#Centrifugal Water Separator Market

Text

Zinc Nitrite Manufacturing Plant Project Report 2024: Industry trends and Plant Setup

Introduction

Zinc nitrite is an inorganic compound used in various applications, including the production of other zinc compounds, corrosion inhibitors, and as a nitrifying agent in the chemical industry. Its unique properties make it valuable across several sectors, including construction, automotive, and agriculture. With the increasing demand for zinc compounds in industrial applications, establishing a zinc nitrite manufacturing plant presents a significant business opportunity. This Zinc Nitrite Manufacturing Plant Project Report outlines the essential components necessary for setting up a successful manufacturing facility, including market analysis, production processes, equipment requirements, and financial projections.

Market Analysis

Industry Overview

The global market for zinc nitrite is expanding due to its widespread applications in various industries. The demand for corrosion-resistant materials, particularly in the automotive and construction sectors, is driving growth. Additionally, as environmental regulations become stricter, the need for effective corrosion inhibitors and sustainable chemical solutions is rising.

Target Market

The primary target market for zinc nitrite production includes:

Chemical Manufacturers: Companies that utilize zinc nitrite in the synthesis of other zinc compounds.

Construction Industry: Manufacturers of paints, coatings, and adhesives that require corrosion inhibitors.

Automotive Sector: Producers of vehicle components that need protective coatings to enhance durability.

Agriculture: Fertilizer manufacturers looking for effective nitrifying agents.

Get a Free Sample Report with Table of Contents @

https://www.expertmarketresearch.com/prefeasibility-reports/zinc-nitrite-manufacturing-plant-project-report/requestsample

Production Process

Raw Materials

The primary raw materials required for zinc nitrite production include:

Zinc Oxide: The main source of zinc for the synthesis of zinc nitrite.

Nitric Acid: A key reactant that provides the nitrite ion necessary for the formation of zinc nitrite.

Water: Used for the reaction and purification processes.

Manufacturing Steps

Preparation of Reactants: High-quality zinc oxide and nitric acid are sourced to ensure optimal reaction conditions.

Chemical Reaction: The production of zinc nitrite involves the reaction of zinc oxide with nitric acid. The reaction typically occurs in a controlled environment to prevent excessive heat and ensure complete conversion.ZnO+2HNO3→Zn(NO2)2+H2O\text{ZnO} + 2\text{HNO}_3 \rightarrow \text{Zn(NO}_2)_2 + \text{H}_2\text{O}ZnO+2HNO3→Zn(NO2)2+H2O

Neutralization: The resulting zinc nitrite solution may be neutralized if necessary to adjust the pH for further processing.

Crystallization: The zinc nitrite is then crystallized from the solution. This involves cooling the solution to promote the formation of solid zinc nitrite crystals.

Separation and Drying: The crystals are separated from the remaining solution through filtration or centrifugation. The separated zinc nitrite is then dried to obtain the final product in powder form.

Quality Control: Rigorous quality control measures are implemented throughout the production process to ensure that the final product meets industry standards and regulatory requirements.

Equipment Requirements

Establishing a zinc nitrite manufacturing plant requires specialized equipment, including:

Reactor Vessels: For conducting the chemical reactions between zinc oxide and nitric acid.

Filtration Units: For separating zinc nitrite crystals from the solution.

Centrifuges: To enhance the separation process.

Crystallizers: For promoting the crystallization of zinc nitrite.

Dryers: To remove moisture from the final product.

Quality Control Laboratory Equipment: For testing the purity and quality of the final product.

Facility Requirements

Location

Choosing an appropriate location for the manufacturing plant is critical. Proximity to raw material suppliers and access to transportation networks can help minimize operational costs and streamline distribution.

Space

The facility should have designated areas for:

Raw material storage

Production area

Crystallization and drying sections

Quality control laboratory

Finished product storage

Administrative offices

Utilities

Ensure the facility has access to essential utilities such as water, electricity, and waste management systems. Compliance with environmental regulations is vital for sustainable operations.

Financial Projections

Initial Investment

The initial investment required for establishing a zinc nitrite manufacturing plant can vary widely based on factors such as location, scale, and technology. Major cost components include:

Land and facility construction

Equipment procurement

Raw material costs

Labor and operational expenses

Regulatory compliance and marketing costs

Revenue Projections

With effective management, a zinc nitrite manufacturing plant can expect to break even within the first 3-5 years. Revenue can be generated through direct sales to chemical manufacturers, construction companies, and other industries requiring zinc nitrite.

Profitability

Profit margins in the chemical manufacturing sector can vary but typically range from 15-25%, depending on market demand and operational efficiency.

Marketing Strategy

To effectively market zinc nitrite, consider the following strategies:

Brand Development: Establish a strong brand identity that emphasizes the quality and effectiveness of the product.

Industry Networking: Attend trade shows and conferences to build relationships with potential clients in the chemical and construction sectors.

Digital Marketing: Utilize online platforms to promote products and reach a broader audience.

Educational Campaigns: Conduct campaigns to inform industries about the benefits and applications of zinc nitrite.

FAQ

1. What is zinc nitrite used for?

Zinc nitrite is primarily used as a corrosion inhibitor, a nitrifying agent in fertilizers, and in the production of other zinc compounds.

2. How is zinc nitrite produced?

Zinc nitrite is produced by reacting zinc oxide with nitric acid, followed by crystallization and drying processes.

3. What safety concerns are associated with zinc nitrite manufacturing?

Safety concerns include handling hazardous chemicals and managing emissions. Strict safety protocols and proper equipment are essential to mitigate risks.

4. What are the startup costs for a zinc nitrite manufacturing plant?

Startup costs can vary significantly based on location and scale, typically including land, equipment, raw materials, and labor. A detailed business plan will help estimate these costs accurately.

5. Can zinc nitrite be sold internationally?

Yes, zinc nitrite can be sold internationally, but compliance with various regulatory standards in different countries is essential for successful export and market entry.

Related Reports

https://www.expertmarketresearch.com/reports/gas-treatment-market

https://www.expertmarketresearch.com/reports/incident-and-emergency-management-market

https://www.expertmarketresearch.com/articles/top-digital-marketing-companies

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: [email protected]

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au

0 notes

Text

Center Enamel Welded Steel Tanks are Durability and Customization for a Wide Range of Applications

Shijiazhuang Zhengzhong Technology Co., Ltd., a leader in the tank manufacturing industry with over 30 years of experience, offers high-quality welded steel tanks designed to meet the specific needs of various industries. Our welded steel tanks are custom-engineered to provide reliable, long-term storage solutions for liquids, bulk materials, and chemicals. We combine advanced production techniques with strict quality control measures to deliver storage tanks that meet international standards and customer expectations.

Design and Durability of Welded Steel Tanks

Welded steel tanks are storage solutions formed through specialized welding techniques that ensure strength and durability. The material selection for these tanks is based on the properties of the stored substances, environmental factors, and safety standards. To maintain resistance against corrosion, high pressure, and extreme temperatures, our welded steel tanks are constructed using top-grade materials, ensuring their longevity and performance.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, welded steel tanks ,pressure vessels and storage tanks roof, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs Solution

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Key Advantages of Welded Steel Tanks:

High Customization: We offer flexibility in the design of tank size, shape, and capacity to suit various storage requirements. This customization enables us to create welded tanks for small-scale storage or large industrial applications.

