the global top five players had a share approximately 83.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

Understanding Reflow Ovens in Surface Mount Technology

Understanding Reflow Ovens in Surface Mount Technology

Reflow ovens play a crucial role in the assembly of printed circuit boards (PCBs) with surface mount electronic components. These ovens facilitate reflow soldering, ensuring reliable connections between components and PCBs. Let’s delve into the details of reflow ovens and their various types.Get more news about Reflow Oven,you can vist our website!

Types of Reflow Ovens:

Infrared and Convection Ovens:

Infrared reflow ovens use ceramic infrared heaters positioned above and below the conveyor belt. These heaters emit radiation, transferring heat to the PCBs. Convection ovens, on the other hand, heat air within chambers and use it to transfer heat via convection and conduction.

Convection ovens provide more accurate temperature control than infrared ovens because they indirectly heat the PCBs using air. This is essential because PCBs and components have varying infrared absorptance.

Some ovens combine infrared radiative heating with convection, known as “infrared convection” ovens. Additionally, certain ovens create an oxygen-free atmosphere by using nitrogen gas during reflow to minimize oxidation of soldered surfaces.

Vapour Phase Ovens:

Vapour phase soldering relies on the phase transition of a heat transfer liquid (e.g., PFPE) condensing on the PCBs. The chosen liquid has a specific boiling point to suit the solder alloy.

Advantages of vapour phase soldering include high energy efficiency, oxygen-free soldering, and prevention of overheating.

Maximum assembly temperatures are limited by the boiling point of the medium, making this process safe and controlled.

Thermal Profiling:

Thermal profiling involves measuring temperature points on a circuit board during the soldering process.

Statistical process control (SPC) helps determine if the reflow process adheres to defined parameters based on soldering technologies and component requirements.

Applications:

Reflow ovens find applications in both high-volume commercial production lines (using conveyorized ovens) and prototyping/hobbyist scenarios (using smaller ovens).

In commercial settings, PCBs travel through multiple individually heated zones, each with adjustable temperature settings.

For hobbyists, small ovens with doors accommodate PCBs for reflow soldering.

In summary, reflow ovens are essential tools for achieving reliable solder joints in surface mount technology. Whether you’re assembling complex electronic devices or experimenting with your DIY projects, understanding reflow ovens ensures successful PCB assembly.

0 notes

Text

Select Material for Your PCBs from Cost and Reliability Considerations

At BST Ceramic PCB, we know well how important the choice of material can be to the performance and the useful life of the PCBs. It may be difficult to determine where economy of cost can be optimally achieved without sacrificing dependability, especially when the choices are countless.

In this article, we will provide you with information to make better decisions when choosing material for your PCBs.

FR-4: The Ever Reliable Material

FR-4, a flame retardant epoxy laminate stays as the leading option for a reason. Due to its inexpensive cost, it is relatively easy to manufacture resulting in its decent electrical characteristics that make it suitable for general low to medium-frequency applications.

However, for your project, as it scales up, you will see the drawbacks of FR-4 very clearly. Operating with higher temperatures, high-frequency signal transmission, and restricted dimensionality challenge the FR-4 board’s reliability limits.

Aluminium Based PCBs

When it comes to high-end and highly critical applications, application-specific alumina ceramic PCBs turn out to be a distinct possibility. Here is why alumina PCBs are the perfect choice:

BestThermalManagement: Alumina possesses dissipation of heat that is associated with high-power devices since it has good thermal conductivity. This means that the system boards can operate at lower temperatures and ensure a longer life for the PCBs used and the reliability of the equipment.

High-Frequency: Alumina's low dielectric constant (Dk) and low dissipation factor (Df) minimize signal loss, making it ideal for high-frequency applications like RF circuits and communication devices.This translates to reliable signal transmission, crucial for error-free operation.

Built to last: Alumina boasts of being highly mechanical and chemically sound with a very high level of dimensional stability as well as the ability to resist warping and harsh chemical, atmospheric and temperature gradients.

Alumina PCBs higher price in comparison with FR-4 can be observed in the primary stage but if one looks intothe overall picture there is a possibility to get more for less. This may make it possible to decrease the utilization of big heatsinks which in turn makes the design of the PCB lighter. Besides, the longevity decreases the chance of early PCB failure, and therefore, expensive replacements.