Durability: Built with premium steel and advanced welding techniques, our tanks withstand harsh conditions and offer long-lasting performance. Rigorous quality control ensures structural integrity.

Superior Sealing: Our welding process guarantees excellent sealing, preventing leaks and ensuring the safe storage of liquids or bulk materials.

Compliance with International Standards: Our welded steel tanks comply with stringent standards, including API 650, BS EN 14015, and GB50341-2014, ensuring their reliability and performance in global markets.

Welded Steel Tank Coating and Corrosion Protection

At Shijiazhuang Zhengzhong Technology Co., Ltd., we prioritize the protection of our welded steel tanks against corrosion. We follow the ISO 12944 standard for corrosion protection, using different primer and topcoat thicknesses based on customer requirements. This approach ensures that our tanks are highly resistant to corrosion and suitable for a range of storage environments.

Applications of Welded Steel Tanks

Our welded steel tanks serve multiple industries, including:

Water Storage: Drinking water, irrigation water, fire water

Wastewater Treatment: Industrial wastewater, sewage

Petroleum and Chemical Storage: Crude oil, refinery distillates, acids, alkalis

Biofuels and Agricultural Storage: Ethanol, vegetable oils

Dry Bulk Goods: Grains, fertilizers

Manufacturing Process and Quality Control

Our production process includes laser cutting, beveling, shot blasting, and priming of steel plates to ensure that our tanks meet the highest quality standards. After fabrication, we conduct rigorous testing to ensure the welds and materials meet the required strength and safety standards.

Welded Steel Tank Manufacturing Process:

Laser cutting of steel plates

Beveling of steel plates

Shot blasting for surface preparation

Application of primer for corrosion resistance

Arc pressing of steel plates to achieve the required shape

On-Site Installation and Professional Support

Once the production of the tanks is complete, we provide professional logistics to ensure safe delivery. Our experienced installation team works on-site to ensure smooth assembly and installation, coordinating with other project teams to deliver tanks that meet client specifications.

Why Choose Shijiazhuang Zhengzhong Technology Co., Ltd. for Welded Steel Tanks?

Over 30 Years of Experience: We are a trusted name in tank manufacturing, with extensive experience in producing durable, high-quality welded steel tanks.

Custom Solutions: Our tanks are highly customizable to meet diverse storage needs across various industries.

Global Projects and Standards: We have successfully implemented projects in over 100 countries, and our tanks meet international standards like API 650, BS EN 14015, and ISO 12944.

Professional Installation and Support: From production to installation, our team ensures that your tanks meet the highest standards of safety and performance.

Shijiazhuang Zhengzhong Technology Co., Ltd. continues to lead the tank manufacturing industry with innovative solutions, outstanding quality, and a commitment to customer satisfaction. For customized welded steel tanks that deliver reliable performance and durability, partner with us for your next storage project.

Contact us today to learn more about our welded steel tanks and how we can tailor a solution to meet your specific needs.

0 notes

Text

Most small cattle farms choose to process cow manure into organic fertilizer when dealing with cow manure, which can not only avoid the pollution of the environment by cow manure and meet the requirements of environmental protection, but also turn waste into treasure. It can also bring extra income for cattle farms through the sales of organic fertilizer and realize the recycling of resources.

For small cattle farms with limited budget, powdered organic fertilizer production line is favored because of its low investment cost, simple operation and quick effect. However, if you want to further improve the added value of products and meet the diversified market demand for granular organic fertilizer, you can consider adding granulation links on the basis of powdered Organic Fertilizer Production Line, such as introducing Rotary Drum Granulator or Disc Granulator.

Rotary Drum Granulator

The Rotary Drum Granulator is one of the ideal equipment for the production of granular organic fertilizer. Through the interaction between the inner wall of the rotating drum and the scraper or the stirring blade, the powder material is gradually extruded and rolled into spherical particles. The equipment has the advantages of large yield, high granulation rate, good particle strength and so on, and can adapt to the granulation needs of a variety of raw materials, including cow manure organic fertilizer with moderate water content. The use of Rotary Drum Granulator can significantly improve the appearance quality and market competitiveness of organic fertilizer, and attract more consumers who pay attention to product form.

Disc Granulator

In contrast, Disc Granulator are known for their simple structure and easy operation and maintenance. It uses the rotating disc surface to make the material roll into balls under the action of centrifugal force, which is suitable for pelleting materials with moderate or slightly lower viscosity. Although the output of the Disc Granulator may be slightly inferior to that of the Rotary Drum Granulator, satisfactory results can also be achieved in the treatment of some specific types of cattle manure organic fertilizer. In addition, the cost of Disc Granulator is relatively low, making them a cost-effective option for small cattle farms with limited budgets.

Complete production line configuration proposal

In the configuration of small Organic Fertilizer Production Line, in addition to the core granulation equipment, it is necessary to consider the equipment of raw material pretreatment, mixing, drying, screening and packaging. For example, raw material pretreatment may include grinders to ensure uniform particle size of cow manure; The mixer is used to fully mix various additives with cow manure to improve the quality of fertilizer; The drying equipment is used to remove the excess water generated in the granulation process to ensure the hardness and stability of the particles; The screening machine is used to separate unqualified large particles and small particles to ensure the quality of finished products; Finally, the packaging machine is used to separate the qualified organic fertilizer for easy storage and transportation.

In the treatment of cow manure, small cattle farms can not only realize the effective use of cow manure, but also significantly improve the added value and market competitiveness of organic fertilizer products by introducing powdered Organic Fertilizer Production Line and combining with granulation equipment such as Rotary Drum Granulator or Disc Granulator, so as to find the best balance between environmental protection and economic benefits.

0 notes

Text

Industrial Centrifugation Market Future Trends to Look Out | Bis Research

Industrial centrifugation is a mechanical process that utilizes centrifugal force to separate particles from a solution based on their size, shape, density, and the viscosity of the medium. This separation technique is widely applied in various industrial sectors to achieve efficient solid-liquid or liquid-liquid separation, dewatering, and purification.

The Industrial Centrifugation Market was valued at $46.1 million in 2023 and is expected to reach $80.6 million by 2033, growing at a CAGR of 5.75% between 2023 and 2033

Industrial Centrifugation Overview

The Industrial Centrifugation Market encompasses the global industry involved in the design, manufacture, sale and servicing of centrifugation equipment used in various industrial applications.

Centrifugation is the process that uses centrifugal force to separate particles from a solution according to there size, shape, density, viscosity of the medium and rotor speed.

Key Components for Industrial Centrifugation

Centrifuge Equipment

Separation Mechanism

Applications

Industrial Centrifugation is essential for

Chemical Industry

Pharmaceutical and Biotechnology

Food and Beverages

Water and Wastewater Treatment

Mining and Minerals

Industrial Centrifugation Market Drivers

Growing demand in biotechnology and pharmaceutical industries

Increase use in food and beverages

Environmental regulations and wastewater treatment

Advancements in centrifugation technology

Rising Awareness of Quality and Safety Standards

Economic Growth and Industrialization in Emerging Markets

Have an understanding of our report Click Here !

Market Segmentation

1 By Type of Centrifuges

Sedimentation Centrifuges

Filtration Centrifuges

Hybrid Centrifuges

2 By Applications

Pharmaceutical and Biotechnology

Food and Beverage

Chemical Industry

3 By Capacity

Horizontal Centrifuges

Vertical Centrifuges

4 By End Users

Food and Beverages

Chemical Companies

Oil and Gas Companies

Mining Companies

Key Market Players

Agilent Technologies, Inc.

Andreas Hettich GmbH & Co. KG

ARI Medical Technology Co., Ltd.

Biolab Scientific

Bioneer Corporation

And many others

Download our sample page to have a better understanding click here !

Recent Developments in the Industrial Centrifugation Market

• In April 2023, Eppendorf, a prominent life science company, unveiled the Centrifuge 5427 R, marking the introduction of Eppendorf's inaugural microcentrifuge equipped with hydrocarbon cooling. This innovation contributes to fostering a more sustainable laboratory environment. Through this advancement, users had the capability to conduct a diverse range of molecular and cell biology applications using a refrigerated device that incorporated a natural cooling agent boasting a nearly zero Global Warming Potential (GWP). The primary goal was to safeguard both samples and the planet.

•In February 2022, Beckman Coulter Life Sciences introduced its most versatile 3-liter benchtop centrifuge to date, the Allegra V-15R refrigerated centrifuge. It featured 10 rotor configurations and 50 programmable runs, along with a comprehensive array of adapters, allowing for a wide range of workflows and applications. These capabilities extended from cell and blood separation to high-throughput screening.

Visit our LifeSciences and Biopharma page click here !

Key Question Answers

Q What is the regulatory framework in the Industrial Centrifugation Market ?

Q What are the key trends and the impact of COVID-19 on the Industrial Centrifugation Market ?

Q What are the major market drivers, challenges, and opportunities in the Industrial Centrifugation Market ?

Q How is each product segment of the Industrial Centrifugation Market expected to grow during the forecast period 2023-2033, and what is the anticipated revenue generated by each of the segments by the end of 2033?

Conclusion

The industrial centrifugation market is poised for substantial growth, driven by a confluence of factors across various industries.

Technological advancements and innovations in centrifugation equipment enhance operational efficiency, reliability, and automation, making these systems more attractive to industries seeking to optimize their processes.

In conclusion, the industrial centrifugation market is on a growth trajectory, supported by diverse applications, technological advancements, regulatory requirements, and expanding industrial activities globally.

0 notes

Text

Unlocking the Power of Lithium Carbonate: From Manufacturing Magic to Game-Changing end uses

Lithium Carbonate - it sounds technical, maybe even a little intimidating. But don't be fooled by the complex name! This versatile inorganic compound is a hidden hero in countless industries, quietly shaping the world around us. From the phones in our pockets to the cars on the road, Lithium Carbonate plays a surprising number of crucial roles. Buckle up, because we're about to dive into the fascinating world of this multifaceted material!

In this blog, we will be diving into Lithium Carbonate’s:

Manufacturing process details

Major end-use applications

Market challenges & scenario

Introduction

Lithium Carbonate, a versatile inorganic compound, finds uses in many different industries. It comes in battery grade, industrial grade, and other grades. In the world of metals (metallurgy), Lithium Carbonate helps produce metal oxides and improve the properties of alloys. For energy storage, it's a critical ingredient in lithium-ion batteries, powering electronics, electric vehicles, and renewable energy systems. Even in medicine, Lithium Carbonate plays a key role as a mood stabilizer for people with bipolar disorder. Beyond healthcare, it strengthens materials in the ceramics and glass industry by lowering melting points and enhancing glazes. Its applications extend even further, including chemical synthesis, and even in aluminum production.

Manufacturing Process

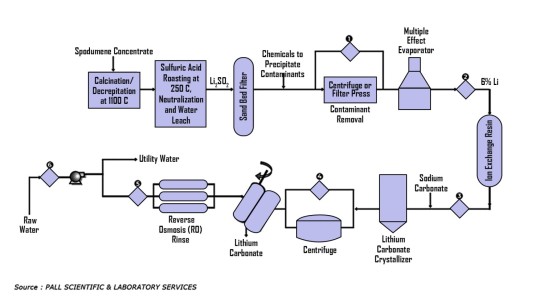

The following process describes a complex method for making Lithium Carbonate from spodumene ore. Spodumene ore, obtained through traditional mining processes, typically harbors lithium content of up to 6% by weight. The process involves various steps like transforming the ore's structure with heat (calcining), removing water from another chemical (dehydrating), and a series of reactions, separations (leaching, thickening, filtering), and precipitations to ultimately isolate and dry pure Lithium Carbonate.

The initial stage of the process involves subjecting spodumene ore to calcination or decrepitation at an extreme temperature of 1,100 °C (2,112 °F), altering its crystal structure to facilitate extraction. Following this, the ore undergoes roasting with sulfuric acid at 250 °C (482 °F), followed by neutralization and water leaching. This process yields a solution containing lithium converted into a lithium sulfate salt solution, alongside other dissolved and particulate impurities.

To remove bulk particulates, a sand bed is utilized, and chemical precipitation is employed to eliminate undesirable contaminants. The separated precipitated contaminants are then isolated from the lithium sulfate stream at location (1) using either a filter press or a centrifuge-type separator. The next step involves concentrating the stream to around 6% lithium, achieved through multiple-effect evaporators staged in series, utilizing heat and vacuum to remove water. At location (2), 1-5 micron-rated filter cartridges are used to separate contaminant particulates.

An ion-exchange resin bed is employed to remove dissolved species, followed by another 1-micron-rated cartridge filter at location (3) to prevent fine particulates from contaminating the final product. Sodium carbonate is introduced to convert lithium sulfate to Lithium Carbonate, which is then separated from the liquid stream using a crystallizer. The solid Lithium Carbonate product is collected via either a centrifuge or a filter press at location (4).

Further separation and processing of Lithium Carbonate particles occur using a belt press filter, including a rinse stage with deionized water. To protect the Reverse Osmosis Membrane System from premature fouling, a 10-micron-rated filter cartridge is employed at location (5). Various process and utility water required throughout the plant undergo purification using a 10-20 micron-rated filter cartridge at location (6) to ensure sufficient purity for these operations.

Major Applications of Lithium Carbonate

Lithium-ion batteries

Lithium Carbonate primarily serves as a precursor for lithium compounds employed in Li-ion batteries. These compounds are crucial components of the battery, comprising electrolyte and cathode. Lithium-ion batteries have transformed the global landscape, enabling portable devices to become increasingly self-sufficient, compact, and stylish. The continuous enhancement of li-ion battery performance has resulted in more durable, dependable batteries capable of powering electric vehicles, smartphones, portable medical devices, and more. The electronics sector is harnessing the potential of lithium to drive its flourishing industry. Despite being a non-renewable energy source, lithium is extensively utilized to facilitate the production of sustainable energy and can be recycled multiple times, ensuring its continued contribution to eco-friendly practices.