At BST Ceramic PCBs, we specialize in high-quality alumina PCBs. Please feel free to contact us right now and tell us your project specifications to know about possible ways to improve your design with our alumina ceramic PCBs performance and affordability.

0 notes

Text

Exploring BGA Technology & it’s Role in Advanced PCB Assembly

In the world of electronics, where miniaturization is one of the primary requirements, it is an ongoing struggle for manufacturers doing PCB assembly in the USA or anywhere in the globe to achieve high functionality, efficiency, and dependability inside a compact space. Ball Grid Array (BGA) is a technology that has completely changed how printed circuit board or PCB assembly is done.

This article talks about BGA technology, highlighting its merits, drawbacks, and essential considerations for its implementation.

What is BGA Technology? Ball Grid Array, is a sophisticated packaging technology commonly employed in electronics manufacturing, particularly for integrated circuits (ICs). It involves mounting the IC onto a substrate and connecting it to the circuit board using an array of tiny solder balls arranged in a grid pattern on the underside of the package. This arrangement provides numerous advantages compared to traditional packaging methods like through-hole technology. BGA packages come in various configurations and sizes to accommodate different applications and circuit complexities.

Why Choose BGA Technology in PCB Assembly?

When compared to more conventional packaging techniques, BGA technology has various benefits:

Increased Component Density: When contrasted with alternative packaging technologies, BGAs enable a greater density of connections in less space. In today's space-constrained electronic gadgets, this density boost is vital.

Better Electrical Performance: High electrical performance, including lower inductance and capacitance, is a result of the shorter electrical route length in BGA packages.

Better Thermal Conduction: Solder balls in ball grid array (BGA) packages dissipate heat from integrated circuits (ICs) more efficiently than leads. Enhanced dependability and Less Signal Noise: By reducing inductance and capacitance, BGA packages provide superior signal integrity, leading to less signal noise and more dependability.

Cost efficient: BGA technology provides an affordable option for intricate PCBs. The removal of lead from PCB assembly streamlines production and has the ability to decrease material costs.

Categories of BGAs:

There is a difference between all BGAs. The two most common kinds are as follows:

Plastic BGA: A plastic ball grid array is the most cost-effective option among the other types of BGAs. The organic laminate substrate is used in these models.

Ceramic BGAs: Use a ceramic substrate for a ceramic ball grid array (CBGA), which has better thermal conductivity and more consistent dimensions. Applications requiring a great level of power and performance are perfect for CBGAs.

Tape Ball Grid Array (TBGA): TBGA packages incorporate a tape-based substrate instead of a traditional ceramic or plastic substrate. They provide a cost-effective solution for medium to high-density applications with improved electrical performance.

Flip-Chip Ball Grid Array (FCBGA): FCBGA packages feature the integrated circuit flipped upside down and mounted directly onto the substrate, allowing for shorter interconnect lengths and improved electrical performance.

Micro Ball Grid Array (μBGA): μBGA packages are smaller versions of traditional BGAs, featuring a higher ball count and tighter pitch. They are commonly used in miniaturized electronic devices such as mobile phones, tablets, and wearables.

Stacked Ball Grid Array (SBGA): SBGA packages consist of multiple BGA layers stacked on top of each other, allowing for increased component density and functionality in a compact form factor.

Plastic Fine-Pitch Ball Grid Array (PFBGA): PFBGA packages feature a finer pitch compared to traditional PBGA packages, allowing for higher pin density and improved electrical performance in space-constrained applications.

These are just a few examples of the types of BGA packages available in the market, each offering unique advantages and characteristics suited to different design requirements and industry standards.

What are the Best Practices for Assembling BGAs?

Take into account these best practices to guarantee the quality and dependability of BGA assemblies:

Utilize Precision Assembly Methods: Make sure that BGA packages are soldered correctly by using reliable soldering techniques like reflow soldering.

Use high-quality inspection tools: If you want your BGA solder junctions to be perfect, you should have high-tech inspection gear like X-ray machines or AOI systems.

Work with Reliable EMS Provider: Partnering with a reliable vendor like PCB Power, can help you to achieve the best quality BGA assembly. With their in-depth expertise in this domain, such organizations can suggest and offer you reliable solutions.

BGA technology is a game-changer when it comes to PCB assembly performance and downsizing. Unleash the full potential of BGAs for your next project by using its advantages and working closely with a certified assembly partner. With the ever-changing landscape of electronic gadgets, BGA technology is poised to dominate the future of printed circuit board assembly.