Glass & Ceramics

Lithium Carbonate's affinity for silicates and other substances renders it invaluable in ceramic and glass sectors. It's instrumental in producing vibrant, long-lasting glazes, sealants, and oven glasses that withstand high temperatures.

Concrete & Adhesives

Lithium Carbonate finds application in expediting the curing and densification processes of concrete, adhesives, flooring screeds, and similar industrial materials. Its presence accelerates the hardening of these substances, effectively reducing construction timelines and expenses.

Pharmaceuticals

Lithium Carbonate demonstrates notable efficacy in managing mood disorders like bipolar disorder, particularly in mitigating manic episodes. Those undergoing maintenance therapy often encounter reduced frequency and severity of manic states.

Market Outlook

The Lithium Carbonate market is experiencing remarkable growth driven by several factors converging toward sustainability. The surge in electric vehicles (EVs) is a key driver as automakers prioritize eco-friendly options, leading to heightened demand for Lithium Carbonate, a crucial component in lithium-ion batteries. Additionally, the pervasive use of portable electronics like smartphones and laptops, along with the integration of renewable energy sources such as solar and wind, is further propelling market expansion. Industrial applications, advancements in battery technology, and a growing consumer preference for clean energy solutions are also contributing to the market's upward trajectory. Overall, with increasing demand from multiple sectors and ongoing technological advancements, the Lithium Carbonate market is positioned for substantial growth in the foreseeable future.

Lithium Carbonate Market Challenges

Despite promising growth prospects, the Lithium Carbonate market faces several hurdles:

Supply and Demand Dynamics: The demand for Lithium Carbonate, particularly from the booming battery production sector, is skyrocketing. However, current supply levels are struggling to keep pace with this rapid growth. This imbalance creates a situation where Lithium Carbonate becomes a precious commodity, potentially leading to shortages and price hikes down the line.

Tackling Price Fluctuations: The Lithium Carbonate market has experienced significant volatility in recent years. Prices can fluctuate dramatically, creating a high degree of uncertainty for businesses involved in the industry. This can discourage long-term investments and make it difficult for companies to plan effectively. To address this challenge, establishing more stable and predictable pricing mechanisms is crucial.

Addressing Environmental Considerations: Lithium extraction processes can raise serious environmental concerns. One major issue is the high volume of water required for extraction, which can put a strain on local water resources. Another concern is the potential for land degradation, as mining activities can disrupt ecosystems and leave behind lasting scars on the landscape. Developing and implementing sustainable extraction practices is essential to ensure the long-term viability of the Lithium Carbonate market while minimizing environmental impact.

New Technological Innovations: The future of battery technology is constantly evolving. Researchers are actively developing alternative battery chemistries and materials that could potentially outperform lithium-ion batteries in terms of energy density, cost, or safety. If these alternatives become commercially viable, they could significantly disrupt the Lithium Carbonate market by reducing reliance on lithium-ion batteries. Staying ahead of these advancements and adapting to new technologies is crucial for the long-term success of the Lithium Carbonate market.

Lithium Carbonate Main Players

Major players operating in the Global Lithium Carbonate market are Albemarle Corporation, LevertonHELM Limited, Lithium Americas Corp., Ganfeng Lithium Co., Ltd., Livent, Orocobre Limited Pty Ltd, Shandong Ruifu Lithium Co., Ltd., SQM S.A., Targray, and Tianqi Lithium, and Others and Others.

Conclusion:

In conclusion, Lithium Carbonate is a useful in various ways. Lithium Carbonate stands as a cornerstone in our modern era, its significance reaching far beyond its traditional medical realm. From powering our portable gadgets and electric vehicles to safeguarding industrial environments through carbon dioxide detection, its versatility knows no bounds. Moreover, its contribution extends to enhancing the durability and aesthetics of ceramics and glass, while also expediting the hardening process of construction materials like concrete. The Lithium Carbonate market is shining a light on a greener tomorrow. Driven by the surging popularity of electric vehicles and a global push for clean energy, demand for this essential battery material is on a sharp upswing. Also, innovation in battery technology and extraction processes, coupled with significant global investments in clean energy initiatives, is propelling the market forward at an even faster pace. As consumers become more environmentally conscious and embrace sustainable solutions like electric vehicles, the future for Lithium Carbonate looks incredibly bright. This rising tide of demand, innovation, and eco-awareness positions the Lithium Carbonate market for significant expansion in the years to come.

0 notes

Text

Top Evaporated Milk Plant in India

At Indian Trade Bird, our prices on evaporated milk plants are the lowest. Cream Separators, Milk Boilers, Mini Dairy Plants, Batch Milk Pasteurizers, Powder Plants, Dairy Pumps, Milk Homogenizers, Chilling Plants, Curd Making Machines, Ghee Plants, Milk Centrifuge Machines, Egg Pasteurization Machines, Can Drip Saver, Skid Mounted Process Modules, Curd Separators, Soya Curd Machines, and many more are among the products of which we are the foremost manufacturer, supplier, exporter, and retailers. Half as much area is occupied by evaporated milk as by its nutritionally comparable fresh milk. Evaporated milk is almost equal to fresh milk when combined with a corresponding amount of water (150%). Because of their durable design and minimal maintenance requirements, our products are of the highest caliber and are well-liked by our customers. Increased bulk density is the purpose of it. Because of our machines' exceptional durability, functionality, and efficiency, they are in high demand in the market.

0 notes

Text

If you’re in need of a bit of gadget that can effectively flow fluid from deep wells, you could want to consider a vertical turbine pump. Please continue reading if you are unaware of what these pumps are.

These are usually custom-made centrifugal pumps. Unlike their horizontal cousins, these pumps are often oriented vertically. These pumps’ ingenious design allows the impeller to be positioned below the fluid level while the motor stays above it.

Pump Types and Parameters for Vertical Turbine Pumping

There is a large selection of vertical turbine pumps on the market, each with unique benefits and drawbacks. It’s totally up to you whatever one works best for you.

There are separate suction barrels known as cans that are used to contain the vertical turbines. This is the canned kind of approach. Because of their larger operating capacity, these pumps are frequently employed for municipal water treatment and hydrocarbon pumping.

One can use a deep-set well pump, which comes in various lengths, to recover water from deep wells. These pumps are frequently used in potable water and agricultural water management systems.

Mixed flow pumps are those that can handle higher fluid flows and feature either an open or enclosed impeller. These Vertical turbine Pumps India are used in municipal water systems, large-scale industrial activities, flood control, and desalination.

0 notes

Text

Evaluation of Starch Manufacturer’s Performance| Analysis and Forecast

Originally published on Spendedge: 5 Best Ways to Evaluate Starch Manufacturer’s Performance

**Supplier Performance Evaluation in the Global Starch Market**

If you've ever pondered why your rice sticks together or your potatoes adhere to the pan, the culprit is starch, a common carbohydrate found in staple starchy foods like rice, potatoes, wheat, maize, and cassava. Starch, an efficient energy storage mechanism for plants, plays a versatile role in industrial applications, from stiffening textiles and shaping paper to enhancing taste in beverages and confectionery. While various starch types exist, including maize, potato, and wheat starch, cornstarch dominates, accounting for approximately 57% of global starch production capacity by raw material in 2016.