For any further queries related to our comprehensive PCB solutions, reach out to us at +1(818) 886 8900 or via email at [email protected].

Read More:- Exploring BGA Technology & it’s Role in Advanced PCB Assembly

0 notes

Text

Choosing the Right High and Low Temperature Shock Test Chamber for Your Testing Needs

High and Low Temperature Thermal Shock Chamber are used in electronic and electrical components, automation components, communication components, automotive parts, metals, chemical materials, plastics and other industries, as well as in the physical changes of national defense industry, aerospace, military industry, BGA, PCB base plates, electronic chip ICs, semiconductor ceramics, and polymer materials,

Testing the repeated tensile force of its materials against high and low temperatures and the chemical change or physical damage produced by the thermal expansion of the product can confirm the quality of the product. It can be used from precision IC to heavy machinery components, and is an indispensable test chamber for product testing in various fields.

The High and Low Temperature Shock Test Chamber for Your Testing Needs simulates the alternating changes of high and low temperature environments, exposing products to problems in harsh environments. It is a very important testing equipment in multiple industrial manufacturing fields.

How to choose a suitable high and low temperature shock test chamber?

The selection of equipment is not as expensive as possible, but rather to choose products that are suitable for oneself. The manufacturer of the High and Low Temperature Shock Test Chamber will tell you how to choose the equipment reasonably:

1. Two chamber vs. three chamber

The two chamber shock only has high and low temperature shocks, while the three chamber shock has a room temperature transition in the middle. For products, there is no transition at room temperature, which is more destructive and imposes stricter requirements on the product.

2. Water cooled vs. air cooled

Normally, a temperature of -40~+150 ℃ for 50L-100L is sufficient for air cooling. A larger capacity and a lower temperature (100L/-70 ℃) for water cooling provide more stable performance.

3. Material and inward dimensions

The cold and hot shock chamber usually has two materials: stainless steel and baking paint, which can be customized according to needs. The stainless steel material is beautiful and easy to care. The baking paint color can be selected by yourself, and can be matched with other equipment colors.

The thickness of the board has an impact on the quality of the equipment, because the thickness of the board is too thin, and the equipment is prone to deformation when the bearing weight is too large or the temperature is too high. Most equipment suppliers choose qualified sheet materials.

The board of conventional equipment is generally 1.0mm or 1.2mm, so the thickness of the material is important for the quality of the equipment. When selecting equipment, it is important to have a clear understanding.

From the perspective of internal chamber size, the specification requires that the product must be placed inside the testing area. Some

The manufacturer places the product inside the air duct, although it is only 10cm away from the testing area, this energy difference is quite significant. And it cannot truly reflect the temperature changes on the surface of the test object. So choose the appropriate inner box size.

On the market, the conventional capacity of the cold and hot shock test chamber is 50L, 80L, 100L, 150L, 225L, 408L, 800L, 1000L, etc. It is recommended that you choose the capacity based on the long-term test demand.

4. Impact temperature

Pay attention to the large range of temperatures that can actually be reached in the testing area. Note that it is not the limit temperature for preheating and precooling chambers. The test load directly affects how many test items can be placed. Generally speaking, the larger the weight, the better.

Select appropriate temperature impact range of cold and hot impact test chamber according to relevant test standards of product materials (national standard/military standard/European and American standard), generally - 40 ℃~+150 ℃- 55℃~+150℃;- 70 ℃~+150 ℃, of course, different impact ranges can also be selected for different products.

High and Low Temperature Thermal Shock Chamber can be used in the temperature shock test and fast-changing temperature test in a wide range such as aviation, air space, electronic components and material research.

HLST-500D has two separate chambers: high temperature chamber and low temperature chamber.

HLST-500T has three separate chambers: high temperature chamber, low temperature chamber and test chamber.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: [email protected], Cell/WhatsApp:+8615317907381

Sales Dep: [email protected], Cell/WhatsApp:+8618117273997

Read the full article

0 notes

Text

What’s Aluminium LED PCB?

Aluminum LED PCB substrate is a metal - based copper-clad sheet with good heat dissipation. A single panel is generally composed of three layers of structure, namely the circuit layer (copper foil), insulation layer and metal base layer. It is commonly found in LED lighting products. There are two sides, the white side is used to weld the LED pins, and the other side is the natural color of aluminum, which is usually coated with heat-conducting gel and then in contact with the heat-conducting part. Among all metal core PCBS, Aluminum LED PCB is the most common type. The base material consists of an aluminum core and standard FR4. It features a thermal cladding that dissipates heat in an efficient manner while cooling components and improving the overall performance of the product. Currently, aluminum-backed PCBS are considered solutions for high power and tight tolerance applications.

2. Aluminum LED PCB with Copper Layer, Dielectric Layer & Aluminum Layer

Aluminum LED PCB has a similar layout to any other printed circuit boards with copper layer(s), solder mask layer(s) and silkscreen(s). Instead of having a fiberglass or plastic substrate, Aluminum LED PCB is made from metal core substrate, which consists of copper layer, dielectric layer and aluminum layer. This substrate is called as Aluminum based copper clad laminate (CCL). The glass reinforced and ceramic filled dielectric layer in-between copper layer and aluminum layer is very thin, but plays a very important role of electric insulation and thermal conductivity (because of minimum thermal resistance) from copper layer to aluminum base. The copper is etched into conductors and metal base is to withdraw thermal (/heat). The superior heat transfer capacity of Aluminum-based PCB helps cooling components while eliminating problems associated with managing fragile ceramics.

3. Thermal conductivity of Aluminium LED PCB

The general thermal conductivity of Aluminum LED PCB is 0.3, 0.6, 1.0, 1.5, 2.0, 3.0, 5.0, 122W/m.k, etc., among which 0.3-1.0w /m.k is the general conductive Aluminum LED PCB, 1.5W/m.k is the middle conductive Aluminum LED PCB, 2.0-3.0w /m.k is the high conductive Aluminum LED PCB. 5.0W/m.k is thin abasal substrate, and 122W/m.k is ultra-high conductivity Aluminum LED PCB, also known as ALC Aluminum LED PCB.

At present, the common Aluminum LED PCB on the market has a thermal conductivity of 1.0, 1.5, 2.0W/m.k high conductivity type Aluminium LED, wherein the thermal conductivity of 1.0W/m.k Aluminum LED PCB is called general Aluminum LED PCB, its insulation layer is composed of epoxy glass cloth bonded sheet; Aluminum LED PCB with thermal conductivity of 1.5W/m.k is called high heat dissipation Aluminum LED PCB, and its insulation layer is composed of epoxy resin or other resins with high thermal conductivity; The Aluminum LED PCB with a thermal conductivity of 2.0W/m.k is called the Aluminum LED PCB for high-frequency circuit, and the insulating layer is composed of polyolefin resin or Polyimide resin glass cloth bonded sheet. The thermal conductivity of Aluminum LED PCB varies according to the copper layer in the circuit. Different processes produce different levels of thermal conductivity.

We currently support Aluminum based CCLs from Ventec, GDM and BoYu with thermal conductivity from 1.0 ~ 7 W/m•K. The Aluminum LED PCB prices of Ventec is much higher than that with GDM and BOYU since material cost, and the prices of high thermal conductivity is higher than low thermal conductivity. Hitechpcb provides a wide range of electrical and thermally conductive interface pads, thermally conductive gap filler, thermal phase change materials and thermally conductive electrically insulating materials, as well as specialized equipment for high volume Aluminum LED PCB manufacturing. Choosing Hitech Circuits PCB as your Aluminum LED PCB supplier, just send your Gerber files and fabrication notes to us, we will deliver qualitied PCB boards to you on time.

4. Dielectric Constant of Aluminium LED PCB

The dielectric constant of Aluminum LED PCB substrate is a special detection method for Aluminum LED PCB. It is a variable Q value series resonance method through the measurement of dielectric constant and dielectric loss factor. The sample and tuning capacitor are connected in series to the high frequency circuit to measure the series circuit The principle of Q value.

The performance of Aluminum LED PCB includes requirements such as peel strength, surface resistivity, minimum breakdown voltage, dielectric constant, flammability and thermal resistance.

5. Classification of Aluminum LED PCB Substrate

Aluminum LED PCB-based copper clad plates are divided into three categories:

The first is the universal aluminum-based copper clad plate, the insulation layer is composed of epoxy glass cloth bonded sheet;

The second is the high heat dissipation aluminum-based copper-clad plate, the insulation layer is composed of high thermal conductivity epoxy resin or other resins;

Third, high frequency circuit aluminum base copper plate, insulation layer by polyolefin resin or Polyimide resin glass cloth bonded sheet.