Given the multitude of starch manufacturers and suppliers globally, it becomes imperative to assess supplier performance and competencies for informed decision-making in future contracts. Here's how buyers can evaluate supplier performance in the global starch market:

**Starch Production Hubs**

**Supplier Evaluation Criteria in the Starch Market:**

1. **Service Resolution Rate:**

- Assess the supplier's responsiveness to buyer complaints regarding starch quality, logistics, quantity, and packaging.

- Complaints should be registered through a designated portal or email, with resolutions expected within six weeks.

2. **Inventory Management Effectiveness:**

- Evaluate the supplier's reliability in effective inventory management.

- Use metrics like reduction in average lead time, ensuring compliance with specified timelines.

- Ensure starch manufacturers maintain adequate safety stock inventory for unusual demands, adhering to JIT principles.

3. **Efficient Plant Utilization Rate:**

- Evaluate starch manufacturers based on their plant utilization rate, with a higher percentage indicating lower variable costs.

- Ideal plant utilization rate in the starch industry is about 50%-60% of total capacity.

4. **Lower Turn Around Time (TAT):**

- Ensure starch suppliers maintain a quick turnaround time (TAT) to respond to fluctuations in buyer demand without compromising quality.

- Ideal TAT in the starch market is around 4-5 days from the date of requirement.

5. **Logistics Capabilities:**

- Assess the supplier's logistics capabilities, considering complications arising from transportation laws and packaging requirements.

- Evaluate the ratio of shipments damaged by shipments delivered to gauge logistics efficiency.

Read more about the supplier assessment criteria for starch manufacturers, including pricing insights, sourcing strategy, key suppliers, procurement best practices, and cost modeling in SpendEdge’s upcoming report on the global starch market.

**Optimized Procedure for Starch Preparation**

**1. Starch Source Selection:**

- Choose an appropriate starch source based on the intended application, selecting from common sources like corn, potato, rice, and wheat.

**2. Raw Material Preparation:**

- Clean the raw material to remove contaminants and mill it to liberate starch granules.

**3. Extraction of Starch:**

- Combine ground raw material with water to create a slurry, determining the water-to-raw-material ratio based on starch content.

- Gelatinize starch granules by heating the slurry, adjusting pH if needed, and introducing alpha-amylase enzymes for breakdown.

- Separate starch slurry from insoluble components through filtration.

**4. Separation and Purification:**

- Allow the starch slurry to settle for separation, then cleanse the starch with water to remove remaining contaminants.

- Use centrifugation or hydrocyclones for further separation.

**5. Drying and Milling:**

- Employ methods like drum drying, flash drying, or air drying to remove excess water based on intended use.

- Mill the starch if necessary to achieve the desired size.

**6. Quality Control and Storage:**

- Test starch for parameters like moisture content, viscosity, and purity.

- Store prepared starch in moisture-proof containers to prevent degradation.

A comprehensive supplier assessment ensures reliable sourcing, effective inventory management, and adherence to quality standards in the global starch market, contributing to a resilient and efficient supply chain.

For more information please contact.

0 notes

Text

Mastering Excellence: Assessing Optimal Performance in Starch Production

Originally Published on: SpendEdge |5 Best Ways to Evaluate Starch Manufacturer’s Performance

Revelations on Global Starch Market Dynamics and Strategic Supplier Appraisal

Starch, a quintessential carbohydrate prevalent in staple foods, emerges as a cornerstone in diverse industrial applications, demanding a meticulous evaluation of starch manufacturers for judicious supplier selection. Notably, cornstarch dominates with a substantial 57% share of the global production capacity. In a densely populated supplier landscape, a nuanced assessment proves pivotal.

Deciphering the Evaluation of Starch Suppliers in a Dynamic Market

1- Service Resolution Rate: Supplier responsiveness to quality, logistics, quantity, and packaging concerns stands as a pivotal criterion. A robust complaint resolution mechanism, ensuring prompt response and resolution within six weeks, serves as a hallmark of supplier competence.

2- Inventory Management Effectiveness: Reliability in inventory management takes center stage, with metrics like reduced lead time indicating supplier effectiveness. Local suppliers aiming for a week, regional suppliers for 15-20 days, and global sourcing within a month, coupled with safety stock and JIT adherence, emerge as pivotal indicators.

3- Efficient Plant Utilization Rate: Supplier evaluation pivots on the plant utilization rate, reflective of lower variable costs. A utilization rate ranging from 50% to 60% signifies cost efficiency, laying the foundation for favorable sourcing rates.

4- Lower Turn Around Time (TAT): The agility of suppliers in meeting fluctuating demands without compromising quality becomes a key determinant. A preferred TAT of 4-5 days from the requirement date ensures JIT delivery, aligning with buyer needs.

5- Logistics Capabilities: Navigating the intricate starch transportation landscape, suppliers are evaluated based on the ratio of shipments damaged to those delivered. A robust logistics capability ensures the secure and intact delivery of shipments.

Optimized Starch Preparation Protocols

Starch Source Selection: Embarking on optimal starch preparation involves selecting a source aligned with the intended application. Diverse options like corn, potato, rice, or wheat each impart distinct properties to the final product.

Raw Material Preparation: Rigorous cleaning and grinding of raw material eliminate contaminants and liberate starch granules by breaking down cell walls, setting the stage for further processing.

Extraction of Starch: A meticulous slurry creation involves combining ground raw material with water, followed by gelatinizing starch granules through controlled heating. pH adjustments, enzyme introductions, and separation processes further refine the starch slurry.

Separation and Purification: Allowing the starch slurry to settle facilitates separation from other ingredients, followed by thorough cleansing with water. Advanced techniques like centrifugation aid in additional separation.

Drying and Milling: Tailoring drying methods to usage requirements—be it drum drying, flash drying, or air drying—ensures the removal of excess water. Milling, if necessary, refines the starch to the desired size.

Quality Control and Storage: Rigorous quality testing for parameters like moisture content, viscosity, gel strength, and purity guarantees adherence to specifications. Storing the prepared starch in moisture-proof containers safeguards against degradation.

Embark on a comprehensive exploration, encompassing pricing insights, strategic sourcing, key suppliers, procurement best practices, and cost modeling, through the forthcoming report by SpendEdge on the global starch market.

Contact us.

0 notes

Text

Separation Systems for Commercial Biotechnology Market May Set Huge Growth by 2028

Latest released the research study on Global Separation Systems for Commercial Biotechnology Market, offers a detailed overview of the factors influencing the global business scope. Separation Systems for Commercial Biotechnology Market research report shows the latest market insights, current situation analysis with upcoming trends and breakdown of the products and services. The report provides key statistics on the market status, size, share, growth factors of the Separation Systems for Commercial Biotechnology The study covers emerging player’s data, including: competitive landscape, sales, revenue and global market share of top manufacturers are Thermo Fisher Scientific (United States), Danaher Corporation (United States), Agilent Technologies (United States), Waters Corporation (United States), Shimadzu Corporation (Japan), Bio-Rad Laboratories (United States), Merck & Co., Inc. (United States), QIAGEN (Germany), Sartorius (Germany), PerkinElmer, Inc. (United States)

Free Sample Report + All Related Graphs & Charts @: https://www.advancemarketanalytics.com/sample-report/17512-global-separation-systems-for-commercial-biotechnology-market

Separation Systems for Commercial Biotechnology Market Definition:

Bioseparation systems are used for the purification and separation of biological products and the equipment used for the separation of biological material from complex mixture or solution includes chromatography, membrane filters, and centrifuges. HPLC is one of the most commonly used separative techniques and also one of the fastest-growing instrumentation fields in the world. HPLCS are considered standard analytical tools in the laboratory to accurately isolate and purify organic molecules, drugs, and some peptide hormones. The United States is a recognized leader in analytical instrumentation used in biological research and thus stands at the forefront of many of the technical innovations being made in the bioprocess field.

Market Trend:

Ultrafiltration and Other Filtration Systems

HPLCS to Monitor Bioprocesses and Purify Large Quantities of Proteins such as Leukocyte Interferon

Market Drivers:

The growing number of biotech firms with huge investments in research and development is the key driving factor for the growth of the market.

Stringent Government Rules & Regulations

Technological Advancement in the Biotechnology Sector

Market Opportunities:

The use of rDNA technology to produce low-volume, high value-added products as well as high-volume products has greatly increased the need to develop more economic bioprocesses.

The Global Separation Systems for Commercial Biotechnology Market segments and Market Data Break Down are illuminated below:

by Application (Vaccines, Hormones, Proteins, Enzymes, Others), End-User (Pharmaceutical, Food & Cosmetics, Agriculture, Life Sciences Research, Others), Method (Liquid Chromatography, Membrane Filtration, Electrophoresis, Niche Separation, Centrifugation, Lab-on-a-Chip, Others)

Region Included are: North America, Europe, Asia Pacific, Oceania, South America, Middle East & Africa

Country Level Break-Up: United States, Canada, Mexico, Brazil, Argentina, Colombia, Chile, South Africa, Nigeria, Tunisia, Morocco, Germany, United Kingdom (UK), the Netherlands, Spain, Italy, Belgium, Austria, Turkey, Russia, France, Poland, Israel, United Arab Emirates, Qatar, Saudi Arabia, China, Japan, Taiwan, South Korea, Singapore, India, Australia and New Zealand etc.

Enquire for customization in Report @: https://www.advancemarketanalytics.com/enquiry-before-buy/17512-global-separation-systems-for-commercial-biotechnology-market

Strategic Points Covered in Table of Content of Global Separation Systems for Commercial Biotechnology Market:

Chapter 1: Introduction, market driving force product Objective of Study and Research Scope the Separation Systems for Commercial Biotechnology market

Chapter 2: Exclusive Summary – the basic information of the Separation Systems for Commercial Biotechnology Market.

Chapter 3: Displayingthe Market Dynamics- Drivers, Trends and Challenges of the Separation Systems for Commercial Biotechnology

Chapter 4: Presenting the Separation Systems for Commercial Biotechnology Market Factor Analysis Porters Five Forces, Supply/Value Chain, PESTEL analysis, Market Entropy, Patent/Trademark Analysis.

Chapter 5: Displaying market size by Type, End User and Region 2015-2020

Chapter 6: Evaluating the leading manufacturers of the Separation Systems for Commercial Biotechnology market which consists of its Competitive Landscape, Peer Group Analysis, BCG Matrix & Company Profile

Chapter 7: To evaluate the market by segments, by countries and by manufacturers with revenue share and sales by key countries (2021-2026).

Chapter 8 & 9: Displaying the Appendix, Methodology and Data Source

Finally, Separation Systems for Commercial Biotechnology Market is a valuable source of guidance for individuals and companies in decision framework.

Data Sources & Methodology

The primary sources involves the industry experts from the Global Separation Systems for Commercial Biotechnology Market including the management organizations, processing organizations, analytics service providers of the industry’s value chain. All primary sources were interviewed to gather and authenticate qualitative & quantitative information and determine the future prospects.

In the extensive primary research process undertaken for this study, the primary sources – Postal Surveys, telephone, Online & Face-to-Face Survey were considered to obtain and verify both qualitative and quantitative aspects of this research study. When it comes to secondary sources Company's Annual reports, press Releases, Websites, Investor Presentation, Conference Call transcripts, Webinar, Journals, Regulators, National Customs and Industry Associations were given primary weight-age.

For Early Buyers | Get Up to 20% Discount on This Premium Report: https://www.advancemarketanalytics.com/request-discount/17512-global-separation-systems-for-commercial-biotechnology-market

What benefits does AMA research study is going to provide?

Latest industry influencing trends and development scenario

Open up New Markets

To Seize powerful market opportunities

Key decision in planning and to further expand market share

Identify Key Business Segments, Market proposition & Gap Analysis

Assisting in allocating marketing investments

Definitively, this report will give you an unmistakable perspective on every single reality of the market without a need to allude to some other research report or an information source. Our report will give all of you the realities about the past, present, and eventual fate of the concerned Market.

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Europe or Southeast Asia.

Contact Us: Craig Francis (PR & Marketing Manager)

AMA Research & Media LLP

Unit No. 429, Parsonage Road Edison, NJ

New Jersey USA – 08837

0 notes

Text

How is Montmorillonite commercially mined and processed for various industrial applications?

Montmorillonite is commercially mined and processed for various industrial applications through the following steps:

Exploration and Mining: The process typically begins with exploration to identify deposits of Montmorillonite-rich clay. Once suitable deposits are found, mining operations are established. Montmorillonite can be found in sedimentary deposits and may be extracted using surface mining methods, such as open-pit mining.

Excavation: Mining equipment, such as bulldozers and backhoes, is used to excavate the Montmorillonite-bearing earth from the deposit. The mined material is then transported to processing facilities.

Crushing and Grinding: At the processing facility, the raw Montmorillonite clay is crushed and ground into smaller particles to increase its surface area and facilitate further processing.

Separation: The crushed material is subjected to separation techniques to remove impurities, rocks, and other minerals that are not Montmorillonite. Techniques like screening and centrifugation are commonly used for this purpose.

Beneficiation: Beneficiation processes may be employed to further refine the Montmorillonite clay. This can involve methods like sedimentation, flotation, or magnetic separation to enhance the purity of the Montmorillonite.

Drying: The clay is dried to reduce its moisture content to a suitable level for processing and to prevent clumping during transportation and storage.

Activation (Optional): Depending on the intended application, Montmorillonite may undergo an activation process. Activation can involve the addition of chemicals to modify the clay's properties, making it more effective for specific uses, such as in drilling fluids or as an adsorbent.

Packaging: Once the Montmorillonite clay is processed and ready for market, it is packaged in various forms, such as bags, bulk containers, or other suitable packaging, for distribution and sale.

Montmorillonite can be used in a wide range of industrial applications, such as drilling fluids, construction materials, cat litter, geosynthetic clay liners, cosmetics, and pharmaceuticals, among others. The specific processing methods and treatment may vary based on the desired properties and requirements for the intended application.