The biggest difference between aluminum clad copper plate and conventional FR-4 clad copper plate is heat dissipation. Compared with 1.5mm thickness of FR-4 clad copper plate and aluminum clad copper plate, the former thermal resistance of 20 ~ 22 ℃, the latter thermal resistance of 1.0 ~ 2.0℃, the latter is much smaller.

6. Aluminum LED PCB Performance:

(1) Heat dissipation

Many double panel, multi - layer plate high density, power, heat distribution is difficult. Conventional printed board substrates such as FR4, CEM3 are bad conductors of heat, insulation between layers, heat does not escape. Local heating of electronic equipment is not excluded, leading to high temperature failure of electronic components, and Aluminum LED PCB can solve this problem of heat dissipation.

(2) Thermal Expansibility

Thermal expansion and cold contraction is the common nature of substances, and the coefficient of thermal expansion of different substances is different. Aluminum based printed board can effectively solve the problem of heat dissipation, so that the printed board components of different substances on the thermal expansion and contraction problem, improve the durability and reliability of the whole machine and electronic equipment. Especially solve SMT (surface mount technology) thermal expansion and shrinkage problems.

(3) Dimensional stability

Aluminum-based printed boards are obviously much more stable in size than those made of insulating materials. Aluminum base printed board, aluminum sandwich board, heating from 30℃ to 140~150℃, the size change is 2.5~3.0%.

(4) Other reasons

Aluminum based printed board, with shielding effect; Instead of brittle ceramic substrate; Safe use of surface mounting technology; Reducing the real effective area of the printed board; Instead of radiator and other components, improve the heat resistance and physical properties of products; Reduce production costs and labor.

7. Why choose Aluminum LED PCB from Hitechpcb? What are the advantages of Aluminum LED PCB?

(1) Good heat dissipation performance: Aluminum LED PCB can reduce the thermal resistance to the minimum, has a smaller thermal resistance, thermal expansion coefficient is closer to copper foil, so that Aluminum LED PCB has excellent thermal conductivity and heat dissipation performance, reduce the module operating temperature, prolong the service life.

High current load: Using the same thickness, the same line width, Aluminum LED PCB substrate can carry higher current.

(2) Good machinability: can replace ceramic substrate, better mechanical endurance. At the same time, high strength and toughness, can realize large area printed board manufacturing and component mounting.

(3) Good electromagnetic shielding: In order to ensure the performance of electronic circuits, some components of electronic products need to prevent electromagnetic radiation and interference. Aluminum LED PCB can act as a shield plate, play the role of shielding electromagnetic wave

(4) Environmental protection: The Aluminum LED PCB used in the raw material is non-toxic and can be recycled. Meet RoHs requirements.

(5)Light weight: Aluminum LED PCB has a surprisingly light weight with excellent strength and elasticity, which is very convenient.

Hitech Circuits can provide high quality and affordable Aluminum LED PCB products for you.

0 notes

Text

Unlocking the Power of Ceramic PCBs: A Game changer in Electronics

Ceramic PCBs (Printed Circuit Boards) are a game-changer in electronics. Unlike regular PCBs made from fiberglass, these use a ceramic base, offering better heat management and durability. They perform exceptionally well in high-temperature and high-power settings.

Why Choose Ceramic PCBs?

Ceramic PCBs have many benefits. They handle heat efficiently, making them perfect for power electronics, LED lights, and car systems. Their strong build means they can withstand tough environments, ensuring your devices last longer and work more reliably.

Applications of Ceramic PCBs

Ceramic PCBs from Hitech Circuits Co. Limited are used in various industries. From aerospace and telecommunications to medical devices and renewable energy, these boards meet diverse needs. With our expertise, Ceramic PCBs provide top-notch performance in any application.

The Hitech Circuits Co. Limited Advantage

At Hitech Circuits Co. Limited, quality and innovation are our priorities. Our modern manufacturing facilities and skilled team ensure every Ceramic PCB meets the highest standards. With years of experience and a focus on customer satisfaction, we are your trusted source for advanced Ceramic PCB solutions.

Conclusion

Discover the unmatched performance and reliability of Ceramic PCBs with Hitech Circuits Co. Limited. Enhance your electronic designs with our cutting-edge circuit boards and explore new possibilities in technology. Choose Hitech Circuits Co. Limited for Ceramic PCBs that set new standards in the electronics industry.

0 notes