It's important to note that environmental regulations and sustainability practices play a significant role in the mining and processing of Montmorillonite and other minerals. Minimizing the environmental impact and ensuring safe working conditions for miners are essential considerations in these processes.

How does Montmorillonite contribute to soil improvement and agricultural practices?

Montmorillonite, a type of clay mineral, contributes to soil improvement and agricultural practices in several ways:

Improved Soil Structure: Montmorillonite has a high cation exchange capacity (CEC), which means it can hold and release essential nutrients and minerals for plant growth. When added to soil, it improves the soil's structure by increasing its ability to retain moisture and nutrients, leading to better aeration and drainage.

Nutrient Retention: Montmorillonite clay can bind and retain nutrients like potassium, calcium, and magnesium, preventing them from leaching out of the soil. This helps maintain a nutrient-rich environment for plants and reduces the need for frequent fertilizer applications.

Enhanced Water Retention: Montmorillonite has excellent water-holding capacity. When added to sandy or well-draining soils, it can significantly increase the soil's water retention, ensuring that plants have access to water during dry periods.

Reduced Erosion: Montmorillonite can help reduce soil erosion by binding soil particles together and stabilizing the soil structure. This is especially beneficial in areas prone to erosion, such as sloped terrain.

pH Buffering: Montmorillonite can help buffer soil pH, making it more resistant to extreme pH fluctuations. This can create a more stable and favorable environment for plant growth.

Increased Cation Exchange Capacity: The addition of Montmorillonite clay increases the soil's CEC, which means it can hold and exchange more essential plant nutrients with the roots, promoting healthier growth.

Better Seed Germination: Montmorillonite's moisture-retention properties can improve seed germination rates, as it ensures a more consistent moisture supply to seeds.

Suppression of Plant Diseases: Montmorillonite may help suppress certain soil-borne plant diseases by altering the microbial environment in the soil. It can reduce the populations of pathogenic microorganisms.

Improved Workability: Montmorillonite can make heavy clay soils easier to work with by improving their structure and reducing their tendency to become compacted.

Reduced Soil Toxicity: In contaminated soils, Montmorillonite can help immobilize heavy metals and contaminants, making the soil less toxic and more suitable for agriculture.

Livestock Health: Montmorillonite is sometimes added to livestock feeds and used in animal husbandry to promote better digestion and overall health in animals.

Montmorillonite is typically applied to soil as a soil conditioner or amendment. The application rates and methods may vary depending on soil type, crop type, and specific agricultural goals. It is important to follow recommended guidelines and consult with agricultural experts to ensure the proper and effective use of Montmorillonite in agricultural practices.

0 notes

Text

Bolted Glass-Lined Cobalt Blue Color Grain Storage Silo: Combining Functionality with Aesthetic Appeal

In the world of agricultural storage solutions, practicality and durability are paramount. Yet, in today's market, aesthetics also play a crucial role. At Shijiazhuang Zhengzhong Technology Co., Ltd, we have successfully merged these aspects with our Bolted Glass-Lined Cobalt Blue Color Grain Storage Silo. This innovative product not only meets the highest standards of functionality and longevity but also adds a visually striking element to any agricultural setup.

The Bolted Glass-Lined Cobalt Blue Color Grain Storage Silo by Shijiazhuang Zhengzhong Technology Co., Ltd is a testament to our dedication to innovation, quality, and customer satisfaction. By combining technical excellence with aesthetic appeal, we provide a storage solution that not only performs exceptionally but also enhances the visual appeal of any agricultural setting. Choose our grain storage silos for a product that delivers on all fronts – durability, functionality, and beauty.

As a leading storage tank manufacturer in China. Center Enamel can provide Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, galvanized steel tanks and aluminum geodesic dome roofs, Wastewater and Biogas Project Equipments for global customers.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Unmatched Durability and Quality

Our bolted glass-lined grain storage silos are engineered with precision and built to last. The cobalt blue color is not just for show; it is a result of our advanced glass-fused-to-steel technology. This process involves fusing a layer of glass to steel at high temperatures, creating a durable, non-reactive, and non-corrosive surface. The result is a silo that is resistant to harsh weather conditions, chemicals, and rust, ensuring long-term performance and minimal maintenance.

Technical Excellence

Superior Coating: The cobalt blue color comes from the glass coating, which provides excellent resistance to abrasion, scratches, and impacts. This makes the silo ideal for storing grain, which can be abrasive to unprotected surfaces.

High-Quality Steel: The structural integrity of our silos is guaranteed by the use of high-quality steel, which provides the necessary strength to withstand the significant loads and stresses associated with large volumes of stored grain.

Modular Design: Our bolted design allows for easy assembly and disassembly, making it convenient for transportation and installation in remote locations. This modularity also enables scalability, allowing for future expansion as storage needs grow.

Aesthetic Appeal

The cobalt blue color of our glass-lined silos is not only functional but also adds a touch of elegance to any agricultural site. This vibrant color stands out against the natural landscape, making the silo a landmark feature. The aesthetic appeal of these silos can enhance the overall visual impact of a farm or grain storage facility, creating a positive impression for visitors and stakeholders.

Versatility and Customization

Understanding that different operations have unique requirements, we offer customization options for our grain storage silos. From varying sizes and capacities to additional features like ventilation systems and temperature control, our team can tailor each silo to meet specific needs. This flexibility ensures that our customers receive a storage solution that is perfectly suited to their operational demands.

Commitment to Sustainability

At Shijiazhuang Zhengzhong Technology Co., Ltd, we are committed to sustainable practices. Our glass-fused-to-steel technology is an environmentally friendly process that reduces the need for frequent maintenance and replacement, thereby minimizing waste. The longevity of our silos means fewer resources are consumed over time, contributing to a more sustainable agricultural industry.

Center Enamel combines the excellent performance of various tanks to provide customers with solutions composed of diverse equipment combinations. This approach allows us to flexibly meet the needs and requirements of different application fields. Throughout the project construction process, the teams at Center Enamel collaborate closely, actively coordinate, and prioritize each step, conducting rigorous checks at every level to ensure the smooth completion of projects.

From being a leader in the Asian GFS tank industry to becoming a diversified environmental equipment smart manufacturer in China, Center Enamel utilizes crucial core technologies to continuously iterate and upgrade equipment in research and development. This drives the sustained high-quality development of the company in the face of new challenges. Leveraging existing brand advantages, technological strengths, and team capabilities, the company will continue to focus on cutting-edge industry technologies. Adhering to a diversified development strategy, Center Enamel aims to elevate environmental business to new heights while jointly creating a beautiful picture of green hills and clear waters.

To learn more about our galvanized steel tanks or to discuss your specific aquaculture needs, please contact us. We are dedicated to providing superior storage solutions tailored to meet your unique requirements.

0 notes

Text

Oil Water Separator Market Size, Share & Industry Analysis By Technology (Gravity, Sponge, Coalescing, Centrifuge, Other), By Industry Vertical (Oil and gas, Chemical, Food and Beverage, Water and Wastewater, Marine, Others) and Regional Forecast, 2022-2029

0 notes

Text

Unveiling the Best Juicers of 2023 for Weight Loss

Are you looking to shed those extra pounds and achieve a healthier lifestyle? If so, juicing might be the perfect solution for you! Juicing has gained immense popularity in recent years, and for a good reason. Not only does it provide a convenient and delicious way to consume essential nutrients, but it can also aid in weight loss. In this article, we will unveil the best juicers of 2023 specifically designed to help you with your weight loss journey. So, let’s dive in and discover the power of juicing!

The Benefits of Juicing for Weight Loss

Before we delve into the best juicers of 2023, let’s explore the incredible benefits of juicing for weight loss. Juicing offers numerous advantages that can contribute to your overall well-being and promote healthy weight loss. Here are some of the key benefits:

High nutrient content: Juicing allows you to consume a concentrated dose of vitamins, minerals, and antioxidants present in fruits and vegetables. These essential nutrients help nourish your body, support your metabolism, and enhance weight loss.

Quick and easy absorption: When you juice fruits and vegetables, you are extracting their liquid and separating it from the insoluble fiber. This makes it easier for your body to absorb the nutrients, providing you with an instant boost of energy.

Hydration: Staying hydrated is crucial for maintaining a healthy weight. Juices are a fantastic way to increase your daily water intake while enjoying a refreshing and flavorful drink.

Natural detoxification: Juicing can support your body’s natural detoxification process by providing it with essential enzymes and antioxidants. This can help eliminate toxins and promote weight loss.

Reduced calorie intake: Juicing allows you to consume a higher volume of fruits and vegetables in liquid form, which ultimately leads to a lower calorie intake compared to eating whole foods. This can be beneficial for weight loss as it creates a calorie deficit.

Choosing the Right Juicer

Now that we understand the incredible benefits of juicing for weight loss, let’s explore the best juicers of 2023. When it comes to juicers, there are various options available in the market. However, it’s essential to choose a juicer that suits your specific needs and provides optimal results. Here are a few factors to consider when selecting a juicer:

Type of juicer: There are different types of juicers available, including centrifugal juicers, masticating juicers, and triturating juicers. Each type has its own unique features and benefits. Consider your preferences, budget, and desired outcomes before making a decision.

Ease of use and cleaning: Juicing should be a convenient process. Look for a juicer that is easy to assemble, disassemble, and clean. This will encourage you to incorporate juicing into your daily routine without any hassle.

Efficiency and yield: Choose a juicer that efficiently extracts juice from fruits and vegetables, resulting in a higher yield. This will ensure that you get the most out of your produce and obtain maximum nutrition.

Noise level: If noise is a concern for you, opt for a juicer that operates quietly. Some juicers have noise-reducing features, making them perfect for early morning or late-night juicing sessions.

Additional features: Some juicers come with extra features such as multiple speed settings, pulp control options, and recipe books. Consider which features are important to you and choose accordingly.

Top Juicers of 2023 for Weight Loss

Now that you have a clear idea of what to look for in a juicer, let’s explore the top juicers of 2023 specifically designed to aid in weight loss:

Read about 15 best juicers in 2023 to lose weight.

Conclusion

Juicing can be a game-changer when it comes to weight loss and overall well-being. By incorporating nutrient-rich juices into your daily routine, you can enjoy a wide range of health benefits while shedding those extra pounds. Remember to choose a juicer that suits your needs, preferences, and budget, so you can embark on your weight loss journey with ease. Whether you opt for a centrifugal, masticating, or triturating juicer, the possibilities are endless. So grab your favorite fruits and vegetables, and start juicing your way to a healthier you!

0 notes

Text

Dental Amalgam Separators Market Size, Type, segmentation, growth and forecast 2023-2030

Dental Amalgam Separators Market

The Dental Amalgam Separators Market is expected to grow from USD 27.00 Million in 2022 to USD 19.00 Million by 2030, at a CAGR of -5.09% during the forecast period.

Dental Amalgam Separators Market Size

Dental amalgam separators are devices that are used to remove amalgam waste generated during dental procedures. The global dental amalgam separators market is segmented based on type, application, and region. The types of dental amalgam separators available in the market include sedimentation, centrifugal, and other types. The applications of dental amalgam separators include hospitals, dental clinics, and other dental facilities. The market is also segmented based on region, including North America, Asia Pacific, Middle East, Africa, Australia, and Europe. Some of the major players operating in the market for dental amalgam separators include Solmetex, MedenteX, METASYS, Dürr Dental, Rebec Environmental, Dental Recycling North America, Air Techniques, M.A.R.S. Bio-Med Processes, and Sinol Dental. Regulatory and legal factors play a vital role in shaping the market conditions of the dental amalgam separators market. Factors like government regulations, environmental standards, and dental associations’ recommendations are critical in shaping the market conditions. The stringent regulatory and legal guidelines expected by governing bodies like the European Commission and the U.S. Environmental Protection Agency are driving the demand for dental amalgam separators in the market. The need to comply with these laws has led to the adoption of amalgam separators by dental facilities to avoid non-compliance.

Dental Amalgam Separators Market Key Player

Solmetex

MedenteX

METASYS

Dürr Dental

Rebec Environmental

Buy Now & Get Exclusive Discount on this https://www.reportprime.com/enquiry/request-discount/11097

Dental Amalgam Separators Market Segment Analysis

The global Dental Amalgam Separators market is largely driven by the rising awareness about the adverse effects of unmanaged mercury waste in dental clinics and laboratories. The increasing implementation of environmental regulations by government bodies is also contributing to the growth of the market. Moreover, the growing demand for dental services across the world is further fueling the demand for dental amalgam separators.

Dental amalgam separators are used to separate amalgam waste from the dental treatment water before it is disposed of, ensuring that the water is not contaminated with mercury and other heavy metals. This technology is becoming increasingly popular as dental clinics and laboratories are trying to reduce their environmental impact by implementing sustainable practices.

The market for dental amalgam separators is witnessing several trends, including the increasing use of amalgam separators that are compliant with international environmental and safety standards, high-efficiency amalgam separators, and easy-to-install separator units. Furthermore, the increasing use of next-generation dental amalgam separators, which have a higher separation efficiency and a lower environmental impact, is also driving the growth of the market.

However, the market for dental amalgam separators is facing several challenges, such as the high cost of these devices and the lack of awareness about their benefits among dental professionals. Additionally, the installation and maintenance of dental amalgam separators require trained personnel, which can be a challenge for dental clinics and laboratories with limited resources.

According to the report's main findings, the global dental amalgam separators market is expected to grow significantly in the coming years, driven by the increasing implementation of environmental regulations and the growing demand for dental services. The report recommends that dental clinics and laboratories should consider investing in high-efficiency and easy-to-install dental amalgam separators to reduce their environmental impact and ensure compliance with international standards. Moreover, the report suggests that governments and regulatory bodies should provide more incentives and support to dental professionals to encourage the adoption of these sustainable practices.

This report covers impact on COVID-19 and Russia-Ukraine wars in detail.

Purchase This Report: https://www.reportprime.com/checkout?id=11097&price=3590

Market Segmentation (by Application):

Hospital

Dental Clinic

Other

Information is sourced from www.reportprime.com

0 notes